Understanding Acoustic Emission for Different Metal Cutting Machinery and Operations

Abstract

:1. Introduction

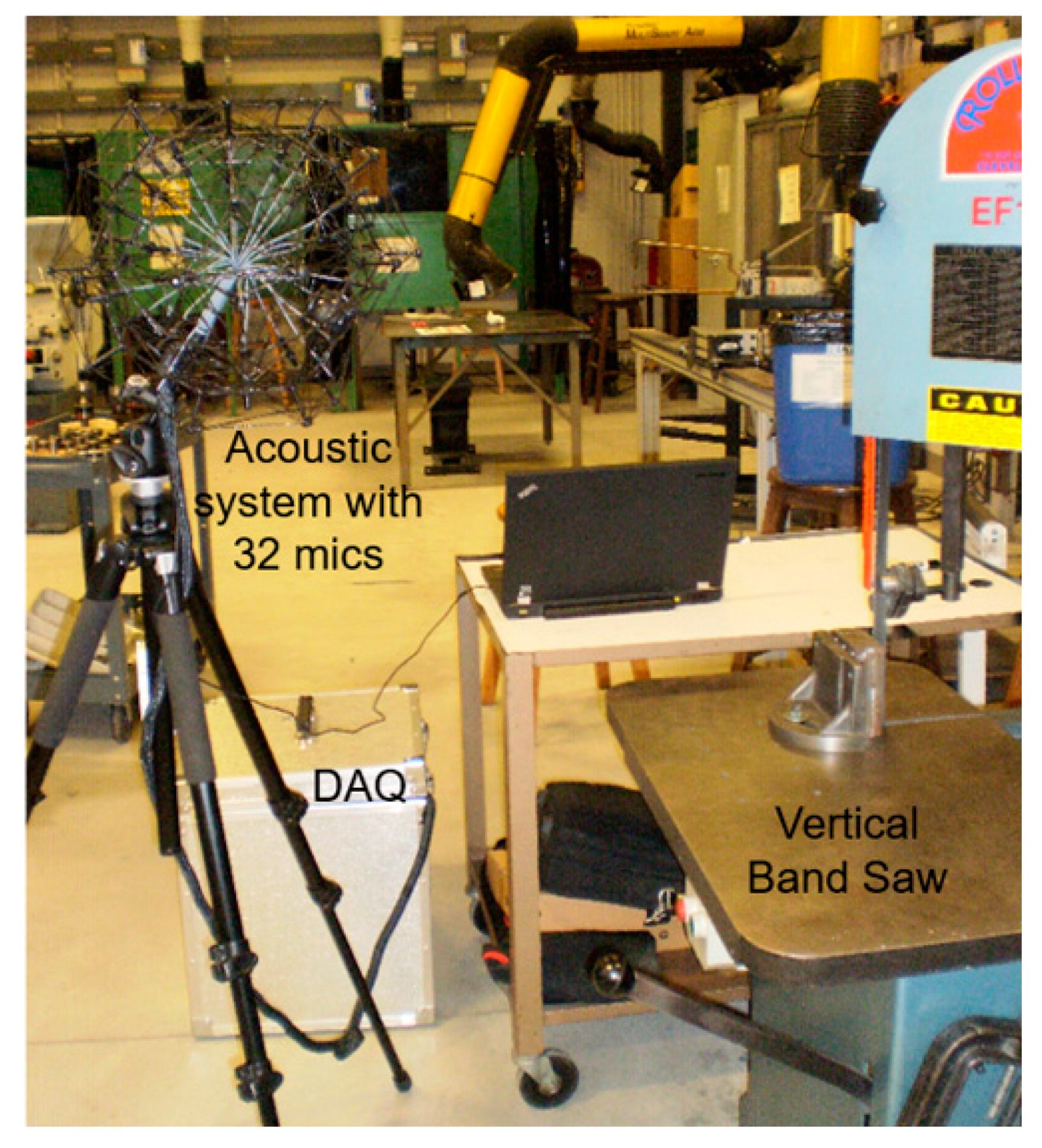

2. Beam Former

- AC Easy 32-element spherical microphone array with integrated USB camera;

- Computer and NoiseImage 4 software; and,

- National Instruments Data Acquisition Unit containing a chassis (NI PXI-1033) with two microphone cards (NI PXI 6240; 48 kHz, 16-bit resolution).

