Molecular Dynamics Simulation Study of Liquid-Assisted Laser Beam Micromachining Process

Abstract

:1. Introduction

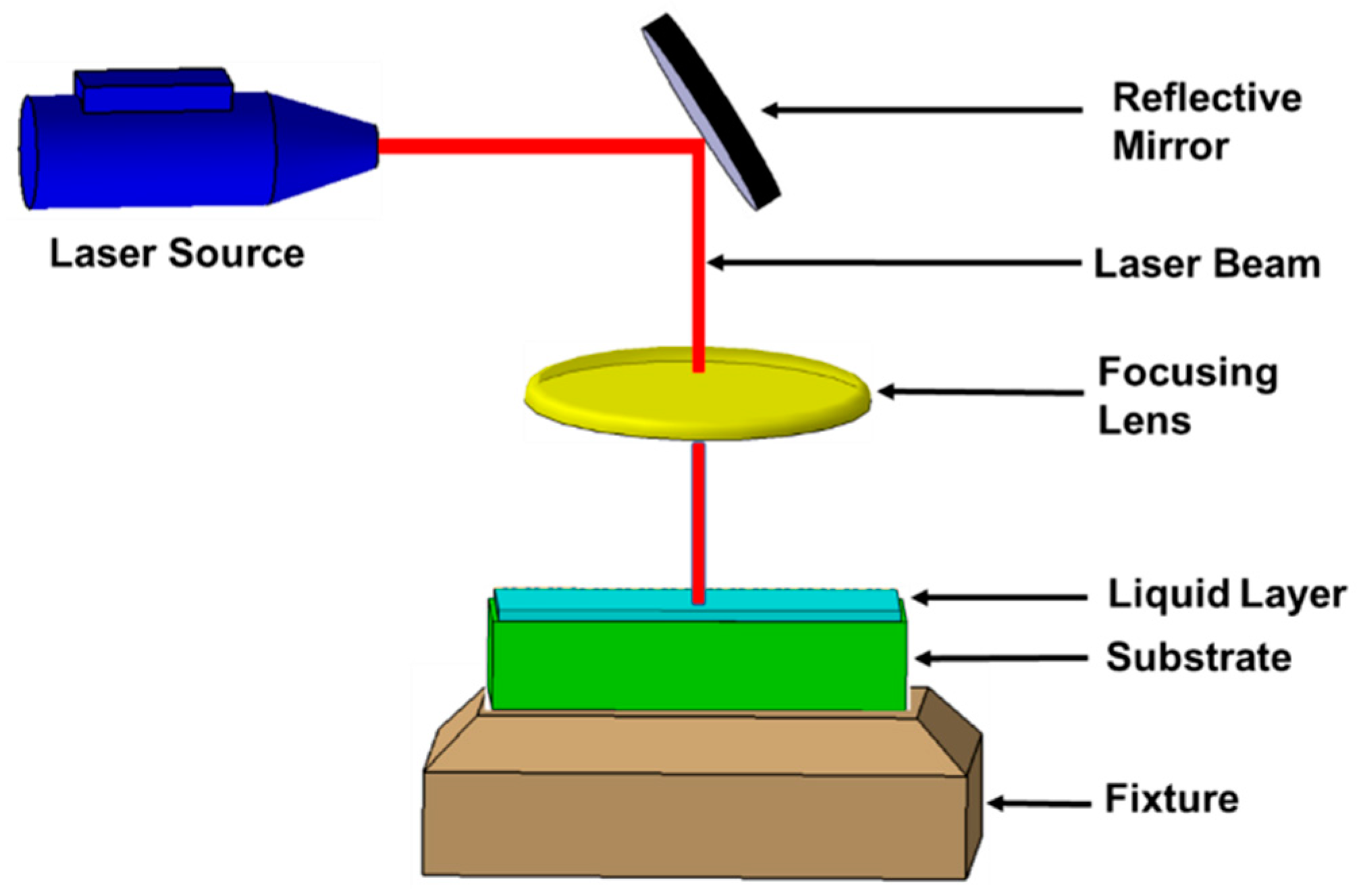

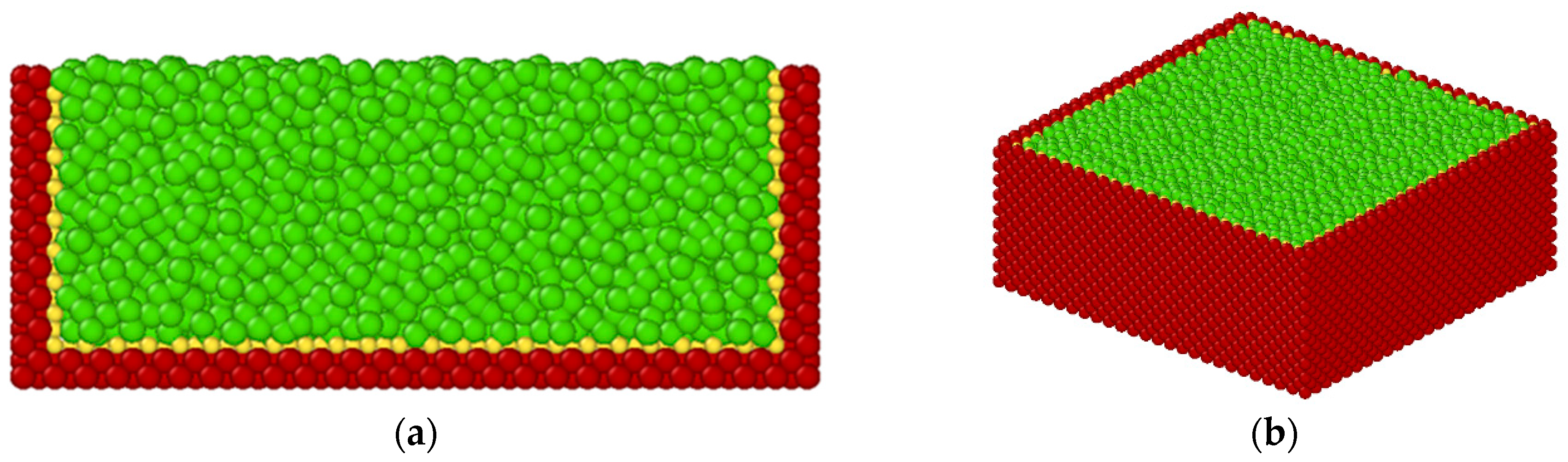

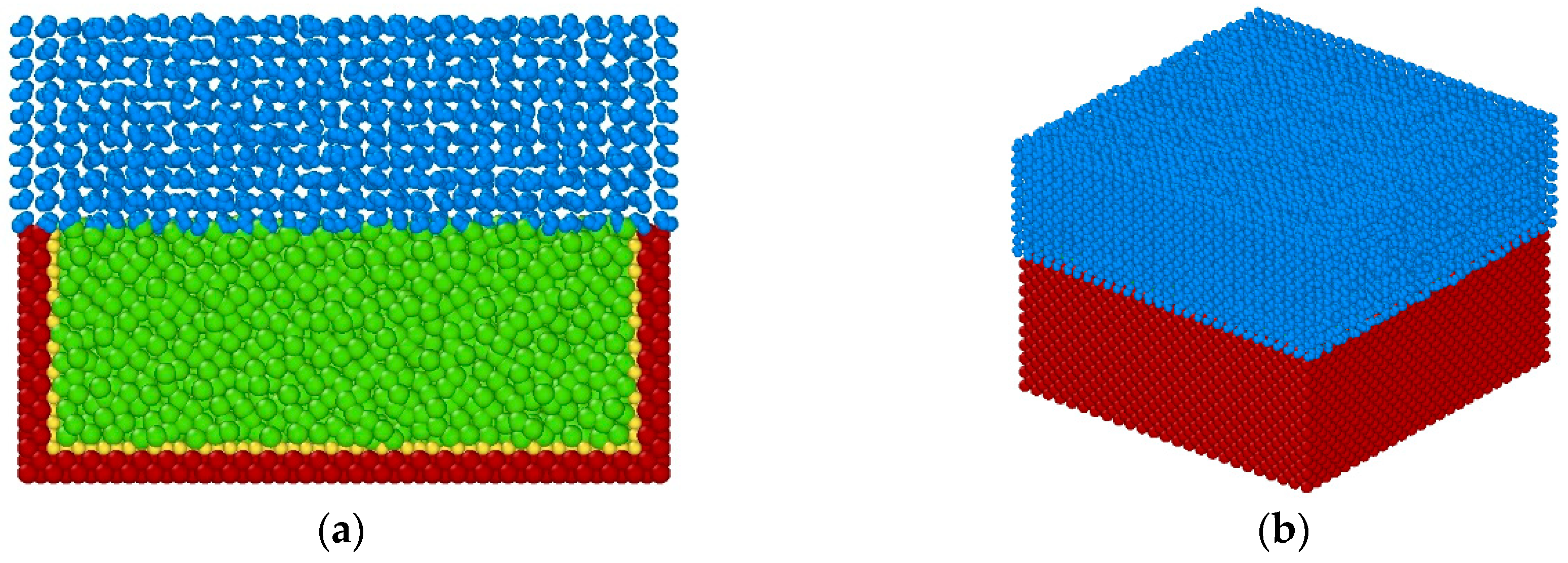

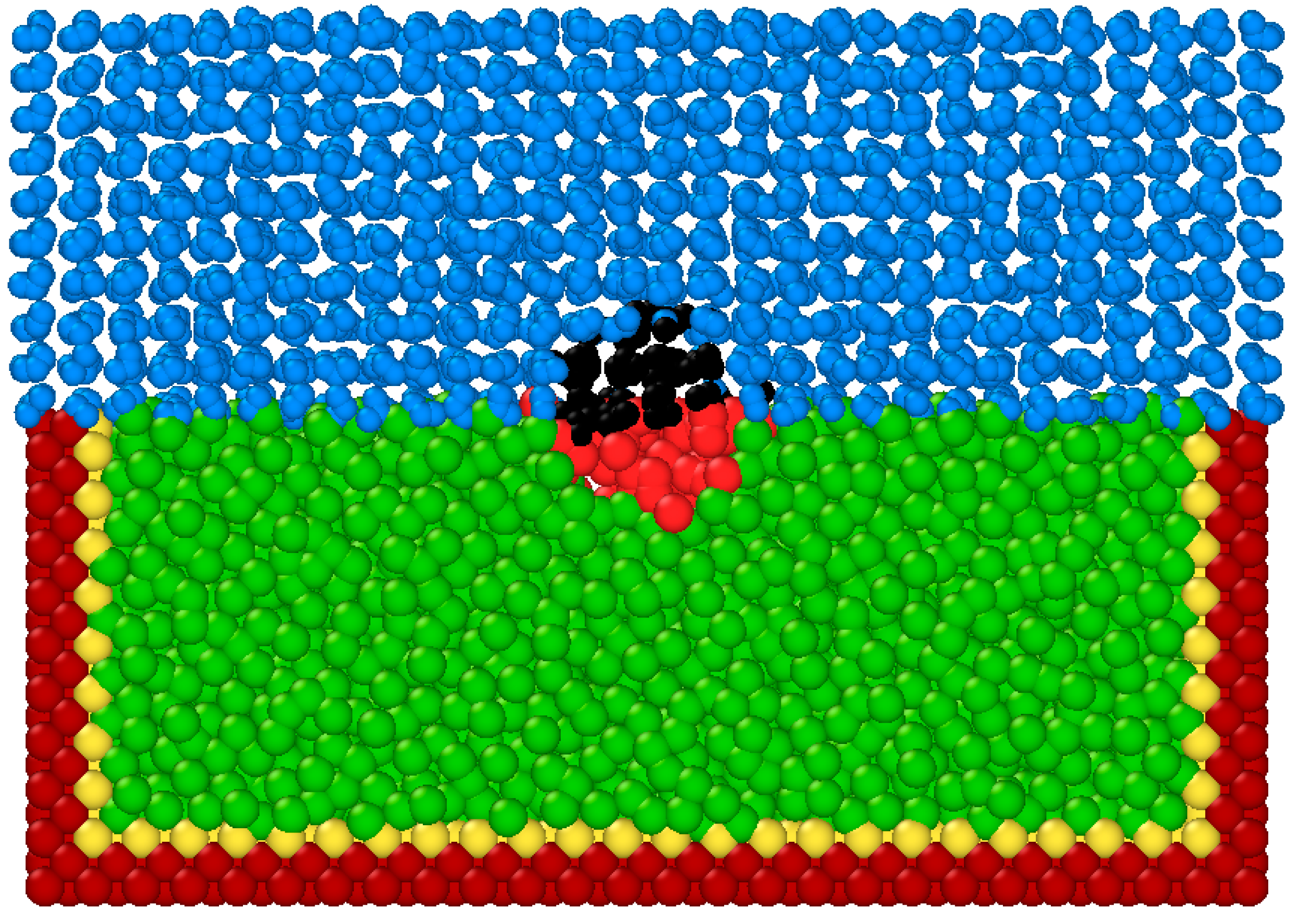

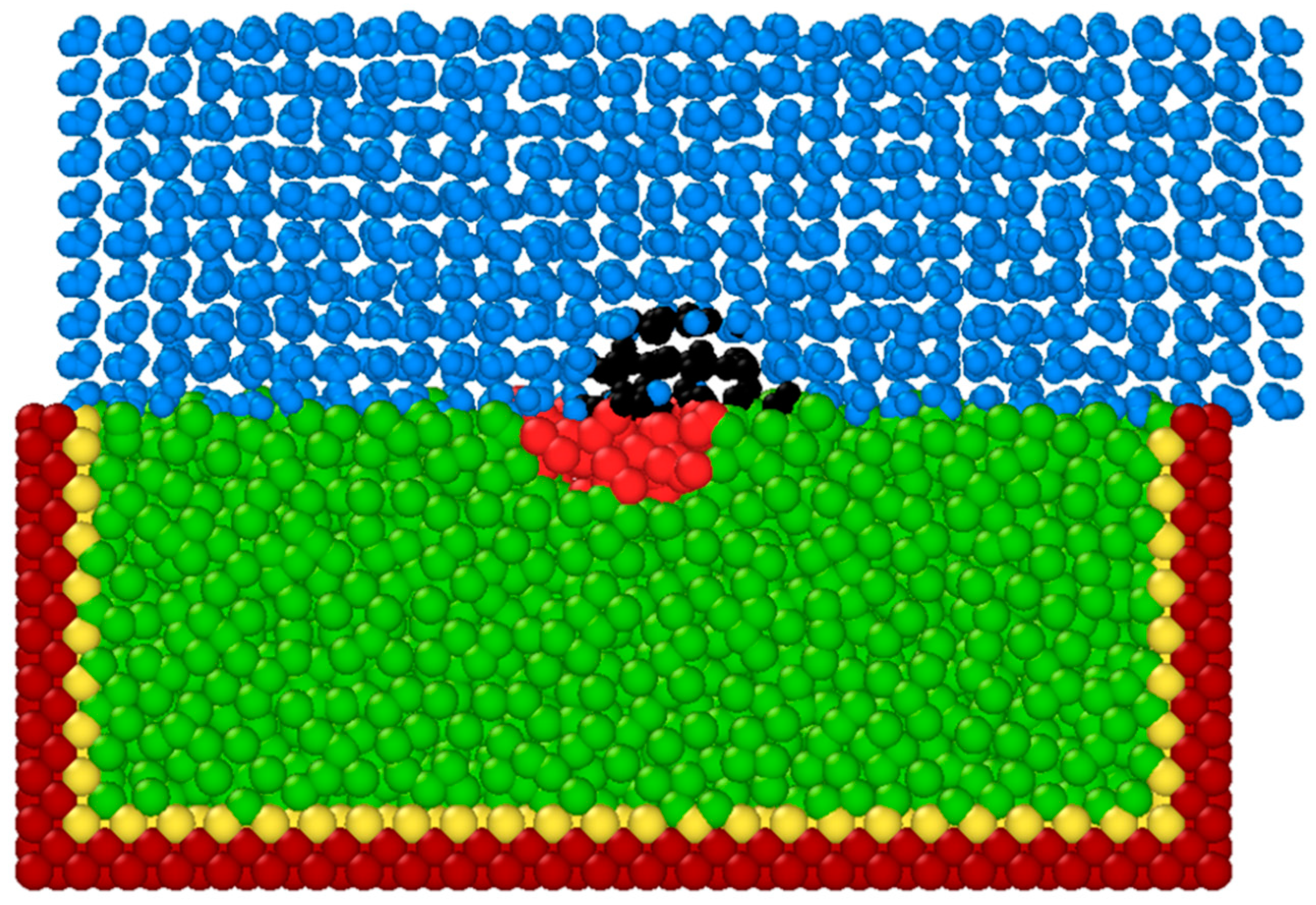

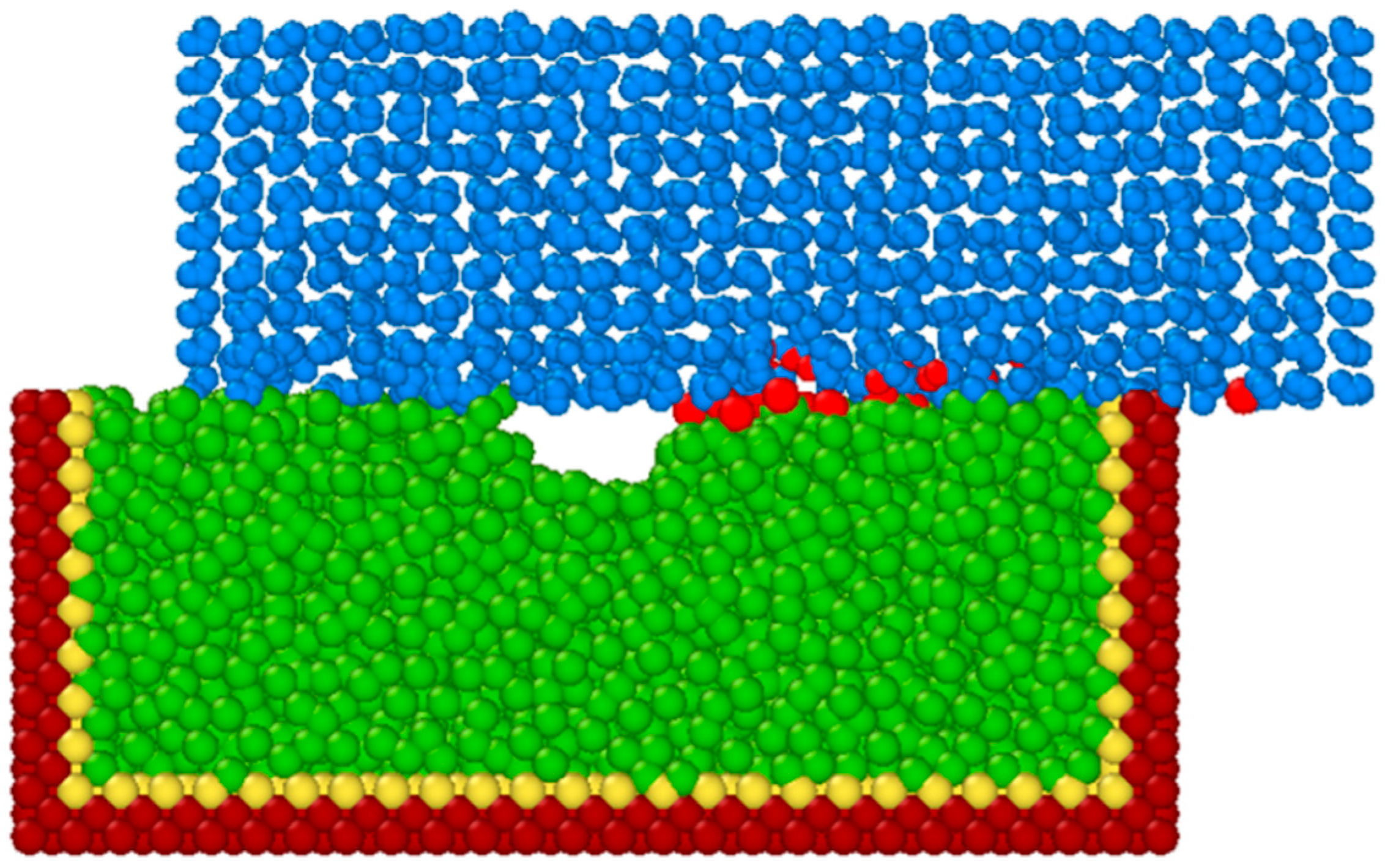

2. Molecular Dynamics Simulation

3. Results and Discussion

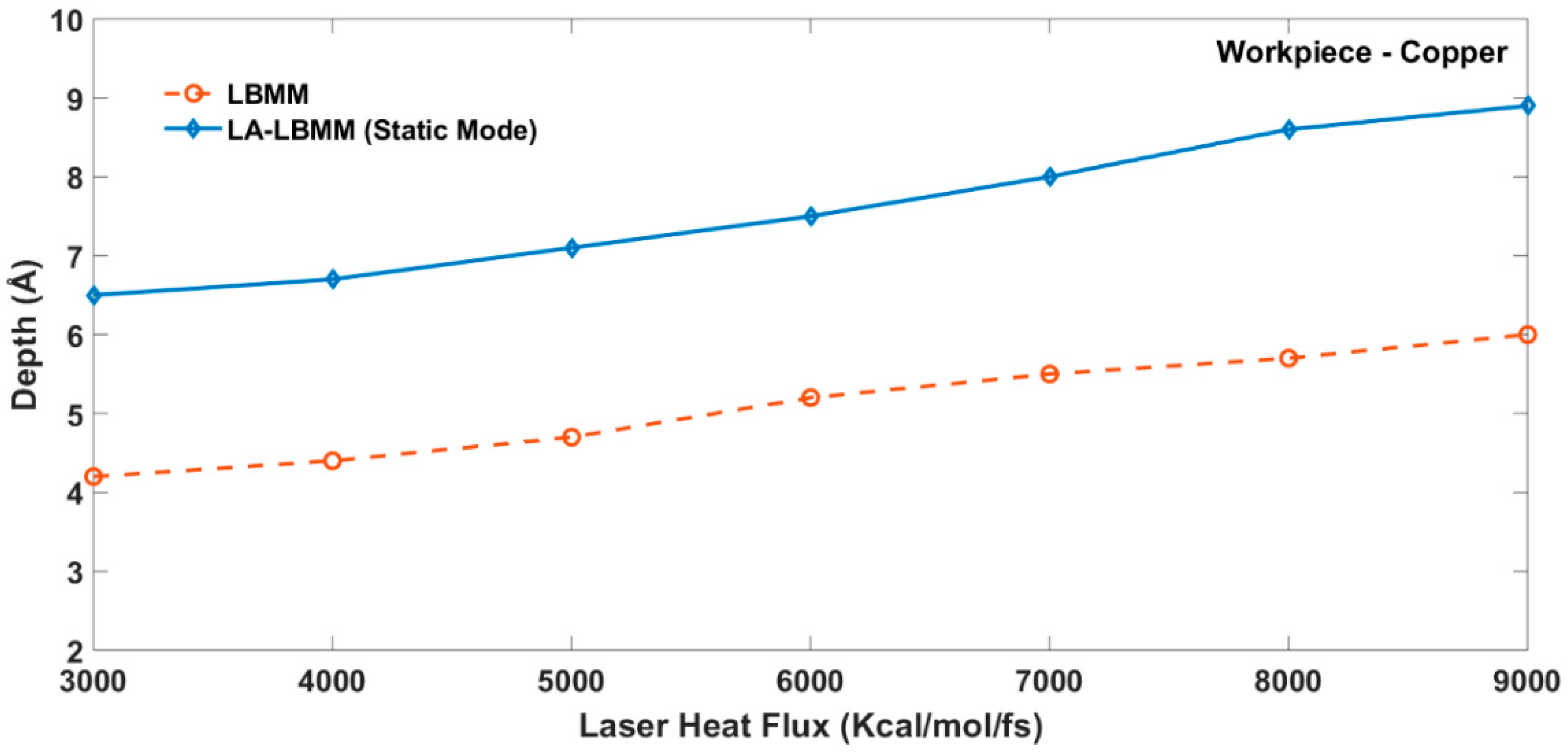

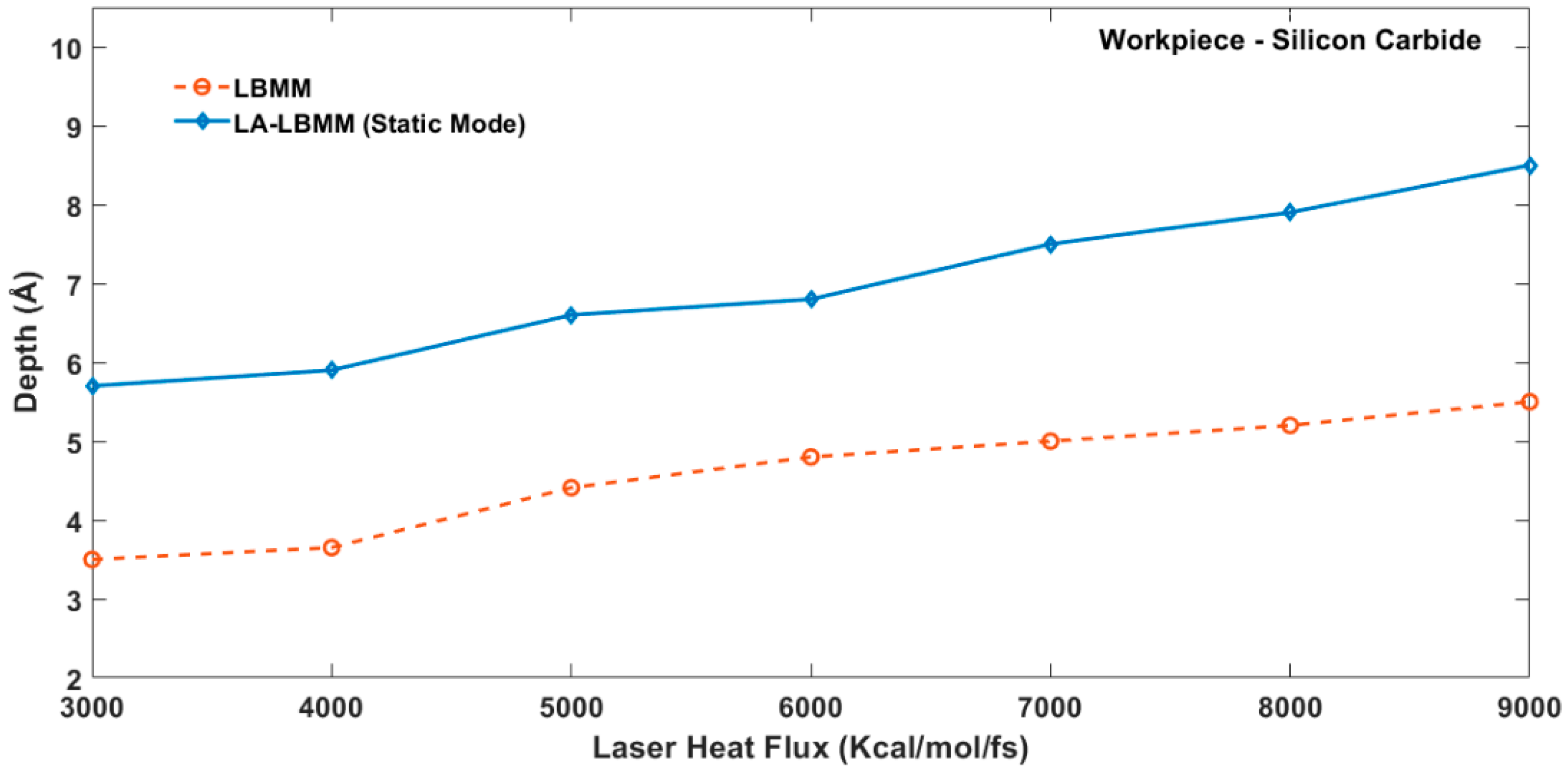

