Analysis of Australian Beers Using Fluorescence Spectroscopy

Abstract

:1. Introduction

2. Materials and Methods

2.1. Beer Samples

2.2. Fluorescence Spectroscopy

3. Results

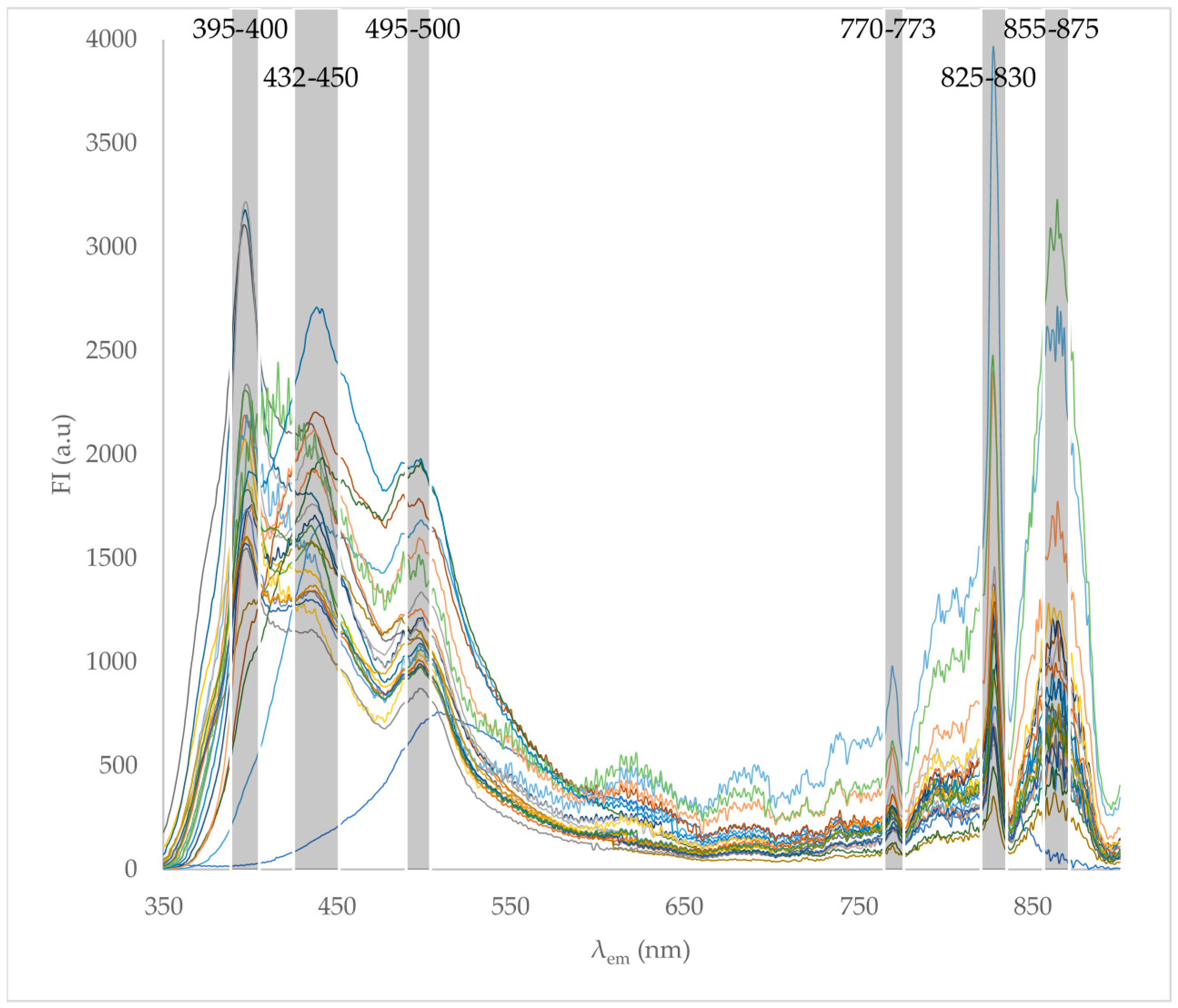

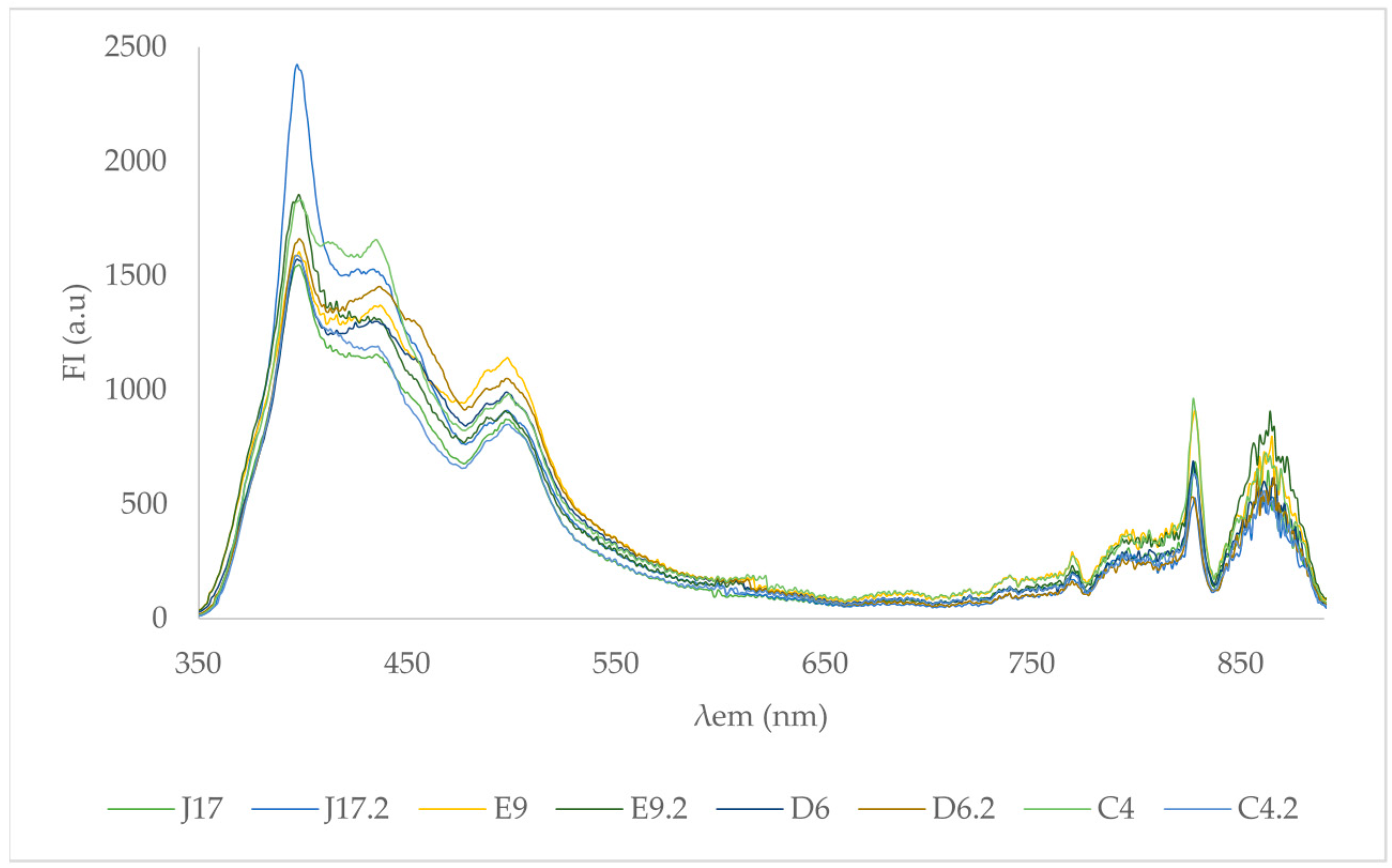

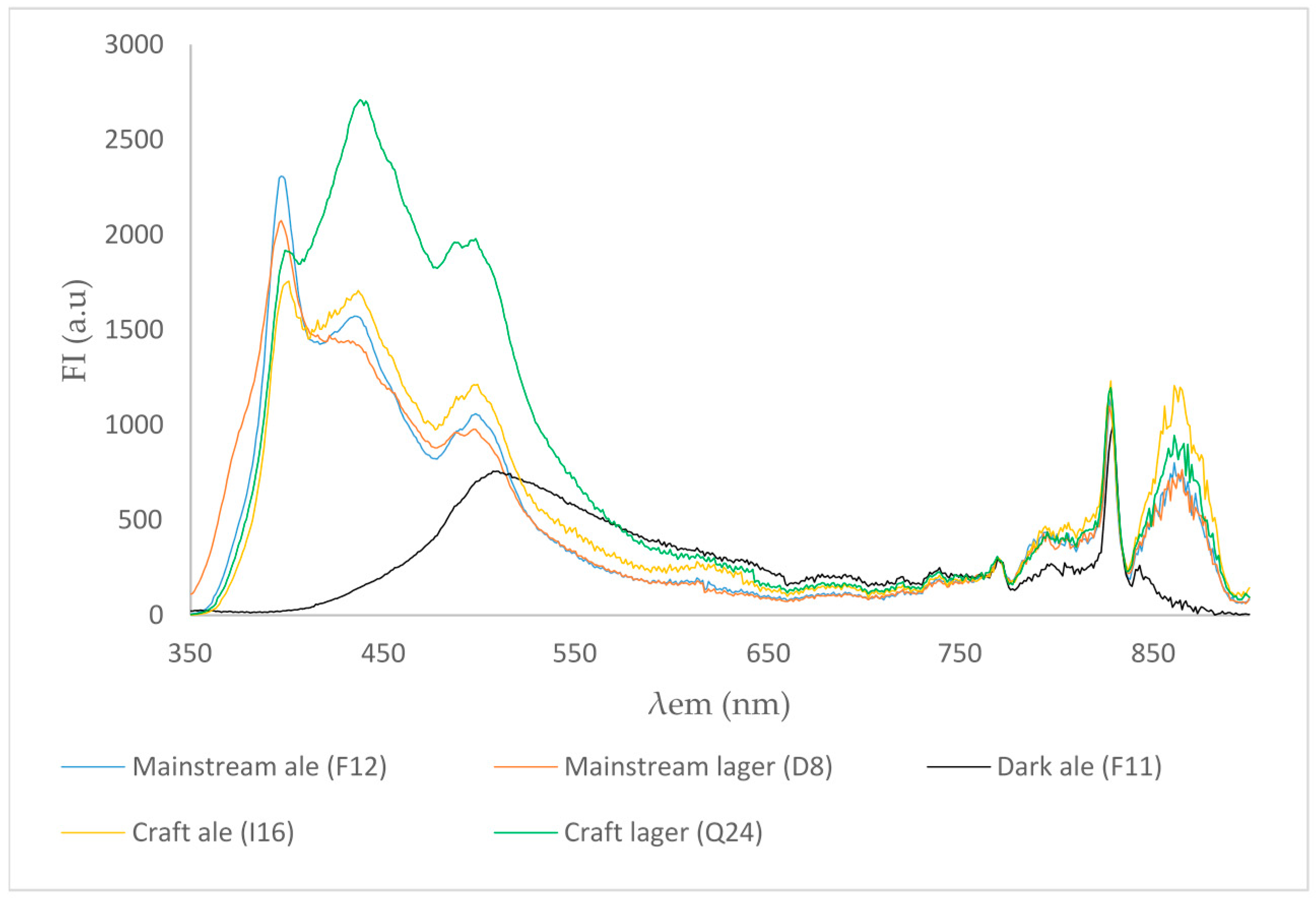

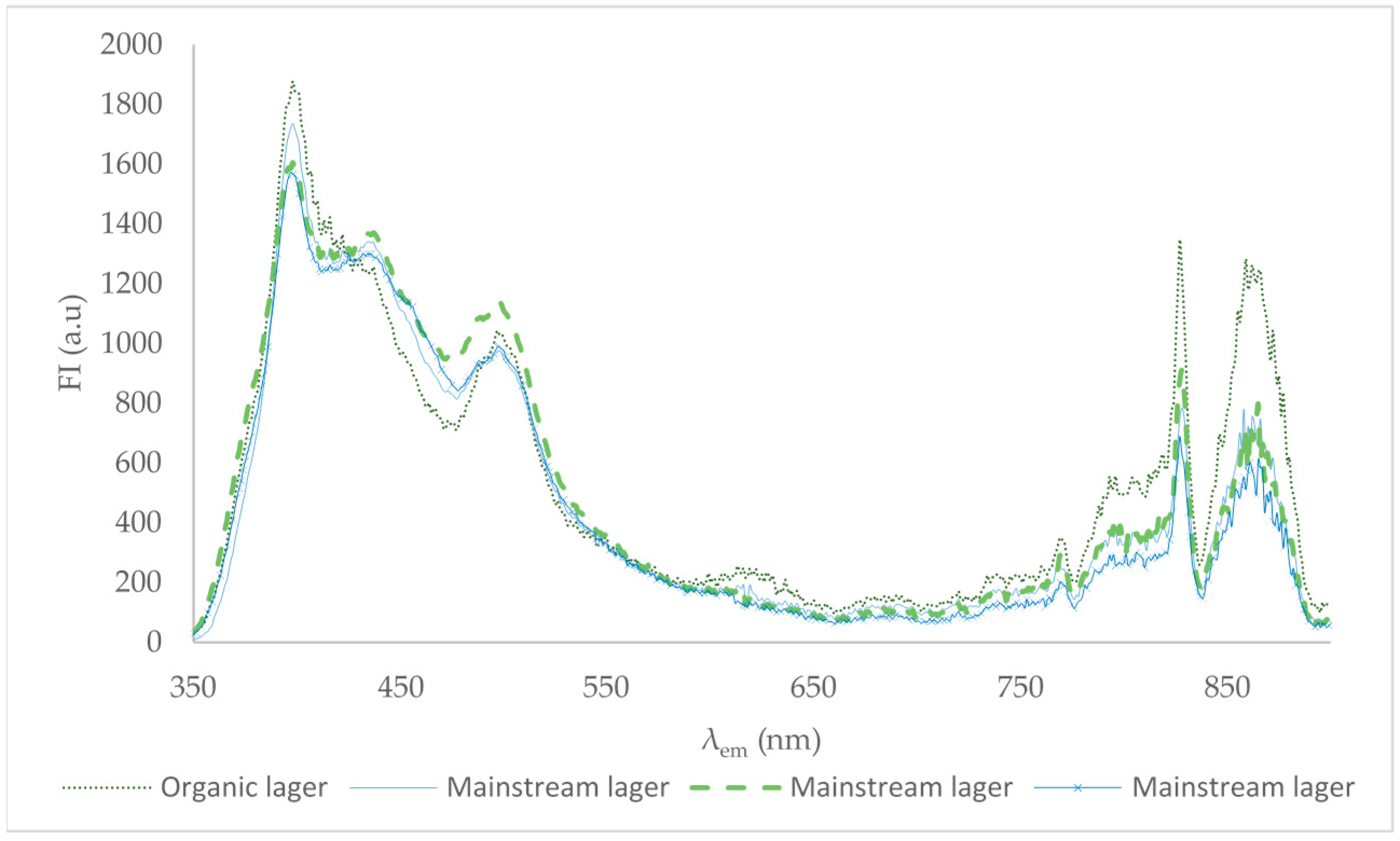

3.1. Synchronous Fluorescence Scan

3.2. Emission Excitation Matrix (EEM) Contour Plots

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Australian Bureau of Statistics. Apparent Consumption of Alcohol. Australia, 2015–16; Cat. No. 4307.0.55.001; Australian Bureau of Statistics: Canberra, Australia, 2017.