3. Experimental Procedure

4. Result and Discussion

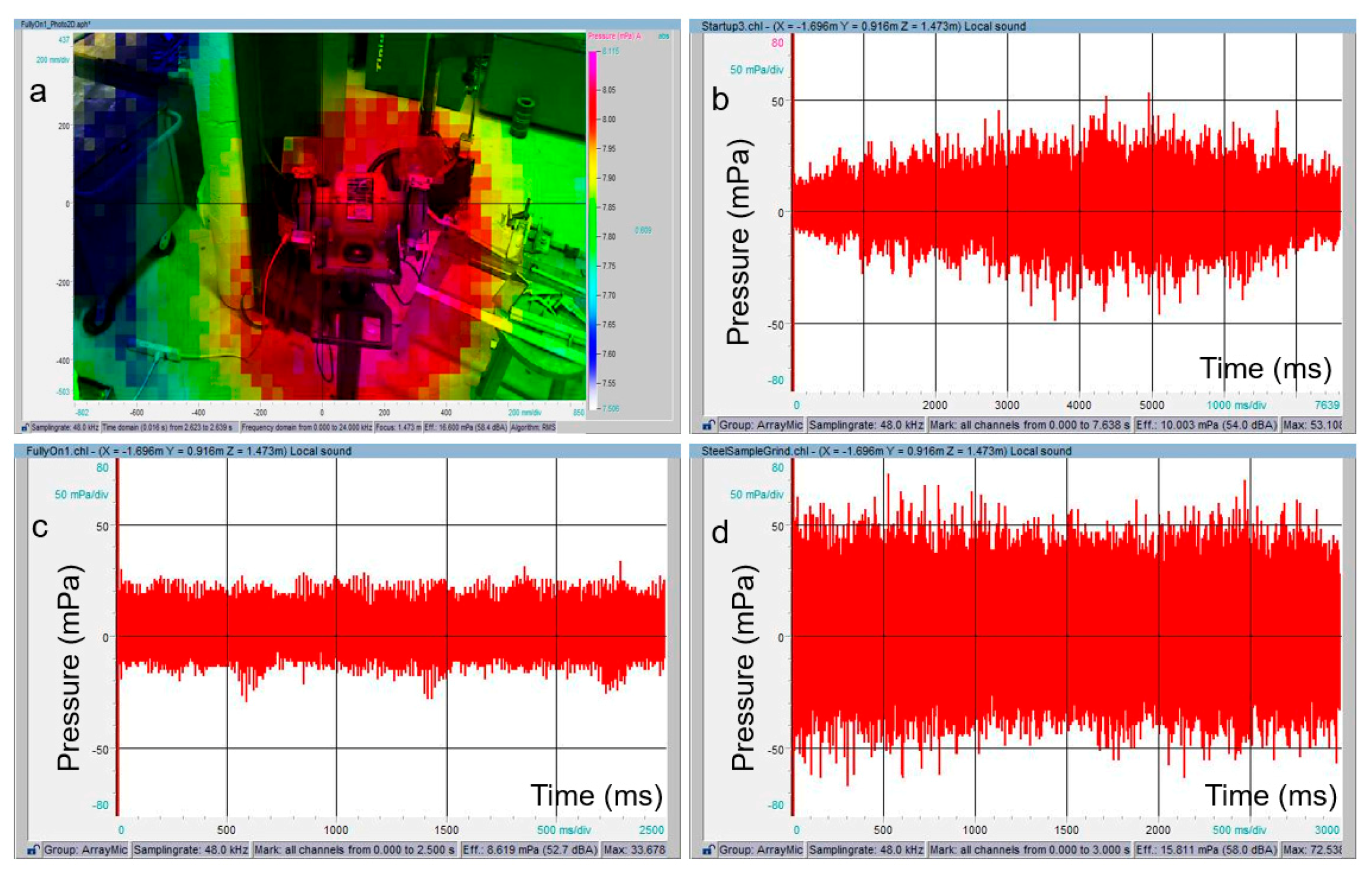

4.1. Bench Grinder

4.2. Surface Grinder

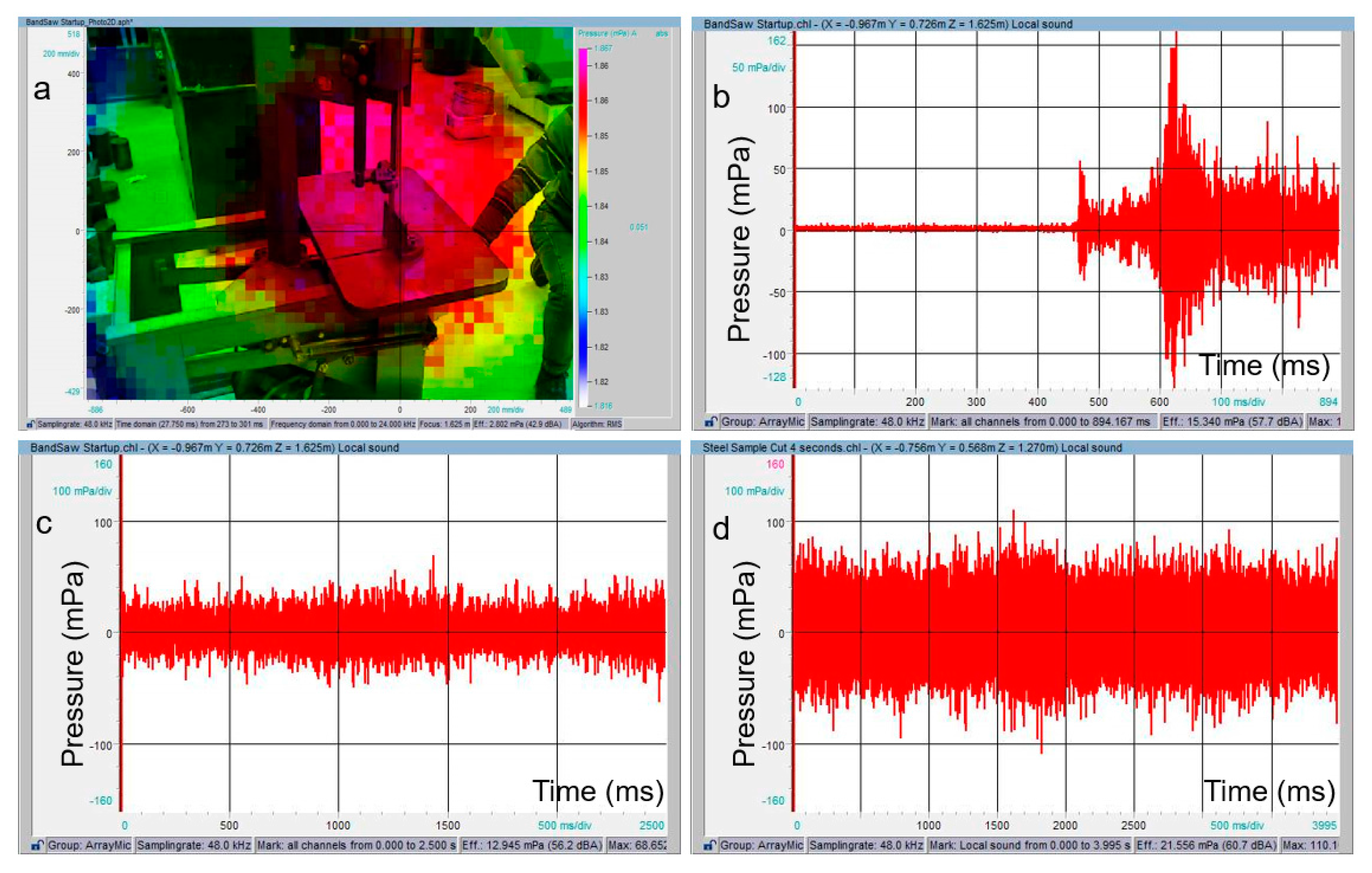

4.3. Vertical Band Saw

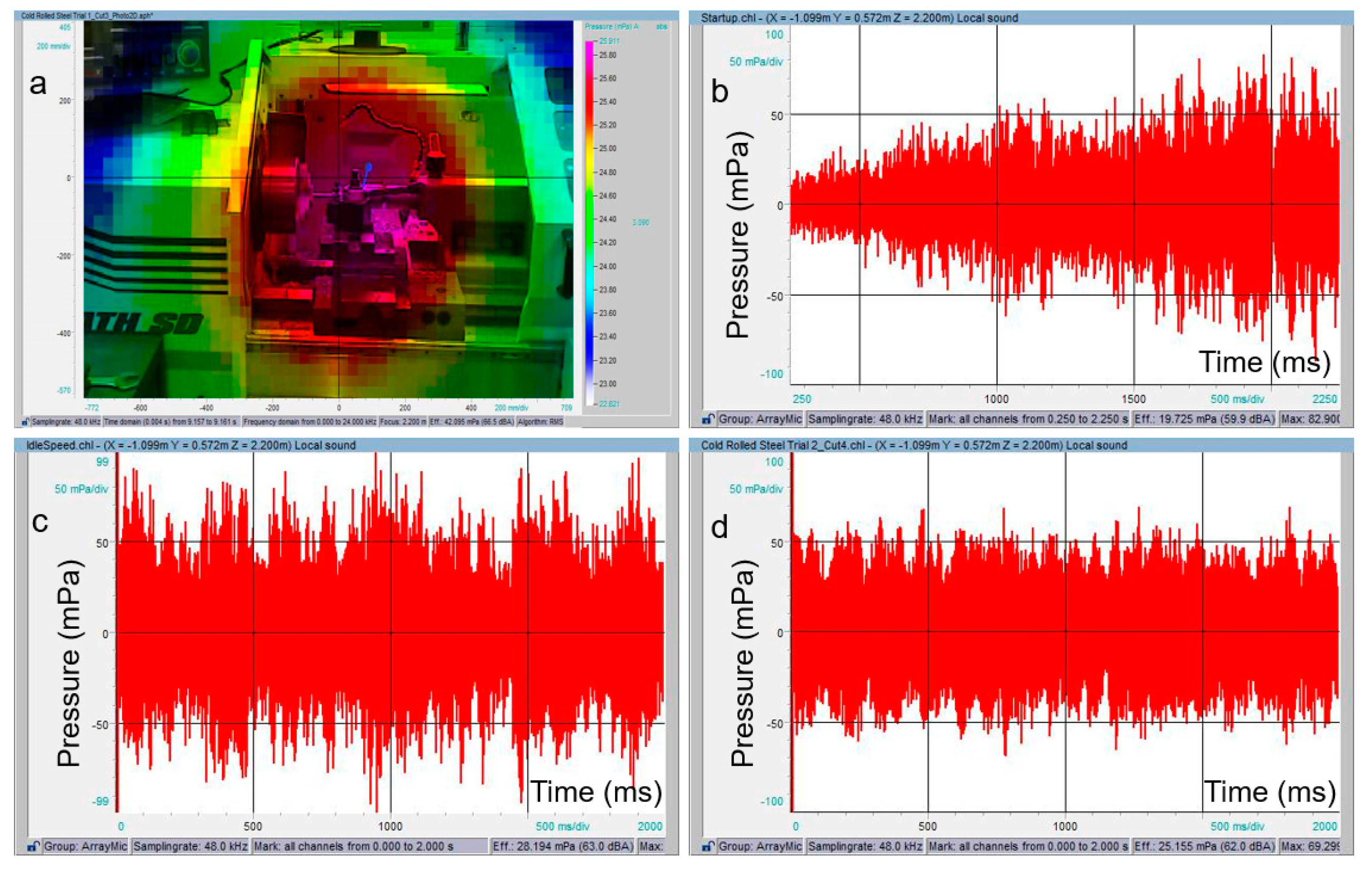

4.4. Lathe Machine

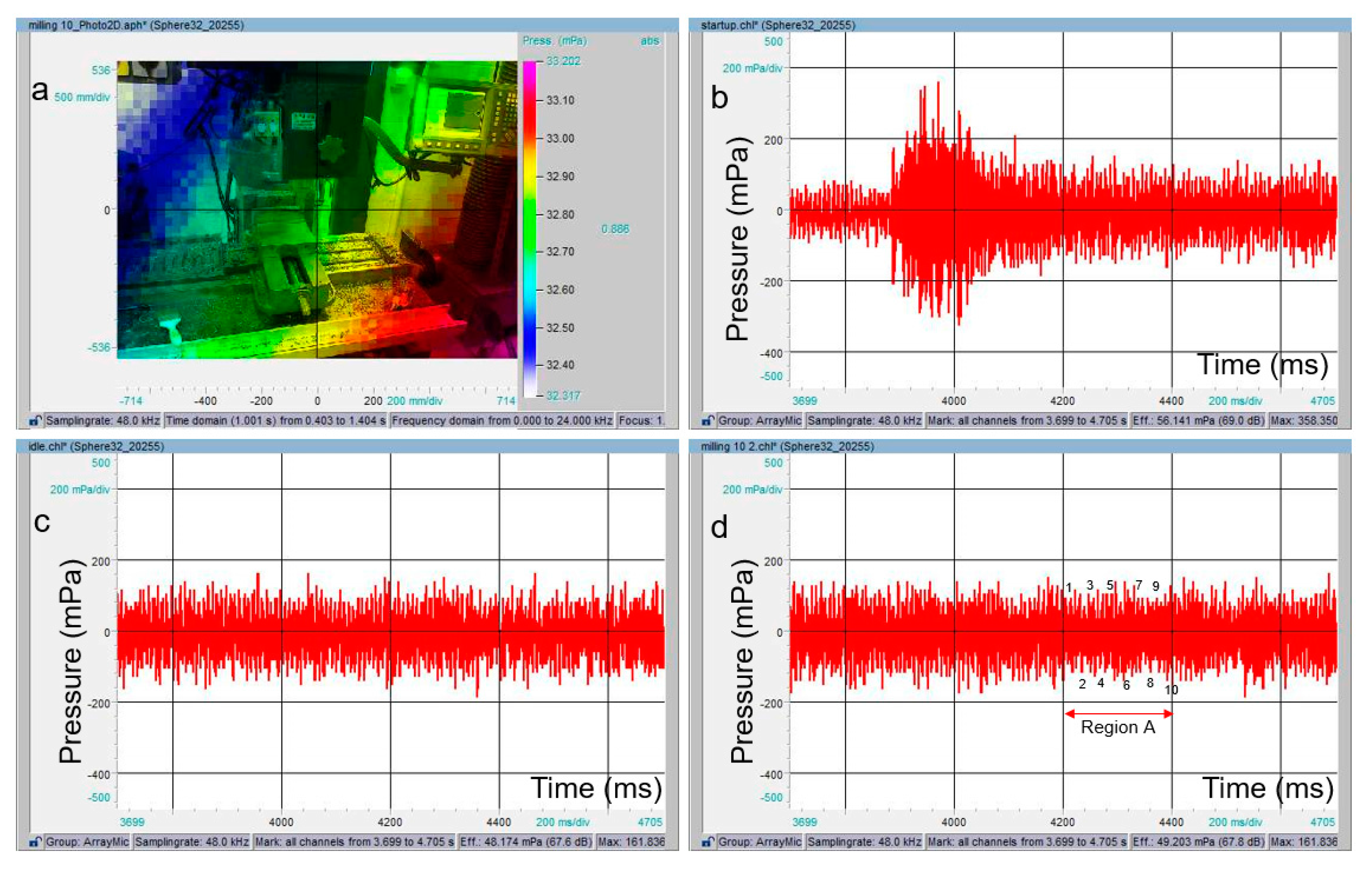

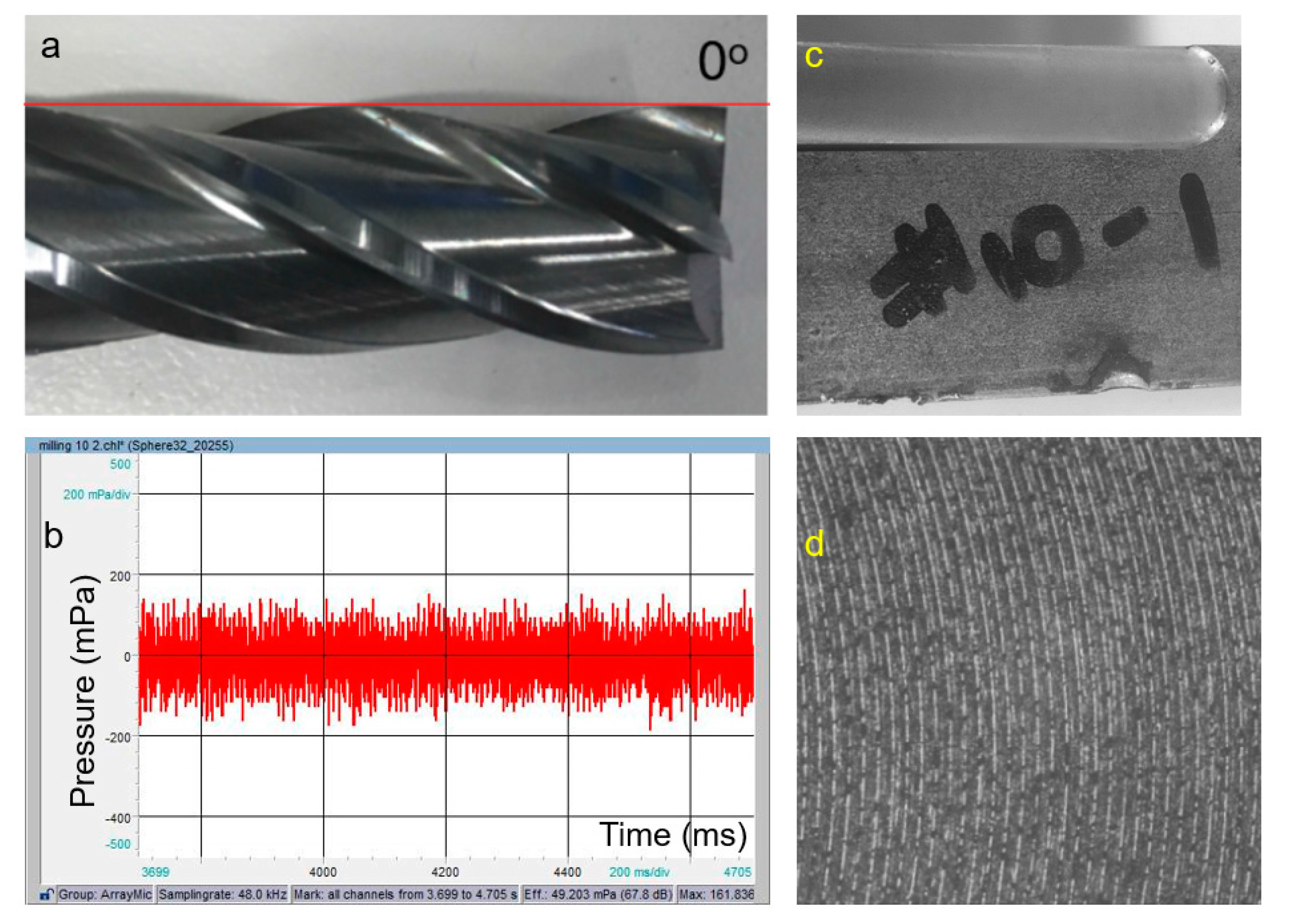

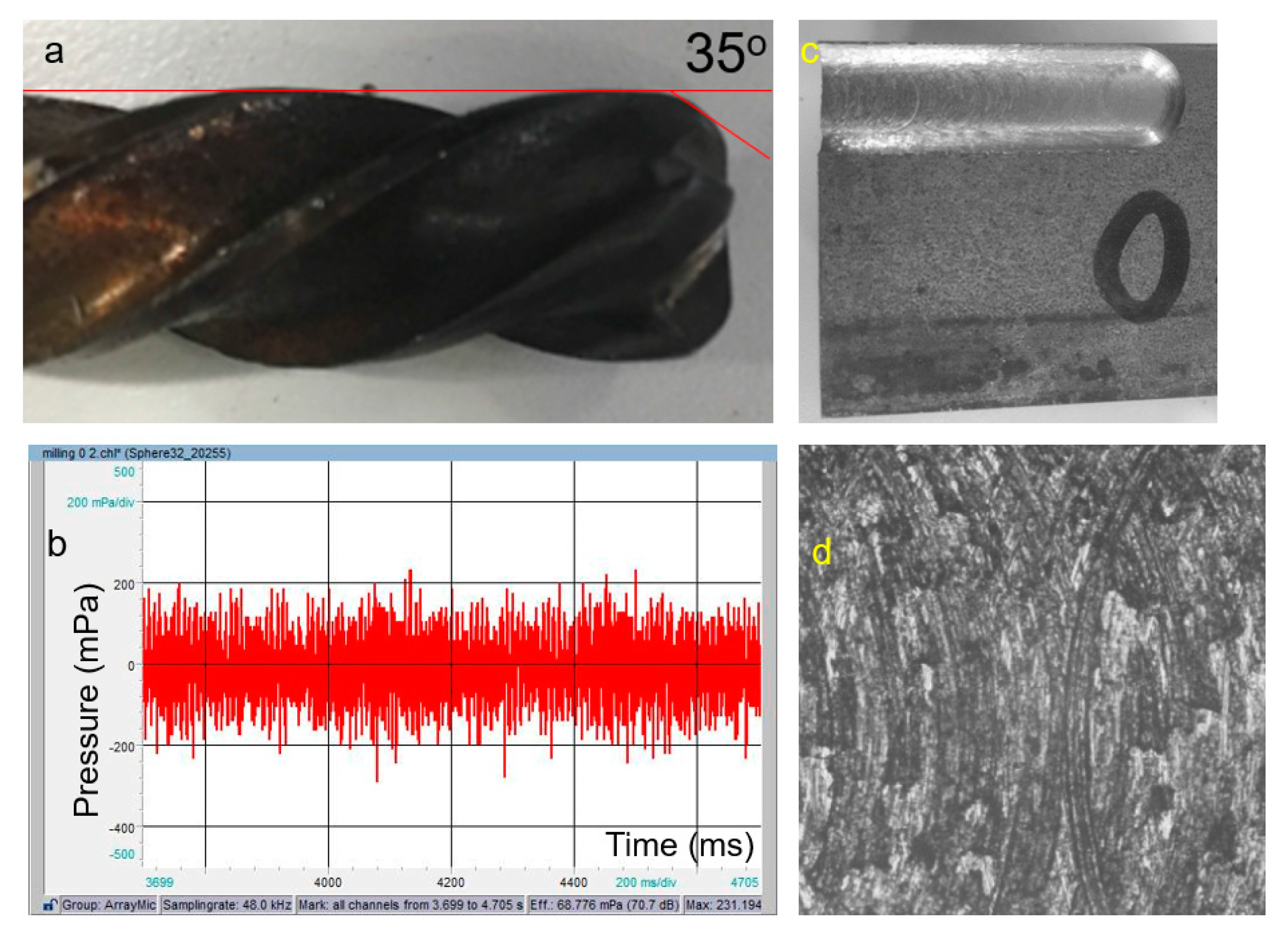

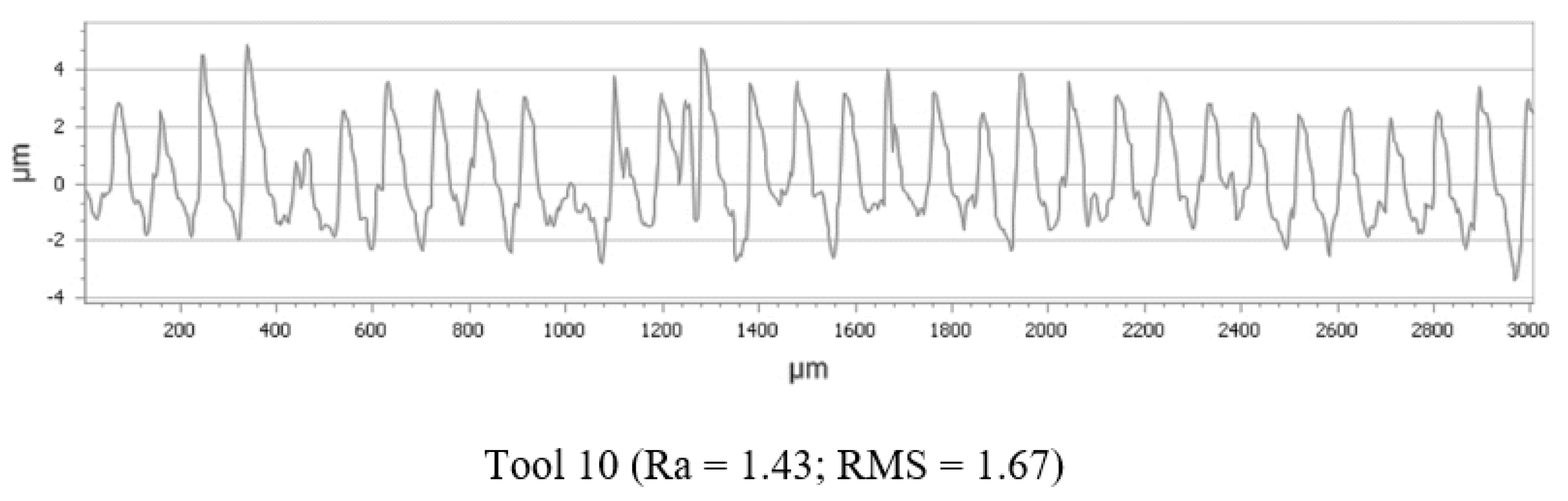

4.5. Vertical Milling Machine

5. Conclusions

- (a)

- Running parameters like the type of tool, rpm, depth and feed of cut are sensitive to the noise pressure.

- (b)

- At machine startup, the noise emission provides the time to get to the idle state. Some of the machines instantly get to the idle state depending on the running rpm, but it also depends on the tool diameter and length of the tool from the motor support. For example, the bench grinder used a bigger disc than the surface grinder and took a longer time to get to the idle state. Similarly, the vertical milling machine has a long tool shaft and provides more vibration than the grinder machine.

