Xanthine Oxidase Inhibitory Activity and Thermostability of Cinnamaldehyde-Chemotype Leaf Oil of Cinnamomum osmophloeum Microencapsulated with β-Cyclodextrin

Abstract

:1. Introduction

2. Results and Discussion

2.1. Composition of Cinnamomum Osmophloeum Leaf Oil

2.2. Optimal Microencapsulation of C. Osmophloeum Leaf Oil with β-Cyclodextrin

2.3. Evaluation of the Thermostability of Leaf Oil Microcapsules by Dry-Heat Aging Test

2.4. Xanthine Oxidase Inhibitory Activities of C. Osmophloeum Leaf Oil Microcapsules

3. Materials and Methods

3.1. Hydrodistillation of Leaf Oil

3.2. GC-MS Analysis of Leaf Oil

3.3. Microencapsulation

3.4. FTIR Analysis

3.5. Dry-Heat Aging Test

3.6. Xanthine Oxidase Inhibitory Assay

3.7. Statistical Analysis

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wang, S.Y.; Yang, C.W.; Liao, J.W.; Zhen, W.W.; Chu, F.H.; Chang, S.T. Essential oil from leaves of Cinnamomum. osmophloeum acts as a xanthine oxidase inhibitor and reduces the serum uric acid levels in oxonate-induced mice. Phytomedicine 2008, 15, 940–945. [Google Scholar] [CrossRef] [PubMed]

- Melgarejo-Flores, B.G.; Ortega-Ramirez, L.A.; Silva-Espinoza, B.A.; Gonzalez-Aguilar, G.A.; Miranda, M.R.A.; Ayala-Zavala, J.F. Antifungal protection and antioxidant enhancement of table grapes treated with emulsions, vapors, and coatings of cinnamon leaf oil. Postharvest Biol. Technol. 2013, 86, 321–328. [Google Scholar] [CrossRef]

- Wu, C.L.; Chang, H.T.; Hsui, Y.R.; Hsu, Y.W.; Liu, J.Y.; Wang, S.Y.; Chang, S.T. Antioxidant-enriched leaf water extracts of Cinnamomum. osmophloeum from eleven provenances and their bioactive flavonoid glycosides. BioResources 2013, 5, 571–580. [Google Scholar] [CrossRef]

- Cheng, B.H.; Sheen, L.Y.; Chang, S.T. Evaluation of anxiolytic potency of essential oil and S-(+)-linalool from Cinnamomum. osmophloeum ct. linalool leaves in mice. J. Tradit. Complement. Med. 2015, 5, 27–34. [Google Scholar] [CrossRef] [PubMed]

- Davaatseren, M.; Jo, Y.J.; Hong, G.P.; Hur, H.J.; Park, S.; Choi, M.J. Studies on the Anti-oxidative function of trans-cinnamaldehyde-included β-cyclodextrin complex. Molecules 2017, 21, 1644. [Google Scholar] [CrossRef] [PubMed]

- Kaiser, C.S.; Rompp, H.; Schmidt, P.C. Supercritical carbon dioxide extraction of chamomile flowers: extraction efficiency, stability, and in-line inclusion of chamomile-carbon dioxide extract in β-cyclodextrin. Phytochem. Anal. 2004, 15, 249–256. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Cao, Y.; Sun, B.; Wang, C. Physicochemical and release characterisation of garlic oil-β-cyclodextrin inclusion complexes. Food Chem. 2011, 127, 1680–1685. [Google Scholar] [CrossRef]

- Pires, M.A.S.; Santos, R.A.S.; Sinisterra, R.D. Pharmaceutical composition of hydrochlorothiazide: β-cyclodextrin: preparation by three different methods, physico-chemical characterization and in vivo diuretic activity evaluation. Molecules 2011, 16, 4482–4499. [Google Scholar] [CrossRef] [PubMed]

- Moya-Ortega, M.D.; Alvarez-Lorenzo, C.; Concheiro, A.; Loftsson, T. Cyclodextrin-based nanogels for pharmaceutical and biomedical applications. Int. J. Pharm. 2012, 428, 152–163. [Google Scholar] [CrossRef] [PubMed]

