Field Evaluation of N95 Filtering Facepiece Respirators on Construction Jobsites for Protection against Airborne Ultrafine Particles

Abstract

:1. Introduction

2. Materials and Methods

2.1. Construction Sites Selected for the Field Study and Descriptions of Sampling Methods

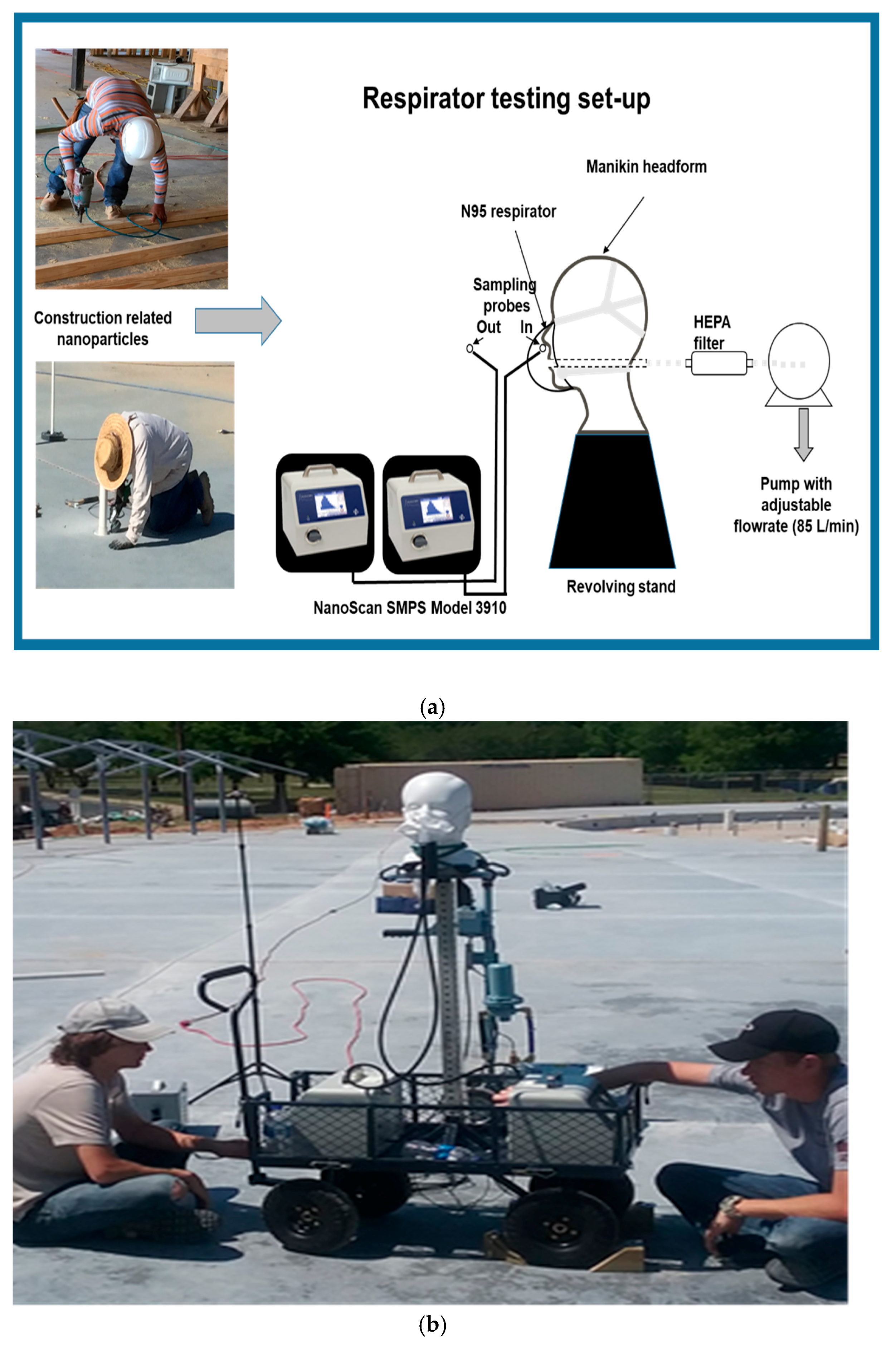

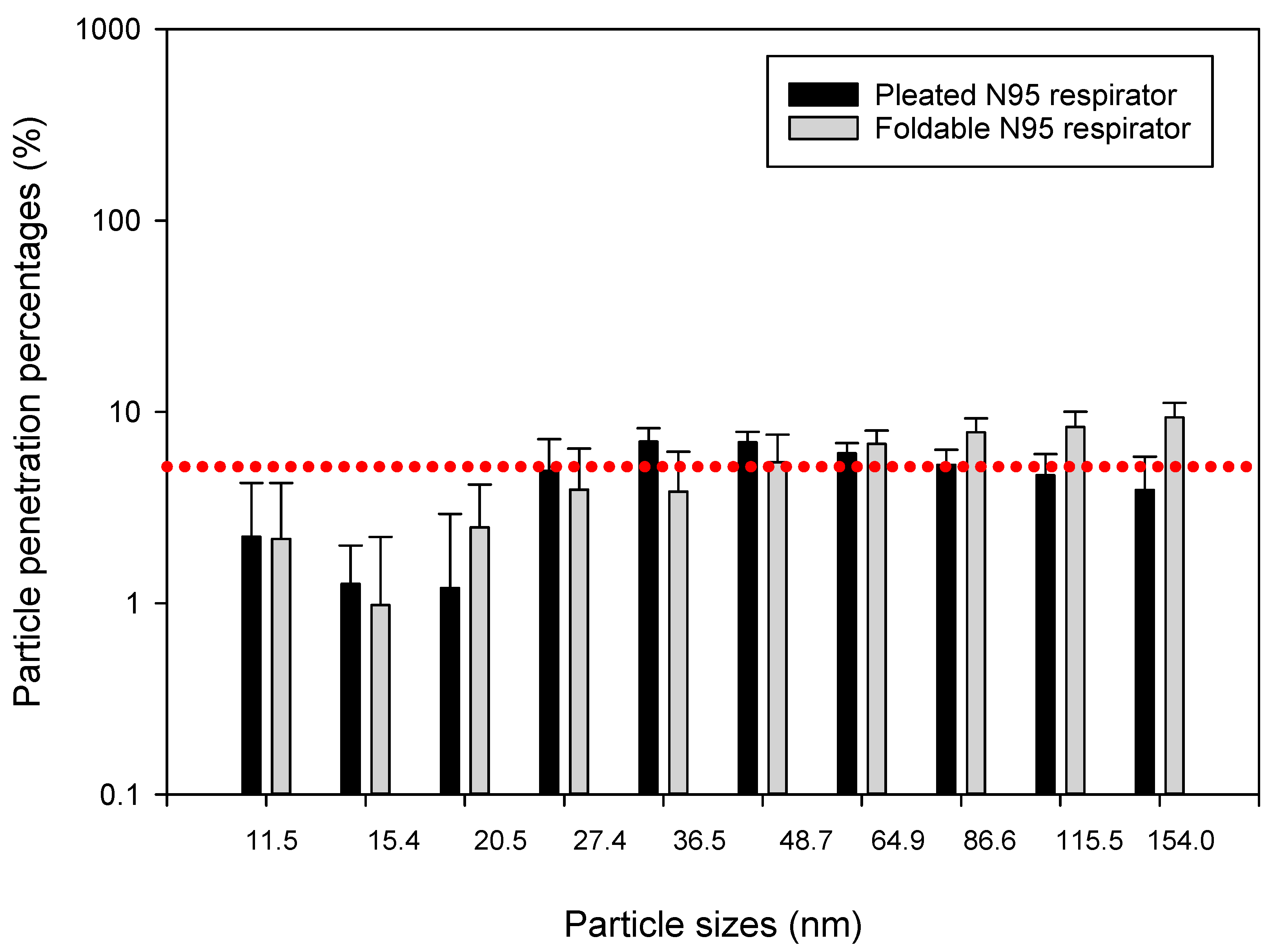

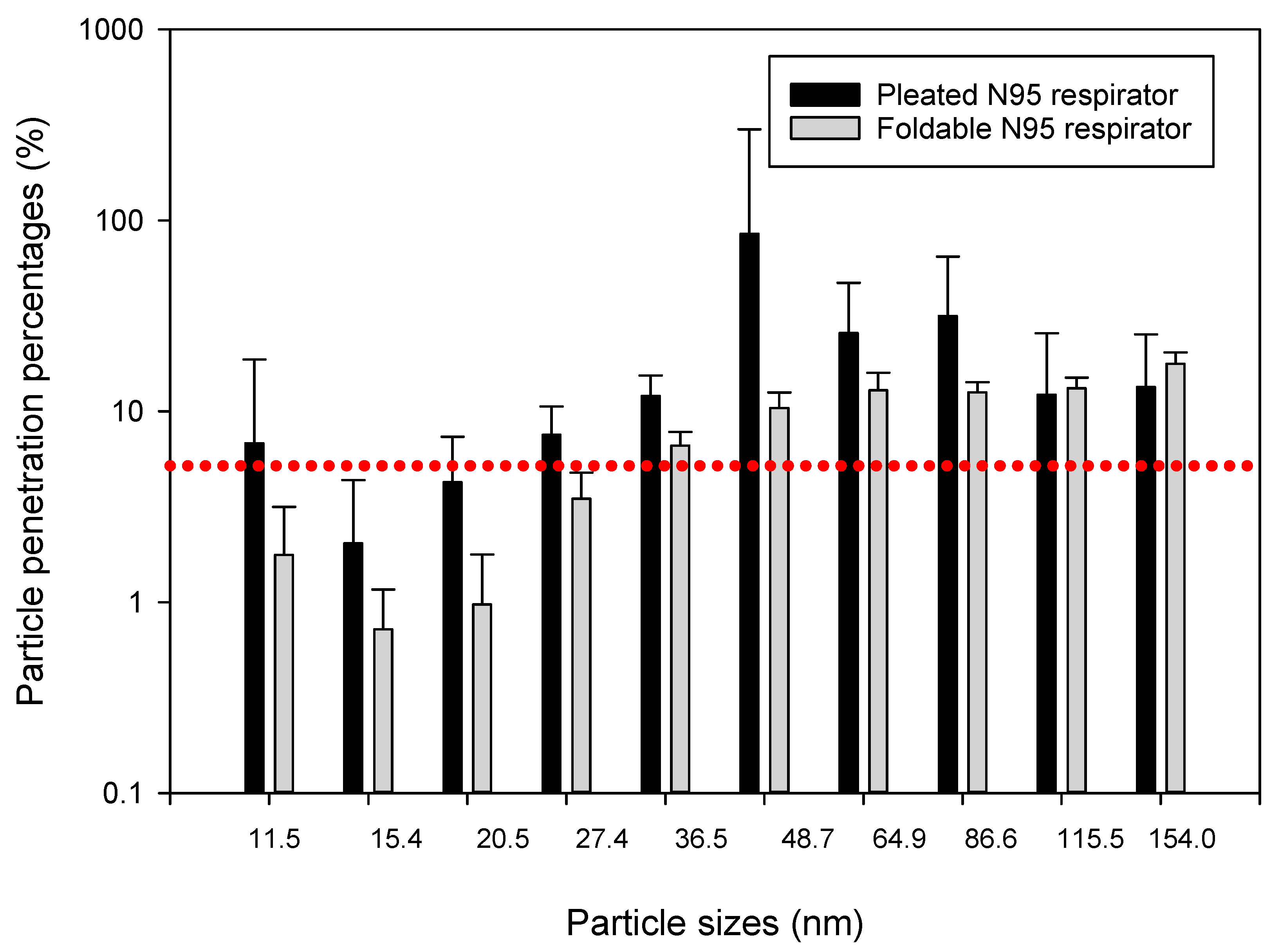

