1. Introduction

Convenience foods can be defined as commercially prepared foods designed for ease of purchase, preparation and consumption [

1]. Such food items can be single elements of a meal or can be complete food items. It is widely believed that the importance of convenience in food is still on the increase, at least in many countries, and that changing demographics are a major driver in this process [

2,

3]. Retailer focus and greater consumer demand for quality maintenance and shelf-life extension of retailed convenience-style food products continues to challenge the development of these food forms. The shelf-life of heat and serve or ready-to-eat foods is usually limited by two factors; microbial growth and the oxygen sensitivity of the product. Therefore, the two main requirements when packaging convenience-style products under modified atmosphere (MA) is that oxygen should be excluded and a fungistatic or bacteriostatic agent be present [

4]. The uses of advanced technologies have been researched in an attempt to exert greater control over the production and stabilisation of convenience-style food products. Technologies such as radiation treatment [

5] and high pressure processing [

6,

7] have been used to increase the shelf-life of convenience-style foods, but are associated with high costs and utilisation issues. Simple and more commonly used technologies such as packaging may prove to be cheaper and more practical in terms of exerting greater process control during the manufacture of convenience-style food products. Technologies like modified atmosphere packaging (MAP) and vacuum packaging are utilised across the food industry to create packaging solutions capable of providing a sufficient shelf-life for the chilled chain distribution of numerous food types. The use and manipulation of such packaging systems have not been exploited sufficiently and in combination with new packaging materials offer opportunities to enhance greater control around food production, especially in the area of convenience-style food production. The use of MAP involves the use of O

2, CO

2 and N

2 in ratios that differ to normal atmospheric air. These altered concentrations retard deterioration processes and maintain foods in a “fresh” state for extended periods of time [

8]. Reduced oxygen levels, to that found in air, is commonly applied to oxygen-sensitive food packaging in order to reduce or delay oxidation reactions in foods. Aerobic microbial growth and oxidation reactions are the principal mechanisms responsible for food deterioration. Elevated levels of CO

2 are utilised for selective antimicrobial effects, primarily targeted towards food spoilage microorganisms [

9]. Vacuum packaging is also utilised in extending shelf-life in foods applications, where the atmosphere that normally surrounds the food is removed. Vacuum packaging of food products can be seen as an effective means of eliminating possible biological and chemical contaminants from the space surrounding the food [

10].

Smart packaging is generally defined as packaging that provides additional levels of useful functionality beyond protecting, containing and providing information about the product [

8,

11]. Smart packaging encompasses and incorporates intelligent and active packaging formats. A smart packaging component can be described as intelligent if it has the ability to sense the environment and communicate its findings with the buyer or consumer; for example an intelligent package is one that can monitor the safety and/or quality condition of a food product and provide early warning to the consumer or food manufacturer [

12]. A form of intelligent packaging that has received much interest is that of optical oxygen sensors [

13,

14,

15]. Fluorescent-based oxygen sensors represent the most promising systems to date for remote measurement of headspace gases in packaged products. A number of disposable oxygen sensing prototypes has been developed that can be produced at low costs and provide rapid determination of oxygen concentration [

15,

16]. Sensors normally consist of a fluorescent or phosphorescent dye encapsulated in a solid polymer matrix and added to a suitable support material. If present, molecular oxygen quenches the luminescent dye and can be quantified against predetermined calibrations. The process is reversible and yields no by-products [

11]. Research utilising optical oxygen sensors across a wide range of foods has been extensively published. Foods ranging from MAP cheese [

17], vacuum packed cheese [

18], MAP and vacuum packed beef [

19], cooked meats [

20], MAP and vacuum packed chicken [

21], as well as

sous vide products [

22] have been monitored for oxygen levels using non-destructive, reversible, optical oxygen sensors. Further research has been carried out in the bottled beverage sector, where oxygen levels were determined in pre-pasteurised beer [

23]. The ability to non-destructively assess the levels of O

2 present immediately after packaging can provide valuable information into the shelf-life and overall quality of the packaged food at any time point during the life-time of the product. Post packaging assessment could lead to the development of acceptable limits that could ensure product quality throughout shelf life and during storage periods [

18].

