Numerical Simulation Study on the Flow Field Out of a Submerged Abrasive Water Jet Nozzle

Abstract

:1. Introduction

2. Mathematical Model

2.1. Main Assumptions

2.2. Governing Equations [14,15,16,17,18,19,20]

2.3. Standard Turbulence Equations

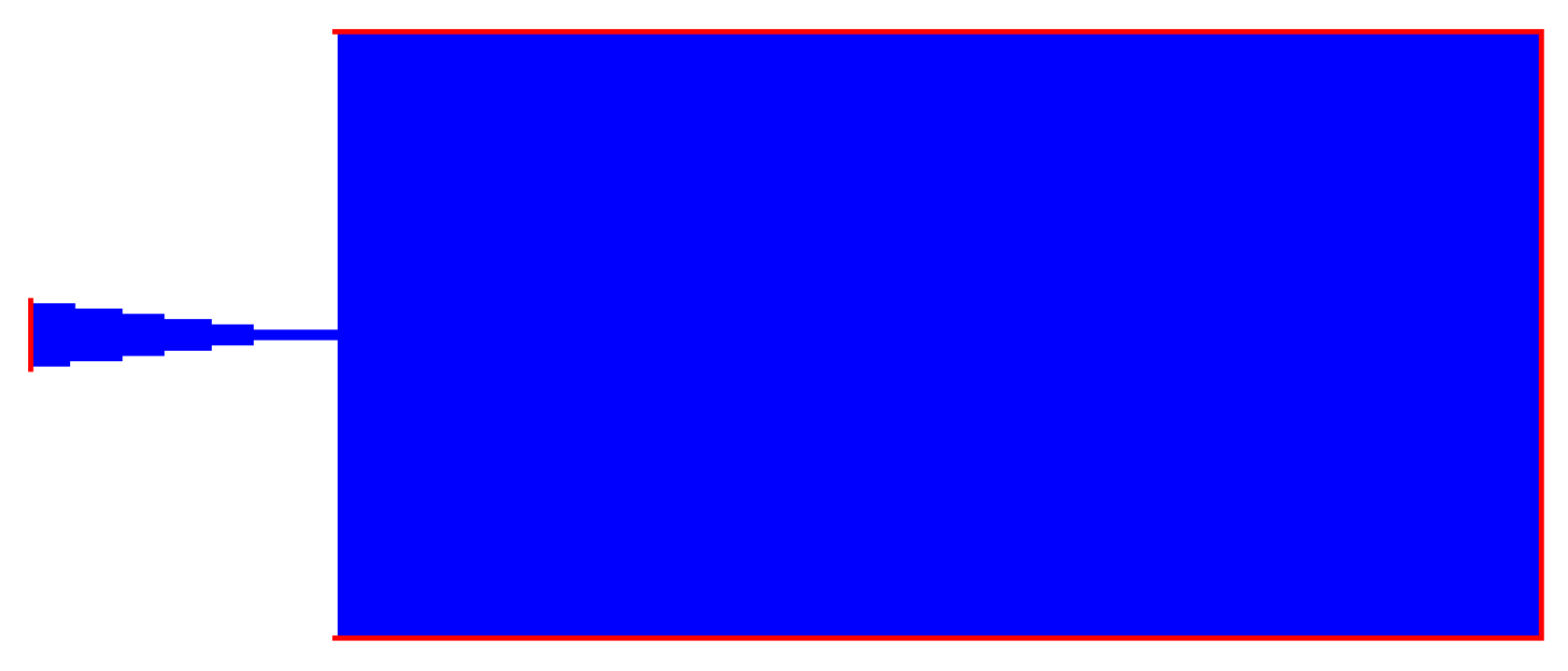

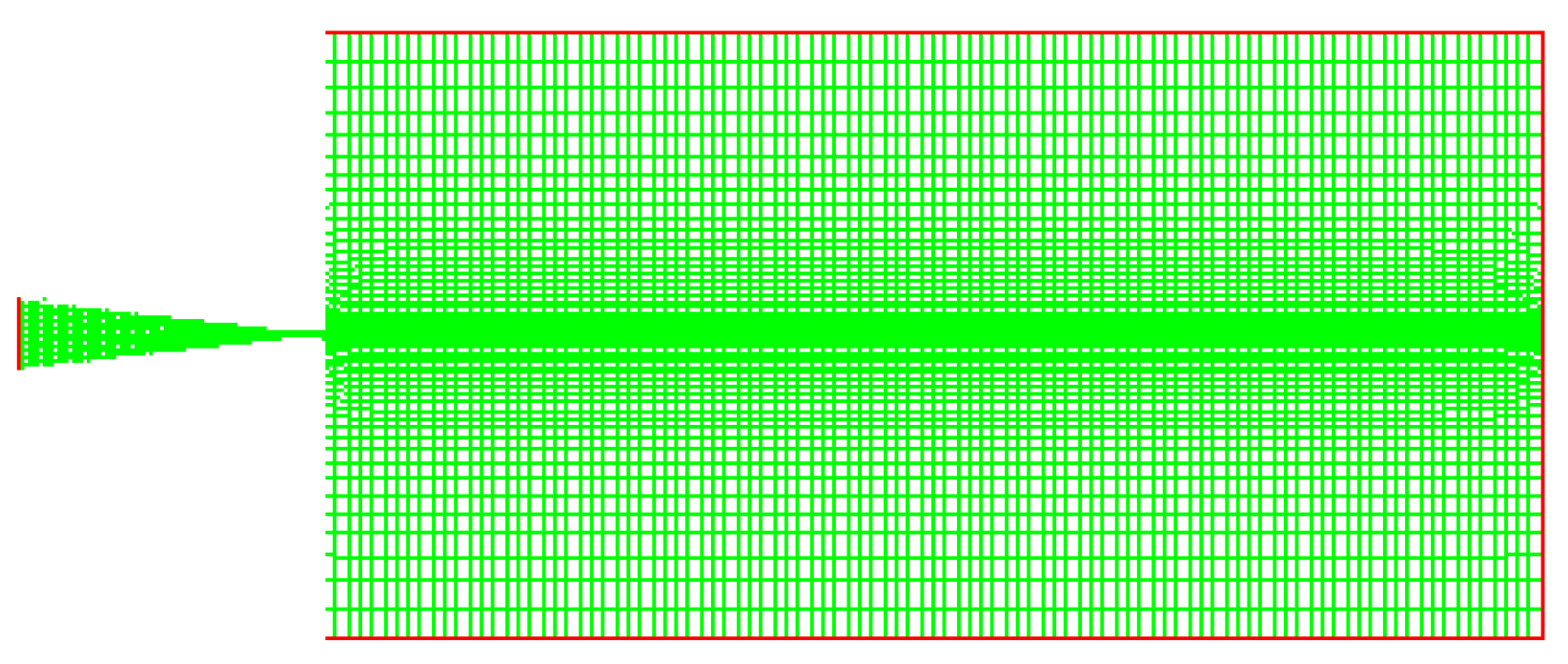

