Mechanical Properties and Wear Behavior of a Novel Composite of Acrylonitrile–Butadiene–Styrene Strengthened by Short Basalt Fiber

Abstract

:1. Introduction

- (1)

- Fabrication of a novel composite material using ABS reinforced for the first time with short basalt fiber (SBF).

- (2)

- Measure the mechanical characteristic properties and durability of the new composite.

- (3)

- Measure the wear behaviors and wear mechanism of the novel composite.

2. Materials and Methods

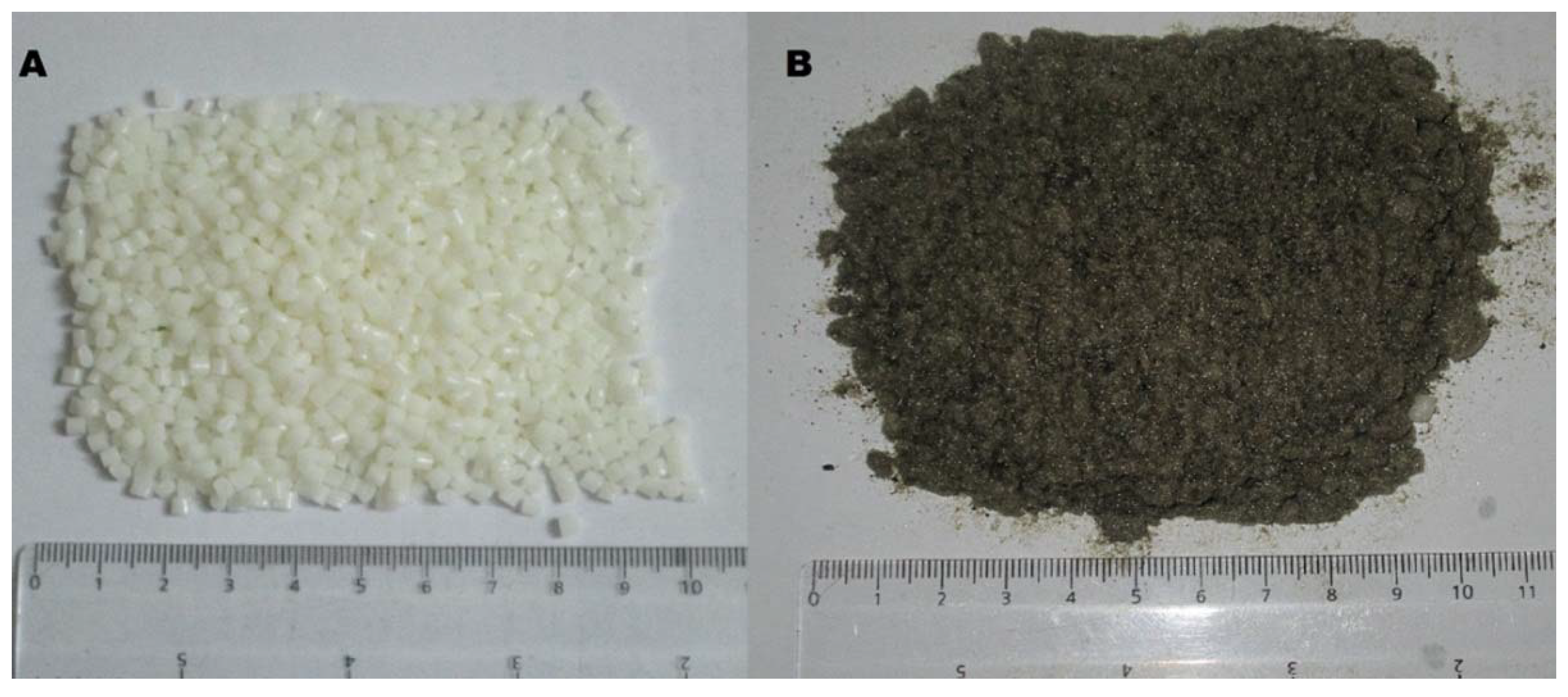

Sample Preparation

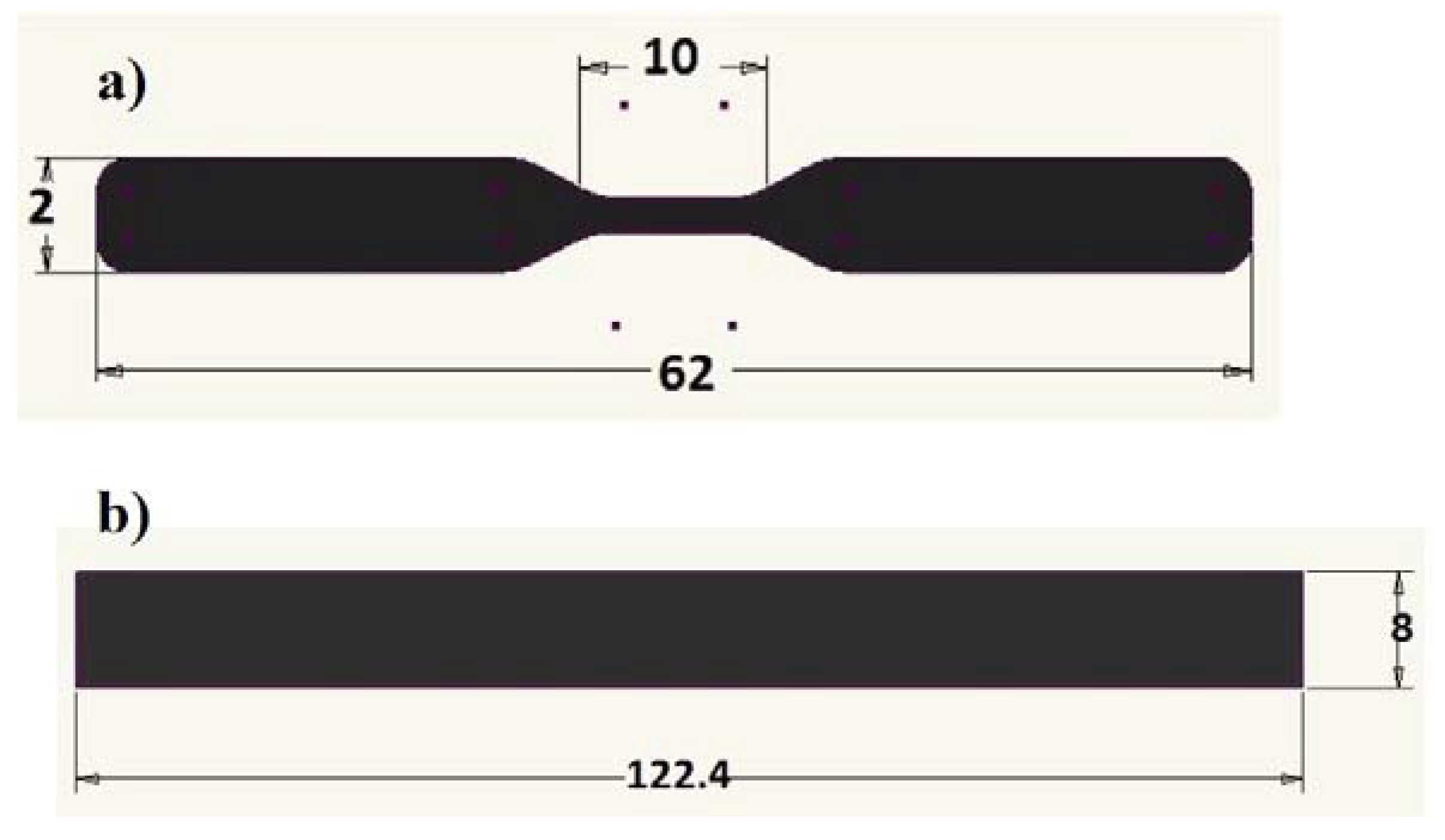

3. Mechanical and Wear Testing

4. Results and Discussion

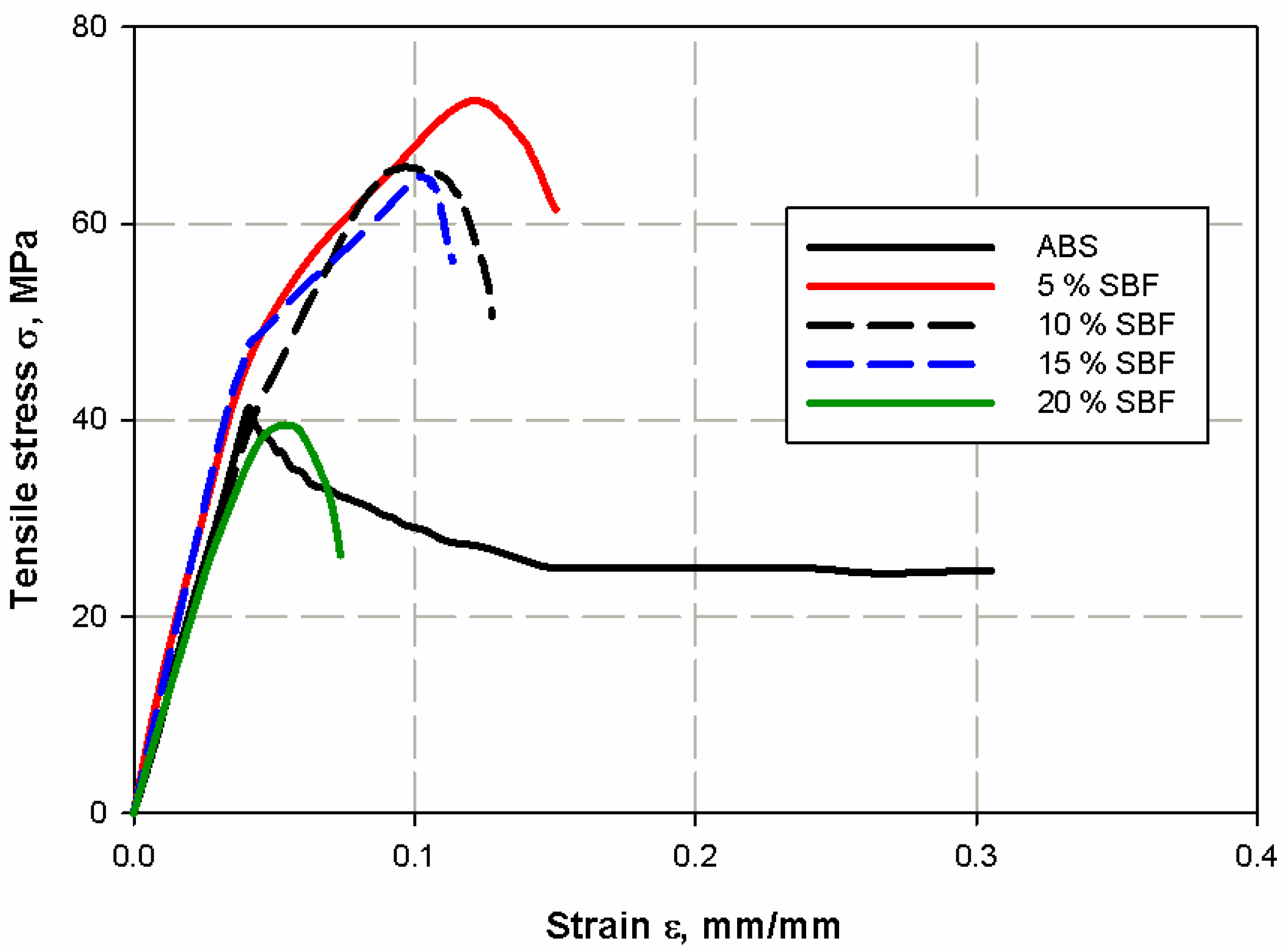

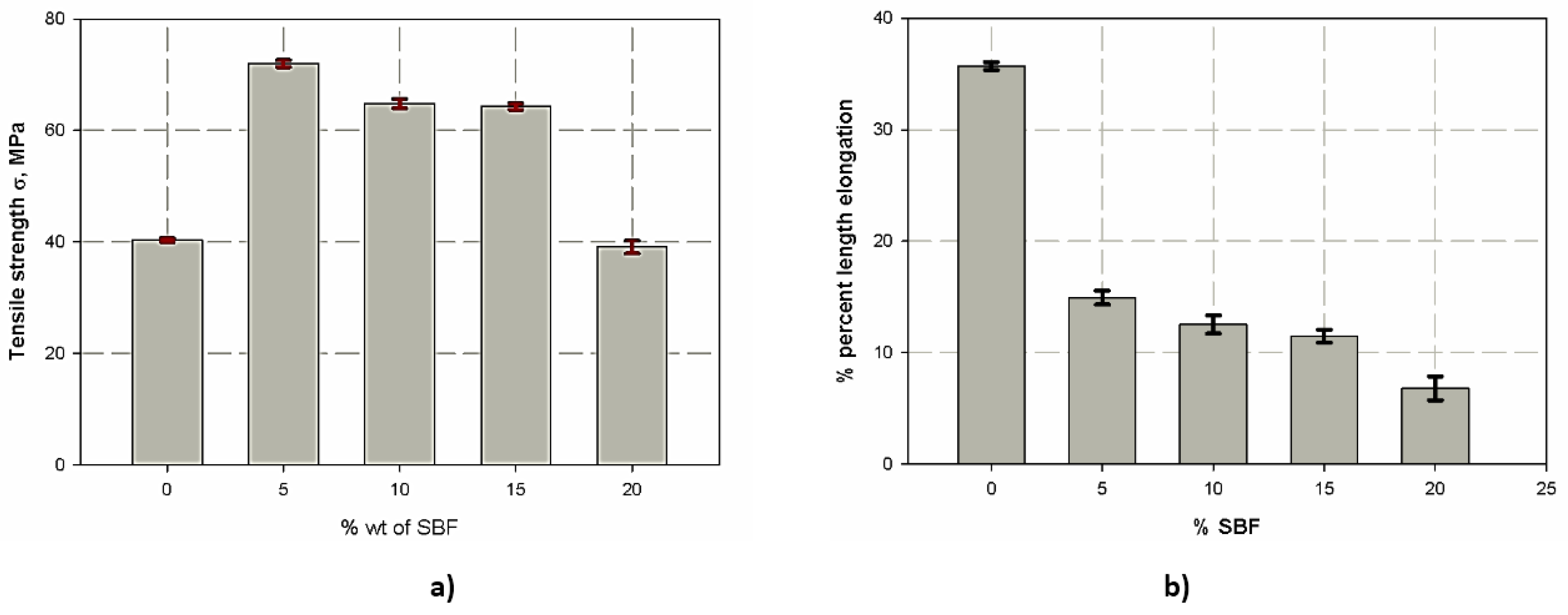

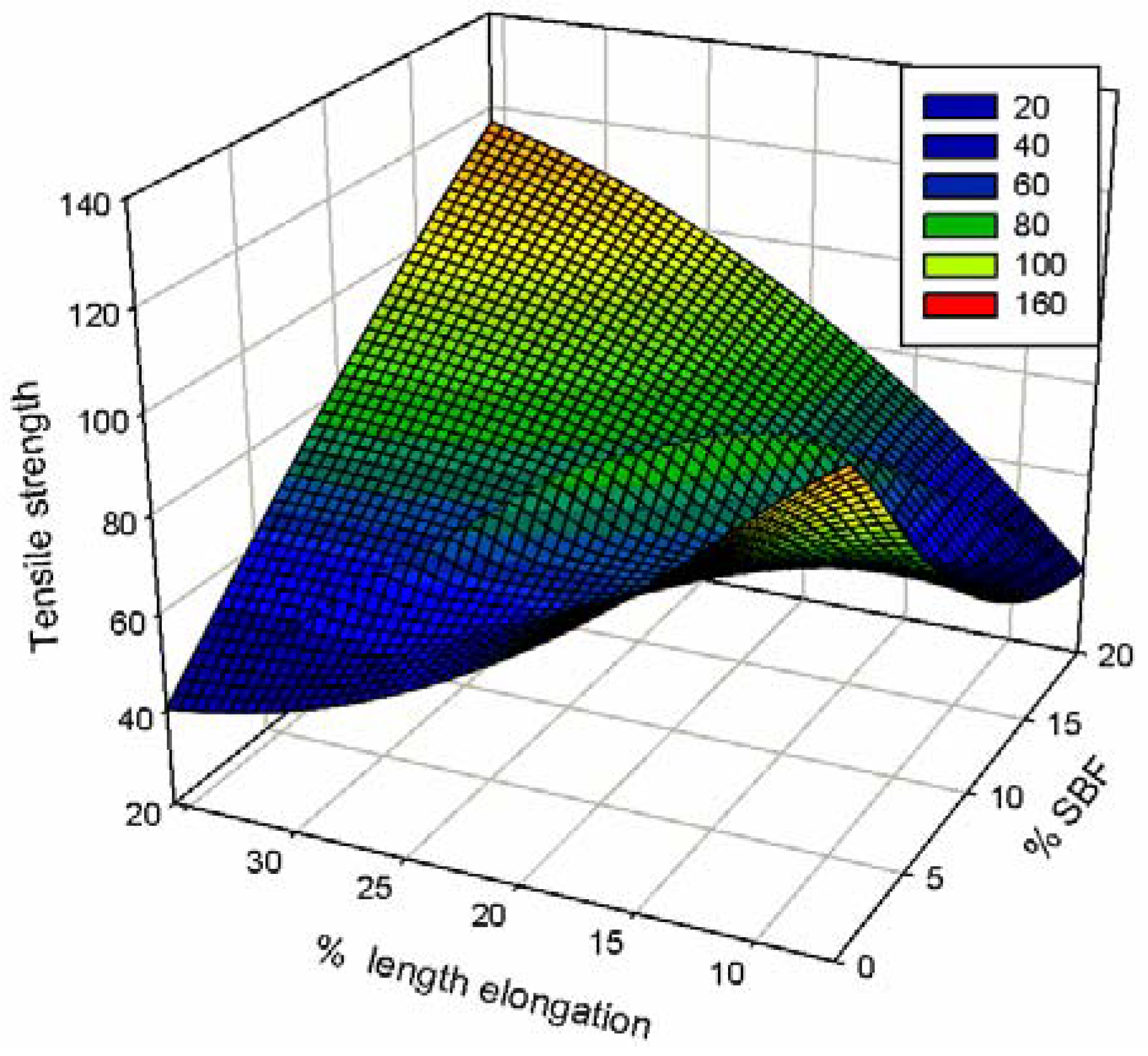

4.1. Tension Test

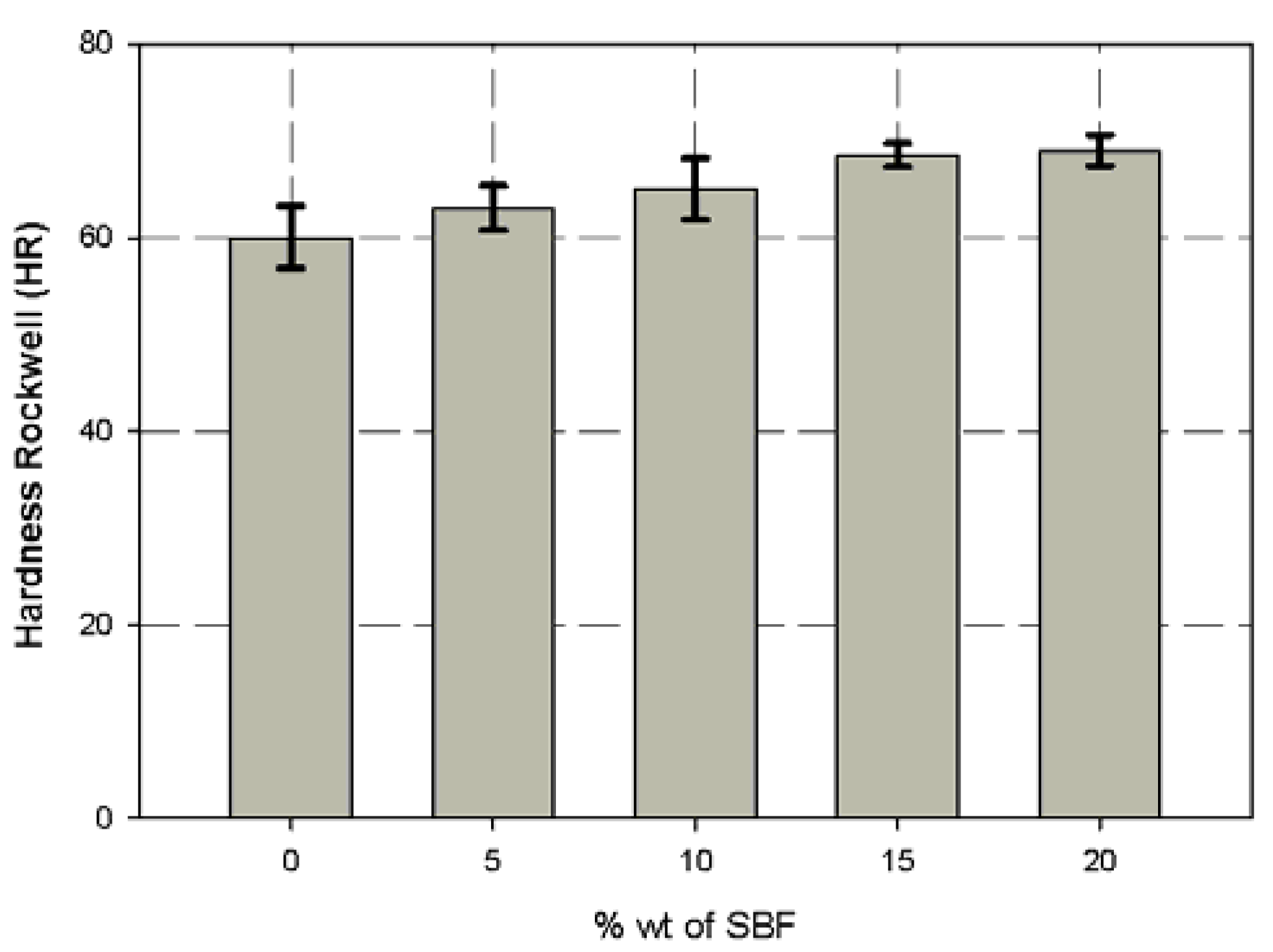

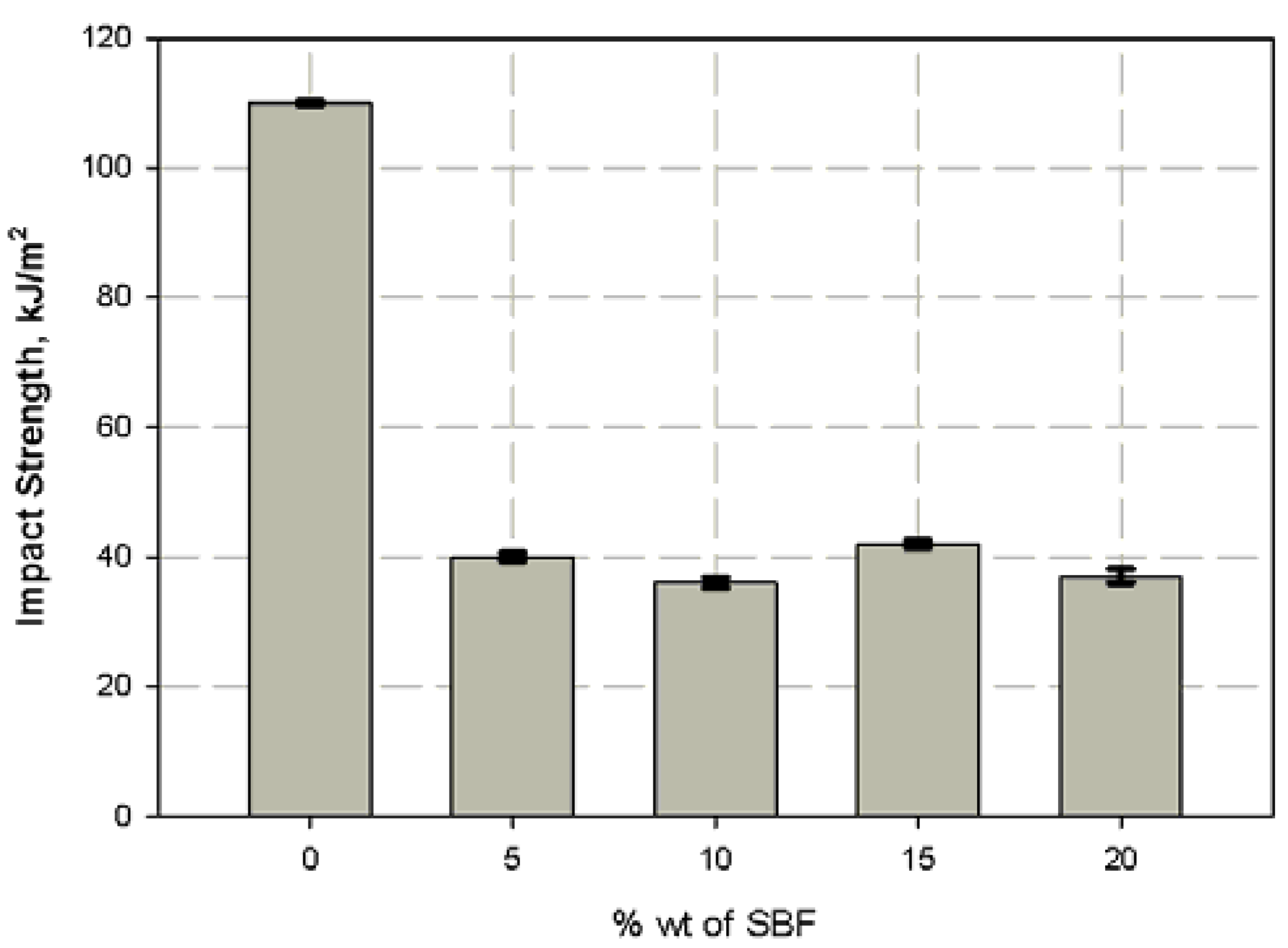

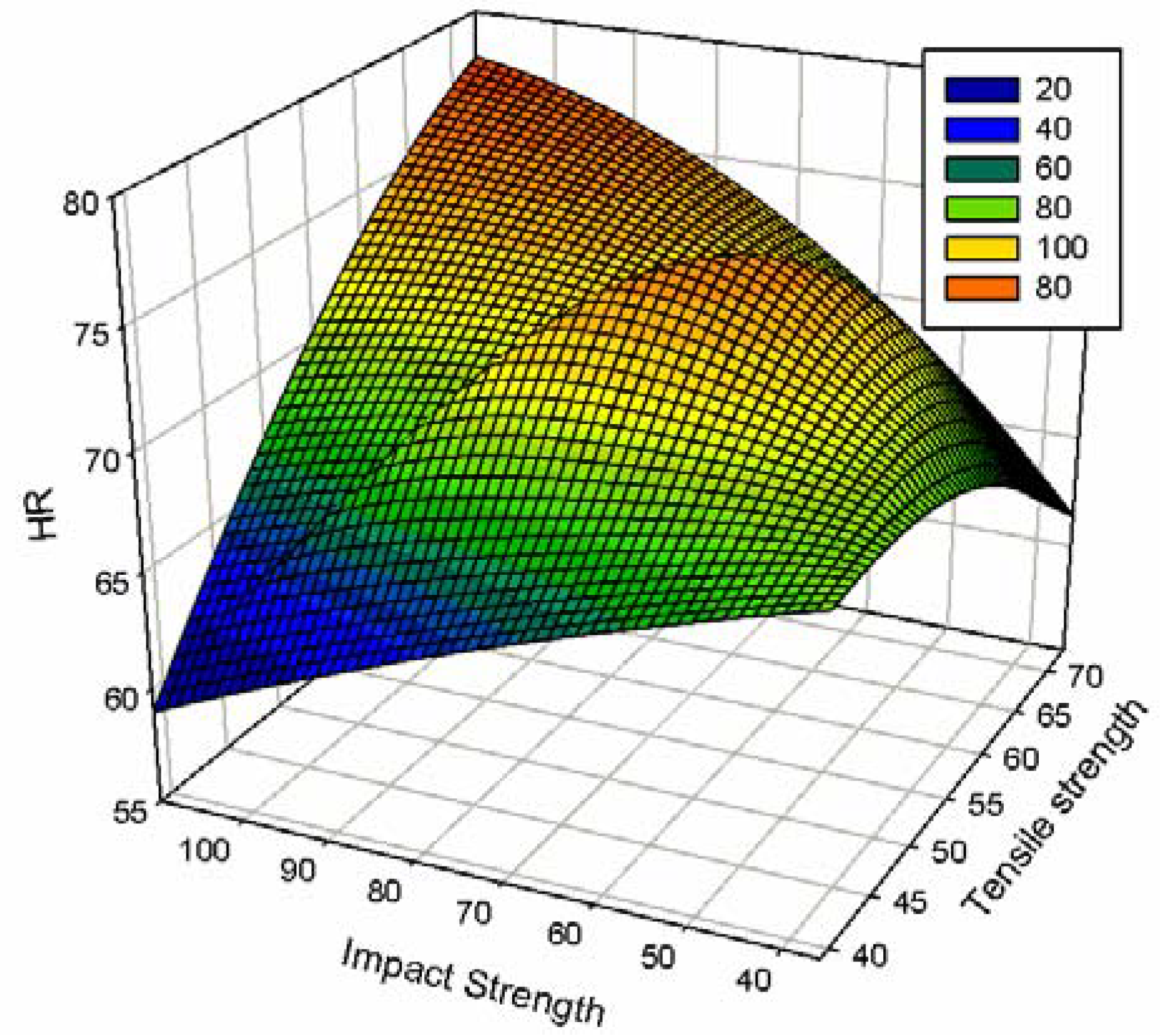

