Room Temperature Ionic Liquids as Green Solvent Alternatives in the Metathesis of Oleochemical Feedstocks

Abstract

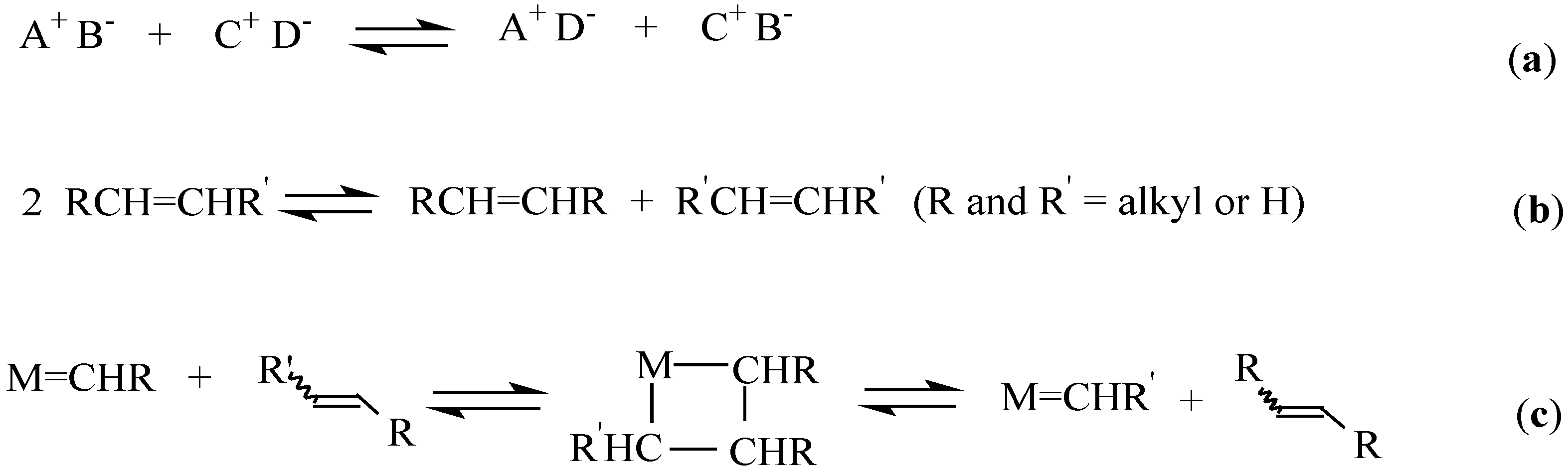

:1. Introduction

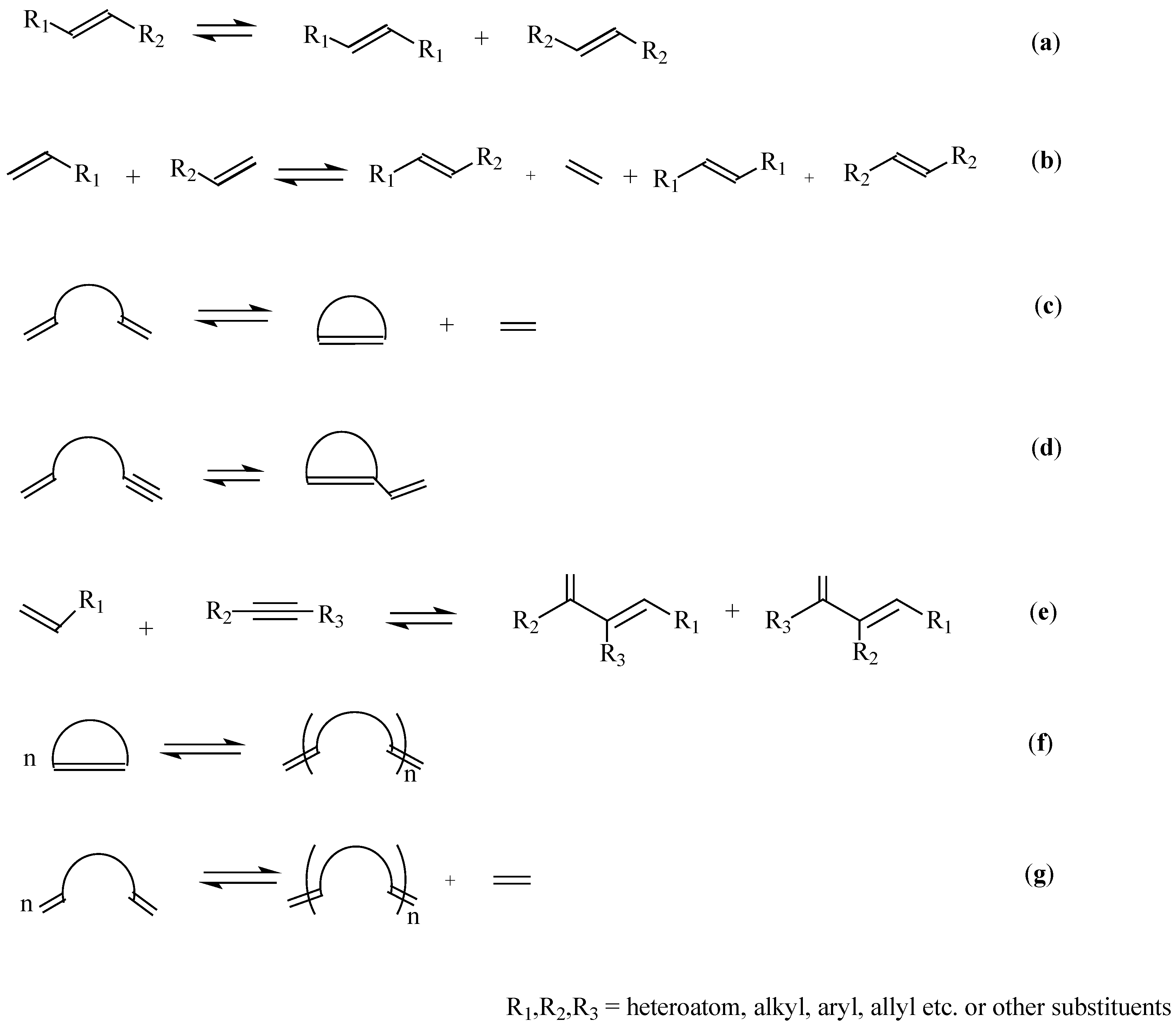

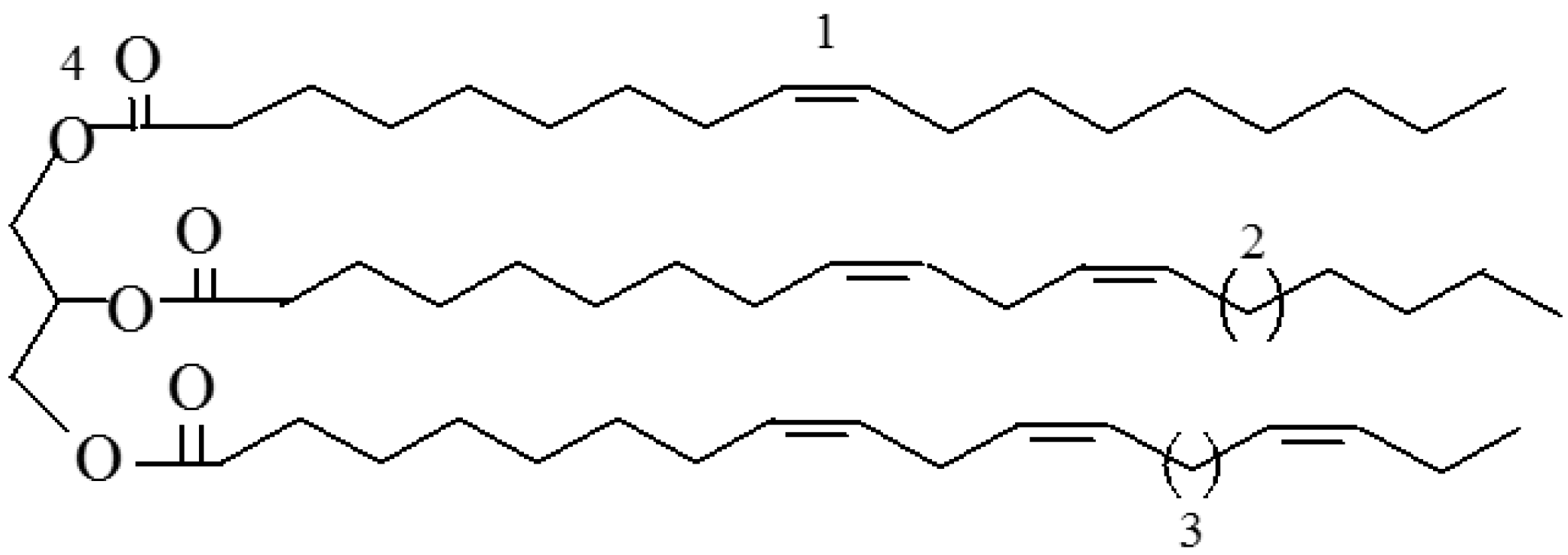

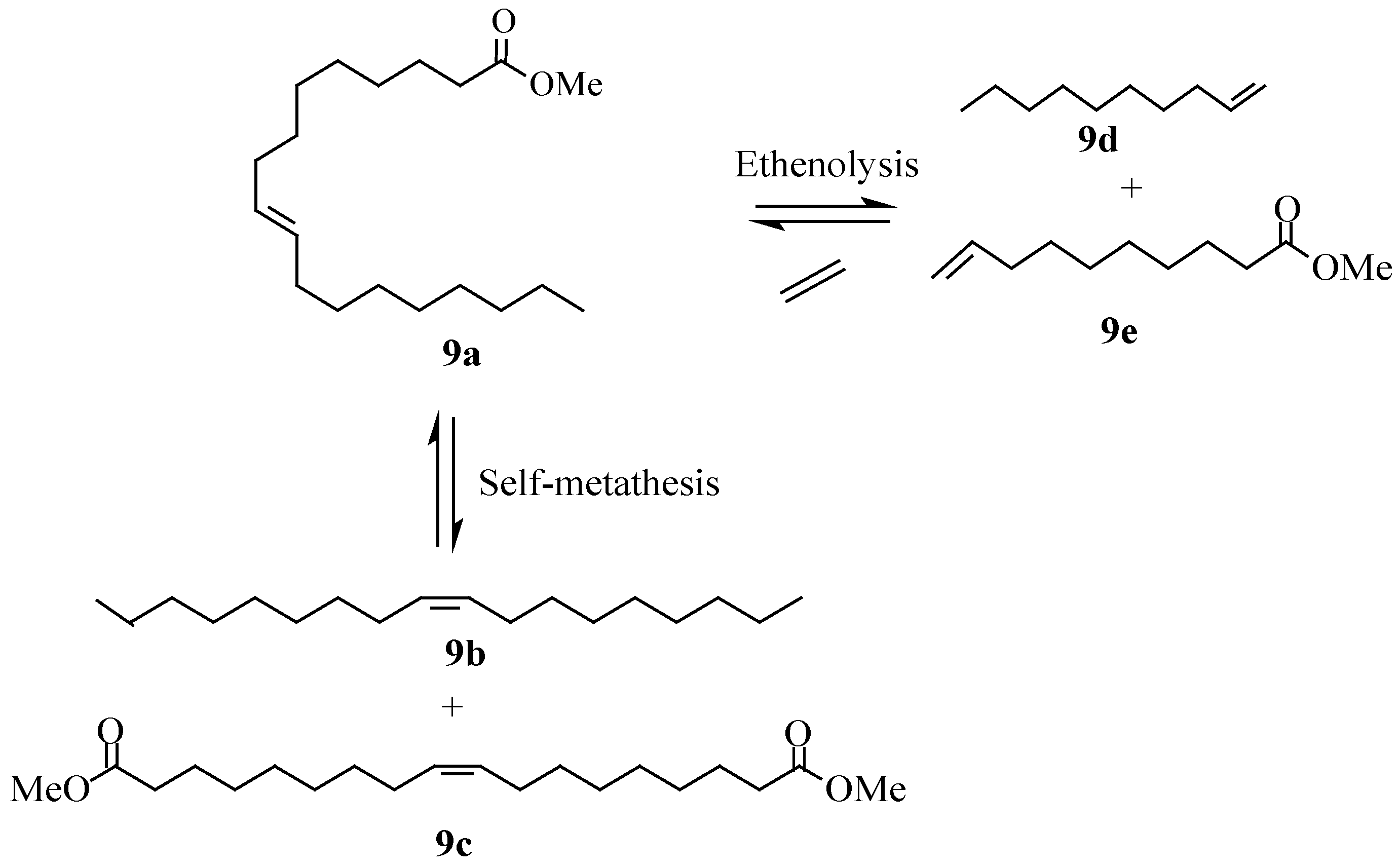

