Seafood and Water Management

Abstract

:1. Introduction

2. Experimental Section

2.1. Sample Material

| Variable | Categories | Number of Samples |

|---|---|---|

| Seafood species | Cod (Gadus morhua) | 20 |

| Pangasius (Pangasius bocourti) | 20 | |

| Salmon (Salmo salar) | 26 | |

| Shrimp (Crangon spp., Penaeus spp., Pandalus spp., peeled) | 24 | |

| Tilapia (Oreochromis spp.) | 20 | |

| Sales temperature | Chilled | 55 |

| Frozen | 55 | |

| Retail outlet | Supermarket, convenience | 26 |

| Supermarket, intermediate | 42 | |

| Supermarket, discounter | 12 | |

| Specialty shop | 18 | |

| Open air market | 12 |

2.2. Moisture Analysis

2.3. Crude Protein Analysis

2.4. Statistical Analysis

3. Results and Discussion

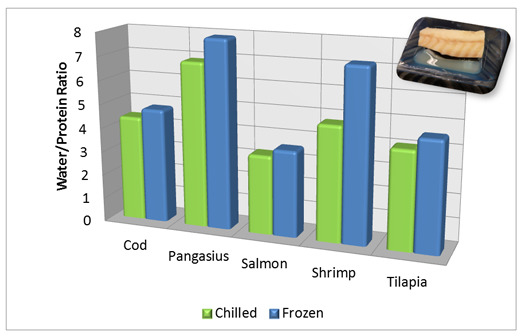

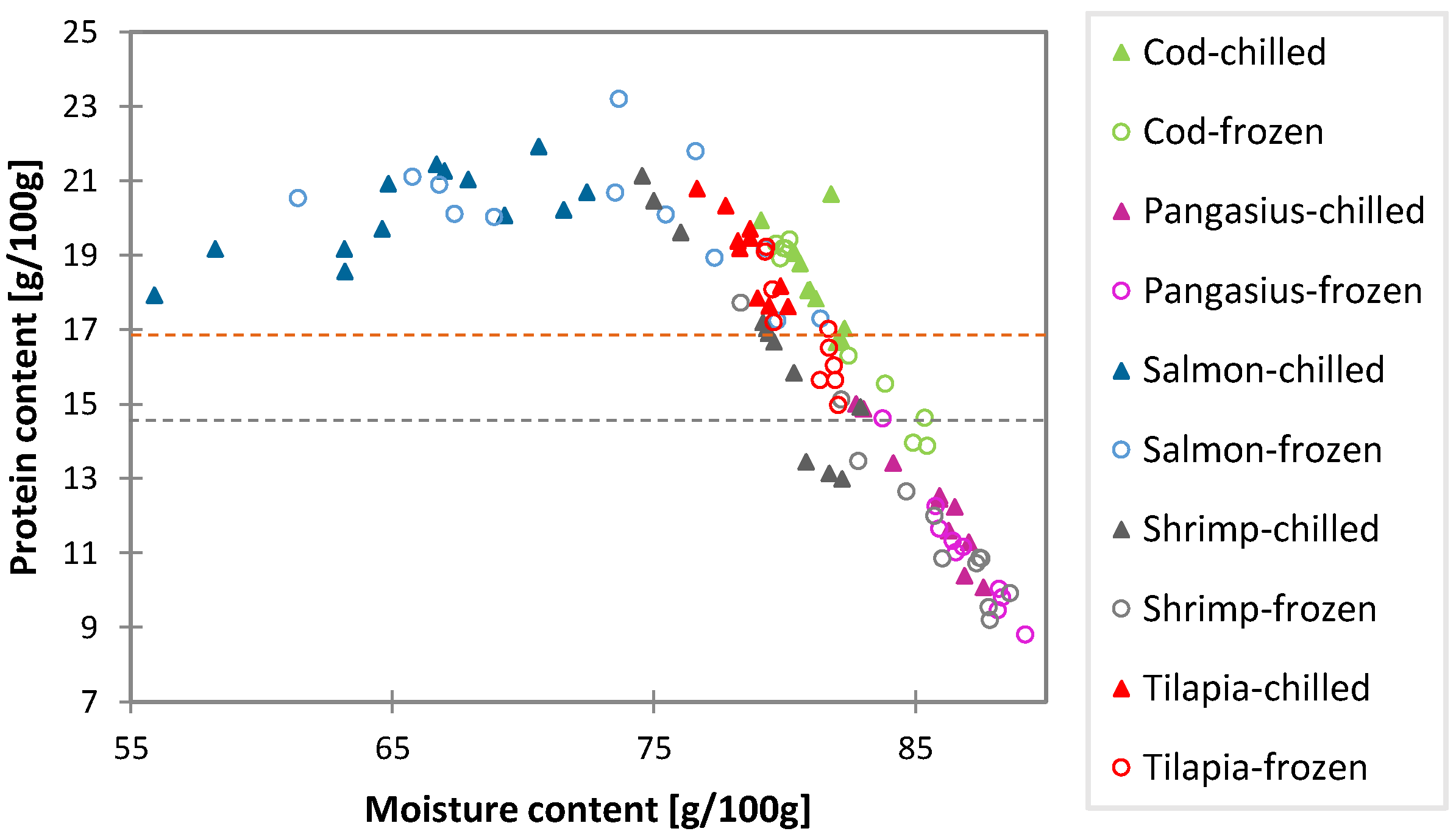

3.1. Water and Protein Contents

| Sample | Moisture Content (g/100 g) | Protein Content (g/100 g) | Water/Protein Ratio |

|---|---|---|---|

| All | 79.4 ± 7.2 | 16.5 ± 3.7 | 4.8 |

| Cod | 81.6 ± 1.9 B,C | 17.6 ± 2.0 II | 4.6 |

| Pangasius | 86.3 ± 1.7 A | 11.7 ± 1.8 IV | 7.4 |

| Salmon | 69.3 ± 6.6 D | 20.1 ± 1.4 I | 3.4 |

| Shrimp | 82.4 ± 4.3 B | 14.2 ± 3.5 III | 5.8 |

| Tilapia | 79.7 ±1.6 C | 18.0 ±1.7 II | 4.4 |

| Chilled | 77.5 ± 7.5 Y | 17.4 ± 3.2 S | 4.4 |

| Frozen | 81.3 ± 6.2 X | 15.5 ± 4.0 T | 5.2 |

| Seafood Species | Sales Temperature | Moisture Content (g/100 g) | Protein Content (g/100 g) | Water/Protein Ratio |