Another form of smart packaging is that of active packaging. This is defined as packaging in which subsidiary constituents have been deliberately included in, or on, either the packaging material or the package headspace to enhance the performance of the package system [

24]. Scavengers, emitters, absorbers and releasers are commonly utilised active packaging materials incorporated to food packaging applications to extend shelf-life. The use of ethanol is particularly effective against mould but can also inhibit the growth of yeasts and bacteria [

25]. Ethanol sachets containing ethanol-release vapour imparts a preservative effect in the packaging headspace [

26]. Many forms of ethanol emitting sachets have been patented and available for purchase including; Ethicap™, Antimould 102™ and Negamold™ (Freund Industrial Co. Ltd.,Tokyo, Japan) and Ageless™ type SE (Mitsubishi Gas Chemical Co. Ltd., Tokyo, Japan). However, limited applications of such technologies have been reported in the scientific literature.

The objective of this study was to assess various packaging technologies and assess their capacity to extend the shelf-life of a range of commercial convenience-style products that were found to have a reduced shelf-life primarily influenced by mould spoilage. The integration of oxygen sensors in food packs to monitor the levels of oxygen remaining in packs post packaging and the application of ethanol emitters in extending the shelf-life of three convenience-style food products were investigated.

2. Experimental Section

2.1. Optical O2 Sensor and Analysis

Optical O2 sensors were prepared by using well known Platinum octaethylporphyrin-ketone (Pt-OEPK) (Luxcel Bioscience, Cork, Ireland), spotted (4 μL) on Durapore paper (Millipore Inc., Bedford, MA, USA), allowed to dry and cut to size of 5 mm. Sensors were then attached to stickers (Avery price marking stickers, California, CA, USA) for adhesion to the underside of packaging laminates. Sensors were read using a Mocon Op-Tech O2 Platinum (Mocon Inc., Minneapolis, MN, USA) measurement device, which allows for instant oxygen readings ranging from 0.001% to 25% O2 in 0.5 s. This system allows for the handheld instrument to be transportable with the use of a portable computer with Mocon Op-Tech software and complies with standards ASTM F2714. Instrumentation underwent calibration using a Cal-Card, where a simple gas-free method of calibration was carried out using two scan zones of 0% O2 and air. All food packs described in this study contained O2 sensors and all packaging samples were read daily using this non-destructive method.

2.2. Ethanol Emitter Preparation

Ethanol emitters (EE) were used as an in pack antimicrobial sachet. They were prepared in house, by using 3 mL of alcohol gel (Selden, Derbyshire, UK) and placed in pouches formed by using Excell LDPE polymer films (supplied by Fispak, Dublin, Ireland) and heat-sealed using a Henkelman Polar 80 vacuum packer and sealer (Henkelman BV, Hertogenbosch, NL, USA). The use of gel-based alcohol provided for the slow release of ethanol vapour into the packaging headspace. Pouches were micro perforated before being placed into food packs to allow for the release of ethanol over time in the headspace of packaging.

2.3. Sample Preparation

Pre-cooked convenience-style foods were made available from an Irish food manufacturer. Products, including; pre-cooked bacon slices (BA), battered sausages (BS) and beef and potato pies (PP) were selected to monitor the efficiency of the packaging process through the shelf-life evaluation of these products as the company in question had highlighted these products as being problematic in terms of reduced shelf-lives due to mycological growth. All samples were packed in thermoformed retail-ready 2 mm thick PS/EVOH/PE trays (250 mm × 170 mm) (<1 cm

3/m

2/24 h O

2 permeability at 20 °C) and contained through the application of a high barrier lidding laminate Cryovac ULM491 (<1 cm

3/m

2/24 h O

2 permeability at 4 °C) at 43 μm thickness which was heat-sealed to the tray after product filling. Each product varied in unit pack content.