2.4. Geometrical Model

2.5. Boundary Conditions

3. Results and Analysis

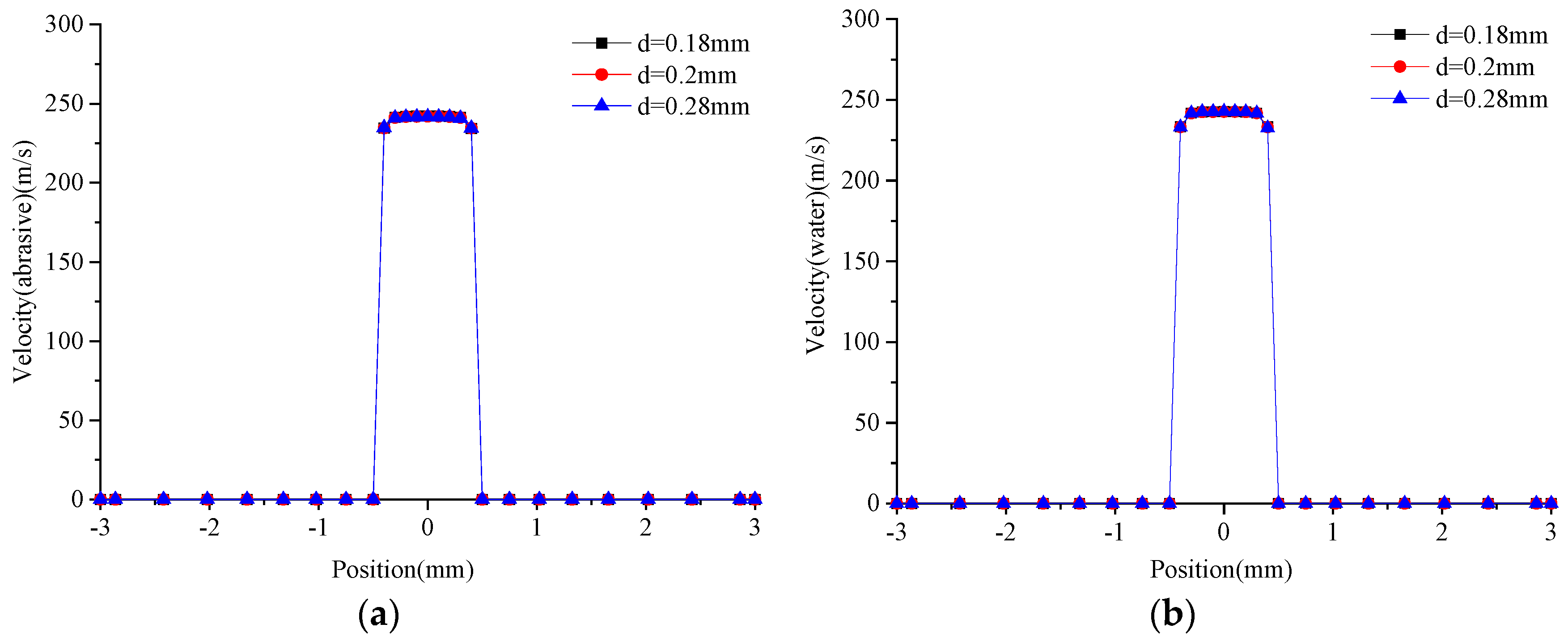

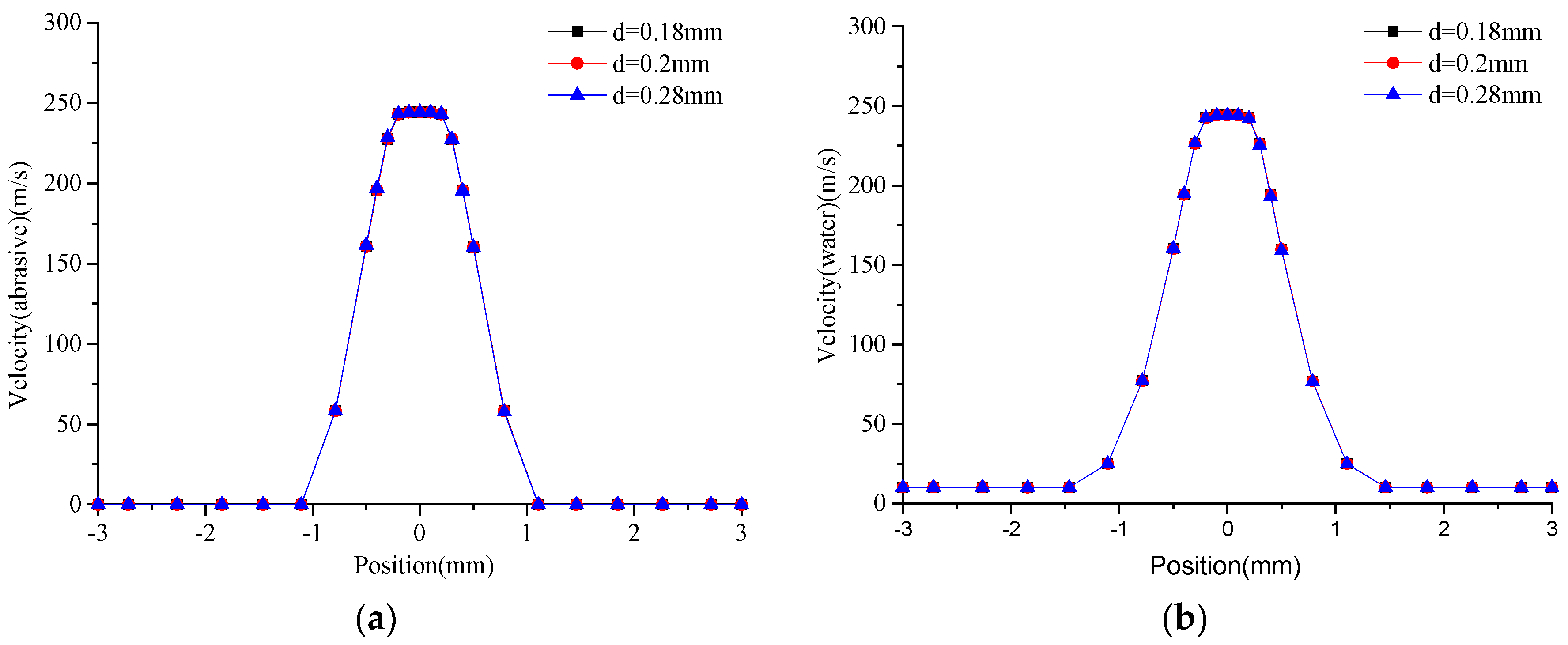