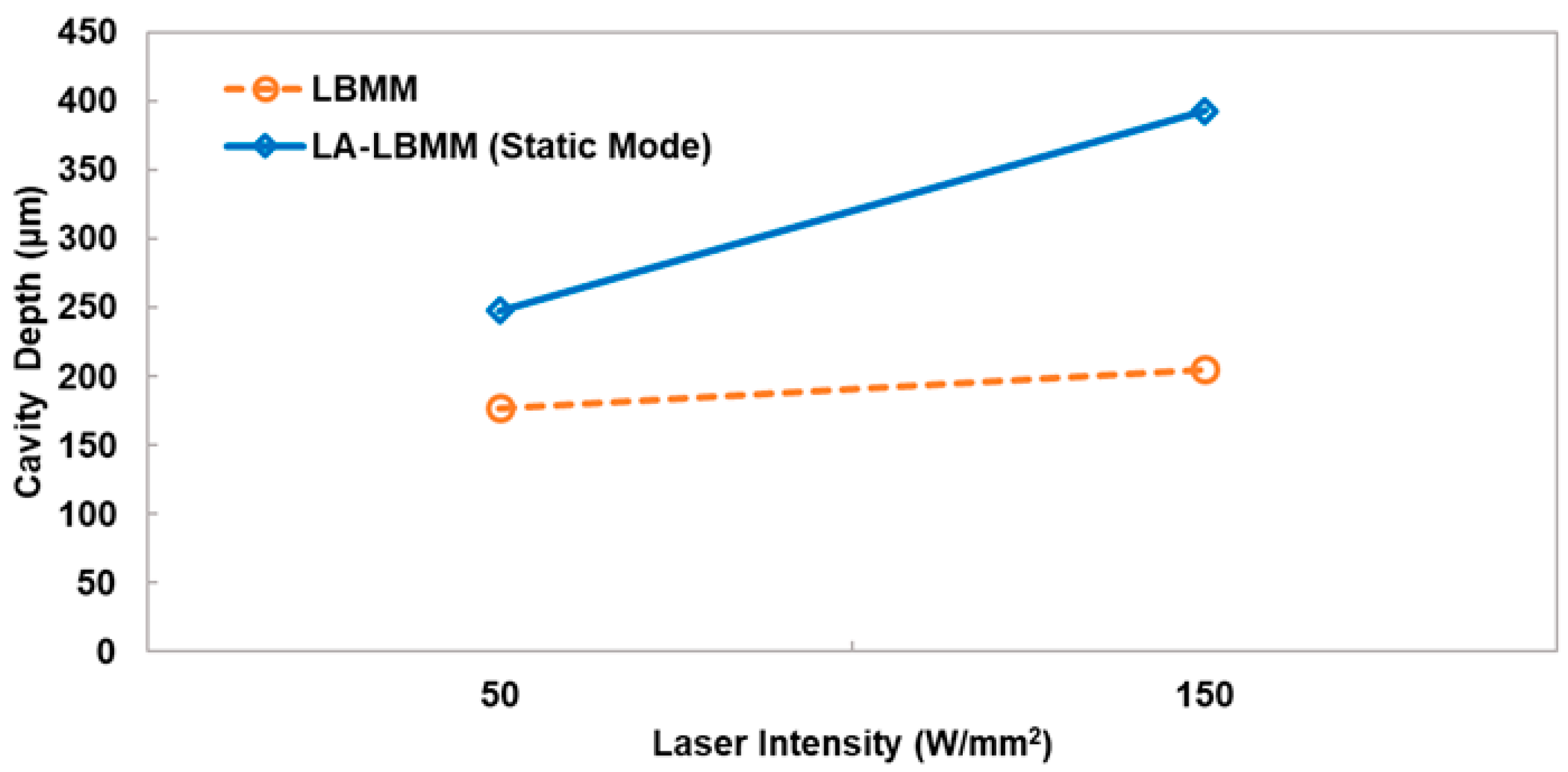

3.1. Effect of Laser Power on Cavity Size during LBMM and LA-LBMM Process

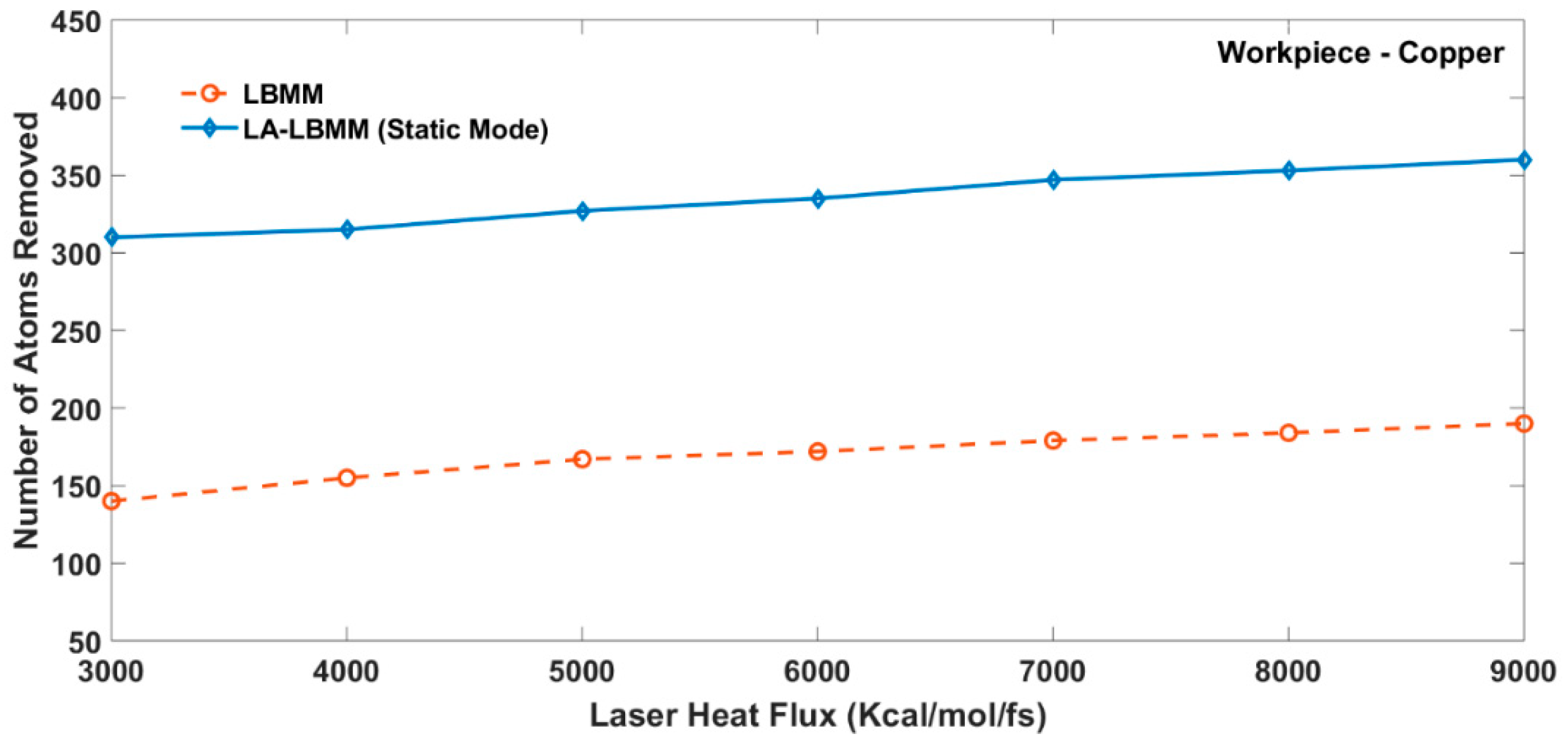

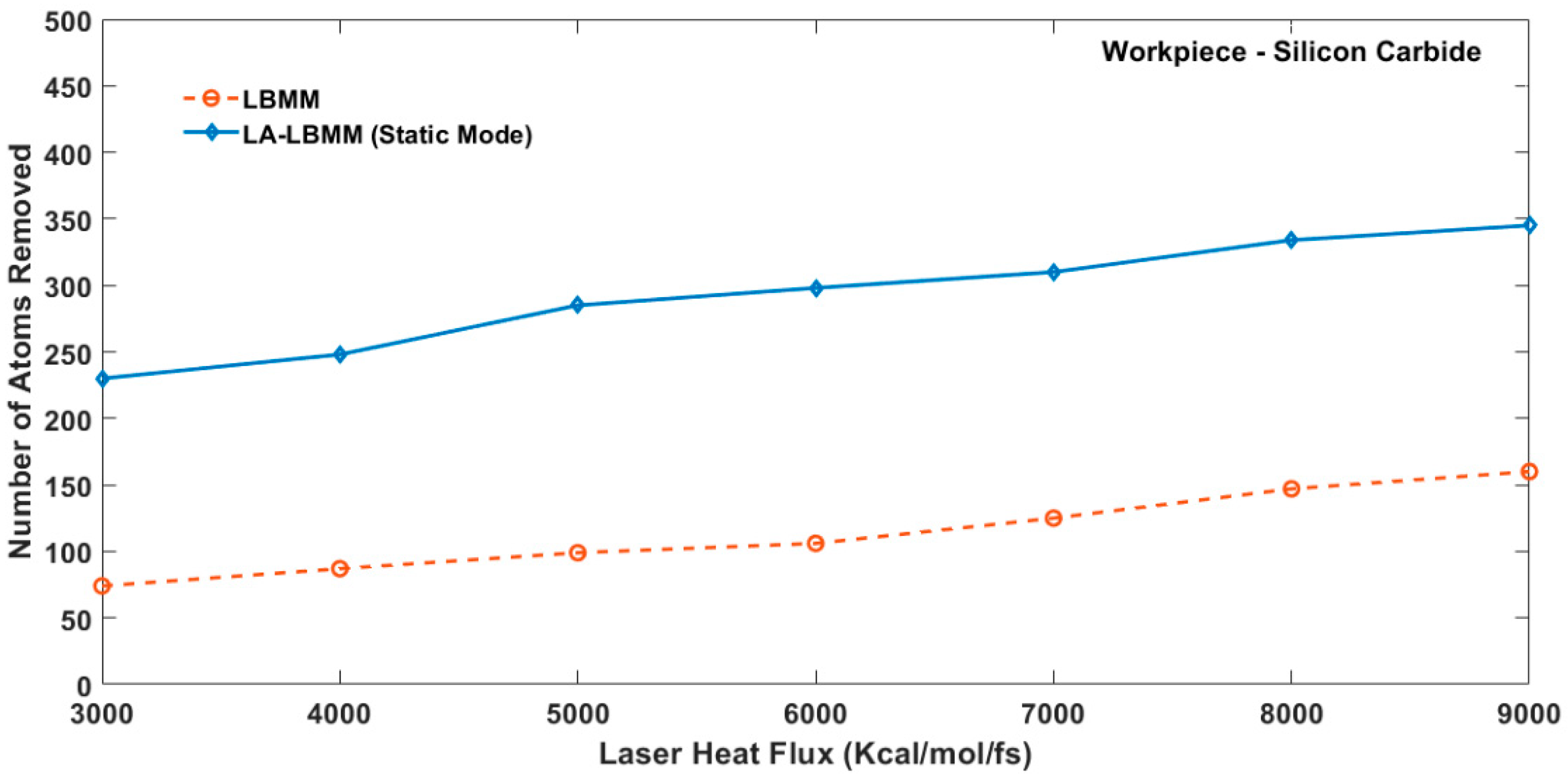

3.2. Effect of Heat Flux on Number of Atoms Removed during the LBMM and LA-LBMM Process

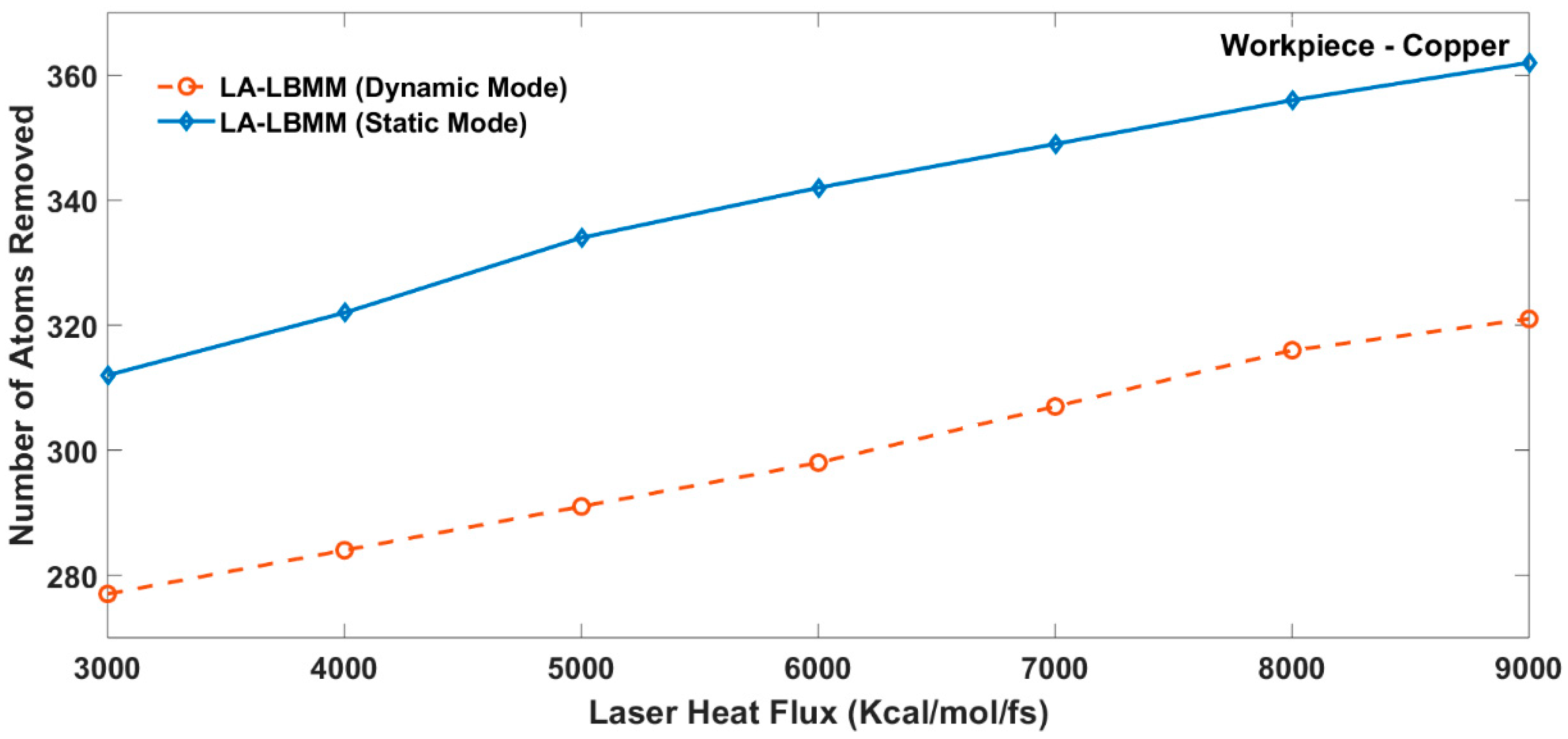

3.3. Comparison between the LA-LBMM Process Static and Dynamic Mode

3.4. Process Mechanisms Involved in LA-LBMM Process

3.4.1. Effect of Thermal Blanket

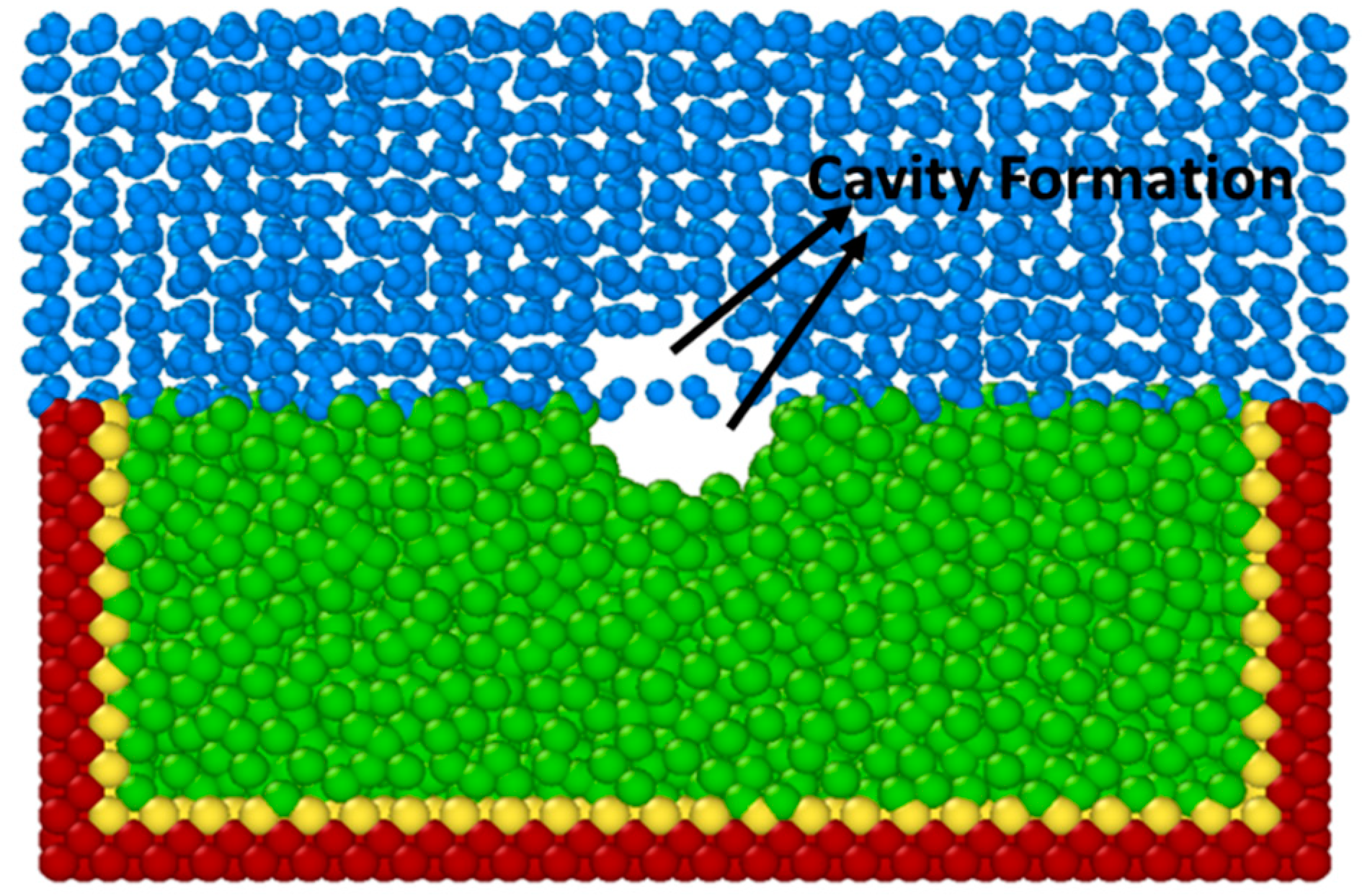

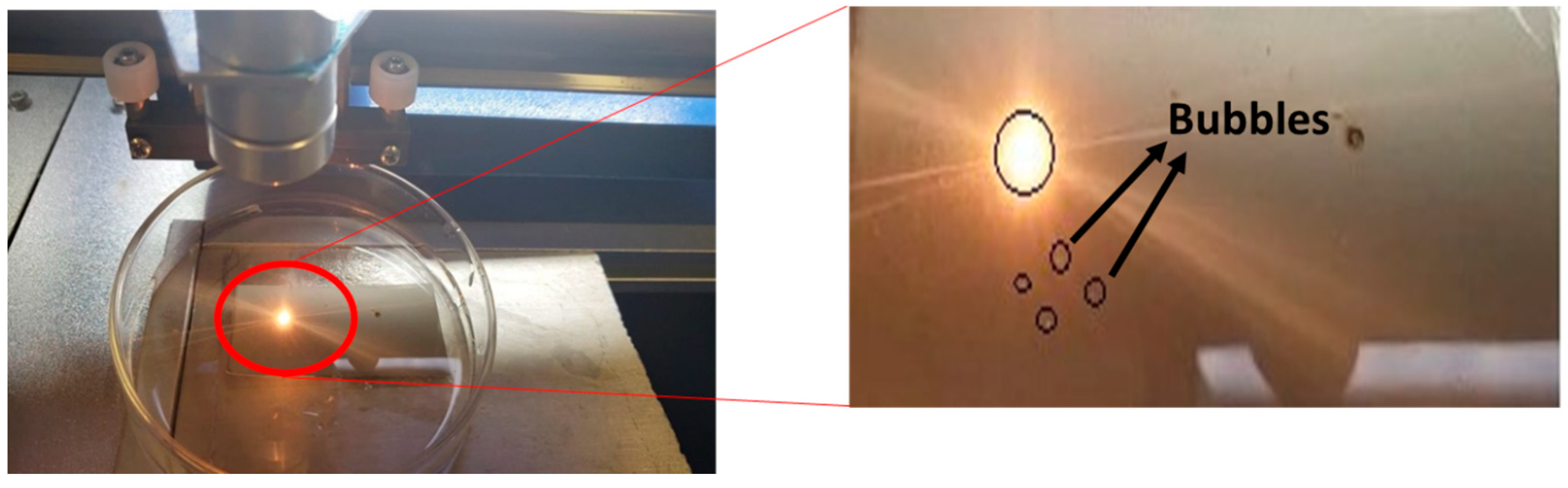

