Comparison of Chip Inlet Geometry in Microfluidic Devices for Cell Studies

Abstract

:1. Introduction

2. Results and Discussion

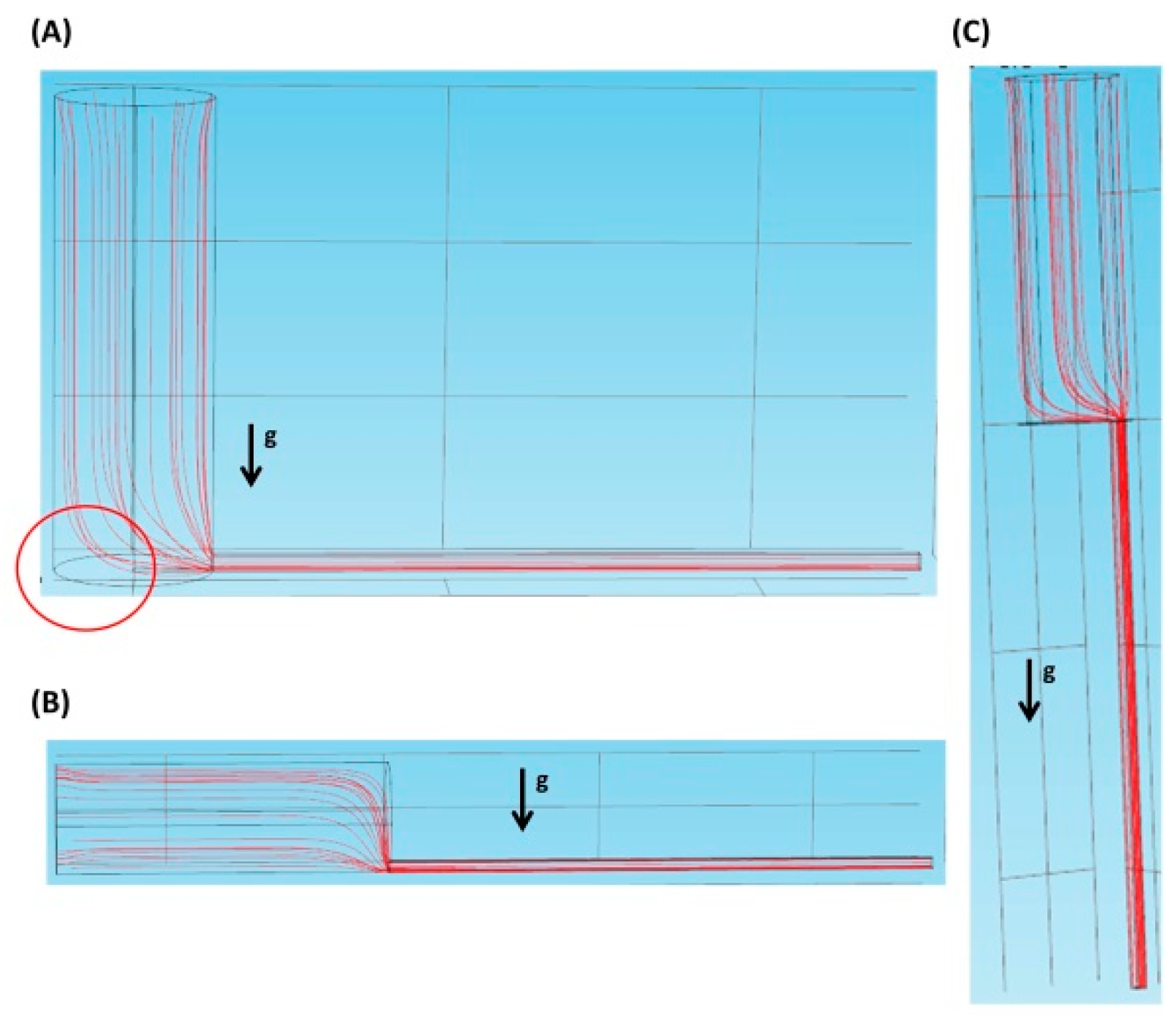

2.1. Velocity Field and Flow Streamline

2.2. Cell Sedimentation

2.3. Effects of Shear Stress

3. Materials and Methods

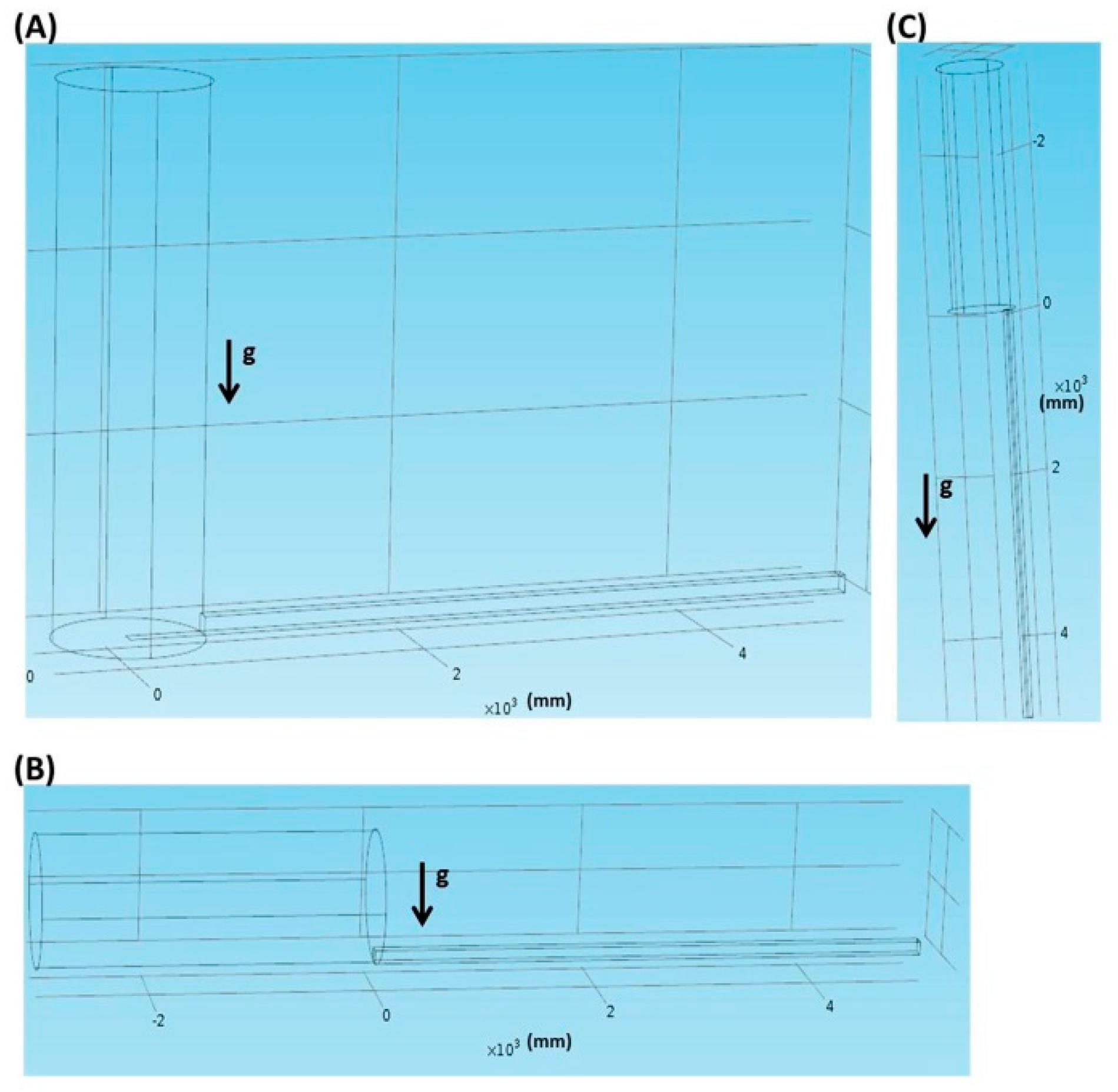

3.1. Different Inlet Geometries

3.2. COMSOL Simulation

4. Conclusions

Acknowledgments

Conflicts of Interest

References

- Cheng, J.Y.; Yen, M.H.; Kuo, C.T.; Young, T.H. A transparent cell-culture microchamber with a variably controlled concentration gradient generator and flow field rectifier. Biomicrofluidics 2008, 2, 24105. [Google Scholar] [CrossRef] [PubMed]

- Terry, S.C.; Jerman, J.H.; Angell, J.B. Gas-Chromatographic Air Analyzer Fabricated on a Silicon-Wafer. IEEE Trans. Electron Devices 1979, 26, 1880–1886. [Google Scholar] [CrossRef]

- Whitesides, G.M.; Ostuni, E.; Takayama, S.; Jiang, X.; Ingber, D.E. Soft lithography in biology and biochemistry. Annu. Rev. Biomed. Eng. 2001, 3, 335–373. [Google Scholar] [CrossRef] [PubMed]

- Kao, Y.C.; Hsieh, M.H.; Liu, C.C.; Pan, H.J.; Liao, W.Y.; Cheng, J.Y.; Kuo, P.L.; Lee, C.H. Modulating chemotaxis of lung cancer cells by using electric fields in a microfluidic device. Biomicrofluidics 2014, 8, 24107. [Google Scholar] [CrossRef] [PubMed]

