1. Introduction

Suspension systems are one of the most critical parts of a vehicle. A successfully designed suspension system should be able to provide safety for the passengers and protect the vehicle from damage caused by road irregularities [

1]. Dynamic loads in vehicles resulting from road irregularities are recognized as a significant factor in causing fatigue damage. In addition, ground-induced vibrations can contribute to a reduction in the driver’s capability to control the vehicle and cause discomfort [

2]. Therefore, a vehicle suspension system has to mitigate vertical vibrations to improve safety and ride comfort performance simultaneously.

Vehicle suspension has been extensively studied for a long time. For all vehicles, passive suspension is designed as a primary suspension system to provide ride comfort, tire deflection, and other dynamic characteristics. A well-designed passive suspension system can mitigate ground-induced vibrations. The problem of the passive vehicle suspension design with an inerter has been taken into account by Hu

et al., concerning the multiple performance requirements including ride comfort suspension deflection and tire grip, and the analytical solutions of the designed six-suspension configurations have been derived [

3]. Chen

et al. have proposed an efficient H

2 optimization method to design passive vehicle suspensions based on a full car model [

4]. In the literature, numerous types of semi-active and active suspensions are currently employed and studied, since the capability of passive suspensions is limited due to the absence of on-line control action. Chen

et al. have proposed a novel structure for a semi-active suspension with an inerter, which consists of a passive part and semi-active part, to obtain performance benefits in their brief study [

5]. The active suspension systems especially have been attracting attention in recent years, and many linear and non-linear control methods for active seat and suspension systems have been proposed [

6]. Guclu has designed a fuzzy logic controller for reducing seat vibrations of a non-linear full vehicle model [

7]. A seat and suspension system with a driver model has been considered in Gundogdu, and an optimal controller has been designed by the use of a genetic algorithm [

8]. Hu

et al. have designed a multiplexed model predictive control for active vehicle suspension systems under the consideration of actuator saturation [

9]. Gysen

et al. have proposed an electromagnetic suspension system to provide additional stability and maneuverability conditions as well as the elimination of road irregularities for vehicle systems [

10]. Wang

et al. have developed a high-force density tubular permanent motor for an active vehicle suspension system in terms of performance optimization [

11]. Onat

et al. have applied a linear parameter-varying (LPV) model-based gain-scheduling controller for a full vehicle active suspension system [

12]. Fialho and Balos have dealt with the LPV gain-scheduling controller for a road adaptive active suspension system [

13]. Among these aforementioned works, it is apparently seen that there are only a few results concerning non-linear suspension control via a parameter-dependent optimal controller to evaluate ride comfort performance in terms of driver body acceleration responses under worst-case road excitations, which is the main motivation factor of this study.

In this paper, the design of a parameter-dependent optimal state-feedback controller is developed to mitigate the ground-induced vertical vibration of a non-linear vehicle system. A proposed controller synthesis is accomplished for the LPV model of non-linear vehicle suspension such that a minimum allowable disturbance attenuation level could be achieved by satisfying a set of LMIs. In the suspension system, the non-linear part of a position-dependent spring and velocity-dependent damping characteristics are assumed as scheduling parameters. In order to reach realistic results, road bumps and very poor random road profiles, are modeled and used as disturbance input. Finally, numerical simulation studies have been presented to illustrate the effectiveness of the proposed approach.

