Analytical and Numerical Temperature Prediction in Direct Metal Deposition of Ti6Al4V

Abstract

:1. Introduction

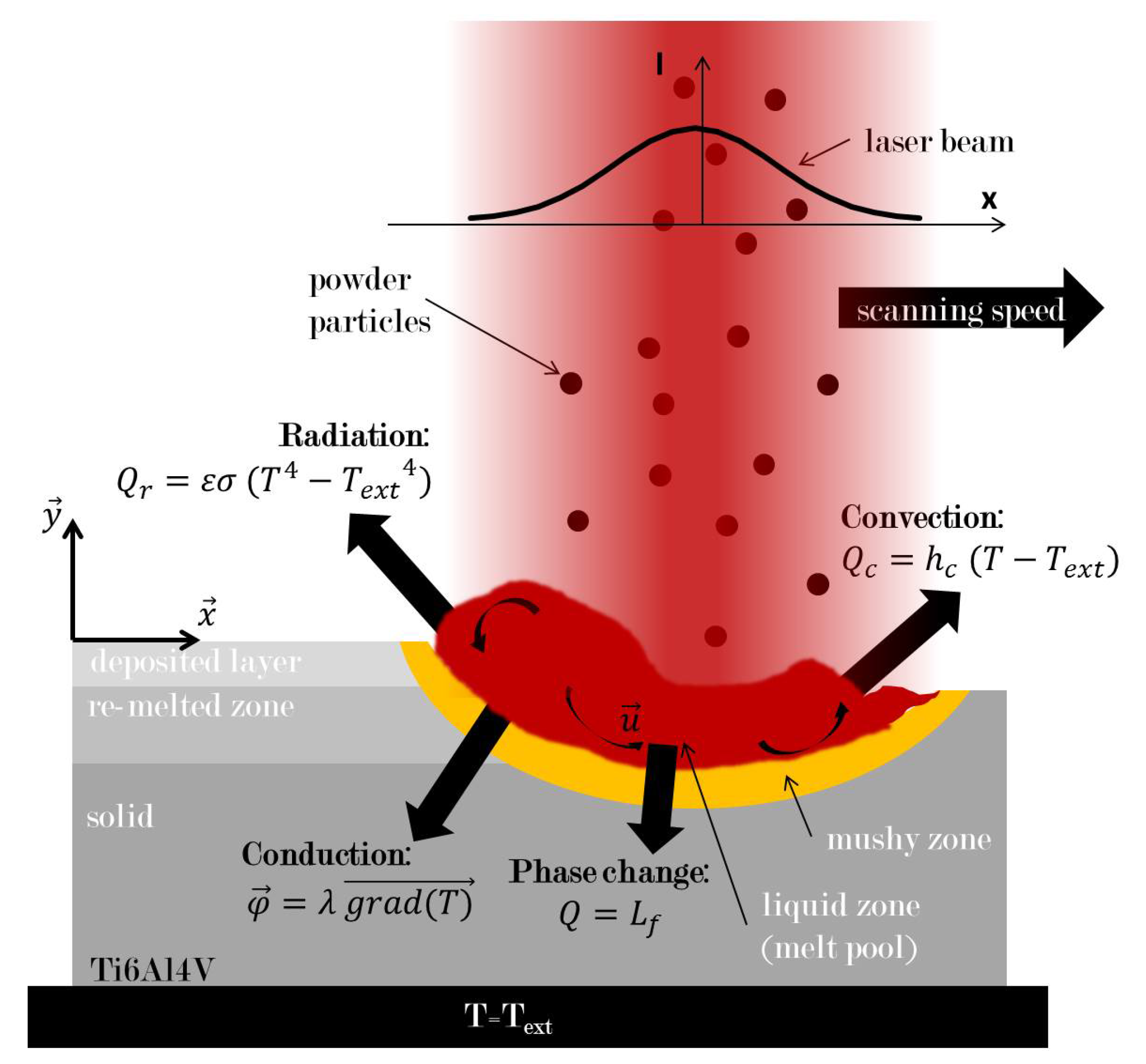

2. Mathematical Modeling of the DMD Process

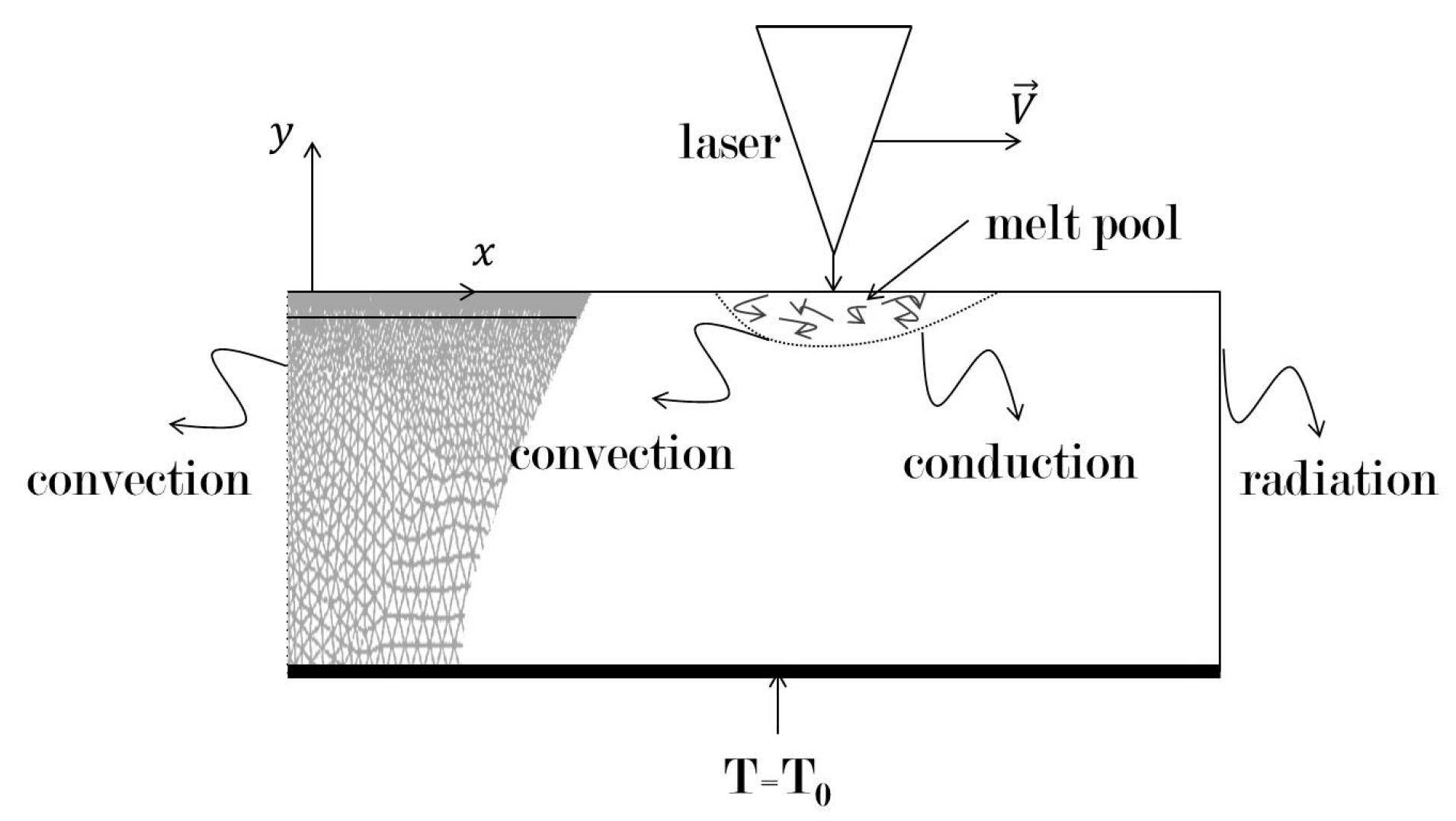

2.1. Numerical Modeling

2.2. Analytical Model

3. Material and Experiment

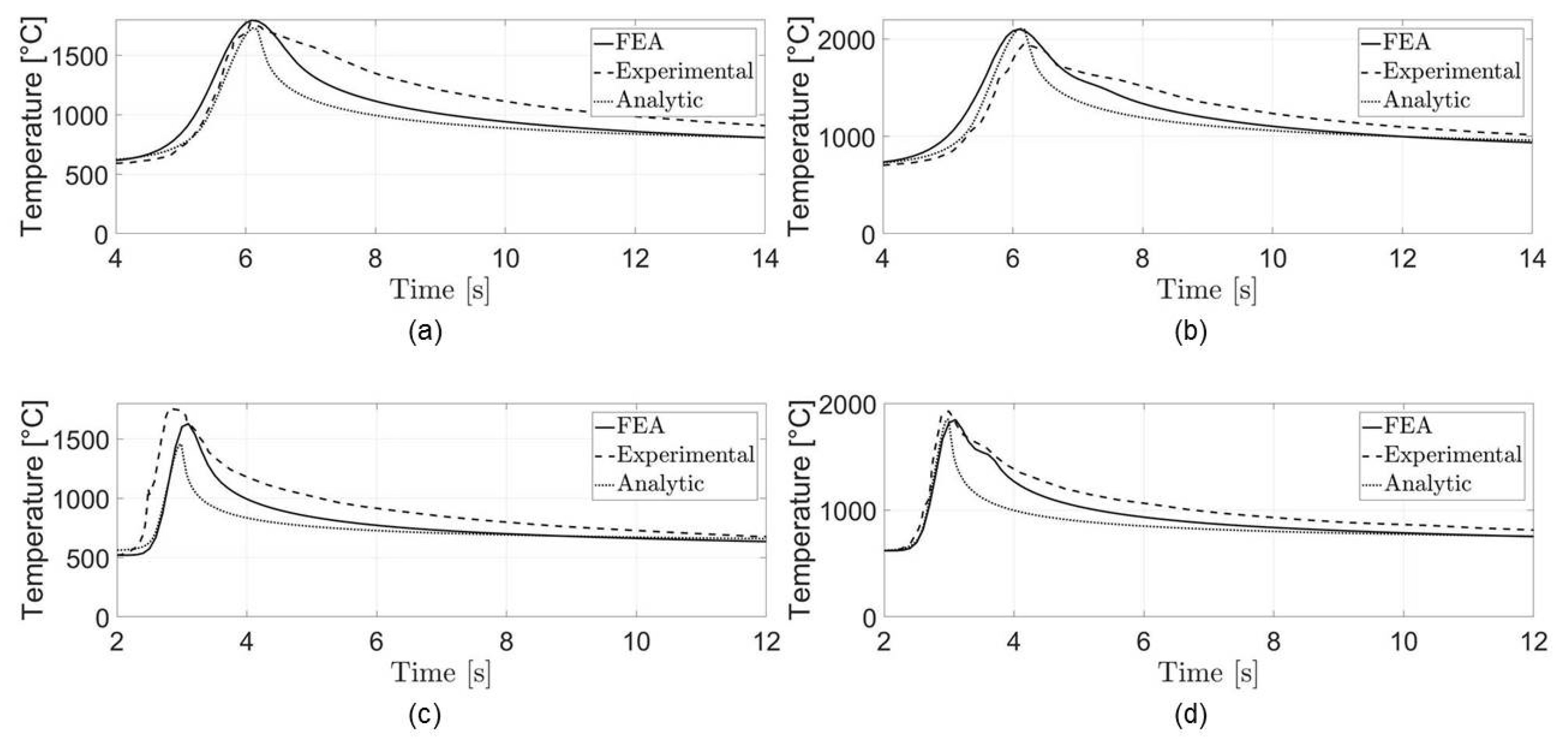

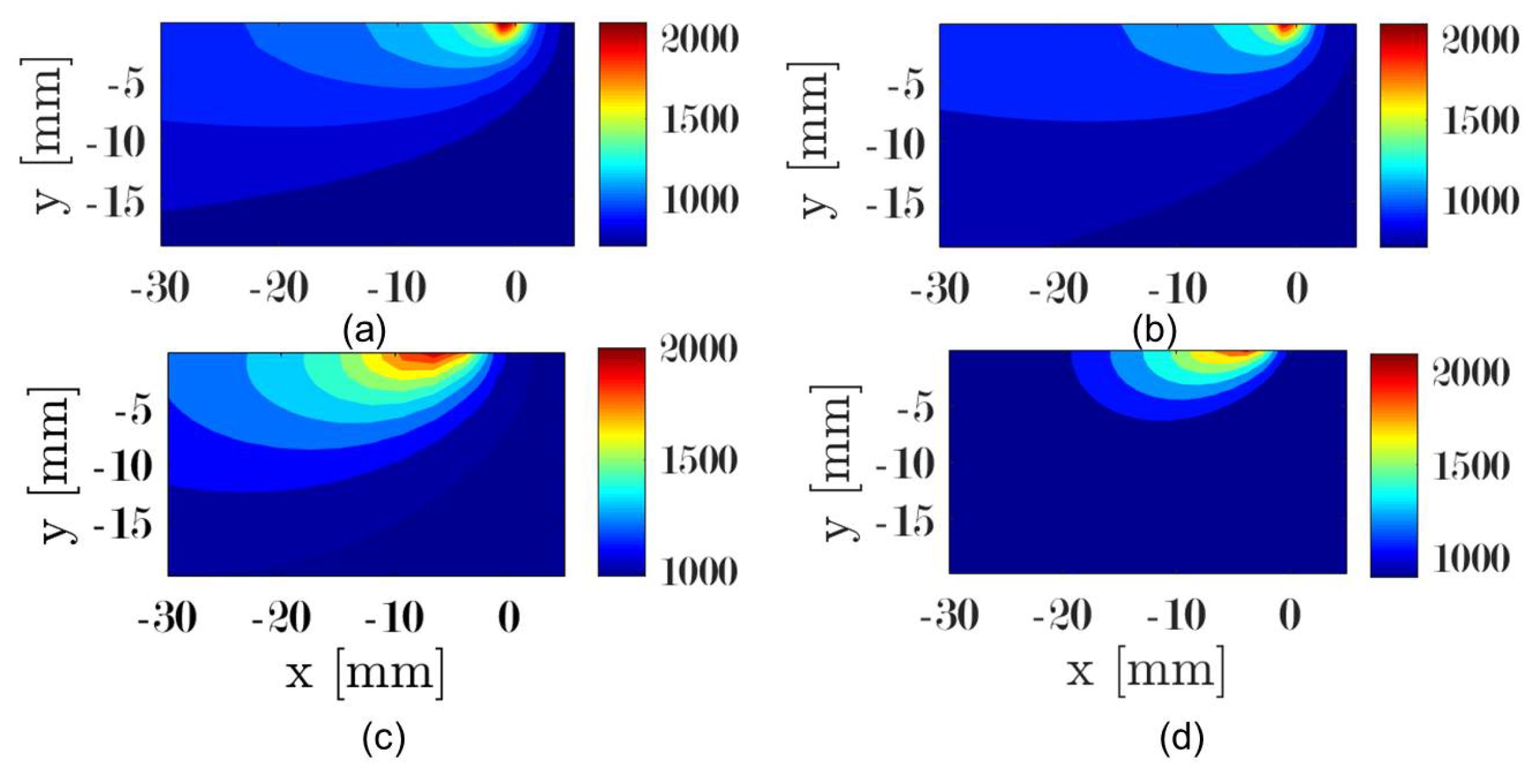

4. Results and Discussion