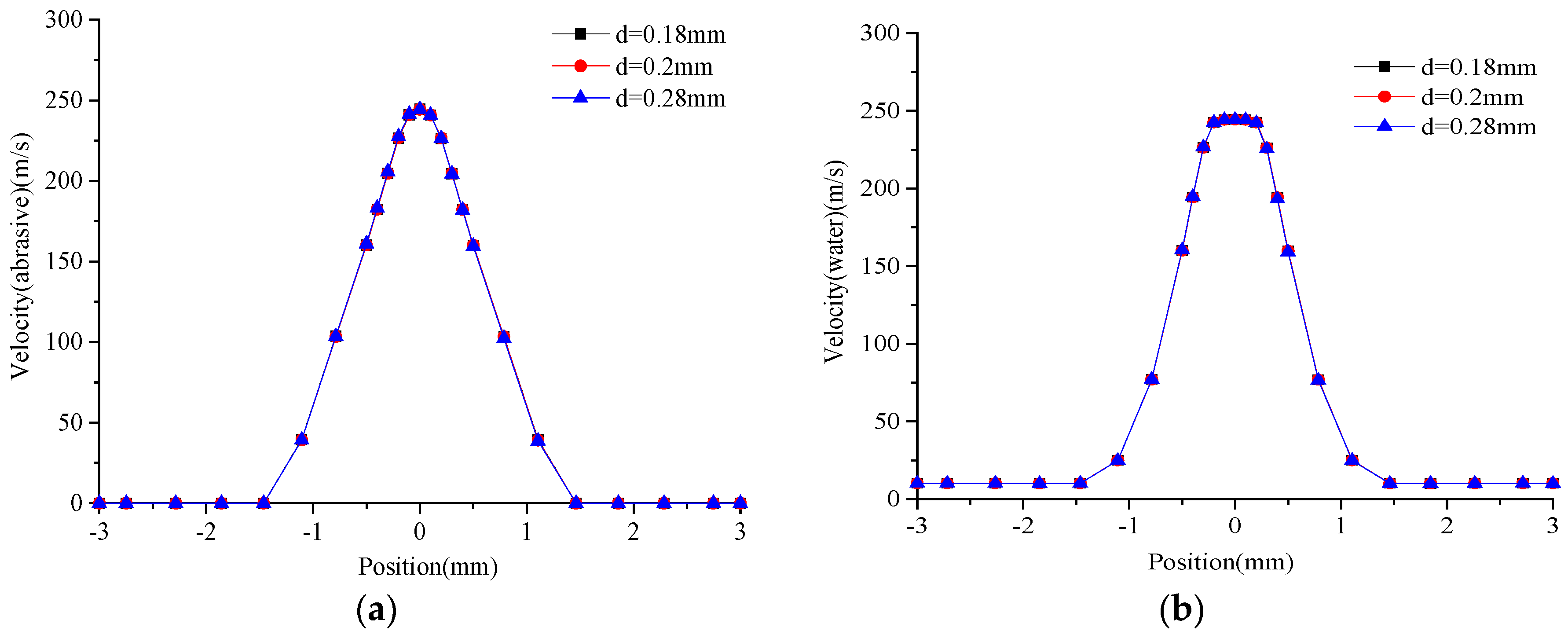

3.1. The Effect of Abrasive Particle Sizes on the Jet Flow Field

- (1)

- Axial velocity distribution

- (2)