2. Integrated Vehicle Seat and Non-Linear Suspension Model with Driver Body

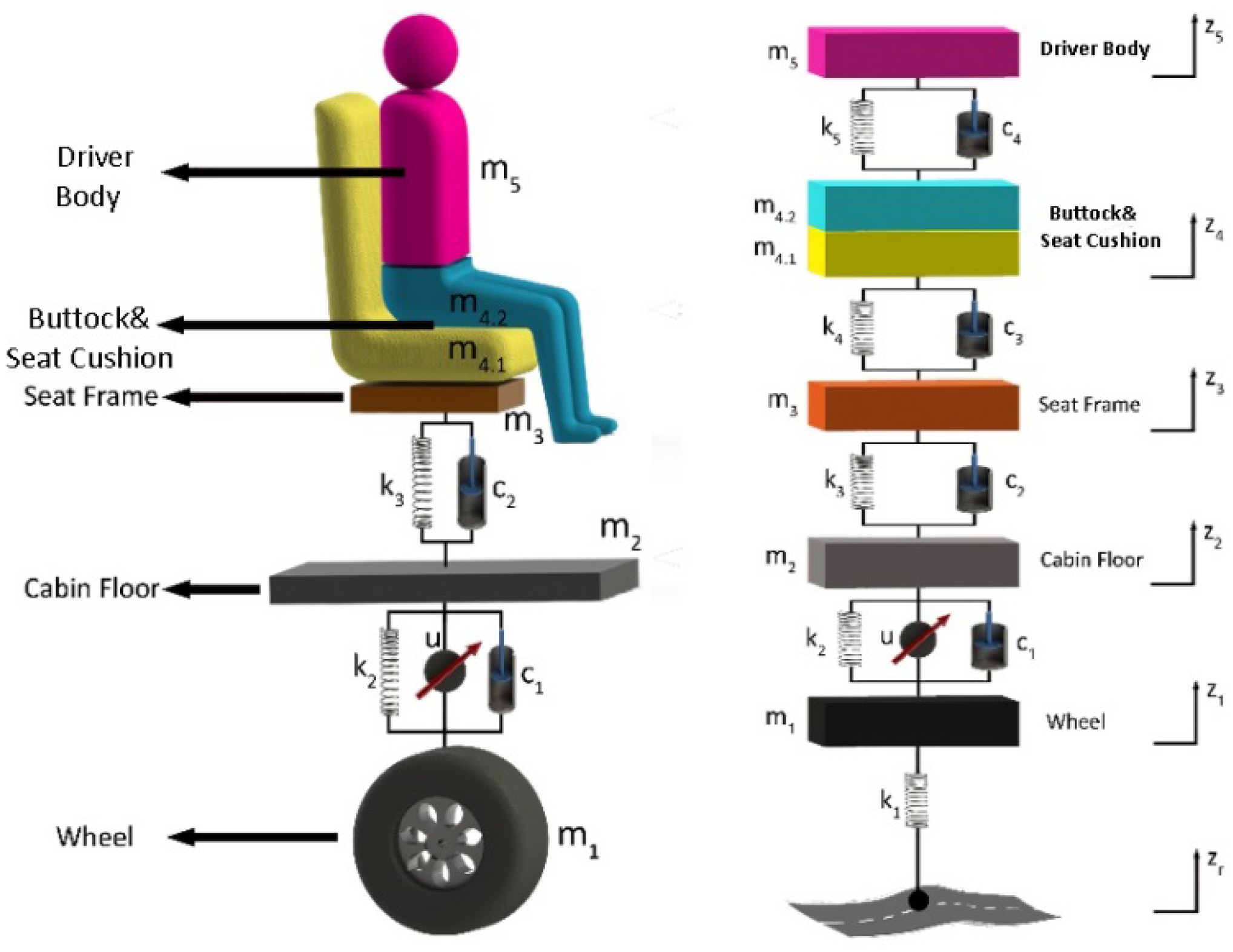

In this study, a five-degree-of-freedom vehicle model, including a quarter car non-linear suspension model, a seat suspension model, and a driver body model, shown in

Figure 1, is considered for the parameter-dependent optimal controller design. This integrated model provides a platform to evaluate ride comfort and vehicle safety performance requirements in terms of driver body acceleration, suspension stroke, and tire deflection responses under worst-case random road disturbances and to develop a parameter-dependent optimal control of a non-linear vehicle suspension system. In this figure,

m1 is the unsprung mass, which represents the wheel assembly,

m2 is the quarter car sprung mass, which represents the vehicle cabin floor,

m3 is the mass of the seat frame,

m41 and

m42 are the masses of human thighs together with buttocks and seated cushion, respectively, and

m5 is the mass of the upper body of a seated human.

z1(

t),

z2(

t),

z3(

t),

z4(

t), and

z5(

t) are the vertical displacements of the corresponding masses, respectively, and

zr(

t) is the road disturbance input.

k1 is the coefficient of tire spring,

c1 and

k2 are the damping and stiffness of the vehicle suspension system, respectively.

c2,

c3 and

k3,

k4 are damping and stiffness of the passive seat suspension system, respectively, and

c4 and

k5 stand for the damping and stiffness of the components inside the human body. In addition,

u(

t) represents the active control force that is applied to the vehicle suspension. The characteristics of the non-linear spring of the vehicle suspension, which is the mathematical model of the well-known hardening spring behavior, is described as follows:

Similar dynamical models with position-dependent stiffness coefficients have been previously reported in the literature [

14,

15,

16]. The quadratic damping feature of the suspension system can be mathematically modeled as:

where the damping coefficient is non-linear. Additionally, the change of the damping coefficient due to the velocity is discussed in [

10,

14]. The dynamic vertical motion of equations for the quarter car active suspension, seat suspension, and driver body are given by

and

To design the parameter-dependent optimal controller, the LPV vehicle suspension model is constructed under the assumption that the modeled vehicle system has two scheduling parameters, which are the non-linear parts of the spring and damping forces. The scheduling parameters vector is defined as:

By the use of the scheduling parameters vector, the dynamic vertical motion of equations can be represented in the matrix form:

where

is the displacement vector,

u(

t) is the control force,

is the disturbance input acting on the system,

F gives the location of the controller, and

E weights the disturbances. These matrices are given as:

and

Here,

Ms is the mass matrix and given as:

where

diag(∙) denotes the diagonal matrix.

is the stiffness matrix, and

Ks0 and

Ks1 can be constructed as

Finally,

is the stiffness matrix, and

Cs0 and

Cs2 can be written as

Using the definition

, the constructed LPV vehicle model can be written in the state-space form as:

where

,

,

,

,

,

,

,

,

, and

.

Here,

A(θ) is the system matrix,

Bu(θ) is the control input matrix, and

Bw(θ) is the disturbance input matrix.