2. Oleochemical Feedstocks in Olefin Metathesis

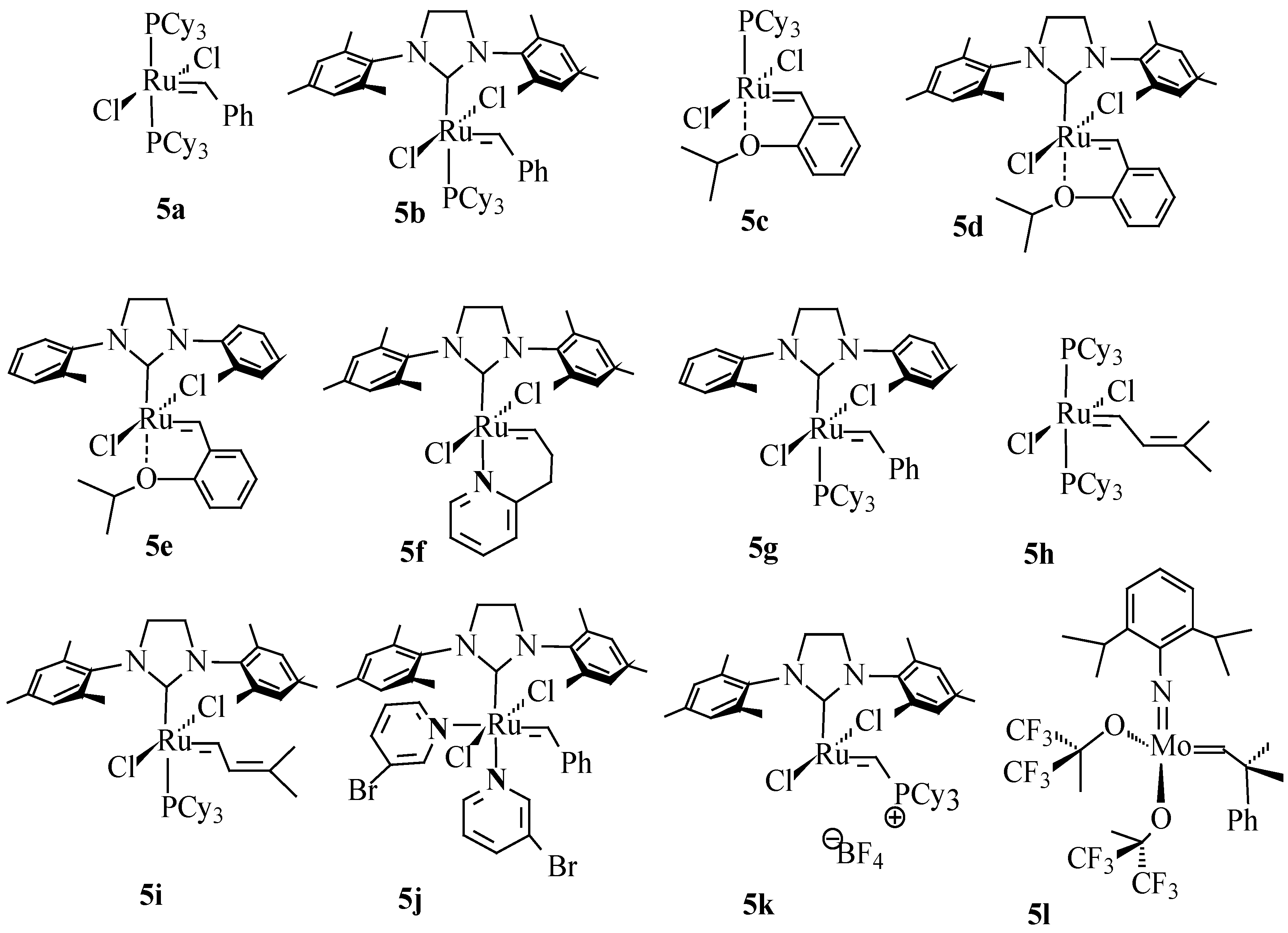

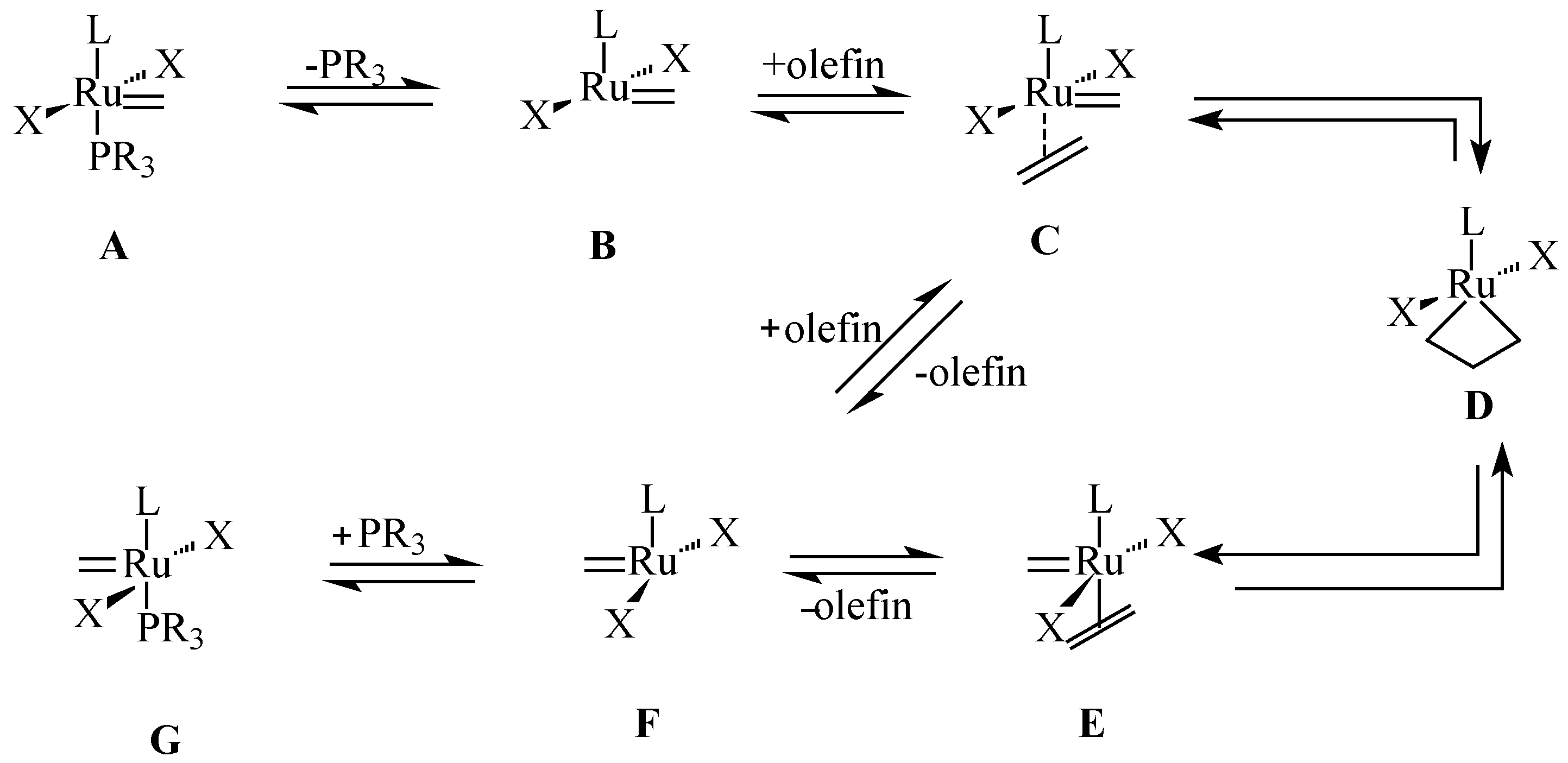

3. Overview of Catalyst Systems

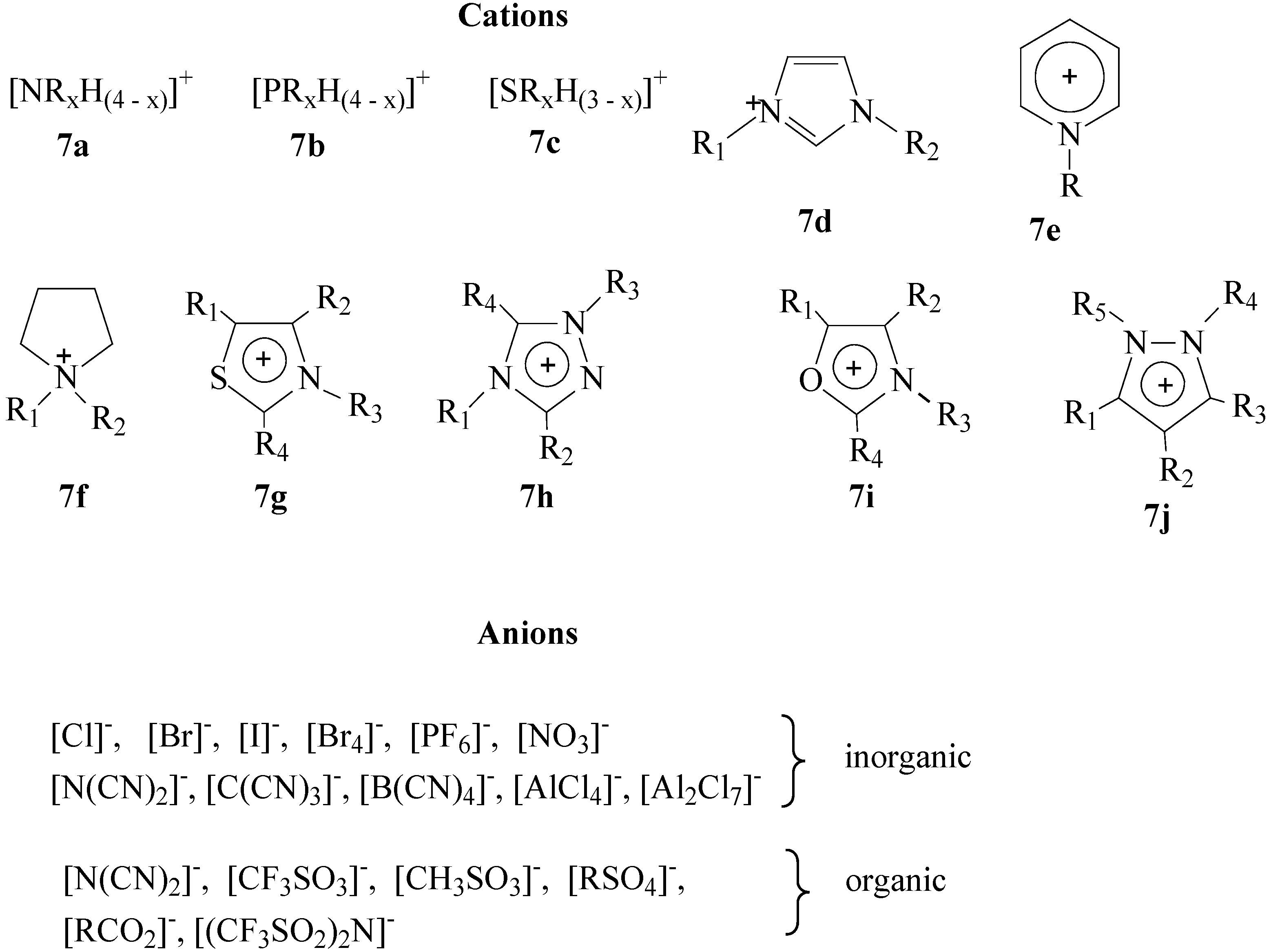

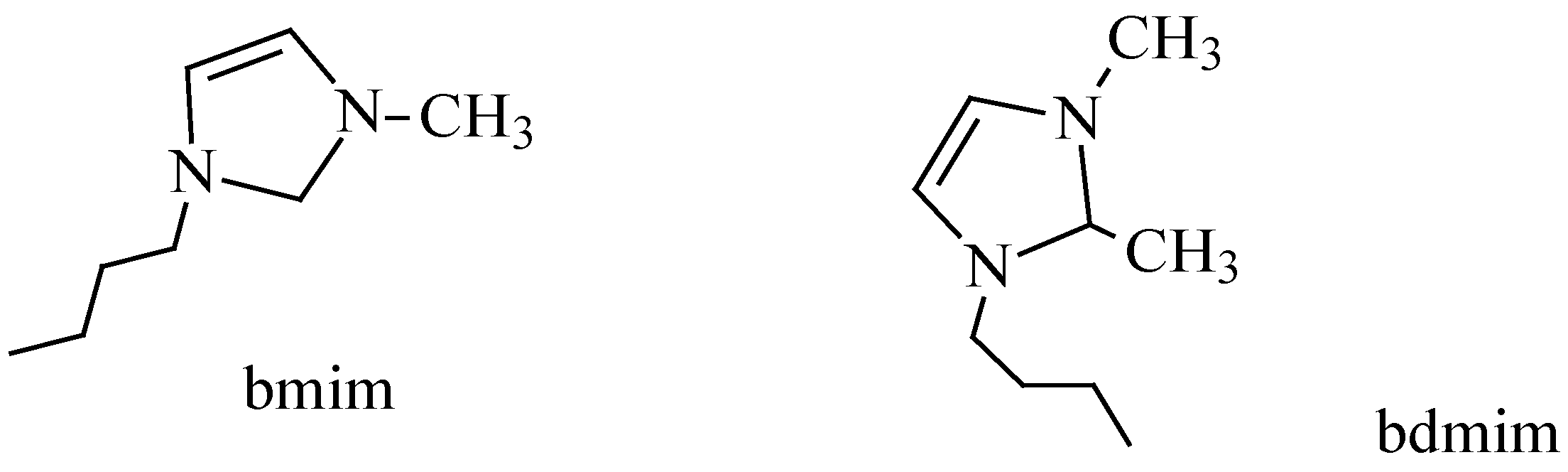

