Water Sorption Isotherm of Pea Starch Edible Films and Prediction Models

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials

2.2. Preparation of Film

2.3. Moisture Sorption Isotherm

| Salt | 5 °C | 15 °C | 25 °C | 40 °C |

|---|---|---|---|---|

| LiCl | 0.113 | 0.113 | 0.113 | 0.112 |

| CH3COOK | 0.291 | 0.234 | 0.225 | 0.216 |

| K2CO3 | 0.431 | 0.432 | 0.432 | 0.423 |

| Mg(NO3)2 | 0.589 | 0.559 | 0.529 | 0.484 |

| NaNO2 | 0.693 | 0.693 | 0.654 | 0.628 |

| NaCl | 0.757 | 0.756 | 0.753 | 0.747 |

| KCl | 0.876 | 0.859 | 0.843 | 0.823 |

| KNO3 | 0.963 | 0.954 | 0.936 | 0.890 |

2.4. Mathematical Modeling

2.5. Determination of the Net Isosteric Heat of Sorption

2.6. Statistical Analysis

3. Results and Discussions

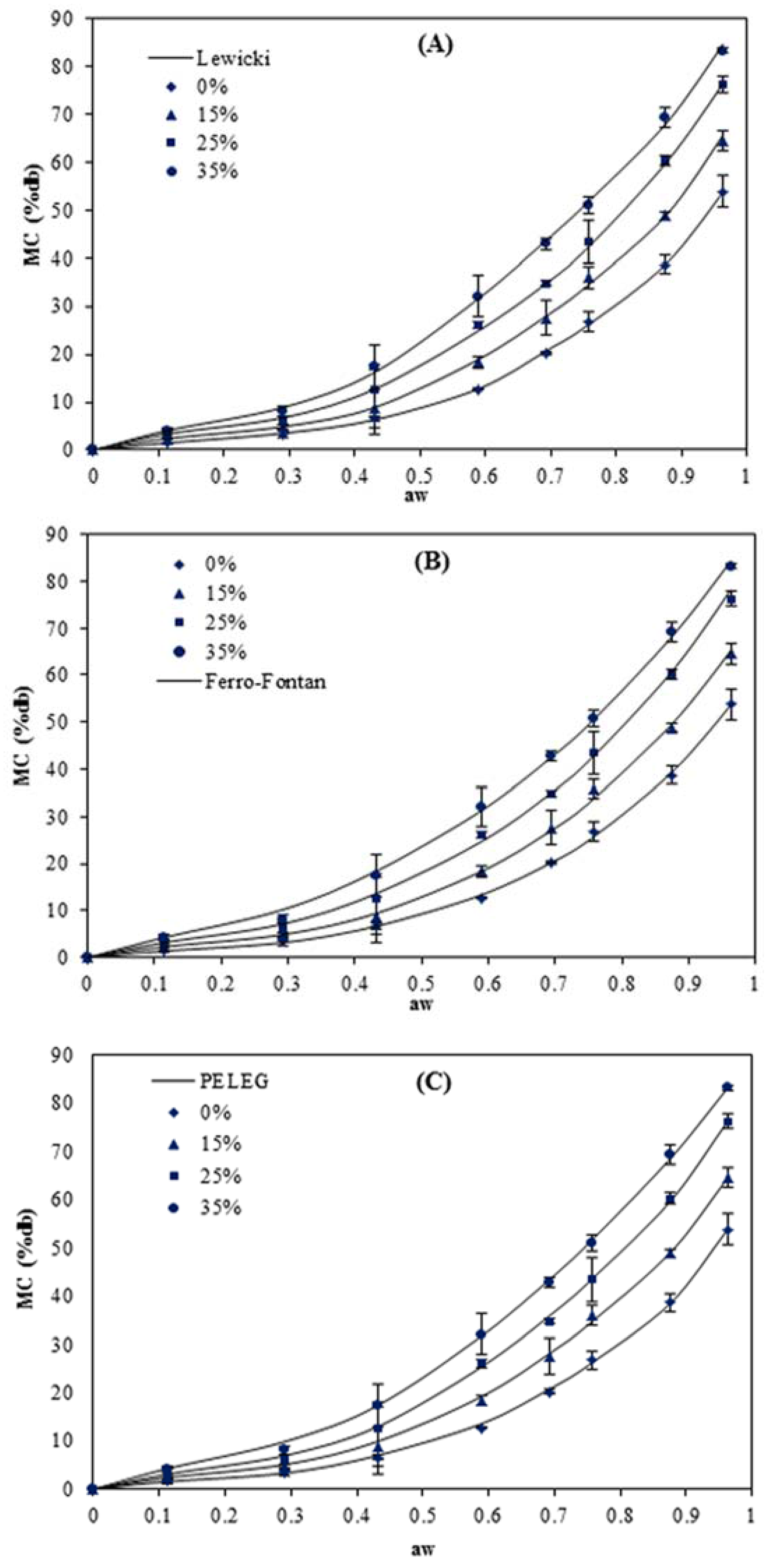

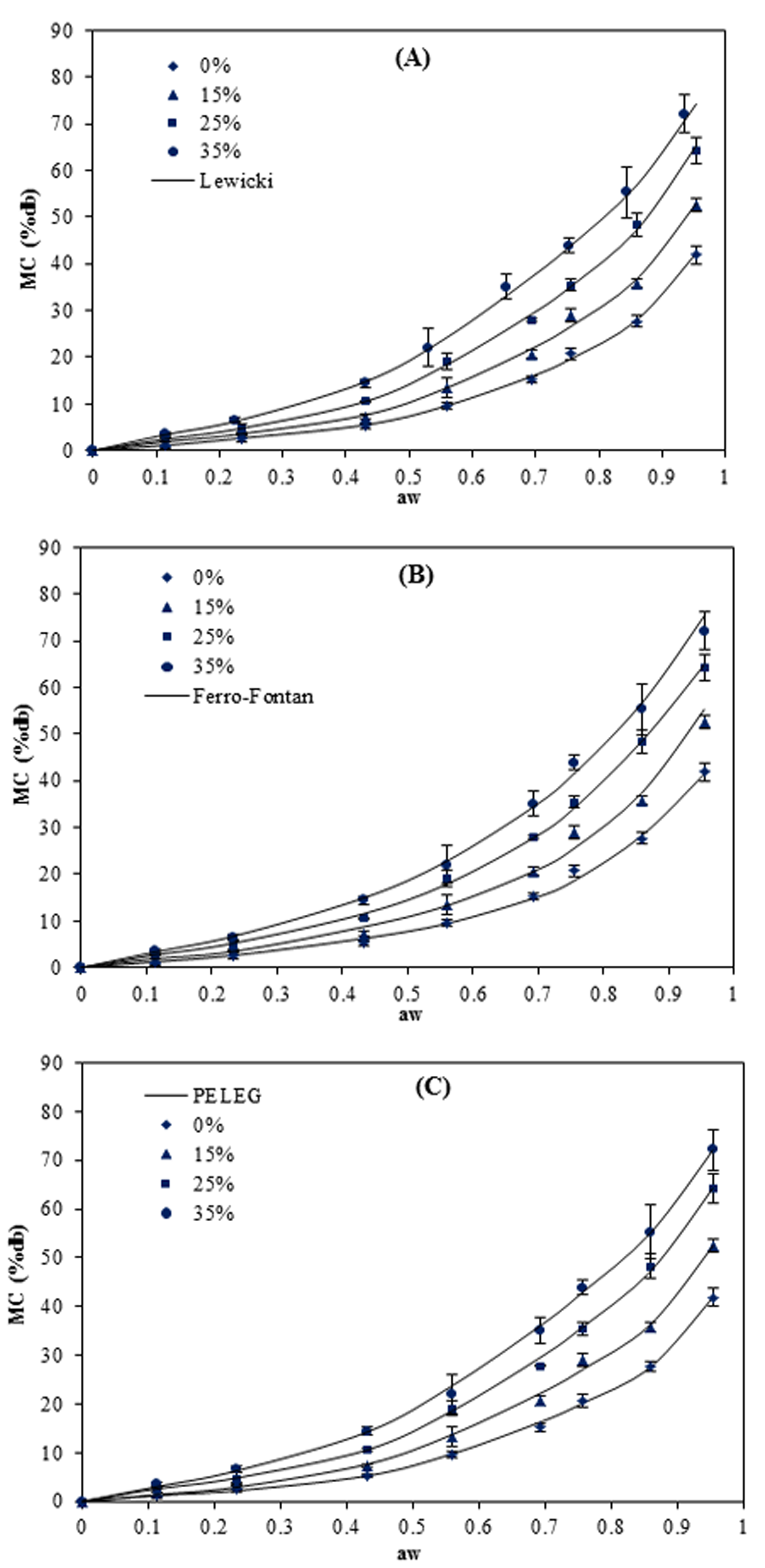

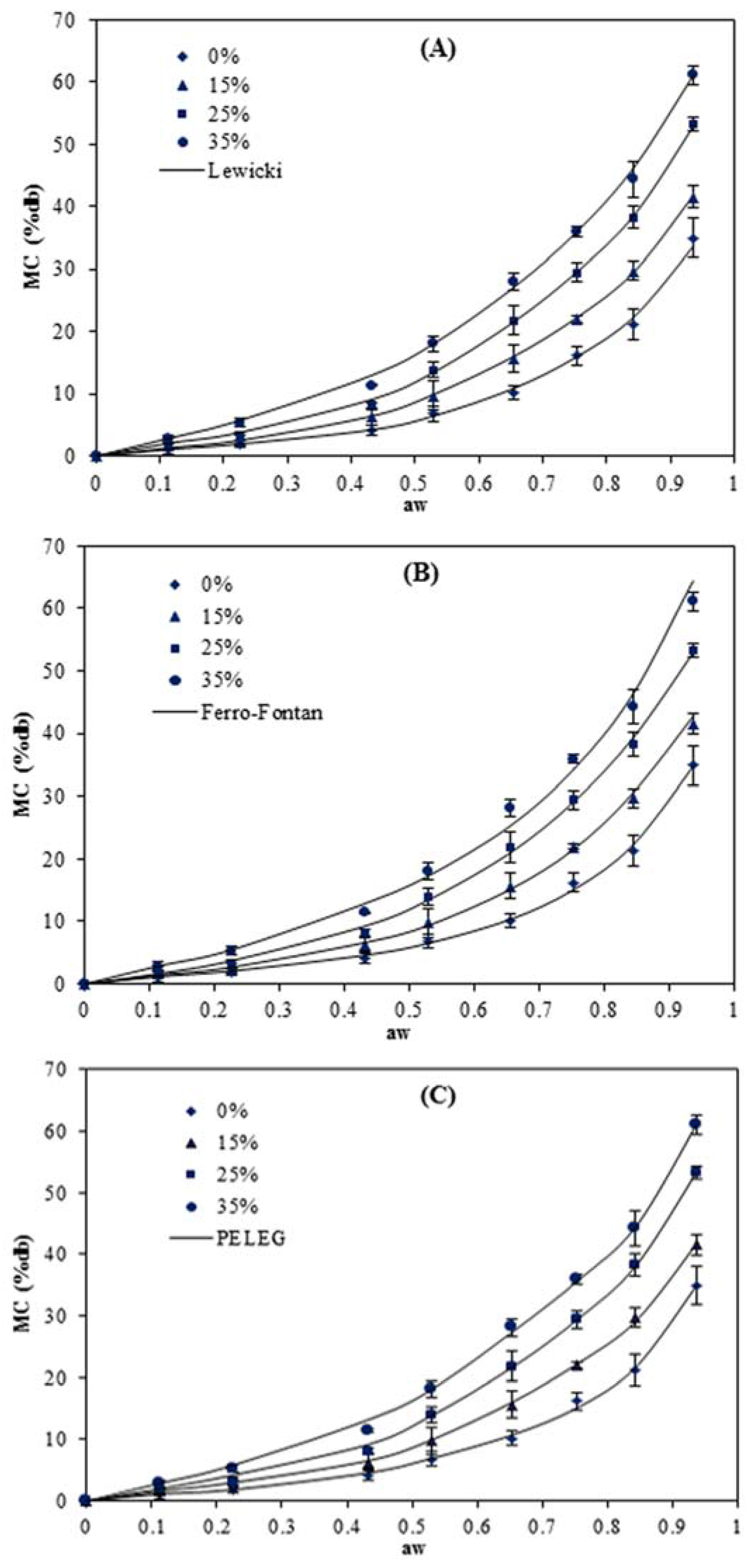

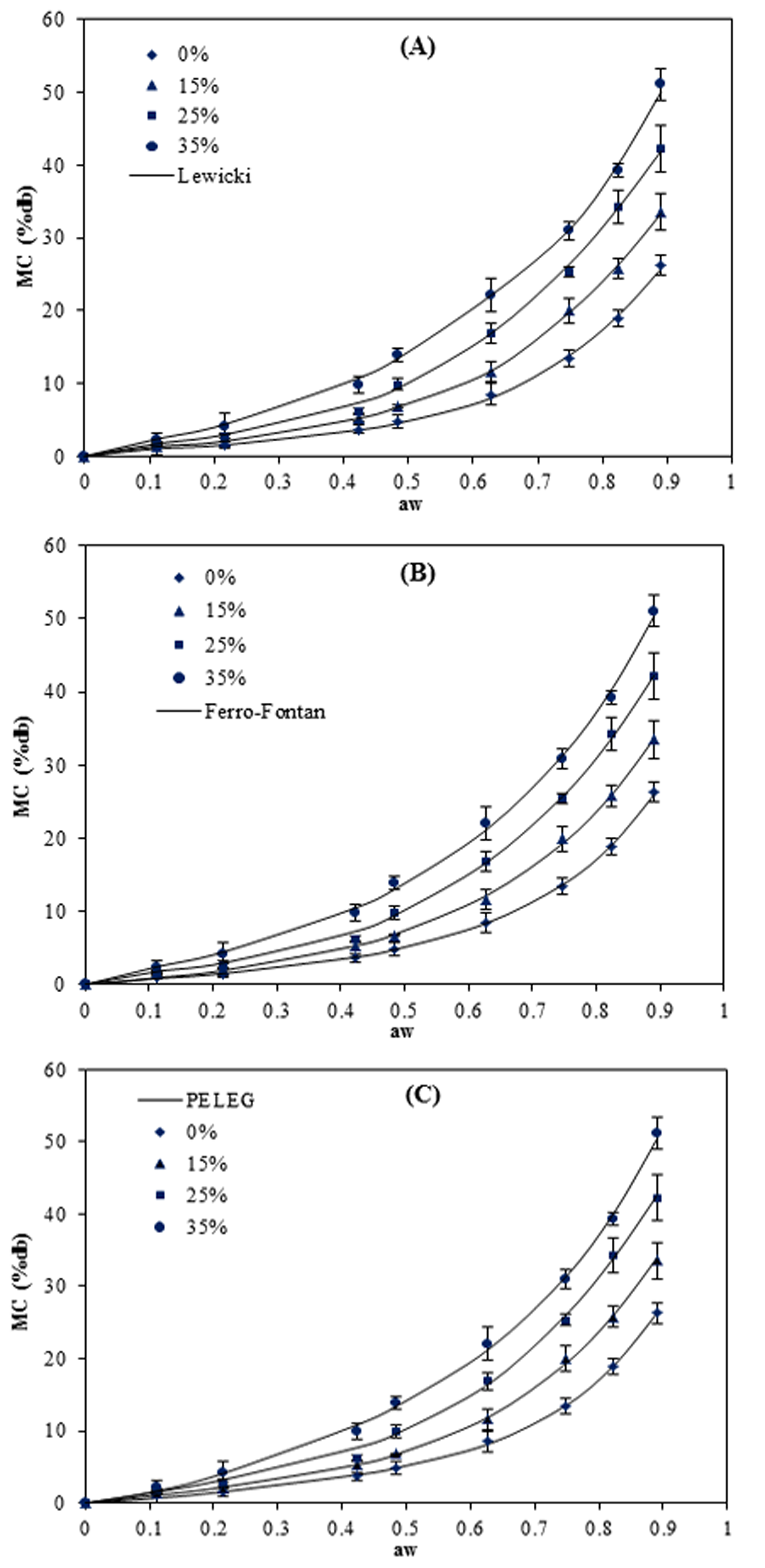

3.1. Moisture Sorption Isotherm

3.2. Modeling of Sorption Isotherms

| Model Constants | Glycerol | ||||

|---|---|---|---|---|---|

| 0% | 15% | 25% | 35% | ||

| BET (0.11–0.50) | m0 | 0.061 | 0.086 | 0.123 | 0.149 |

| C | 6.228 | 4.276 | 3.159 | 3.090 | |

| Me | 17.813 | 17.014 | 12.910 | 11.407 | |

| R2 | 0.914 | 0.939 | 0.976 | 0.978 | |

| GAB (0.11–0.96) | m0 | 0.105 | 0.128 | 0.153 | 0.200 |

| C | 2.096 | 1.825 | 1.779 | 0.632 | |

| K | 0.893 | 0.888 | 0.848 | 0.670 | |

| Me | 9.688 | 9.669 | 7.352 | 2.273 | |

| R2 | 0.993 | 0.992 | 0.989 | 0.999 | |

| PELEG (0.11–0.96) | k1 | 0.641 | 0.725 | 0.898 | 0.986 |

| k2 | 0.500 | 0.666 | 0.794 | 0.808 | |

| n1 | 2.699 | 2.547 | 2.339 | 1.971 | |

| n2 | 42.861 | 44.040 | 64.782 | 53.221 | |

| Me | 2.980 | 4.108 | 3.363 | 2.433 | |

| R2 | 1.000 | 1.000 | 0.999 | 0.999 | |

| Oswin (0.11–0.96) | K0 | 0.165 | 0.194 | 0.259 | 0.331 |

| n0 | 0.410 | 0.411 | 0.371 | 0.317 | |

| Me | 36.746 | 34.435 | 34.668 | 36.267 | |

| R2 | 0.970 | 0.975 | 0.965 | 0.934 | |

| Ferro–Fontan (0.11–0.96) | γ | 0.070 | 0.108 | 0.098 | 0.125 |

| α | 1.162 | 1.124 | 1.248 | 1.291 | |

| r | 0.844 | 0.958 | 0.791 | 0.796 | |