- Szente, L.; Szeman, J.; Sohajda, T. Analytical characterization of cyclodextrins: History, official methods and recommended new techniques. J. Pharm. Biomed. Anal. 2016, 130, 347–365. [Google Scholar] [CrossRef] [PubMed]

- Waleczek, K.J.; Marques, H.M.C.; Hempel, B.; Schmidt, P.C. Phase solubility studies of pure (2)-α-bisabolol and camomile essential oil with β-cyclodextrin. Eur. J. Pharm. Biopharm. 2003, 55, 247–251. [Google Scholar] [CrossRef]

- Iacovino, R.; Caso, J.V.; Rapuano, F.; Russo, A.; Isidori, M.; Lavorgna, M.; Gaetano Malgieri, G.; Isernia, C. Physicochemical characterization and cytotoxic activity evaluation of hydroxymethylferrocene: β-Cyclodextrin inclusion complex. Molecules 2012, 17, 6056–6070. [Google Scholar] [CrossRef] [PubMed]

- Ciobanu, A.; Mallard, I.; Landy, D.; Brabie, G.; Nistor, D.; Fourmentin, S. Retention of aroma compounds from Mentha piperita essential oil by cyclodextrins and crosslinked cyclodextrin polymers. Food Chem. 2013, 138, 291–297. [Google Scholar] [CrossRef] [PubMed]

- Donato, C.D.; Lavorgna, M.; Fattorusso, R.; Isernia, C.; Isidori, M.; Malgieri, G.; Piscitelli, C.; Russo, C.; Russo, L.; Iacovino, R. Alpha- and beta-cyclodextrin inclusion complexes with 5-fluorouracil: characterization and cytotoxic activity evaluation. Molecules 2016, 22, 1868. [Google Scholar] [CrossRef] [PubMed]

- Szejtli, J. Introduction and general overview of cyclodextrin chemistry. Chem. Rev. 1998, 98, 1743–1753. [Google Scholar] [CrossRef] [PubMed]

- Hill, L.E.; Gomes, C.; Taylor, T.M. Characterization of beta-cyclodextrin inclusion complexes containing essential oils (trans-cinnamaldehyde, eugenol, cinnamon bark, and clove bud extracts) for antimicrobial delivery applications. LWT-Food Sci. Technol. 2013, 51, 86–93. [Google Scholar] [CrossRef]

- Spada, G.; Gavini, E.; Cossu, M.; Rassu, G.; Carta, A.; Giunchedi, P. Evaluation of the effect of hydroxypropyl β-cyclodextrin on topical administration of milk thistle extract. Carbohydr. Polym. 2013, 92, 40–47. [Google Scholar] [CrossRef] [PubMed]

- Quintans, J.S.S.; Menezes, P.P.; Santos, M.R.V.; Bonjardim, L.R.; Almeida, J.R.G.S.; Gelain, D.P.; Araujo, A.A.S.; Quintans-Junior, L.J. Improvement of p-cymene antinociceptive and anti-inflammatory effects by inclusion in β-cyclodextrin. Phytomedicine 2013, 20, 436–440. [Google Scholar] [CrossRef] [PubMed]

- Jiang, S.; Li, J.N.; Jiang, Z.T. Inclusion reactions of β-cyclodextrin and its derivatives with cinnamaldehyde in Cinnamomum. loureirii essential oil. Eur. Food Res. Technol. 2010, 230, 543–550. [Google Scholar] [CrossRef]

- Ayala-Zavala, J.F.; Soto-Valdez, H.; Gonzalez-Leon, A.; Alvarez-Parrilla, E.; Martin-Belloso, O.; Gonzalez-Aguilar, G.A. Microencapsulation of cinnamon leaf (Cinnamomum. zeylanicum) and garlic (Allium sativum) oils in β-cyclodextrin. J. Incl. Phenom. Macrocycl. Chem. 2008, 60, 359–368. [Google Scholar] [CrossRef]

- Trotta, F.; Zanetti, M.; Camino, G. Thermal degradation of cyclodextrins. Polym. Degrad. Stab. 2000, 69, 373–379. [Google Scholar] [CrossRef]

