Obtaining Ready-to-Eat Blue Corn Expanded Snacks with Anthocyanins Using an Extrusion Process and Response Surface Methodology

Abstract

:1. Introduction

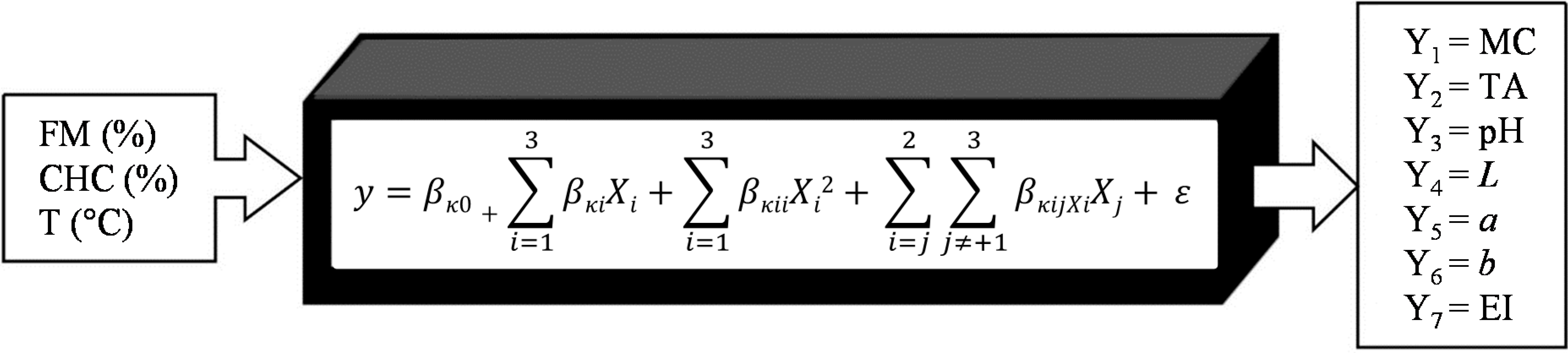

2. Results and Discussion

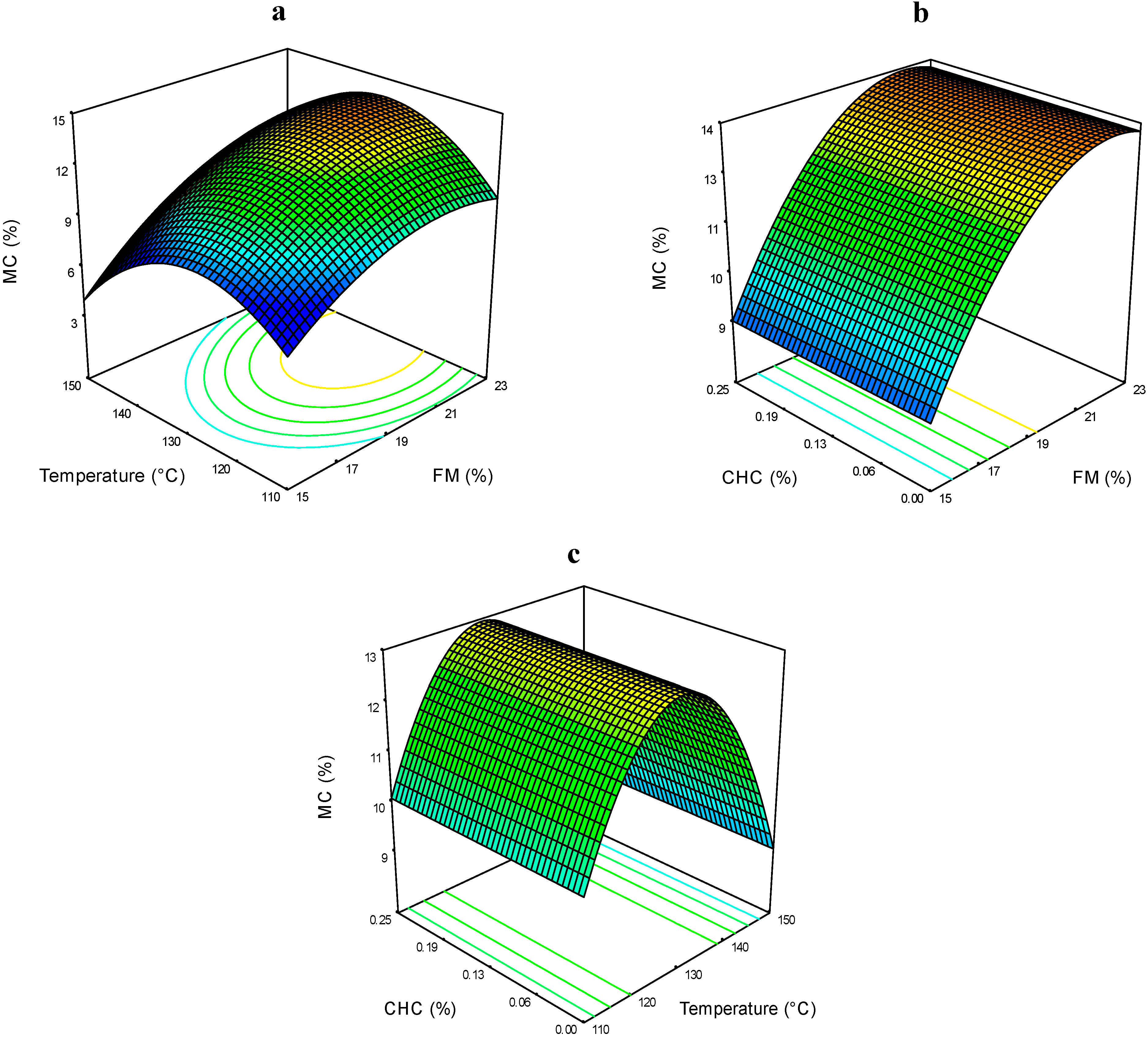

2.1. Effects of FM, CHC and T on Extrudates Moisture Content (MC)

| Coefficients | MC a | TA | pH | L | a | b | EI |

|---|---|---|---|---|---|---|---|

| Intercept | |||||||

| β | 13.45 | 147.63 | 6.85 | 21.61 | 3.87 | −0.27 | 2.13 |

| Lineal | |||||||

| β1 | 1.51 *** | 5.55ns | 0.021ns | −2.54 *** | −0.35 *** | −0.23 *** | −0.45 *** |