- Radial velocity distribution

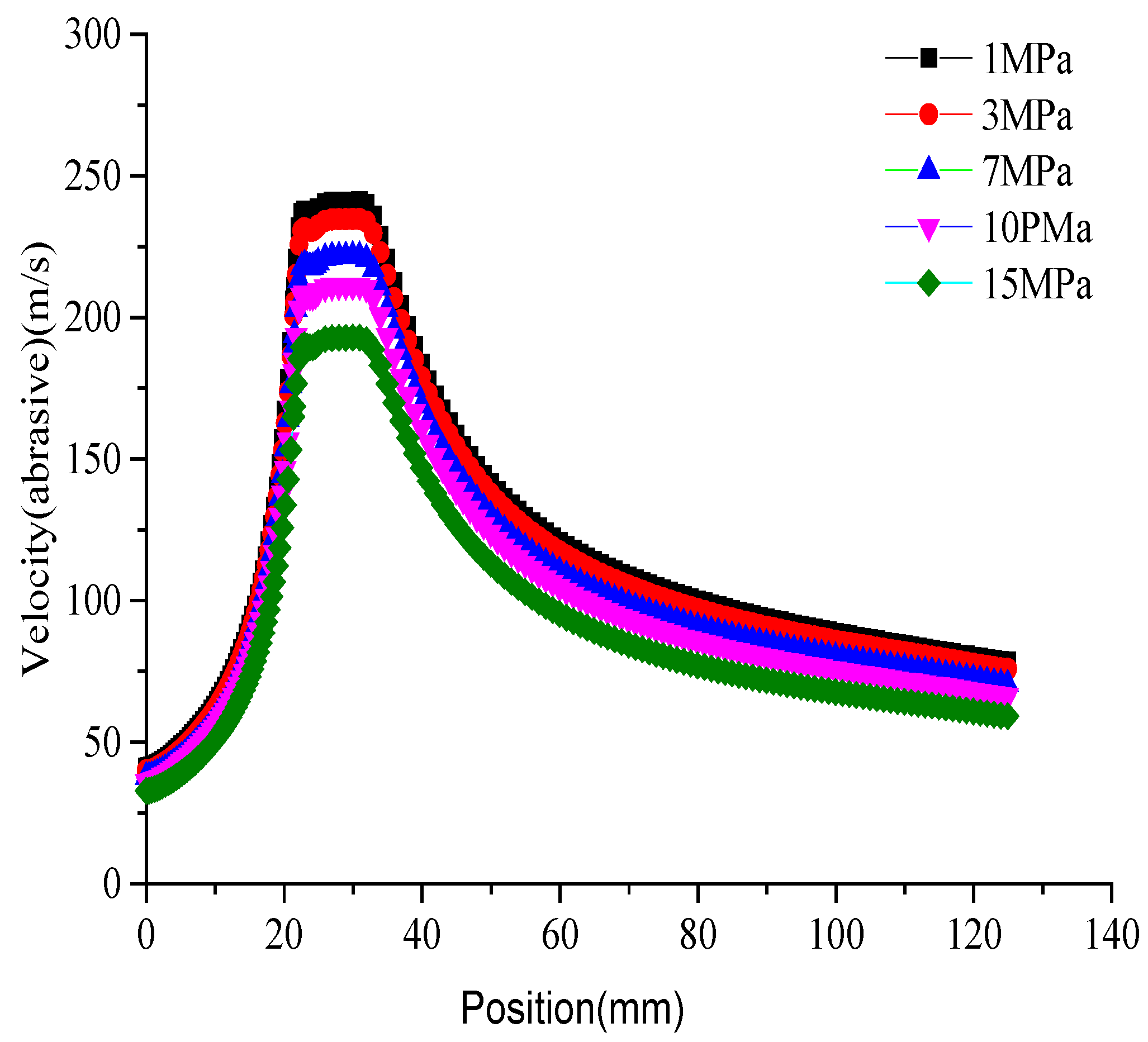

