Effect of Czech Hop Varieties on Aroma of Dry-Hopped Lager Beer

Abstract

:1. Introduction

2. Materials and Methods

2.1. Chemicals

2.2. Hop Samples

2.3. Procedure for Dry-Hopped and Control Lager Beer Preparation

Procedure for Dry Hopping

2.4. GC-MS Analysis

2.4.1. Determination of Hop Essential Oils in Hop Pellets

Procedure for Isolation of the Oil Fraction Using Steam Distillation

Conditions for GC-MS

- –

- Carrier gas: helium (1 mL/min);

- –

- Capillary column: HP-5MS (30 m × 0.25 mm, coating width 0.25 μm);

- –

- Temperature program: 60 °C (5 min) → 2 °C/min →150 °C → 5 °C/min → 220 °C (5 min) → 20 °C/min → 300 °C (5 min);

- –

- Injection: 1 μL of sample, split 1:30, T = 260 °C;

- –

- MS conditions: scan mode, m/z = 35–350;

- –

- Length of analysis: 88 min.

Data Evaluation

2.4.2. Determination of Hop Essential OILS in Beer

Procedure for Isolation of the Oil Fraction Using Steam Distillation

Conditions for GC-MS

- –

- Carrier gas: helium (1 mL/min);

- –

- Capillary column: HP-5MS (30 m × 0.25 mm, coating width 0.25 μm);

- –

- Temperature program: 40 °C (3 min) → 5 °C/min → 220 °C → 20 °C/min → 300 °C (5 min);

- –

- Injection: 1 μL of sample, split 1:30, T = 280 °C;

- –

- Length of analysis: 49 min.