| β2 | −0.33ns | 1.93ns | −0.0009ns | 0.46ns | 0.18 *** | −0.016ns | 0.002ns |

| β3 | 0.050ns | 0.39ns | −0.013ns | 0.29ns | 0.011ns | −0.004ns | −0.015ns |

| Quadratic | |||||||

| β11 | −0.66 ** | 2.86ns | −0.008ns | 1.11 *** | 0.17 *** | 0.13 ** | 0.11 ** |

| β22 | −1.29 *** | 7.39 * | −0.035ns | 0.31ns | 0.23 *** | 0.030ns | −0.009ns |

| β33 | −0.40ns | 2.05ns | −0.001ns | 0.38ns | −0.0007ns | 0.063ns | 0.001ns |

| Interaction | |||||||

| β12 | 0.27ns | −4.94ns | −0.006ns | −0.62ns | −0.15 ** | −0.005ns | −0.005ns |

| β13 | 0.25ns | 3.26ns | 0.0003ns | −0.016ns | −0.16 ** | 0.020ns | −0.035ns |

| β23 | −0.005ns | −1.66ns | 0.020ns | 0.53ns | 0.033ns | 0.010ns | 0.021ns |

| R2 | 0.89 | 0.44 | 0.17 | 0.89 | 0.92 | 0.72 | 0.95 |

| Process Factors a | Response Variables b | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Tr c | FM | T | CHC | MC | TA | pH | L | a | b | EI |

| X1 | X2 | X3 | Y1 | Y2 | Y3 | Y4 | Y5 | Y6 | Y7 | |

| 1 | 19 (0) d | 130 (0) | 0.13 (0) | 13.6 | 150.7 | 6.8 | 22.43 | 4.01 | −0.33 | 2.13 |

| 2 | 15 (−1.682) | 130 (0) | 0.13 (0) | 10.0 | 141.1 | 6.8 | 28.89 | 5.01 | 0.35 | 3.26 |

| 3 | 19 (0) | 130 (0) | 0.13 (0) | 14.0 | 154.7 | 6.8 | 21.4 | 3.83 | −0.35 | 2.05 |

| 4 | 19 (0) | 130 (0) | 0.13 (0) | 13.3 | 130.4 | 6.8 | 22.38 | 4.00 | −0.04 | 2.19 |

| 5 | 21.38 (1) | 141.89 (1) | 0.2 (1) | 12.3 | 174 | 6.9 | 21.47 | 3.69 | −0.38 | 1.78 |

| 6 | 19 (0) | 130 (0) | 0.13 (0) | 13.2 | 153.8 | 6.9 | 20.96 | 3.76 | −0.12 | 2.19 |

| 7 | 19 (0) | 130 (0) | 0.25 (1.682) | 13.1 | 143.5 | 6.7 | 22.49 | 4.17 | 0.11 | 2.02 |

| 8 | 21.38 (1) | 118.11 (−1) | 0.05 (−1) | 11.9 | 165.5 | 6.8 | 19.44 | 4.13 | −0.17 | 1.72 |

| 9 | 19 (0) | 130 (0) | 0 (−1.682) | 13.1 | 142.6 | 7.1 | 23.44 | 3.73 | −0.40 | 2.33 |

| 10 | 21.38 (1) | 141.89 (1) | 0.05 (−1) | 11.6 | 176.9 | 6.7 | 20.17 | 4.05 | −0.22 | 1.80 |

| 11 | 16.62 (−1) | 141.89 (1) | 0.05 (−1) | 8.5 | 170.8 | 6.7 | 25.72 | 4.77 | 0.32 | 2.54 |

| 12 | 16.62 (−1) | 118.11 (−1) | 0.2 (1) | 9.4 | 144.5 | 6.8 | 23.96 | 4.33 | 0.12 | 2.62 |

| 13 | 23 (1.682) | 130 (0) | 0.13 (0) | 14.7 | 149.5 | 7.0 | 21.18 | 3.83 | −0.28 | 1.71 |

| 14 | 21.38 (1) | 118.11 (−1) | 0.2 (1) | 12.4 | 183.4 | 6.8 | 20.83 | 3.58 | −0.32 | 1.76 |

| 15 | 19 (0) | 110 (−1.682) | 0.13 (0) | 11.0 | 163.3 | 6.8 | 21.21 | 4.25 | −0.23 | 2.21 |

| 16 | 16.62 (−1) | 141.89 (1) | 0.2 (1) | 8.0 | 169.1 | 6.8 | 29.28 | 4.97 | 0.14 | 2.80 |

| 17 | 19 (0) | 150 (1.682) | 0.13 (0) | 10.1 | 153 | 6.8 | 22.35 | 4.94 | −0.25 | 2.08 |

| 18 | 16.62 (−1) | 118.11 (−1) | 0.05 (−1) | 9.7 | 153.8 | 6.7 | 24.7 | 4.2 | 0.41 | 2.58 |

| 19 | 19 (0) | 130 (0) | 0.13 (0) | 13.0 | 142.3 | 6.9 | 20.73 | 3.87 | −0.44 | 2.14 |

| 20 | 19 (0) | 130 (0) | 0.13 (0) | 13.1 | 157.4 | 6.9 | 21.63 | 3.73 | −0.33 | 2.06 |