Table 1 highlights the number of product units present in each pack, for each commercial product-type. Repeat samples were also prepared with ethanol emitters (EE) placed in packs and compared. Packaging was carried out using an FP Speedy 2 (ILPRA, Italy) packaging station, sealing two trays per cycle. A combined process of vacuum (1–2 s) application followed by gas flushing and sealing (2.5 s) using a gas mix of 30% CO

2 and 70% N

2 (BOC gases, Ireland), process designed to exclude in-pack O

2. The level of vacuum pressure and gas fill was carried out to manufacturers packaging settings listed in

Table 1. Unit specifications showed that the equipment had a pressure capacity which ranged from 0 to 0.60 MPa (Max.) for vacuum and gas fill.

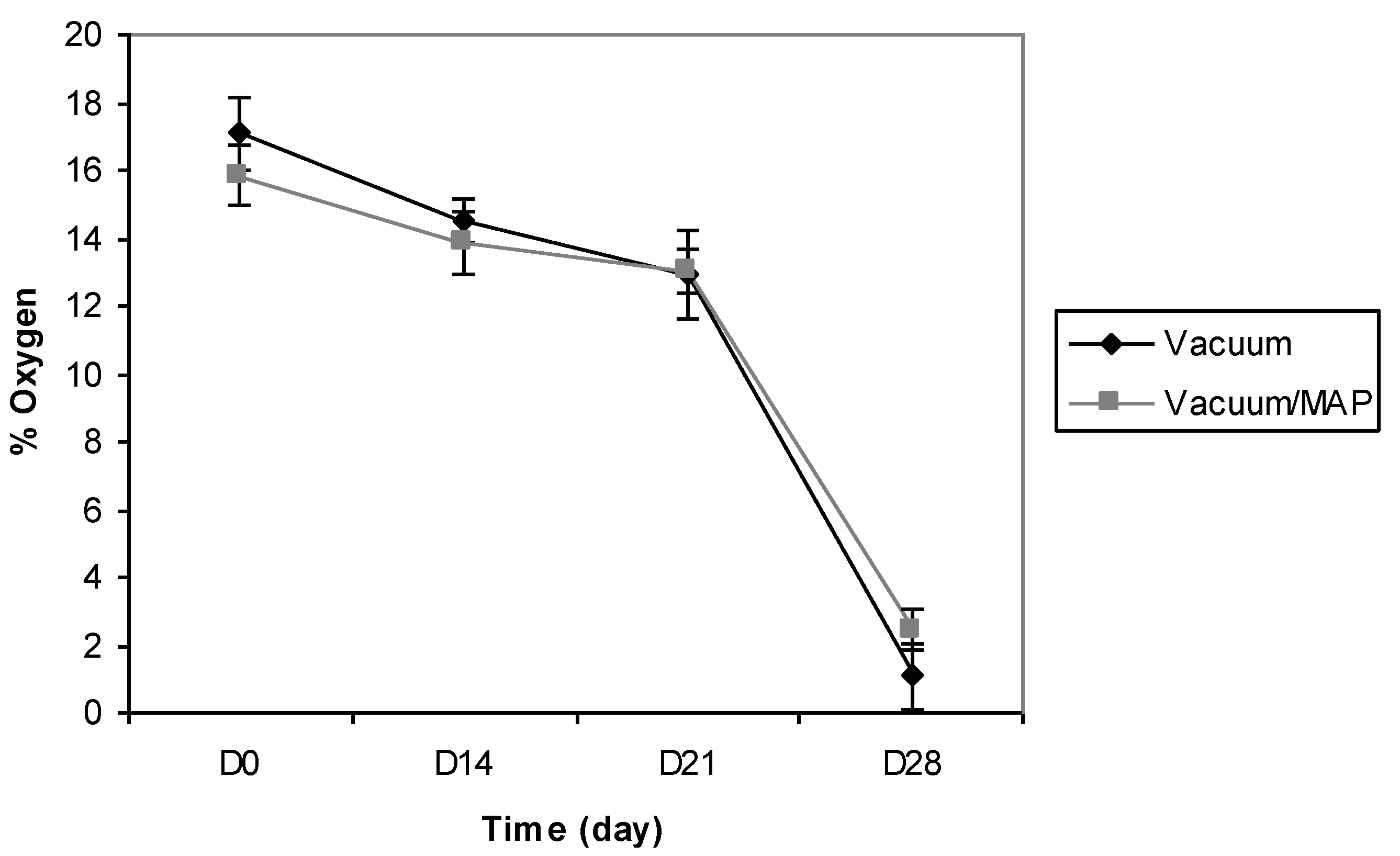

Table 1 also presents the new packaging settings selected for the shelf-life optimisation study. Samples packaged under normal conditions were prepared with the use of a sensor which was pre-attached to laminate materials prior to entering the packaging process. All samples were monitored over time to determine the level of O

2 present immediately following pack sealing and following its removal from the processing line. Subsequently, repeat samples were produced to compare the effects of applying a range of different pressure settings for both the vacuum and gas flushing processes on line and determining the impact of these process modifications on O

2 levels in product packs. All samples were refrigerated at 4 °C immediately after packaging.

Table 1.

Sample list with packaging settings (Vacuum—V/Gas—G) expressed in MPa.

Table 1.

Sample list with packaging settings (Vacuum—V/Gas—G) expressed in MPa.

| Sample | Abbreviation | No. of Units | Original Packaging | New Packaging |

|---|

| per Pack | Settings (MPa) | Settings (MPa) |

|---|

| Battered Sausages | BS | 6 | V (0.20)/G (0.06) | V (0.35)/G (0.02) |

| | | | or V (0.01) | |

| Bacon Slices | BA | 8 | V (0.01) | V (0.35)/G (0.02) |