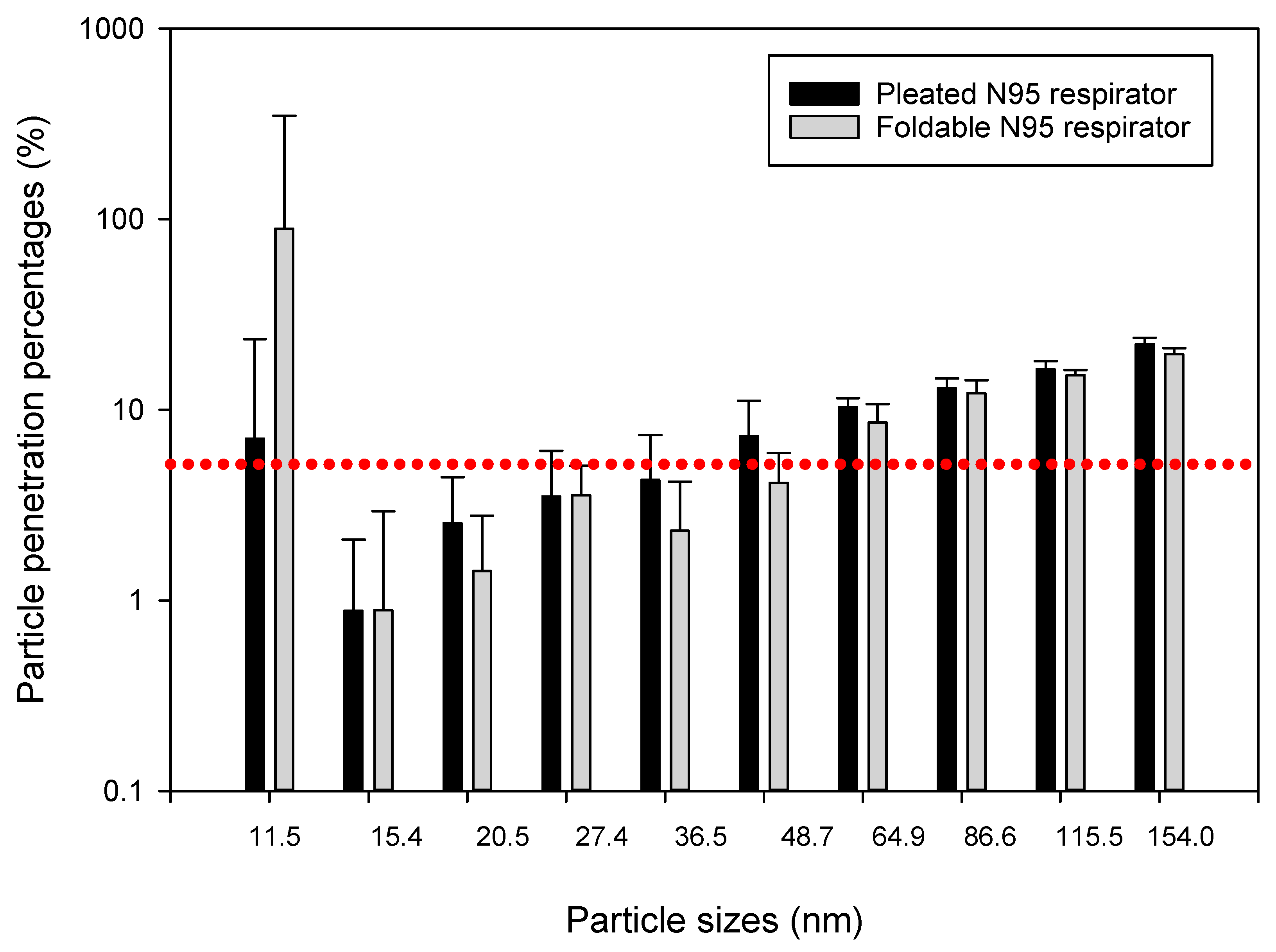

2.2. Assessment of Filtration Efficiency (Simulated Protection Factor) of N95 Filtering Facepiece Respirators against Airborne Nanoparticles at Field Conditions during Construction Works