| Me | 5.464 | 6.662 | 6.739 | 1.908 | |

| R2 | 0.994 | 0.992 | 0.989 | 0.998 | |

| Henderson (0.11–0.96) | A | 11.349 | 12.828 | 20.319 | 37.910 |

| B | 0.418 | 0.408 | 0.411 | 0.426 | |

| Me | 39.758 | 38.581 | 40.850 | 42.510 | |

| R2 | 0.970 | 0.973 | 0.957 | 0.917 | |

| Lewicki (0.11–0.96) | F | 0.489 | 0.513 | 0.761 | 1.484 |

| G | 0.198 | 0.221 | 0.168 | 0.058 | |

| H | 3.146 | 2.675 | 2.467 | 3.105 | |

| Me | 1.908 | 1.465 | 2.107 | 0.895 | |

| R2 | 1.000 | 1.000 | 0.999 | 1.000 | |

| Iglesias–Chirife (0.11–0.65) | A | 0.096 | 0.115 | 0.148 | 0.181 |

| B | 1.572 | 1.933 | 3.378 | 5.340 | |

| Me | 13.622 | 11.033 | 5.988 | 5.072 | |

| R2 | 0.987 | 0.992 | 0.997 | 0.996 | |

| Flory–Huggins (0.11–0.96) | A | 0.999 | 1.210 | 2.655 | 4.270 |

| B | 4.462 | 4.428 | 3.752 | 3.097 | |

| Me | 14.833 | 15.236 | 8.319 | 4.775 | |

| R2 | 0.985 | 0.981 | 0.984 | 0.998 | |

| Model Constants | Glycerol | ||||

|---|---|---|---|---|---|

| 0% | 15% | 25% | 35% | ||

| BET (0.11–0.50) | m0 | 0.044 | 0.061 | 0.083 | 0.116 |

| C | 13.807 | 8.780 | 8.314 | 7.480 | |

| Me | 8.785 | 13.334 | 6.840 | 5.579 | |

| R2 | 0.952 | 0.932 | 0.977 | 0.993 | |

| GAB (0.11–0.96) | m0 | 0.079 | 0.098 | 0.102 | 0.180 |

| C | 6.223 | 2.680 | 2.510 | 3.144 | |

| K | 0.918 | 0.922 | 0.912 | 0.869 | |

| Me | 10.344 | 7.961 | 7.089 | 5.042 | |

| R2 | 0.990 | 0.995 | 0.989 | 0.993 | |

| PELEG (0.11–0.96) | k1 | 0.549 | 0.679 | 0.706 | 0.900 |

| k2 | 0.782 | 0.827 | 1.083 | 1.519 | |

| n1 | 2.837 | 2.826 | 2.445 | 2.210 | |

| n2 | 50.955 | 78.354 | 46.823 | 44.471 | |

| Me | 4.353 | 4.217 | 4.270 | 3.349 | |

| R2 | 1.000 | 0.999 | 0.998 | 0.999 | |

| Oswin (0.11–0.96) | K0 | 0.127 | 0.157 | 0.187 | 0.268 |

| n0 | 0.479 | 0.466 | 0.458 | 0.396 | |

| Me | 25.312 | 24.900 | 17.415 | 23.917 | |

| R2 | 0.984 | 0.981 | 0.989 | 0.977 | |

| Ferro–Fontan (0.11–0.96) | γ | 9.082 | 13.138 | 25.611 | 13.993 |

| α | 1.077 | 1.076 | 1.052 | 1.193 | |

| r | 1.052 | 1.101 | 1.265 | 0.901 | |

| Me | 7.906 | 6.875 | 6.225 | 4.475 | |

| R2 | 0.991 | 0.994 | 0.993 | 0.993 | |