- (c)

- During the idle condition the machine produced constant noise pressure.

- (d)

- For loading conditions, the noise pressure depends on the parameters like rpm, depth, and feed of cut. It is hypothesized that the machine will produce less noise with a higher rpm and lower feed and depth of cut.

- (e)

- With noise pressure data and knowing the tool i.e., how many bits in the tool or how many tooth in the saw, the rpm can be calculated. It is hypothesized that in a similar way the depth and feed of cut can also be determined.

- (f)

- With a set amount of parameters, the point where the effective sound pressure saturates is the time when the tool change would be required.

- (g)

- Knowledge of noise pressure can help in determining the variables which increase the tool health and life.

Acknowledgments

Conflicts of Interest

References

- Aramesh, M.; Shaban, Y.; Yacout, S.; Attia, M.H.; Kishawy, H.A.; Balazinski, M. Survival life analysis applied to tool life estimation with variable cutting conditions when machining titanium metal matrix composites (Ti-MMCs). Mach. Sci. Technol. 2016, 20, 132–147. [Google Scholar] [CrossRef]

- Lopes Da Silva, R.H.; Bacci Da Silva, M.; Hassui, A. A probabilistic neural network applied in monitoring tool wear in the end milling operation via acoustic emission and cutting power signals. Mach. Sci. Technol. 2016, 20, 386–405. [Google Scholar] [CrossRef]

- Bhuiyan, M.S.H.; Choudhury, I.A. Investigation of tool wear and surface finish by analyzing vibration signals in turning ASSAB-705 steel. Mach. Sci. Technol. 2015, 19, 236–261. [Google Scholar] [CrossRef]

- Sanjay, C.; Neema, M.L.; Chin, C.W. Modeling of tool wear in drilling by statistical analysis and artificial neural network. J. Mater. Process. Technol. 2005, 170, 494–500. [Google Scholar] [CrossRef]

- Nouri, M.; Fussell, B.K.; Ziniti, B.L.; Linder, E. Real-time tool wear monitoring in milling using a cutting condition independent method. Int. J. Mach. Tools Manuf. 2015, 89, 1–13. [Google Scholar] [CrossRef]