2.3. Experiments with Charge Neutralized N95 Respirators

2.4. Data Analysis

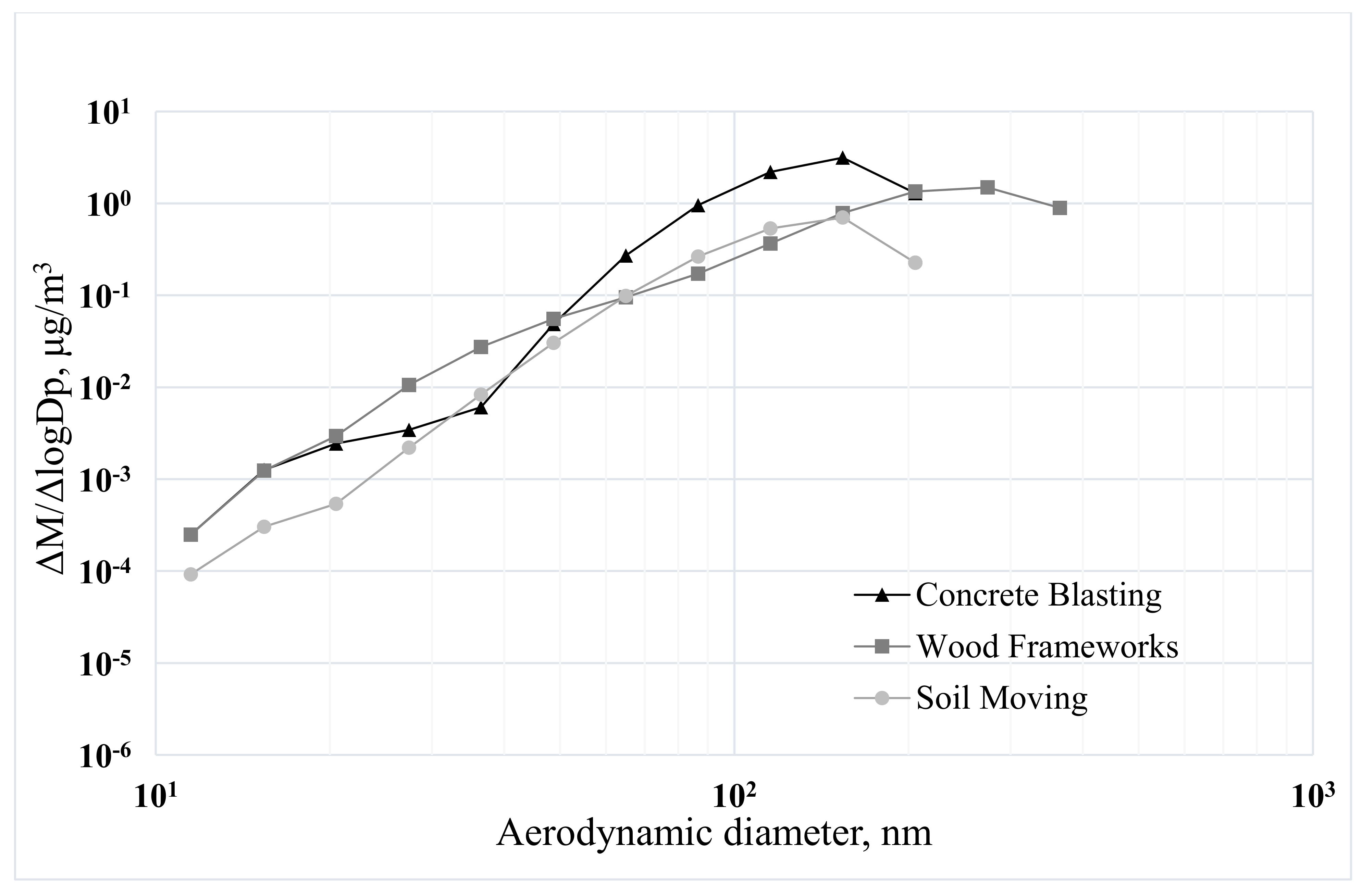

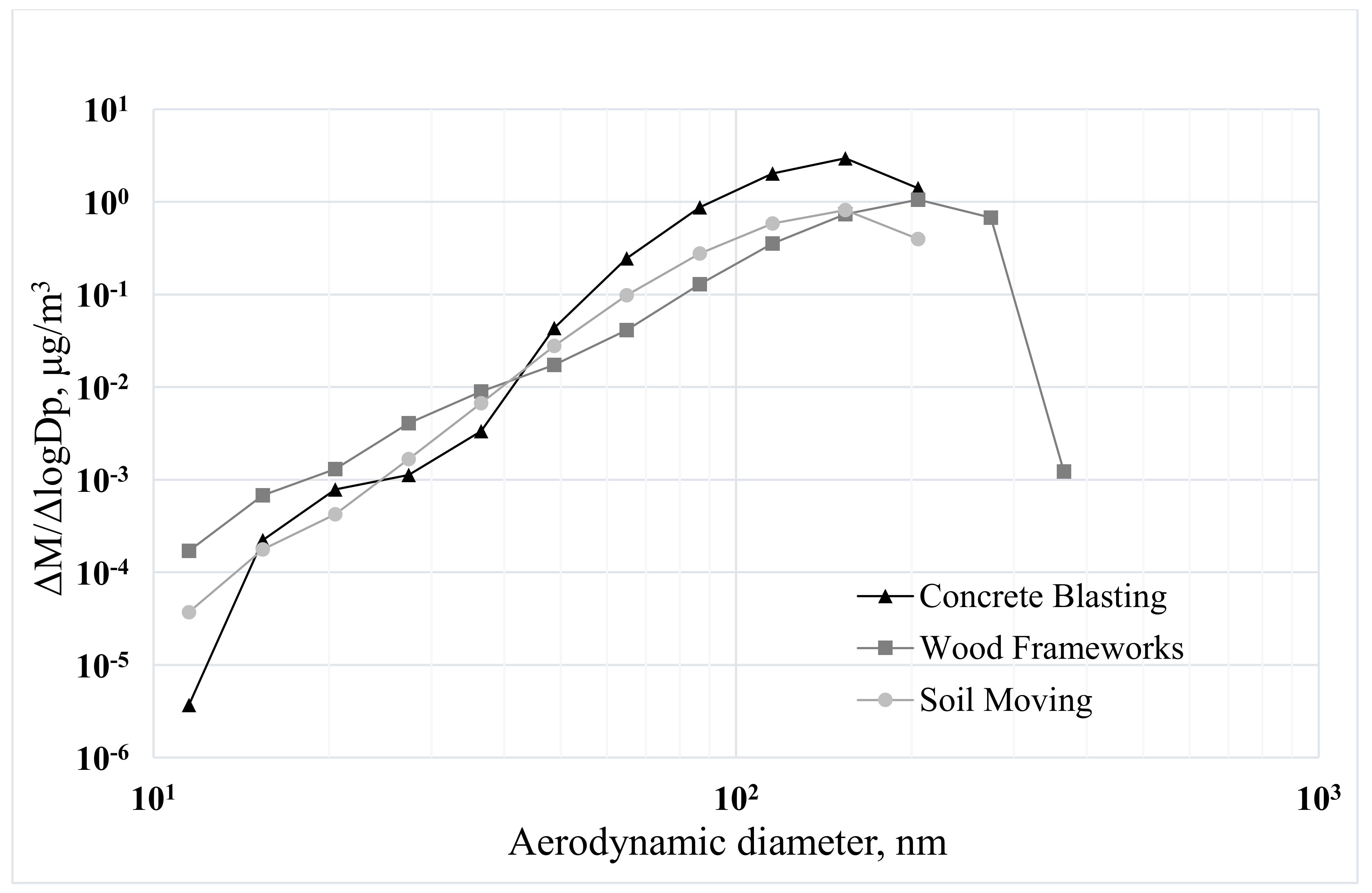

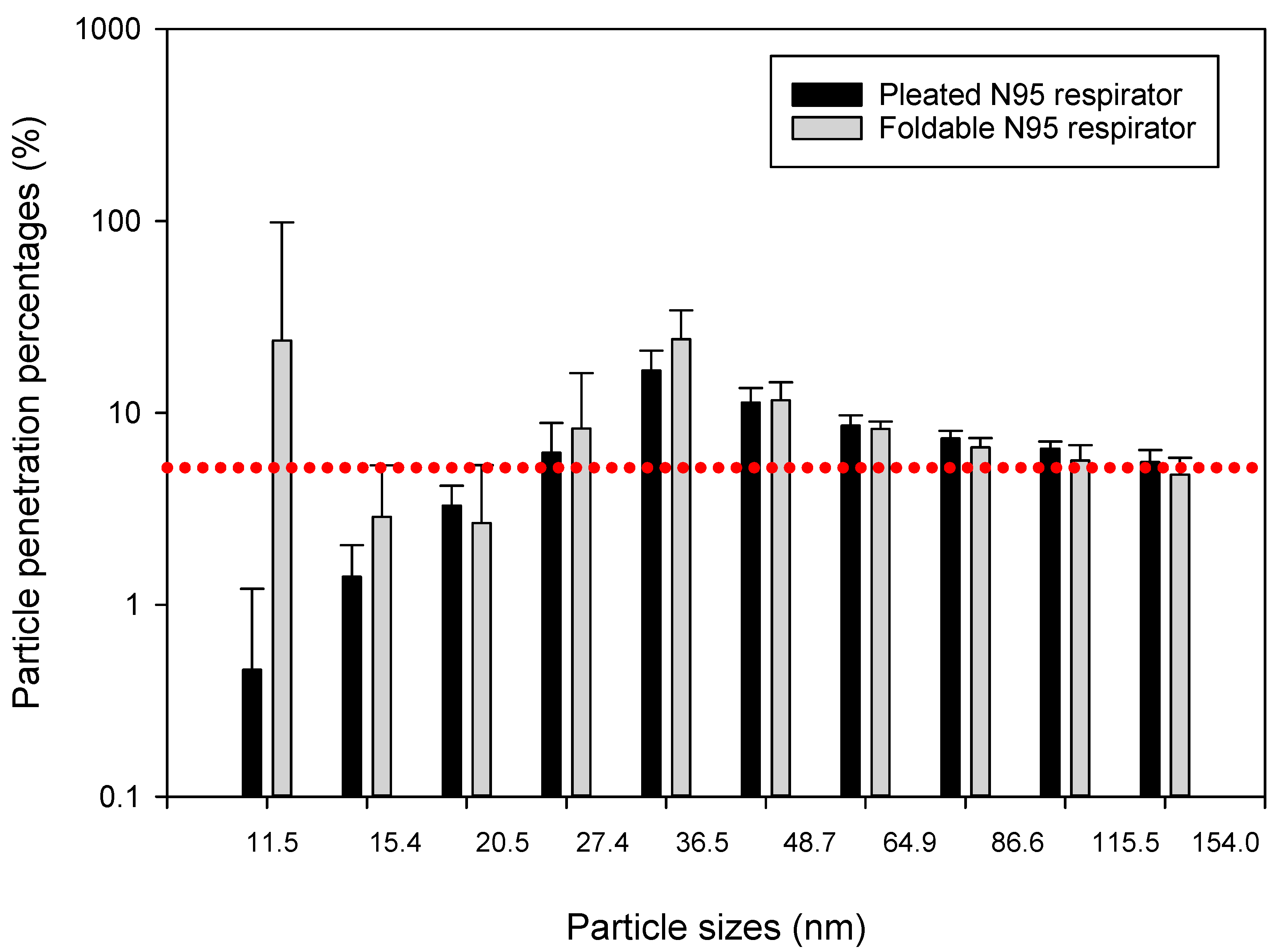

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References and Note

- Thorpe, A.; Ritchie, A.S.; Gibson, M.J.; Brown, R.C. Measurements of the effectiveness of dust control on cut-off saws used in the construction industry. Ann. Occup. Hyg. 1999, 43, 443–456. [Google Scholar] [CrossRef]

- Croteau, G.A.; Guffey, S.E.; Flanagan, M.E.; Seixas, N.S. The effect of local exhaust ventilation controls on dust exposures during concrete cutting and grinding activities. Am. Ind. Hyg. Assoc. J. 2002, 63, 458–467. [Google Scholar] [CrossRef]

- Azarmi, F.; Kumar, P.; Mulheron, M. The exposure to coarse, fine and ultrafine particle emissions from concrete mixing, drilling and cutting activities. J. Hazard. Mater. 2014, 279, 268–279. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kumar, P.; Mulheron, M.; Fisher, B.; Harrison, R.M. New Directions: Airborne ultrafine particle dust from building activities-A source in need of quantification. Atmos. Environ. 2012, 56, 262–264. [Google Scholar] [CrossRef] [Green Version]

- National Nanotechnology Initiative. Standards for Nanotechnology. Available online: https://www.nano.gov/you/standards (accessed on 31 August 2018).

- ASTM 2456-06 Standard Terminology Relating to Nanotechnology. Available online: http://www.astm.org/Standard/index.shtml (accessed on 30 August 2018).

- Zimmer, A.T.; Maynard, A.D. Investigation of the aerosols produced by a high-speed, hand-held grinder using various substrates. Ann. Occup. Hyg. 2002, 46, 663–672. [Google Scholar]

- BLS (US Bureau of Labor Statistics). Construction. Available online: http://data.bls.gov/timeseries/CES2000000001?data_tool=XGtable (accessed on 28 April 2018).

- Buzea, C.; Pacheco, I.I.; Robbie, K. Nanomaterials and nanoparticles: Sources and toxicity. Biointerphases 2007, 2, MR17-71. [Google Scholar] [CrossRef] [PubMed]

- Hoet, P.H.; Brüske-Hohlfeld, I.; Salata, O.V. Nanoparticles—Known and unknown health risks. J. Nanobiotechnol. 2004, 2, 12. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lee, S.; Yun, H.S.; Kim, S.H. The comparative effects of mesoporous silica nanoparticles and colloidal silica on inflammation and apoptosis. Biomaterials 2011, 32, 9434–9443. [Google Scholar] [CrossRef] [PubMed]

- Fedeli, C.; Selvestrel, F.; Tavano, R.; Segat, D.; Mancin, F.; Papini, E. Catastrophic inflammatory death of monocytes and macrophages by overtaking of a critical dose of endocytosed synthetic amorphous silica nanoparticles serum protein complexes. Nanomedicine 2013, 8, 1101–1126. [Google Scholar] [CrossRef] [PubMed]

- Kupferschmidt, N.; Qazi, K.R.; Kemi, C.; Vallhov, H.; Garcia-Bennett, A.E.; Gabrielsson, S.; Scheynius, A. Mesoporous silica particles potentiate antigen-specific T-cell responses. Nanomedicine 2014, 9, 1835–1846. [Google Scholar] [CrossRef] [PubMed]