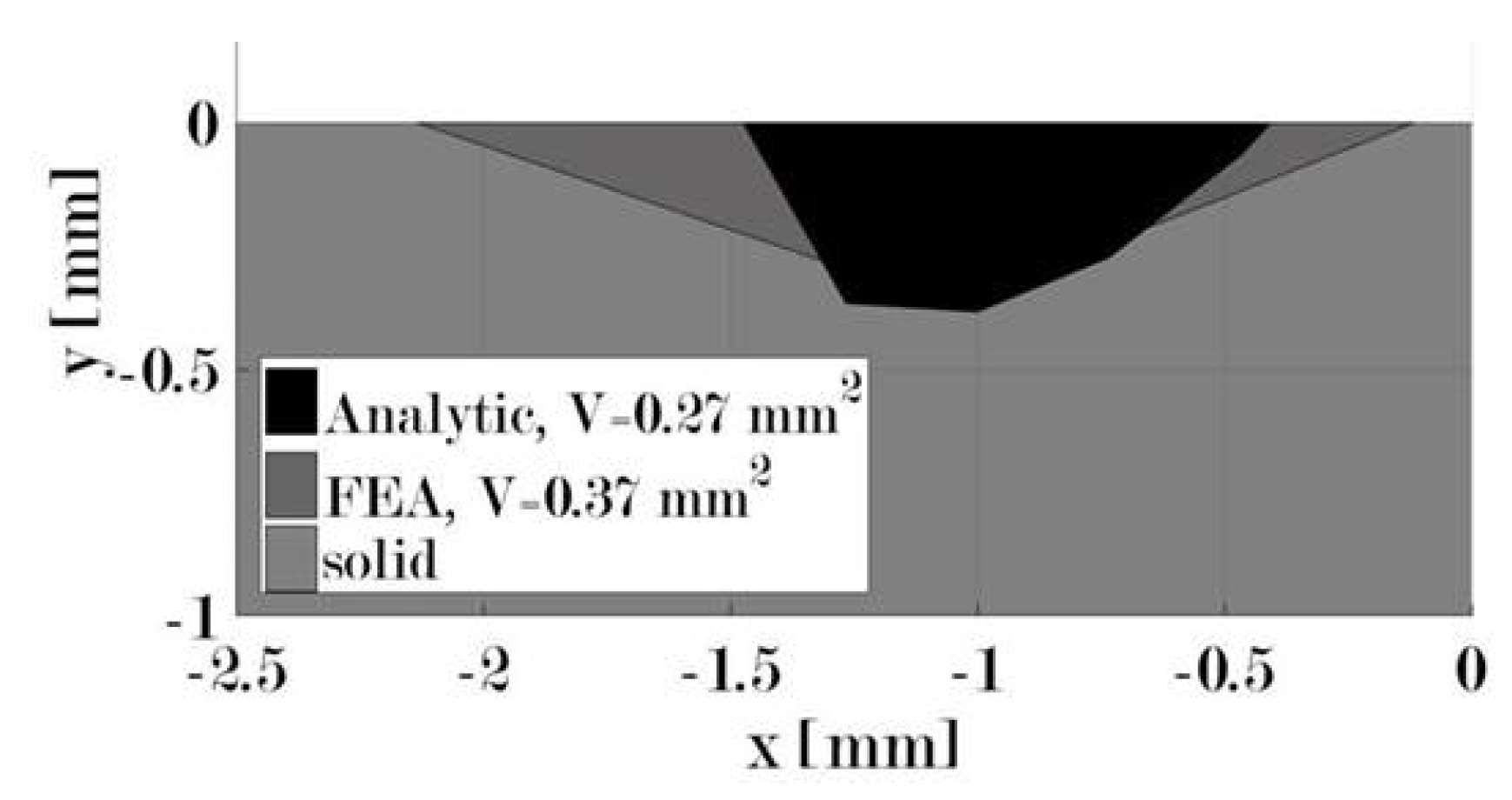

4.1. Surface and Subsurface Temperature

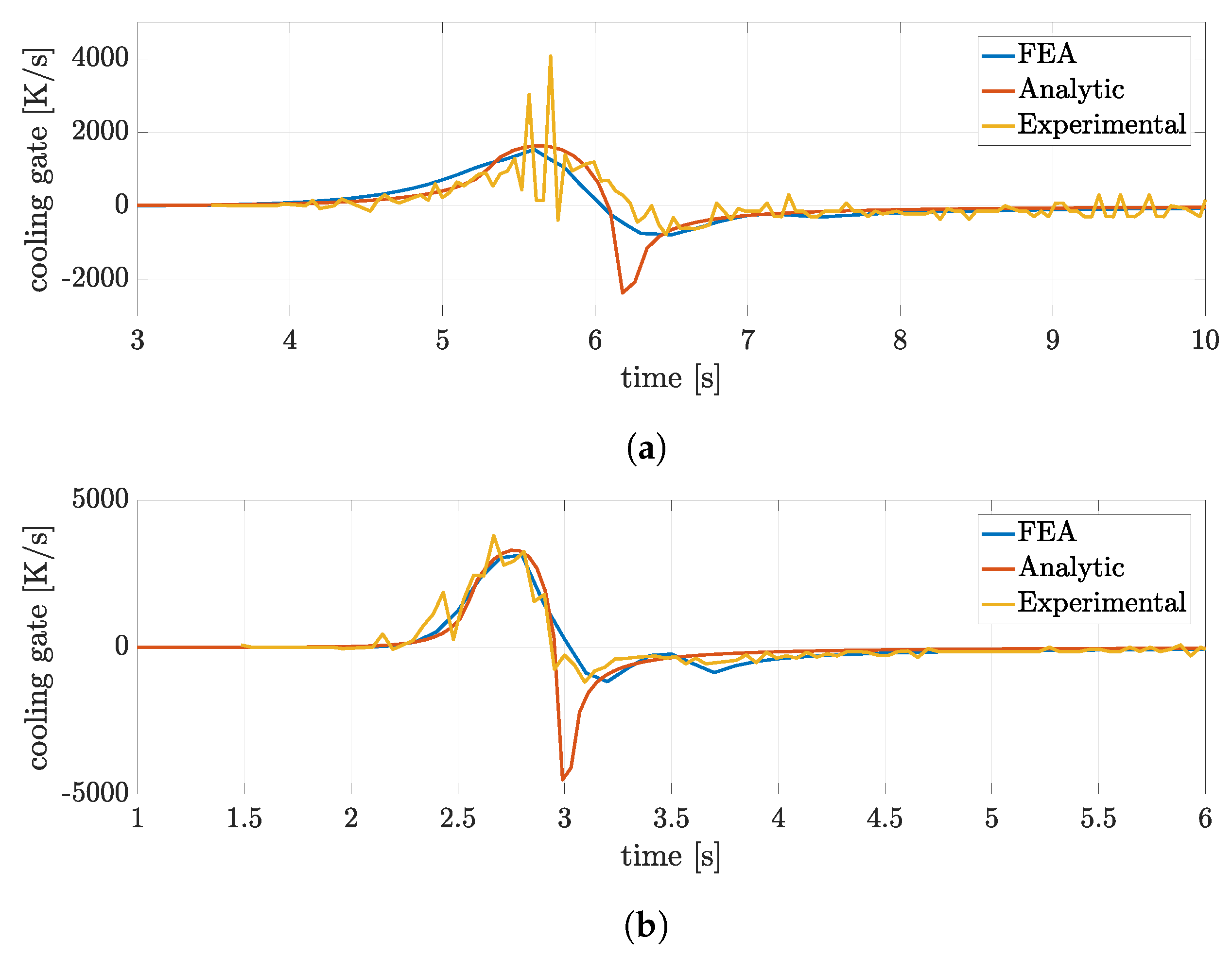

4.2. Cooling Rate Comparison

4.3. Sensitivity Analysis Based on the Analytical Model

4.3.1. Influence of the Laser Power

4.3.2. Influence of the Scanning Speed

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Leino, M.; Pekkarinen, J.; Soukka, R. The Role of Laser Additive Manufacturing