1. Introduction

There is growing support in the technical and scientific literature that green composites can provide mechanical properties analogous to synthetic composites and, therefore, will replace their traditional counterparts in future automotive applications [

1,

2,

3,

4]. Substituting petroleum-resourced automotive compounds typically of reinforced with glass-fiber polymers (GFRP) by composites of renewable substances is becoming increasingly imperative, not only as a modern trend but as a necessity towards a more sustainable society in terms of materials use [

5,

6]. Consequently, it is anticipated by both industrial practice and academia that producers, end-users and the environment may benefit equally from that shift [

7,

8]. Broadly speaking, the term “sustainable” is used to describe composites which are made entirely from annually renewable materials or a mix of synthetics and natural products at a discretionary percentage. In that sense, the former is considered more environmentally friendly when compared to composites made of petroleum resourced constituents like GFRPs.

One way to balance sustainable materials use and manufacturing cost in automotive panels is by the use of composites containing renewable materials. A number of automakers and academic studies have explored and presented practical examples of plant-based solutions for automotive parts including trim parts in dashboards, door panels, parcel shelves, seat cushions, backrests, cabin linings and so on [

5,

9,

10,

11,

12,

13,

14,

15]. One can see an increasing interest in replacing fiberglass by introducing natural plant fibers such as jute, flax, hemp, sisal and ramie because of the environmental benefits achieved due to the density of natural fibers comparing to glass fibers [

6,

12,

16,

17,

18]. Subsequently, green composites have the potential of multiple gains in terms of economic/mechanical performance, environmental impact and public acceptance when compared with fossil-derived plastics, metals and traditional synthetic resourced composites.

Some researchers have combined technical cost modeling along with life cycle assessment (LCA) to complement an analysis of composite aircraft components [

19] or Life Cycle Cost (LCC) coupled with LCA [

20,

21] to analyze the economic and environmental impact associated with a product. However, for the present study, considering cost implications of logistics and manufacturing processes in different design alternatives is more important, and these are not well estimated by traditional cost models, i.e., technical cost models or LCC. These make use of deterministic historical cost databases and elemental quantities from product design to estimate cost which may lead to inaccurate calculations. For instance, when substituting materials on an existing process, we must also take into account characteristics of the process employed (distinct yields, operating rates, tooling life, etc.), which also need to change accordingly with the material price [

22]. The LCC explicitly does not take into account the decision makers’ limited ability to make rational decisions under uncertainty [

23]. Especially in the early stages of development, as described by Kirchain and Field [

22], cost descriptions by accounting systems cannot be used alone to understand how it will vary in response to changes in part design, material, or operating conditions, not to mention wholesale process technology change.

The LCC analysis is a resource and data-intensive process [

23,

24], making it difficult, if not impossible, to model future costs and various components of cost in disaggregate level. A rigorous approach to such a quantitative assessment requires unreasonable time and effort that risks bringing the discussion to a more qualitative level, or, even worse, abandoning this approach [

25]. It incorporates diverse factors in a practical manner with a judicious mix of quantitative and qualitative aspects [

24]. In fact, in the literature, there is no formal guideline and reliable past data to perform an LCC analysis [

24,

26], which appear the main reasons for the tardy adoption of LCC [

24]. Additionally, traditional cost models rely wholly on historical data quantities from product design, which may not exist for novel technologies [

27]. These cost assessment tools are retrospective, directed toward the performance of existing plants and products and tasked with informing the decisions of plant management rather than the decisions of those in design and R&D offices [

22,

28]. A possible approach to tackle the above problems is to use a PBCM, which regards cost as a function of technical factors, such as cycle time, downtime, reject rate, consumed materials, equipment and tooling requirements.