A0,

Bu0, and

Bw0 are the constant and real matrices. The constant and real valued matrices,

A1,

A2,

Bu1,

Bu2, and

Bw1,

Bw2 represent the change in system dynamics that are caused by the variations of scheduling parameters. The state variables of the LPV model are the displacements and velocities of the each mass. The control vector and disturbance vector are assumed to be in the forms

and

, respectively. The non-linear vehicle system parameters [

14] and driver body parameters [

3] are assumed to be as follows:

m1 = 36 kg,

m2 = 240 kg,

m3 = 15 kg,

m4 =

m41 +

m42 = 1 + 7.8 = 8.8 kg,

m5 = 43.4 kg,

c1 = 980 Ns/m,

c2 = 830 Ns/m,

c3 = 200 Ns/m,

c4 = 1485 Ns/m,

k1 = 160 KN/m,

k2 = 16 KN/m,

k3 = 31 KN/m,

k4 = 18 KN/m, and

k5 = 44.130 KN/m.

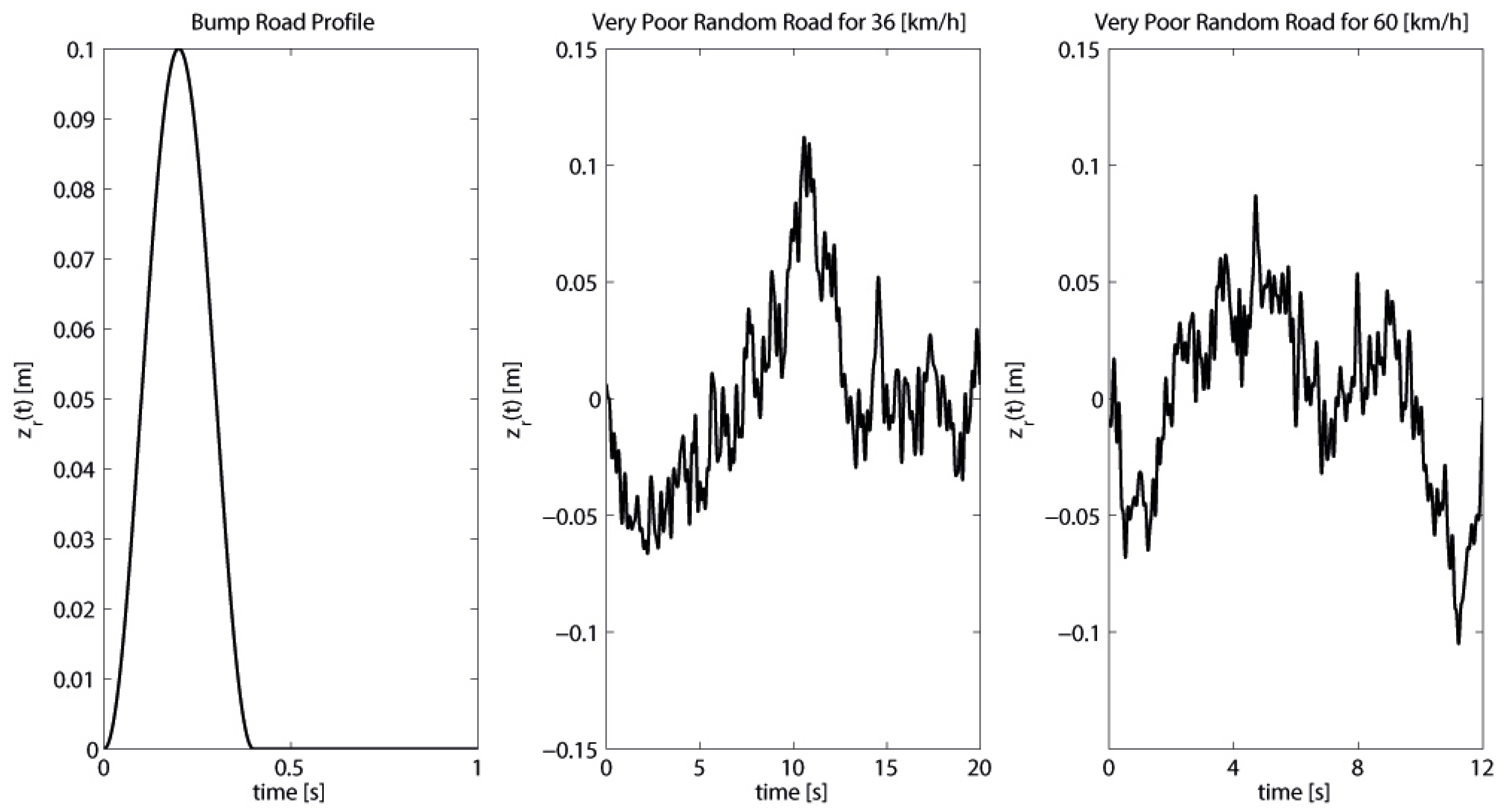

In this study, three typical road profiles are used as disturbance inputs, which are applied to the vehicle wheel. The road bump profile is considered first to reveal the transient response characteristic, which is given by:

where

a and

l are height and length of the bump, respectively, and

V0 is the vehicle velocity [

6]. Here, road bump profile parameters are chosen as

a = 0.1 m,

l = 5 m, and

V0 = 45 km/h. Then, ISO2631 very poor random road profile is used as the worst-case disturbance input for the different vehicle velocities [