- Argent, N. Heading down to the local? Australian rural development and the evolving spatiality of the craft beer sector. J. Rural Stud. 2017. [Google Scholar] [CrossRef]

- Preedy, V.R. Beer in Health and Disease Prevention; Academic Press: Cambridge, MA, USA, 2011. [Google Scholar]

- Marconi, O.; Sileoni, V.; Ceccaroni, D.; Perretti, G. The use of rice in brewing. In Advances in International Rice Research; InTech: London, UK, 2017. [Google Scholar]

- Bogdan, P.; Kordialik-Bogacka, E. Alternatives to malt in brewing. Trends Food Sci. Technol. 2017, 65, 1–9. [Google Scholar] [CrossRef]

- Karoui, R.; Blecker, C. Fluorescence spectroscopy measurement for quality assessment of food systems—A review. Food. Bioprocess Technol. 2011, 4, 364–386. [Google Scholar] [CrossRef]

- Bro, R. Exploratory study of sugar production using fluorescence spectroscopy and multi-way analysis. Chemom. Intell. Lab. Syst. 1999, 46, 133–147. [Google Scholar] [CrossRef]

- Becker, E.M.; Christensen, J.; Frederiksen, C.S.; Haugaard, V.K. Front-face fluorescence spectroscopy and chemometrics in analysis of yogurt: Rapid analysis of riboflavin. J. Dairy Sci. 2003, 86, 2508–2515. [Google Scholar] [CrossRef]

- Christensen, J.; Povlsen, V.T.; Sorensen, J. Application of fluorescence spectroscopy and chemometrics in the evaluation of processed cheese during storage. J. Dairy Sci. 2003, 86, 1101–1107. [Google Scholar] [CrossRef]

- Kongbonga, Y.G.M.; Ghalila, H.; Onana, M.B.; Majdi, Y.; Lakhdar, Z.B.; Mezlini, H.; Sevestre-Ghalila, S. Characterization of vegetable oils by fluorescence spectroscopy. Food Nutr. Sci. 2011, 2, 692. [Google Scholar] [CrossRef]

- Kyriakidis, N.B.; Skarkalis, P. Fluorescence spectra measurement of olive oil and other vegetable oils. J. AOAC Int. 2000, 83, 1435–1439. [Google Scholar] [PubMed]

- Karoui, R.; Dufour, E.; Bosset, J.O.; De Baerdemaeker, J. The use of front face fluorescence spectroscopy to classify the botanical origin of honey samples produced in switzerland. Food Chem. 2007, 101, 314–323. [Google Scholar] [CrossRef]

- Tóthová, J.; Žiak, Ľ.; Sádecká, J. Characterization and classification of distilled drinks using total luminescence and synchronous fluorescence spectroscopy. Acta Chim. Slovaca 2008, 1, 265–275. [Google Scholar]

- Sikorska, E.; Gorecki, T.; Khmelinskii, I.V.; Sikorski, M.; De Keukeleire, D. Fluorescence spectroscopy for characterization and differentiation of beers. J. Inst. Brew. 2004, 110, 267–275. [Google Scholar] [CrossRef]

- Sikorska, E.; Gorecki, T.; Khmelinskii, I.V.; Sikorski, M.; De Keukeleire, D. Monitoring beer during storage by fluorescence spectroscopy. Food Chem. 2006, 96, 632–639. [Google Scholar] [CrossRef]

- Insinska-Rak, M.; Sikorska, E.; Czerwinska, I.; Kruzinska, A.; Nowacka, G.; Sikorski, M. Fluorescence spectroscopy for analysis of beer. Pol. J. Food Nutr. Sci. 2007, 57, 239–243. [Google Scholar]

- Tan, J.; Li, R.; Jiang, Z.T. Chemometric classification of chinese lager beers according to manufacturer based on data fusion of fluorescence, uv and visible spectroscopies. Food Chem. 2015, 184, 30–36. [Google Scholar] [CrossRef] [PubMed]

- Apperson, K.; Leiper, K.A.; McKeown, I.P.; Birch, D.J. Beer fluorescence and the isolation, characterisation and silica adsorption of haze-active beer proteins. J. Inst. Brew. 2002, 108, 193–199. [Google Scholar] [CrossRef]

- Dreve, S.; Voica, C.; Dragan, F.; Georgiu, M. Instrumental Analysis for Differentiation of Beers and Evaluation of Beer Ageing. AIP Conf. Proc. 2013, 290–293. [Google Scholar] [CrossRef]