Data Evaluation

3. Results

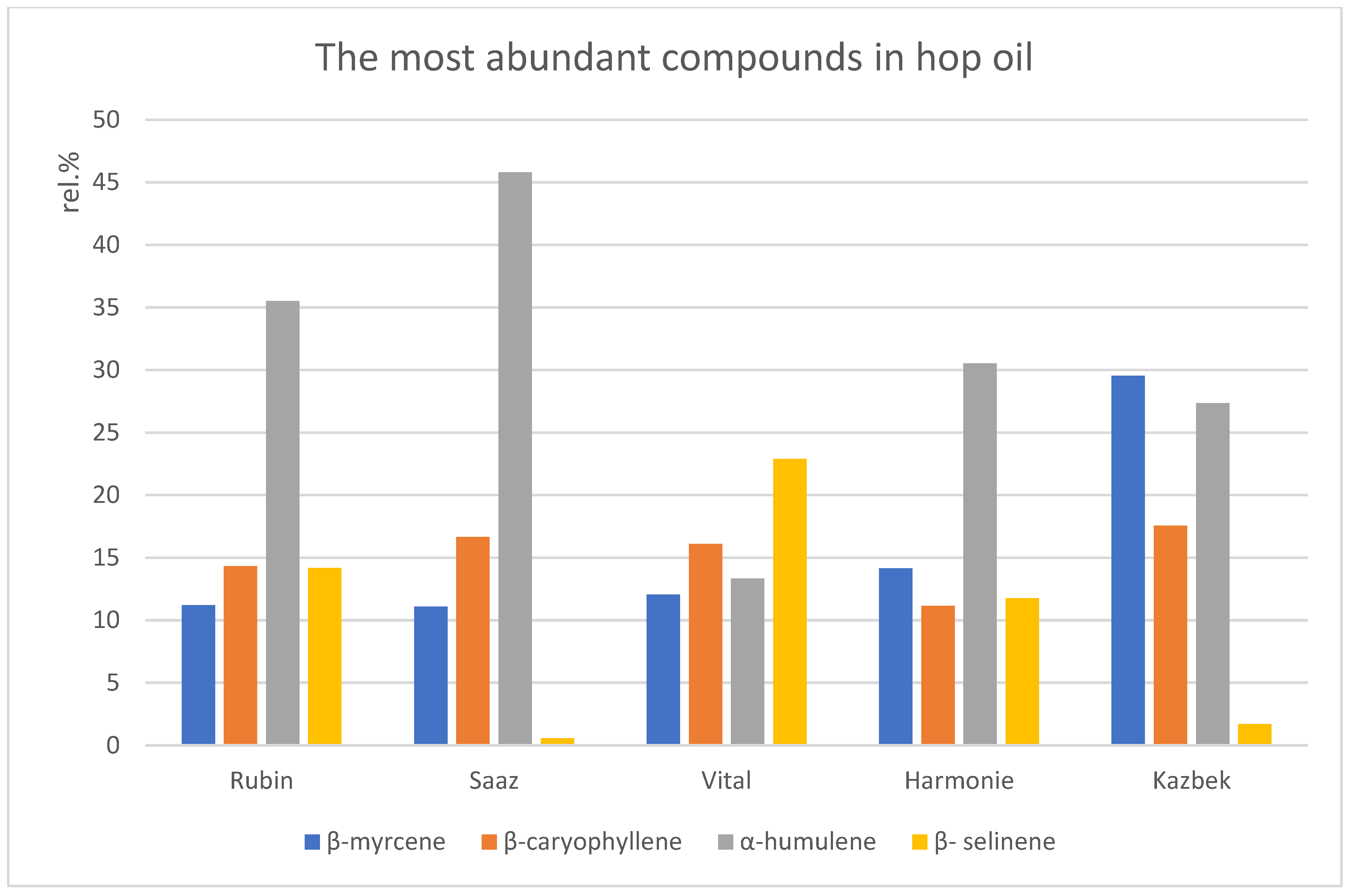

3.1. Analysis of Hop Pellet Essential Oils

Hop Addition for Dry Hopping

3.2. Analysis of Hop Oil in Beer

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Cultivar | Rubín | Saaz | Vital | Harmonie | Kazbek |