- Muller, J.; Gonzalez-Martinez, C.; Chiralt, A. Poly(lactic) acid (PLA) and starch bilayer films, containing cinnamaldehyde, obtained by compression moulding. Eur. Polym. J. 2017, 95, 56–70. [Google Scholar] [CrossRef]

- Liu, H.; Yang, G.; Tang, Y.; Cao, D.; Qi, T.; Qi, Y.; Fan, G. Physicochemical characterization and pharmacokinetics evaluation of β-caryophyllene/β-cyclodextrin inclusion complex. Int. J. Pharm. 2013, 450, 304–310. [Google Scholar] [CrossRef] [PubMed]

- Ferreira, F.R.; Valentim, I.B.; Ramones, E.L.C.; Trevisan, M.T.S.; Olea-Azar, C.; Perez-Cruz, F.; Abreu, F.C.; Goulart, M.O.F. Antioxidant activity of the mangiferin inclusion complex with β-cyclodextrin. LWT-Food Sci. Technol. 2013, 51, 129–134. [Google Scholar] [CrossRef]

- Wang, X.; Luo, Z.; Xiao, Z. Preparation, characterization, and thermal stability of β-cyclodextrin/soybean lecithin inclusion complex. Carbohydr. Polym. 2014, 101, 1027–1032. [Google Scholar] [CrossRef] [PubMed]

- Kamimura, J.A.; Santos, E.H.; Hill, L.E.; Gomes, C.L. Antimicrobial and antioxidant activities of carvacrol microencapsulated in hydroxypropyl-beta-cyclodextrin. LWT-Food Sci. Technol. 2014, 57, 701–709. [Google Scholar] [CrossRef]

- Guimaraes, A.G.; Oliveira, M.A.; Alves, R.S.; Menezes, P.P.; Serafini, M.R.; Araujo, A.A.S.; Bezerra, D.P.; Quintans, L.J. Encapsulation of carvacrol, a monoterpene present in the essential oil of oregano, with β-cyclodextrin, improves the pharmacological response on cancer pain experimental protocols. Chem. Biol. Interact. 2015, 227, 69–76. [Google Scholar] [CrossRef] [PubMed]

- Nascimento, S.S.; Araujo, A.A.S.; Brito, R.G.; Serafini, M.R.; Menezes, P.P.; DeSantana, J.M.; Lucca, W.; Alves, P.B.; Blank, A.F.; Oliveira, R.C.M.; et al. Cyclodextrin-complexed Ocimum. basilicum leaves essential oil increases Fos protein expression in the central nervous system and produce an antihyperalgesic effect in animal models for fibromyalgia. Int. J. Mol. Sci. 2015, 16, 547–563. [Google Scholar] [CrossRef] [PubMed]

- Bomfim, L.M.; Menezes, L.R.; Rodrigues, A.C.; Dias, R.B.; Rocha, C.A.; Soares, M.B.; Neto, A.F.; Nascimento, M.P.; Campos, A.F.; Silva, L.C.; et al. Antitumour activity of the microencapsulation of Annona vepretorum essential oil. Basic Clin. Pharmacol. Toxicol. 2016, 118, 208–213. [Google Scholar] [CrossRef] [PubMed]

- Adams, R.P. Identification of Essential Oil Components by Gas. Chromatography/Mass Spectrometry; Allured Publishing Corporation: Carol Stream, IL, USA, 2007; pp. 6–398. ISBN 978-1932633214. [Google Scholar]

- Abarca, R.L.; Rodriguez, F.J.; Guarda, A.; Galotto, M.J.; Bruna, J.E. Characterization of beta-cyclodextrin inclusion complexes containing an essential oil component. Food Chem. 2016, 196, 968–975. [Google Scholar] [CrossRef] [PubMed]

- Chang, H.T.; Su, Y.C.; Chang, S.T. Studies on photostability of butyrylated, milled wood lignin using spectroscopic analyses. Polym. Degrad. Stab. 2006, 91, 816–822. [Google Scholar] [CrossRef]

- Ahmad, N.S.; Farman, M.; Najmi, M.H.; Mian, K.B.; Hasan, A. Pharmacological basis for use of Pistacia. integerrima leaves in hyperuricemia and gout. J. Ethnopharmacol. 2008, 117, 478–482. [Google Scholar] [CrossRef] [PubMed]