- Walker, G.M.; Sai, J.Q.; Richmond, A.; Stremler, M.; Chung, C.Y.; Wikswo, J.P. Effects of flow and diffusion on chemotaxis studies in a microfabricated gradient generator. Lab Chip 2005, 5, 611–618. [Google Scholar] [CrossRef] [PubMed]

- Huang, C.W.; Cheng, J.Y.; Yen, M.H.; Young, T.H. Electrotaxis of lung cancer cells in a multiple-electric-field chip. Biosens. Bioelectron. 2009, 24, 3510–3516. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.S.; Peng, S.W.; Lin, K.H.; Cheng, J.Y. Electrotaxis of lung cancer cells in ordered three-dimensional scaffolds. Biomicrofluidics 2012, 6, 14102. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.S.; Peng, S.W.; Cheng, J.Y. In vitro electrical-stimulated wound-healing chip for studying electric field-assisted wound-healing process. Biomicrofluidics 2012, 6, 34117. [Google Scholar] [CrossRef] [PubMed]

- Lo, K.Y.; Wu, S.Y.; Sun, Y.S. A microfluidic device for studying the production of reactive oxygen species and the migration in lung cancer cells under single or coexisting chemical/electrical stimulation. Microfluid Nanofluid 2016, 20. [Google Scholar] [CrossRef]

- Pang, L.; Shen, S.F.; Ma, C.; Ma, T.T.; Zhang, R.; Tian, C.; Zhao, L.; Liu, W.M.; Wang, J.Y. Deformability and size-based cancer cell separation using an integrated microfluidic device. Analyst 2015, 140, 7335–7346. [Google Scholar] [CrossRef] [PubMed]

- Sun, J.S.; Liu, C.; Li, M.M.; Wang, J.D.; Xianyu, Y.L.; Hu, G.Q.; Jiang, X.Y. Size-based hydrodynamic rare tumor cell separation in curved microfluidic channels. Biomicrofluidics 2013, 7, 11802. [Google Scholar] [CrossRef] [PubMed]

- McFaul, S.M.; Lin, B.K.; Ma, H.S. Cell separation based on size and deformability using microfluidic funnel ratchets. Lab Chip 2012, 12, 2369–2376. [Google Scholar] [CrossRef] [PubMed]

- Li, P.; T'ian, Y.; Pappas, D. Comparison of Inlet Geometry in Microfluidic Cell Affinity Chromatography. Anal. Chem. 2011, 83, 774–781. [Google Scholar] [CrossRef] [PubMed]

- Gossett, D.R.; Weaver, W.M.; Mach, A.J.; Hur, S.C.; Tse, H.T.K.; Lee, W.; Amini, H.; di Carlo, D. Label-free cell separation and sorting in microfluidic systems. Anal. Bioanal. Chem. 2010, 397, 3249–3267. [Google Scholar] [CrossRef] [PubMed]

- Hou, H.W.; Warkiani, M.E.; Khoo, B.L.; Li, Z.R.; Soo, R.A.; Tan, D.S.W.; Lim, W.T.; Han, J.; Bhagat, A.A.S.; Lim, C.T. Isolation and retrieval of circulating tumor cells using centrifugal forces. Sci. Rep. UK 2013, 3, 1259. [Google Scholar] [CrossRef] [PubMed]

- Lee, M.G.; Shin, J.H.; Bae, C.Y.; Choi, S.Y.; Park, J.K. Label-Free Cancer Cell Separation from Human Whole Blood Using Inertial Microfluidics at Low Shear Stress. Anal. Chem. 2013, 85, 6213–6218. [Google Scholar] [CrossRef] [PubMed]

- Zhao, W.A.; Cui, C.H.; Bose, S.; Guo, D.G.; Shen, C.; Wong, W.P.; Halvorsen, K.; Farokhzad, O.C.; Teo, G.S.L.; Phillips, J.A.; et al. Bioinspired multivalent DNA network for capture and release of cells. Proc. Natl. Acad. Sci. USA 2012, 109, 19626–19631. [Google Scholar] [CrossRef] [PubMed]

- Xia, N.; Hunt, T.P.; Mayers, B.T.; Alsberg, E.; Whitesides, G.M.; Westervelt, R.M.; Ingber, D.E. Combined microfluidic-micromagnetic separation of living cells in continuous flow. Biomed. Microdevices 2006, 8, 299–308. [Google Scholar] [CrossRef] [PubMed]