|---|---|---|---|---|---|

| Determined Compounds | Relative Mass Percentage (rel. %) | ||||

| β-pinene | 0.24 | 0.21 | 0.95 | 0.27 | 0.73 |

| β-myrcene | 11.20 | 11.09 | 12.05 | 14.15 | 29.55 |

| 2-methylbutyl-2-methylpropanoate | 0.77 | 0.13 | 1.62 | 0.16 | 0.58 |

| limonene | 0.13 | 0.11 | 0.48 | 0.24 | 0.36 |

| ocimene | 0.08 | 0.06 | 0.04 | 0.04 | 0.43 |

| 2-nonanone | 0.08 | 0.20 | 0.88 | 0.21 | N.D. |

| linalool | 0.62 | 0.46 | 3.63 | 1.40 | 1.05 |

| nonanal | N.D. | 0.05 | N.D. | N.D. | N.D. |

| 3-methylbutyl-3 methylbutanoate | 0.19 | N.D. | 0.54 | 0.03 | 0.06 |

| camphor | 0.30 | 0.30 | 0.37 | 0.24 | 0.29 |

| 2-decanone | N.D. | 0.28 | 1.39 | 0.22 | 0.06 |

| methyl nonanoate | N.D. | N.D. | 0.24 | 0.06 | 0.01 |

| heptyl isobutyrate | N.D. | N.D. | 0.04 | 0.01 | 0.02 |

| geraniol | 0.18 | 0.12 | 0.53 | 0.08 | 0.54 |

| (E)-citral | N.D. | 0.01 | 0.04 | 0.02 | N.D. |

| 2-undecanone | 0.45 | 1.65 | 7.06 | 1.30 | 0.48 |

| methyl decanoate | 0.38 | 0.29 | 1.51 | 0.28 | 0.04 |

| methyl geranate | 1.15 | 0.82 | 2.29 | 1.36 | 0.60 |

| α-cubenene | N.D. | 0.04 | N.D. | N.D. | 0.08 |

| ylangene | 0.15 | 0.17 | 0.20 | 0.16 | 0.20 |

| copaene | 0.65 | 0.78 | 0.42 | 0.60 | 0.63 |

| geranyl acetate | N.D. | N.D. | N.D. | N.D. | 0.10 |

| 2-dodecanone | 0.09 | 0.23 | 0.95 | 0.12 | 0.11 |

| β-caryophyllene | 14.33 | 16.64 | 16.09 | 11.15 | 17.56 |

| β-cubenene | 0.44 | 0.37 | 0.31 | 0.29 | 0.49 |

| α-bergamotene | N.D. | 0.57 | 0.33 | 0.03 | N.D. |

| α-humulene | 35.53 | 45.79 | 13.33 | 30.52 | 27.34 |

| nerylacetate | 3.87 | 2.17 | 4.07 | 3.11 | 1.99 |

| γ-muurolene | 3.93 | 2.01 | 0.07 | 0.11 | 0.22 |

| β-selinene | 14.16 | 0.57 | 22.89 | 11.75 | 1.68 |

| α-selinene | N.D. | N.D. | N.D. | 13.92 | 2.51 |

| α-muurolene | 0.65 | 1.11 | 0.71 | 0.62 | 0.56 |

| geranyl butyrate | N.D. | N.D. | N.D. | N.D. | 1.36 |

| ν-cadinene | 1.93 | 2.51 | 1.02 | 1.28 | 1.78 |

| δ-cadinene | 3.03 | 3.79 | 2.21 | 2.55 | 3.13 |

| cadina-1,4-dien | 0.32 | 0.32 | 0.11 | 0.24 | 0.28 |

| α-cadinene | 0.36 | 0.44 | 0.14 | 0.31 | 0.34 |

| α-calacorene | 0.16 | 0.31 | 0.35 | 0.19 | 0.19 |

| (E)-nerolidol | N.D. | N.D. | N.D. | N.D. | 0.50 |

| caryophyllene oxide | 0.42 | 0.96 | 1.05 | 0.29 | 0.89 |

| humulene epoxide I | 1.63 | 3.87 | 0.67 | 1.27 | 1.31 |

| caryophyllene alcohol | 0.08 | 0.24 | 0.15 | N.D. | 0.16 |

| epi-bicyclosesquiphellandrene | 0.59 | 0.33 | 0.33 | 0.33 | 0.31 |

| copaene | 0.08 | 0.05 | N.D. | 0.04 | 0.07 |

| α-cadinol | 1.28 | 0.40 | N.D. | N.D. | 0.13 |

| pentadecanone | 0.05 | 0.21 | 0.62 | 0.12 | 0.03 |

| farnesol | 0.47 | 0.40 | 0.27 | 0.29 | 1.17 |

References

- Almaguer, C.; Schönberger, C.; Gastl, M.; Arendt, E.K.; Becker, T. Humulus lupulus—A story that begs to be told. A review. J. Inst. Brew. 2014, 120, 289–314. [Google Scholar] [CrossRef]

- Titus, B.M.; Lerno, L.A.; Beaver, J.W.; Byrnes, N.K.; Heymann, H.; Oberholster, A. Impact of Dry Hopping on Beer Flavor Stability. Foods 2021, 10, 1264. [Google Scholar] [CrossRef] [PubMed]

- Simpson, W.J. Cambridge Prize Lecture. Studies on the sensitivity of lactic acid bacteria to hop bitter acids. J. Inst. Brew. 1993, 99, 405–411. [Google Scholar] [CrossRef]

- Aberl, A.; Coelhan, M. Determination of Volatile Compounds in Different Hop Varieties by Headspace-Trap GC/MS—In Comparison with Conventional Hop Essential Oil Analysis. J. Agric. Food Chem. 2012, 60, 2785–2792. [Google Scholar] [CrossRef] [PubMed]

- Dresel, M.; Van Opstaele, F.; Praet, T.; Jaskula-Goiris, B.; Van Holle, A.; Naudts, D.; De Keukeleire, D.; De Cooman, L. Investigation of the impact of the hop variety and the hopping technology on the analytical volatile profile of single-hopped worts and beers. Brew. Sci. 2013, 66, 162–175. [Google Scholar]

- Van Opstaele, F.; De Causmaecker, B.; Guido, A.; De Cooman, L. Characterization of Novel Varietal Floral Hop Aromas by Headspace Solid Phase Microextraction and Gas Chromatography—Mass Spectrometry/Olfactometry. J. Agric. Food Chem. 2012, 60, 12270–12281. [Google Scholar] [CrossRef]

- Van Opstaele, F.; Rouck, G.; Clippeleer, J.; Aerts, G.; Cooman, L. Analytical and Sensory Assessment of Hoppy Aroma and Bitterness of Conventionally Hopped and Advanced Hopped Pilsner Beers. J. Inst. Brew. 2010, 116, 445–458. [Google Scholar] [CrossRef]

