Perspectives on Novel Technologies of Processing and Monitoring the Safety and Quality of Prepared Food Products

Abstract

:1. Introduction

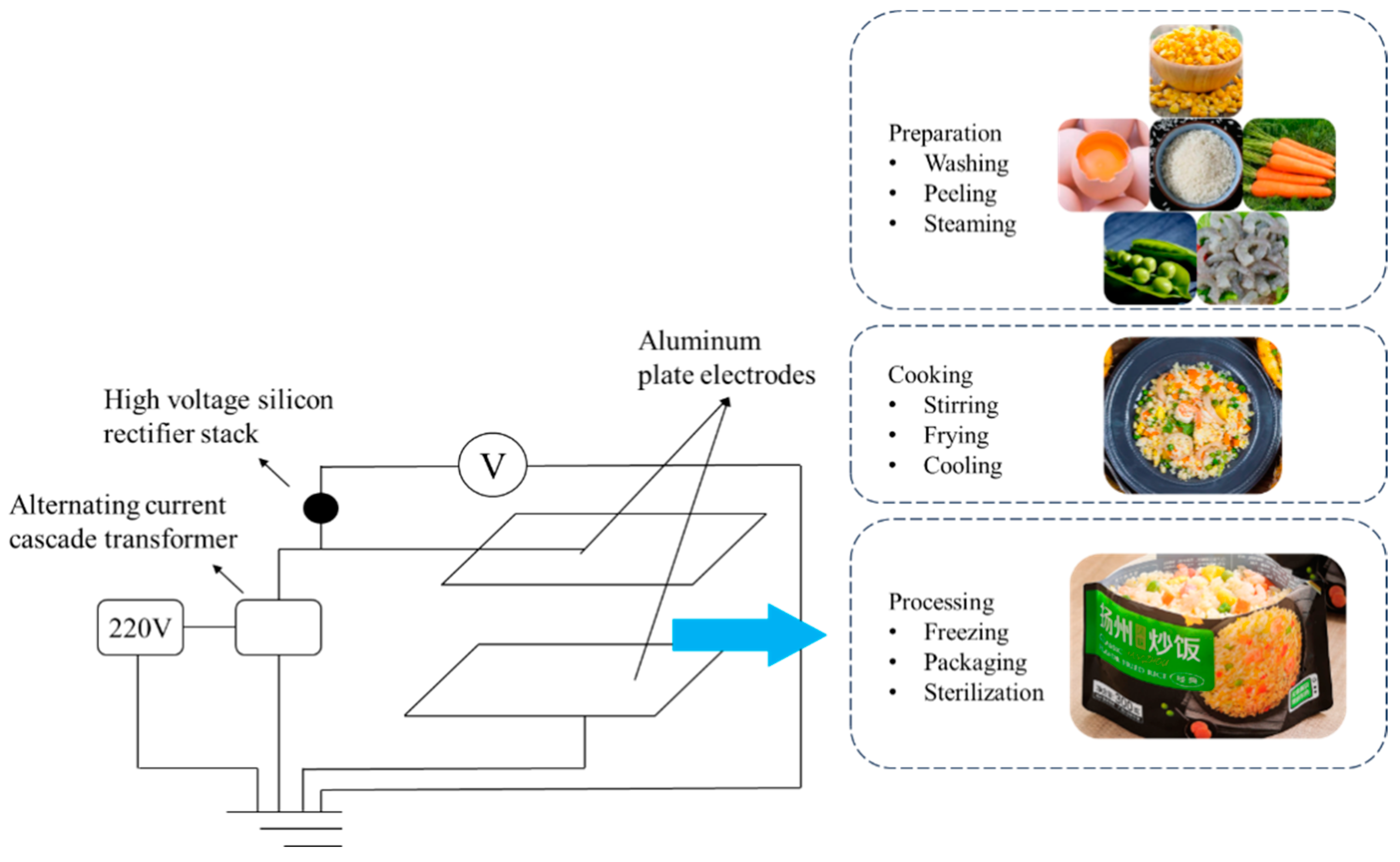

2. Potential Processing Technologies for Prepared Fried Rice

2.1. Sterilization Technologies

2.1.1. Irradiation

2.1.2. High-Voltage Electric Field

2.1.3. Microwave

2.1.4. Radio Frequency

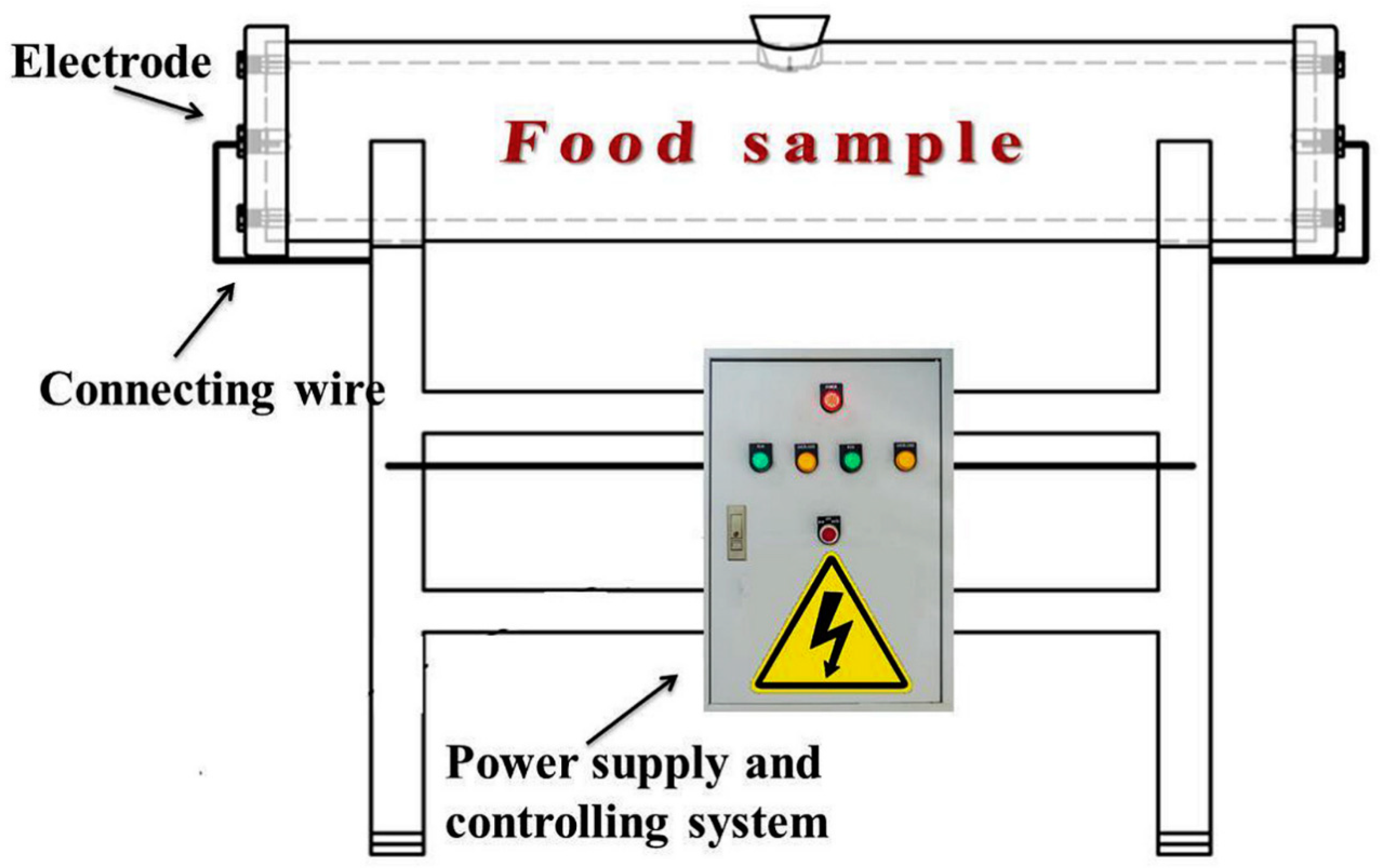

2.1.5. Ohmic Heating

3. Potential Quality and Safety Monitoring Technologies for Prepared Fried Rice

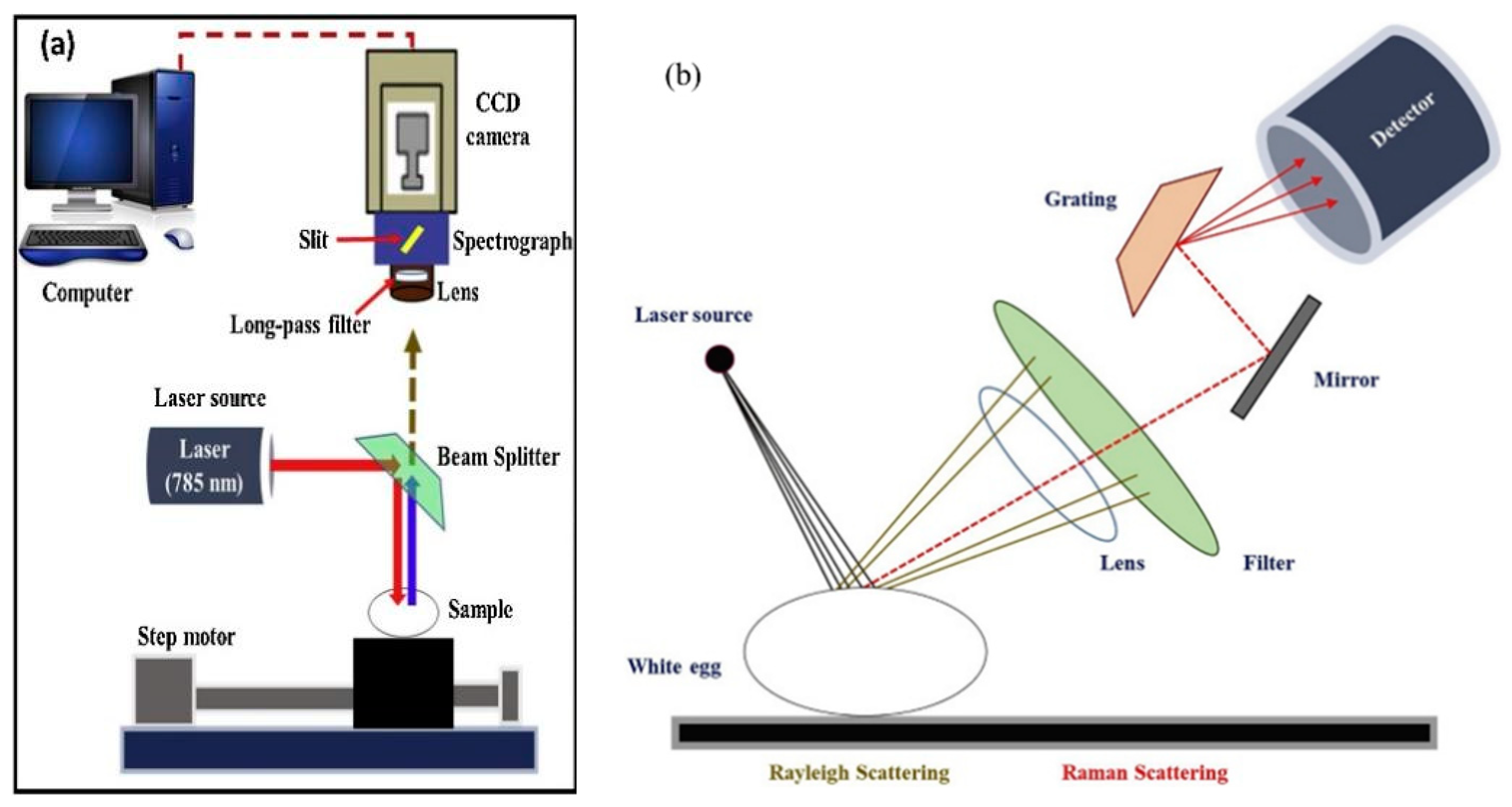

3.1. Raman Spectroscopy Imaging Technology

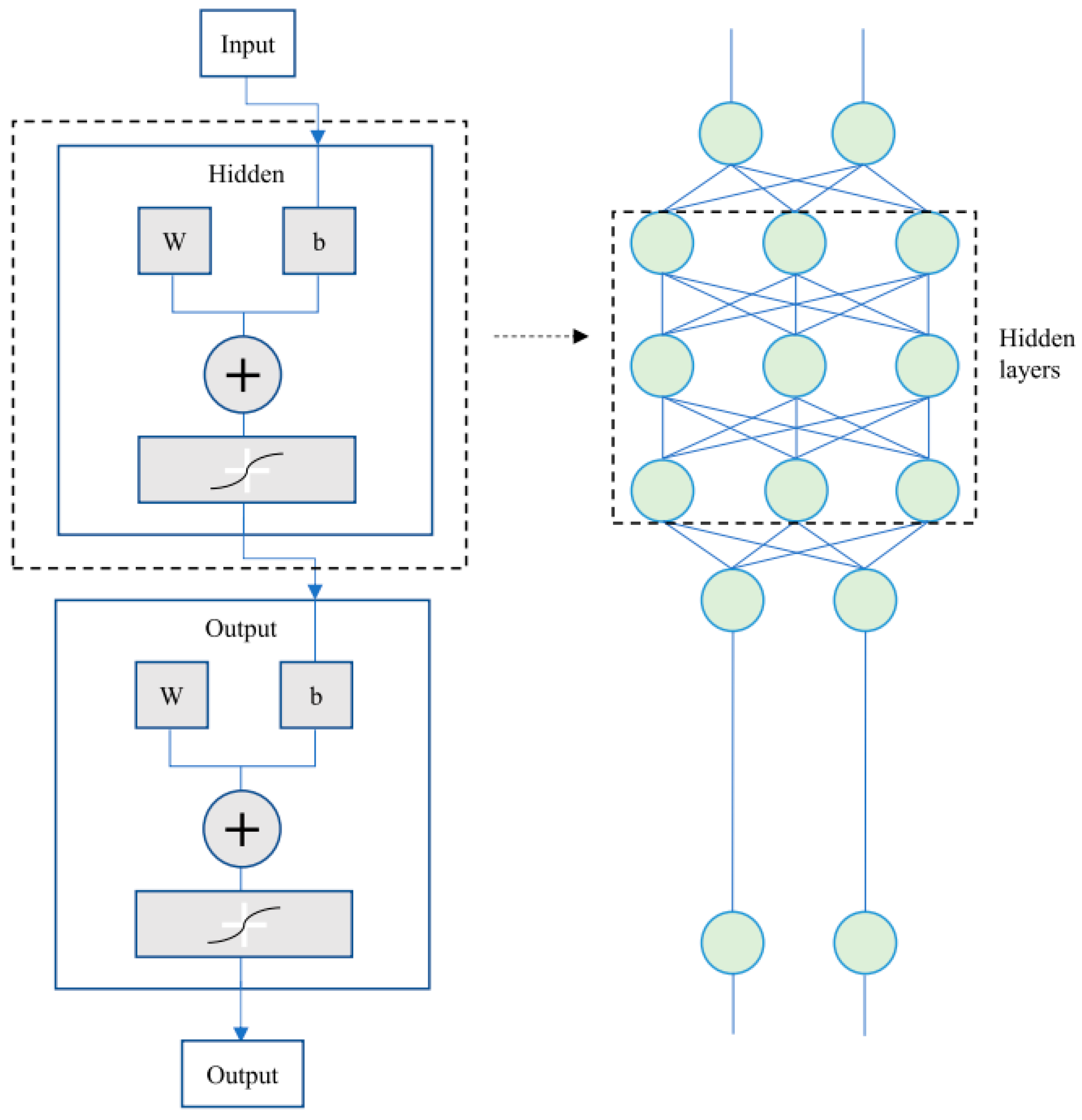

3.2. Near-Infrared Spectroscopy Imaging Technology

3.3. Low-Field Nuclear Magnetic Resonance Technology

4. Conclusions and Future Trends

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yu, Q.; Zhang, M.; Ju, R.; Mujumdar, A.S.; Wang, H. Advances in prepared dish processing using efficient physical fields: A review. Crit. Rev. Food Sci. Nutr. 2022, 1–15. [Google Scholar]

- The State Council of China. Opinions of the General Office of the State Council on Further Promoting the Development of the Agricultural Product Processing Industry. Available online: http://www.gov.cn/zhengce/content/2016-12/28/content_5153844.htm (accessed on 28 December 2016).

- Aimedia Consulting. China Prepared Dishes Industry Analysis Report 2021; Ai Media Restaurant Research Institute: Guangzhou, China, 2021. [Google Scholar]

- Huang, M.; Zhang, M.; Bhandari, B. Recent development in the application of alternative sterilization technologies to prepared dishes: A review. Crit. Rev. Food Sci. Nutr. 2019, 59, 1188–1196. [Google Scholar] [CrossRef]

- Maneerote, J.; Noomhorm, A.; Takhar, P.S. Optimization of processing conditions to reduce oil uptake and enhance physico-chemical properties of deep fried rice crackers. LWT Food Sci. Technol. 2009, 42, 805–812. [Google Scholar] [CrossRef]