| Beef & Potato Pie | PP | 4 | V (0.01) | V (0.35)/G (0.02) |

2.4. Microbial Analysis

Microbial testing was carried on samples for Total Viable Counts (TVC) and yeasts and moulds. Samples were tested on a weekly basis for 5 weeks (35 days). TVC was determined using total viable count agar (Sigma-Aldrich, MO, USA), with dilutions of 10

1–10

6 and incubated at 30 °C for 48 h. Limits for total viable count (TVC) were log

10 6 [

27]. Yeast and mould counts were assessed using dilutions described above and plated on compact dry yeast and mould plates (Hyserve, Uffling, Germany) and incubated at 25 °C for 7 days. Colonies were counted and presented in log

10 cfu/g sample and limits were exceeded when mould counts reached 10

5/g or 5 log10 (cfu/g) [

27].

2.5. Sensory Analysis Design

Sensory analysis was carried out to determine if the use of EE had an effect on product quality perception. Twenty-six panellists were chosen form University College Cork, Ireland to partake in the study. The selection criteria for panellists included; availability to attend on each day of the study, motivation and were regular consumers of ready-cooked products, especially product types similar to those being assessed in this study. Panellists were all aged between 21 and 40 and consisted of a 50:50 male and female balance. Testing was carried out in accordance with ISO standards [

28], where individual booths were provided and samples were assigned random three digit codes for blind assessment. Panellists were asked to rate descriptors on a ten point scale. A list of descriptors used for products can be seen in

Table 2. Sensory analysis was assessed on day 14 and 35, to allow maximum exposure of foods to ethanol over a 35-day shelf-life. Panellists were provided with six samples, consisting of three products packaged at new packaging settings and replicates packaged with ethanol emitters. Samples were presented in a cooked state as instructed by pack guidelines.