- Zelenin, S.; Hansson, J.; Ardabili, S.; Ramachandraiah, H.; Brismar, H.; Russom, A. Microfluidic-based isolation of bacteria from whole blood for sepsis diagnostics. Biotechnol. Lett. 2015, 37, 825–830. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.G.; Willing, B.; Bjerketorp, J.; Jansson, J.K.; Hjort, K. Soft inertial microfluidics for high throughput separation of bacteria from human blood cells. Lab Chip 2009, 9, 1193–1199. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.J.; Jeong, K.J.; Hashimoto, M.; Kwon, A.H.; Rwei, A.; Shankarappa, S.A.; Tsui, J.H.; Kohane, D.S. Synthetic Ligand-Coated Magnetic Nanoparticles for Microfluidic Bacterial Separation from Blood. Nano Lett. 2014, 14. [Google Scholar] [CrossRef] [PubMed]

- Fredrickson, C.K.; Fan, Z.H. Macro-to-micro interfaces for microfluidic devices. Lab Chip 2004, 4, 526–533. [Google Scholar] [CrossRef] [PubMed]

- Kortmann, H.; Blank, L.M.; Schmid, A. A rapid, reliable, and automatable lab-on-a-chip interface. Lab Chip 2009, 9, 1455–1460. [Google Scholar] [CrossRef] [PubMed]

- Zhu, L.; Peh, X.L.; Ji, H.M.; Teo, C.Y.; Feng, H.H.; Liu, W.T. Cell loss in integrated microfluidic device. Biomed. Microdevices 2007, 9, 745–750. [Google Scholar] [CrossRef] [PubMed]

- Li, M.W.; Huynh, B.H.; Hulvey, M.K.; Lunte, S.M.; Martin, R.S. Design and characterization of poly(dimethylsiloxane)-based valves for interfacing continuous-flow sampling to microchip electrophoresis. Anal. Chem. 2006, 78, 1042–1051. [Google Scholar] [CrossRef] [PubMed]

- Chisti, Y. Hydrodynamic damage to animal cells. Crit. Rev. Biotechnol. 2001, 21, 67–110. [Google Scholar] [CrossRef] [PubMed]

- Davies, P.F.; Remuzzi, A.; Gordon, E.J.; Dewey, C.F., Jr.; Gimbrone, M.A., Jr. Turbulent fluid shear stress induces vascular endothelial cell turnover in vitro. Proc. Natl. Acad. Sci. USA 1986, 83, 2114–2117. [Google Scholar] [CrossRef] [PubMed]

- Prokop, A.; Bajpai, R.K. The sensitivity of biocatalysts to hydrodynamic shear stress. Adv. Appl. Microbiol. 1992, 37, 165–232. [Google Scholar]

- Zoro, B.J.H.; Owen, S.; Drake, R.A.L.; Hoare, M. The impact of process stress on suspended anchorage-dependent mammalian cells as an indicator of likely challenges for regenerative medicines. Biotechnol. Bioeng. 2008, 99, 468–474. [Google Scholar] [CrossRef] [PubMed]

- Lo, K.Y.; Zhu, Y.; Tsai, H.F.; Sun, Y.S. Effects of shear stresses and antioxidant concentrations on the production of reactive oxygen species in lung cancer cells. Biomicrofluidics 2013, 7, 64108. [Google Scholar] [CrossRef] [PubMed]

- Lu, H.; Koo, L.Y.; Wang, W.M.; Lauffenburger, D.A.; Griffith, L.G.; Jensen, K.F. Microfluidic shear devices for quantitative analysis of cell adhesion. Anal. Chem. 2004, 76, 5257–5264. [Google Scholar] [CrossRef] [PubMed]

- Sample Availability: Not available.

| Flow Velocity 1 (m/s) | 0.00001 | 0.00002 | 0.00005 | 0.0001 | 0.001 | 0.01 |

|---|---|---|---|---|---|---|

| Mass flow rate (μL/min) | 0.471 | 0.942 | 2.355 | 4.71 | 47.1 | 471 |

| Shear stress (Pa) | 0.07536 | 0.15072 | 0.3768 | 0.7536 | 7.536 | 75.36 |

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Y.-S. Comparison of Chip Inlet Geometry in Microfluidic Devices for Cell Studies. Molecules 2016, 21, 778. https://doi.org/10.3390/molecules21060778

Sun Y-S. Comparison of Chip Inlet Geometry in Microfluidic Devices for Cell Studies. Molecules. 2016; 21(6):778. https://doi.org/10.3390/molecules21060778

Chicago/Turabian StyleSun, Yung-Shin. 2016. "Comparison of Chip Inlet Geometry in Microfluidic Devices for Cell Studies" Molecules 21, no. 6: 778. https://doi.org/10.3390/molecules21060778