- Lim, S.-T.; Han, J.-A. Improvement in antioxidant functionality and shelf life of yukwa (fried rice snack) by turmeric (Curcuma longa L.) powder addition. Food Chem. 2016, 199, 590–596. [Google Scholar] [CrossRef] [PubMed]

- Cho, S.-J.; Jo, M.N. Changes in physical properties of Yukwa (fried rice snack) by soybean extract concentration and incubation time. Food Sci. Biotechnol. 2018, 27, 433–440. [Google Scholar] [CrossRef]

- Schreiber, N.; Hackl, G.; Reisinger, A.C.; Zollner-Schwetz, I.; Eller, K.; Schlagenhaufen, C.; Pietzka, A.; Czerwenka, C.; Stark, T.D.; Kranzler, M.; et al. Acute Liver Failure after Ingestion of Fried Rice Balls: A Case Series of Bacillus cereus Food Poisonings. Toxins. 2022, 14, 12. [Google Scholar] [CrossRef] [PubMed]

- Huang, L.; Hwang, C.A. One-step dynamic analysis of growth kinetics of Bacillus cereus from spores in simulated fried rice—Model development, validation, and Marko Chain Monte Carlo simulation. Food Microbiol. 2022, 103, 103935. [Google Scholar] [CrossRef] [PubMed]

- Jiang, H.; Zhang, M.; Chen, J. Effect of Processing Methods on Flavor Quality of Vegetable Balls after Boiling. J. Food Sci. Biotechnol. 2021, 40, 58–64. [Google Scholar]

- Ding, Y.; Xiao, Y.; Ouyang, Q.; Luo, F.; Lin, Q. Modulating the in vitro digestibility of chemically modified starch ingredient by a non-thermal processing technology of ultrasonic treatment. Ultrason. Sonochemistry 2021, 70, 105350. [Google Scholar] [CrossRef]

- Asaithambi, N.; Singh, S.K.; Singha, P. Current status of non-thermal processing of probiotic foods: A review. J. Food Eng. 2021, 303, 110567. [Google Scholar] [CrossRef]

- Ribeiro, N.G.; Xavier-Santos, D.; Campelo, P.H.; Guimarães, J.T.; Pimentel, T.C.; Duarte, M.C.K.H.; Freitas, M.Q.; Esmerino, E.A.; Silva, M.C.; Cruz, A.G. Dairy foods and novel thermal and non-thermal processing: A bibliometric analysis. Innov. Food Sci. Emerg. Technol. 2022, 76, 102934. [Google Scholar] [CrossRef]