- Christensen, J.; Norgaard, L.; Bro, R.; Engelsen, S.B. Multivariate autofluorescence of intact food systems. Chem. Rev. 2006, 106, 1979–1994. [Google Scholar] [CrossRef] [PubMed]

- Sauer, M.; Hofkens, J.; Enderlein, J. Handbook of Fluorescence Spectroscopy and Imaging; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2011; pp. I–IX. [Google Scholar]

- Engelen, S.; Moller, S.F.; Hubert, M. Automatically identifying scatter in fluorescence data using robust techniques. Chemom. Intell. Lab. Syst. 2007, 86, 35–51. [Google Scholar] [CrossRef]

- Sikorska, E.; Gliszczynska-Swiglo, A.; Insinska-Rak, M.; Khmelinskii, I.; De Keukeleire, D.; Sikorski, M. Simultaneous analysis of riboflavin and aromatic amino acids in beer using fluorescence and multivariate calibration methods. Anal. Chim. Acta 2008, 613, 207–217. [Google Scholar] [CrossRef] [PubMed]

- Sikorska, E.; Khmelinskii, I.; Sikorski, M. Fluorescence methods for analysis of beer. In Beer in Health and Disease Prevention; Elsevier: Amsterdam, The Netherlands, 2009. [Google Scholar]

| Beer Manufacturer 1 | Sample Name 2 | ABV (%) 2 | IBU 2 | Style 2 |

|---|---|---|---|---|

| A | 1 | 4.5 | 14 | Craft Lager |

| B | 2 | 4.8 | 40 | Craft Ale |

| C | 3 | 3.5 | 22 | Helles |

| C | 4 | 4.2 | 18 | Craft Lager |

| C | 4.2 | 4.2 | 18 | Craft Lager |

| C | 5 | 5 | 18 | Wheat beer |

| D | 6 | 4.9 | 25 | Lager |

| D | 6.2 | 4.9 | 25 | Lager |

| D | 7 | 4.9 | 23 | Lager |

| D | 8 | 3.5 | 25 | Lager |

| E | 9 | 3.5 | 15 | Lager |

| E | 9.2 | 3.5 | 15 | Lager |

| E | 10 | 4.4 | 19 | Lager |

| F | 11 | 4.5 | - | Dark ale |

| F | 12 | 3.5 | - | Pale ale |

| G | 13 | 4.5 | 25 | Craft Ale |

| H | 14 | 3.5 | - | Lager |

| H | 15 | 0.9 | - | Lager |

| I | 16 | 4.5 | 27 | Craft Ale |

| J | 17 | 5 | 16 | Lager |

| J | 17.2 | 5 | 16 | Lager |

| K | 18 | 4.2 | - | Craft Ale |

| L | 19 | 4.5 | 20 | Ale |

| M | 20 | 5.9 | 34 | Lager |

| N | 21 | 4.5 | 15 | Wheat beer |

| O | 22 | 4.6 | - | Lager |

| P | 23 | 4.6 | 17 | Lager |

| Q | 24 | 4.9 | 32 | Craft |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gordon, R.; Cozzolino, D.; Chandra, S.; Power, A.; Roberts, J.J.; Chapman, J. Analysis of Australian Beers Using Fluorescence Spectroscopy. Beverages 2017, 3, 57. https://doi.org/10.3390/beverages3040057

Gordon R, Cozzolino D, Chandra S, Power A, Roberts JJ, Chapman J. Analysis of Australian Beers Using Fluorescence Spectroscopy. Beverages. 2017; 3(4):57. https://doi.org/10.3390/beverages3040057

Chicago/Turabian StyleGordon, Russell, Daniel Cozzolino, Shaneel Chandra, Aoife Power, Jessica J. Roberts, and James Chapman. 2017. "Analysis of Australian Beers Using Fluorescence Spectroscopy" Beverages 3, no. 4: 57. https://doi.org/10.3390/beverages3040057

APA StyleGordon, R., Cozzolino, D., Chandra, S., Power, A., Roberts, J. J., & Chapman, J. (2017). Analysis of Australian Beers Using Fluorescence Spectroscopy. Beverages, 3(4), 57. https://doi.org/10.3390/beverages3040057