| Henderson (0.11–0.96) | A | 7.431 | 9.028 | 10.555 | 18.236 |

| B | 0.404 | 0.397 | 0.390 | 0.397 | |

| Me | 29.147 | 29.615 | 22.422 | 31.165 | |

| R2 | 0.984 | 0.979 | 0.986 | 0.968 | |

| Lewicki (0.11–0.96) | F | 0.237 | 0.352 | 0.296 | 0.569 |

| G | 0.344 | 0.297 | 0.367 | 0.246 | |

| H | 0.450 | 2.162 | 0.981 | 2.180 | |

| Me | 1.664 | 2.624 | 2.133 | 1.708 | |

| R2 | 0.999 | 1.000 | 1.000 | 1.000 | |

| Iglesias–Chirife (0.11–0.65) | A | 0.071 | 0.085 | 0.095 | 1.426 |

| B | 1.893 | 2.662 | 4.612 | 5.622 | |

| Me | 11.114 | 8.512 | 4.613 | 1.998 | |

| R2 | 0.991 | 0.992 | 0.995 | 0.999 | |

| Flory–Huggins (0.11–0.96) | A | 0.579 | 0.874 | 1.095 | 2.954 |

| B | 4.910 | 4.649 | 4.569 | 3.684 | |

| Me | 20.798 | 18.667 | 21.679 | 11.052 | |

| R2 | 0.977 | 0.972 | 0.972 | 0.987 | |

| Model Constants | Glycerol | ||||

|---|---|---|---|---|---|

| 0% | 15% | 25% | 35% | ||

| BET (0.11–0.50) | m0 | 0.040 | 0.051 | 0.072 | 0.086 |

| C | 12.081 | 11.562 | 10.276 | 8.791 | |

| Me | 9.321 | 11.223 | 6.201 | 7.380 | |

| R2 | 0.942 | 0.928 | 0.978 | 0.974 | |

| GAB (0.11–0.96) | m0 | 0.057 | 0.082 | 0.097 | 0.158 |

| C | 4.354 | 4.166 | 2.838 | 2.099 | |

| K | 0.937 | 0.927 | 0.922 | 0.881 | |

| Me | 6.643 | 8.005 | 4.774 | 5.993 | |

| R2 | 0.997 | 0.997 | 0.996 | 0.997 | |

| PELEG (0.11–0.96) | k1 | 0.377 | 0.518 | 0.617 | 0.801 |

| k2 | 0.558 | 0.561 | 0.641 | 0.749 | |

| n1 | 2.375 | 2.505 | 2.361 | 2.426 | |

| n2 | 25.021 | 24.454 | 27.416 | 24.179 | |

| Me | 4.860 | 2.913 | 4.451 | 5.396 | |

| R2 | 1.000 | 1.000 | 0.998 | 0.998 | |

| Oswin (0.11–0.96) | K0 | 0.099 | 0.132 | 0.166 | 0.218 |

| n0 | 0.525 | 0.517 | 0.490 | 0.450 | |

| Me | 15.811 | 20.650 | 16.138 | 21.559 | |

| R2 | 0.992 | 0.988 | 0.989 | 0.976 | |

| Ferro–Fontan (0.11–0.96) | γ | 7.551 | 7.566 | 12.186 | 8.768 |

| α | 1.060 | 1.088 | 1.083 | 1.195 | |

| r | 1.081 | 0.961 | 1.047 | 0.811 | |

| Me | 3.543 | 5.231 | 3.581 | 4.556 | |

| R2 | 0.998 | 0.998 | 0.996 | 0.997 | |

| Henderson (0.11–0.96) | A | 5.654 | 6.870 | 8.716 | 12.130 |