- Ankolekar, C.; Rahmati, T.; Labbe, R.G. Detection of toxigenic Bacillus cereus and Bacillus thuringiensis spores in US rice. Int. J. Food Microbiol. 2009, 128, 460–466. [Google Scholar] [CrossRef] [PubMed]

- Wang, R.; Sun, L.; Wang, Y.; Deng, Y.; Fang, Z.; Liu, Y.; Liu, Y.; Sun, D.; Deng, Q.; Gooneratne, R. Growth and Hemolysin Production Behavior of Vibrio parahaemolyticus in Different Food Matrices. J. Food Prot. 2018, 81, 246–253. [Google Scholar] [CrossRef] [PubMed]

- Soni, A.; Oey, I.; Silcock, P.; Bremer, P.J. Impact of temperature, nutrients, pH and cold storage on the germination, growth and resistance of Bacillus cereus spores in egg white. Food Res. Int. 2018, 106, 394–403. [Google Scholar] [CrossRef]

- Guinebretiere, M.H.; Girardin, H.; Dargaignaratz, C.; Carlin, F.; Nguyen-The, C. Contamination flows of Bacillus cereus and spore-forming aerobic bacteria in a cooked, pasteurized and chilled zucchini puree processing line. Int. J. Food Microbiol. 2003, 82, 223–232. [Google Scholar] [CrossRef] [PubMed]

- Tirloni, E.; Bernardi, C.; Ghelardi, E.; Celandroni, F.; Cattaneo, P.; Stella, S. Bacillus cereus in fried rice meals: Natural occurrence, strain dependent growth and haemolysin (HBL) production. LWT Food Sci. Technol. 2019, 114, 108393. [Google Scholar] [CrossRef]

- Chang, H.-J.; Lee, J.-H.; Han, B.-R.; Kwak, T.-K.; Kim, J. Prevalence of the levels of Bacillus cereus in fried rice dishes and its exposure assessment from Chinese-style restaurants. Food Sci. Biotechnol. 2011, 20, 1351–1359. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, K.; Zhang, Z.; Tian, S.; Liu, M.; Li, X.; Han, Y.; Zhu, K.; Liu, H.; Yang, C.; et al. A Severe Gastroenteritis Outbreak of Salmonella enterica Serovar Enteritidis Linked to Contaminated Egg Fried Rice, China, 2021. Front. Microbiol. 2021, 12, 779749. [Google Scholar] [CrossRef]

- Wang, R.; Hu, X.; Deng, Y.; Gooneratne, R. Effect of Food Matrix Type on Growth Characteristics of and Hemolysin Production by Vibrio alginolyticus. J. Food Prot. 2021, 84, 1411–1420. [Google Scholar] [CrossRef]