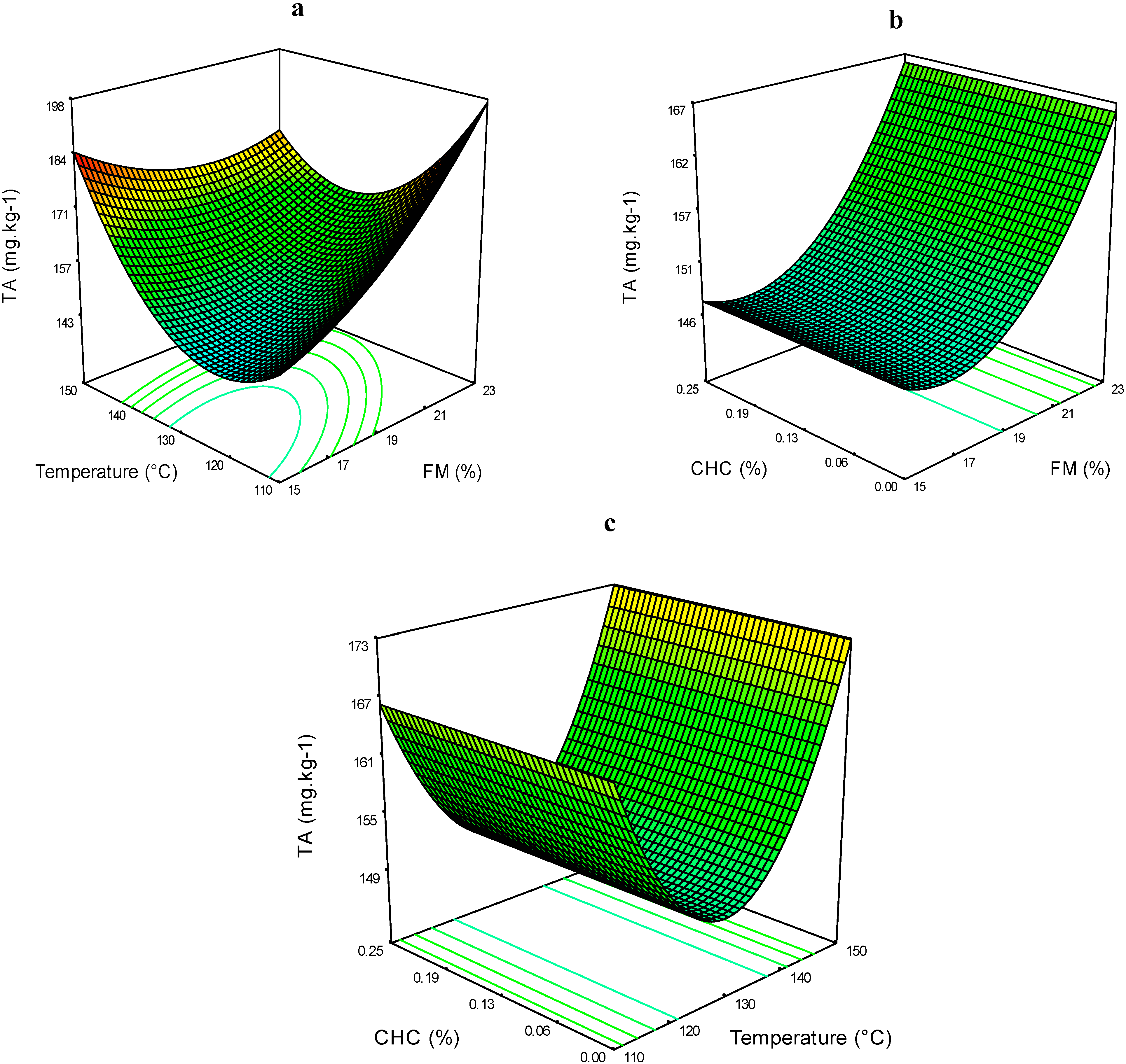

2.2. Effects of FM, CHC and T on Total Anthocyanins (TA)

2.3. Effects of FM, CHC and T on pH

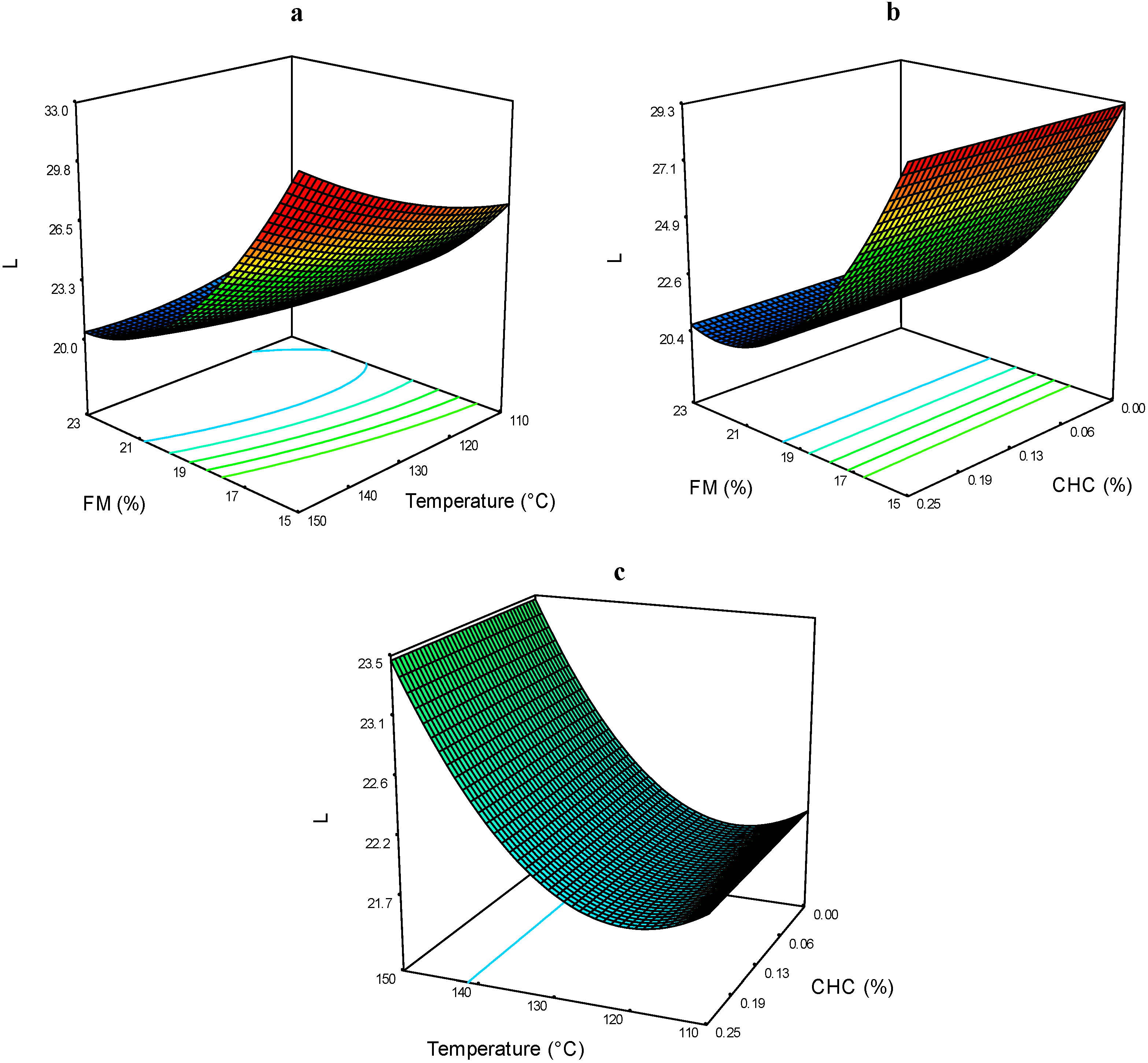

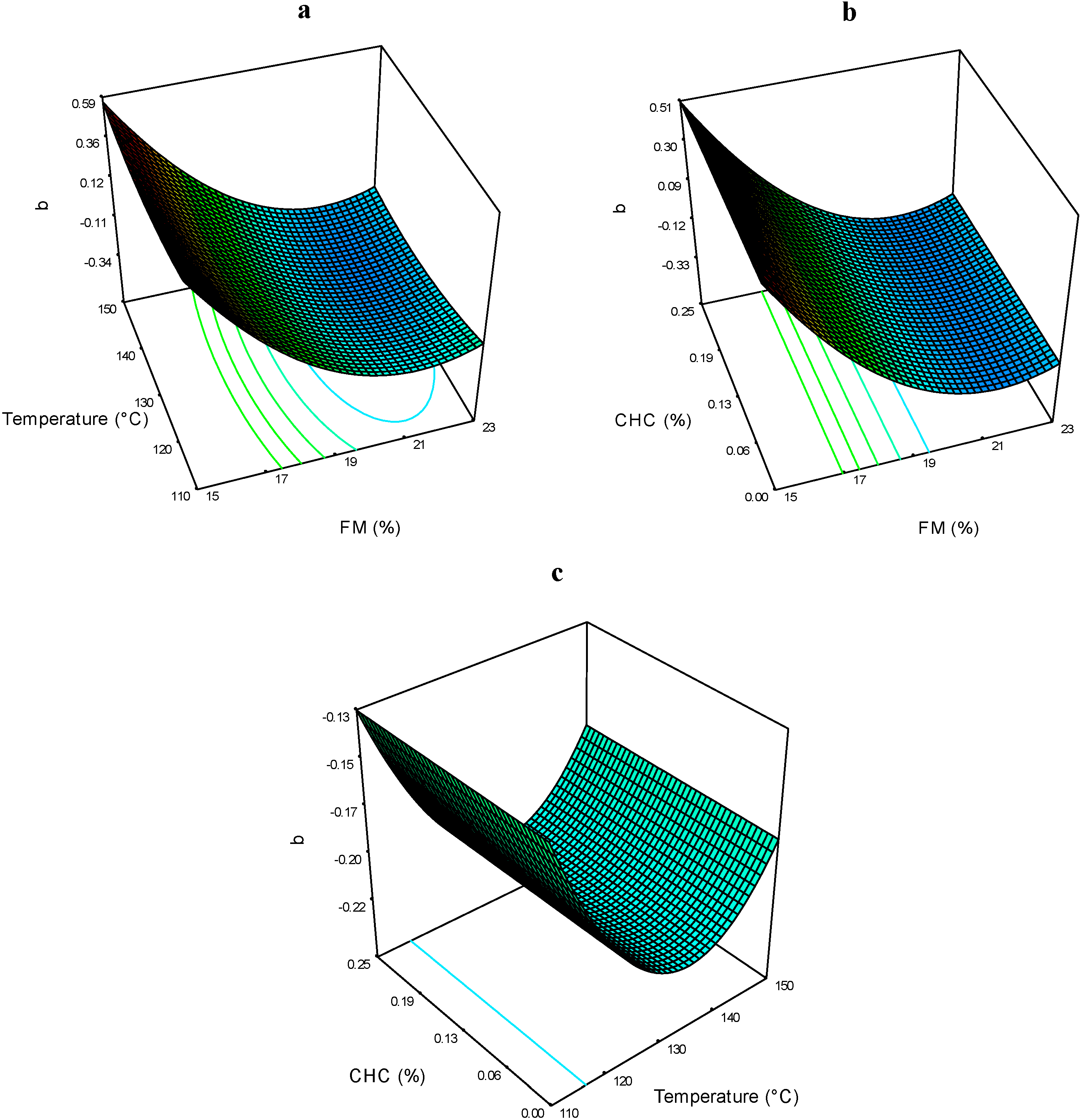

2.4. Effects of FM, CHC and T on Color Parameters (L, a, b)

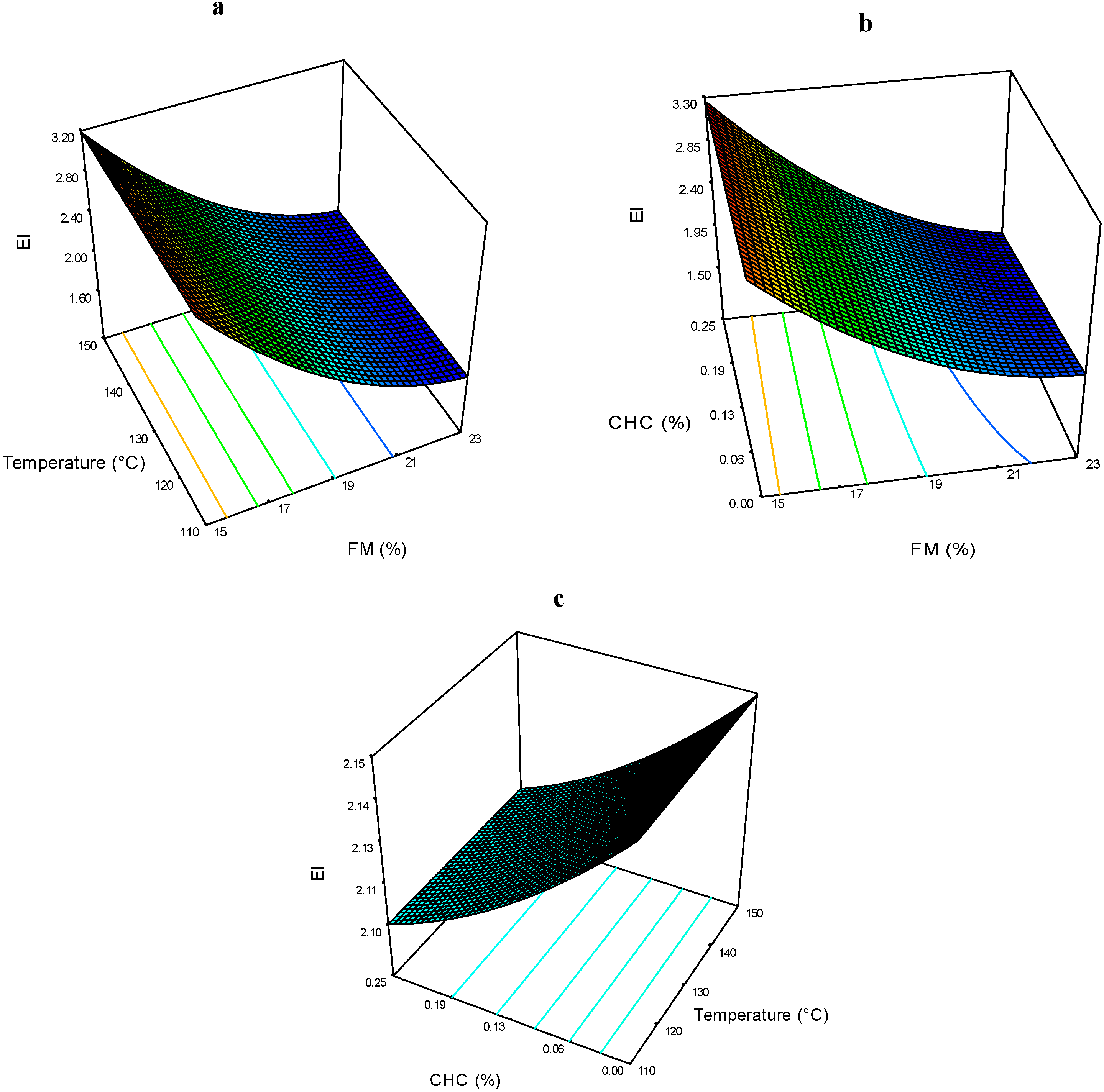

2.5. Effects of FM, CHC and T on Expansion Index (EI)

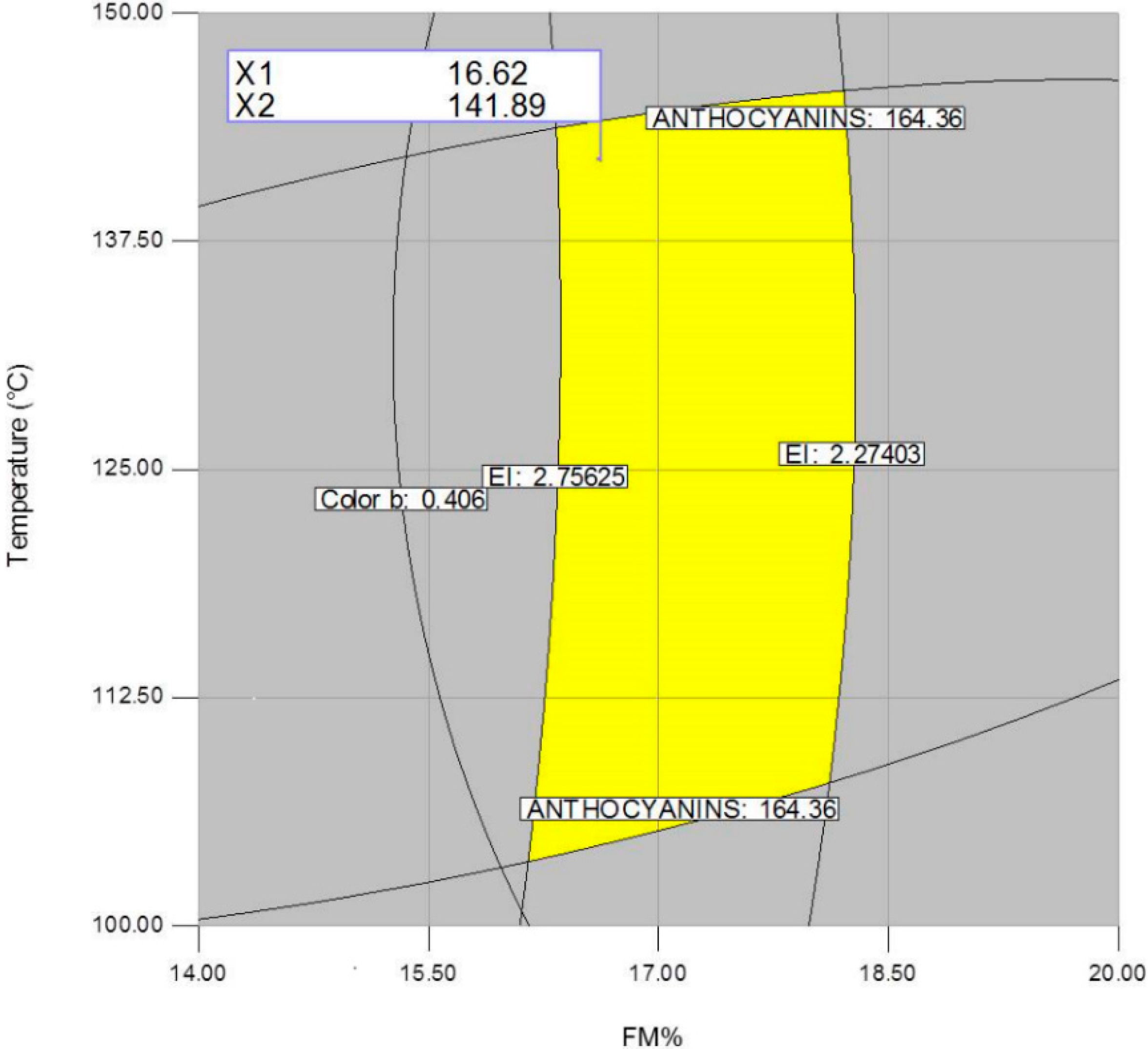

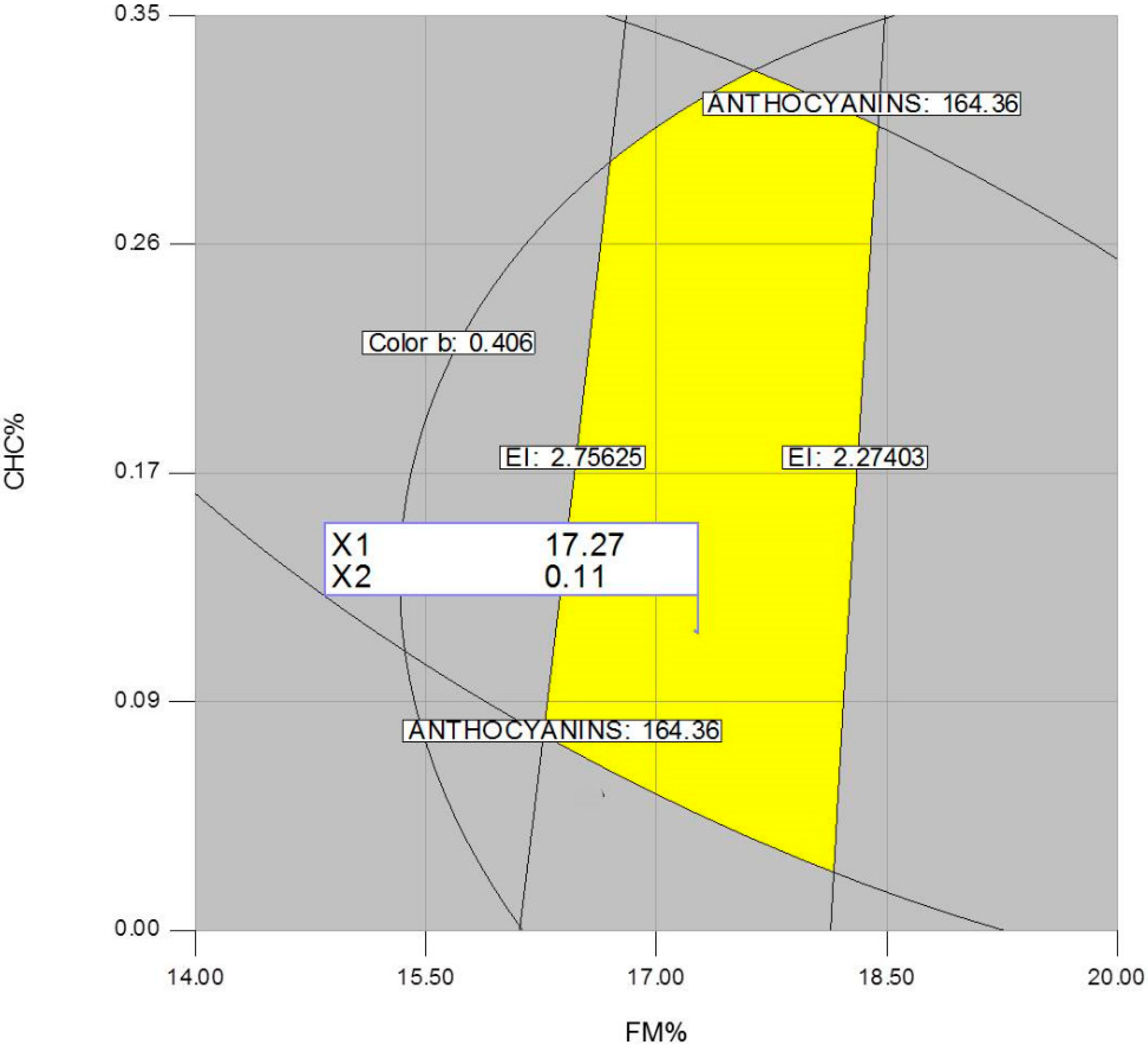

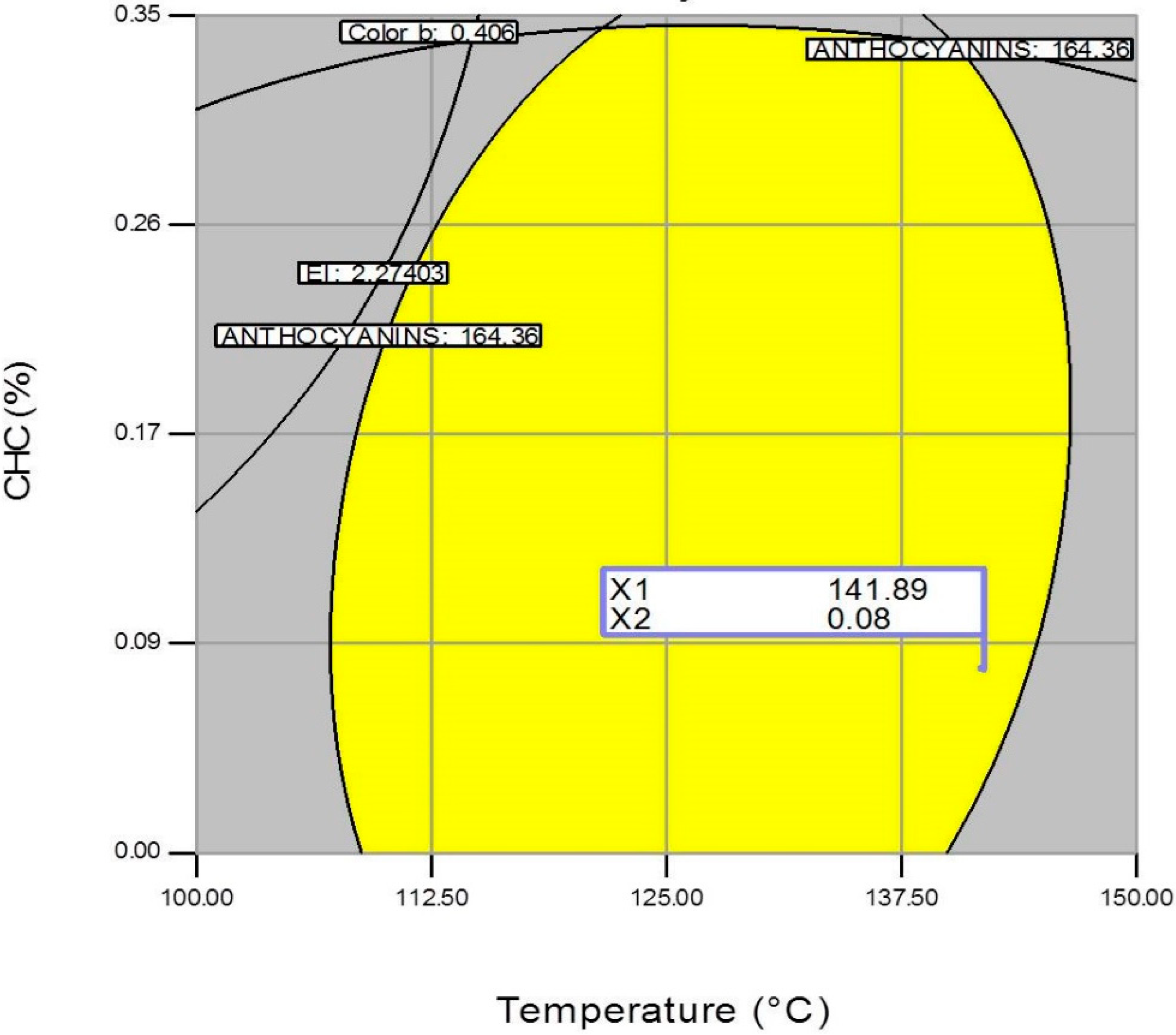

2.6. Optimization and Model Prediction Performance

Evaluations of the Expanded Nixtamalized Blue Corn Snacks Produced with the Optimum Extrusion Conditions

| Response Variable | Predicted Value | Experimental Value |

|---|---|---|