| B | 0.402 | 0.387 | 0.384 | 0.385 | |

| Me | 18.286 | 24.909 | 21.403 | 26.724 | |

| R2 | 0.994 | 0.989 | 0.988 | 0.973 | |

| Lewicki (0.11–0.96) | F | 0.198 | 0.301 | 0.308 | 0.587 |

| G | 0.365 | 0.324 | 0.351 | 0.231 | |

| H | 3.256 | 3.703 | 2.590 | 3.357 | |

| Me | 3.364 | 2.682 | 1.054 | 2.841 | |

| R2 | 1.000 | 1.000 | 1.000 | 1.000 | |

| Iglesias–Chirife (0.11–0.65) | A | 0.059 | 0.081 | 0.096 | 0.117 |

| B | 1.925 | 1.929 | 3.405 | 4.565 | |

| Me | 8.090 | 10.807 | 3.505 | 3.961 | |

| R2 | 0.993 | 0.986 | 0.990 | 0.996 | |

| Flory–Huggins (0.11–0.96) | A | 0.382 | 0.557 | 0.966 | 1.846 |

| B | 5.170 | 5.043 | 4.611 | 4.085 | |

| Me | 26.223 | 23.089 | 21.889 | 14.115 | |

| R2 | 0.978 | 0.983 | 0.981 | 0.992 | |

| Model Constants | Glycerol | ||||

|---|---|---|---|---|---|

| 0% | 15% | 25% | 35% | ||

| BET (0.11–0.50) | m0 | 0.036 | 0.045 | 0.060 | 0.079 |

| C | 11.613 | 10.907 | 10.774 | 9.746 | |

| Me | 8.712 | 9.245 | 5.241 | 3.756 | |

| R2 | 0.956 | 0.939 | 0.988 | 0.988 | |

| GAB (0.11–0.96) | m0 | 0.050 | 0.068 | 0.082 | 0.121 |

| C | 1.175 | 0.816 | 0.793 | 0.483 | |

| K | 0.916 | 0.899 | 0.866 | 0.862 | |

| Me | 6.474 | 5.899 | 6.447 | 5.112 | |

| R2 | 0.995 | 0.996 | 0.998 | 0.996 | |

| PELEG (0.11–0.96) | k1 | 0.168 | 0.171 | 0.184 | 0.203 |

| k2 | 0.550 | 0.731 | 0.911 | 0.946 | |

| n1 | 1.297 | 0.911 | 0.764 | 0.633 | |

| n2 | 8.568 | 7.502 | 7.945 | 6.300 | |

| Me | 7.920 | 5.338 | 4.309 | 4.200 | |

| R2 | 0.997 | 0.998 | 1.000 | 0.998 | |

| Oswin (0.11–0.96) | K0 | 0.092 | 0.121 | 0.139 | 0.189 |

| n0 | 0.561 | 0.553 | 0.564 | 0.503 | |

| Me | 17.298 | 22.958 | 13.425 | 17.766 | |

| R2 | 0.978 | 0.973 | 0.986 | 0.971 | |

| Ferro–Fontan (0.11–0.96) | γ | 3.411 | 3.579 | 5.613 | 6.280 |

| α | 1.153 | 1.204 | 1.120 | 1.202 | |

| r | 0.731 | 0.649 | 0.813 | 0.735 | |

| Me | 5.078 | 5.677 | 5.719 | 4.493 | |

| R2 | 0.998 | 0.998 | 0.999 | 0.996 | |

| Henderson (0.11–0.96) | A | 5.016 | 6.034 | 6.422 | 9.177 |

| B | 0.393 | 0.378 | 0.367 | 0.372 | |

| Me | 19.361 | 26.530 | 17.221 | 22.929 | |