- Tahergorabi, R.; Matak, K.E.; Jaczynski, J. Application of electron beam to inactivate Salmonella in food: Recent developments. Food Res. Int. 2012, 45, 685–694. [Google Scholar] [CrossRef]

- Chen, Q.; Cao, M.; Chen, H.; Gao, P.; Fu, Y.; Liu, M.; Wang, Y.; Huang, M. Effects of gamma irradiation on microbial safety and quality of stir fry chicken dices with hot chili during storage. Radiat. Phys. Chem. 2016, 127, 122–126. [Google Scholar] [CrossRef]

- Feliciano, C.P.; de Guzman, Z.M.; Tolentino, L.M.M.; Asaad, C.O.; Cobar, M.L.C.; Abrera, G.B.; Baldos, D.T.; Diano, G.T. Microbiological quality of brown rice, ready-to-eat pre-cut fresh fruits, and mixed vegetables irradiated for immuno-compromised patients. Radiat. Phys. Chem. 2017, 130, 397–399. [Google Scholar] [CrossRef]

- Feng, X.; Ahn, D.U. Volatile profile, lipid oxidation and protein oxidation of irradiated ready-to-eat cured turkey meat products. Radiat. Phys. Chem. 2016, 127, 27–33. [Google Scholar] [CrossRef]

- Li, X.; Farid, M. A review on recent development in non-conventional food sterilization technologies. J. Food Eng. 2016, 182, 33–45. [Google Scholar] [CrossRef]

- Munshi, M.K.; Sukhi, F.A.; Huque, R.; Hossain, A.; Mahbub, S.; Hoque, S.A.; Hossain, T.; Khan, M.S.I.; Hossain, M.F. Combination impacts of gamma radiation and low temperature on the toxin-producing Bacillus cereus isolated from fried and steam rice. J. Food Process. Preserv. 2021, 45, 192–200. [Google Scholar] [CrossRef]

- Ben-Fadhel, Y.; Saltaji, S.; Khlifi, M.A.; Salmieri, S.; Dang Vu, K.; Lacroix, M. Active edible coating and gamma-irradiation as cold combined treatments to assure the safety of broccoli florets (Brassica oleracea L.). Int. J. Food Microbiol. 2017, 241, 30–38. [Google Scholar] [CrossRef]

- Wang, Q.; Li, Y.; Sun, D.-W.; Zhu, Z. Enhancing Food Processing by Pulsed and High Voltage Electric Fields: Principles and Applications. Crit. Rev. Food Sci. Nutr. 2018, 58, 2285–2298. [Google Scholar] [CrossRef]

- Mosqueda-Melgar, J.; Raybaudi-Massilia, R.M.; Martin-Belloso, O. Influence of treatment time and pulse frequency on Salmonella Enteritidis, Escherichia coli and Listeria monocytogenes populations inoculated in. melon and watermelon juices treated by pulsed electric fields. Int. J. Food Microbiol. 2007, 117, 192–200. [Google Scholar] [CrossRef] [PubMed]

- Zhu, N.; Yu, N.; Zhu, Y.; Wei, Y.; Zhang, H.; Sun, A.D. Inactivation of Pichia rhodanensis in relation to membrane and intracellular compounds due to microchip pulsed electric field (MPEF) treatment. PLoS ONE 2018, 13, e0198467. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhao, W.; Yang, R.; Zhang, H.Q. Recent advances in the action of pulsed electric fields on enzymes and food component proteins. Trends Food Sci. Technol. 2012, 27, 83–96. [Google Scholar] [CrossRef]

- Fernandez-Diaz, M.D.; Barsotti, L.; Dumay, E.; Cheftel, J.C. Effects of Pulsed Electric Fields on Ovalbumin Solutions and Dialyzed Egg White. J. Agric. Food Chem. 2000, 48, 2332–2339. [Google Scholar] [CrossRef]

- Martin, O.; Qin, B.L.; Chang, F.J.; BarbosaCanovas, G.V.; Swanson, B.G. Inactivation of Escherichia coli in skim milk by high intensity pulsed electric fields. J. Food Process Eng. 1997, 20, 317–336. [Google Scholar] [CrossRef]

- Huang, H.; Sun, W.; Xiong, G.; Shi, L.; Jiao, C.; Wu, W.; Li, X.; Qiao, Y.; Liao, L.; Ding, A.; et al. Effects of HVEF treatment on microbial communities and physicochemical properties of catfish fillets during chilled storage. LWT 2020, 131, 109667. [Google Scholar] [CrossRef]

- Qi, M.; Zhao, R.; Liu, Q.; Yan, H.; Zhang, Y.; Wang, S.; Yuan, Y. Antibacterial activity and mechanism of high voltage electrostatic field (HVEF) against Staphylococcus aureus in medium plates and food systems. Food Control 2021, 120, 107566. [Google Scholar] [CrossRef]

- Hsieh, C.-W.; Lai, C.-H.; Lee, C.-H.; Ko, W.-C. Effects of High-Voltage Electrostatic Fields on the Quality of Tilapia Meat during Refrigeration. J. Food Sci. 2011, 76, M312–M317. [Google Scholar] [CrossRef] [PubMed]

- Ko, W.-C.; Yang, S.-Y.; Chang, C.-K.; Hsieh, C.-W. Effects of adjustable parallel high voltage electrostatic field on the freshness of tilapia (Orechromis niloticus) during refrigeration. LWT Food Sci. Technol. 2016, 66, 151–157. [Google Scholar] [CrossRef]

- Huang, H.; Gao, T.; Qian, X.; Wu, W.; Fan, X.; Shi, L.; Xiong, G.; Ding, A.; Li, X.; Qiao, Y.; et al. In Vitro Antibacterial Mechanism of High-Voltage Electrostatic Field against Acinetobacter johnsonii. Foods 2022, 11, 955. [Google Scholar] [CrossRef]

- Auksornsri, T.; Songsermpong, S. Lethality and quality evaluation of in-packaged ready-to-eat cooked Jasmine rice subjected to industrial continuous microwave pasteurization. Int. J. Food Prop. 2016, 20, 1856–1865. [Google Scholar] [CrossRef] [Green Version]

- Viji, P.; Rao, B.M.; Debbarma, J.; Ravishankar, C.N. Research developments in the applications of microwave energy in fish processing: A review. Trends Food Sci. Technol. 2022, 123, 222–232. [Google Scholar] [CrossRef]

- Peng, J.; Tang, J.; Barrett, D.M.; Sablani, S.S.; Anderson, N.; Powers, J.R. Thermal pasteurization of ready-to-eat foods and vegetables: Critical factors for process design and effects on quality. Crit. Rev. Food Sci. Nutr. 2017, 57, 2970–2995. [Google Scholar] [CrossRef]

- Kim, H.S.; Choi, S.J.; Yoon, K.S. Efficacy Evaluation of Control Measures on the Reduction of Staphylococcus aureus in Salad and Bacillus cereus in Fried Rice Served at Restaurants. Foodborne Pathog. Dis. 2018, 15, 198–209. [Google Scholar] [CrossRef]

- Montero, M.L.; Sablani, S.; Tang, J.; Ross, C.F. Characterization of the sensory, chemical, and microbial quality of microwave-assisted, thermally pasteurized fried rice during storage. J. Food Sci. 2020, 85, 2711–2719. [Google Scholar] [CrossRef]

- Guo, Q.; Sun, D.-W.; Cheng, J.-H.; Han, Z. Microwave processing techniques and their recent applications in the food industry. Trends Food Sci. Technol. 2017, 67, 236–247. [Google Scholar] [CrossRef]