4.2. Hardness and Impact Tests

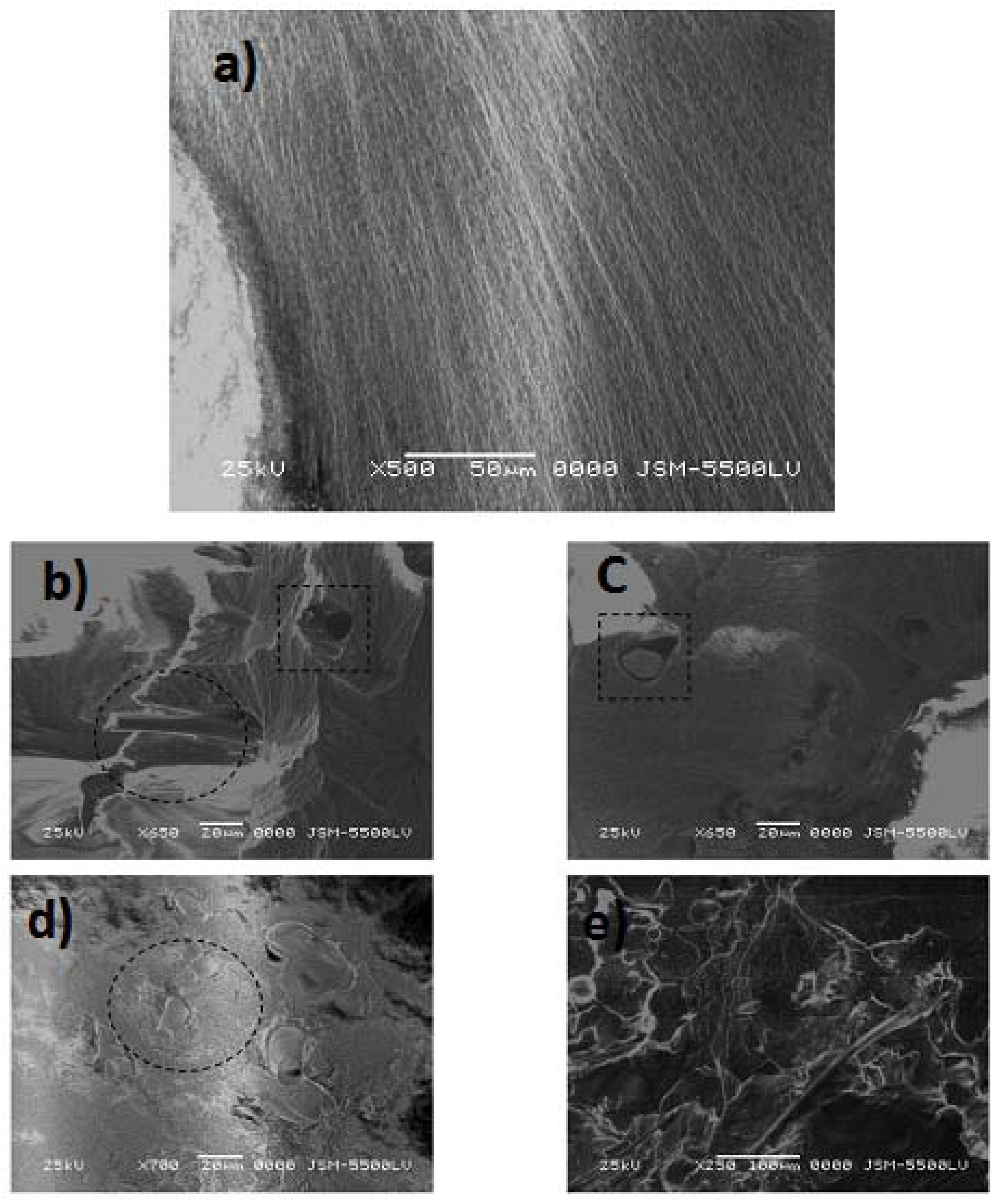

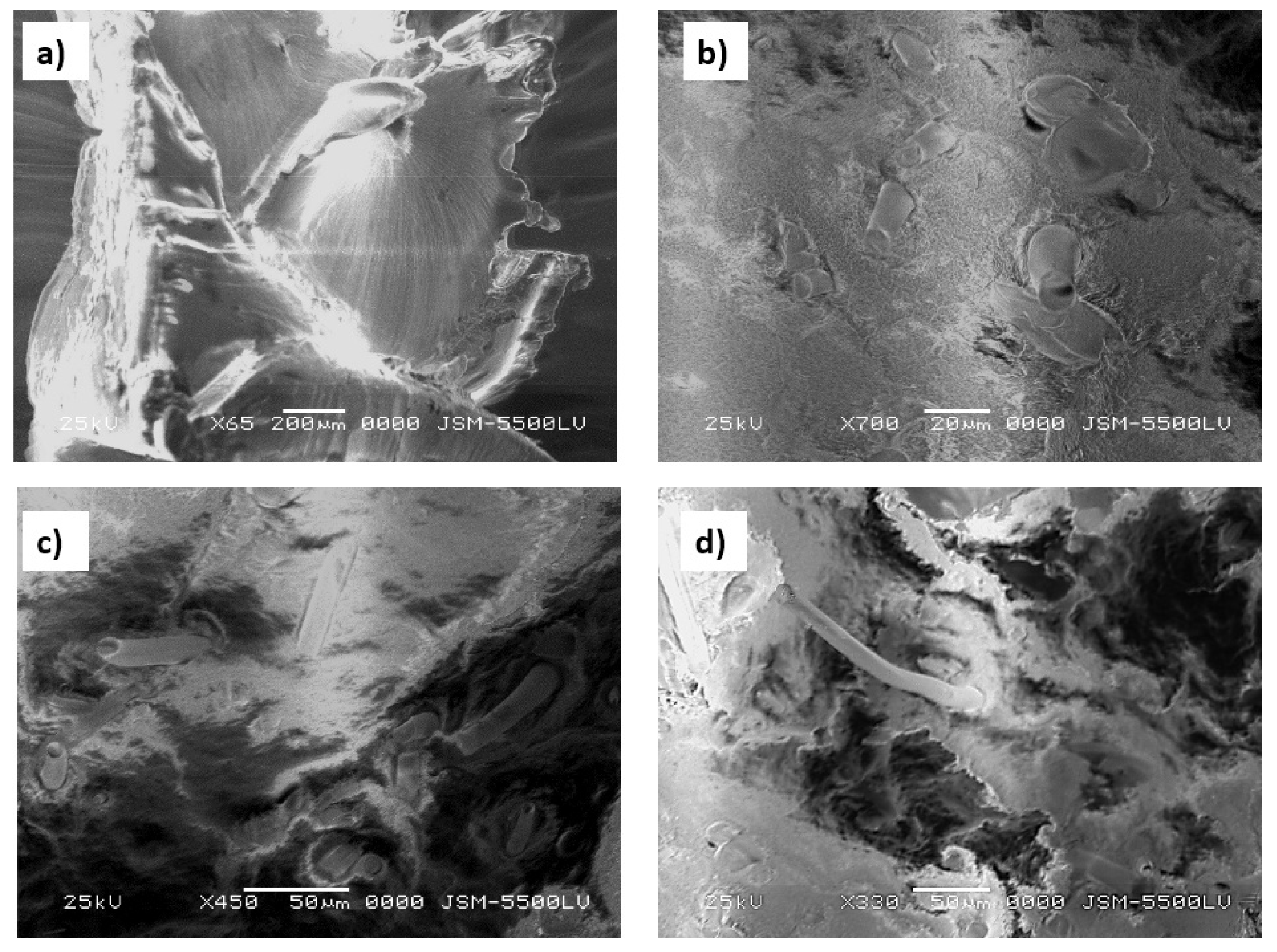

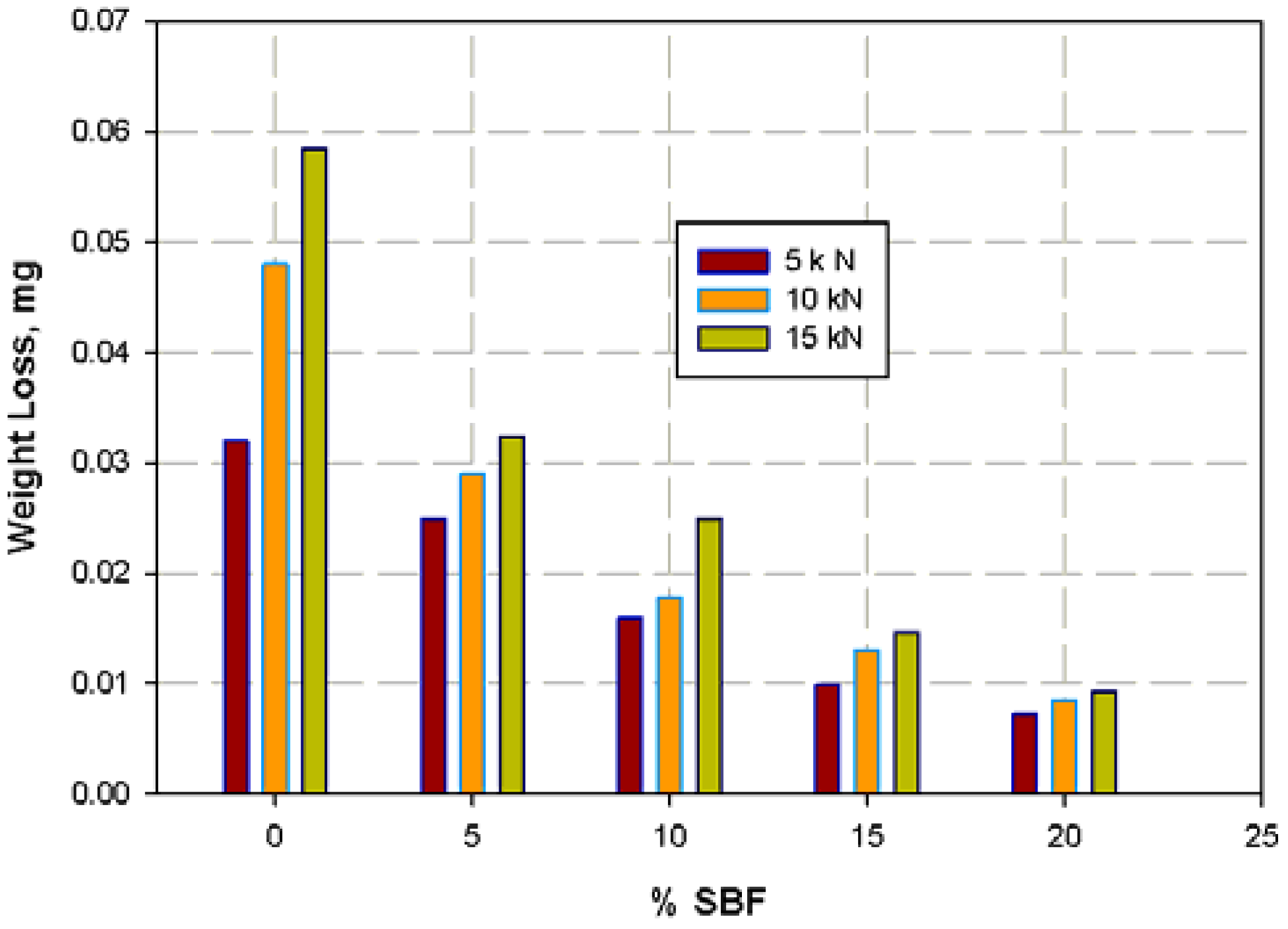

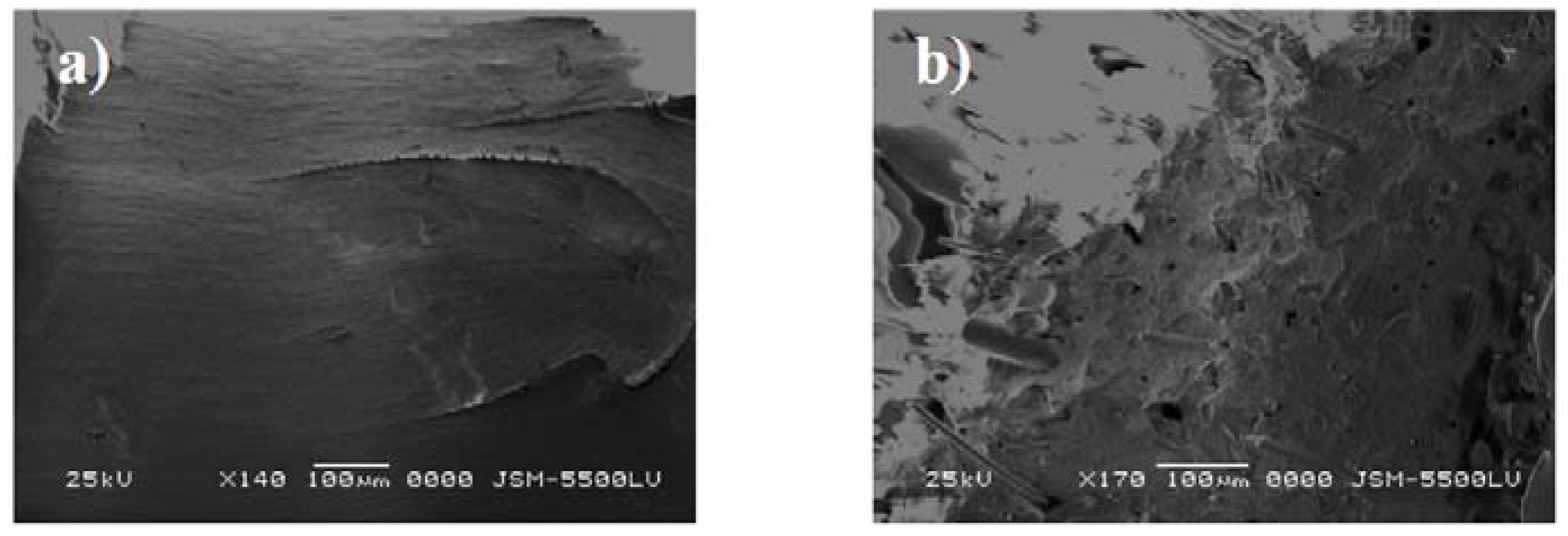

4.3. Wear Test

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Li, Y.; Shimizu, H. Improvement in toughness of poly(l-lactide) (PLLA) through reactive blending with acrylonitrile–butadiene–styrene copolymer (ABS): Morphology and properties. Eur. Polym. J. 2009, 45, 738–746. [Google Scholar] [CrossRef]

- Sarasini, F.; Tirillò, J.; Valente, M.; Valente, T.; Cioffi, S.; Iannace, S.; Sorrentino, L. Effect of basalt fiber hybridization on the impact behavior under low impact velocity of glass/basalt woven fabric/epoxy resin composites. Compos. Part A Appl. Sci. Manuf. 2013, 47, 109–123. [Google Scholar] [CrossRef]

- Czigány, T. Trends in fiber reinforcements-the future belongs to basalt fiber. Express Polym. Lett. 2007. [Google Scholar] [CrossRef]