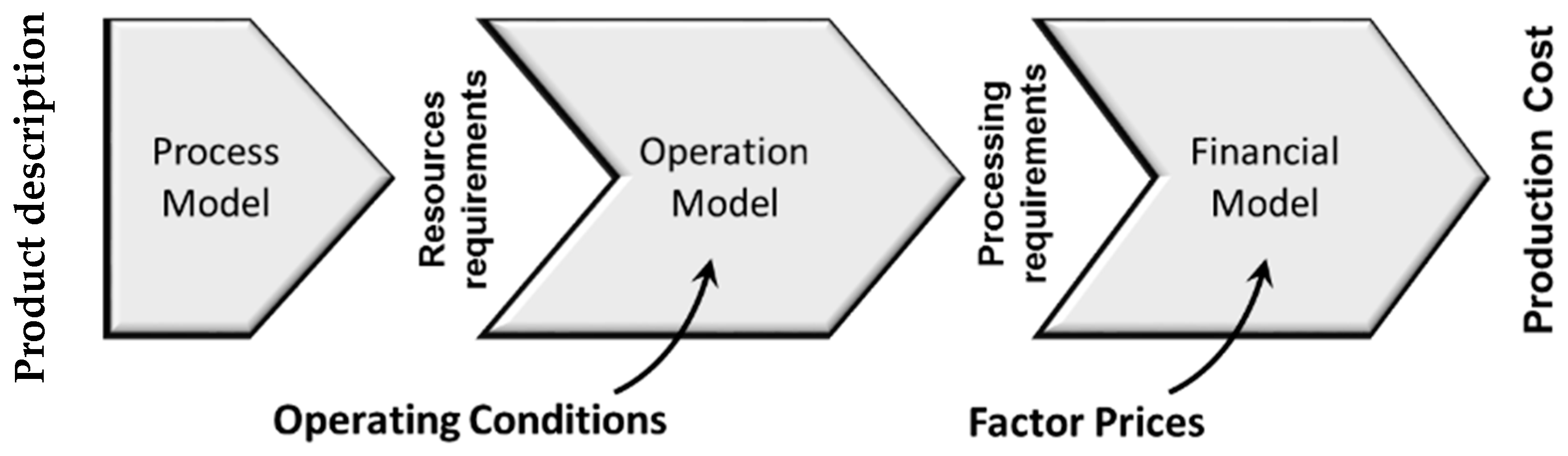

The Process-Based Cost Modeling (PBCM) analyses between alternatives of product and process designs to tie manufacturing cost to the technical and design parameters. These models allow the decision maker to make choices early in the design process, avoiding costly strategic errors in product development and deployment [

22]. Understanding the effect of technical cost drivers provide insight for managers and engineers on which process improvements are most critical to lower production costs [

29]. In general, they all allow for fine tuning of parameters for analytical methods rather than time-consuming experimentation [

22]. A categorization of product present cost estimation models including qualitative (intuitive and analogical) and quantitative (parametric and analytical) methods have been extensively reported by Niazi, Dai, Balabani and Seneviratne [

30]. The PBCM as introduced by Kirchain and Field and further updated and analyzed by Field et al., integrates operational requirements with physical relationships to evaluate the financial impacts on a manufacturing process [

22,

31].

In the research field of environmental analysis, a number of studies have assessed the environmental impact of automotive parts made of green composites [

12,

32,

33]. However, they did not incorporate economic metrics in their analysis to further support their sets of choices. Additionally, the LCA technique is extremely data intensive and thus the lack of data can restrict the conclusions that can be drawn from a particular study [

34]. For instance, LCA is primarily focused on detailed environmental reports for finished products [

35] and requires information that is mostly unavailable in early stages of concept development [

35,

36,

37]. Furthermore, 80% of the environmental burden of a product is determined in the early stages of design when many decisions are still fluid [

35]. Despite LCA’s more accurate assessment of environmental impact and the fact that it has a broader list of environmental indicators, it is time-consuming with respect to the complexity of each process step [

38], i.e., setting up inventory data can be one of the most labor and time-intensive stages of an LCA [

34].

