Synthesis and Electrochemical Performance of Ni-Doped VO2(B) as a Cathode Material for Lithium Ion Batteries

Abstract

:1. Introduction

2. Experimental

2.1. Synthesis of Ni-Doped VO2(B)

2.2. Characterization

2.3. Electrochemical Tests

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Harks, P.P.R.M.L.; Mulder, F.M.; Notten, P.H.L. In situ methods for Li-ion battery research: A review of recent developments. J. Power Sources 2015, 288, 92–105. [Google Scholar] [CrossRef] [Green Version]

- Goodenough, J.B.; Park, K.S. The Li-ion rechargeable battery: A perspective. J. Am. Chem. Soc. 2013, 135, 1167–1176. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.; Lin, F.; Doeff, M.M.; Tong, W. A review of Ni-based layered oxides for rechargeable Li-ion batteries. J. Mater. Chem. A 2017, 5, 874–901. [Google Scholar] [CrossRef]

- Yang, Z.; Zhang, J.; Kintner-Meyer, M.C.; Lu, X.; Choi, D.; Lemmon, J.P.; Liu, J. Electrochemical energy storage for green grid. Chem. Rev. 2011, 111, 3577–3613. [Google Scholar] [CrossRef] [PubMed]

- Huie, M.M.; Bock, D.C.; Takeuchi, E.S.; Marschilok, A.C.; Takeuchi, K.J. Cathode materials for magnesium and magnesium-ion based batteries. Coord. Chem. Rev. 2015, 287, 15–27. [Google Scholar] [CrossRef]

- Li, H.; He, P.; Wang, Y.; Hosono, E.; Zhou, H. High-surface vanadium oxides with large capacities for lithium-ion batteries: from hydrated aerogel to nanocrystalline VO2(B), V6O13 and V2O5. J. Mater. Chem. 2011, 21, 10999–11009. [Google Scholar] [CrossRef]

- Ding, N.; Feng, X.; Liu, S.; Xu, J.; Fang, X.; Lieberwirth, I.; Chen, C. High capacity and excellent cyclability of vanadium (IV) oxide in lithium battery applications. Electrochem. Commun. 2009, 11, 538–541. [Google Scholar] [CrossRef]

- Yan, B.; Li, X.; Bai, Z.; Lin, L.; Chen, G.; Song, X.; Xiong, D.; Li, D.; Sun, X. Superior sodium storage of novel VO2 nano-microspheres encapsulated into crumpled reduced graphene oxide. J. Mater. Chem. A 2017, 5, 4850–4860. [Google Scholar] [CrossRef]

- Niu, C.; Meng, J.; Han, C.; Zhao, K.; Yan, M.; Mai, L. VO2 nanowires assembled into hollow microspheres for high-rate and long-life lithium batteries. Nano Lett. 2014, 14, 2873–2878. [Google Scholar] [CrossRef]

- Reddy, C.V.S.; Walker, E.H., Jr.; Wicker, S.A., Sr.; Williams, Q.L.; Kalluru, R.R. Synthesis of VO2 (B) nanorods for Li battery application. Curr. Appl. Phys. 2009, 9, 1195–1198. [Google Scholar] [CrossRef]

- Mai, L.; Wei, Q.; An, Q.; Tian, X.; Zhao, Y.; Xu, X.; Xu, L.; Chang, L.; Zhang, Q. Nanoscroll Buffered Hybrid Nanostructural VO2 (B) Cathodes for High-Rate and Long-Life Lithium Storage. Adv. Mater. 2013, 25, 2969–2973. [Google Scholar] [CrossRef]

- Zhao, Q.; Jiao, L.; Peng, W.; Gao, H.; Yang, J.; Wang, Q.; Du, H.; Li, L.; Qi, Z.; Si, Y.; et al. Facile synthesis of VO2 (B)/carbon nanobelts with high capacity and good cyclability. J. Power Sources 2012, 199, 350–354. [Google Scholar] [CrossRef]

- Wang, F.; Liu, Y.; Liu, C.Y. Hydrothermal synthesis of carbon/vanadium dioxide core–shell microspheres with good cycling performance in both organic and aqueous electrolytes. Electrochim. Acta 2010, 55, 2662–2666. [Google Scholar] [CrossRef]

- Liu, G.; Du, Y.; Liu, W.; Wen, L. Study on the action mechanism of doping transitional elements in spinel LiNi0. 5Mn1. 5O4. Electrochim. Acta 2016, 209, 308–314. [Google Scholar] [CrossRef]

- Fang, D.L.; Li, J.C.; Liu, X.; Huang, P.F.; Xu, T.R.; Qian, M.C.; Zheng, C.H. Synthesis of a Co–Ni doped LiMn2O4 spinel cathode material for high-power Li-ion batteries by a sol–gel mediated solid-state route. J. Alloys Compd. 2015, 640, 82–89. [Google Scholar] [CrossRef]

- Zou, Z.G.; Hou, Z.L.; Wang, J.L.; Gao, Y.; Wan, Z.D. Hydrothermal Synthesis and Electrochemical Performance of Al-doped VO2(B) as Cathode Materials for Lithium-Ion Battery. Int. J. Electrochem. Sci. 2017, 12, 4979–4989. [Google Scholar] [CrossRef]

- Han, S.C.; Zou, Z.G.; Lv, T.T.; Wu, X.Y.; Yang, Q. Synthesis and electrochemical performance of Ag- doped VO2(B) as cathode materials. CIESC J. 2018, 69, 1741–1748. [Google Scholar]

- Zhang, B.; Ming, L.; Tong, H.; Zhang, J.F.; Zheng, J.C.; Wang, X.W.; Li, H.; Cheng, L. Ni-doping to improve the performance of LiFeBO3/C cathode material for lithium-ion batteries. J. Alloys Compd. 2018, 740, 382–388. [Google Scholar] [CrossRef]

