Towards Sustainable Machining of Inconel 718 Using Nano-Fluid Minimum Quantity Lubrication

Abstract

:1. Introduction

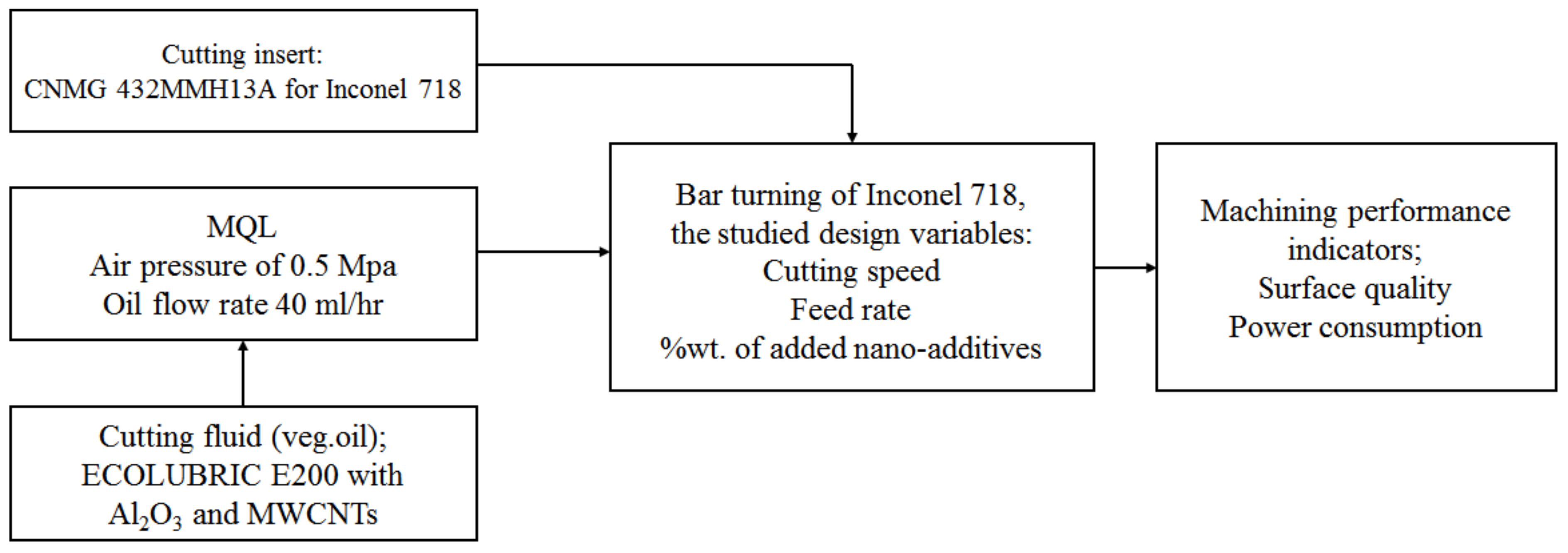

2. Experimentation and Methodology

3. Results and Discussions

4. Conclusions

- Both nanofluids offer better results for surface quality, and energy consumption; however, MWCNTs presents better performance than Al2O3 nano-fluid. The analysis of the measured surface roughness, and energy consumption results showed that the nano-additives weight percentage has a significant effect on all previous characteristics, either using MWCNTs or Al2O3.

- The nano-fluids improvements were mainly due to the superior tribological and heat transfer characteristics of the added nano-additives, which improve the interface bonding between the cutting tool and workpiece surfaces. In addition, the nano-fluids offer a better heat dissipation performance, which retains the cutting tool original hardness and accordingly reduces the severe rubbing of the workpiece with the flank face.

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Jafarian, F.; Umbrello, D.; Golpayegani, S.; Darake, Z. Experimental investigation to optimize tool life and surface roughness in Inconel 718 machining. Mater. Manuf. Process. 2016, 31, 1683–1691. [Google Scholar] [CrossRef]

- Akhtar, W.; Sun, J.; Chen, W. Effect of machining parameters on surface integrity in high speed milling of super alloy GH4169/Inconel 718. Mater. Manuf. Process. 2016, 31, 620–627. [Google Scholar] [CrossRef]

- Miller, S. Advanced materials mean advanced engines. Interdiscip. Sci. Rev. 1995, 20, 117–129. [Google Scholar] [CrossRef]

- Davim, J.P. Machining of Hard Materials; Springer Science & Business Media: Berlin, Germany, 2011. [Google Scholar]

- Amrita, M.; Srikant, R.; Sitaramaraju, A. Performance evaluation of nanographite-based cutting fluid in machining process. Mater. Manuf. Process. 2014, 29, 600–605. [Google Scholar] [CrossRef]