- Ghosh, N.; Ravi, Y.B.; Patra, A.; Mukhopadhyay, S.; Paul, S.; Mohanty, A.R.; Chattopadhyay, A.B. Estimation of tool wear during CNC milling using neural network-based sensor fusion. Mech. Syst. Signal Process. 2007, 21, 466–479. [Google Scholar] [CrossRef]

- Patra, K.; Pal, S.K.; Bhattacharyya, K. Artificial neural network based prediction of drill flank wear from motor current signals. Appl. Soft Comput. J. 2007, 7, 929–935. [Google Scholar] [CrossRef]

- Aliustaoglu, C.; Ertunc, H.M.; Ocak, H. Tool wear condition monitoring using a sensor fusion model based on fuzzy inference system. Mech. Syst. Signal. Process. 2009, 23, 539–546. [Google Scholar] [CrossRef]

- Dimla, D.E. Sensor signals for tool-wear monitoring in metal cutting operations—A review of methods. Int. J. Mach. Tools Manuf. 2000, 40, 1073–1098. [Google Scholar] [CrossRef]

- Trent, E.M.; Wright, P.K. Metal Cutting, 4th ed.; Butterworth-Heinemann: Boston, MA, USA, 2000. [Google Scholar]

- Carvalho, S.R.; Lima e Silva, S.M.M.; Machado, A.R.; Guimarães, G. Temperature determination at the chip–tool interface using an inverse thermal model considering the tool and tool holder. J. Mater. Process. Technol. 2006, 179, 97–104. [Google Scholar] [CrossRef]

- Majumdar, P.; Jayaramachandran, R.; Ganesan, S. Finite element analysis of temperature rise in metal cutting process. Appl. Therm. Eng. 2005, 25, 2152–2168. [Google Scholar] [CrossRef]

- Shih, A.J. Finite element analysis of orthogonal metal cutting mechanics. Int. J. Mach. Tools Manuf. 1996, 36, 255–273. [Google Scholar] [CrossRef]

- Tay, A.A.O. A review of methods of calculating machining temperature. J. Mater. Process. Technol. 1993, 36, 225–257. [Google Scholar] [CrossRef]

- Smithey, D.W.; Kapoor, S.G.; DeVor, R.E. A new mechanistic model for predicting worn tool cutting forces. Machining Science and Technology. Mach. Sci. Technol. 2001, 5, 23–42. [Google Scholar] [CrossRef]