The Eco-Audit tool has been employed by a number of studies to evaluate sensible heat storage materials [

39,

40], wall hung boilers [

25] and wind turbines [

41] for their environmental performance. The tool can be used as an integrated approach to assist in design decisions that are followed by further cost analysis and LCA [

37]. An LCA is highly desirable and can provide valuable information about the total environmental performance in a way that the Eco-Audit tool cannot. As such, the Eco-Audit points to the aspects of design that a fuller LCA should examine as a product assessment tool. A rational explanation of the Eco-Audit tool approach is found in the CES EduPack Eco-Audit tool white paper [

35]. Few reliable indicators are accounted for when ranking materials and processes within the assessment. These indicators include energy consumption, the global warming potential, and the end of life possibilities (regarding useful, practical scenarios, e.g., of downcycling). This leads to a more “streamlined” method which condenses eco-information of material production into a single indicator, e.g., CO

2 produced per unit weight of material manufactured. Hence, not all parameters provided by a full LCA study are explored. The Eco-Audit foregoes the use inventory data from international databases unlike the primary ones needed in LCA [

25], and that is one of the reasons why LCA is more accurate for a more in-depth level of environmental analysis of the system under study. The Eco-Audit tool, although not as thorough as other more advanced tools for LCA, still enables a meaningful comparison of alternatives at a fraction of the effort of building the analysis in terms of energy consumption and carbon footprint. In contrast, more advanced tools for LCA like SimaPro may be more accurate in assessing environmental impact in more depth, they are also in general extremely time-consuming to set up. There is, therefore, a trade-off between time to setup and accuracy of the results, which is in fact mitigated by the uncertainty regarding a number of parameters that need to be in place to use a full LCA which renders its use extremely difficult.

We suggest that under this method, PBCM and Eco-Audit, one can first translate the complex and interrelated consequences of design and process technology changes into a cost metric, followed by an initial idea of the environmental impact in the very early stage of product design. Unlike the researchers Witik et al., 2012 and Yang et al., 2017, we intend to bridge the gap of cost estimation and environmental impact in concept design phase by the combination of the PBCM and eco-impact assessment. These well-established methods are employed as a practical way to assess financial cost and environmental impact for the case of a buggy hood part at the conceptual phase of the product. We utilize this model to guide design decisions when materials and processes are not yet established, but a rough estimation of cost and energy of the design is needed.