- Tian, J.; Chen, J.; Lv, F.; Chen, S.; Chen, J.; Liu, D.; Ye, X. Domestic cooking methods affect the phytochemical composition and antioxidant activity of purple-fleshed potatoes. Food Chem. 2016, 197, 1264–1270. [Google Scholar] [CrossRef] [PubMed]

- Fan, L.P.; Zhang, M.; Mujumdar, A.S. Vacuum frying of carrot chips. Dry. Technol. 2005, 23, 645–656. [Google Scholar] [CrossRef]

- Geedipalli, S.S.R.; Rakesh, V.; Datta, A.K. Modeling the heating uniformity contributed by a rotating turntable in microwave ovens. J. Food Eng. 2007, 82, 359–368. [Google Scholar] [CrossRef]

- Regier, M.; Knoerzer, K.; Schubert, H. The Microwave Processing of Foods 2. In Microwave Heating and the Dielectric Properties of Foods, 2nd ed.; Woodhead Publishing: Sawston, UK, 2017; pp. 23–43. [Google Scholar]

- Wang, R.; Zhang, M.; Mujumdar, A.S.; Jiang, H. Effect of salt and sucrose content on dielectric properties and microwave freeze drying behavior of re-structured potato slices. J. Food Eng. 2011, 106, 290–297. [Google Scholar] [CrossRef]

- Wang, R.; Zhang, M.; Mujumdar, A.S. Effect of Osmotic Dehydration on Microwave Freeze-Drying Characteristics and Quality of Potato Chips. Dry. Technol. 2010, 28, 798–806. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, M.; Shan, L.; Fang, Z.X. Microwave-vacuum heating parameters for processing savory crisp bighead carp (Hypophthalmichthys nobilis) slices. J. Food Eng. 2007, 79, 885–891. [Google Scholar] [CrossRef]

- Wang, X.; Xu, H.; Zhu, Y.; Liu, C.; Liu, H.; Liu, C.; Fu, H.; Zheng, X. Improvement of Temperature Uniformity of Instant Rice Inside Plastic Rectangular Container Under Microwave Reheating. J. Northeast. Agric. Univ. 2018, 25, 79–89. [Google Scholar]

- Wang, Y.C.; Zhang, M.; Mujumdar, A.S.; Mothibe, K.J.; Azam, S.M.R. Study of Drying Uniformity in Pulsed Spouted Microwave-Vacuum Drying of Stem Lettuce Slices with Regard to Product Quality. Dry. Technol. 2013, 31, 91–101. [Google Scholar] [CrossRef]

- Piza, L.V.; Von Atzingen, G.V.; Costa, E.J.X. Electronic Instrumentation and Computational Simulation to Evaluate the Combined Use of Microwave and Infrared Technologies for Reheating Biphasic Foods. Int. J. Food Eng. 2019, 15, 20180192. [Google Scholar] [CrossRef]

- Chen, C.; Zhang, M.; Liu, W.C.; Lin, Z.H. Baking characteristic improvement and starch retrogradation inhibition of Chinese pancakes by hydrocolloids. J. Food Process. Preserv. 2022, 46, e16529. [Google Scholar] [CrossRef]

- Chen, C. Study on Edible Quality Improvement of Fresh/Cooling and Reheating of Pre-Made Pancake. Master’s Thesis, Jiangnan University, Wuxi, China, 2022. Available online: https://kns.cnki.net/KCMS/detail/detail.aspx?dbname=CMFD202301&filename=1022642003.nh (accessed on 8 July 2023).

- Zhang, Z.N.; Zhang, M.Q.; Zhang, B.; Wang, Y.Y.; Zhao, W. Radio frequency energy regulates the multi-scale structure, digestive and physicochemical properties of rice starch. Food Biosci. 2022, 47, 101616. [Google Scholar] [CrossRef]

- Jiao, Y.; Tang, J.; Wang, Y.; Koral, T.L. Radio-Frequency Applications for Food Processing and Safety. Annu. Rev. Food Sci. Technol. 2018, 9, 105–127. [Google Scholar] [CrossRef] [Green Version]

- Luechapattanaporn, K.; Wang, Y.; Wang, J.; Tang, J.; Hallberg, L.M.; Dunne, C.P. Sterilization of Scrambled Eggs in Military Polymeric Trays by Radio Frequency Energy. J. Food Sci. 2006, 70, E288–E294. [Google Scholar] [CrossRef]

- Xu, J.; Zhang, M.; An, Y.; Roknul, A.S.; Adhikari, B. Effects of radio frequency and high pressure steam sterilisation on the colour and flavour of prepared Nostoc sphaeroides. J. Sci. Food Agric. 2018, 98, 1719–1724. [Google Scholar] [CrossRef]

- Xu, J.C.; Zhang, M.; Bhandari, B.; Kachele, R. ZnO nanoparticles combined radio frequency heating: A novel method to control microorganism and improve product quality of prepared carrots. Innov. Food Sci. Emerg. Technol. 2017, 44, 46–53. [Google Scholar] [CrossRef] [Green Version]

- Lan, R.; Qu, Y.; Ramaswamy, H.S.; Wang, S. Radio frequency reheating behavior in a heterogeneous food: A case study of pizza. Innov. Food Sci. Emerg. Technol. 2020, 65, 102478. [Google Scholar] [CrossRef]

- Wang, J.; Luechapattanaporn, K.; Wang, Y.; Tang, J. Radio-frequency heating of heterogeneous food—Meat lasagna. J. Food Eng. 2012, 108, 183–193. [Google Scholar] [CrossRef]

- Gavahian, M.; Tiwari, B.K.; Chu, Y.H.; Ting, Y.W.; Farahnaky, A. Food texture as affected by ohmic heating: Mechanisms involved, recent findings, benefits, and limitations. Trends Food Sci. Technol. 2019, 86, 328–339. [Google Scholar] [CrossRef]

- Jittanit, W.; Khuenpet, K.; Kaewsri, P.; Dumrongpongpaiboon, N.; Hayamin, P.; Jantarangsri, K. Ohmic heating for cooking rice: Electrical conductivity measurements, textural quality determination and energy analysis. Innov. Food Sci. Emerg. Technol. 2017, 42, 16–24. [Google Scholar] [CrossRef]

- Mannozzi, C.; Fauster, T.; Haas, K.; Tylewicz, U.; Romani, S.; Dalla Rosa, M.; Jaeger, H. Role of thermal and electric field effects during the pre-treatment of fruit and vegetable mash by pulsed electric fields (PEF) and ohmic heating (OH). Innov. Food Sci. Emerg. Technol. 2018, 48, 131–137. [Google Scholar] [CrossRef]

- Gavahian, M.; Chu, Y.H.; Farahnaky, A. Effects of ohmic and microwave cooking on textural softening and physical properties of rice. J. Food Eng. 2019, 243, 114–124. [Google Scholar] [CrossRef]

- Zareifard, M.R.; Ramaswamy, H.S.; Trigui, M.; Marcotte, M. Ohmic heating behaviour and electrical conductivity of two-phase food systems. Innov. Food Sci. Emerg. Technol. 2003, 4, 45–55. [Google Scholar] [CrossRef]

- Benabderrahmane, Y.; Pain, J.P. Thermal behaviour of a solid/liquid mixture in an ohmic heating sterilizer—Slip phase model. Chem. Eng. Sci. 2000, 55, 1371–1384. [Google Scholar] [CrossRef]

- Icier, F.; Ilicali, C. Temperature dependent electrical conductivities of fruit purees during ohmic heating. Food Res. Int. 2005, 38, 1135–1142. [Google Scholar] [CrossRef]

