School of Materials and Chemical Engineering, Xi’an Technological University, Xi’an 710021, China

Metals 2023, 13(3), 577; https://doi.org/10.3390/met13030577 - 13 Mar 2023

Cited by 4 | Viewed by 1901

Abstract

The surface evolution of vermicular cast iron in a high frequent cyclic plasma and facial cooling airflow was studied to understand the behavior and mechanism in different cooling conditions under a unique thermal shock environment. Results indicated that both the mass and linear

[...] Read more.

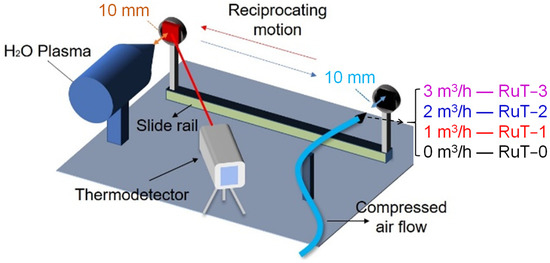

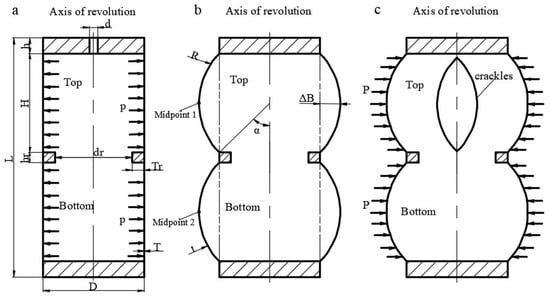

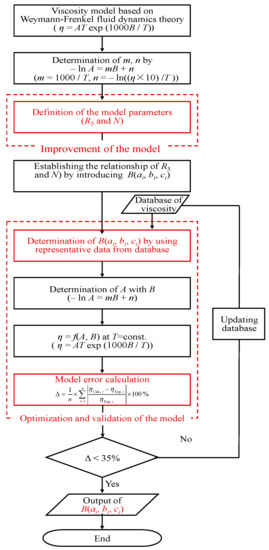

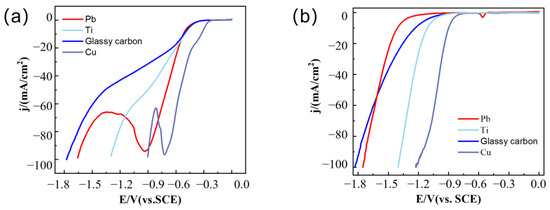

The surface evolution of vermicular cast iron in a high frequent cyclic plasma and facial cooling airflow was studied to understand the behavior and mechanism in different cooling conditions under a unique thermal shock environment. Results indicated that both the mass and linear loss presented titled inverted V-shaped relationships with the flux of the cooling airflow, while the change in roughness decreased continuously. As the cooling airflow rose, the eroded zone was reduced, the iron oxides lessened, and fluctuation of the surface temperature weakened. In combination with the thermodynamic calculations and thermal analysis, it was confirmed that the oxidation and mechanical erosion had contrary tendencies with the rising flux in the facial cooling airflow. The transformation of the dominant factor from oxidation to peeling off by thermal stress and scouring resulted in the evolution of mass and thickness. The surface oxides dominated the change in the roughness.

Full article

(This article belongs to the Special Issue Recent Advances in Cast Irons)

▼

Show Figures