Improving the Tribological Properties of Gear Synchronizations by Adjusting the Metalworking Fluid Composition of the Grinding Process

Abstract

:1. Introduction

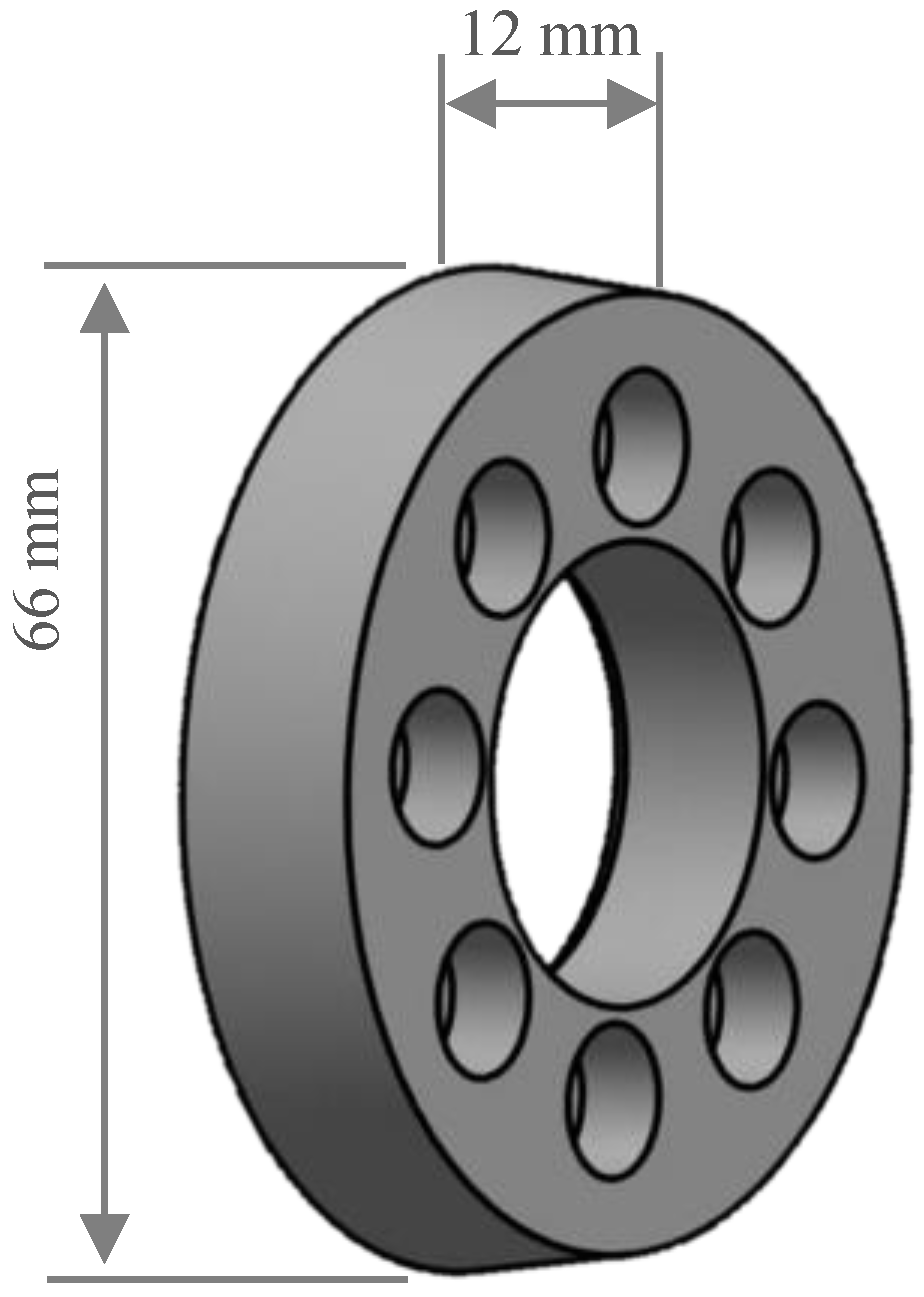

2. Experimental Set-Up

3. Results and Discussion

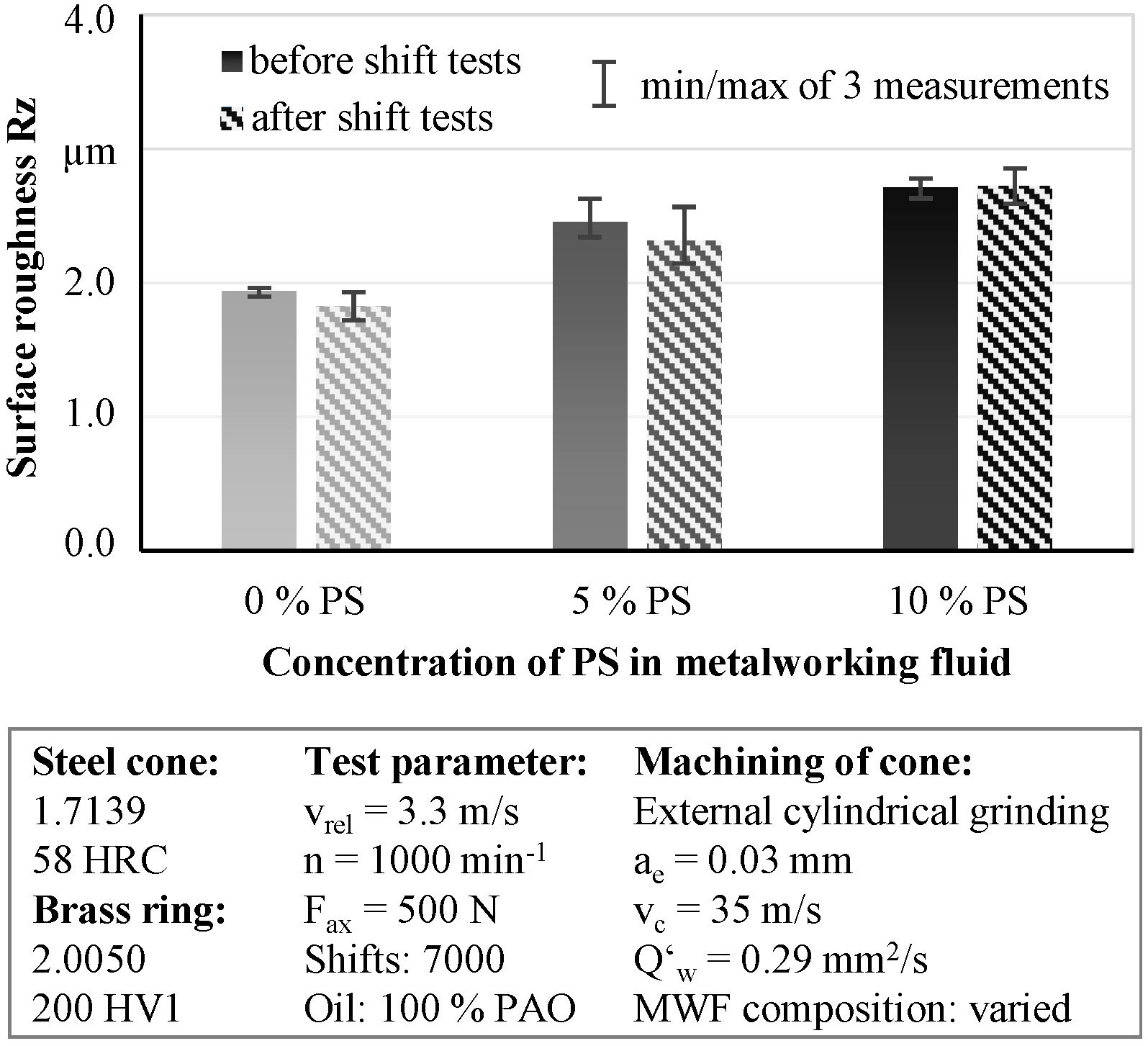

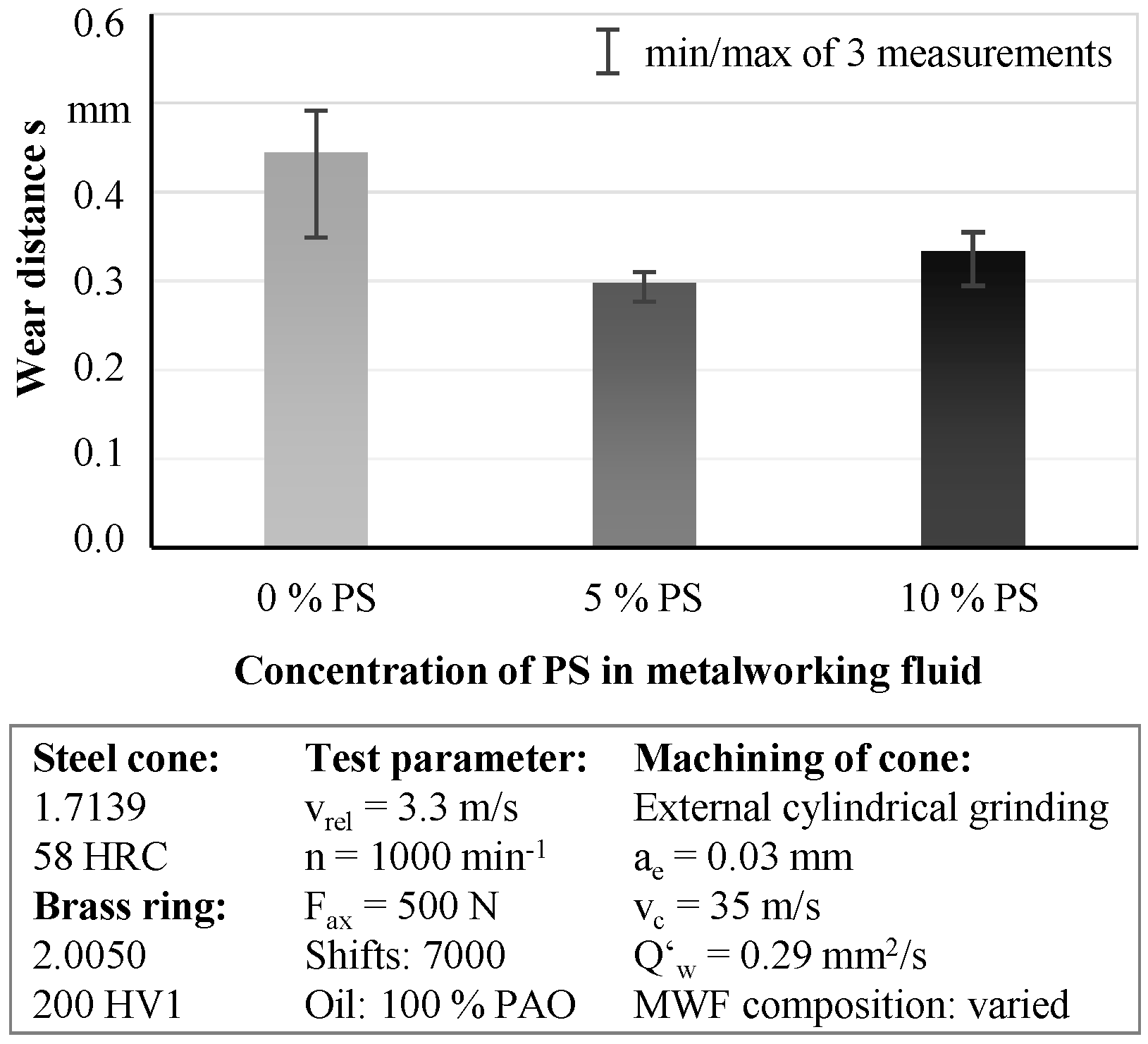

3.1. Variation of the Polysulfide (PS) Concentration