17]. The road disturbance can be considered as the vibration, and it is typically specified as a random process with a ground displacement power spectral density of

where

is a reference frequency, ϕ is a frequency, and

n1 and

n2 are road roughness constants [

17]. The

value can be computed by measuring the roughness of the road. The road irregularities can be constructed by the following series, when the vehicle horizontal speed

v0 is assumed to be constant,

, where

,

,

l is the length of the road segment,

, and ϕ

n are treated as random variables that follow uniform distribution in the interval

.

Nf limits the frequency range. The very poor random road profile parameters are chosen according the ISO2631 standards as

n1 = 2,

n2 = 1.5,

Nf = 100,

l = 200, and

. The vehicle velocities are considered as 36 and 60 km/h [

17]. The modeled bump and ISO2631 very poor random road disturbances for 36 and 60km/h are shown in

Figure 2.

In order to demonstrate the effects of the non-linear characteristics of the spring and damper of the vehicle suspension system, a simulation study is also carried out, which is given in

Table 1 for the comparison of behaviors of the linear and non-linear suspension systems. The linear suspension model can be easily obtained when the non-linear spring and damper parts,

and

are removed from Equations (3) and (4), respectively. The corresponding peak-to-peak vibration amplitude values and RMS values of cabin floor displacement and acceleration responses are compared for both the linear vehicle system and the non-linear vehicle system in

Table 1 against the very poor random road disturbance inputs for 36 and 60 km/h.

3. Parameter Dependent Optimal Controller Design for LPV Systems

In this paper, a state-feedback LPV controller is designed to mitigate the vertical vibrations of a non-linear vehicle suspension system. LPV methods have received considerable attention in recent years [

18]. LPV-based controller design is a gain-scheduling control method to enable the application of linear methods on the control of non-linear systems. The conventional approach to gain scheduling is a repetitive design procedure with a gridding of an operating domain. Despite the fact that such implementations frequently enjoy success and are deployed in many realistic control systems, conventional techniques provide no guarantee for stability or performance. At this stage, LPV methods guarantee Lyapunov stability and specific performance objectives for non-linear systems [

19]. Therefore, to guarantee the closed-loop stability and improve system performance, a LPV-based control algorithm is very suitable for the vibration attenuation of non-linear vehicle suspension systems.

The control objectives are to guarantee the closed-loop stability and disturbance attenuation in the sense of

L2 norm. First, solvability conditions for the

L2 gain controller that depends on the measured scheduling parameters are expressed in terms of a set of LMIs. Then, a coupling constraint is added to the controller design, which fulfills the multiconvexity condition [

20]. Consider the following LPV system:

where

is the state vector,

is the control input,

is the disturbance input acting on the system, and

is the controlled output. Then,

, and

is a vector of scheduling parameters. The state-space matrices

A(θ),

Bu(θ),

Bw(θ),

C(θ),

Du(θ), and

Dw(θ) depend affinely on the parameters θ

i. It is assumed that lower and upper bound are available for parameter values and rates of variation. Each parameter θ

i ranges between known extremal values

and

,

This assumption means that the scheduling parameters vector θ is valued in a hyper-rectangle called the parameter box. In the sequel,

denotes the set 2

k vertices or corners of this parameter box. The rate of variation

is well defined at all times and satisfies

where

are known lower and upper bounds on

. Similarly, Equation (21) delimits on hyper-rectangle of

Rk with corners in

Then, our goal is to design an optimal state-feedback LPV controller that depends on the scheduling parameters θ

i, expressed as

, which ensures the quadratic stability of the system Equation (18), with a Lyapunov function depending on

’s with a disturbance attenuation level γ. Using this control law, one obtains the closed-loop system as

The following theorem presents an optimal state-feedback LPV controller synthesis.

Theorem: Consider the closed-loop system Equation (23) with a parameter dependence on θi, assume that the parameter trajectories and their derivatives range in hyper-rectangles Equations (20) and (22), and let and denote the corner sets of these hyper-rectangles. For a given non-negative scalar constant, , the closed-loop system Equation (23) is parameter-dependent quadratically stable with the disturbance attenuation level, γ, if there is a positive definite parameter-dependent symmetric matrix and a rectangular matrix for each vertex of Equations (20) and (22) subject to

and

where

. Then,

is an

L2 gain of the resulting closed-loop system from

to

for all

, and the control law

is an LPV controller associated with γ.