2. Materials and Methods

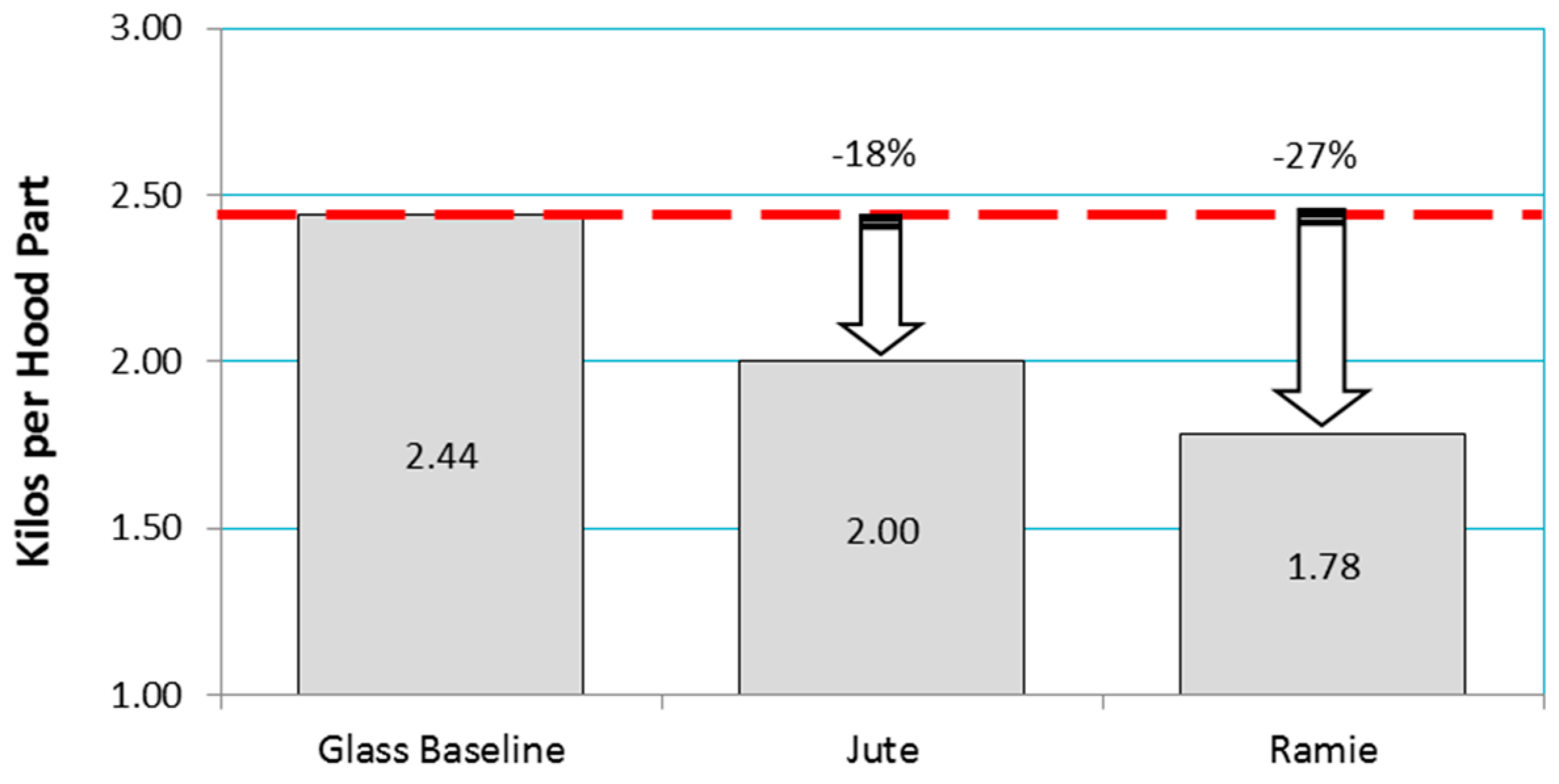

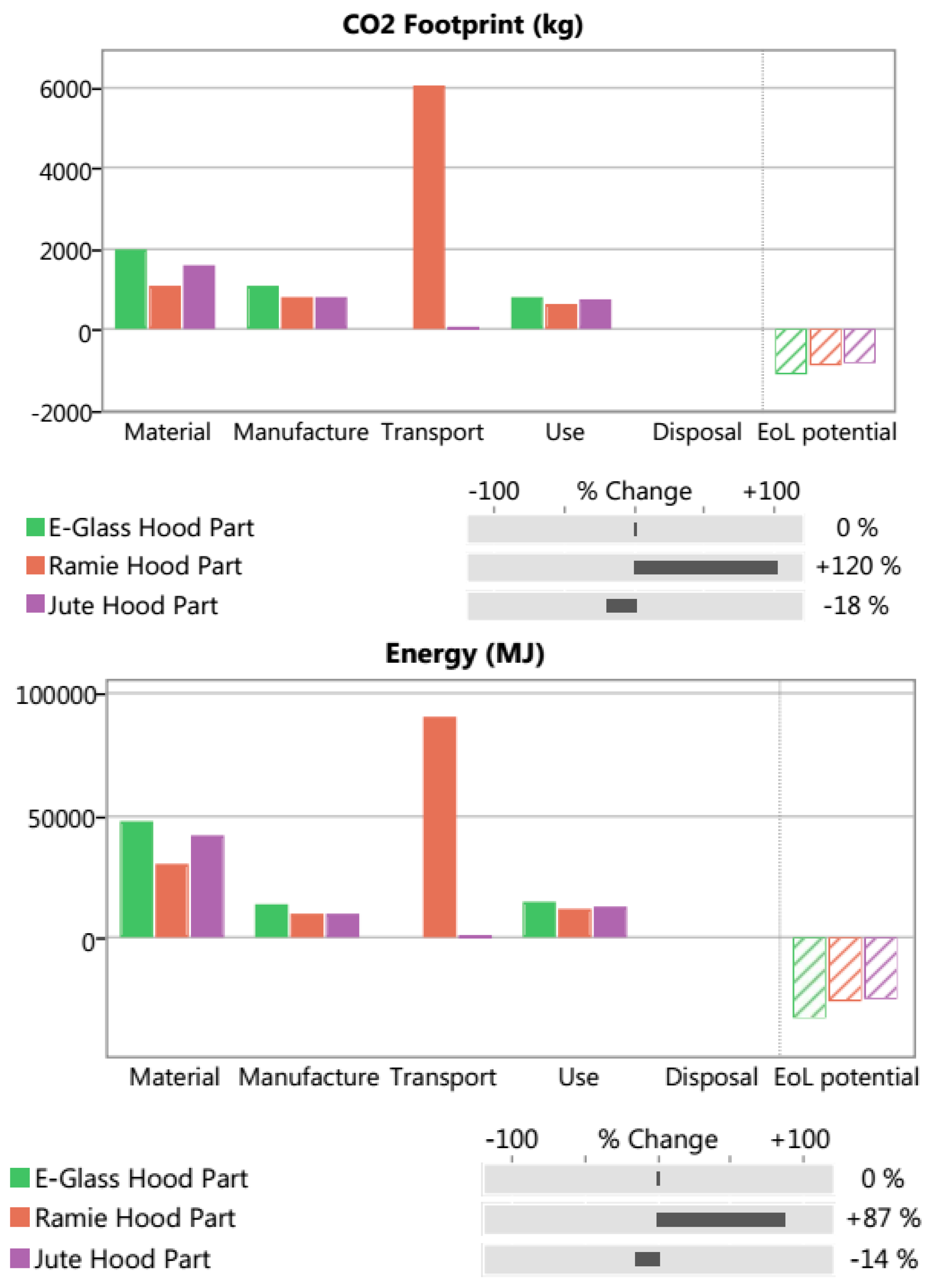

We developed a green composite using a polymer (aliphatic polyester with recycled vegetable oils) and plant-based fabrics in the automotive hood (hinged engine cover) of a buggy vehicle. Our aim is to identify and compare the larger contributors to the environmental burden caused in different phases in the manufacturing of the component. We especially expect to reduce the part’s weight and develop a composite that will best balance environmental performance and affordable production cost compared to its conventional counterparts. Ancel Ltda—Rio Claro, Brazil (a composite manufacturer) has been employing an eco-design strategy by exploring plant-based fabrics as promising reinforcements while minimizing manufacturing cost and leading to environmental improvements. This approach contributes to noticeable weight savings (18–27%) which in turn can contribute to a higher maximum range concerning fuel economy while also reducing the atmospheric CO

2 emissions in the long run [

12,

42,

43]. Similar environmental performance findings have been issued by Mitsubishi [

15] and Toyota [

44] when incorporating natural fiber reinforcements in their car’s components. In another example, a 60% reduction in manufacturing energy expenditure can be realized by integrating natural fibers (abaca) on composites panels reported for the Mercedes-Benz A-Class model [

45].