- Khandekar, S.; Sankar, M.R.; Agnihotri, V.; Ramkumar, J. Nano-cutting fluid for enhancement of metal cutting performance. Mater. Manuf. Process. 2012, 27, 963–967. [Google Scholar] [CrossRef]

- Li, B.; Li, C.; Zhang, Y.; Wang, Y.; Jia, D.; Yang, M.; Zhang, N.; Wu, Q.; Han, Z.; Sun, K. Heat transfer performance of MQL grinding with different nanofluids for Ni-based alloys using vegetable oil. J. Clean. Prod. 2017, 154, 1–11. [Google Scholar] [CrossRef]

- Davim, J.P.; Sreejith, P.; Silva, J. Turning of brasses using minimum quantity of lubricant (MQL) and flooded lubricant conditions. Mater. Manuf. Process. 2007, 22, 45–50. [Google Scholar] [CrossRef]

- Emami, M.; Sadeghi, M.; Sarhan, A.A. Investigating the effects of liquid atomization and delivery parameters of minimum quantity lubrication on the grinding process of Al2O3 engineering ceramics. J. Manuf. Process. 2013, 15, 374–388. [Google Scholar] [CrossRef]

- Kalita, P.; Malshe, A.P.; Kumar, S.A.; Yoganath, V.; Gurumurthy, T. Study of specific energy and friction coefficient in minimum quantity lubrication grinding using oil-based nanolubricants. J. Manuf. Process. 2012, 14, 160–166. [Google Scholar] [CrossRef]

- Nanomaterials, U.R. The Advanced Nanomaterials Provider. US Research Nanomaterials; US Research Nanomaterials, Inc.: Houston, TX, USA, 2009. [Google Scholar]

- Adams, M. ACCURATUS, Materials; ACCURATUS: Eagan, MN, USA, 2013. [Google Scholar]

- Nam, J.S.; Lee, P.H.; Lee, S.W. Experimental characterization of micro-drilling process using nanofluid minimum quantity lubrication. Int. J. Mach. Tools Manuf. 2011, 51, 649–652. [Google Scholar] [CrossRef]

- Lee, P.H.; Nam, J.S.; Li, C.; Lee, S.W. An experimental study on micro-grinding process with nanofluid minimum quantity lubrication (MQL). Int. J. Precis. Eng. Manuf. 2012, 13, 331–338. [Google Scholar] [CrossRef]

- Kim, J.S.; Kim, J.W.; Lee, S.W. Experimental characterization on micro-end milling of titanium alloy using nanofluid minimum quantity lubrication with chilly gas. Int. J. Adv. Manuf. Technol. 2017, 91, 2741–2749. [Google Scholar] [CrossRef]

- Hegab, H.; Kishawy, H.A.; Gadallah, M.H.; Umer, U.; Deiab, I. On machining of Ti-6Al-4V using multi-walled carbon nanotubes-based nano-fluid under minimum quantity lubrication. Int. J. Adv. Manuf. Technol. 2018, 97, 1593–1603. [Google Scholar] [CrossRef]

- Hegab, H.; Umer, U.; Deiab, I.; Kishawy, H. Performance evaluation of Ti–6Al–4V machining using nano-cutting fluids under minimum quantity lubrication. Int. J. Adv. Manuf. Technol. 2018, 95, 4229–4241. [Google Scholar] [CrossRef]

- Hegab, H.; Umer, U.; Soliman, M.; Kishawy, H.A. Effects of nano-cutting fluids on tool performance and chip morphology during machining Inconel 718. Int. J. Adv. Manuf. Technol. 2018, 96, 3449–3458. [Google Scholar] [CrossRef]

- Raju, R.A.; Andhare, A.; Sahu, N.K. Performance of multi-walled carbon nanotube-based nanofluid in turning operation. Mater. Manuf. Process. 2017, 32, 1490–1496. [Google Scholar] [CrossRef]

- El-Bestawi, M.A.; El-Wardany, T.I.; Yan, D.; Tan, M. Performance of whisker-reinforced ceramic tools in milling nickel-based superalloy. CIRP Ann. Manuf. Technol. 1993, 42, 99–102. [Google Scholar] [CrossRef]

- Bhatt, A.; Attia, H.; Vargas, R.; Thomson, V. Wear mechanisms of WC coated and uncoated tools in finish turning of Inconel 718. Tribol. Int. 2010, 43, 1113–1121. [Google Scholar] [CrossRef]

- Prabhu, S.; Uma, M.; Vinayagam, B. Surface roughness prediction using Taguchi-fuzzy logic-neural network analysis for CNT nanofluids based grinding process. Neural Comput. Appl. 2015, 26, 41–55. [Google Scholar] [CrossRef]

- Krajnik, P.; Pusavec, F.; Rashid, A. Nanofluids: Properties, applications and sustainability aspects in materials processing technologies. In Advances in Sustainable Manufacturing; Springer: Berlin/Heidelberg, Germany, 2011; pp. 107–113. [Google Scholar]