3.4.2. Effect of Cavity and Bubble Formation

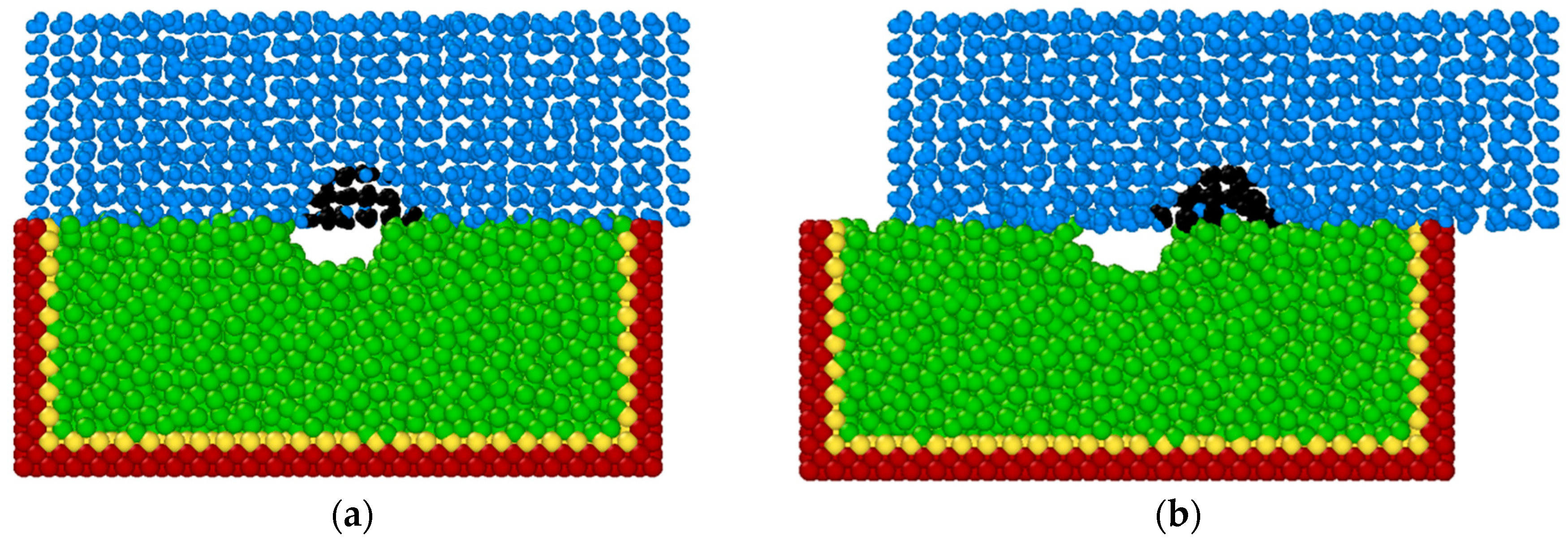

3.4.3. Effect of Flowing Water Removing Debris

3.5. Validation of MD Simulation Results with Experimentation

4. Conclusions

- The MD simulation study revealed that the cavity machined during the LA-LBMM process is having more depth than that of LBMM process. It is attributed to the fact that the thermal energy is entrapped in the machining zone. The velocity of the vaporized atoms is lower during the LA-LBMM process due to the presence of a layer of water molecules above the substrate;