Proof: Let us choose an affine quadratic Lyapunov function,

, such that

and

along all admissible parameter trajectories and, for all initial conditions,

. Provided that

and their time derivatives

vary in compact sets, this guarantees asymptotic stability. The closed-loop system Equation (23) is affinely quadratically stable if there is a parameter-dependent symmetric Lyapunov matrix,

. Taking the time derivative of

along the system trajectory Equation (23), one obtains

and

In addition, closed-loop system Equation (23) has an affine quadratic

L2 gain performance, γ, with the condition

which holds for all admissible parameter trajectories

and

for

. Then, substituting the closed-loop system Equation (23) into the condition Equation (29), one obtains

On the other hand, let us define an extended state vector as

. Then, one can easily see that Equation (29) and

are equivalent. Hence, if

is satisfied, negative definiteness of Equation (29) is also satisfied, where

Applying the Schur complement formula [

20] on Equation (31),

is congruent to

where

. Pre- and post-multiplying Equation (32) by

, where

, and applying the variable change

, inequality Equation (32) is congruent to

where

with

and

As for affine quadratic stability, Equations (33) and (34) put an infinite number of constraints on the unknowns

. For tractability, Equations (33) and (34) are reduced to a system of finitely many LMIs by imposing multiconvexity. The implications of multiconvexity for scalar quadratic functions are clarified by the following lemma [

20].

Lemma [20]: Consider a scalar quadratic function of

,

and assume that

is multiconvex, that is,

Then,

is negative in the hyper-rectangle Equation (19) if and only if it takes negative values at the corners of Equation (19): that is, if and only if

for all

in the vertex set

given by Equation (20). The multiconvexity condition can be constructed by considering the inequality Equation (33) as a quadratic function in the form of Equation (35). Then, inequality Equation (37) is resulted which is equivalent to Equation (36) by the use of the lemma.

For clarity, representation of

in the form of Equation (35) can be shown:

for all Equations (20) and (22). As it can be observed from

Section 2, scheduling parameters are located in only a few entries of the parameter-dependent matrices. Since the matrices,

,

,

,

,

, and

are mostly low ranked, strict inequalities are not constituted easily. A simple solution to this numerical problem is proposed in [

20]. By implanting non-negative scalars

into Equation (37), Equation (25) is obtained. This completes the proof.

4. Numerical Simulation Study

In this section, an extensive number of simulations are carried out to illustrate the effectiveness of the proposed controller. To improve the driver’s ride comfort and essential performance requirement, a parameter-dependent optimal controller is designed which is scheduling online according to suspension stroke and its variation rate. To ensure that both responses are within permissible limits, the performance output vector

z(

t) is constructed as

where

,

,

,

,

,

,

,

,

and

. These matrices are chosen to represent the following variables:

as a specified performance output vector. To achieve a minimum

L2 gain from

w(

t) to

z(

t) for all

, the proposed theorem is applied to this problem, and the minimum allowable disturbance attenuation level γ is calculated as 14.72 and a parameter-dependent optimal state-feedback control law is constructed as

, where

and

. In order to demonstrate the proposed controller performance, bump and very poor random road irregularities are used as the disturbance input as modeled in

Section 2 and shown in

Figure 2.