- Skuland, T.; Øvrevik, J.; Låg, M.; Refsnes, M. Role of size and surface area for pro-inflammatory responses to silica nanoparticles in epithelial lung cells: Importance of exposure conditions. Toxicol. In Vitro 2014, 28, 146–155. [Google Scholar] [CrossRef] [PubMed]

- Guichard, Y.; Maire, M.A.; Sébillaud, S.; Fontana, C.; Langlais, C.; Micillino, J.C.; Darne, C.; Roszak, J.; Stępnik, M.; Fessard, V.; et al. Genotoxicity of synthetic amorphous silica nanoparticles in rats following short-term exposure. Part 2: Intratracheal instillation and intravenous injection. Environ. Mol. Mutagen. 2015, 56, 228–244. [Google Scholar] [CrossRef] [PubMed]

- Tarantini, A.; Huet, S.; Jarry, G.; Lanceleur, R.; Poul, M.; Tavares, A.; Vital, N.; Louro, H.; João Silva, M.; Fessard, V. Genotoxicity of synthetic amorphous silica nanoparticles in rats following short-term exposure. Part 1: Oral route. Environ. Mol. Mutagen. 2015, 56, 218–227. [Google Scholar] [PubMed]

- Park, H.J.; Sohn, J.H.; Kim, Y.J.; Park, Y.H.; Han, H.; Park, K.H.; Lee, K.; Choi, H.; Um, K.; Choi, I.H.; et al. Acute exposure to silica nanoparticles aggravate airway inflammation: Different effects according to surface characteristics. Exp. Mol. Med. 2015, 47, e173. [Google Scholar] [CrossRef] [PubMed]

- Falck, G.C.M.; Lindberg, H.K.; Suhonen, S.; Vippola, M.; Vanhala, E.; Catalan, J.; Savolainen, K.; Norppa, H. Genotoxic effects of nanosized and fine TiO2. Hum. Exp. Toxicol. 2009, 28, 339–352. [Google Scholar] [CrossRef] [PubMed]

- Beatriz, S.P.; Luis, N.; Leonor, C.; Laura, M.; Elena, M.; Yolanda, F.N. Imaging techniques and scanning electron microscopy as tools for characterizing a Si-based material used in air monitoring applications. Materials 2016, 9, 109. [Google Scholar] [CrossRef] [PubMed]

- Masri, S.; Kang, C.M.; Koutrakis, P. Composition and sources of fine and coarse particles collected during 2002–2010 in Boston, MA. J. Air Waste Manag. Assoc. 2015, 65, 287–297. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pisani, C.; Gaillard, J.C.; Nouvel, V.; Odorico, M.; Armengaud, J.; Prat, O. High-throughput, quantitative assessment of the effects of low-dose silica nanoparticles on lung cells: Grasping complex toxicity with a great depth of field. BMC Genom. 2015, 16, 315. [Google Scholar] [CrossRef] [PubMed]

- De Jong, W.H.; Borm, P.J. Drug delivery and nanoparticles: Applications and hazards. Int. J. Nanomed. 2008, 3, 133–149. [Google Scholar] [CrossRef]

- Singh, J.; Mukherjee, A.; Sengupta, S.K.; Im, J.; Peterson, G.W.; Whitten, J.E. Sulfur dioxide and nitrogen dioxide adsorption on zinc oxide and zirconium hydroxide nanoparticles and the effect on photoluminescence. Appl. Surf. Sci. 2012, 258, 5778–5785. [Google Scholar] [CrossRef]

- Meeker, J.D.; Cooper, M.R.; Lefkowitz, D.; Susi, P. Engineering control technologies to reduce occupational silica exposures in masonry cutting and tuckpointing. Public Health Rep. 2009, 124 (Suppl. 1), 101–111. [Google Scholar] [CrossRef] [PubMed]

- Rappaport, S.M.; Goldberg, M.; Susi, P.A.M.; Herrick, R.F. Excessive exposure to silica in the US construction industry. Ann. Occup. Hyg. 2003, 47, 111–122. [Google Scholar] [PubMed]

- OSHA (US Occupational Safety and Health Administration). Available online: https://www.osha.gov/Publications/OSHA3902.pdf (accessed on 28 April 2018).

- TLVs and BEIs: Threshold Limit Values for Chemical Substances and Physical Agents and Biological Exposure Indices; ACGIH: Cincinnati, OH, USA, 2012.

- McKeever, D.B. Estimated Annual Timber Products Consumption in Major End Uses in the United States, 1950–2006; General Technical Report FPL-GTR-181; USDA: Washington, DC, USA, 2009; pp. 1–47.