- Nickerson, G.B.; Van Engel, L. Hop Aroma Component Profile and the Aroma Unit. J. Am. Soc. Brew. Chem. 1992, 50, 77–81. [Google Scholar] [CrossRef]

- Guadagni, D.G.; Buttery, R.G.; Okano, S.; Burr, H.K. Additive Effect of Sub-Threshold Concentrations of Some Organic Compounds Associated with Food Aromas. Nature 1963, 200, 1288–1289. [Google Scholar] [CrossRef]

- Takoi, K.; Degueil, M.; Shinkaruk, S.; Thibon, C.; Kurihara, T.; Toyoshima, K.; Ito, K.; Bennetau, B.; Dubourdieu, D.; Tominaga, T. Specific Flavor Compounds Derived from Nelson Sauvin Hop and Synergy of these Compounds. Brew. Sci. 2009, 62, 108–118. [Google Scholar]

- Takoi, K.; Itoga, Y.; Koie, K.; Kosugi, T.; Shimase, M.; Katayama, Y.; Nakayama, Y.; Watari, J. The Contribution of Geraniol Metabolism to the Citrus Flavour of Beer: Synergy of Geraniol and β-Citronellol Under Coexistence with Excess Linalool. J. Inst. Brew. 2010, 116, 251–260. [Google Scholar] [CrossRef]

- Kralj, D.; Zupanec, J.; Vasilj, D.; Kralj, S.; Pšeničnik, J. Variability of essential oils of hops, Humulus lupulus L. J. Inst. Brew. 1991, 97, 197–206. [Google Scholar] [CrossRef]

- Hop Varieties: Premium Quality Hops. Available online: https://www.yakimachief.com/commercial/hop-varieties.html (accessed on 30 January 2022).

- Czech Hop Varieties. Available online: http://www.czhops.cz/index.php?option=com_content&view=category&layout=blog&id=34&Itemid=101&lang=en (accessed on 30 January 2022).

- Wolfe, P.; Qian, M.C.; Shellhammer, T.H. The Effect of Pellet Processing and Exposure Time on Dry Hop Aroma Extraction. In Flavor Chemistry of Wine and Other Alcoholic Beverages; Qian, M.C., Shellhammer, T.H., Eds.; ACS Symposium Series 1104; American Chemical Society: Washington, DC, USA, 2012; pp. 203–215. [Google Scholar]

- Jelínek, L.; Sneberger, M.; Karabin, M.; Dostálek, P. Comparison of Czech Hop Cultivars Based on their Contents of Secondary Metabolites. Czech J. Food Sci. 2010, 28, 309–316. [Google Scholar] [CrossRef] [Green Version]

- Kippenberger, M.; Hanke, S.; Biendl, M.; Stettner, G.; Lagemann, A. Transfer of nitrate and various pesticides into beer during dry hopping. Brew. Sci. 2014, 67, 1–9. [Google Scholar]

- Kaltner, D.; Forster, C.; Flleher, M.; Nielsen, T.P. The influence of dry hopping on three different beer styles. Brauwelt Int. 2013, 6, 355–359. [Google Scholar]

- Mitter, W.; Cocuzza, S. Dry hopping—A study of various parameters. Brew. Beverage Ind. Int. 2013, 4, 70–74. [Google Scholar]

- Forster, A.; Gahr, A. On the fate of certain hop substances during dry hopping. Brew. Sci. 2013, 66, 93–103. [Google Scholar]

- Hanke, S. Linalool—A Key Contributor to Hop Aroma. MBAA, Global Emerging Issues. 2009. Available online: https://www.mbaa.com (accessed on 15 June 2022).

