Performance of the Commercial PP/ZnS:Cu and PP/ZnS:Ag Scintillation Screens for Fast Neutron Imaging

Abstract

:1. Introduction

2. Materials and Methods

3. Results

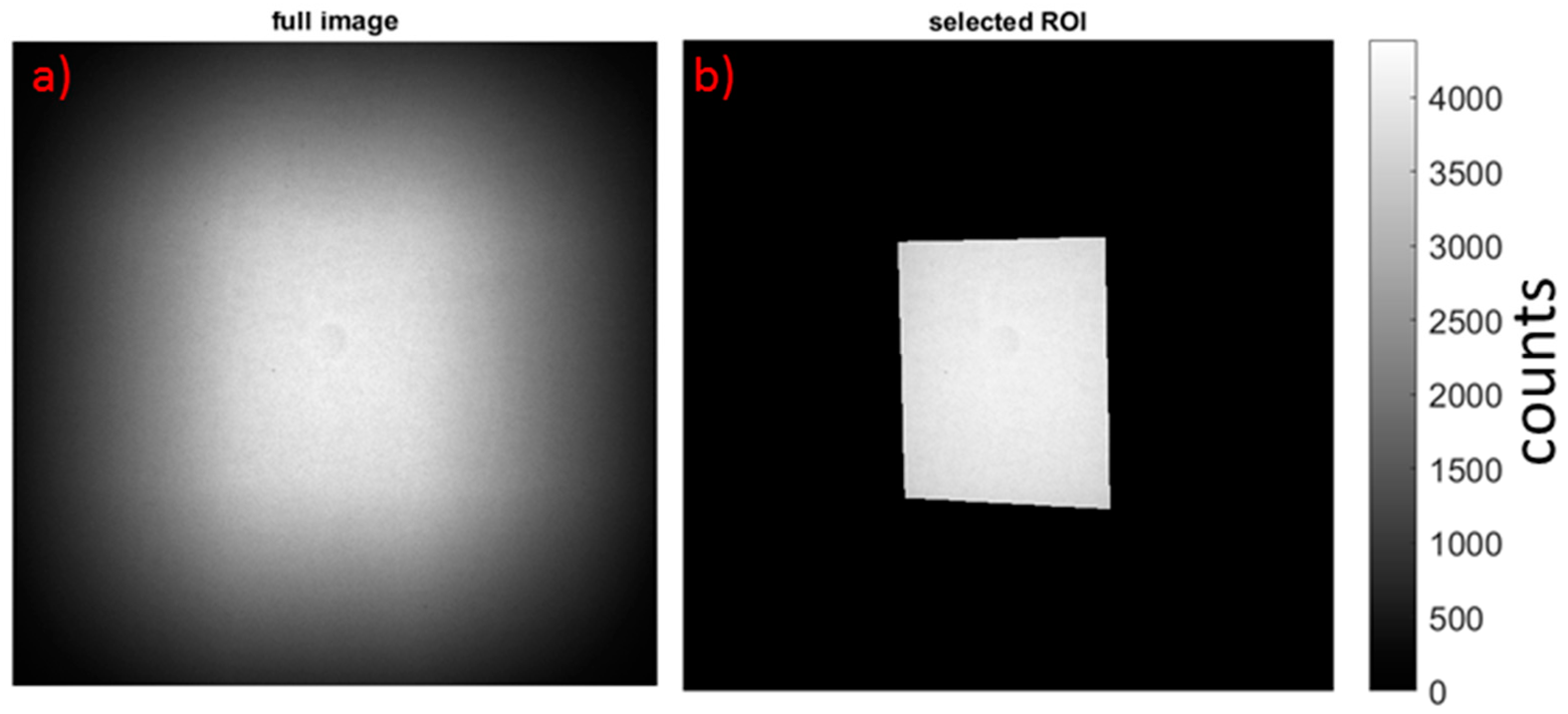

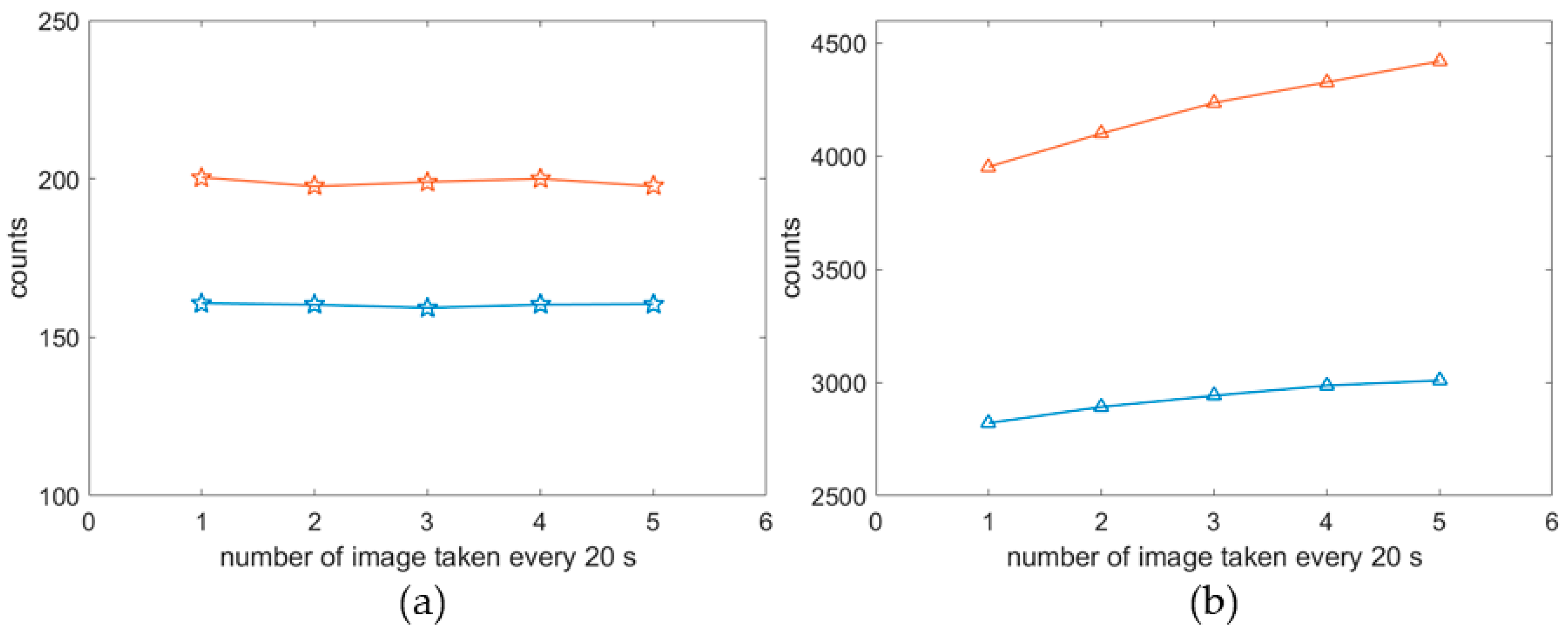

3.1. Light Output Analysis

3.2. Gamma Sensitivity of Sctinttilator Screens

3.3. Influence of the Exposure Times

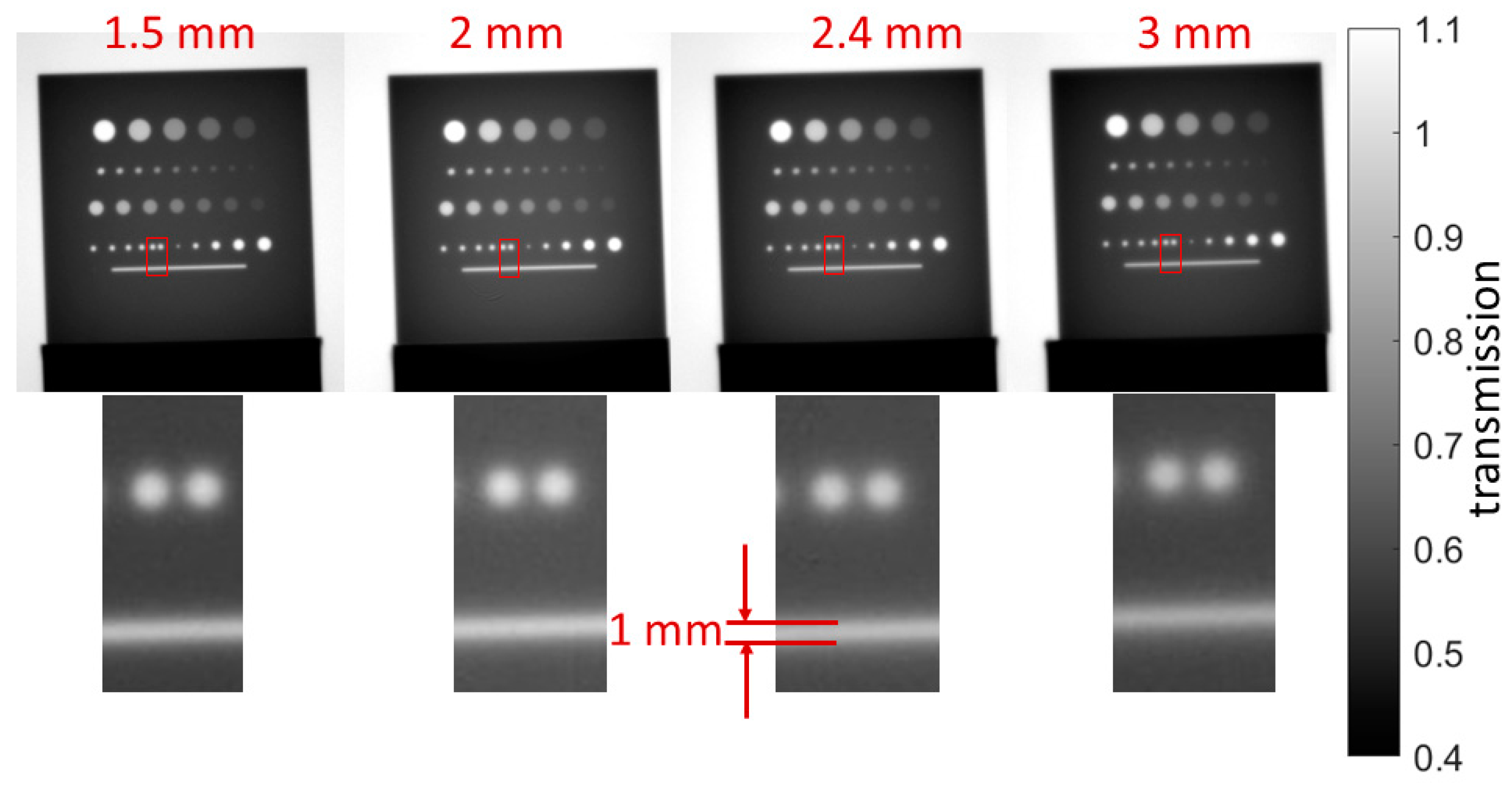

3.4. Spatial Resolution Considerations

4. Discussion

Author Contributions

Conflicts of Interest

References

- Kaestner, A.P.; Hartmann, S.; Kühne, G.; Frei, G.; Grünzweig, C.; Josic, L.; Schmid, F.; Lehmann, E.H. The ICON beamline—A facility for cold neutron imaging at SINQ. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrom. Detect. Assoc. Equip. 2011, 659, 387–393. [Google Scholar] [CrossRef]

- Kardjilov, N.; Hilger, A.; Manke, I.; Woracek, R.; Banhart, J. CONRAD-2: The new neutron imaging instrument at the Helmholtz-Zentrum Berlin. J. Appl. Crystallogr. 2016, 49, 195–202. [Google Scholar] [CrossRef]

- Schulz, M.; Schillinger, B. ANTARES: Cold neutron radiography and tomography facility. J. Large-Scale Res. Facil. 2015, 1, 17. [Google Scholar] [CrossRef]

- NIST Neutron Imaging Facility (NIF). Available online: https://www.nist.gov/laboratories/tools-instruments/neutron-imaging-facility-nif (accessed on 16 October 2017).