Sample Availability: Samples of the microcapsules are available from the authors. |

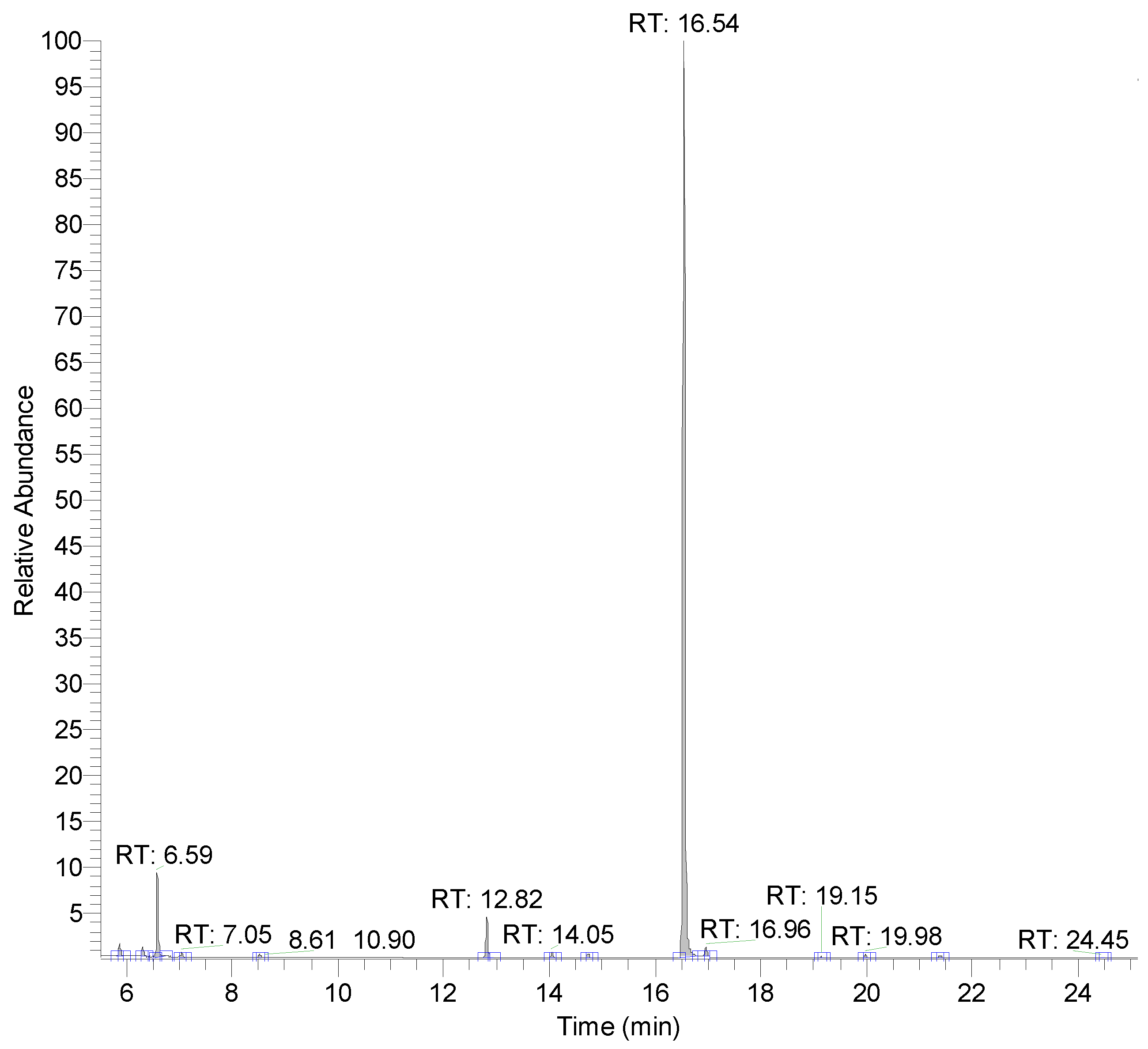

| Rt (min) * | KI ** | Constituent | Formula | Content (%) | Identification Method |