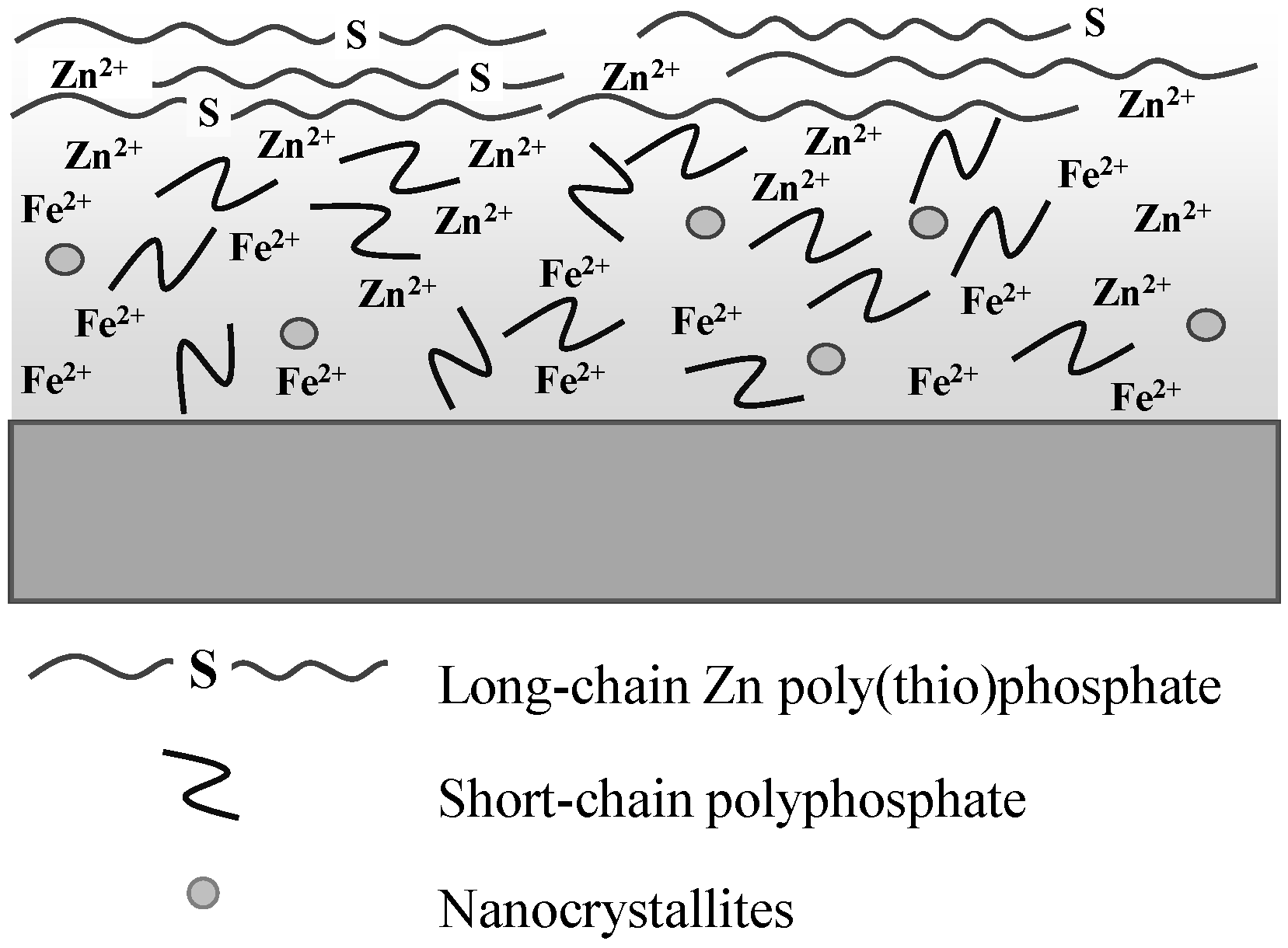

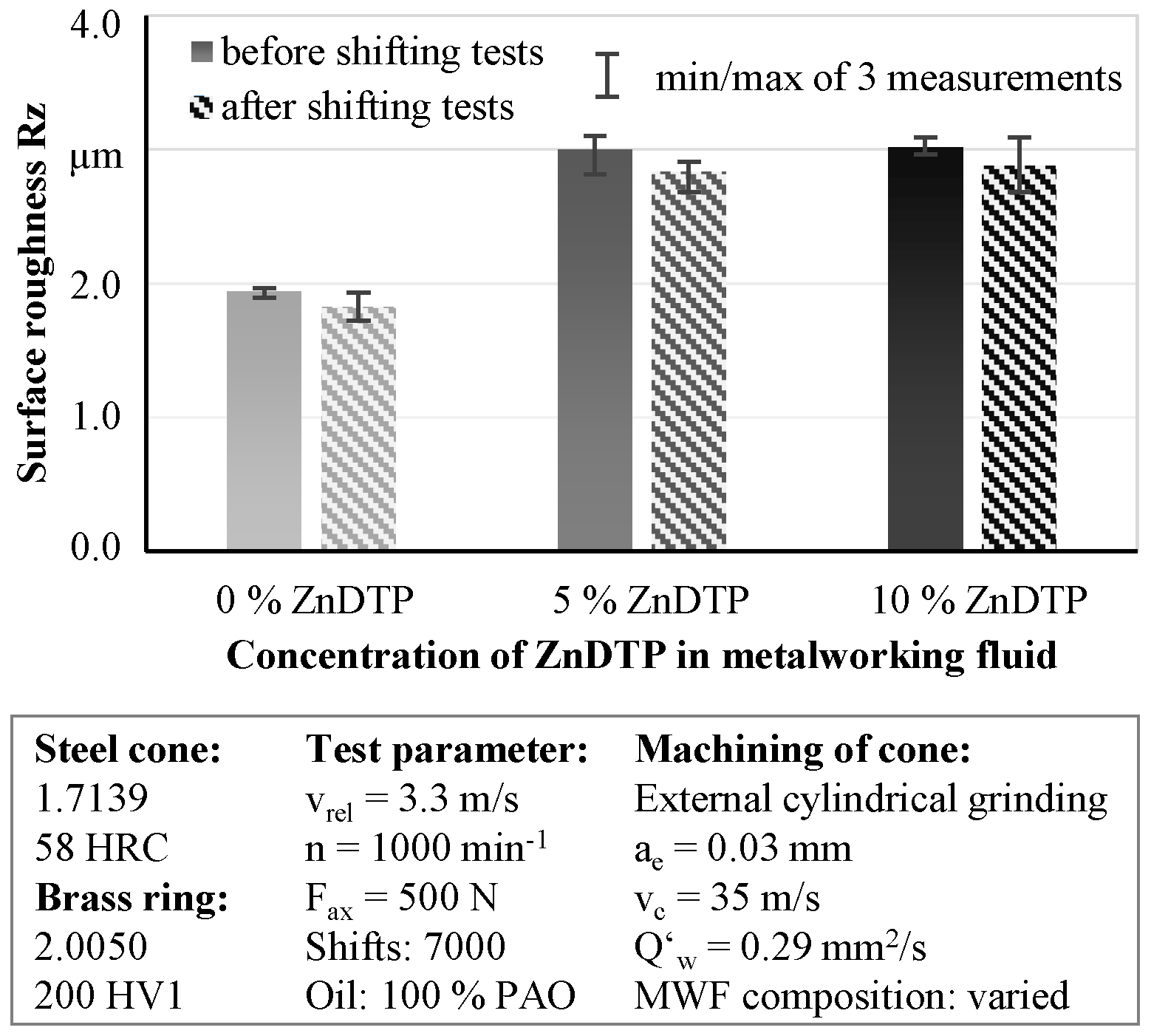

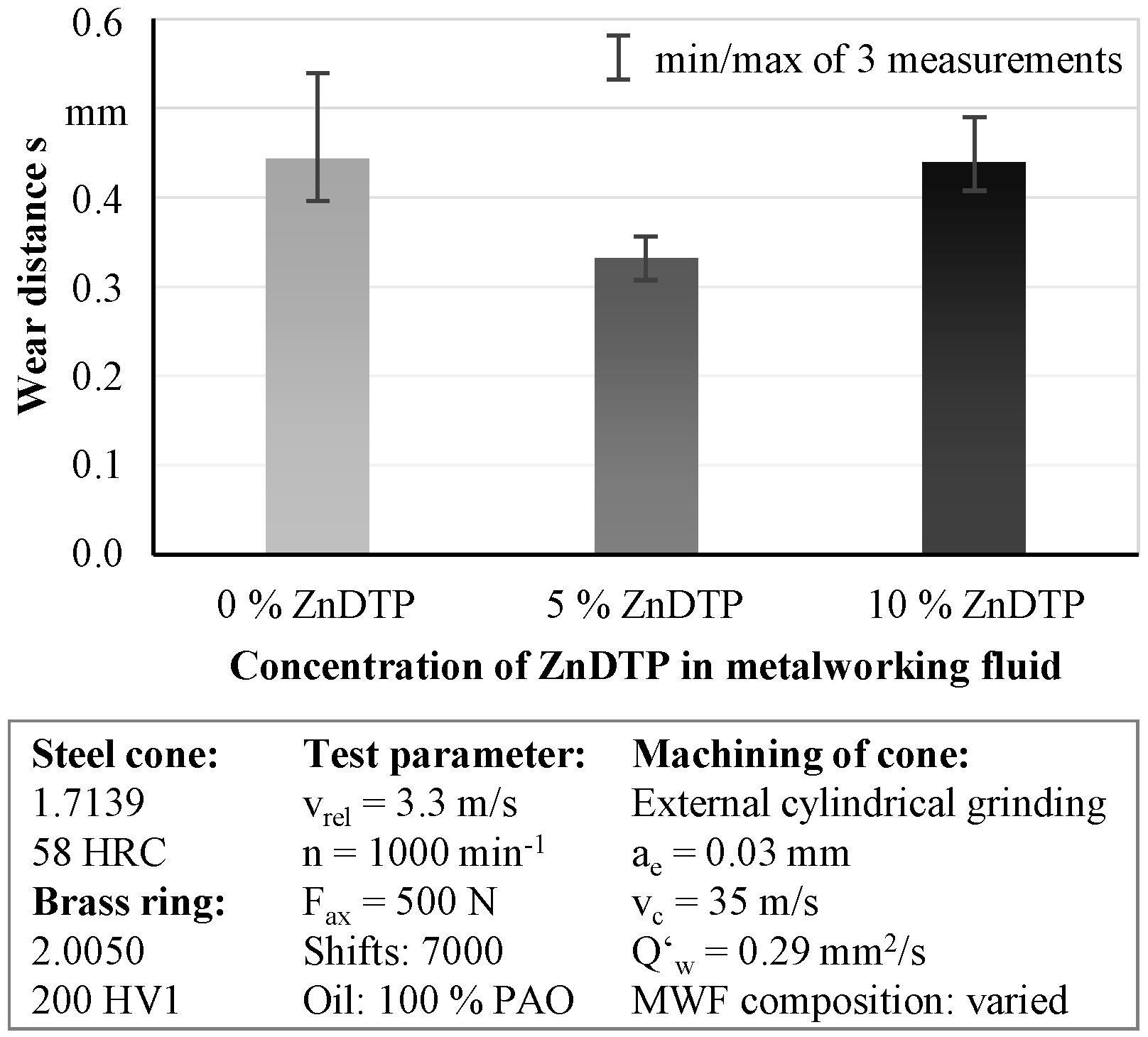

3.2. Variation of the Zincdialkyldithiophosphate (ZnDTP) Concentration

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Clark, J.R.; Grant, M.B. The effect of surface finish on component performance. Int. J. Mach. Tools Manuf. 1992, 32, 57–66. [Google Scholar] [CrossRef]