| R2 | 0.982 | 0.976 | 0.988 | 0.970 | |

| Lewicki (0.11–0.96) | F | 0.682 | 0.948 | 0.717 | 0.515 |

| G | 0.102 | 0.087 | 0.175 | 0.222 | |

| H | 9.002 | 8.227 | 9.130 | 2.671 | |

| Me | 3.778 | 5.264 | 1.486 | 1.308 | |

| R2 | 0.999 | 0.998 | 1.000 | 1.000 | |

| Iglesias–Chirife (0.11–0.65) | A | 0.057 | 0.075 | 0.75 | 0.102 |

| B | 1.541 | 1.652 | 3.370 | 4.311 | |

| Me | 7.160 | 9.439 | 2.473 | 3.329 | |

| R2 | 0.980 | 0.979 | 0.996 | 0.993 | |

| Flory–Huggins (0.11–0.96) | A | 0.303 | 0.452 | 0.449 | 1.196 |

| B | 5.381 | 5.232 | 5.414 | 4.504 | |

| Me | 27.921 | 24.716 | 28.821 | 20.898 | |

| R2 | 0.988 | 0.991 | 0.989 | 0.990 | |

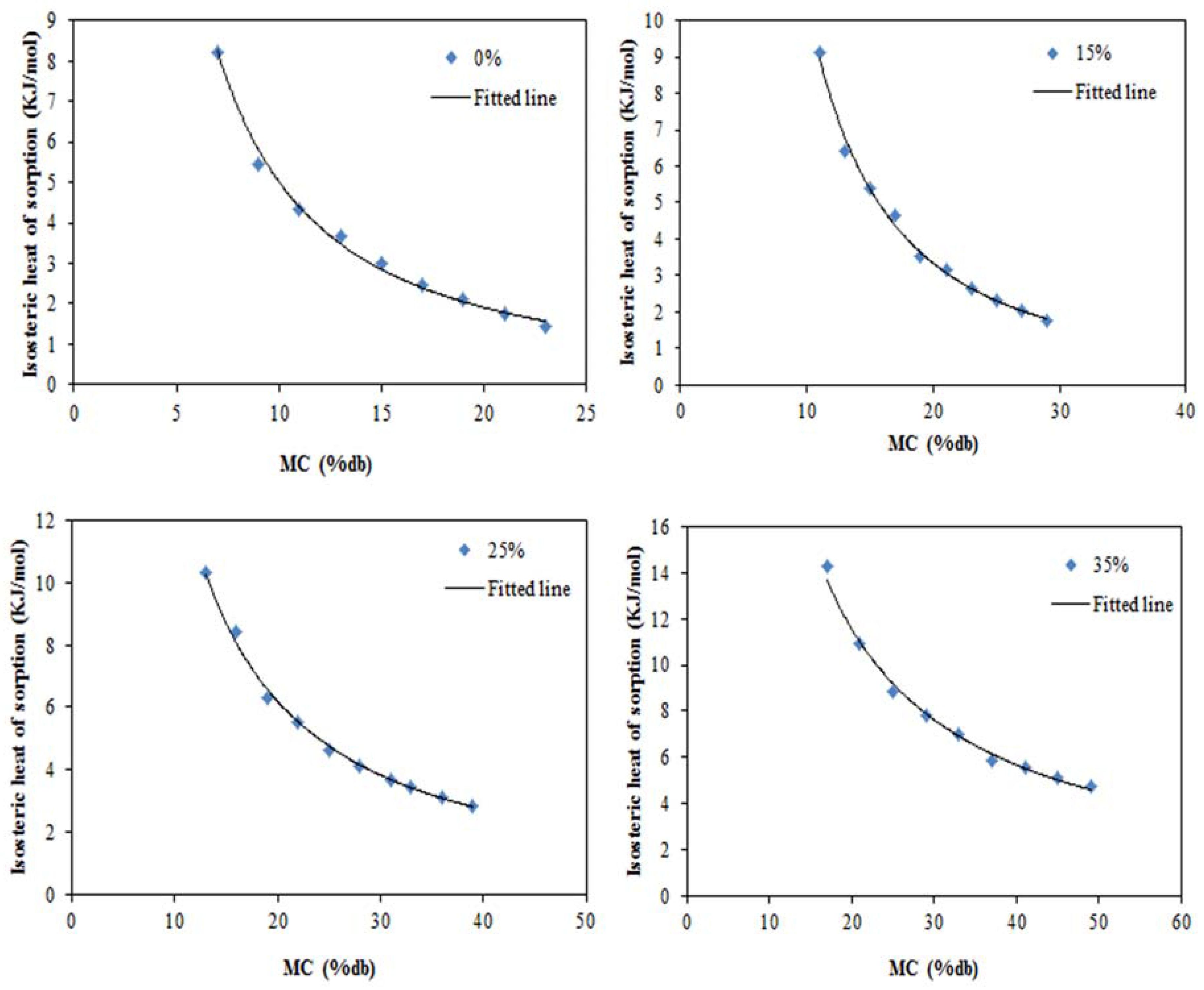

3.3. Net Isosteric Heat of Sorption

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Baldwin, E.A.; Nisperos-Carriedo, M.O.; Baker, R.A. Use of edible coatings to preserve quality of lightly (and slightly) processed products. Crit. Rev. Food Sci. Nutr. 1995, 35, 509–524. [Google Scholar] [CrossRef] [PubMed]

- Park, H.J. Development of advanced edible coatings for fruits. Trends Food Sci. Technol. 1999, 10, 254–260. [Google Scholar] [CrossRef]

- Jagadish, R.S.; Raj, B. Properties and sorption studies of polyethylene oxide-starch blended films. Food Hydrocoll. 2011, 25, 1572–1580. [Google Scholar] [CrossRef]

- Rachtanapun, P.; Tongdeesoontorn, W. Effect of naoh concentration on sorption isotherm of carboxymethyl rice starch films and prediction mmodels. Chiang Mai J. Sci. 2011, 38, 380–388. [Google Scholar]

- Chowdhury, T.; Das, M. Moisture sorption isotherm and isosteric heat of sorption of edible films made from blends of starch, amylose and methyl cellulose. Int. Food Res. J. 2012, 19, 669–1678. [Google Scholar]

- Kaymak-Ertekin, F.; Gedik, A. Sorption isotherms and isosteric heat of sorption for grapes, apricots, apples and potatoes. LWT Food Sci. Technol. 2004, 37, 429–438. [Google Scholar] [CrossRef]

- Van Soest, J.J.G.; Benes, K.; de Wit, D. The influence of acid hydrolysis of potato starch on the stress-strain propoerties of thermoplastic starch. Starch Stärke 1995, 47, 429–434. [Google Scholar] [CrossRef]