|---|---|---|---|---|---|

| 5.86 | 938 | α-Pinene | C10H16 | 1.09 | MS, KI |

| 6.30 | 955 | Camphene | C10H16 | 0.79 | MS, KI |

| 6.59 | 965 | Benzaldehyde | C7H6O | 7.16 | MS, KI |

| 7.05 | 982 | β-Pinene | C10H16 | 0.36 | MS, KI |

| 8.61 | 1033 | Limonene | C10H16 | 0.21 | MS, KI |

| 12.82 | 1164 | 3-Phenylpropionaldehyde | C9H10O | 3.62 | MS, KI |

| 14.05 | 1198 | Methyl chavicol | C10H12O | 0.55 | MS, KI |

| 14.72 | 1219 | cis-Cinnamaldehyde | C9H8O | 0.50 | MS, KI |

| 16.54 | 1273 | trans-Cinnamaldehyde | C9H8O | 84.13 | MS, KI |

| 16.96 | 1285 | l-Bornyl acetate | C12H20O2 | 0.92 | MS, KI |

| 19.15 | 1351 | Eugenol | C10H12O2 | 0.03 | MS, KI |

| 19.98 | 1376 | α-Copaene | C15H24 | 0.34 | MS, KI |

| 21.40 | 1420 | β-Caryophyllene | C15H24 | 0.29 | MS, KI |

| 24.45 | 1517 | δ-Cadinene | C15H24 | 0.02 | MS, KI |

| Specimen | Specimen:β-CD (w/w) | EtOH:H2O (v/v) | Yield (%) |

|---|---|---|---|

| trans-Cinnamaldehyde | 0:100 | 1:5 | 0.0 ± 0.0 c * |

| 10:90 | 1:5 | 68.8 ± 1.1 b | |

| 15:85 | 1:5 | 83.7 ± 0.7 a | |

| 20:80 | 1:5 | 72.8 ± 1.2 b | |

| 25:75 | 1:5 | 70.8 ± 1.5 b | |

| trans-Cinnamaldehyde | 15:85 | 1:7 | 75.5 ± 1.2 B |

| 15:85 | 1:5 | 83.7 ± 0.7 A | |

| 15:85 | 1:4 | 85.0 ± 0.9 A | |

| 15:85 | 1:3 | 87.3 ± 1.1 A | |

| 15:85 | 1:2 | 65.0 ± 1.8 C | |

| Leaf oil | 15:85 | 1:3 | 86.3 ± 2.0 |

| Specimen | IC50 (μg/mL) |

|---|---|

| β-CD | — |

| Cin oil | 11.2 ± 0.7 b ** |

| β-CD/Cin oil | 83.3 ± 2.0 a |

| Allopurinol * | 0.5 ± 0.1 c |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, C.-Y.; Yeh, T.-F.; Hsu, F.-L.; Lin, C.-Y.; Chang, S.-T.; Chang, H.-T. Xanthine Oxidase Inhibitory Activity and Thermostability of Cinnamaldehyde-Chemotype Leaf Oil of Cinnamomum osmophloeum Microencapsulated with β-Cyclodextrin. Molecules 2018, 23, 1107. https://doi.org/10.3390/molecules23051107

Huang C-Y, Yeh T-F, Hsu F-L, Lin C-Y, Chang S-T, Chang H-T. Xanthine Oxidase Inhibitory Activity and Thermostability of Cinnamaldehyde-Chemotype Leaf Oil of Cinnamomum osmophloeum Microencapsulated with β-Cyclodextrin. Molecules. 2018; 23(5):1107. https://doi.org/10.3390/molecules23051107

Chicago/Turabian StyleHuang, Chi-Ya, Ting-Feng Yeh, Fu-Lan Hsu, Chun-Ya Lin, Shang-Tzen Chang, and Hui-Ting Chang. 2018. "Xanthine Oxidase Inhibitory Activity and Thermostability of Cinnamaldehyde-Chemotype Leaf Oil of Cinnamomum osmophloeum Microencapsulated with β-Cyclodextrin" Molecules 23, no. 5: 1107. https://doi.org/10.3390/molecules23051107