- Menezes, P.L.; Kishore; Kailas, S.V.; Lovell, M.R. Response of materials as a function of grinding angle on friction and transfer layer information. Int. J. Adv. Manuf. Technol. 2010, 49, 485–495. [Google Scholar] [CrossRef]

- Goeke, S.; Biermann, D.; Stickel, D.; Stemmer, P.; Fischer, A.; Geenen, K.; Huth, S.; Theisen, W. Enhancing the Surface Integrity of Tribologically Stressed Contacting Surfaces by an Adjusted Surface Topography. Procedia CIRP 2014, 13, 214–218. [Google Scholar] [CrossRef]

- Karpuschewski, B.; Welzel, F.; Risse, K.; Schorgel, M. Reduction of Friction in the Cylinder Running Surface of Internal Combustion Engines by the Finishing Process. Procedia CIRP 2016, 45, 87–90. [Google Scholar] [CrossRef]

- Seidel, B.; Wagner, A.; Brinksmeier, E. Influence of dressing conditions in grinding process on tribological properties of gear synchronizations. HTM J. Heat Treat. Mater. 2017, in press. [Google Scholar]

- Walter, A. Tribophysikalische und Tribochemische Vorgänge in der Kontaktzone bei der Zerspanung. Ph.D. Thesis, University of Bremen, Bremen, Germany, 2002. [Google Scholar]

- Berlet, P.; Dienwiebel, M.; Scherge, M. The effect of sample finishing on the tribology of metal/metal lubricated contacts. Wear 2010, 268, 1518–1523. [Google Scholar] [CrossRef]

- Kirchner, E. Leistungsübertragung in Fahrzeuggetrieben, Grundlagen der Auslegung, Entwicklung und Validierung von Fahrzeuggetrieben und anderen Komponenten; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Poll, G.; Spreckels, M. Influence of temperature distribution on the tribological performance of automotive synchronisers. Tribol. Ser. 2003, 41, 613–621. [Google Scholar] [CrossRef]