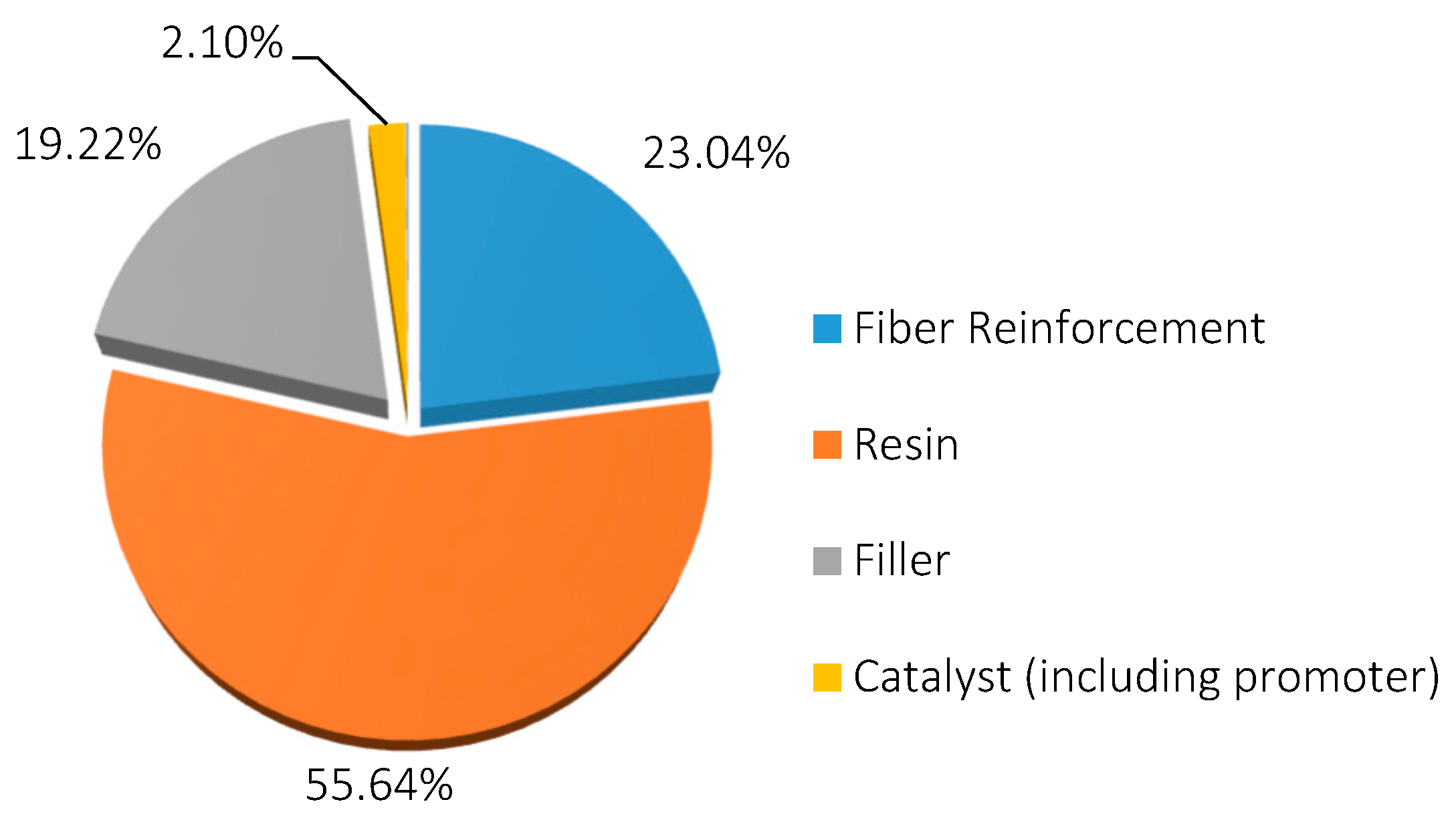

Ancel has been working towards the development of a green composite reinforced with natural fiber fabrics in the hood of a buggy vehicle. The latter will comprise a means of transportation intended for urban use, typically along coastal areas. This type of vehicle is designed for a very narrow niche market and therefore the batch size for this target group is limited. The conditions at Ancel’s production line are used to describe the operational baseline scenario. Next, we generated a common framework that generalizes operational and financial conditions for each alternative solution, thereby highlighting the technical factors that influence manufacturing cost and plant’s characteristics. By definition, the PBCM involves three interrelated and interdependent models: a technical process model, a production operations model, and a financial accounting model which all map in detail the product’s and process’ characteristics.

The very same baseline scenario regarding its environmental footprint is evaluated via the Eco-Audit, a plug-in tool of CES Selector© (Granta Design, Cambridge, UK) [

46]. Eco-Audit incorporates an extensive materials’ database where materials records are listed along with their mechanical/environmental performance and production characteristics. From a designer’s point of view, the development of more environmentally-friendly products enforces the consideration of environmental aspects in concurrence with traditional technical and economic aspects from the onset of design activities [

47]. On a second level, it assists in making materials and process choices that would minimize the energy spent to sequester the CO

2 as much as possible.