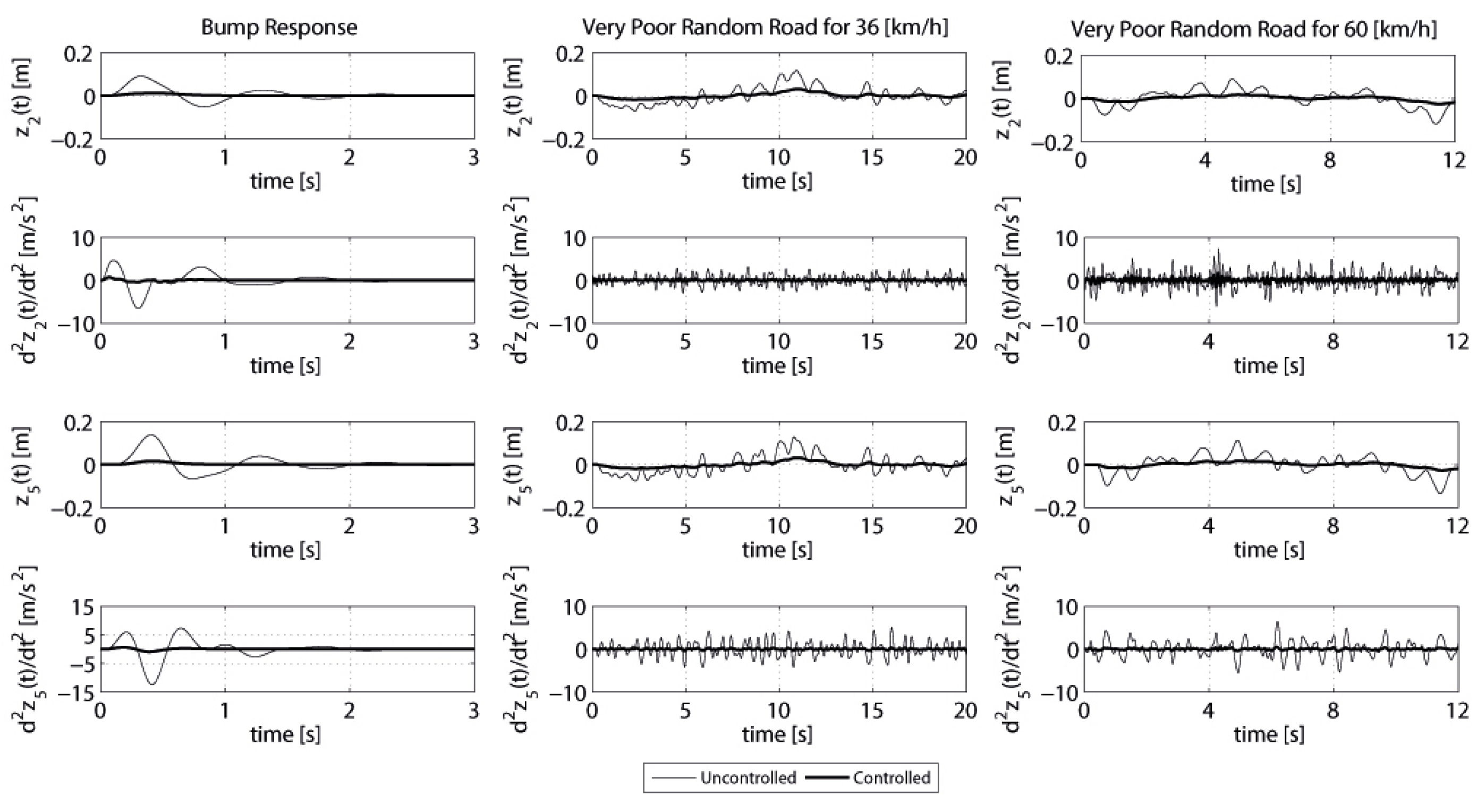

Figure 3 shows the time responses of the vertical displacements and accelerations of cabin floor and driver body of the considered vehicle system, respectively. As can be observed from this figure, very successful vibration suppression is achieved by the use of the designed controller. Note that the designed controller achieves good control performance on ride comfort in terms of the peak value of driver body acceleration.

To evaluate the proposed controller performance on different performance aspects, vehicle suspension stroke and tire deflection properties are shown in

Figure 4. This figure reveals that the designed controller has a satisfactory control performance and achieves a good trade-off.