- Duckworth, R.B. Future needs in water sorption in food stuffs. In Physical Properties of Foods; Jowitt, R., Escher, F., Hallstrom, B., Mefert, H., Spiess, W., Vos, G., Eds.; Elsevier Applied Science: London, UK, 1983; pp. 93–102. [Google Scholar]

- Rizvi, S.S.H. Thermodynamics of foods in dehydration. In Engineering Properties of Food; Rao, M., Rizvi, S., Eds.; Marcel Dekker: New York, NY, USA, 1986; pp. 133–214. [Google Scholar]

- Sebti, I.; Delves-Broughton, J.; Coma, V. Physicochemical properties and bioactivity of nisin-containing cross-linked hydroxypropylmethylcellulose films. J. Agric. Food Chem. 2003, 51, 6468–6474. [Google Scholar] [CrossRef] [PubMed]

- Talja, R.A.; Helén, H.; Roos, Y.H.; Jouppila, K. Effect of various polyols and polyol contents on physical and mechanical properties of potato starch-based films. Carbohydr. Polym. 2007, 67, 288–295. [Google Scholar] [CrossRef]

- Talja, R.A.; Helén, H.; Roos, Y.H.; Jouppila, K. Effect of type and content of binary polyol mixtures on physical and mechanical properties of starch-based edible films. Carbohydr. Polym. 2008, 71, 269–276. [Google Scholar] [CrossRef]

- Myllärinen, P.; Partanen, R.; Seppälä, J.; Forssell, P. Effect of glycerol on behaviour of amylose and amylopectin films. Carbohydr. Polym. 2002, 50, 355–361. [Google Scholar] [CrossRef]

- Galdeano, M.C.; Mali, S.; Grossmann, M.V.E.; Yamashita, F.; García, M.A. Effects of plasticizers on the properties of oat starch films. Mater. Sci. Eng. C 2009, 29, 532–538. [Google Scholar] [CrossRef]

- Mali, S.; Sakanaka, L.S.; Yamashita, F.; Grossmann, M.V.E. Water sorption and mechanical properties of cassava starch films and their relation to plasticizing effect. Carbohydr. Polym. 2005, 60, 283–289. [Google Scholar] [CrossRef]

- Müller, C.M.O.; Yamashita, F.; Laurindo, J.B. Evaluation of the effects of glycerol and sorbitol concentration and water activity on the water barrier properties of cassava starch films through a solubility approach. Carbohydr. Polym. 2008, 72, 82–87. [Google Scholar] [CrossRef]