- Garbe, U.; Ahuja, Y.; Ibrahim, R.; Li, H.; Aldridge, L.; Salvemini, F.; Paradowska, A.Z. Industrial application experiments on the neutron imaging instrument DINGO. Phys. Procedia 2017, 88, 13–18. [Google Scholar] [CrossRef]

- Kiyanagi, Y.; Kamiyama, T.; Sato, H.; Shinohara, T.; Kai, T.; Aizawa, K.; Arai, M.; Harada, M.; Sakai, K.; Oikawa, K.; et al. Design study of the imaging beam line at J-PARC MLF, ERNIS. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrom. Detect. Assoc. Equip. 2011, 651, 16–20. [Google Scholar] [CrossRef]

- Kockelmann, W.; Burca, G.; Kelleher, J.F.; Kabra, S.; Zhang, S.Y.; Rhodes, N.J.; Schooneveld, E.M.; Sykora, J.; Pooley, D.E.; Nightingale, J.B.; et al. Status of the Neutron Imaging and Diffraction Instrument IMAT. Phys. Procedia 2015, 69, 71–78. [Google Scholar] [CrossRef]

- Bilheux, H.; Herwig, K.; Keener, S.; Davis, L. Overview of the conceptual design of the future venus neutron imaging beam line at the spallation neutron source. Phys. Procedia 2015, 69, 55–59. [Google Scholar] [CrossRef]

- Strobl, M. The Scope of the Imaging Instrument Project ODIN at ESS. Phys. Procedia 2015, 69, 18–26. [Google Scholar] [CrossRef]

- Bücherl, T.; Söllradl, S. NECTAR: Radiography and tomography station using fission neutrons. J. Large-Scale Res. Facil. 2015, 1, 19. [Google Scholar] [CrossRef]

- Mühlbauer, M.J.; Bücherl, T.; Genreith, C.; Knapp, M.; Schulz, M.; Söllradl, S.; Wagner, F.M.; Ehrenberg, H. The Thermal Neutron Beam Option for NECTAR at MLZ. Phys. Procedia 2017, 88, 148–153. [Google Scholar] [CrossRef]

- Woracek, R.; Santisteban, J.; Fedrigo, A.; Strobl, M. Diffraction in neutron imaging—A review. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrom. Detect. Assoc. Equip. 2017. [Google Scholar] [CrossRef]

- Strobl, M.; Manke, I.; Kardjilov, N.; Hilger, A.; Dawson, M.; Banhart, J. Advances in neutron radiography and tomography. J. Phys. D Appl. Phys. 2009, 42, 243001. [Google Scholar] [CrossRef]

- Rücker, U.; Cronert, T.; Voigt, J.; Dabruck, J.P.; Doege, P.-E.; Ulrich, J.; Nabbi, R.; Beßler, Y.; Butzek, M.; Büscher, M.; et al. The Jülich high-brilliance neutron source project. Eur. Phys. J. Plus 2016, 131, 19. [Google Scholar] [CrossRef]

- Adams, R.; Zboray, R.; Prasser, H.-M. A novel fast-neutron tomography system based on a plastic scintillator array and a compact D–D neutron generator. Appl. Radiat. Isot. 2016, 107, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Adams, R.; Bort, L.; Zboray, R.; Prasser, H.-M. Development and characterization of a D–D fast neutron generator for imaging applications. Appl. Radiat. Isot. 2015, 96, 114–121. [Google Scholar] [CrossRef] [PubMed]

- High Yield Neutron Generator—Phoenix Nuclear Labs. Available online: http://phoenixnuclearlabs.com/product/high-yield-neutron-generator/ (accessed on 18 October 2017).