- Shirsat, N.; Lyng, J.G.; Brunton, N.P.; McKenna, B. Ohmic processing: Electrical conductivities of pork cuts. Meat Sci. 2004, 67, 507–514. [Google Scholar] [CrossRef] [PubMed]

- Gavahian, M.; Chu, Y.-H.; Sastry, S. Extraction from Food and Natural Products by Moderate Electric Field: Mechanisms, Benefits, and Potential Industrial Applications. Compr. Rev. Food Sci. Food Saf. 2018, 17, 1040–1052. [Google Scholar] [CrossRef] [Green Version]

- Kaur, N.; Singh, A.K. Ohmic Heating: Concept and Applications-A Review. Crit. Rev. Food Sci. Nutr. 2016, 56, 2338–2351. [Google Scholar] [CrossRef]

- Somavat, R.; Mohamed, H.M.H.; Chung, Y.K.; Yousef, A.E.; Sastry, S.K. Accelerated inactivation of Geobacillus stearothermophilus spores by ohmic heating. J. Food Eng. 2012, 108, 69–76. [Google Scholar] [CrossRef]

- De Alwis, A.A.P.; Fryer, P.J. A finite-element analysis of heat generation and transfer during ohmic heating of food. Chem. Eng. Sci. 1990, 45, 1547–1559. [Google Scholar] [CrossRef]

- Kim, S.S.; Kang, D.H. Synergistic effect of carvacrol and ohmic heating for inactivation of E-coli O157:H7, S. Typhimurium, L-monocytogenes, and MS-2 bacteriophage in salsa. Food Control 2017, 73, 300–305. [Google Scholar] [CrossRef]

- Kim, S.S.; Kang, D.H. Combination treatment of ohmic heating with various essential oil components for inactivation of food-borne pathogens in buffered peptone water and salsa. Food Control 2017, 80, 29–36. [Google Scholar] [CrossRef]

- Choi, W.; Kim, S.S.; Park, S.H.; Ahn, J.B.; Kang, D.H. Numerical analysis of rectangular type batch ohmic heater to identify the cold point. Food Sci. Nutr. 2020, 8, 648–658. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Choi, W.; Lee, S.H.; Kim, C.T.; Jun, S. A finite element method based flow and heat transfer model of continuous flow microwave and ohmic combination heating for particulate foods. J. Food Eng. 2015, 149, 159–170. [Google Scholar] [CrossRef]

- Joe, S.Y.; So, J.H.; Hwang, S.H.; Cho, B.K.; Lee, W.H.; Kang, T.Y.; Lee, S.H. Application of Ohmic-Vacuum Combination Heating for the Processing of Senior-Friendly Food (Multiphase Food): Experimental Studies and Numerical Simulation. Foods 2021, 10, 138. [Google Scholar] [CrossRef]

- Samaranayake, C.P.; Sastry, S.K. Electrode and pH effects on electrochemical reactions during ohmic heating. J. Electroanal. Chem. 2005, 577, 125–135. [Google Scholar] [CrossRef]

- Byanju, B.; Rahman, M.M.; Hojilla-Evangelista, M.P.; Lamsal, B.P. Effect of high-power sonication pretreatment on extraction and some physicochemical properties of proteins from chickpea, kidney bean, and soybean. Int. J. Biol. Macromol. 2020, 145, 712–721. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, K.; Li, Z.; Li, J.; Lin, H. Raman spectroscopic techniques for nondestructive analysis of agri-foods: A state-of-the-art review. Trends Food Sci. Technol. 2021, 118, 490–504. [Google Scholar] [CrossRef]

- Lopez-Maestresalas, A.; Arazuri, S.; Garcia, I.; Mangado, J.; Jaren, C. A Review of the Application of Near-Infrared Spectroscopy for the Analysis of Potatoes. J. Agric. Food Chem. 2013, 61, 5413–5424. [Google Scholar] [CrossRef] [Green Version]

- Li, X.; Xing, C.; Wang, Z.; Sun, W.; Wu, C.; Xu, G.; Wang, X. LF-NMR intelligent evaluation for lipid oxidation indices of polar compound distribution, fatty acid unsaturation, and dynamic viscosity: Preference and mechanism. Food Res. Int. 2022, 161, 111807. [Google Scholar] [CrossRef]

- Olivares Díaz, E.; Kawamura, S.; Matsuo, M.; Kato, M.; Koseki, S. Combined analysis of near-infrared spectra, colour, and physicochemical information of brown rice to develop accurate calibration models for determining amylose content. Food Chem. 2019, 286, 297–306. [Google Scholar] [CrossRef]

- Li, X.Q.; Kahlon, T.; Wang, S.; Friedman, M. Low Acrylamide Flatbreads Prepared from Colored Rice Flours and Relationship to Asparagine and Proximate Content of Flours and Flatbreads. Foods 2021, 10, 2909. [Google Scholar] [CrossRef]

- Flores, M.; Mora, L.; Reig, M.; Toldra, F. Risk assessment of chemical substances of safety concern generated in processed meats. Food Sci. Hum. Wellness 2019, 8, 244–251. [Google Scholar] [CrossRef]

- Gao, P.Y.; Cha, R.T.; Luo, H.Z.; Xu, Y.R.; Zhang, P.; Han, L.; Wang, X.H.; Zhang, Z.L.; Jiang, X.Y. Development of antimicrobial oxidized cellulose film for active food packaging. Carbohydr. Polym. 2022, 278. [Google Scholar] [CrossRef] [PubMed]

- Hai, Y.D.; Tran-Lam, T.T.; Nguyen, T.Q.; Vu, N.D.; Ma, K.H.; Le, G.T. Acrylamide in daily food in the metropolitan area of Hanoi, Vietnam. Food Addit. Contam. Part B Surveill. 2019, 12, 159–166. [Google Scholar] [CrossRef] [PubMed]

- Ye, Z.H.; Chen, X.T.; Zhu, H.Y.; Liu, X.Q.; Deng, W.H.; Song, W.; Li, D.X.; Hou, R.Y.; Cai, H.M.; Peng, C.Y. Aggregating-agent-assisted surface-enhanced Raman spectroscopy-based detection of acrylamide in fried foods: A case study with potato chips. Food Chem. 2023, 403, 134377. [Google Scholar] [CrossRef]

- Cheng, J.; Zhang, S.; Wan, S.; Wang, P.L.; Su, X.O.; Xie, J.C. Rapid and sensitive detection of acrylamide in fried food using dispersive solid-phase extraction combined with surface-enhanced Raman spectroscopy. Food Chem. 2019, 276, 157–163. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.Y.; Ma, J.; Sun, D.W. Raman spectroscopic techniques for detecting structure and quality of frozen foods: Principles and applications. Crit. Rev. Food Sci. Nutr. 2021, 61, 2623–2639. [Google Scholar] [CrossRef]

- Yaseen, T.; Sun, D.-W.; Cheng, J.-H. Raman imaging for food quality and safety evaluation: Fundamentals and applications. Trends Food Sci. Technol. 2017, 62, 177–189. [Google Scholar] [CrossRef]

- Zhang, W.; Tang, S.; Jin, Y.; Yang, C.; He, L.; Wang, J.; Chen, Y. Multiplex SERS-based lateral flow immunosensor for the detection of major mycotoxins in maize utilizing dual Raman labels and triple test lines. J. Hazard. Mater. 2020, 393, 122348. [Google Scholar] [CrossRef]