- Neudörfer, S. Thermomechanische Einflüsse auf Die Tribologie von Synchronisierungen. Ph.D. Thesis, University of Hannover, Hannover, Germany, 2008. [Google Scholar]

- Lösche, T. Das tribologische Verhalten von Synchronisierungen unter Berücksichtigung des Beanspruchungskollektivs. Ph.D. Thesis, University of Hannover, Hannover, Germany, 1997. [Google Scholar]

- Brinksmeier, E.; Meyer, D.; Huesmann-Cordes, A.G.; Herrmann, C. Metalworking fluids—Mechanisms and performance. CIRP Ann. Manuf. Technol. 2015, 64, 605–628. [Google Scholar] [CrossRef]

- Martin, J.M.; Grossiord, C.; Le Mogne, T.; Bec, S.; Tonck, A. The two-layer structure of Zndtp tribofilms—Part I: AES, XPS and XANES analyses. Tribol. Int. 2001, 34, 523–530. [Google Scholar] [CrossRef]

- Brüning, C. Massenspektrometrische Untersuchungen zum Einfluss der Temperatur auf die Bildung und Zusammensetzung tribologischer Schichten nasslaufender Synchronisationsreibkörper. Ph.D. Thesis, University of Münster, Münster, Germany, 2010. [Google Scholar]

- Attar, H.; Ehtemam-Haghighi, S.; Kent, D.; Okulov, I.V.; Wendrock, H.; Bönisch, M.; Volegov, A.S.; Calin, M.; Eckert, J.; Dargusch, M.S. Nanoindentation and wear properties of Ti and Ti-TiB composite materials produced by selective laser melting. Mater. Sci. Eng. A 2017, 688, 20–26. [Google Scholar] [CrossRef]

- Ehtemam-Haghighi, S.; Prashanth, K.G.; Attar, H.; Chaubey, A.K.; Cao, G.H.; Zhang, L.C. Evaluation of mechanical and wear properties of Ti—xNb—7Fe alloys designed for biomedical applications. Mater. Des. 2016, 111, 592–599. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| External Cylindrical Plunge Grinding | |

| Grinding wheel circumferential speed vc | 35 m/s |

| Workpiece circumferential speed vw | 17.5 m/min |

| Depth of cut ae | 0.03 mm |

| Feed per revolution f | 0.001 mm/U |

| Specific material removal rate Q’w | 0.29 mm2/s |

| Dressing with Single-Point Dresser | |

| Overlapping rate in dressing Ud | 8 |

| Depth of dressing cut aed | 0.02 µm |

| No. | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| PAO (%) | 100 | 95 | 90 | 95 | 90 |

| PS (%) | - | 5 | 10 | - | - |

| ZnDTP (%) | - | - | - | 5 | 10 |

| Parameter | Value |

|---|---|

| Steel synchronizer cone | 1.7139/16MnCrs5 |

| Brass synchronizer ring | 2.0550/CW713R |

| Circumferential speed before gear shift vrel | 3.3 m/s |

| Number of revolutions before gear shift n | 1000 min−1 |

| Axial force Fax | 500 N |

| Total shifts | 7000 |

| Cycle time ts | 3 s |

| Transmission oil | 100% PAO |

| Transmission oil temperature Tl | 80 °C |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Seidel, B.; Wagner, A.; Brinksmeier, E. Improving the Tribological Properties of Gear Synchronizations by Adjusting the Metalworking Fluid Composition of the Grinding Process. J. Manuf. Mater. Process. 2017, 1, 4. https://doi.org/10.3390/jmmp1010004

Seidel B, Wagner A, Brinksmeier E. Improving the Tribological Properties of Gear Synchronizations by Adjusting the Metalworking Fluid Composition of the Grinding Process. Journal of Manufacturing and Materials Processing. 2017; 1(1):4. https://doi.org/10.3390/jmmp1010004

Chicago/Turabian StyleSeidel, Benedikt, André Wagner, and Ekkard Brinksmeier. 2017. "Improving the Tribological Properties of Gear Synchronizations by Adjusting the Metalworking Fluid Composition of the Grinding Process" Journal of Manufacturing and Materials Processing 1, no. 1: 4. https://doi.org/10.3390/jmmp1010004