- Zhang, B.; Chen, H.; Tong, H.; Wang, X.; Zheng, J.; Yu, W.; Zhang, J.; Li, J.; Zhang, W. Synthesis and electrochemical performance of Ni doped Na3V2(PO4)3/C cathode materials for sodium ion batteries. J. Alloys Compd. 2017, 728, 976–983. [Google Scholar] [CrossRef]

- Asif, M.; Rashad, M.; Ali, Z.; Qiu, H.; Li, W.; Pan, L.; Hou, Y. Ni-doped MnO2/CNT nanoarchitectures as a cathode material for ultra-long life magnesium/lithium hybrid ion batteries. Mater. Today Energy 2018, 10, 108–117. [Google Scholar] [CrossRef]

- Yu, A.; Kumagai, N.; Liu, Z.; Lee, J.Y. A new method for preparing lithiated vanadium oxides and their electrochemical performance in secondary lithium batteries. J. Power Sources 1998, 74, 117–121. [Google Scholar] [CrossRef]

- Liu, Y.C.; Wu, N.L.; Liu, W.R. Electrochemical Properties of Al3+/Cl− Doped-0.2Li2MnO3·0.8LiNiO2 Cathode Materials for Lithium-Ion Batteries. J. Nanosci. Nanotechnol. 2018, 18, 68–74. [Google Scholar] [CrossRef]

- Piffard, Y.; Leroux, F.; Guyomard, D.; Mansot, J.L.; Tournoux, M. The amorphous oxides MnV2O6 + δ (0 < δ < 1) as high capacity negative electrode materials for lithium batteries. J. Power Sources 1997, 68, 698–703. [Google Scholar]

- Hu, F.; ZHANG, C.H.; Zhang, S.; Ming, X.; Chen, G.; WEI, Y.J.; WANG, C.Z. Electrochemical cycled structure of MnV2O6 nanoribbons synthesized via hydrothermal route. Chem. Res. Chin. Univ. 2011, 27, 528–530. [Google Scholar]

- Yang, L.C.; Gao, Q.S.; Tang, Y.; Wu, Y.P.; Holze, R. MoO2 synthesized by reduction of MoO3 with ethanol vapor as an anode material with good rate capability for the lithium ion battery. J. Power Sources 2008, 179, 357–360. [Google Scholar] [CrossRef]

- Huang, Y.; Lu, H.; Gu, H.; Fu, J.; Mo, S.; Wei, C.; Miao, Y.; Liu, T. A CNT@ MoSe2 hybrid catalyst for efficient and stable hydrogen evolution. Nanoscale 2015, 7, 18595–18602. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Li, C.; Zhang, H.P.; Fu, L.J.; Wu, Y.P.; Wu, H.Q. Kinetic study on LiFePO4/C nanocomposites synthesized by solid state technique. J. Power Sources 2006, 159, 717–720. [Google Scholar] [CrossRef]

- Wang, L.L.; Sun, Z.Z.; Yi, W.T.; Ma, P.H. The Applications of EIS in the Research of LiFePO4 as the Cathode Materials of Li-ion Batteries. J. Salt Lake Res. 2008, 16, 21–26. [Google Scholar]

| Sample Designation | Ni:V Atomic Percentage (Starting Composition) | Ni:V Atomic Percentage (Actual Composition) |

|---|---|---|

| Ni0 | 0 | 0 |

| Ni1 | 1% | 0.45% |

| Ni2 | 2% | 0.66% |

| Ni3 | 3% | 1.50% |

| Ni4 | 4% | 1.80% |

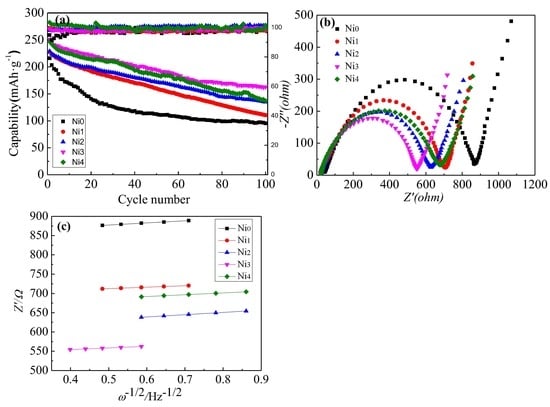

| Sample Designation | σ | DLi |

|---|---|---|

| Ni0 | 58.2773 | 2.82 × 10−15 |

| Ni1 | 46.5196 | 4.426 × 10−15 |

| Ni2 | 42.7479 | 5.24 × 10−15 |

| Ni3 | 37.4864 | 6.815 × 10−15 |

| Ni4 | 55.2987 | 3.13 × 10−15 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Q.; Zou, Z.; Wu, X.; Li, S.; Zhang, Y. Synthesis and Electrochemical Performance of Ni-Doped VO2(B) as a Cathode Material for Lithium Ion Batteries. Batteries 2019, 5, 46. https://doi.org/10.3390/batteries5020046

Yang Q, Zou Z, Wu X, Li S, Zhang Y. Synthesis and Electrochemical Performance of Ni-Doped VO2(B) as a Cathode Material for Lithium Ion Batteries. Batteries. 2019; 5(2):46. https://doi.org/10.3390/batteries5020046

Chicago/Turabian StyleYang, Qian, Zhengguang Zou, Xingyu Wu, Shengyu Li, and Yanjiao Zhang. 2019. "Synthesis and Electrochemical Performance of Ni-Doped VO2(B) as a Cathode Material for Lithium Ion Batteries" Batteries 5, no. 2: 46. https://doi.org/10.3390/batteries5020046