- Deák, T.; Czigány, T. Chemical composition and mechanical properties of basalt and glass fibers: A comparison. Text. Res. J. 2009, 79, 645–651. [Google Scholar] [CrossRef]

- Czigány, T.; Vad, J.; Pölöskei, K. Basalt fiber as a reinforcement of polymer composites. Period. Polytech. Eng. Mech. Eng. 2005, 49, 3. [Google Scholar]

- Jiang, L.; Lam, Y.; Tam, K.; Chua, T.; Sim, G.; Ang, L. Strengthening acrylonitrile-butadiene-styrene (ABS) with nano-sized and micron-sized calcium carbonate. Polymer 2005, 46, 243–252. [Google Scholar] [CrossRef]

- Sepet, H.; Tarakcioglu, N.; Misra, R. Determination of the mechanical, thermal and physical properties of nano-CaCO3 filled high-density polyethylene nanocomposites produced in an industrial scale. J. Compos. Mater. 2016, 50, 3445–3456. [Google Scholar] [CrossRef]

- Abdelhaleem, A.M.; Abdellah, M.Y.; Fathi, H.I.; Dewidar, M. Mechanical properties of ABS embedded with basalt fiber fillers. J. Manuf. Sci. Prod. 2016, 16, 69–74. [Google Scholar] [CrossRef]

- Lopresto, V.; Leone, C.; de Iorio, I. Mechanical characterisation of basalt fibre reinforced plastic. Compos. Part B Eng. 2011, 42, 717–723. [Google Scholar] [CrossRef]

- Difallah, B.B.; Kharrat, M.; Dammak, M.; Monteil, G. Mechanical and tribological response of ABS polymer matrix filled with graphite powder. Mater. Des. 2012, 34, 782–787. [Google Scholar] [CrossRef]

- Colombo, C.; Vergani, L.; Burman, M. Static and fatigue characterisation of new basalt fibre reinforced composites. Compos. Struct. 2012, 94, 1165–1174. [Google Scholar] [CrossRef]

- Jeevanantham, R.; Venketaramanamurthy, V.; Rajeswari, D. Mechanical and wear characterization of basalt fiber reinforced polyurethane composites. Int. J. Adv. Eng. Technol. 2016. [Google Scholar] [CrossRef]