2.6. Statistical Analysis

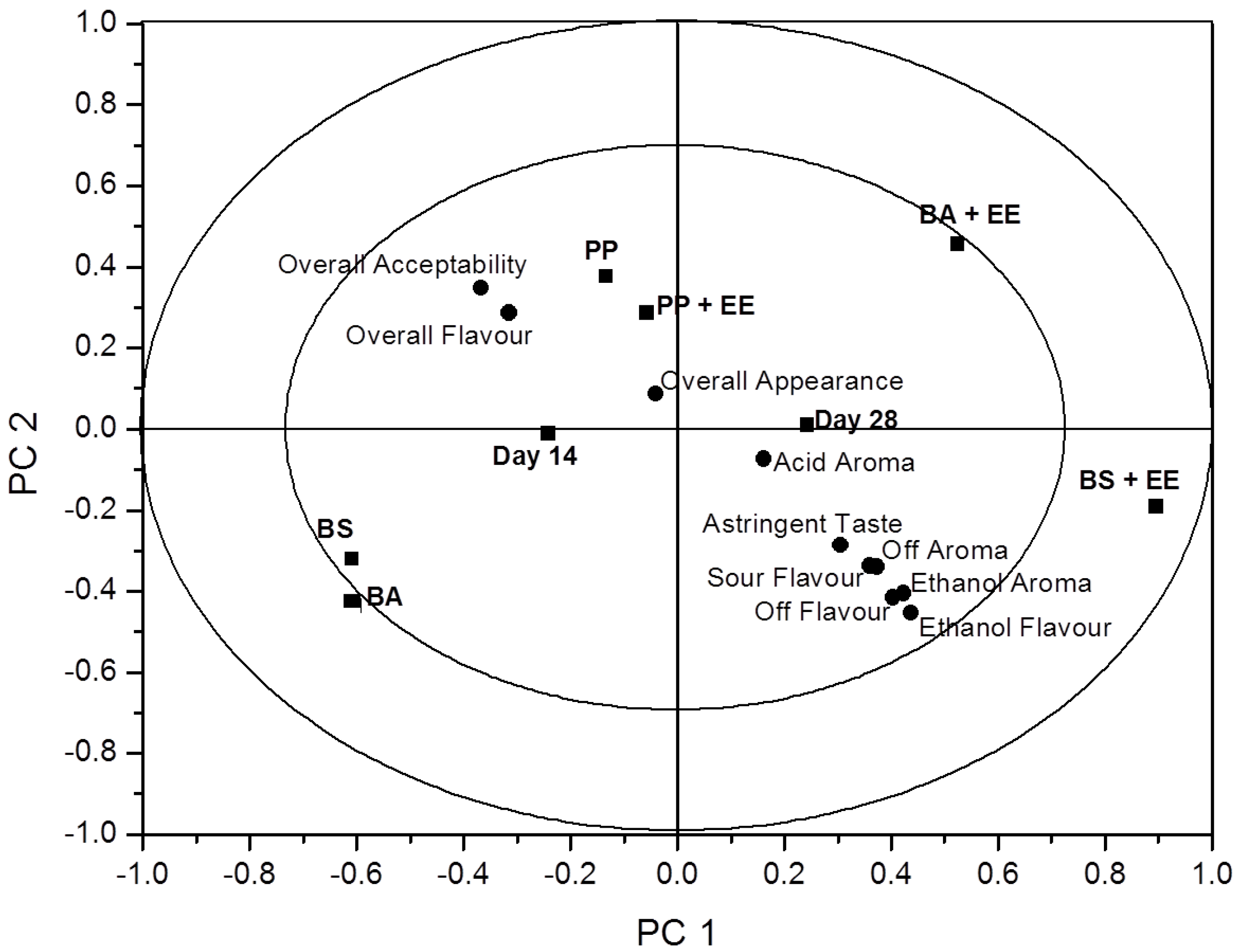

Raw data was accumulated from sensory evaluation and processed using ANOVA-partial least squares regression (APLSR). The optimal number of components in the APLSR models presented was determined to be two principle components (

Figure 1). Principle component (PC) 1

versus PC 2 is presented, as other PC’s did not yield any additional information. The validated explained variance for the model constructed was 18.52% and the calibrated variance was 25.43%. To derive the significance indictors for the relationships determined in the quantitative APLSR, regression coefficients were analysed by Jack-Knifing (

Table 3). All analyses were performed using the Unscrambler Software, version 7.6 (Camo ASA, Trondheim, Norway).