- King, A.; Dickinson, R.J. Biotransformation of monoterpene alcohols by Saccharomyces cerevisiae, Torulaspora delbrueckii and Kluyveromyces lactis. Yeast 2000, 16, 499–506. [Google Scholar] [CrossRef]

- Forster, A.; Gahr, A.; Van Opstaele, F. On the transfer rate of geraniol with dry hopping. Brew. Sci. 2014, 67, 60–62. [Google Scholar]

- Kollmannsberger, H.; Biendl, M.; Nitz, S. Occurence of glycosidically bound flavour compounds in hops, hop products and beer. Monatsschr. Brauwiss. 2006, 5, 83–89. [Google Scholar]

- Takoi, K.; Koie, K.; Itoga, Y.; Katayama, Y.; Shimase, M.; Nakayama, Y.; Watari, J. Biotransformation of Hop-Derived Monoterpene Alcohols by Lager Yeast and Their Contribution to the Flavor of Hopped Beer. J. Agric. Food Chem. 2010, 58, 5050–5058. [Google Scholar] [CrossRef] [PubMed]

- Dieckmann, R.H.; Palamand, S.R. Autoxidation of some constituents of hops. I. Monoterpene hydrocarbon, myrcene. J. Agric. Food Chem. 1974, 22, 498–503. [Google Scholar] [CrossRef]

- Haslbeck, K.; Bub, S.; Schoenberger, C.; Zarnkow, M.; Jacob, F.; Coelhan, M. On the Fate of β-Myrcene during Fermentation—The Role of Stripping and Uptake of Hop Oil Components by Brewer’s Yeast in Dry-Hopped Wort and Beer. Brew. Sci. 2017, 70, 159–169. [Google Scholar]

- Salamon, R.V.; Dabija, A.; Ferencz, Á.; Tankó, G.; Ciocan, M.E.; Codină, G.G. The Effect of Dry Hopping Efficiency on β -Myrcene Dissolution into Beer. Plants 2022, 11, 1043. [Google Scholar] [CrossRef]

- Peacock, V.E.; Deinzer, M.L. Fate of Hop Oil Components in Beer. J. Am. Soc. Brew. Chem. 1988, 46, 104–107. [Google Scholar] [CrossRef]

- Pickett, J.A.; Sharpe, F.R.; Peppard, T.L. Aerial oxidation of humulene. Chem. Ind. 1977, 1, 30–31. [Google Scholar]

- Yang, X.; Lederer, C.; McDaniel, M.; Deinzer, M. Chemical analysis and sensory evaluation of hydrolysis products of humulene epoxides II and III. J. Agric. Food Chem. 1993, 41, 1300–1304. [Google Scholar] [CrossRef]

- Jelínek, L.; Müllerová, J.; Karabín, M.; Dostálek, P. The secret of dry hopped beers—Review. Kvas. Prum. 2018, 64, 287–296. [Google Scholar] [CrossRef]

| Cultivar | Country | Aroma | α-Acid Content (wt. %) * | Total Oil (mL/100g) | Myrcene (rel.%) | α- Humulene (rel. %) | β- Caryophyllene (rel.%) | H:C (Ratio) |

|---|---|---|---|---|---|---|---|---|

| Amarillo | USA | Floral, citrus | 7–11 | 1–2.3 | 40–50 | 19–24 | 7–10 | 1.9–3.4 |

| Citra | USA | Citrus, tropical fruit | 11–15 | 1.5–3 | 60–70 | 7–12 | 5–8 | 0.9–2.4 |

| Cascade | USA | Floral, citrus, spicy | 5.5–9 | 0.8–2.5 | 45–60 | 14–20 | 5–9 | 1.5–4 |

| Nelson Sauvin | New Zealand | Fruity | 12–13 | 1.1 | 22–23 | 36.4 | 10.70 | 3.4 |

| Hallertauer Mittelfrüh | Germany | Floral, citrus, spicy | 3–5.5 | 0.7.1.3 | 14–16 | 55–55.2 | 14.5–14.7 | 3.7–3.8 |

| Tettnang Tettnanger | Germany | Spicy, herbal | 3–6 | 0.5–0.9 | 20–35 | 20–30 | 6–11 | 1.8–5 |

| Spalter Select | Germany | Grassy, spicy | 3–6.5 | 0.6–0.9 | 20–40 | 10–22 | 4–10 | 1–5.5 |

| Vital | Czech Republic | Spicy | 12–16 | 1.8–2.9 | 40–60 | 2–5 | 5–8 | 0.25–1 |

| Saaz | Czech Republic | Floral, citrus, spicy, herbal | 3–5 | 0.5–0.9 | 25–40 | 15–25 | 5–8 | 1.9–5 |

| Kazbek | Czech Republic | Spicy, lemon | 5–8 | 1.06–2.1 | 40–55 | 20–35 | 10–15 | 1.3–3.5 |