- The number of atoms removed during LA-LBMM process is found to be significantly higher than that during LBMM process. The LA-LBMM process in dynamic mode showed lesser material removal compared with that of static mode;

- A comparison between the LA-LBMM processes in static and dynamic modes showed the material removal in higher in the case of static mode compared with dynamic mode. However, the surface finish obtained in dynamic mode is better than static mode because of the removal of machining debris;

- The MD simulation study revealed various mechanisms involved in the LA-LBMM process including the formation of a thermal blanket and the formation of cavities and bubbles in the vicinity of the machined region. The LA-LBMM process in dynamic mode suggested the removal of debris from the machining region, leading to reduced re-deposition of molten material on the cavity surface;

- The results of the MD simulation study are consistent with findings of experimental results of both the LBMM and LA-LBMM processes.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Mishra, S.; Yadava, V. Laser beam micromachining (lbmm)—A review. Opt. Lasers Eng. 2015, 73, 89–122. [Google Scholar] [CrossRef]

- Athanasiou, C.-E.; Bellouard, Y.A. Monolithic micro-tensile tester for investigating silicon dioxide polymorph micromechanics, fabricated and operated using a femtosecond laser. Micromachines 2015, 6, 1365–1386. [Google Scholar] [CrossRef]

- Suriano, R.; Kuznetsov, A.; Eaton, S.M.; Kiyan, R.; Cerullo, G.; Osellame, R.; Chichkov, B.N.; Levi, M.; Turri, S. Femtosecond laser ablation of polymeric substrates for the fabrication of microfluidic channels. Appl. Surf. Sci. 2011, 257, 6243–6250. [Google Scholar] [CrossRef]

- Dubey, A.K.; Yadava, V. Laser beam machining—A review. Int. J. Mach. Tools Manuf. 2008, 48, 609–628. [Google Scholar] [CrossRef]

- Feng, Q.; Picard, Y.; Liu, H.; Yalisove, S.; Mourou, G.; Pollock, T. Femtosecond laser micromachining of a single-crystal superalloy. Scr. Mater. 2005, 53, 511–516. [Google Scholar] [CrossRef]