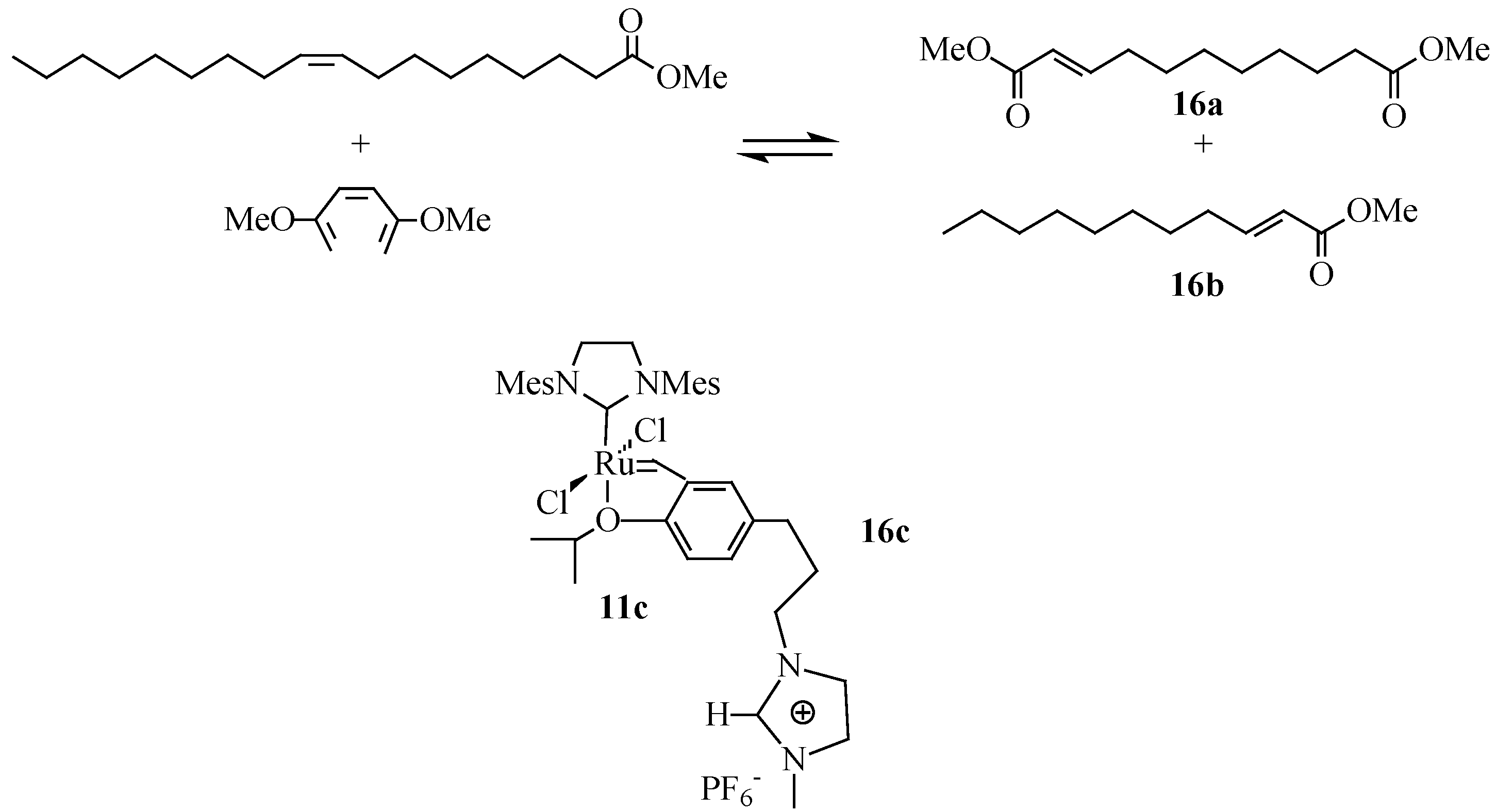

4. RTILs as Green Solvent Alternatives

Properties of RTILs

- Ability to dissolve many organic, inorganic and organometallic compounds.

- Immiscibility with many organic solvents.

- High polarity.

- Loosely coordinating bulky ions.

- Generally very low vapor pressures and low volatility.

- Thermal stability up to 300 °C approximately.

- High thermal conductivity and a large electrochemical window.

- Most have a liquid window of up to 200 °C which enables wide kinetic control.

- Nonaqueous polar alternatives for phase transfer processes.