Table 2.

List of descriptors for sensory analysis.

Table 2.

List of descriptors for sensory analysis.

| Attribute | Description |

|---|

| Overall Appearance | 0 = Extremely Dislike, 10 = Extremely Like |

| Off Aroma | 0 = None, 10 = Extreme |

| Ethanol Aroma | 0 = None, 10 = Extreme |

| Acid Aroma | 0 = None, 10 = Extreme |

| Overall Flavour Liking | 0 = Extremely Dislike, 10 = Extremely Like |

| Off Flavour | 0 = None, 10 = Extreme |

| Sour Flavour | 0 = None, 10 = Extreme |

| Astringent Taste | 0 = None, 10 = Extreme |

| Ethanol Flavour | 0 = None, 10 = Extreme |

| Overall acceptability | 0 = Extremely Unacceptable, 10 = Extremely Unacceptable |

Figure 1.

An overview of the variation found in the mean data from the ANOVA-partial least squares regression (APLSR) correlation loadings plot for each of the eight treatment groups assessed by a trained sensory group. Shown are the loadings of the X- and Y-variables for the first two principle components (PC’s) for averaged data validated over replicates. ■ = sample and days of analysis; ● = sensory descriptor.

Figure 1.

An overview of the variation found in the mean data from the ANOVA-partial least squares regression (APLSR) correlation loadings plot for each of the eight treatment groups assessed by a trained sensory group. Shown are the loadings of the X- and Y-variables for the first two principle components (PC’s) for averaged data validated over replicates. ■ = sample and days of analysis; ● = sensory descriptor.

Table 3.

Significance of estimated regression coefficients (ANOVA p-values) for the relationships of sensory terms as derived by jack-knifing uncertainty testing of ready cooked foods.

Table 3.

Significance of estimated regression coefficients (ANOVA p-values) for the relationships of sensory terms as derived by jack-knifing uncertainty testing of ready cooked foods.

| | Sample | Time |

|---|

| | BS | BS + EE | PP | PP + EE | BA | BA + EE | Day 14 | Day 35 |

|---|

| Overall Appearance | 0.93 ns | −0.33 ns | 0.27 ns | 0.23 ns | 0.47 ns | 0.78 ns | 0.64 ns | 0.58 ns |

| Off Aroma | −0.003 ** | 0.001 *** | 0.001 *** | −0.004 ** | −0.85 ns | −0.001 *** | −0.40 ns | 0.42 ns |

| Ethanol Aroma | 0.001 *** | 0.001 *** | 0.001 *** | −0.003 ** | −0.90 ns | −0.001 *** | −0.61 ns | 0.64 ns |

| Acid Aroma | −0.04 * | 0.02 * | −0.19 ns | −0.17 ns | −0.53 ns | −0.28 ns | −0.59 ns | 0.63 ns |

| Overall Flavour Liking | 0.002 ** | 0.001 *** | 0.002 ** | 0.004 ** | 0.99 ns | 0.001 *** | 0.67 ns | −0.61 ns |

| Off Flavour | −0.002 ** | 0.001 *** | −0.003 ** | −0.005 ** | −0.74 ns | −0.001 *** | −0.56 ns | 0.38 ns |

| Sour Flavour | −0.003 ** | 0.001 *** | −0.002 ** | −0.007 ** | −0.83 ns | −0.001 *** | −0.48 ns | 0.46 ns |

| Astringent Taste | −0.002 ** | 0.001 *** | −0.015 * | −0.02 * | −0.94 ns | −0.001 *** | −0.81 ns | 0.77 ns |

| Ethanol Flavour | 0.001 *** | 0.001 *** | 0.001 *** | −0.002 ** | −0.65 ns | −0.001 *** | −0.48 ns | 0.37 ns |

| Overall Acceptablility | 0.003 ** | 0.001 *** | 0.001 *** | 0.002 ** | 0.75 ns | 0.001 *** | 0.45 ns | −0.42 ns |