- Wang, C.; Cheng, K.; Nelson, N.; Sawangsri, W.; Rakowski, R. Cutting force-based analysis and correlative observations on the tool wear in diamond turning of single crystal silicon. J. Eng. Manuf. 2014, 229, 1–7. [Google Scholar] [CrossRef]

- Alonso, F.J.; Salgado, D.R. Analysis of the structure of vibration signals for tool wear detection. Mech. Syst. Signal Process. 2008, 22, 735–748. [Google Scholar] [CrossRef]

- Dimla, D.E. The impact of cutting conditions on cutting forces and vibration signals in turning with plane face geometry inserts. J. Mater. Process. Technol. 2004, 155–156, 1708–1715. [Google Scholar] [CrossRef]

- Dimla, D.E.; Lister, P.M. On-line metal cutting tool condition monitoring I: Force and vibration analyses. Int. J. Mach. Tools Manuf. 2000, 40, 739–768. [Google Scholar] [CrossRef]

- Ghani, A.K.; Choudhury, I.A.; Husni. Study of tool life, surface roughness and vibration in machining nodular cast iron with ceramic tool. J. Mater. Process. Technol. 2002, 37, 11–22. [Google Scholar] [CrossRef]

- Altintas, Y.; Lee, P. Prediction of ball-end milling forces from orthogonal cutting data. Int. J. Mach. Tools Manuf. 1996, 36, 1059–1072. [Google Scholar]

- Jemielniak, K.; Arrazola, P.J. Application of AE and cutting force signals in tool condition monitoring in micro-milling. CIRP J. Manuf. Sci. Technol. 2008, 1, 97–102. [Google Scholar] [CrossRef]

- Said, M.B.; Saï, K.; Saï, W.B. An investigation of cutting forces in machining with worn ball-end mill. J. Mater. Process. Technol. 2009, 29, 3198–3217. [Google Scholar] [CrossRef]

- Rangwala, S.; Dornfeld, D. A study of acoustic emission generated during orthogonal metal cutting—1: energy analysis. Int. J. Mech. Sci. 1991, 33, 471–487. [Google Scholar] [CrossRef]

- Dornfeld, D.A.; Kannatey-Asibu, E. Acoustic emission during orthogonal metal cutting. Int. J. Mech. Sci. 1980, 22, 285–296. [Google Scholar] [CrossRef]

- Kannatey-Asibu, E.; Dornfeld, D.A. A study of tool wear using statistical analysis of metal cutting acoustic emission. Wear 1982, 76, 247–261. [Google Scholar] [CrossRef]

- Kannatey-Asibu, E.; Emel, E. Linear discriminant function analysis of acoustic emission signals for cutting tool monitoring. Mech. Syst. Signal Process. 1987, 1, 333–347. [Google Scholar] [CrossRef]

- Farrelly, F.A.; Petri, A.; Pitolli, L. Statistical properties of acoustic emission signals from metal cutting processes. J. Acoust. Soc. Am. 2004, 116, 981–986. [Google Scholar] [CrossRef]

- Teti, R.; Jamielniak, K.; O’Donnell, G.; Dornfield, D. Advanced monitoring of machining operations. CIRP Ann.—Manuf. Technol. 2010, 59, 171–739. [Google Scholar] [CrossRef]

- Baccar, D.; Soffker, D. Wear detection by means of wavelet-based acoustic emission analysis. Mech. Syst. Signal Process. 2015, 60–61, 198–207. [Google Scholar] [CrossRef]

- Jamielniak, K.; Otman, O. Tool failure detection based on analysis of acoustic emission signals. J. Mater. Process. Technol. 1998, 76, 192–197. [Google Scholar] [CrossRef]

- Yan, D.; El-Wardany, T.; Elbestawi, M. A multi-sensor strategy for tool failure detection in milling. Int. J. Mach. Tools Manuf. 1995, 35, 383–398. [Google Scholar] [CrossRef]

- Milner, J.; Roth, J. Condition monitoring for indexable carbide end mill using acceleration data. Mach. Sci. Technol. 2010, 14, 63–80. [Google Scholar] [CrossRef]

- Nikhare, C.; Ragai, I.; Loker, D.; Sweeney, S.; Conklin, C.; Roth, J.T. Investigation of acoustic signals during W1 tool steel quenching. In Proceedings of the ASME International Manufacturing Science and Engineering Conference, Charlotte, NC, USA, 8–12 June 2015; pp. 1–9. [Google Scholar]

- Erich, N.J.; Nikhare, C.P.; Conklin, C.; Loker, D.R. Study of acoustic signals and mechanical properties dependence during cold drawn A36 steel quenching. In Proceedings of the International Deep Drawing Research Group Conference, Shanghai, China, 31 May–3 June 2015; pp. 338–346. [Google Scholar]

- Jaeckel, O. Strengths and weaknesses of calculating beam forming in the time domain. In Proceedings of the 1st Berlin Beam Forming Conference, Berlin, Germany, 21–22 November 2006; pp. 1–10. [Google Scholar]

- Romenskiy, I.; Jaeckel, O. Improvement of Source Separation for Phased Microphone Array Measurements. In Proceedings of the 2nd Berlin Beam Forming Conference, Berlin, Germany, 19–20 February 2008; pp. 1–8. [Google Scholar]