- Chen, W.; Hao, H.; Jong, M.; Cui, J.; Shi, Y.; Chen, L.; Pham, T.M. Quasi-static and dynamic tensile properties of basalt fibre reinforced polymer. Compos. Part B Eng. 2017, 125, 123–133. [Google Scholar] [CrossRef]

- Khosravi, H.; Eslami-Farsani, R. Enhanced mechanical properties of unidirectional basalt fiber/epoxy composites using silane-modified Na+-montmorillonite nanoclay. Polym. Test. 2016, 55, 135–142. [Google Scholar] [CrossRef]

- Scalici, T.; Pitarresi, G.; Badagliacco, D.; Fiore, V.; Valenza, A. Mechanical properties of basalt fiber reinforced composites manufactured with different vacuum assisted impregnation techniques. Compos. Part B Eng. 2016, 104, 35–43. [Google Scholar] [CrossRef]

- Wu, G.; Wang, X.; Wu, Z.; Dong, Z.; Zhang, G. Durability of basalt fibers and composites in corrosive environments. J. Compos. Mater. 2015, 49, 873–887. [Google Scholar] [CrossRef]

- Matkó, S.; Anna, P.; Marosi, G.; Szep, A.; Keszei, S.; Czigany, T.; Pölöskei, K. Use of reactive surfactants in basalt fiber reinforced polypropylene composites. In Macromolecular Symposia; WILEY-VCH Verlag: Weinheim, Germany, 2003; pp. 255–268. [Google Scholar]

- Czigány, T. Basalt fiber reinforced hybrid polymer composites. In Materials Science Forum; Trans Tech Publications: Zürich, Switzerland, 2005; pp. 59–66. [Google Scholar]

- Bashtannik, P.; Ovcharenko, V.; Boot, Y.A. Effect of combined extrusion parameters on mechanical properties of basalt fiber-reinforced plastics based on polypropylene. Mech. Compos. Mater. 1997, 33, 600–603. [Google Scholar] [CrossRef]

- Liu, Q.; Shaw, M.T.; Parnas, R.S.; McDonnell, A.M. Investigation of basalt fiber composite aging behavior for applications in transportation. Polym. Compos. 2006, 27, 475–483. [Google Scholar] [CrossRef]

- Jancar, J. Effect of interfacial shear strength on the mechanical response of polycarbonate and PP reinforced with basalt fibers. Compos. Interfaces 2006, 13, 853–864. [Google Scholar] [CrossRef]

- Artemenko, S. Polymer composite materials made from carbon, basalt, and glass fibres. Structure and properties. Fibre Chem. 2003, 35, 226–229. [Google Scholar] [CrossRef]

- Wei, B.; Cao, H.; Song, S. Tensile behavior contrast of basalt and glass fibers after chemical treatment. Mater. Des. 2010, 31, 4244–4250. [Google Scholar] [CrossRef]

- Manikandan, V.; Jappes, J.W.; Kumar, S.S.; Amuthakkannan, P. Investigation of the effect of surface modifications on the mechanical properties of basalt fibre reinforced polymer composites. Compos. Part B Eng. 2012, 43, 812–818. [Google Scholar] [CrossRef]

- Park, J.-M.; Shin, W.-G.; Yoon, D.-J. A study of interfacial aspects of epoxy-based composites reinforced with dual basalt and SiC fibres by means of the fragmentation and acoustic emission techniques. Compos. Sci. Technol. 1999, 59, 355–370. [Google Scholar] [CrossRef]