Methods of Metals in Repair, Refurbishment and Remanufacturing—Enabling Circular Economy. Phys. Procedia 2016, 83, 752–760. [Google Scholar] [CrossRef]

- Liu, R.; Wang, Z.; Sparks, T.; Liou, F.; Newkirk, J. 13-Aerospace applications of laser additive manufacturing. In Laser Additive Manufacturing; Brandt, M., Ed.; Woodhead Publishing Series in Electronic and Optical Materials; Woodhead Publishing: Sawston, UK, 2017; pp. 351–371. [Google Scholar]

- Bikas, H.; Stavropoulos, P.; Chryssolouris, G. Additive manufacturing methods and modelling approaches: A critical review. Int. J. Adv. Manuf. Technol. 2016, 83, 389–405. [Google Scholar] [CrossRef]

- Thompson, S.M.; Bian, L.; Shamsaei, N.; Yadollahi, A. An overview of Direct Laser Deposition for additive manufacturing; Part I: Transport phenomena, modeling and diagnostics. Addit. Manuf. 2015, 8, 36–62. [Google Scholar] [CrossRef]

- Rai, A.; Markl, M.; Körner, C. A coupled Cellular Automaton—Lattice Boltzmann model for grain structure simulation during additive manufacturing. Comput. Mater. Sci. 2016, 124, 37–48. [Google Scholar] [CrossRef]

- Kelly, S.M. Characterization and Thermal Modeling of Laser Formed Ti-6Al-4V. Ph.D. Thesis, Virginia Tech, Blacksburg, VA, USA, 2002. [Google Scholar]

- Fergani, O.; Berto, F.; Welo, T.; Liang, S.Y. Analytical modelling of residual stress in additive manufacturing. Fatigue Fract. Eng. Mater. Struct. 2017, 40, 971–978. [Google Scholar] [CrossRef]

- Bontha, S.; Klingbeil, N.W.; Kobryn, P.A.; Fraser, H.L. Thermal process maps for predicting solidification microstructure in laser fabrication of thin-wall structures. J. Mater. Process. Technol. 2006, 178, 135–142. [Google Scholar] [CrossRef]