|---|---|---|---|---|

| Cod | Chilled (n = 10) | 81.1 ± 1.0 B,C | 18.3 ± 1.3 II,III | 4.4 |

| Frozen (n = 10) | 82.2 ± 2.5 B | 17.0 ± 2.4 III,IV | 4.8 | |

| Δ Frozen-chilled | +1.1 (+1.4%) | −1.3 (−7.1%) | +0.4 (+10.0%) | |

| Pangasius | Chilled (n = 10) | 85.6 ± 1.7 A | 12.4 ± 1.7 V | 6.9 |

| Frozen (n = 10) | 86.9 ± 1.6 A | 11.0 ± 1.7 V | 7.9 | |

| Δ Frozen-chilled | +1.3 (+1.5%) | −1.4 (−11.3%) | +1.0 (+14.4%) | |

| Salmon | Chilled (n = 13) | 65.8 ± 4.9 E | 20.2 ± 1.2 I | 3.3 |

| Frozen (n = 13) | 72.9 ± 6.2 D | 20.1 ± 1.7 I | 3.6 | |

| Δ Frozen-chilled | +7.1 (+10.8%) | −0.1 (−0.5%) | +0.3 (+10.0%) | |

| Shrimp | Chilled (n = 12) | 79.2 ± 2.7 C | 16.6 ± 2.8 IV | 4.8 |

| Frozen (n = 12) | 85.5 ± 3.1 A | 11.9 ± 2.5 V | 7.2 | |

| Δ Frozen-chilled | +6.3 (+8.0%) | −4.7 (−28.3%) | +2.4 (+50.0%) | |

| Tilapia | Chilled (n = 10) | 78.7 ±1.0 C | 19.0 ±1.1 I,II | 4.1 |

| Frozen (n = 10) | 80.8 ± 1.2 B,C | 16.9 ± 1.5 III,IV | 4.6 | |

| Δ Frozen-chilled | +2.1 (+2.7%) | −2.1 (−11.1%) | +0.5 (+12.0%) |

3.2. Comparison of Nitrogen Factors

| Fish Species | Chilled Products | Frozen Products | ||

|---|---|---|---|---|

| Below Minimal Nitrogen Factor | Exceeding Minimal Nitrogen Factor | Below Minimal Nitrogen Factor | Exceeding Minimal Nitrogen Factor | |

| Cod | 1 | 9 | 5 | 5 |

| Pangasius | 10 | 0 | 10 | 0 |

| Shrimp | 3 | 9 | 10 | 2 |

| Tilapia | 3 | 7 | 7 | 3 |

| Sum | 17 (40%) | 25 (60%) | 32 (76%) | 10 (24%) |

4. Conclusions

Author Contributions

Conflicts of Interest

References

- Sriket, P.; Benjakul, S.; Visessanguan, W.; Kijroongrojana, K. Comparative studies on chemical composition and thermal properties of black tiger shrimp (Penaeus monodon) and white shrimp (Penaeus vannamei) meats. Food Chem. 2007, 103, 1199–1207. [Google Scholar] [CrossRef]

- Regulation (EC) No. 178/2002 of the European Parliament and of the Council of 28 January 2002 Laying Down the General Principles and Requirements of Food Law, Establishing the European Food Safety Authority and Laying Down Procedures in Matters of Food Safety. Available online: http://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=CONSLEG:2002R0178:20090807:EN:PDF (accessed on 21 July 2014).

- Moore, J.C.; Spink, J.; Lipp, M. Development and application of a database of food ingredient fraud and economically motivated adulteration from 1980 to 2010. J. Food Sci. 2012, 77, R118–R126. [Google Scholar] [CrossRef] [PubMed]

- RASFF (The Rapid Alert System for Food and Feed)—Food and Feed Safety Alerts. Available online: http://ec.europa.eu/food/safety/rasff/index_en.htm (accessed on 21 July 2014).

- Breck, J.E. Body composition in fishes: Body size matters. Aquaculture 2014, 433, 40–49. [Google Scholar] [CrossRef]

- AOAC (Association of Official Analytical Chemists). AOAC Official Method 950.46 Moisture in Meat. In Official Methods of Analysis, 15th ed.; AOAC International: Arlington, VA, USA, 1990. [Google Scholar]

- UK Association of Frozen Food Producers; British Frozen Food Federation; British Retail Consortium; British Hospitality Association; Sea Fish Industry Authority; LACOTS; Association of Public Analysist. Code of Practice on the Declaration of Fish Content in Fish Products. Available online: http://www.seafish.org/media/Publications/Fish_Content_CoP.pdf (accessed on 21 July 2014).

- De Greef, K.H.; Verstegen, M.W.A.; Kemp, B. Validation of a porcine growth model with emphasis on chemical body compostion. Livest. Prod. Sci. 1992, 32, 163–180. [Google Scholar]

- Yeannes, M.I.; Almandos, M.E. Estimation of fish proximate composition starting from water content. J. Food Compos. Anal. 2003, 16, 81–92. [Google Scholar]

- Regulation (EC) No. 543/2008 of 16 June 2008 Laying Down Detailed Rules for the Application of Council Regulation (EC) No 1234/2007 as Regards the Marketing Standards for Poultry Meat. Available online: http://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:32008R0543 (accessed on 21 July 2014).

- Ranken, M.D.; Kill, R.C.; Baker, C.G.J. Food Industries Manual, 24th ed.; Blackie Academic and Professional: London, UK, 1997; pp. 37–39. [Google Scholar]

- Nederlands Visbureau. Visconsumptie in 2013—GfK Jaarcijfers. 2014. Available online: http://www.visspecialisten.nl/l/library/download/30769 (accessed on 21 November 2014).