| TA (mg·kg−1) a | 160 | 158.87 ± 2.26 c |

| Color b b | 0.10 | −0.45 ± 0.08 c |

| Expansion Index | 2.66 | 3.19 ± 0.11 d |

3. Experimental Section

3.1. Raw Material

3.2. Extrusion Process

3.3. Extrudate Evaluations

3.3.1. Moisture Content (MC)

3.3.2. Total Anthocyanins (TA)

3.3.3. pH

3.3.4. Color

3.3.5. Expansion Index (EI)

3.4. Experimental Design and Statistical Analysis

3.5. Optimization of the Extrusion Process

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Swinburn, B.A.; Caterson, I.; Seidell, J.C.; James, W.P.T. Diet, nutrition and the prevention of excess weight gain and obesity. Public Health Nutr. 2004, 7, 123–146. [Google Scholar] [PubMed]

- Mendoza-Díaz, S.; Ortíz-Valerio, M.C.; Castaño-Tostado, E.; Figueroa-Cárdenas, J.D.; Reynoso-Camacho, R.; Ramos-Gómez, M.; Campos-Vega, R.; Loarca-Piña, G.F. Antioxidant capacity and antimutagenic activity of anthocyanin and carotenoid extracts from nixtamalized pigmented creole maize races (Zea mays L.). Plant Food Hum. Nutr. 2012, 67, 442–449. [Google Scholar] [CrossRef]

- De Pascual-Teresa, S.; Santos-Buelga, C.; Rivas-Gonzalo, J.C. LC-MS analysis of anthocyanins from purple corn cob. J. Sci. Food Agric. 2002, 82, 1003–1006. [Google Scholar]

- Bridle, P.; Timberlake, C.F. Anthocyanins as natural food colours—Selected aspects. Food Chem. 1997, 58, 103–109. [Google Scholar] [CrossRef]