5. Applications of RTILs in Metathesis of Oleochemical Feedstocks

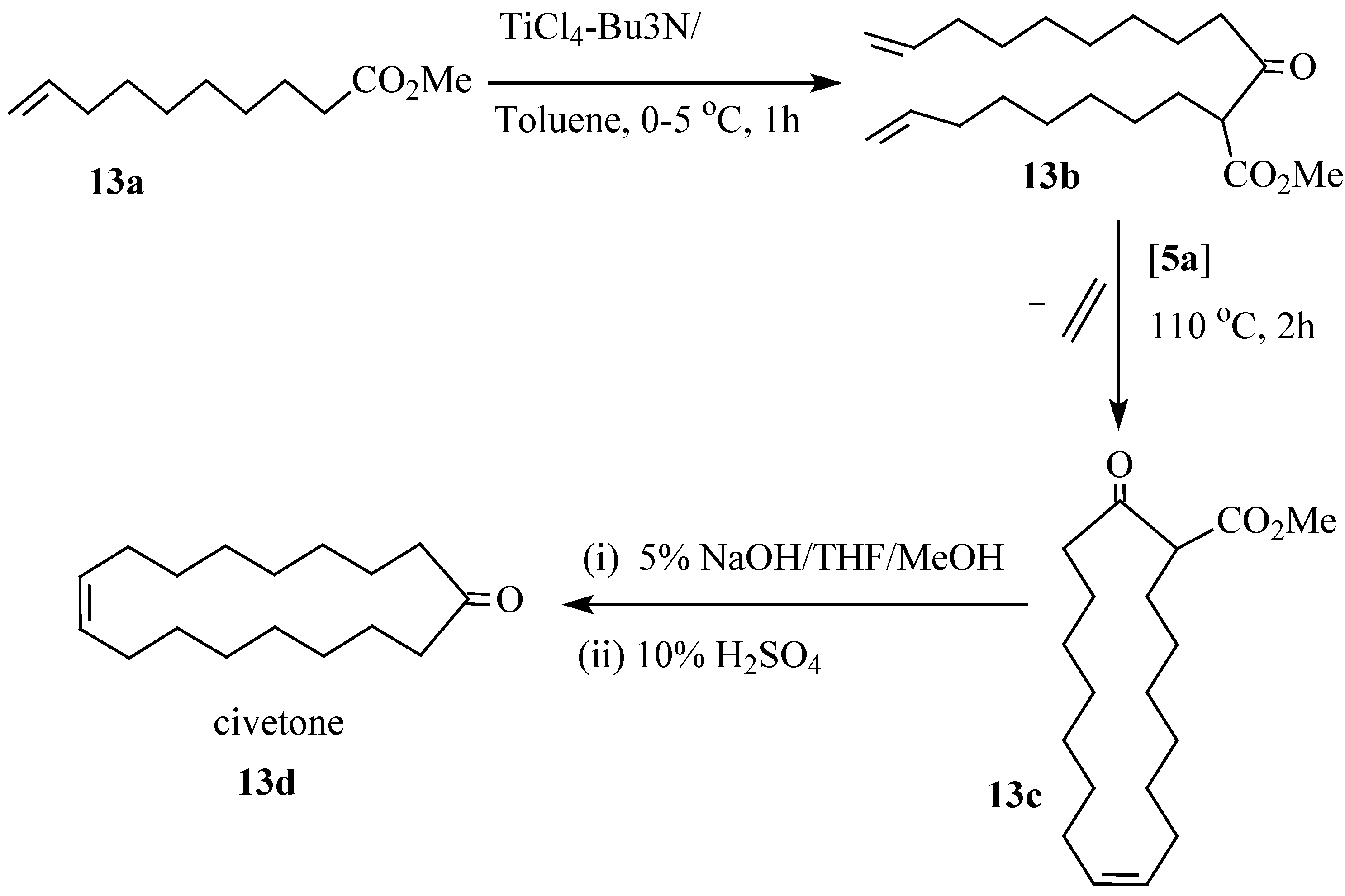

5.1. Self-Metathesis

| Solvent/RTIL | Temperature/°C | Conversion/% | Selectivity/% | Substrate/Ru |

|---|---|---|---|---|

| Catalyst 5a | ||||

| DCM | 20 | 49 | 100 | 102 |

| 100 | 59 | 71 | ||

| DCE | 20 | 51 | 100 | 102 |

| [bmim][PF6] | 20 | 50 | 100 | 104 |

| 60 | 59 | 99 | ||

| [bmim][BF4] | 20 | 54 | 100 | 104 |

| 60 | 61 | 95 | ||

| [bmim][NTf2] | 20 | 51 | 100 | 104 |

| 60 | 61 | 99 | ||

| Catalyst 5b | ||||

| DCM | 20 | 52 | 100 | 102 |

| 120 | 81 | 27 | ||

| DCE | 20 | 51 | 100 | 102 |

| [bmim][PF6] | 20 | 53 | 100 | 104 |

| 60 | 75 | 81 | ||

| [bmim][BF4] | 20 | 59 | 100 | 104 |

| 60 | 78 | 87 | ||

| [bmim][NTf2] | 20 | 61 | 99 | 104 |

| 60 | 73 | 72 | ||

| RTIL | Temperature/°C | Conversion/% | Selectivity/% | Substrate/Ru |

|---|---|---|---|---|

| Catalyst 5c | ||||

| [bmim][PF6] | 40 | 57 | 99 | 102 |

| 60 | 60 | 97 | ||

| [bmim][BF4] | 40 | 58 | 99 | 102 |

| 60 | 60 | 97 | ||

| Catalyst 5d | ||||

| [bdmim][PF6] | 40 | 81 | 98 | 102 |

| 60 | 90 | 95 | ||

| [bdmim][BF4] | 40 | 85 | 99 | 102 |

| 60 | 92 | 95 | ||

| RTIL | Temperature/°C | Conversion/% | Selectivity/% | Substrate/Ru |

|---|---|---|---|---|

| Catalyst 5a | ||||

| [bmim][PF6] | 60 | 45 | 99 | 102 |

| [bmim][BF4] | 60 | 41 | 99 | |

| [bmim][NTf2] | 60 | 38 | 99 | |

| Catalyst 5b | ||||

| [bdmim][PF6] | 60 | 58 | 99 | 102 |

| [bmim][BF4] | 60 | 56 | 99 | |

| [bdmim][NTf2] | 60 | 55 | 99 | 102 |

5.2. Ethenolysis

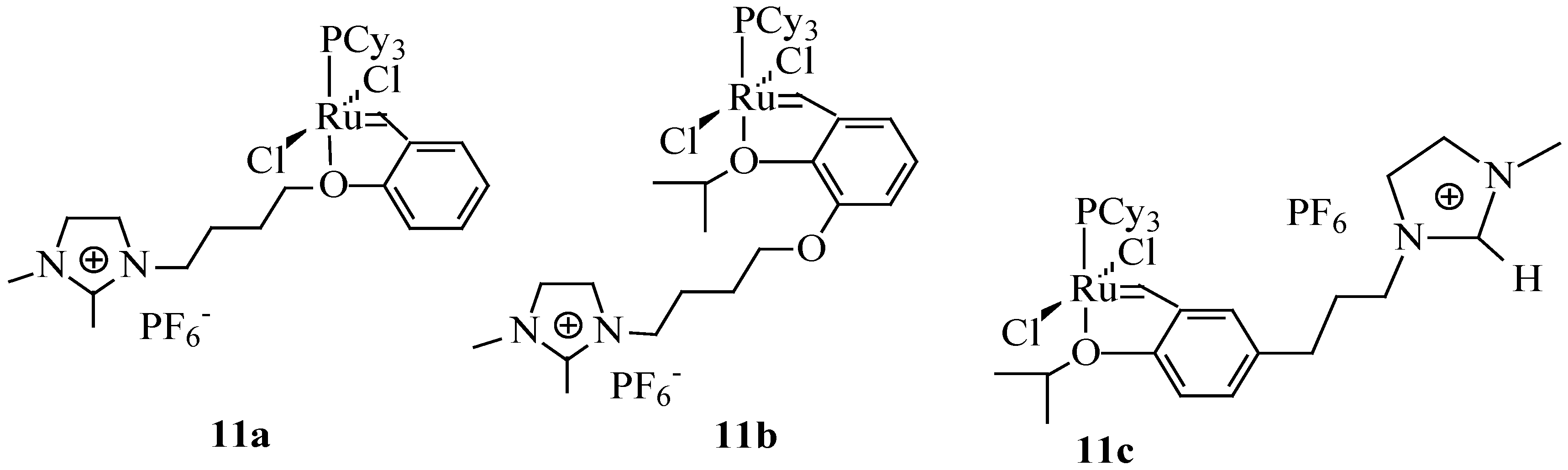

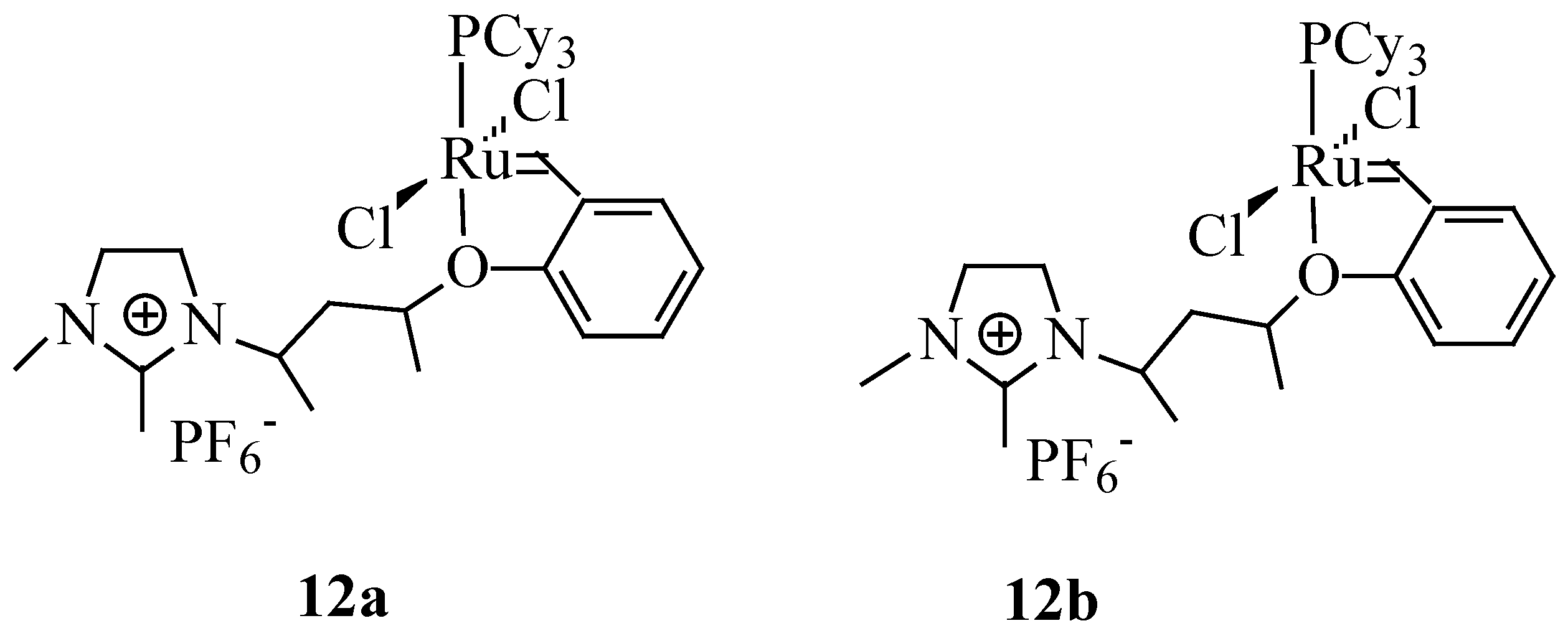

5.3. Cross-Metathesis in Biphasic Systems

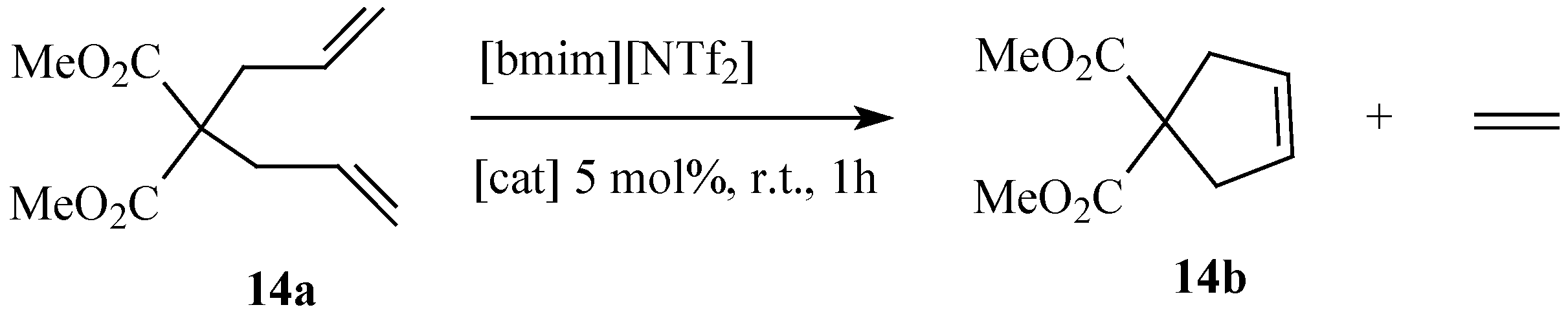

5.4. Ring Closing Metathesis

5.5. Metathesis Using Supported Ionic Liquid Phase

5.6. Limitations with RTILs

6. Future Directions

7. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Banks, R.L.; Bailey, G.C. Olefin disproportionation: A new catalytic process. Ind. Eng. Chem. Prod. Res. Dev. 1964, 3, 170–173. [Google Scholar]

- Calderon, N.; Chen, H.Y.; Scott, K.W. Olefin metathesis—A novel reaction for skeletal transformations of unsaturated hydrocarbons. Tetrahedron Lett. 1967, 34, 3327–3329. [Google Scholar]