- Mangat, P.S. Strength and deformation characteristics of an acrylic polymer-cement composite. Matér. Constr. 1978, 11, 435–443. [Google Scholar] [CrossRef]

- Girgin, Z.C.; Yıldırım, M.T. Usability of basalt fibres in fibre reinforced cement composites. Mater. Struct. 2016, 49, 3309–3319. [Google Scholar] [CrossRef]

- Alaimo, G.; Valenza, A.; Enea, D.; Fiore, V. The durability of basalt fibres reinforced polymer (BFRP) panels for cladding. Mater. Struct. 2016, 49, 2053–2064. [Google Scholar] [CrossRef]

- Abdellah, M.Y.; Gelany, A.; Mohamed, A.F.; Khoshaim, A.B. Protection of limestone coated with different polymeric materials. Am. J. Mech. Eng. 2017, 5, 51–57. [Google Scholar] [CrossRef]

- Abdellah, M.Y. Delamination modeling of double cantilever beam of unidirectional composite laminates. Fail. Anal. Prev. 2017, 17, 1011–1018. [Google Scholar] [CrossRef]

- Abdellah, M.Y.; Hassan, M.K.; El-Ainin, H.A. Plasticity and formability controlling of cast iron using thermo-mechanical treatment. Am. J. Mater. Eng. Technol. 2014, 2, 38–42. [Google Scholar]

- Fiore, V.; Scalici, T.; di Bella, G.; Valenza, A. A review on basalt fibre and its composites. Compos. Part B Eng. 2015, 74, 74–94. [Google Scholar] [CrossRef]

- Sudeepan, J.; Kumar, K.; Barman, T.K.; Sahoo, P. Study of mechanical and tribological properties of ABS/ZnO polymer composites. Adv. Mater. Manuf. Charact. 2015, 5, 1–11. [Google Scholar] [CrossRef]

- Zhang, X.; Pei, X.; Wang, Q. Friction and wear properties of basalt fiber reinforced/solid lubricants filled polyimide composites under different sliding conditions. J. Appl. Polym. Sci. 2009, 114, 1746–1752. [Google Scholar] [CrossRef]

- Mohamed, K.H.; Mohammed, Y.A.; Azabi, S.K.; Marzouk, W.W. Investigation of the mechanical behavior of novel fiber metal laminates. Int. J. Mech. Mechatron. Eng. 2015, 15, 112–118. [Google Scholar]

- LG Chem. Available online: http://www.lgchem.com.tr/index.php (accessed on 25 October 2015).

- Ahmed, F.M.; Mohammed, Y.A.; Mohammed, K.H. Relaxation and compressive characteristic in composite glass fiber reinforced pipes. Int. J. Sci. Eng. Res. 2015, 6. [Google Scholar]

- Militký, J.; Kovačič, V.; Bajzík, V. Mechanical properties of basalt filaments. Fibres Text. Eastern Eur. 2007, 15, 64–65. [Google Scholar]

- Militký, J.; Kovačič, V.R.; Rubnerová, J. Influence of thermal treatment on tensile failure of basalt fibers. Eng. Fract. Mech. 2002, 69, 1025–1033. [Google Scholar] [CrossRef]

- ASTM D3039/D 3039M. Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials; ASTM International: West Conshohocken, PA, USA, 1995. [Google Scholar]

- ASTM D6110-17. Standard Test Method for Determining the Charpy Impact Resistance of Notched Specimens of Plastics; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- ASTM D785-08. Standard Test Method for Rockwell Hardness of Plastics and Electrical Insulating Materials; ASTM International: West Conshohocken, PA, USA, 2005. [Google Scholar]

- ASTM G132-96. Standard Test Method for Pin Abrasion Testing; ASTM international: West Conshohocken, PA, USA, 2013. [Google Scholar]

- Chotirat, L.; Chaochanchaikul, K.; Sombatsompop, N. On adhesion mechanisms and interfacial strength in acrylonitrile–butadiene–styrene/wood sawdust composites. Int. J. Adhes. Adhes. 2007, 27, 669–678. [Google Scholar] [CrossRef]

- Wu, S. Phase structure and adhesion in polymer blends: A criterion for rubber toughening. Polymer 1985, 26, 1855–1863. [Google Scholar] [CrossRef]

- Margolina, A.; Wu, S. Percolation model for brittle-tough transition in nylon/rubber blends. Polymer 1988, 29, 2170–2173. [Google Scholar] [CrossRef]

- Nakamura, Y.; Yamaguchi, M.; Okubo, M.; Matsumoto, T. Effect of particle size on the fracture toughness of epoxy resin filled with spherical silica. Polymer 1992, 33, 3415–3426. [Google Scholar] [CrossRef]

- Bahadur, S.; Gong, D. The action of fillers in the modification of the tribological behavior of polymers. Wear 1992, 158, 41–59. [Google Scholar] [CrossRef]

| Raw Material | Density () | Melt Flow Index () | Particle Size () | Diameter () |

|---|---|---|---|---|

| Acrylonitrile–butadiene–styrene (ABS) | 1.04 | 21 | - | - |

| Short basalt fiber (SBF) | - | - | 3:50 | Less than 6.5 |

| Parameter Pressure in (Bar) | First Stage | Second Stage | Third Stage | Fourth Stage | Fifth Stage |

|---|---|---|---|---|---|

| Injection | 140 | 140 | 140 | 130 | 130 |

| Closing | 80 | 80 | 80 | 30 | 100 |

| Holding | 100 | 100 | 100 | - | - |

| Opening | 60 | 60 | 60 | 60 | 60 |

| Charging | 100 | 100 | 100 | - | - |

| Samples | Tensile Strength (MPa) | SDV | Elongation at Break (%) | SDV | Young’s Modulus (MPa) |

|---|---|---|---|---|---|

| ABS | 40.32 | 0.36 | 35.7 | 0.36 | 1450 |

| ABS + 5%SBF | 72.69 | 0.63 | 14.94 | 0.62 | 1481 |

| ABS + 10%SBF | 64.82 | 0.82 | 12.53 | 0.81 | 1099.7 |

| ABS + 15%SBF | 64.29 | 0.58 | 11.46 | 0.57 | 1117.2 |

| ABS + 20%SBF | 39.07 | 1.16 | 6.79 | 1.062 | 871.3 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abdellah, M.Y.; Fathi, H.I.; Abdelhaleem, A.M.M.; Dewidar, M. Mechanical Properties and Wear Behavior of a Novel Composite of Acrylonitrile–Butadiene–Styrene Strengthened by Short Basalt Fiber. J. Compos. Sci. 2018, 2, 34. https://doi.org/10.3390/jcs2020034

Abdellah MY, Fathi HI, Abdelhaleem AMM, Dewidar M. Mechanical Properties and Wear Behavior of a Novel Composite of Acrylonitrile–Butadiene–Styrene Strengthened by Short Basalt Fiber. Journal of Composites Science. 2018; 2(2):34. https://doi.org/10.3390/jcs2020034

Chicago/Turabian StyleAbdellah, Mohammed Y., Hesham I. Fathi, Ayman M. M. Abdelhaleem, and Montasser Dewidar. 2018. "Mechanical Properties and Wear Behavior of a Novel Composite of Acrylonitrile–Butadiene–Styrene Strengthened by Short Basalt Fiber" Journal of Composites Science 2, no. 2: 34. https://doi.org/10.3390/jcs2020034