| Wye Challenger | UK | Fruity, herbal, cedar | 6.5–8.5 | 1–1.7 | 30–42 | 5 | 9.5 | 2.6 |

| Type of Beer | Control | Rubin | Saaz | Vital | Harmonie | Kazbek |

|---|---|---|---|---|---|---|

| Determined compounds | Concentration in beer (μg/L) | |||||

| β-myrcene | 7 | 101 | 23 | 61 | 78 | 75 |

| 2-methylbutyl-2-methylpropanoate | N.D. | 59 | 8 | 47 | 29 | 35 |

| limonene | N.D. | * | * | * | * | * |

| 2-nonanone | N.D. | N.D. | N.D | 45 | N.D. | N.D. |

| linalool | 25 | 146 | 83 | 321 | 323 | 186 |

| nonanal | 18 | N.D. | 20 | N.D. | N.D. | N.D. |

| β-citronellol | 17 | 37 | 28 | 40 | 37 | 64 |

| geraniol | N.D. | * | * | 22 | * | 179 |

| 2-undecanone | 11 | 57 | 56 | 84 | 60 | 35 |

| 2-dodekanol | 6 | 35 | 23 | 48 | 30 | 133 |

| methyl geranate | N.D. | 153 | * | 118 | 247 | * |

| α-humulene | N.D. | N.D. | N.D. | N.D. | N.D. | N.D. |

| (E)-nerolidol | 20 | 59 | 25 | 34 | 38 | 75 |

| caryophyllene oxide | * | * | * | 100 | * | 137 |

| humulene epoxide I | 262 | 383 | 499 | 299 | 493 | 405 |

| α-cadinol | * | * | 94 | * | * | * |

| farnesol | 30 | 73 | 34 | 34 | 63 | 51 |

| SUM | 397 | 1104 | 893 | 1252 | 1403 | 1258 |

| Control beer-subtracted SUM | - | 707 | 496 | 855 | 1006 | 861 |

| Cultivar | Rubin | Saaz | Vital | Harmonie | Kazbek |

|---|---|---|---|---|---|

| Determined compounds | TR (%) | ||||

| β-myrcene | 3.4 | 0.6 | 2.4 | 1.6 | 0.8 |

| 2-methylbutyl-2-methylpropanoate | 31.3 | 24.4 | 15.8 | 57.1 | 21.9 |

| 2-nonanone | N.D. | N.D. | 27.4 | N.D. | N.D. |

| linalool | 80.2 | 52.0 | 44.3 | 69.8 | 55.4 |

| geraniol | N.D. | N.D. | 22.4 | N.D. | 120.4 |

| 2-undecanone | 41.3 | 11.1 | 5.6 | 12.3 | 17.4 |

| methyl geranate | 54.2 | N.D. | 28.0 | 59.5 | 0 |

| (E)-nerolidol | N.D. | N.D. | N.D. | N.D. | 54.0 |

| caryophyllene oxide | N.D. | N.D. | 51.9 | N.D. | 55.53 |

| humulene epoxide I | 30.2 | 25.2 | 29.9 | 59.7 | 39.3 |

| α-cadinol | N.D. | 96.9 | N.D. | N.D. | N.D. |

| farnesol | 37.7 | 3.8 | 8.0 | 37.4 | 6.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tusha, K.; Nešpor, J.; Jelínek, L.; Vodičková, H.; Kinčl, T.; Dostálek, P. Effect of Czech Hop Varieties on Aroma of Dry-Hopped Lager Beer. Foods 2022, 11, 2520. https://doi.org/10.3390/foods11162520

Tusha K, Nešpor J, Jelínek L, Vodičková H, Kinčl T, Dostálek P. Effect of Czech Hop Varieties on Aroma of Dry-Hopped Lager Beer. Foods. 2022; 11(16):2520. https://doi.org/10.3390/foods11162520

Chicago/Turabian StyleTusha, Kejda, Jakub Nešpor, Lukáš Jelínek, Hana Vodičková, Tomáš Kinčl, and Pavel Dostálek. 2022. "Effect of Czech Hop Varieties on Aroma of Dry-Hopped Lager Beer" Foods 11, no. 16: 2520. https://doi.org/10.3390/foods11162520