- Mol, J.C. Applications of olefin metathesis in oleochemistry: An example of green chemistry. Green Chem. 2002, 4, 5–13. [Google Scholar] [CrossRef]

- Mol, J.C. Catalytic metathesis of unsaturated fatty acid esters and oils: Catalytic conversion of renewables. Top. Catal. 2004, 27, 97–104. [Google Scholar]

- Plugge, M.F.C.; Mol, J.C. A new synthesis of civetone. Synlett 1991, 70, 507–508. [Google Scholar] [CrossRef]

- Ivin, K.J. Some recent applications of the olefin metathesis in organic synthesis: A review. J. Mol. Catal. A Chem. 1998, 133, 1–16. [Google Scholar]

- Copéret, C. Stereoselectivity of supported alkene metathesis catalysts: A goal and a tool to characterize active sites. Beilstein J. Org. Chem. 2011, 7, 13–21. [Google Scholar] [PubMed]

- Loupy, A.; Tchoubar, B.; Astruc, D. Salt effects resulting from exchange between two ion-pairs and their critical role on reaction pathways. Chem. Rev. 1992, 92, 1141–1165. [Google Scholar]

- Hérisson, J.-L.; Chauvin, Y. Catalyse de transformation des olefins par les complexes du tungsténe II. Télomérisation des olefins cycliques en presence dʹoléfines acycligues. Makromol. Chem. 1971, 141, 161–176. [Google Scholar] [CrossRef]

- De Espinosa, L.M.; Meier, M.A.R. Olefin metathesis of renewable platform chemicals. Top. Organomet. Chem. 2012, 39, 1–44. [Google Scholar]

- Fischmeister, C.; Bruneau, C. RTILS in catalytic olefin metathesis reactions. Top. Organomet. Chem. 2013, 51, 287–305. [Google Scholar]

- Miao, S.; Wang, P.; Su, Z.; Zhang, S. Vegetable-oil-based polymers as future polymeric biomaterials. Acta Biomater. 2014, 10, 1692–1704. [Google Scholar] [CrossRef] [PubMed]

- Lligadas, G.; Ronda, J.C.; Galià, M.; Cádiz, V. Renewable polymeric materials from vegetable oils: A perspective. Mater. Today 2013, 16, 337–343. [Google Scholar]

- Meier, M.A.R. Metathesis with oleochemicals: New approaches for the utilization of plant oils as renewable resources in polymer science. Macromol. Chem. Phys. 2009, 210, 1073–1079. [Google Scholar]

- Hoveyda, A.H.; Zhugralin, A.R. The remarkable metal-catalysed olefin metathesis reaction. Nature 2007, 37, 2433–2442. [Google Scholar] [CrossRef] [PubMed]

- Sanford, M.S.; Ulman, M.; Grubbs, R.H. New insights into the mechanism of Ruthenium-catalyzed olefin metathesis reactions. J. Am. Chem. Soc. 2001, 123, 749–750. [Google Scholar] [PubMed]