- Klingbeil, N.; Bontha, S.; Brown, C.; Gaddam, D. Effects of Process Variables and Size Scale on Solidification Microstructure in Laser-Based Solid Freeform Fabrication of Ti-6Al-4V. In Proceedings of the Solid Freeform Fabrication SFF, Austin, TX, USA, 2–4 August 2004. [Google Scholar]

- Hoadley, A.F.A.; Rappaz, M. A thermal model of laser cladding by powder injection. Metall. Trans. B 1992, 23, 631–642. [Google Scholar] [CrossRef]

- Picasso, M.; Hoadley, A. Finite element simulation of laser surface treatments including convection in the melt pool. Int. J. Numer. Methods Heat Fluid Flow 1994, 4, 61–83. [Google Scholar] [CrossRef]

- Toyserkani, E.; Khajepour, A.; Corbin, S. 3-D finite element modeling of laser cladding by powder injection: Effects of laser pulse shaping on the process. Opt. Lasers Eng. 2004, 41, 849–867. [Google Scholar] [CrossRef]

- Shamsaei, N.; Yadollahi, A.; Bian, L.; Thompson, S.M. An overview of Direct Laser Deposition for additive manufacturing; Part II: Mechanical behavior, process parameter optimization and control. Addit. Manuf. 2015, 8, 12–35. [Google Scholar] [CrossRef]

- Cao, X.; Ayalew, B. Control-oriented MIMO modeling of laser-aided powder deposition processes. In Proceedings of the 2015 American Control Conference (ACC), Chicago, IL, USA, 1–3 July 2015; pp. 3637–3642. [Google Scholar]

- Peyre, P.; Aubry, P.; Fabbro, R.; Neveu, R.; Longuet, A. Analytical and numerical modelling of the direct metal deposition laser process. J. Phys. D Appl. Phys. 2008, 41, 025403. [Google Scholar] [CrossRef]

- Elsen, M.V.; Baelmans, M.; Mercelis, P.; Kruth, J.P. Solutions for modelling moving heat sources in a semi-infinite medium and applications to laser material processing. Int. J. Heat Mass Transf. 2007, 50, 4872–4882. [Google Scholar] [CrossRef]

- Paul, S.; Singh, R.; Yan, W. Thermal model for additive restoration of mold steels using crucible steel. J. Manuf. Process. 2016, 24 Pt 2, 346–354. [Google Scholar] [CrossRef]

- Li, J.; Li, L.; Stott, F. Comparison of volumetric and surface heating sources in the modeling of laser melting of ceramic materials. Int. J. Heat Mass Transf. 2004, 47, 1159–1174. [Google Scholar] [CrossRef]

- Parekh, R.; Buddu, R.K.; Patel, R. Multiphysics Simulation of Laser Cladding Process to Study the Effect of Process Parameters on Clad Geometry. Procedia Technol. 2016, 23, 529–536. [Google Scholar] [CrossRef]

- Vásquez, F.; Ramos-Grez, J.A.; Walczak, M. Multiphysics simulation of laser—Material interaction during laser powder depositon. Int. J. Adv. Manuf. Technol. 2012, 59, 1037–1045. [Google Scholar] [CrossRef]

- Kumar, A.; Roy, S. Effect of three-dimensional melt pool convection on process characteristics during laser cladding. Comput. Mater. Sci. 2009, 46, 495–506. [Google Scholar] [CrossRef]

- Morville, S.; Carin, M.; Peyre, P.; Gharbi, M.; Carron, D.; Le Masson, P.; Fabbro, R. 2D longitudinal modeling of heat transfer and fluid flow during multilayered. J. Laser Appl. 2012, 40, 1–9. [Google Scholar]

- Morville, S. Modélisation Multiphysique du Procédé de Fabrication Rapide par Projection Laser en vue D’améliorer L’état de Surface Final. Ph.D. Thesis, Université de Bretagne Sud, Bretagne, France, 2012. [Google Scholar]

- Klindworth, D.; Grepl, M.A.; Vossen, G. Certified reduced basis methods for parametrized parabolic partial differential equations with non-affine source terms. Comput. Methods Appl. Mech. Eng. 2012, 209–212, 144–155. [Google Scholar] [CrossRef]