- Cervera, M.F.; Karjalainen, M.; Airaksinen, S.; Rantanen, J.; Krogars, K.; Heinamaki, J.; Colarte, A.I.; Yliruusi, J. Physical stability and moisture sorption of aqueous chitosan-amylose starch films plasticized with polyols. Eur. J. Pharm. Biopharm. 2004, 58, 69–76. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Han, J.H. Sorption isotherm and plasticization effect of moisture and plasticizers in pea starch film. J. Food Sci. 2008, 73, E313–E324. [Google Scholar] [CrossRef] [PubMed]

- Farahnaky, A.; Saberi, B.; Majzoobi, M. Effect of glycerol on physical and mechanical properties of wheat starch edible films. J. Texture Stud. 2013, 44, 176–186. [Google Scholar] [CrossRef]

- Labuza, T.P.; Kaanane, A.; Chen, J.Y. Effect of temperature on the moisture sorption isotherms and water activity shift of two dehydrated foods. J. Food Sci. 1985, 50, 385–392. [Google Scholar] [CrossRef]

- Rizvi, S.S.H. Thermodynamic properties of foods in dehydration. In Engineering Properties of Foods; Rao, A., Rizvi, S.S.H., Datta, A.K., Eds.; CRC: Boca Raton, FL, USA, 2005. [Google Scholar]

- Al-Muhtaseb, A.H.; McMinn, W.A.M.; Magee, T.R.A. Water sorption isotherms of starch powders: Part 1: Mathematical description of experimental data. J. Food Eng. 2004, 61, 297–307. [Google Scholar] [CrossRef]

- McMinn, W.A.M.; Al-Muhtaseb, A.A.; Magee, T.R.A. Assessment of two- and three-parameter lewicki models for description of sorption phenomena of starch materials. J. Sci. Food Agric. 2004, 84, 1695–1700. [Google Scholar] [CrossRef]

- Suppakul, P.; Chalernsook, B.; Ratisuthawat, B.; Prapasitthi, S.; Munchukangwan, N. Empirical modeling of moisture sorption characteristics and mechanical and barrier properties of cassava flour film and their relation to plasticizing-antiplasticizing effects. LWT Food Sci. Technol. 2013, 50, 290–297. [Google Scholar] [CrossRef]

- Perdomo, J.; Cova, A.; Sandoval, A.J.; García, L.; Laredo, E.; Müller, A.J. Glass transition temperatures and water sorption isotherms of cassava starch. Carbohydr. Polym. 2009, 76, 305–313. [Google Scholar] [CrossRef]

- Brett, B.; Figueroa, M.; Sandoval, A.J.; Barreiro, J.A.; Müller, A.J. Moisture sorption characteristics of starchy products: Oat flour and rice flour. Food Biophys. 2009, 4, 151–157. [Google Scholar] [CrossRef]

- Bennaceur, S.; Draoui, B.; Touati, B.; Benseddik, A.; Saad, A.; Bennamoun, L. Determination of the moisture-sorption isotherms and isosteric heat of henna leaves. J. Eng. Phys. Thermophys. 2015, 88, 52–62. [Google Scholar] [CrossRef]

- Al-Muhtaseb, A.H.; McMinn, W.A.M.; Magee, T.R.A. Moisture sorption isotherm characteristics of food products: A review. Food Bioprod. Process. 2002, 80, 118–128. [Google Scholar] [CrossRef]

- Enyinnaya Chinma, C.; Chukwuma Ariahu, C.; Alakali, J. Moisture sorption and thermodynamic properties of cassava starch and soy protein concentrate based edible films. Int. J. Food Sci. Technol. 2013, 48, 2400–2407. [Google Scholar] [CrossRef]

- Coupland, J.N.; Shaw, N.B.; Monahan, F.J.; Dolores O’Riordan, E.; O’Sullivan, M. Modeling the effect of glycerol on the moisture sorption behavior of whey protein edible films. J. Food Eng. 2000, 43, 25–30. [Google Scholar] [CrossRef]

- Chen, C.H.; Kuo, W.S.; Lai, L.S. Rheological and physical characterization of film-forming solutions and edible films from tapioca starch/decolorized hsian-tsao leaf gum. Food Hydrocoll. 2009, 23, 2132–2140. [Google Scholar] [CrossRef]

- Shih, F.F.; Daigle, K.W.; Champagne, E.T. Effect of rice wax on water vapour permeability and sorption properties of edible pullulan films. Food Chem. 2011, 127, 118–121. [Google Scholar] [CrossRef]

- Ayadi, F.; Dole, P. Stoichiometric interpretation of thermoplastic starch water sorption and relation to mechanical behavior. J. Food Eng. 2011, 84, 872–880. [Google Scholar] [CrossRef]

- Godbillot, L.; Dole, P.; Joly, C.; Rogé, B.; Mathlouthi, M. Analysis of water binding in starch plasticized films. Food Chem. 2006, 96, 380–386. [Google Scholar] [CrossRef]

- Liu, Z. Edible films and coatings from starches. In Innovations in Food Packaging; Han, J., Ed.; Elsevier Science: London, UK, 2005; pp. 318–338. [Google Scholar]

- Urquhart, A.R. Sorption of water by cellulose and starch. In Recent Advances in the Chemistry of Cellulose and Starch; Honeyman, J., Ed.; Heywood & Company: London, UK, 1959; pp. 240–264. [Google Scholar]

- Flores, S.; Famá, L.; Rojas, A.M.; Goyanes, S.; Gerschenson, L. Physical properties of tapioca-starch edible films: Influence of filmmaking and potassium sorbate. Food Res. Int. 2007, 40, 257–265. [Google Scholar] [CrossRef]

- Famá, L.; Rojas, A.M.; Goyanes, S.; Gerschenson, L. Mechanical properties of tapioca-starch edible films containing sorbates. LWT Food Sci. Technol. 2005, 38, 631–639. [Google Scholar] [CrossRef]

- Cerqueira, M.A.; Souza, B.W.S.; Teixeira, J.A.; Vicente, A.A. Effect of glycerol and corn oil on physicochemical properties of polysaccharide films—A comparative study. Food Hydrocoll. 2012, 27, 175–184. [Google Scholar] [CrossRef] [Green Version]

- Kowalczyk, D.; Kordowska-Wiater, M.; Sołowiej, B.; Baraniak, B. Physicochemical and antimicrobial properties of biopolymer-candelilla wax emulsion films containing potassium sorbate—A comparative study. Food Bioprocess Technol. 2015, 8, 567–579. [Google Scholar] [CrossRef]