- Sanford, M.S.; Love, J.A.; Grubbs, R.H. Mechanism and activity of ruthenium olefin metathesis catalysts. J. Am. Chem. Soc. 2001, 123, 6543–6554. [Google Scholar] [CrossRef] [PubMed]

- Adlhart, C.; Chen, P. Mechanism and activity of ruthenium olefin metathesis catalysts: The role of ligands and substrates from a theoretical perspective. J. Am. Chem. Soc. 2004, 126, 3496–3510. [Google Scholar] [CrossRef] [PubMed]

- Scott, S.L. Catalytic transformation of seed oil derivatives via olefin metathesis. HELIA 2007, 30, 133–142. [Google Scholar]

- Weskamp, T.; Schattenmann, W.C.; Spiegler, M.; Hermann, W.A. A novel class of ruthenium catalysts for olefin metathesis. Angew. Chem. Int. Ed. 1998, 37, 2490–2493. [Google Scholar]

- Hoveyda, A.H.; Gillingham, D.G.; van Veldhuizen, J.J.; Kataoka, O.; Garber, S.B.; Kingsbury, J.B.; Harrity, J.P.A. Ru complexes bearing bidentate carbenes: From innocent curiosity to uniquely effective catalysts for olefin metathesis. Org. Biomol. Chem. 2004, 2, 8–23. [Google Scholar] [CrossRef] [PubMed]

- Śledź, P.; Mauduit, M.; Grela, K. Olefin metathesis in ionic liquids. Chem. Soc. Rev. 2008, 37, 2433–2442. [Google Scholar] [PubMed]

- Cornils, B.; Herrmann, W.A. Aqueous-Phase Organometallic Catalysis—Concept and Applications; Wiley/VCH: Weinheim, Germany, 1998. [Google Scholar]

- Joo, F.; Beck, M.T. Formation and catalytic properties of water-soluble phosphine complexes. React. Kinet. Catal. Lett. 1975, 2, 257–263. [Google Scholar]

- Kuntz, E. Homogeneous catalysis in water. Chemtech 1987, 17, 570–575. [Google Scholar]

- Horvath, I.T.; Rabai, J. Facile catalyst separation without water: Flourous biphase hydroformylation of olefins. Science 1994, 266, 72–75. [Google Scholar] [CrossRef] [PubMed]

- Horvath, I.T. Flourous phases. In Aqueous-phase Organometallic Catalysis-Concepts and Applications; Cornils, B., Herrmann, W.A., Eds.; Wiley/VCH: Weinheim, Germany, 1998; p. 548. [Google Scholar]

- Jessop, P.G.; Ikariya, T.; Noyori, R. Homogeneous catalysis in supercritical fluids. Chem. Rev. 1999, 99, 475–493. [Google Scholar] [PubMed]

- Welton, T. Room temperature ionic liquids: Solvents for synthesis and catalysis. Chem. Rev. 1999, 99, 2071–2084. [Google Scholar] [PubMed]

- Sugden, S.H.; Wilkins, H. The parachor and chemical constitution. Part X11. Fused metals and salts. J. Chem. Soc. 1929, 1291–1298. [Google Scholar]

- Gorman, J. Faster, better, cleaner?: New liquids take aim at old-fashioned chemistry. Sci. News 2001, 160, 156–158. [Google Scholar] [CrossRef]

- Tavares, A.P.M.; Rodrígues, O.; Macedo, E.A. New generations of ionic liquids applied to enzymatic biocatalysis. In Ionic Liquids—New Aspects for the Future; Kadokawa, J., Ed.; Intech: Rijeka, Croatia, 2013; pp. 537–556. [Google Scholar]

- Peric, B.; Martí, E.; Sierra, J.; Cruańas, R.; Garau, M.A. Green chemistry: Ecotoxicity and biodegradability of ionic liquids. In Recent Advances in Pharmaceutical Sciences II; Muńoz-Torrero, D., Haro, D., Vallés, J., Eds.; Transworld Research Network: Kerala, India, 2012; pp. 89–113. [Google Scholar]

- Bond, D.R.; Jackson, G.E.; Joao, H.C.; Hofmeyr, M.N.; Modro, T.A.; Nassimbeni, L.R. Liquid clathrates. J. Chem. Soc. Chem. Commun. 1989, 24, 1910–1911. [Google Scholar]

- Hill, M.G.; Lamanna, W.M.; Mann, K.R. Tetrabutylammonium tetrakis[3, 5-bis(trifluoromethyl)phenyl]borate as a non-coordinating electrolyte: Reversible 1e-oxidations of ruthenocene, osmocene, and Rh2(TM4)42+. Inorg. Chem. 1991, 30, 4687–4690. [Google Scholar]

- Sun, J.; Forsyth, M.; Mac Farlane, D.R. Room temperature molten salts based on quartenary ammonium ion. J. Phys. Chem. B 1998, 102, 8858–8861. [Google Scholar]

- Olivier-Bourbigou, H.; Magna, L. Ionic liquids: Perspectives for organic and catalytic reactions. J. Mol. Catal. A Chem. 2002, 182, 419–437. [Google Scholar]

- Miyatake, K.; Yamamoto, K.; Endo, K.; Tsuchida, E. Superacidified reaction of sulfides and esters for the direct synthesis of sulfonium derivatives. J. Org. Chem. 1998, 63, 7522–7524. [Google Scholar] [PubMed]

- Wilkes, J.S.; Levisky, J.A.; Wilson, R.A.; Hussey, C.L. Dialkylimidazolium chloroaluminate melts: A new class of room temperature ionic liquids for electroscopy, spectroscopy and synthesis. Inorg. Chem. 1982, 21, 1263–1264. [Google Scholar]

- Fannin, A.A., Jr.; King, L.A.; Levisky, J.A.; Wilkes, J.S. Properties of 1,3-dialkylimidazolium chloride-aluminium chloride ionic liquids. 1. Ion interactions by nuclear magnetic resonance spectroscopy. J. Phys. Chem. 1984, 88, 2609–2614. [Google Scholar] [CrossRef]

- Thomas, P.A.; Marvey, B.B. C18:1 methyl ester metathesis in [bmim][X] type ionic liquids. Int. J. Mol. Sci. 2009, 11, 5020–5030. [Google Scholar]

- Bonhˆote, P.; Dias, A.P.; Papageorgiou, K.; Kalyanasundaram, K.; Grätzel, M. Hydrophobic, highly conductive ambient-temperature molten salts. Inorg. Chem. 1996, 35, 1168–1178. [Google Scholar]

- Hurley, F.H.; Weir, T.P. Electrodeposition of metals from fused quarternary ammonium salts. J. Electrochem. Soc. 1951, 98, 203–206. [Google Scholar]

- Gale, R.J.; Osteryoung, R.A. Infrared spectral investigations of room-temperature aluminium chloride-1-butylpyridinium chloride melts. Inorg. Chem. 1980, 19, 2240–2242. [Google Scholar]

- Tait, S.; Osteryoung, R.A. Infrared study of ambient-temperature chloroaluminates as a function of melt acidity. Inorg. Chem. 1984, 23, 4352–4360. [Google Scholar] [CrossRef]

- Mac Farlane, D.R.; Meakin, P.; Sun, J.; Amini, N.; Forsyth, M. Pyrrolidinium imides: A new family of molten salts and conductive plastic crystal phases. J. Phys. Chem. B. 1999, 103, 4164–4170. [Google Scholar] [CrossRef]

- Davis, J.H., Jr.; Forrester, K.J. Thiazolium-ion based organic ionic liquids. Tetrahedron Lett. 1999, 40, 1621–1622. [Google Scholar] [CrossRef]

- Vestergaard, B.B.; Petrushina, N.J.I.; Hjuler, H.A.; Berg, R.W.; Begtrup, M. Molten triazolium chloride systems as new aluminium battery electrolytes. J. Electrochem. Soc. 1993, 140, 3108–3113. [Google Scholar]

- Jorapur, Y.R.; Chi, D.Y. Ionic Liquids: An Environmentally Friendly Media for Nucleophilic Substitution Reactions. Bull. Korean Chem. Soc. 2006, 27, 345–354. [Google Scholar]