- Salinas, M.Y.; Martínez, B.F.; Soto, H.M.; Ortega, P.R.; Arellano, V.J.L. Efecto de la Nixtamalización sobre las Antocianinas del Grano de Maíces Pigmentados. Agrociencia 2003, 37, 617–628. [Google Scholar]

- Aguayo-Rojas, J.; Mora-Rochín, S.; Cuevas-Rodríguez, E.; Serna-Saldivar, S.; Gutierrez-Uribe, J.; Reyes-Moreno, C.; Milán-Carrillo, J. Phytochemicals and antioxidant capacity of tortillas obtained after lime-cooking extrusion process of Whole Pigmented Mexican Maize. Plant Food Hum. Nutr. 2012, 67, 178–185. [Google Scholar] [CrossRef]

- Escalante-Aburto, A.; Ramírez-Wong, B.; Torres-Chávez, P.I.; Figueroa-Cárdenas, J.D.; López-Cervantes, J.; Barrón-Hoyos, J.M.; Morales-Rosas, I. Effect of extrusion processing parameters on anthocyanin content and physicochemical properties of nixtamalized blue corn expanded extrudates. CyTA—J. Food 2013, 11, 29–37. [Google Scholar] [CrossRef]

- Camacho-Hernández, I.L.; Zazueta-Morales, J.J.; Gallegos-Infante, J.A.; Aguilar-Palazuelos, E.; Rocha Guzmán, N.E.; Navarro-Cortez, R.O.; Jacobo-Valenzuela, N.; Gómez-Aldapa, C.A. Effect of extrusion conditions on physicochemical characteristics and anthocyanin content of blue corn third generations snacks. CyTA—J. Food 2014, 12, 320–330. [Google Scholar] [CrossRef]

- Cortés-Gómez, A.; San Martín-Martínez, E.; Martínez-Bustos, F.; Vázquez-Carrillo, G.M. Tortillas of blue maize (Zea mays L.) prepared by a fractionated process of nixtamalization: Analysis using response surface mehtodology. J. Food Eng. 2005, 66, 273–281. [Google Scholar] [CrossRef]