- Zhang, Y.; Han, J.H. Plasticization of pea starch films with monosaccharides and polyols. J. Food Sci. 2006, 71, E253–E261. [Google Scholar] [CrossRef]

- Strauss, U.P.; Porcja, R.J.; Chen, Y. Volume effects of starch water interactions. In Water Relationships in Foods; Levine, H., Slade, L., Eds.; Plenum Press: New York, NY, USA, 1991; pp. 351–364. [Google Scholar]

- Mali, S.; Grossmann, M.V.E.; García, M.A.; Martino, M.N.; Zaritzky, N.E. Effects of controlled storage on thermal, mechanical and barrier properties of plasticized films from different starch sources. J. Food Eng. 2006, 75, 453–460. [Google Scholar] [CrossRef]

- Palipane, K.B.; Driscoll, R.H. Moisture sorption characteristics of in-shell macadamia nuts. J. Food Eng. 1993, 18, 63–76. [Google Scholar] [CrossRef]

- Su, J.F.; Huang, Z.; Zhao, Y.H.; Yuan, X.Y.; Wang, X.Y.; Li, M. Moisture sorption and water vapor permeability of soy protein isolate/poly(vinyl alcohol)/glycerol blend films. Ind. Crop. Prod. 2010, 31, 266–276. [Google Scholar] [CrossRef]

- Peng, G.; Chen, X.; Wu, W.; Jiang, X. Modeling of water sorption isotherm for corn starch. J. Food Eng. 2007, 80, 562–567. [Google Scholar] [CrossRef]

- Talla, A. Predicting sorption isotherms and net isosteric heats of sorption of maize grains at different temperatures. Int. J. Food Eng. 2014, 10, 393–401. [Google Scholar] [CrossRef]

- Brunauer, S.; Emmett, P.H.; Teller, E. Adsorption of gases in multimolecular layers. J. Am. Chem. Soc. 1938, 60, 309–319. [Google Scholar] [CrossRef]

- Enrione, J.I.; Hill, S.E.; Mitchell, J.R. Sorption behavior of mixtures of glycerol and starch. J. Agric. Food Chem. 2007, 55, 2956–2963. [Google Scholar] [CrossRef] [PubMed]

- Chatakanonda, P.; Dickinson, L.C.; Chinachoti, P. Mobility and distribution of water in cassava and potato starches by 1 H and 2 H NMR. J. Agric. Food Chem. 2003, 51, 7445–7449. [Google Scholar] [CrossRef] [PubMed]

- Mishra, S.; Rai, T. Morphology and functional properties of corn, potato and tapioca starches. Food Hydrocoll. 2006, 20, 557–566. [Google Scholar] [CrossRef]

- Timmermann, E.O.; Chirife, J.; Iglesias, H.A. Water sorption isotherms of foods and foodstuffs: Bet or gab parameters? J. Food Eng. 2001, 48, 19–31. [Google Scholar] [CrossRef]

- Tongdeesoontorn, W.; Mauer, L.J.; Wongruong, S.; Rachtanapun, P. Water vapour permeability and sorption isotherms of cassava starch based films blended with gelatin and carboxymethyl cellulose. Asian J. Food Agro Ind. 2009, 2, 501–514. [Google Scholar]

- Turhan, M.; Sayar, S.; Gunasekaran, S. Application of peleg model to study water absorption in chickpea during soaking. J. Food Eng. 2002, 53, 153–159. [Google Scholar] [CrossRef]

- Yazdani, M.; Sazandehchi, P.; Azizi, M.; Ghobadi, P. Moisture sorption isotherms and isosteric heat for pistachio. Eur. Food Res. Technol. 2006, 223, 577–584. [Google Scholar] [CrossRef]

- Cadden, A.M. Moisture sorption characteristics of several food fibers. J. Food Sci. 1988, 53, 1150–1155. [Google Scholar] [CrossRef]

- Jayendra Kumar, A.; Singh, R.R.B.; Patil, G.R.; Patel, A.A. Effect of temperature on moisture desorption isotherms of kheer. LWT Food Sci. Technol. 2005, 38, 303–310. [Google Scholar] [CrossRef]

- Iglesias, H.A.; Chirife, J. Equilibrium moisture contents of air dried beef. Dependence on drying temperature. Int. J. Food Sci. Technol. 1976, 11, 565–573. [Google Scholar] [CrossRef]

- Bahloul, N.; Boudhrioua, N.; Kechaou, N. Moisture desorption-adsorption isotherms and isosteric heats of sorption of tunisian olive leaves (olea europaea L.). Ind. Crop. Prod. 2008, 28, 162–176. [Google Scholar] [CrossRef]

- Palou, E.; López-Malo, A.; Argaiz, A. Effect of temperature on the moisture sorption isotherms of some cookies and corn snacks. J. Food Eng. 1997, 31, 85–93. [Google Scholar] [CrossRef]

- Samapundo, S.; Devlieghere, F.; Meulenaer, B.D.; Atukwase, A.; Lamboni, Y.; Debevere, J.M. Sorption isotherms and isosteric heats of sorption of whole yellow dent corn. J. Food Eng. 2007, 79, 168–175. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saberi, B.; Vuong, Q.V.; Chockchaisawasdee, S.; Golding, J.B.; Scarlett, C.J.; Stathopoulos, C.E. Water Sorption Isotherm of Pea Starch Edible Films and Prediction Models. Foods 2016, 5, 1. https://doi.org/10.3390/foods5010001

Saberi B, Vuong QV, Chockchaisawasdee S, Golding JB, Scarlett CJ, Stathopoulos CE. Water Sorption Isotherm of Pea Starch Edible Films and Prediction Models. Foods. 2016; 5(1):1. https://doi.org/10.3390/foods5010001

Chicago/Turabian StyleSaberi, Bahareh, Quan V. Vuong, Suwimol Chockchaisawasdee, John B. Golding, Christopher J. Scarlett, and Costas E. Stathopoulos. 2016. "Water Sorption Isotherm of Pea Starch Edible Films and Prediction Models" Foods 5, no. 1: 1. https://doi.org/10.3390/foods5010001

APA StyleSaberi, B., Vuong, Q. V., Chockchaisawasdee, S., Golding, J. B., Scarlett, C. J., & Stathopoulos, C. E. (2016). Water Sorption Isotherm of Pea Starch Edible Films and Prediction Models. Foods, 5(1), 1. https://doi.org/10.3390/foods5010001