- Zhao, J.H.; Yuan, H.C.; Peng, Y.J.; Hong, Q.; Liu, M.H. Detection of Ractopamine and Clenbuterol Hydrochloride Residues in Pork Using Surface Enhanced Raman Spectroscopy. J. Appl. Spectrosc. 2017, 84, 76–81. [Google Scholar] [CrossRef]

- Long, Y.; Huang, W.; Wang, Q.; Fan, S.; Tian, X. Integration of textural and spectral features of Raman hyperspectral imaging for quantitative determination of a single maize kernel mildew coupled with chemometrics. Food Chem. 2022, 372, 131246. [Google Scholar] [CrossRef]

- Tao, F.; Yao, H.; Hruska, Z.; Rajasekaran, K.; Qin, J.; Kim, M. Use of line-scan Raman hyperspectral imaging to identify corn kernels infected with Aspergillus flavus. J. Cereal Sci. 2021, 102, 103364. [Google Scholar] [CrossRef]

- Joshi, R.; Lohumi, S.; Joshi, R.; Kim, M.S.; Qin, J.; Baek, I.; Cho, B.-K. Raman spectral analysis for non-invasive detection of external and internal parameters of fake eggs. Sens. Actuators B Chem. 2020, 303, 127243. [Google Scholar] [CrossRef]

- Sun, Q. A Study on Intelligent Drying Quality Detection of Typical Fruits and Vegetables Based on the Combination of LF-NMR and NIR. Ph.D. Dissertation, Jiangnan University, Wuxi, China, 2022. Available online: https://kns.cnki.net/KCMS/detail/detail.aspx?dbname=CDFDLAST2023&filename=1022642213.nh (accessed on 8 July 2023).

- Wang, C.; Wang, C.; Wang, X.; Wang, K.; Zhu, Y.; Rong, Z.; Wang, W.; Xiao, R.; Wang, S. Magnetic SERS Strip for Sensitive and Simultaneous Detection of Respiratory Viruses. ACS Appl. Mater. Interfaces 2019, 11, 19495–19505. [Google Scholar] [CrossRef]

- Tai, Y.H.; Lo, S.C.; Montagne, K.; Tsai, P.C.; Liao, C.C.; Wang, S.H.; Chin, I.S.; Xing, D.; Ho, Y.L.; Huang, N.T.; et al. Enhancing Raman signals from bacteria using dielectrophoretic force between conductive lensed fiber and black silicon. Biosens. Bioelectron. 2021, 191, 113463. [Google Scholar] [CrossRef]

- Cao, C.; Li, P.; Liao, H.; Wang, J.; Tang, X.; Yang, L. Cys-functionalized AuNP substrates for improved sensing of the marine toxin STX by dynamic surface-enhanced Raman spectroscopy. Anal. Bioanal. Chem. 2020, 412, 4609–4617. [Google Scholar] [CrossRef]

- Sun, Y.; Zhai, X.; Xu, Y.; Liu, C.; Zou, X.; Li, Z.; Shi, J.; Huang, X. Facile fabrication of three-dimensional gold nanodendrites decorated by silver nanoparticles as hybrid SERS-active substrate for the detection of food contaminants. Food Control 2021, 122, 107772. [Google Scholar] [CrossRef]

- Zhao, Q.; Zhang, H.; Fu, H.; Wei, Y.; Cai, W. Raman reporter-assisted Au nanorod arrays SERS nanoprobe for ultrasensitive detection of mercuric ion (Hg (2+)) with superior anti-interference performances. J. Hazard. Mater. 2020, 398, 122890. [Google Scholar] [CrossRef]

- Zhang, Y.; Huang, Y.; Kang, Y.; Miao, J.; Lai, K. Selective recognition and determination of malachite green in fish muscles via surface-enhanced Raman scattering coupled with molecularly imprinted polymers. Food Control 2021, 130, 108367. [Google Scholar] [CrossRef]

- Su, L.; Hu, H.; Tian, Y.; Jia, C.; Wang, L.; Zhang, H.; Wang, J.; Zhang, D. Highly Sensitive Colorimetric/Surface-Enhanced Raman Spectroscopy Immunoassay Relying on a Metallic Core-Shell Au/Au Nanostar with Clenbuterol as a Target Analyte. Anal. Chem. 2021, 93, 8362–8369. [Google Scholar] [CrossRef]

- Dias, L.A.F.; Jussiani, E.I.; Appoloni, C.R. Reference Raman Spectral Database of Commercial Pesticides. J. Appl. Spectrosc. 2019, 86, 166–175. [Google Scholar] [CrossRef]

- Walsh, K.B.; McGlone, V.A.; Han, D.H. The uses of near infra-red spectroscopy in postharvest decision support: A review. Postharvest Biol. Technol. 2020, 163, 111139. [Google Scholar] [CrossRef]

- Nallan Chakravartula, S.S.; Cevoli, C.; Balestra, F.; Fabbri, A.; Rosa, M.D. Evaluation of the effect of edible coating on mini-buns during storage by using NIR spectroscopy. J. Food Eng. 2019, 263, 46–52. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, M.; Mujumdar, A.S. Technological innovations or advancement in detecting frozen and thawed meat quality: A review. Crit. Rev. Food Sci. Nutr. 2021, 63, 1483–1499. [Google Scholar] [CrossRef] [PubMed]

- Shi, S.; Feng, J.; Yang, L.; Xing, J.; Pan, G.; Tang, J.; Wang, J.; Liu, J.; Cao, C.; Jiang, Y. Combination of NIR spectroscopy and algorithms for rapid differentiation between one-year and two-year stored rice. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2023, 291, 122343. [Google Scholar] [CrossRef]

- Lapchareonsuk, R.; Sirisomboon, P. Sensory Quality Evaluation of Rice Using Visible and Shortwave Near-Infrared Spectroscopy. Int. J. Food Prop. 2015, 18, 1128–1138. [Google Scholar] [CrossRef]

- Onmankhong, J.; Sirisomboon, P. Texture evaluation of cooked parboiled rice using nondestructive milled whole grain near infrared spectroscopy. J. Cereal Sci. 2021, 97, 103151. [Google Scholar] [CrossRef]

- Li, L.; Zhang, M.; Bhandari, B.; Zhou, L. LF-NMR online detection of water dynamics in apple cubes during microwave vacuum drying. Dry. Technol. 2018, 36, 2006–2015. [Google Scholar] [CrossRef]

- Deidda, R.; Sacre, P.-Y.; Clavaud, M.; Coïc, L.; Avohou, H.; Hubert, P.; Ziemons, E. Vibrational spectroscopy in analysis of pharmaceuticals: Critical review of innovative portable and handheld NIR and Raman spectrophotometers. TrAC Trends Anal. Chem. 2019, 114, 251–259. [Google Scholar] [CrossRef]

- Jiang, Q.; Zhang, M.; Mujumdar, A.S.; Wang, D. Non-destructive quality determination of frozen food using NIR spectroscopy-based machine learning and predictive modelling. J. Food Eng. 2023, 343, 111374. [Google Scholar] [CrossRef]

- Togersen, G.; Arnesen, J.F.; Nilsen, B.N.; Hildrum, K.I. On-line prediction of chemical composition of semi-frozen ground beef by non-invasive NIR spectroscopy. Meat Sci. 2003, 63, 515–523. [Google Scholar] [CrossRef]

- Reis, M.M.; Rosenvold, K. Early on-line classification of beef carcasses based on ultimate pH by near infrared spectroscopy. Meat Sci. 2014, 96, 862–869. [Google Scholar] [CrossRef] [PubMed]