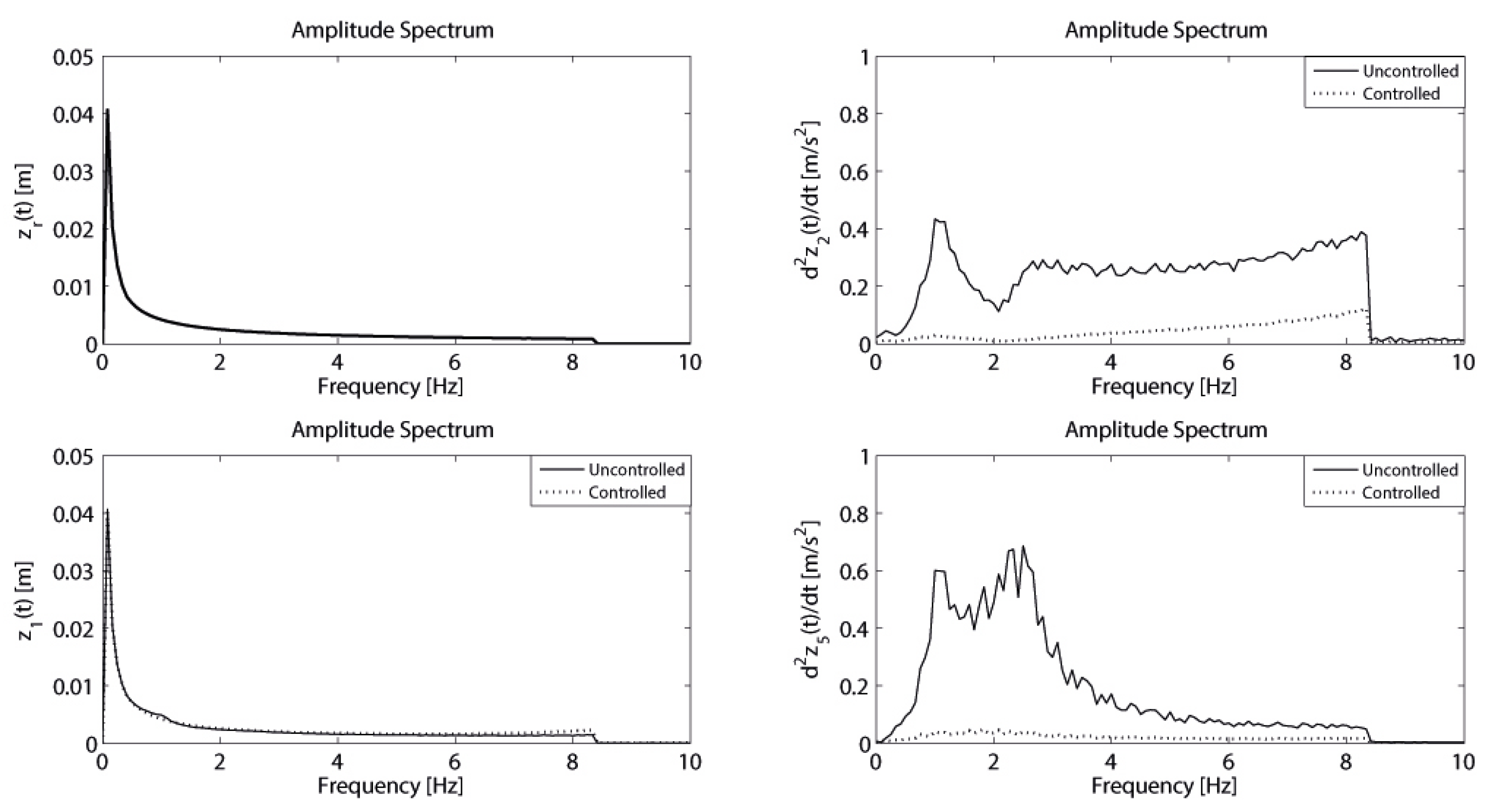

Figure 5 demonstrates the amplitude spectrum plots of displacement of the very poor random road profile, as well as displacement responses of the vehicle wheel and acceleration responses of the cabin floor and driver body for both controlled and uncontrolled cases under very poor random road excitation at 60 km/h.

As expected, frequency content of the zr(t) for 60 km/h is limited to 8.33 Hz. Note that computation of random road roughness is based on the summation of different sine waves as . Upper bound of the frequency content can be easily obtained by the multiplication of nw0, where the upper bound of the n is given as 100 and takes the value of 0.5236 for l = 200 m and v0 = 16.67 m/s. Therefore, the maximum value of the nw0 is 52.36 rad/s and 8.33 Hz.

As can be seen from

Figure 5, there is no degradation in the performance of the closed-loop control system when the displacement response plot of the vehicle wheel with controlled and uncontrolled cases is compared. Note that the proposed controller largely reduces the cabin floor and driver body accelerations compared to the uncontrolled system and therefore achieves a very successful ride comfort performance.