- Tötzke, C.; Manke, I.; Hilger, A.; Choinka, G.; Kardjilov, N.; Arlt, T.; Markötter, H.; Schröder, A.; Wippermann, K.; Stolten, D.; et al. Large area high resolution neutron imaging detector for fuel cell research. J. Power Sources 2011, 196, 4631–4637. [Google Scholar] [CrossRef]

- Schillinger, B.; Lehmann, E. Scientific Reviews: Detectors for Neutron Imaging. Neutron News 2006, 17, 19–21. [Google Scholar] [CrossRef]

- Lehmann, E.H.; Tremsin, A.; Grünzweig, C.; Johnson, I.; Boillat, P.; Josic, L. Neutron imaging—Detector options in progress. J. Instrum. 2011, 6, 1–15. [Google Scholar] [CrossRef]

- Cortesi, M.; Zboray, R.; Adams, R.; Dangendorf, V.; Prasser, H.M. Concept of a novel fast neutron imaging detector based on THGEM for fan-beam tomography applications. J. Instrum. 2012, 7, C02056. [Google Scholar] [CrossRef]

- Cortesi, M.; Zboray, R.; Adams, R.; Dangendorf, V.; Meshkian, M.; Prasser, H.-M. Development of large-area THGEM detectors for investigation of thermal-hydraulic phenomena using neutron imaging. J. Instrum. 2013, 8, C10009. [Google Scholar] [CrossRef]

- Cortesi, M.; Dangendorf, V.; Zboray, R.; Prasser, H.-M. A novel fast-neutron detector concept for energy-selective imaging and imaging spectroscopy. Rev. Sci. Instrum. 2014, 85, 73305. [Google Scholar] [CrossRef] [PubMed]

- Mor, I.; Vartsky, D.; Bar, D.; Feldman, G.; Goldberg, M.B.; Katz, D.; Sayag, E.; Shmueli, I.; Cohen, Y.; Tal, A.; et al. High spatial resolution fast-neutron imaging detectors for Pulsed Fast-Neutron Transmission Spectroscopy. J. Instrum. 2009, 4, P05016. [Google Scholar] [CrossRef]

- Brandis, M.; Vartsky, D.; Dangendorf, V.; Bromberger, B.; Bar, D.; Goldberg, M.B.; Tittelmeier, K.; Friedman, E.; Czasch, A.; Mardora, I.; et al. Neutron measurements with Time-Resolved Event-Counting Optical Radiation (TRECOR) detector. J. Instrum. 2012, 7, C04003. [Google Scholar] [CrossRef]

- Matsubayashi, M.; Hibiki, T.; Mishima, K.; Yoshii, K.; Okamoto, K. Development of a fast neutron radiography converter using wavelength-shifting fibers. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrom. Detect. Assoc. Equip. 2003, 510, 325–333. [Google Scholar] [CrossRef]

- Zou, Y.; Guo, L.; Guo, Z.; Tang, G.; Zhang, G. Development of a converter made of scintillator and wavelength-shifting fibers for fast neutron radiography. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrom. Detect. Assoc. Equip. 2009, 605, 73–76. [Google Scholar] [CrossRef]

- Guo, J.; Bücherl, T.; Zou, Y.; Guo, Z.; Tang, G. Comparison of the performance of different converters for neutron radiography and tomography using fission neutrons. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrom. Detect. Assoc. Equip. 2009, 605, 69–72. [Google Scholar] [CrossRef]

- Ronda, C.R. Emission and Excitation Mechanisms of Phosphors. In Luminescence: From Theory to Applications; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2007; pp. 1–34. [Google Scholar]

- Yang, W.; Bin, T.; Heyong, H.; Bin, L.; Ke, T.; Yong, S.; Wei, Y.; Chao, C. The study of zinc sulphide scintillator for fast neutron radiography. Phys. Procedia 2013, 43, 205–215. [Google Scholar] [CrossRef]

- Scintillators: RC TRITEC AG, Teufen AR. Available online: http://www.rctritec.com/en/scintillators.html (accessed on 16 October 2017).