- ISO 1442:1997 Meat and Meat Products—Determination of Moisture Content (Reference Method). Available online: http://www.iso.org/iso/catalogue_detail.htm?csnumber=6037 (accessed on 21 July 2014).

- ISO 937:1978 Meat and Meat Products—Determination of Nitrogen Content (Reference Method). Available online: http://www.iso.org/iso/catalogue_detail.htm?csnumber=5356 (accessed on 21 July 2014).

- Honikel, K.O. Moisture and water-holding capacity. In Handbook of Muscle Foods Analysis, 1st ed.; Nollet, L.M.L., Toldrá, F., Eds.; CRC Press: Boca Raton, FL, USA, 2009; pp. 315–334. [Google Scholar]

- Wold, J.P.; Isaksson, T. Non-destructive determination of fat and moisture in whole Atlantic salmon by near-infrared diffuse spectroscopy. J. Food Sci. 1997, 62, 734–736. [Google Scholar] [CrossRef]

- He, H.-J.; Wu, D.; Sun, D.-W. Non-destructive and rapid analysis of moisture distribution in farmed Atlantic salmon (Salmo salar) fillets using visible and near-infrared hyperspectral imaging. Innov. Food Sci. Emerg. Technol. 2013, 18, 237–245. [Google Scholar] [CrossRef]

- Greaser, M.L. Proteins. In Handbook of Muscle Foods Analysis, 1st ed.; Nollet, L.M.L., Toldrá, F., Eds.; CRC Press: Boca Raton, FL, USA, 2009; pp. 57–73. [Google Scholar]

- Krzynowek, J.; Murphy, J. Proximate Composition, Energy, Fatty Acid, Sodium, and Cholesterol Content of Finfish, Shellfish, and Their Products; US Department of Commerce: Gloucester, MA, USA, 1987; pp. 3–42.

- Colwell, P.; Ellison, L.R.; Walker, M.J.; Elahi, S.; Burns, D.T.; Gray, K. Nitrogen factors for Atlantic Salmon, Salmo salar, farmed in Scotland and in Norway and for the derived ingredient, “salmon frame mince”, in fish products. J. Assoc. Public Anal. 2011, 39, 44–78. [Google Scholar]

- Rathod, N.; Pagarkar, A. Biochemical and sensory quality changes of fish cutlets, made from pangasius fish (Pangasianodon hypophtalmus), during storage in refrigerated display unit at −15 to −18 °C. Int. J. Food Agric. Vet. Sci. 2013, 3, 1–8. [Google Scholar]

- Karl, H.; Lehmann, I.; Rehbein, H.; Schubring, R. Composition and quality attributes of conventionally and organically farmed Pangasius fillets (Pangasius hypophtalmus) on the German market. Int. J. Food Sci. Technol. 2010, 45, 56–66. [Google Scholar] [CrossRef]

- Olagunju, A.; Muhammad, A.; Mada, S.B.; Mohammed, A.; Mohammed, H.A.; Mahmoud, K.T. Nutrient composition of Tilapia zilli, Hemi-synodontis membranacea, Clupea harengus and Scomber scombrus consumed in Zaria. World J. Life Sci. Med. Res. 2012, 2, 16–19. [Google Scholar]

- Tan, Y.T. Proximate composition of freshwater fish—Grass carp, Puntius gonionotus and Tilapia. Hydrobiologia 1971, 37, 361–366. [Google Scholar] [CrossRef]

- Analytical Methods Committee. Seafood nitrogen factors. Anal. Methods 2014, 6, 4490–4492. [Google Scholar]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Van Ruth, S.M.; Brouwer, E.; Koot, A.; Wijtten, M. Seafood and Water Management. Foods 2014, 3, 622-631. https://doi.org/10.3390/foods3040622

Van Ruth SM, Brouwer E, Koot A, Wijtten M. Seafood and Water Management. Foods. 2014; 3(4):622-631. https://doi.org/10.3390/foods3040622

Chicago/Turabian StyleVan Ruth, Saskia M., Erwin Brouwer, Alex Koot, and Michiel Wijtten. 2014. "Seafood and Water Management" Foods 3, no. 4: 622-631. https://doi.org/10.3390/foods3040622