As is mentioned in

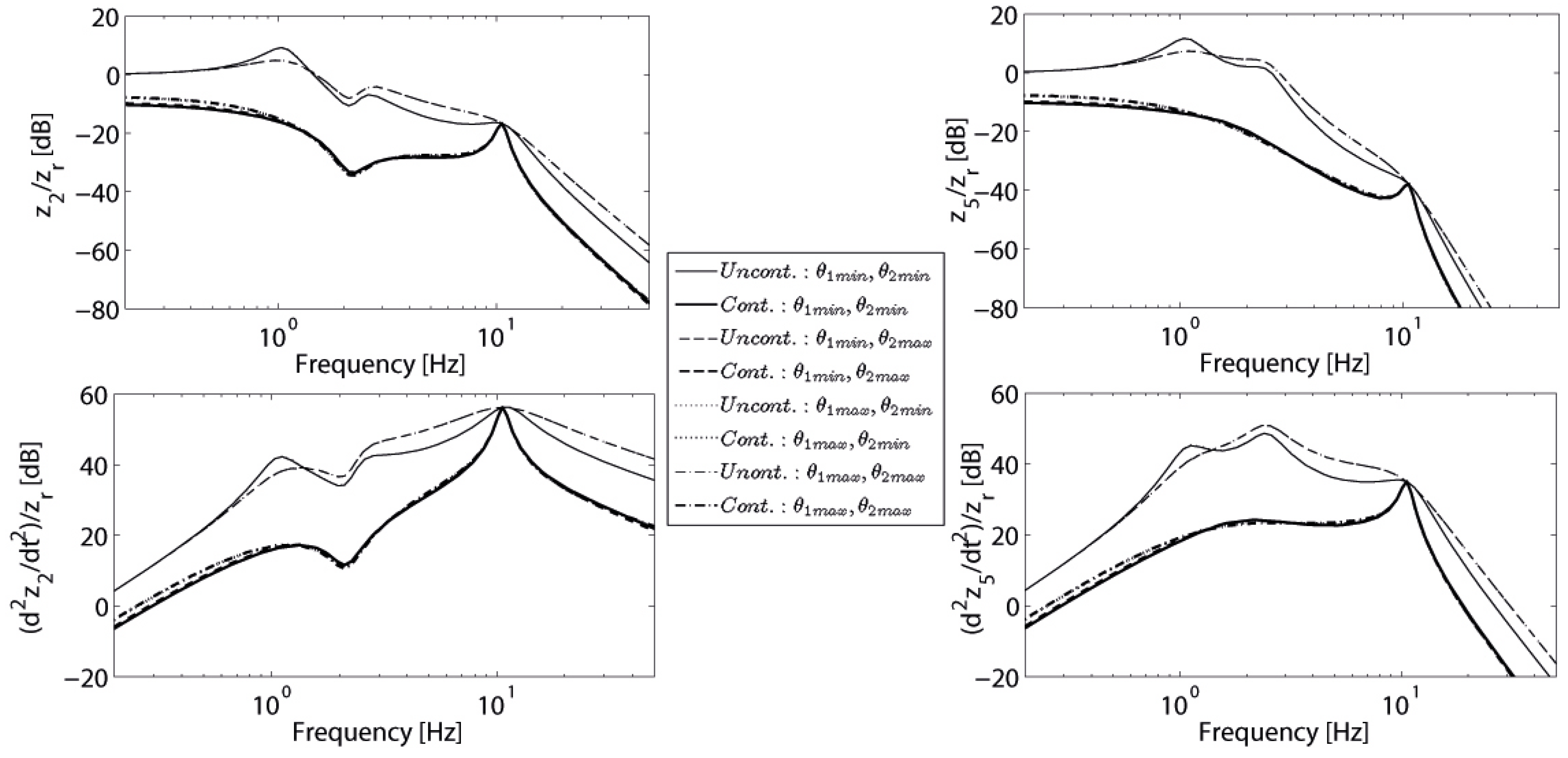

Section 3, the parameter-dependent controller design for the LPV system is a kind of gain-scheduling control method. In this method, the value of the controller gain matrix of the proposed controller does not remain fixed while the controller is in operation; rather, it is modified in accordance with the scheduling parameters. Therefore, the frequency responses can be obtained by assuming that time-varying parameters are frozen for their vertex points.

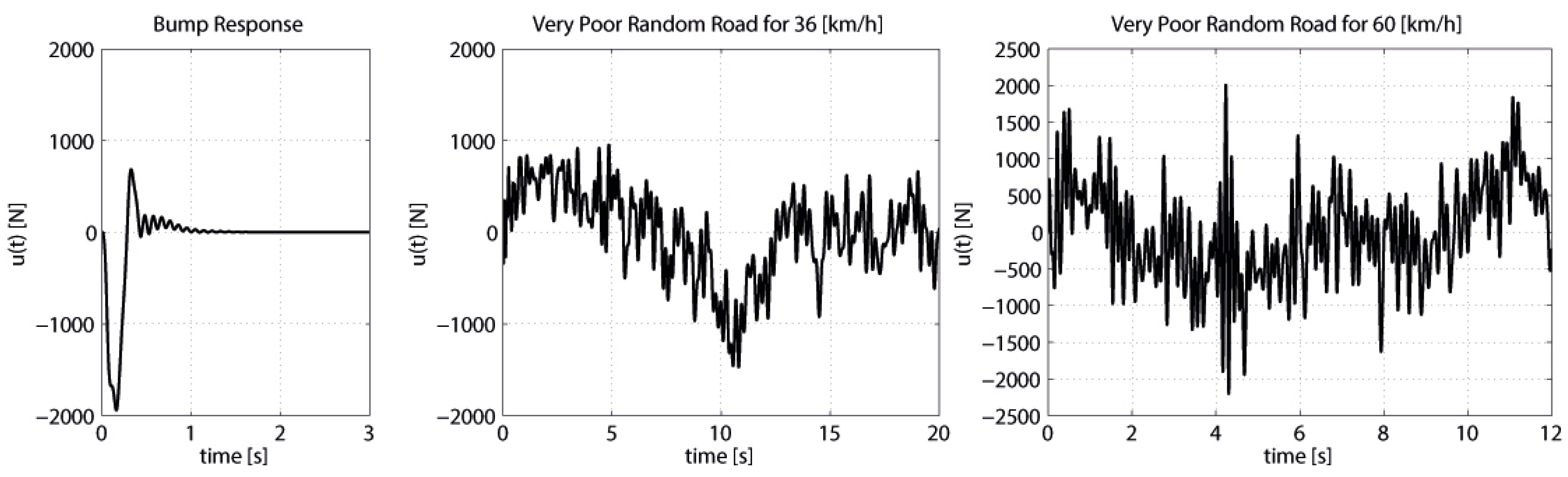

Figure 6 shows the frequency responses of the displacements and accelerations of the cabin floor and driver body, respectively, for both controlled and uncontrolled cases when the frozen scheduling parameters for their vertex points are considered. As expected, high gain responses belong to the uncontrolled system. When the response plots of the system with uncontrolled and controlled cases are compared, a superior improvement in the mitigation of the resonance values is obtained by the proposed controller. On the other hand,

Figure 7 demonstrates that the change in control forces the inputs for the bump and very poor random road excitations. As can be observed from this figure, the applied control forces, which range within maximum ±2200 N for the worst-case road excitations, are very suitable to produce for practical implementations, as discussed in [

6,

10,

11].

In this section, the root mean square (RMS) value, which is the statistic measure of the magnitude of varying quantity, is employed to investigate the active suspension performance. The RMS analysis method is very useful for evaluating active control performance when the variants are positive and negative [

6]. The corresponding RMS values of the vertical cabin floor, driver body displacement, acceleration responses, suspension stroke, and tire deflection responses are compared for both the controlled and uncontrolled cases in

Table 2 for the bump and very poor random road disturbance inputs at different velocities, respectively.