- Hussey, C.L. The electrochemistry of room temperature haloaluminate molten salts. In Chemistry of Nonaqueous Solutions: Current Progress; Mamantov, G., Popov, A.I., Eds.; VCH: New York, NY, USA, 1994; pp. 227–275. [Google Scholar]

- Brennecke, J.F.; Maginn, E.J. Ionic liquids: Innovative fluids for chemical processing. AIChE J. 2001, 47, 2384–2388. [Google Scholar]

- Garcia, M.T.; Gathergood, N.; Scammells, P.J. Biodegradable ionic liquids Part II. Effect of the anion and toxicology. Green Chem. 2005, 7, 9–14. [Google Scholar] [CrossRef]

- Tao, G.-H.; He, L.; Sun, N.; Kou, Y. New generation ionic liquids: Cations derived from amino acids. Chem. Commun. 2005, 28, 3562–3564. [Google Scholar] [CrossRef] [PubMed]

- Yang, Q.; Dionysiou, D.D. Photolytic degradation of chlorinated phenols in room temperature ionic liquids. J. Photochem. Photobiol. A: Chem. 2004, 165, 229–240. [Google Scholar]

- Seddon, K.R. Room-temperature ionic liquids-neoteric solvents for clean catalysis. Kinet. Catal. 1996, 37, 693–697. [Google Scholar]

- Lagrost, C.; Carrié, D.; Vaultier, M.; Hapiot, P. Reactivities of some electrogenerated organic cation radicals in room-temperature ionic liquids: Toward an alternative to volatile organic solvents? J. Phys. Chem. A 2003, 107, 745–752. [Google Scholar] [CrossRef]

- Shariati, A.; Peters, C.J. High-pressure phase equilibria of systems with ionic liquids. J. Supercrit. Fluids 2005, 34, 171–176. [Google Scholar]

- Shariati, A.; Gutkowski, K.; Peters, C.J. Comparison of the phase behavior of some selected binary systems with ionic liquids. AIChE J. 2005, 51, 1532–1540. [Google Scholar]

- Zhao, H.; Xia, S.; Ma, P. Use of ionic liquids as green solvents for extractions. J. Chem. Technol. Biotechnol. 2005, 80, 1089–1096. [Google Scholar]

- Keskin, S.; Kayrak-Talay, D.; Akman, U.; Hortaçsu, Ö. A review of ionic liquids towards supercritical fluid applications. J. Supercrit. Fluids 2007, 43, 150–180. [Google Scholar] [CrossRef]

- Thomas, P.A.; Marvey, B.B.; Ebenso, E.E. Metathesis of fatty acid ester derivatives in 1,1-dialkyl and 1,2,3-trialkyl imidazolium type ionic liquids. Int. J. Mol. Sci. 2011, 12, 3989–3997. [Google Scholar] [PubMed]

- Consorti, C.S.; Aydos, G.L.P.; Ebeling, G.; Dupont, J. Multiphase catalytic isomerization of linoleic acid by transition metal complexes in ionic liquids. Appl. Catal. A 2009, 371, 114–120. [Google Scholar]

- Khorasvi, E.; Snymanska-Buzar, T. Ring opening metathesis polymerization and related chemistry. Nato Sci. Ser. 2000, 56, 381. [Google Scholar]

- Thurier, C.; Fischmeister, C.; Bruneau, C.; Olivier-Bourbigou, H.; Dixneuf, P.H. Ethenolysis of methyl oleate in room-temperature ionic liquids. ChemSusChem. 2008, 118, 118–122. [Google Scholar]

- Aydos, G.L.P.; Leal, B.C.; Perez-Lopez, O.W.; Dupont, J. Ionic-tagged catalytic systems applied to the ethenolysis of methyl oleate. Catal. Commun. 2014, 53, 57–61. [Google Scholar] [CrossRef]

- Boelhouwer, C.; Mol, J.C. Metathesis of fatty acid esters. J. Am. Oil Chem. Soc. 1984, 61, 425–430. [Google Scholar] [CrossRef]

- Hamasaki, R.; Funakoshi, S.; Misaki, T.; Tanabe, Y. A highly efficient synthesis of civetone. Tetrahedron 2000, 56, 7423–7425. [Google Scholar]

- Thurier, C.; Fischmeister, C.; Bruneau, C.; Olivier-Bourbigou, H.; Dixneuf, P.H. Ionic imdazolium containing ruthenium complexes and olefin metathesis in ionic liquids. J. Mol. Catal. A Chem. 2007, 268, 127–133. [Google Scholar]

- Audic, N.; Clavier, H.; Mauduit, M.; Guillemin, J.-C. An ionic liquid-supported Ruthenium carbene complex: A robust and recyclable catalyst for ring-closing olefin metathesis in ionic liquids. J. Am. Chem. Soc. 2003, 125, 9248–9249. [Google Scholar] [PubMed]

- Duque, R.; Ochsner, E.; Clavier, H.; Caijo, F.; Nolan, S.P.; Mauduit, M.; Cole-Hamilton, D.J. Continuous flow homogeneous alkene metathesis with built-in catalyst separation. Green Chem. 2011, 13, 1187–1195. [Google Scholar]

- Patel, J.; Mujcinovic, S.; Jackson, W.R.; Robinson, A.J.; Serelisand, A.K.; Such, C. High conversion and productive catalyst turn overs in cross-metathesis reactions of natural oils with 2-butene. Green Chem. 2006, 8, 450–454. [Google Scholar]

- Jiḿenez-Rodriguez, C.; Eastham, G.R.; Cole-Hamilton, D.J. Dicarboxylic acid esters from the carbonylation of unsaturated esters under mild conditions. Inorg. Chem. Commun. 2005, 10, 878–881. [Google Scholar] [CrossRef]

- Patel, J.; Elaridi, J.; Jackson, W.R.; Robinson, A.J.; Serelisand, A.K.; Such, C. Cross-metathesis of unsaturated natural oils with 2-butene. High conversion and productive catalyst turnovers. Chem. Commun. 2005, 44, 5546–5547. [Google Scholar]

- Kerton, F. Alternative Solvents for Green Chemistry:RCS Green Chemistry Book Series; The Royal Society of Chemistry: London, UK, 2009; pp. 118–142. [Google Scholar]

- Sowmiah, S.; Srinivasadesikan, V.; Tseng, M.-C.; Chu, Y.-H. On the chemical stabilities of Ionic liquids. Molecules 2005, 14, 3780–3813. [Google Scholar] [CrossRef] [PubMed]

- Andreussi, O.; Marzari, N. Transport properties of RTILs from classical molecular dynamics. J. Chem. Phys. 2012, 137, 044508. [Google Scholar]

- Ghandi, K. A review of ionic liquids, their limits and applications. Green Sustain. Chem. 2014, 4, 44–53. [Google Scholar]

- Fishmeister, C.; Bruneau, C. RTILs in catalytic olefin metathesis reactions. In Ionic Liquids (ILs) in Organometallic Catalysis; Dupont, J., Kollar, L., Eds.; Springer-Verlag: Berlin, Germany, 2015; pp. 287–306. [Google Scholar]

- Pagni, R.M. Ionic liquids as alternatives to traditional organic and inorganic solvents. In Green Industrial Applications of Ionic Liquids; Rogers, R.D., Seddon, R.K., Volkov, S., Eds.; Springer Science and Business Media: London, UK, 2003; pp. 105–127. [Google Scholar]

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Thomas, P.A.; Marvey, B.B. Room Temperature Ionic Liquids as Green Solvent Alternatives in the Metathesis of Oleochemical Feedstocks. Molecules 2016, 21, 184. https://doi.org/10.3390/molecules21020184

Thomas PA, Marvey BB. Room Temperature Ionic Liquids as Green Solvent Alternatives in the Metathesis of Oleochemical Feedstocks. Molecules. 2016; 21(2):184. https://doi.org/10.3390/molecules21020184

Chicago/Turabian StyleThomas, Priya A., and Bassy B. Marvey. 2016. "Room Temperature Ionic Liquids as Green Solvent Alternatives in the Metathesis of Oleochemical Feedstocks" Molecules 21, no. 2: 184. https://doi.org/10.3390/molecules21020184