- Mora-Rochid, S.; Gutiérrez-Uribe, J.A.; Serna-Saldívar, S.O.; Sánchez-Peña, P.; Reyes-Moreno, C.; Milán-Carrillo, J. Phenolic content and antioxidant activity of tortillas produced from pigmented maize processed by conventional nixtamalization or extrusion cooking. J. Cereal Sci. 2010, 52, 502–508. [Google Scholar] [CrossRef]

- Méndez, L.I.R.; Cárdenas, J.D.F.; Gómez, M.R.; Lagunas, L.L.M. Nutraceutical properties of flour and tortillas made with an ecological nixtamalization process. J. Food Sci. 2013, 78, C1529–C1534. [Google Scholar] [PubMed]

- Guy, R. Snack foods. In Extrusion Cooking. Technologies and Applications, 1st ed.; Guy, R., Ed.; CRC: Boca Raton, FL, USA, 2001; pp. 161–181. [Google Scholar]

- Nayak, B.; Berrios, J.D.J.; Powers, J.R.; Tang, J. Thermal degradation of anthocyanins from purple potato (Cv. Purple Majesty) and impact on antioxidant capacity. J. Agric. Food Chem. 2011, 59, 11040–11049. [Google Scholar] [CrossRef] [PubMed]

- Jing, P.; Giusti, M.M. Effects of extraction conditions on improving the field and quality of an anthocyanins-rich purple corn (Zea mays L.) color extract. J. Food Sci. 2007, 72, C363–C368. [Google Scholar] [CrossRef] [PubMed]

- Zazueta-Morales, J.J.; Martínez-Bustos, F.; Jacobo-Valenzuela, N.; Ordorica-Falomir, C.; Paredes-López, O. Effect of the addition of calcium hydroxide on some characteristics of extruded products from blue maize (Zea mays L.) using response surface methodology. J. Sci. Food Agric. 2001, 81, 1379–1386. [Google Scholar] [CrossRef]

- Sadilova, E.; Stintzing, F.C.; Carle, R. Thermal degradation of acylated and nonacylated anthocyanins. J. Food Sci. 2006, 71, C504–C512. [Google Scholar] [CrossRef]

- Sánchez-Madrigal, M.A.; Quintero-Ramos, A.; Martínez-Bustos, F.; Meléndez-Pizarro, C.O.; Ruíz-Gutiérrez, M.G.; Camácho-Dávila, A.; Torres-Chávez, P.I.; Ramírez-Wong, B. Effect of different calcium sources on the bioactive compounds stability of extruded and nixtamalized blue maize flours. J. Food Sci. Technol. 2014. [Google Scholar] [CrossRef]

- Arhaliass, A.; Bouvier, J.M.; Legrand, J. Melt growth and shrinkage at the exit of the die in the extrusion-cooking process. J. Food Eng. 2003, 60, 185–192. [Google Scholar] [CrossRef]

- Thymi, S.; Krokida, M.K.; Pappa, A.; Maroulis, Z.B. Structural properties of extruded corn starch. J. Food Eng. 2005, 68, 519–526. [Google Scholar] [CrossRef]

- Altan, A.; McCarthy, K.L.; Maskan, M. Extrusion cooking of barley flour and process parameter optimization by using response surface methodology. J. Sci. Food Agric. 2008, 88, 1648–1659. [Google Scholar] [CrossRef]

- AACC International. Moisture-air-oven methods (Approved October 30, 1975; Reapproved November 3, 1999). In Approved Methods of Analysis, 11th ed.; AACC International: St. Paul, MN, USA, 1995; Method 44-15.02. [Google Scholar]

- Abdel-Aal, E.S.M.; Hucl, P. A rapid method for quantifying total anthocyanins in blue aleurone and purple pericarp wheats. Cereal Chem. 1999, 76, 350–354. [Google Scholar] [CrossRef]

- AACC International. Hydrogen-Ion Activity (pH) (Approved October 30, 1975; Reapproved November 3, 1999). In Approved Methods of Analysis, 11th ed.; AACC International: St. Paul, MN, USA, 1995; Mthod 02-52.01. [Google Scholar]

- Myers, R.H.; Montgomery, D.C.; Anderson-Cook, C.M. The analysis of second-order response surfaces. In Response Surface Methodology. Process and Product Optimization Using Designed Experiments, 3rd ed.; Myers, R.H., Montgomery, D.C., Anderson-Cook, C.M., Eds.; Wiley: Hoboken, NJ, USA, 2009; pp. 219–264. [Google Scholar]

- Sample Availability: Samples of the compounds are not available from the authors.

© 2014 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Escalante-Aburto, A.; Ramírez-Wong, B.; Torres-Chávez, P.I.; López-Cervantes, J.; Figueroa-Cárdenas, J.D.D.; Barrón-Hoyos, J.M.; Morales-Rosas, I.; Ponce-García, N.; Gutiérrez-Dorado, R. Obtaining Ready-to-Eat Blue Corn Expanded Snacks with Anthocyanins Using an Extrusion Process and Response Surface Methodology. Molecules 2014, 19, 21066-21084. https://doi.org/10.3390/molecules191221066

Escalante-Aburto A, Ramírez-Wong B, Torres-Chávez PI, López-Cervantes J, Figueroa-Cárdenas JDD, Barrón-Hoyos JM, Morales-Rosas I, Ponce-García N, Gutiérrez-Dorado R. Obtaining Ready-to-Eat Blue Corn Expanded Snacks with Anthocyanins Using an Extrusion Process and Response Surface Methodology. Molecules. 2014; 19(12):21066-21084. https://doi.org/10.3390/molecules191221066

Chicago/Turabian StyleEscalante-Aburto, Anayansi, Benjamín Ramírez-Wong, Patricia Isabel Torres-Chávez, Jaime López-Cervantes, Juan De Dios Figueroa-Cárdenas, Jesús Manuel Barrón-Hoyos, Ignacio Morales-Rosas, Néstor Ponce-García, and Roberto Gutiérrez-Dorado. 2014. "Obtaining Ready-to-Eat Blue Corn Expanded Snacks with Anthocyanins Using an Extrusion Process and Response Surface Methodology" Molecules 19, no. 12: 21066-21084. https://doi.org/10.3390/molecules191221066