- Byrne, D.M. The Taguchi approach to parameter design. Qual. Prog. 1987, 20, 19–26. [Google Scholar]

- Rabiei, F.; Rahimi, A.; Hadad, M. Performance improvement of eco-friendly MQL technique by using hybrid nanofluid and ultrasonic-assisted grinding. Int. J. Adv. Manuf. Technol. 2017, 93, 1001–1015. [Google Scholar] [CrossRef]

- Krishna, P.V.; Srikant, R.; Rao, D.N. Experimental investigation on the performance of nanoboric acid suspensions in SAE-40 and coconut oil during turning of AISI 1040 steel. Int. J. Mach. Tools Manuf. 2010, 50, 911–916. [Google Scholar] [CrossRef]

- Prasad, M.; Srikant, R. Performance evaluation of nano graphite inclusions in cutting fluids with MQL technique in turning of AISI 1040 steel. Int. J. Res. Eng. Technol. 2013, 2, 381–393. [Google Scholar]

- Sayuti, M.; Sarhan, A.A.; Hamdi, M. An investigation of optimum SiO2 nanolubrication parameters in end milling of aerospace Al6061-T6 alloy. Int. J. Adv. Manuf. Technol. 2013, 67, 833–849. [Google Scholar] [CrossRef]

- Rahmati, B.; Sarhan, A.A.; Sayuti, M. Investigating the optimum molybdenum disulfide (MoS2) nanolubrication parameters in CNC milling of AL6061-T6 alloy. Int. J. Adv. Manuf. Technol. 2014, 70, 1143–1155. [Google Scholar] [CrossRef]

- Sharma, P.; Sidhu, B.S.; Sharma, J. Investigation of effects of nanofluids on turning of AISI D2 steel using minimum quantity lubrication. J. Clean. Prod. 2015, 108, 72–79. [Google Scholar] [CrossRef]

- Revuru, R.S.; Pasam, V.K.; Syed, I.; Paliwal, U.K. Development of finite element based model for performance evaluation of nano cutting fluids in minimum quantity lubrication. CIRP J. Manuf. Sci. Technol. 2018, 21, 75–85. [Google Scholar] [CrossRef]

- Eltaggaz, A.; Hegab, H.; Deiab, I.; Kishawy, H.A. Hybrid nano-fluid-minimum quantity lubrication strategy for machining austempered ductile iron (ADI). Int. J. Interact. Des. Manuf. 2018, 1–9. [Google Scholar] [CrossRef]

- Eltaggaz, A.; Zawada, P.; Hegab, H.A.; Deiab, I.; Kishawy, H.A. Coolant strategy influence on tool life and surface roughness when machining ADI. Int. J. Adv. Manuf. Technol. 2018, 94, 3875–3887. [Google Scholar] [CrossRef]

- Loos, M. Carbon Nanotube Reinforced Composites: CNT Polymer Science and Technology; Elsevier: New York, NY, USA, 2014. [Google Scholar]

| Inconel 718 Cutting Processes | |

|---|---|

| Cutting insert | CNMG 432MMH13A (ANSI) |

| Tool holder | KENNAMETAL MCLNL-164DNC5, clearance angle 0° and rake angle −5°, nose radius of 0.793 mm (Honed edge) |

| Cutting Test No. | Cutting Speed (m/min) | Feed Rate (mm/rev) | Added Nano-Additives (wt.%) |

|---|---|---|---|

| 1 | 30 | 0.2 | 0 |

| 2 | 30 | 0.3 | 2 |

| 3 | 30 | 0.4 | 4 |

| 4 | 40 | 0.2 | 2 |

| 5 | 40 | 0.3 | 4 |

| 6 | 40 | 0.4 | 0 |

| 7 | 50 | 0.2 | 4 |

| 8 | 50 | 0.3 | 0 |

| 9 | 50 | 0.4 | 2 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hegab, H.; Kishawy, H.A. Towards Sustainable Machining of Inconel 718 Using Nano-Fluid Minimum Quantity Lubrication. J. Manuf. Mater. Process. 2018, 2, 50. https://doi.org/10.3390/jmmp2030050

Hegab H, Kishawy HA. Towards Sustainable Machining of Inconel 718 Using Nano-Fluid Minimum Quantity Lubrication. Journal of Manufacturing and Materials Processing. 2018; 2(3):50. https://doi.org/10.3390/jmmp2030050

Chicago/Turabian StyleHegab, Hussien, and Hossam A. Kishawy. 2018. "Towards Sustainable Machining of Inconel 718 Using Nano-Fluid Minimum Quantity Lubrication" Journal of Manufacturing and Materials Processing 2, no. 3: 50. https://doi.org/10.3390/jmmp2030050