- Bücherl, T.; Von Gostomski, C.L.; Breitkreutz, H.; Jungwirth, M.; Wagner, F.M. NECTAR—A fission neutron radiography and tomography facility. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrom. Detect. Assoc. Equip. 2011, 651, 86–89. [Google Scholar] [CrossRef]

- Jungwirth, M.; Breitkreutz, H.; Wagner, F.M.; Bücherl, T. Determination of the photon spectrum in an intense fission neutron beam. J. Instrum. 2012, 7, C03022. [Google Scholar] [CrossRef]

- Andor’s iKon-L High Dynamic Range CCD Camera. Available online: http://www.andor.com/scientific-cameras/ikon-xl-and-ikon-large-ccd-series/ikon-l-936 (accessed on 16 October 2017).

- Bücherl, T.; Kalthoff, O.; von Gostomski, C.L. A feasibility study on reactor based fission neutron radiography of 200-L waste packages. Phys. Procedia 2017, 88, 64–72. [Google Scholar] [CrossRef]

- Grünzweig, C.; Frei, G.; Lehmann, E.; Kühne, G.; David, C. Highly absorbing gadolinium test device to characterize the performance of neutron imaging detector systems. Rev. Sci. Instrum. 2007, 78, 53708. [Google Scholar] [CrossRef] [PubMed]

| dscint (mm) | FWHM (PP/ZnS:Ag) | FWHM (PP/ZnS:Cu) | Spatial Freqency at MTF 10% (lp/mm) (PP/ZnS:Ag) | Spatial Freqency at MFT 10% (lp/mm) (PP/ZnS:Cu) |

|---|---|---|---|---|

| 1.5 | 1.5 | 1.53 | 2 | 2 |

| 2.0 | 1.62 | 1.70 | 1.7 | 1.6 |

| 2.4 | 1.71 | 1.80 | 1.6 | 1.4 |

| 3.0 | 1.79 | 2.00 | 1.4 | 1.2 |

| dscint (mm) | c/a (PP/ZnS:Ag) | c/a (PP/ZnS:Cu) | dPb (mm) (PP/ZnS:Ag) 1% γ | dPb (mm) (PP/ZnS:Ag) 10% γ | dPb (mm) (PP/ZnS:Cu) 1% γ | dPb (mm) (PP/ZnS:Cu) 10% γ |

|---|---|---|---|---|---|---|

| 1.5 | 2.0 | 1.1 | 95 | 36 | 144 | 68 |

| 2.0 | 3.3 | 1.0 | 68 | 20 | 141 | 67 |

| 2.4 | 1.7 | 1.1 | 96 | 40 | 150 | 70 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Makowska, M.G.; Walfort, B.; Zeller, A.; Grünzweig, C.; Bücherl, T. Performance of the Commercial PP/ZnS:Cu and PP/ZnS:Ag Scintillation Screens for Fast Neutron Imaging. J. Imaging 2017, 3, 60. https://doi.org/10.3390/jimaging3040060

Makowska MG, Walfort B, Zeller A, Grünzweig C, Bücherl T. Performance of the Commercial PP/ZnS:Cu and PP/ZnS:Ag Scintillation Screens for Fast Neutron Imaging. Journal of Imaging. 2017; 3(4):60. https://doi.org/10.3390/jimaging3040060

Chicago/Turabian StyleMakowska, Malgorzata G., Bernhard Walfort, Albert Zeller, Christian Grünzweig, and Thomas Bücherl. 2017. "Performance of the Commercial PP/ZnS:Cu and PP/ZnS:Ag Scintillation Screens for Fast Neutron Imaging" Journal of Imaging 3, no. 4: 60. https://doi.org/10.3390/jimaging3040060