- De Oliveira, U.; Ocelík, V.; Hosson, J.D. Analysis of coaxial laser cladding processing conditions. Surf. Coat. Technol. 2005, 197, 127–136. [Google Scholar] [CrossRef]

- Li, Y.; Zhou, K.; Tor, S.B.; Chua, C.K.; Leong, K.F. Heat transfer and phase transition in the selective laser melting process. Int. J. Heat Mass Transf. 2017, 108 Pt B, 2408–2416. [Google Scholar] [CrossRef]

- Carslaw, H.S.; Jaeger, J.C. Conduction of Heat in Solids; Oxford University Press: Oxford, UK, 1959. [Google Scholar]

- Schneider, M. Laser Cladding with Powder, Effect of Some Machining Parameters. Ph.D. Thesis, University of Twente, Enschede, The Netherlands, 1998. [Google Scholar]

- Laakso, P.; Riipinen, T.; Laukkanen, A.; Andersson, T.; Jokinen, A.; Revuelta, A.; Ruusuvuori, K. Optimization and Simulation of SLM Process for High Density H13 Tool Steel Parts. Phys. Procedia 2016, 83, 26–35. [Google Scholar] [CrossRef]

- Dai, K.; Shaw, L. Finite element analysis of the effect of volume shrinkage during laser densification. Acta Mater. 2005, 53, 4743–4754. [Google Scholar] [CrossRef]

- Pouzet, S. Fabrication Additive de Composites à Matrice Titane par Fusion Laser de Poudre Projetée. Ph.D. Thesis, ENSAM, Paris, France, 2015. [Google Scholar]

- Yadroitsev, I.; Yadroitsava, I. Evaluation of residual stress in stainless steel 316L and Ti6Al4V samples produced by selective laser melting. Virtual Phys. Prototyp. 2015, 10, 67–76. [Google Scholar] [CrossRef]

| Numerical Model | Analytical Model | |

|---|---|---|

| Material properties | temperature dependent | constant |

| Assumption | fixed geometry | fixed geometry |

| 2D finite geometry | 2D semi infinite geometry no latent heat of fusion steady state assumption | |

| Boundary conditions | radiation, convection and laser input | only the laser input |

| Ti | Al | V | Fe | O | N | C | H |

|---|---|---|---|---|---|---|---|

| 6.2 | 4.2 | 0.18 | 0.1 | 0.01 | 0.02 | 0.001 |

| Symbol | Value | Unit | Name |

|---|---|---|---|

| T | K | temperature field | |

| 4400 [32] | kg/m | density | |

| [500–800] [32] | J/(kg · K) | heat capacity | |

| [5–35] [32] | W/(m · K) | thermal conductivity | |

| [0–1] | 1 | liquid fraction | |

| 1823 | K | liquidus temperature | |

| 1773 | K | solidus temperature | |

| 25 | C | ambient temperature | |

| J/kg | latent heat | ||

| W/(m· K) | Stefan–Boltzmann constant | ||

| 24 [22] | convection coefficient | ||

| 1 | emissivity | ||

| P | [200–400] | W | laser power |

| I | W/m | laser heat flux | |

| r | 70 | m | laser spot radius |

| V | [0.2–0.4] | m/s | scanning speed |

| A | 1 | laser absorption coefficient | |

| 1 | Absorptance of the workpiece | ||

| B | 2 | 1 | Gaussian shape factor |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

De La Batut, B.; Fergani, O.; Brotan, V.; Bambach, M.; El Mansouri, M. Analytical and Numerical Temperature Prediction in Direct Metal Deposition of Ti6Al4V. J. Manuf. Mater. Process. 2017, 1, 3. https://doi.org/10.3390/jmmp1010003

De La Batut B, Fergani O, Brotan V, Bambach M, El Mansouri M. Analytical and Numerical Temperature Prediction in Direct Metal Deposition of Ti6Al4V. Journal of Manufacturing and Materials Processing. 2017; 1(1):3. https://doi.org/10.3390/jmmp1010003

Chicago/Turabian StyleDe La Batut, Benoit, Omar Fergani, Vegard Brotan, Markus Bambach, and Mohamed El Mansouri. 2017. "Analytical and Numerical Temperature Prediction in Direct Metal Deposition of Ti6Al4V" Journal of Manufacturing and Materials Processing 1, no. 1: 3. https://doi.org/10.3390/jmmp1010003