- Qu, F.; Ren, D.; He, Y.; Nie, P.; Lin, L.; Cai, C.; Dong, T. Predicting pork freshness using multi-index statistical information fusion method based on near infrared spectroscopy. Meat Sci. 2018, 146, 59–67. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Zhuang, H.; Yoon, S.-C.; Wang, W.; Jiang, H.; Jia, B.; Li, C. Quality Assessment of Intact Chicken Breast Fillets Using Factor Analysis with Vis/NIR Spectroscopy. Food Anal. Methods 2017, 11, 1356–1366. [Google Scholar] [CrossRef]

- Peyvasteh, M.; Popov, A.; Bykov, A.; Meglinski, I. Meat freshness revealed by visible to near-infrared spectroscopy and principal component analysis. J. Phys. Commun. 2020, 4, 095011. [Google Scholar] [CrossRef]

- Porep, J.U.; Kammerer, D.R.; Carle, R. On-line application of near infrared (NIR) spectroscopy in food production. Trends Food Sci. Technol. 2015, 46, 211–230. [Google Scholar] [CrossRef]

- Zhu, F. NMR spectroscopy of starch systems. Food Hydrocoll. 2017, 63, 611–624. [Google Scholar] [CrossRef]

- Yu, X.; Wang, Z.; Zhang, Y.; Wadood, S.A.; Wei, Y. Study on the water state and distribution of Chinese dried noodles during the drying process. J. Food Eng. 2018, 233, 81–87. [Google Scholar] [CrossRef]

- Niu, L.; Li, J.; Chen, M.-S.; Xu, Z.-F. Determination of oil contents in Sacha inchi (Plukenetia volubilis) seeds at different developmental stages by two methods: Soxhlet extraction and time-domain nuclear magnetic resonance. Ind. Crops Prod. 2014, 56, 187–190. [Google Scholar] [CrossRef]

- Chen, L.; Tian, Y.; Sun, B.; Wang, J.; Tong, Q.; Jin, Z. Rapid, accurate, and simultaneous measurement of water and oil contents in the fried starchy system using low-field NMR. Food Chem. 2017, 233, 525–529. [Google Scholar] [CrossRef] [PubMed]

- Paesani, C.; Gómez, M. Effects of the pre-frying process on the cooking quality of rice. Lwt 2021, 140, 110743. [Google Scholar] [CrossRef]

- Ali, S.; Zhang, W.; Rajput, N.; Khan, M.A.; Li, C.B.; Zhou, G.H. Effect of multiple freeze-thaw cycles on the quality of chicken breast meat. Food Chem. 2015, 173, 808–814. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Liu, D.; Zhou, G.; Xu, X.; Qi, J.; Shi, P.; Xia, T. Meat quality and cooking attributes of thawed pork with different low field NMR T21. Meat Sci. 2011, 92, 79–83. [Google Scholar] [CrossRef]

- Sun, Q.; Zhang, M.; Yang, P. Combination of LF-NMR and BP-ANN to monitor water states of typical fruits and vegetables during microwave vacuum drying. LWT 2019, 116, 108548. [Google Scholar] [CrossRef]

- Zhao, L.; Zhang, M.; Wang, H.; Mujumdar, A.S. Monitoring of free fatty acid content in mixed frying oils by means of LF-NMR and NIR combined with BP-ANN. Food Control 2022, 133, 108599. [Google Scholar] [CrossRef]

- Zhang, Q.; Saleh, A.S.M.; Shen, Q. Discrimination of Edible Vegetable Oil Adulteration with Used Frying Oil by Low Field Nuclear Magnetic Resonance. Food Bioprocess Technol. 2012, 6, 2562–2570. [Google Scholar] [CrossRef]

- Li, M.; Li, B.; Zhang, W. Rapid and non-invasive detection and imaging of the hydrocolloid-injected prawns with low-field NMR and MRI. Food Chem. 2018, 242, 16–21. [Google Scholar] [CrossRef] [PubMed]

| Brands | Introduction | Representative Products | Features | Main Ingredients | Official Website | Other Information (Reprieved from https://nlc.chinanutri.cn/fq/, accessed on: 8 July 2023) |

|---|---|---|---|---|---|---|

|

| Mixed fried rice |

|

| https://www.haitonggroup.com/, accessed on: 8 July 2023 |

|

| Korean kimchi grilled sausage fried rice |

| |||||

| Japanese eel fried rice |

| |||||

|

| Yangzhou fried rice |

|

| http://www.sanquan.com/sanquan, accessed on: 8 July 2023 | |

| Cantonese fried rice |

| |||||

| Thai fried rice |

| |||||

|

| Mixed fried rice |

|

| http://www.hysp1960.com/, accessed on: 8 July 2023 | |

|

| New Orleans-style chicken fried rice |

|

| http://www.yumchina.com/Brand, accessed on: 8 July 2023 | |

| Sichuan tender beef Japanese fried rice |

| |||||

| Laver salmon fried rice |

| |||||

|

| European-style country beef fried rice |

|

| http://www.wusjt.com, accessed on: 8 July 2023 | |

| Bacon fried rice |

| |||||

| Tuna fried rice |

|

| Analytes | Excitation Laser and Spectral Range | Results | References | |

|---|---|---|---|---|

| Microorganisms | Viruses: influenza AH1N1 virus and human adenovirus | 785 nm 1100–1600 cm−1 | LODH1N1 = 50 pfu/mL LODHAdV = 50 pfu/mL | [102] |

| Bacteria: Escherichia coli (E. coli ATCC 25922 and K-12 strains) on culture plate | 633 nm 600–1800 cm−1 | LOD = 6 × 104 CFU/mL | [103] | |

| Fungi: Aspergillus flavus (AF36, AF13) infect corn kernels | 785 nm 103–2831 cm−1 | All prediction accuracy ≥ 75.55% | [103] | |

| Mycotoxins | AFB1 in peanut extracts | 785 nm 400–1800 cm−1 | LOD = 0.5μg/L | [103] |

| Biotoxins | Saxitoxin (STX) | 785 nm 400–2000 cm−1 | LOD = 1 × 10−7 M | [104] |

| Pesticides | Carbamate: thiram in apple juice | 785 nm 500–1600 cm−1 | LOD = 86.1μg/L | [105] |

| Food authenticity | Authenticating Australian grain-fed and grass-fed beef products | 785 nm 600–1900 cm−1 | All discrimination accuracy ≥ 83% | [105] |

| Metal ions | Hg2+ in natural ground and lake water | 785 nm 200–1800 cm−1 | LOD = 0.1 nm | [106] |

| Drug residues | Tetracycline in water | 532 nm 200–1800 cm−1 | LOD = 10−9 m | [106] |

| Malachite green in grass carp, bream fish, and crucian fillets | 633 nm 400–1800 cm−1 | LOD = 0.5μg/L | [107] | |

| Clenbuterol in pork, chicken, and sausage | 785 nm 400–1600 cm−1 | LOD = 0.05 ng/mL | [108] | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, J.; Zhang, M.; Fang, Z. Perspectives on Novel Technologies of Processing and Monitoring the Safety and Quality of Prepared Food Products. Foods 2023, 12, 3052. https://doi.org/10.3390/foods12163052

Huang J, Zhang M, Fang Z. Perspectives on Novel Technologies of Processing and Monitoring the Safety and Quality of Prepared Food Products. Foods. 2023; 12(16):3052. https://doi.org/10.3390/foods12163052

Chicago/Turabian StyleHuang, Jinjin, Min Zhang, and Zhongxiang Fang. 2023. "Perspectives on Novel Technologies of Processing and Monitoring the Safety and Quality of Prepared Food Products" Foods 12, no. 16: 3052. https://doi.org/10.3390/foods12163052