- Lee, T.; Harper, M.; Slaven, J.E.; Lee, K.; Rando, R.J.; Maples, E.H. Wood dust sampling: Field evaluation of personal samplers when large particles are present. Ann. Occup. Hyg. 2010, 55, 180–191. [Google Scholar] [PubMed]

- Enarson, D.A.; Chan-Yeung, M. Characterization of health effects of wood dust exposures. Am. J. Ind. Med. 1990, 17, 33–38. [Google Scholar] [CrossRef] [PubMed]

- Mračková, E.; Krišťák, Ľ.; Kučerka, M.; Gaff, M.; Gajtanska, M. Creation of wood dust during wood processing: Size analysis, dust separation, and occupational health. BioResources 2015, 11, 209–222. [Google Scholar] [CrossRef]

- Tjoe Nij, E.; Hilhorst, S.; Spee, T.; Spierings, J.; Steffens, F.; Lumens, M.; Heederik, D. Dust control measures in the construction industry. Ann. Occup. Hyg. 2003, 47, 211–218. [Google Scholar] [PubMed]

- Johnson, A.T. Respirator masks protect health but impact performance: A review. J. Biol. Eng. 2016, 10, 4. [Google Scholar] [CrossRef] [PubMed]

- Larson, E.L.; Liverman, C.T. Preventing Transmission of Pandemic Influenza and Other Viral Respiratory Diseases: Personal Protective Equipment for Healthcare Workers; National Academies Press: Washington, DC, USA, 2011. [Google Scholar]

- Rengasamy, S.; King, W.P.; Eimer, B.C.; Shaffer, R.E. Filtration performance of NIOSH-approved N95 and P100 filtering facepiece respirators against 4 to 30 nanometer-size nanoparticles. J. Occup. Environ. Hyg. 2008, 5, 556–564. [Google Scholar] [CrossRef] [PubMed]

- Rengasamy, S.; Eimer, B.C. Nanoparticle penetration through filter media and leakage through face seal interface of N95 filtering facepiece respirators. Ann. Occup. Hyg. 2012, 56, 568–580. [Google Scholar]

- Kaminski, H.; Kuhlbusch, T.A.; Rath, S.; Götz, U.; Sprenger, M.; Wels, D.; Polloczek, J.; Bachmann, V.; Dziurowitz, N.; Kiesling, H.J.; et al. Comparability of mobility particle sizers and diffusion chargers. J. Aerosol Sci. 2013, 57, 156–178. [Google Scholar] [CrossRef]

- Watson, J.G.; Chow, J.C.; Sodeman, D.A.; Lowenthal, D.H.; Chang, O.M.C.; Park, K.; Wang, X. Comparison of four Scanning Mobility Particle Sizers at the Fresno Supersite. Particuology 2011, 9, 204–209. [Google Scholar] [CrossRef]

- Asbach, C.; Kaminski, H.; Von Barany, D.; Kuhlbusch, T.A.; Monz, C.; Dziurowitz, N.; Pelzer, J.; Vossen, K.; Berlin, K.; Dietrich, S.; et al. Comparability of portable nanoparticle exposure monitors. Ann. Occup. Hyg. 2012, 56, 606–621. [Google Scholar] [PubMed]

- Electronic mail and telephone conversations between TSI, Inc. representative and the authors, May and June 2017.

- Lee, K.; Slavcev, A.; Nicas, M. Respiratory protection against Mycobacterium tuberculosis: Quantitative fit test outcomes for five type N95 filtering-facepiece respirators. J. Occup. Environ. Hyg. 2004, 1, 22–28. [Google Scholar] [CrossRef] [PubMed]

- National Institute for Occupational Safety and Health (NIOSH). 42 CFR 84 Respiratory Protective Devices; Final Rules and Notice; Federal Register 60:110; U.S. Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health: Washington, DC, USA, 1997.

- Brown, R.C. Air Filtration: An Integrated Approach to the Theory and Applications of Fibrous Filters; Elsevier: Pergamon, Turkey, 1993. [Google Scholar]

- Martin, S.B., Jr.; Moyer, E.S. Electrostatic respirator filter media: Filter efficiency and most penetrating particle size effects. Appl. Occup. Environ. Hyg. 2000, 15, 609–617. [Google Scholar] [CrossRef] [PubMed]

- Rengasamy, S.; Verbofsky, R.; King, W.B.; Shaffer, R.E. Nanoparticle penetration through NIOSH-approved N95 filtering-facepiece respirators. J. Int. Soc. Respir. Prot. 2007, 24, 49–59. [Google Scholar]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Adhikari, A.; Mitra, A.; Rashidi, A.; Ekpo, I.; Schwartz, J.; Doehling, J. Field Evaluation of N95 Filtering Facepiece Respirators on Construction Jobsites for Protection against Airborne Ultrafine Particles. Int. J. Environ. Res. Public Health 2018, 15, 1958. https://doi.org/10.3390/ijerph15091958

Adhikari A, Mitra A, Rashidi A, Ekpo I, Schwartz J, Doehling J. Field Evaluation of N95 Filtering Facepiece Respirators on Construction Jobsites for Protection against Airborne Ultrafine Particles. International Journal of Environmental Research and Public Health. 2018; 15(9):1958. https://doi.org/10.3390/ijerph15091958

Chicago/Turabian StyleAdhikari, Atin, Aniruddha Mitra, Abbas Rashidi, Imaobong Ekpo, Jacob Schwartz, and Jefferson Doehling. 2018. "Field Evaluation of N95 Filtering Facepiece Respirators on Construction Jobsites for Protection against Airborne Ultrafine Particles" International Journal of Environmental Research and Public Health 15, no. 9: 1958. https://doi.org/10.3390/ijerph15091958