| Test Machine | Power | RPM | Condition/Age | # of Motors | # of Bearings |

|---|---|---|---|---|---|

| Bench Grinder | 115v AC, 0.56 kW | 3450 | Very Good | 1 | >2 |

| Surface Grinder | 240v AC, 0.74 kW | 2800 | Good | 1 | >4 |

| Vertical Band Saw | 115v AC, 0.74 kW | 1725 | Good | 1 | >6 |

| Lathe | 240v AC, 7.45 kW | 150–2500 | Very Good | >1 | >10 |

| Vertical milling machine | 240v AC, 2.24 kW | 150–2500 | Good | >1 | >10 |

| Test Machine | Power | RPM | Tool Condition | Material Used |

|---|---|---|---|---|

| Bench Grinder | 115v AC, 0.56 kW | 3450 | Tool 9 | 1018 Steel |

| Surface Grinder | 240v AC, 0.74 kW | 2800 | Tool 9 | 1018 Steel |

| Vertical Band Saw | 115v AC, 0.74 kW | 1725 | Tool 9 | 1018 Steel |

| Lathe | 240v AC, 7.45 kW | 750 | Tool 9 | 1018 Steel |

| Vertical milling machine | 240v AC, 2.24 kW | 750 | Tool 10 | 1018 Steel |

| Test Machine | Effective Sound Pressure (mPa) | ||

|---|---|---|---|

| Startup | Idle | Load | |

| Bench Grinder | 10.00 | 8.62 | 15.81 |

| Surface Grinder | 6.84 | 8.19 | 12.43 |

| Vertical Band Saw | 15.34 | 12.95 | 21.55 |

| Lathe | 19.72 | 28.19 | 25.15 |

| Vertical milling machine | 56.14 | 48.17 | 49.20 |

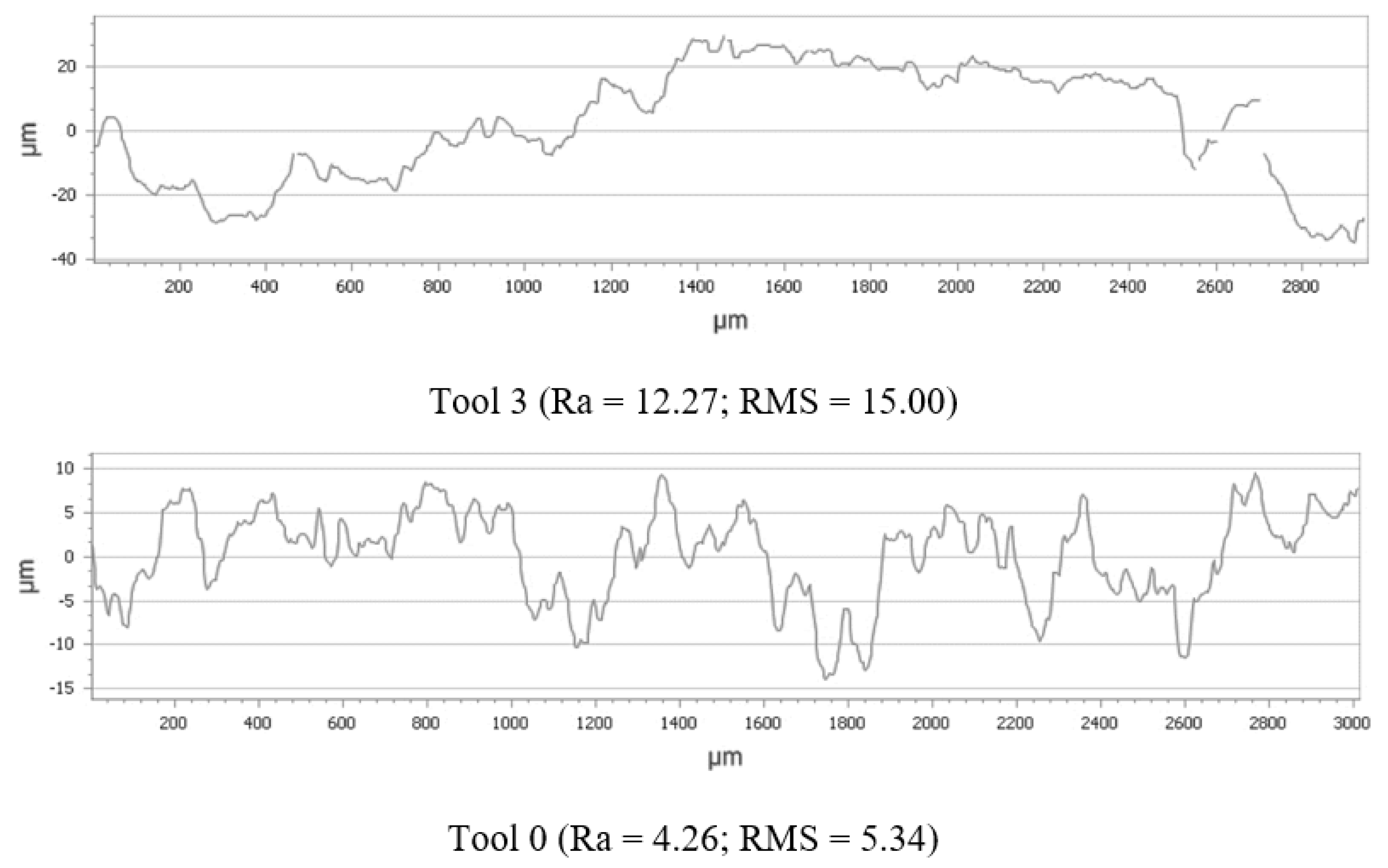

| Tool Condition | Effective Sound Pressure (mPa) |

|---|---|

| Tool 10 | 49.20 |

| Tool 3 | 67.71 |

| Tool 0 | 68.77 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nikhare, C.P.; Conklin, C.; Loker, D.R. Understanding Acoustic Emission for Different Metal Cutting Machinery and Operations. J. Manuf. Mater. Process. 2017, 1, 7. https://doi.org/10.3390/jmmp1010007

Nikhare CP, Conklin C, Loker DR. Understanding Acoustic Emission for Different Metal Cutting Machinery and Operations. Journal of Manufacturing and Materials Processing. 2017; 1(1):7. https://doi.org/10.3390/jmmp1010007

Chicago/Turabian StyleNikhare, Chetan P., Chris Conklin, and David R. Loker. 2017. "Understanding Acoustic Emission for Different Metal Cutting Machinery and Operations" Journal of Manufacturing and Materials Processing 1, no. 1: 7. https://doi.org/10.3390/jmmp1010007