- Chung, C.K.; Lin, S.L. CO2 laser micromachined crackless through holes of pyrex 7740 glass. Int. J. Mach. Tools Manuf. 2010, 50, 961–968. [Google Scholar] [CrossRef]

- Ghidelli, M.; Gravier, S.; Blandin, J.-J.; Pardoen, T.; Raskin, J.-P.; Mompiou, F. Compositional-induced structural change in ZrxNi100−x thin film metallic glasses. J. Alloys Compd. 2014, 615, S348–S351. [Google Scholar] [CrossRef]

- Peng, C.; Cheng, L.; Mansuripur, M. Experimental and theoretical investigations of laser-induced crystallization and amorphization in phase-change optical recording media. J. Appl. Phys. 1997, 82, 4183–4191. [Google Scholar] [CrossRef]

- Garcia-Giron, A.; Sola, D.; Peña, J. Liquid-assisted laser ablation of advanced ceramics and glass-ceramic materials. Appl. Surf. Sci. 2016, 363, 548–554. [Google Scholar] [CrossRef] [Green Version]

- Mistry, V.; James, S. Finite element analysis and simulation of liquid-assisted laser beam machining process. Int. J. Adv. Manuf. Technol. 2017, 94, 2325–2331. [Google Scholar] [CrossRef]

- Parmar, M.; James, S. Experimental and modeling study of liquid-assisted—Laser beam micromachining of smart ceramic materials. J. Manuf. Mater. Process. 2018, 2, 28. [Google Scholar] [CrossRef]

- Tangwarodomnukun, V.; Likhitangsuwat, P.; Tevinpibanphan, O.; Dumkum, C. Laser ablation of titanium alloy under a thin and flowing water layer. Int. J. Mach. Tools Manuf. 2015, 89, 14–28. [Google Scholar] [CrossRef]

- Alahmari, A.M.; Ahmed, N.; Darwish, S. Laser beam micro-machining under water immersion. Int. J. Adv. Manuf. Technol. 2016, 83, 1671–1681. [Google Scholar] [CrossRef]

- Bharatish, A.; Narasimha Murthy, H.N.; Anand, B.; Madhusoodana, C.D.; Praveena, G.S.; Krishna, M. Characterization of hole circularity and heat affected zone in pulsed CO2 laser drilling of alumina ceramics. Opt. Laser Technol. 2013, 53, 22–32. [Google Scholar] [CrossRef]

- Teixidor, D.; Ferrer, I.; Ciurana, J.; Özel, T. Optimization of process parameters for pulsed laser milling of micro-channels on aisi h13 tool steel. Robot. Comput. Integr. Manuf. 2013, 29, 209–218. [Google Scholar] [CrossRef]

- Ali, N.; Bashir, S.; Akram, M.; Mahmood, K. Effect of dry and wet ambient environment on the pulsed laser ablation of titanium. Appl. Surf. Sci. 2013, 270, 49–57. [Google Scholar] [CrossRef]

- Bashir, S.; Rafique, M.S.; Nathala, C.S.; Husinsky, W. Surface and structural modifications of titanium induced by various pulse energies of a femtosecond laser in liquid and dry environment. Appl. Phys. A 2014, 114, 243–251. [Google Scholar] [CrossRef]

- Gomez-Rosas, G.; Rubio-González, C.; Ocaña, J.; Molpeceres, C.; Porro, J.; Morales, M.; Casillas, F.; Mora-Gonzalez, M.; Peña-Lecona, F. Application of laser shock processing system by underwater irradiation (1064 nm) in metal surface. AIP Conf. Proc. 2008, 992, 1123–1128. [Google Scholar]

- Yan, Y.; Li, L.; Sezer, K.; Wang, W.; Whitehead, D.; Ji, L.; Bao, Y.; Jiang, Y. CO2 laser underwater machining of deep cavities in alumina. J. Eur. Ceram. Soc. 2011, 31, 2793–2807. [Google Scholar] [CrossRef]

- Tangwarodomnukun, V.; Wang, J.; Huang, C.; Zhu, H. Heating and material removal process in hybrid laser-waterjet ablation of silicon substrates. Int. J. Mach. Tools Manuf. 2014, 79, 1–16. [Google Scholar] [CrossRef]

- Nedialkov, N.; Imamova, S.; Atanasov, P.; Berger, P.; Dausinger, F. Mechanism of ultrashort laser ablation of metals: Molecular dynamics simulation. Appl. Surf. Sci. 2005, 247, 243–248. [Google Scholar] [CrossRef]

- Herrmann, R.F.; Gerlach, J.; Campbell, E.E. Molecular dynamics simulation of laser ablation of silicon. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 1997, 122, 401–404. [Google Scholar] [CrossRef]

- Meng, X.; Zhou, J.; Huang, S.; Su, C.; Sheng, J. Properties of a laser shock wave in al-cu alloy under elevated temperatures: A molecular dynamics simulation study. Materials 2017, 10, 73. [Google Scholar] [CrossRef] [PubMed]

- Shih, C.-Y.; Wu, C.; Shugaev, M.V.; Zhigilei, L.V. Atomistic modeling of nanoparticle generation in short pulse laser ablation of thin metal films in water. J. Colloid Interface Sci. 2017, 489, 3–17. [Google Scholar] [CrossRef] [PubMed]

- Zhou, W.; Gong, K.; Wan, J.; Quan, L.; Chu, Y.; Cao, Y. Molecular dynamics simulation study on ablation of silicon by water-jet-guided laser. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2016, 231, 1217–1225. [Google Scholar] [CrossRef]

- Plimpton, S. Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef]

- Foiles, S.; Baskes, M.; Daw, M. Embedded-atom-method functions for the fcc metals cu, Ag, Au, Ni, Pd, Pt, and their alloys. Phys. Rev. B 1986, 33, 7983. [Google Scholar] [CrossRef]

- Huang, Z.G.; Guo, Z.N.; Chen, X.; Yue, T.M.; To, S.; Lee, W.B. Molecular dynamics simulation for ultrafine machining. Mater. Manuf. Process. 2006, 21, 393–397. [Google Scholar] [CrossRef]

- Jones, J.E. In On the determination of molecular fields.—II. From the equation of state of a gas. Proc. R. Soc. Lond. A 1924, 106, 463–477. [Google Scholar] [CrossRef]

| Parameter | O-O | Cu-O | Si-O | C-O |

|---|---|---|---|---|

| Equilibrium distance (σ, Å) | 3.166 | 2.644 | 3.629 | 2.744 |

| Cohesive energy (ε, 10−3, eV) | 6.736 | 43 | 231.9 | 62.0 |

| Cut-off distance (Å) | 9.8 | 5 | 10.0 | 7.0 |

| Materials | Substrates |

|

| Water | H2O Block 30 Å Thick, 9000 Molecules | |

| Operating Conditions | Initial Temperature | 293 K |

| Laser Heat Flux | 3000 Kcal/mol/fs (Low)–9000 Kcal/mol/fs (High) | |

| Potential Used | EAM, Tersoff, Lennard-Jones (LJ) | |

| Duration of Simulation | 1 picosecond (ps) |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Menon, V.A.; James, S. Molecular Dynamics Simulation Study of Liquid-Assisted Laser Beam Micromachining Process. J. Manuf. Mater. Process. 2018, 2, 51. https://doi.org/10.3390/jmmp2030051

Menon VA, James S. Molecular Dynamics Simulation Study of Liquid-Assisted Laser Beam Micromachining Process. Journal of Manufacturing and Materials Processing. 2018; 2(3):51. https://doi.org/10.3390/jmmp2030051

Chicago/Turabian StyleMenon, Vivek Anand, and Sagil James. 2018. "Molecular Dynamics Simulation Study of Liquid-Assisted Laser Beam Micromachining Process" Journal of Manufacturing and Materials Processing 2, no. 3: 51. https://doi.org/10.3390/jmmp2030051