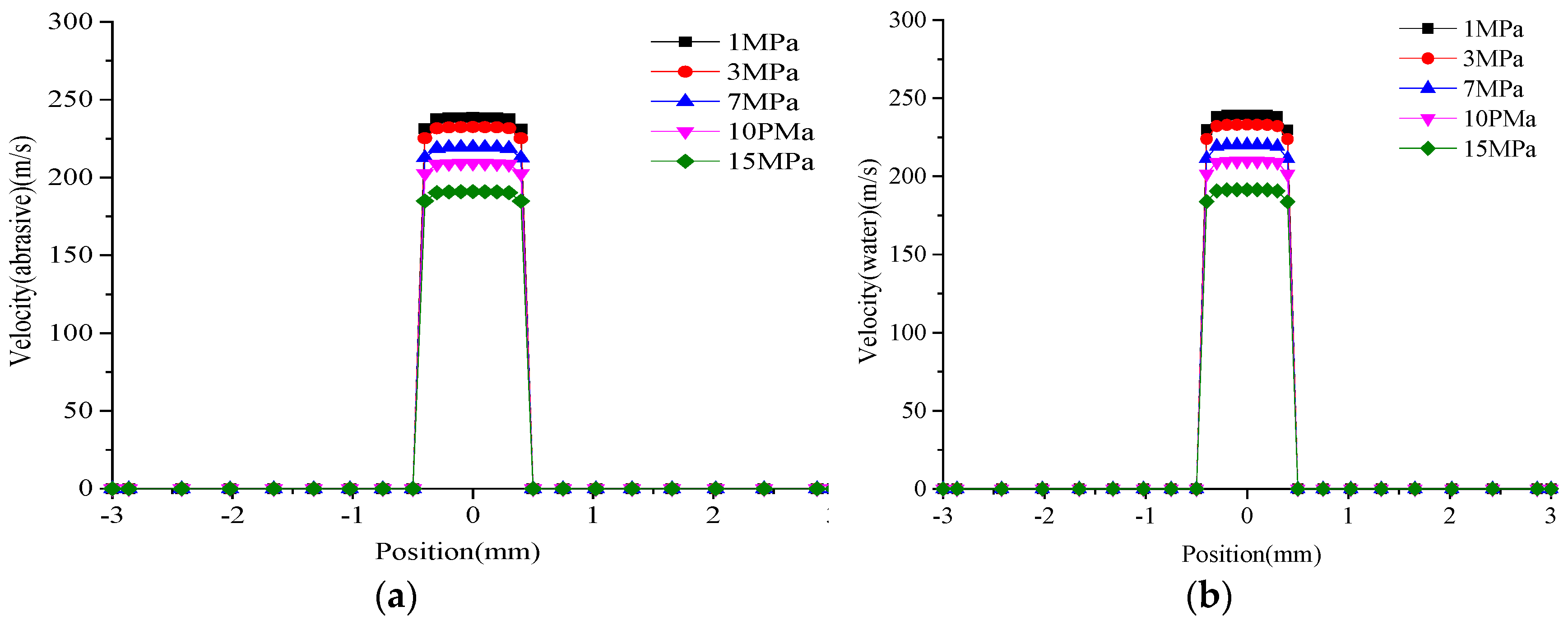

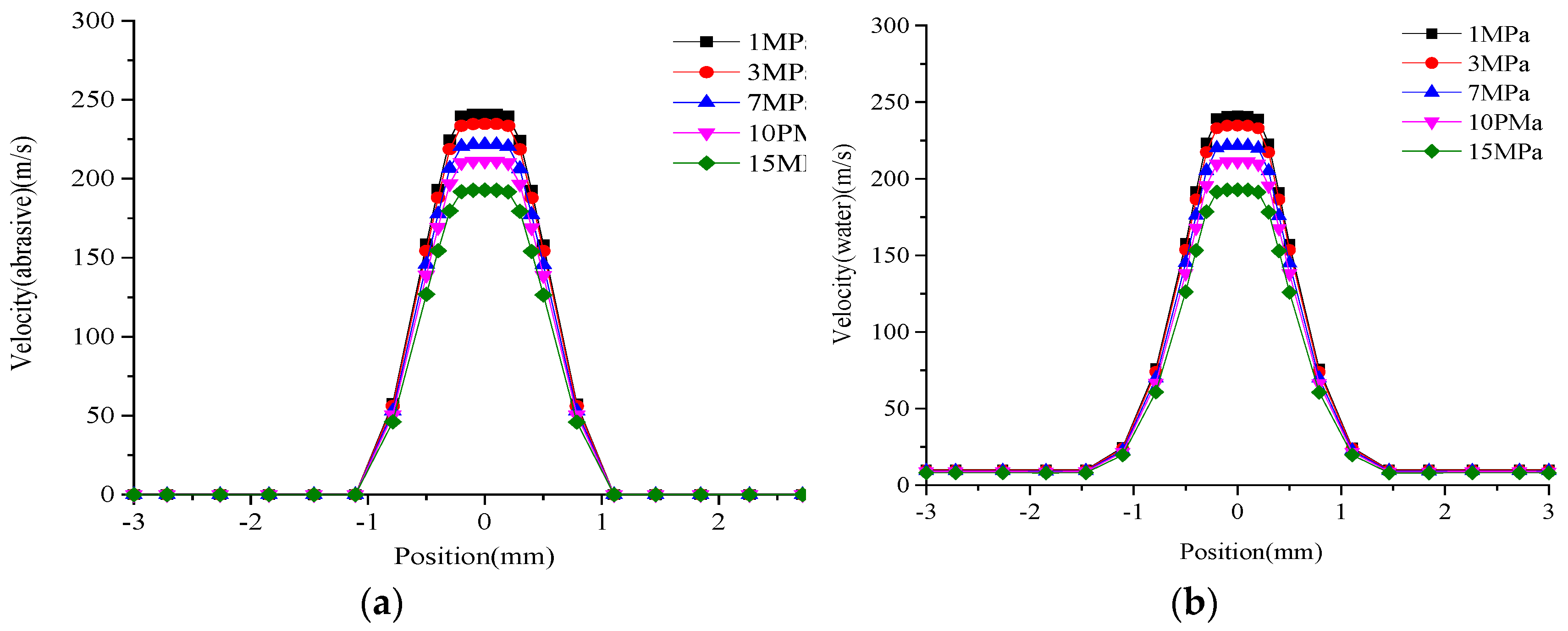

3.2. The Influence of Confining Pressure on the Jet Flow Field

- (1)

- Axial velocity distribution

- (2)

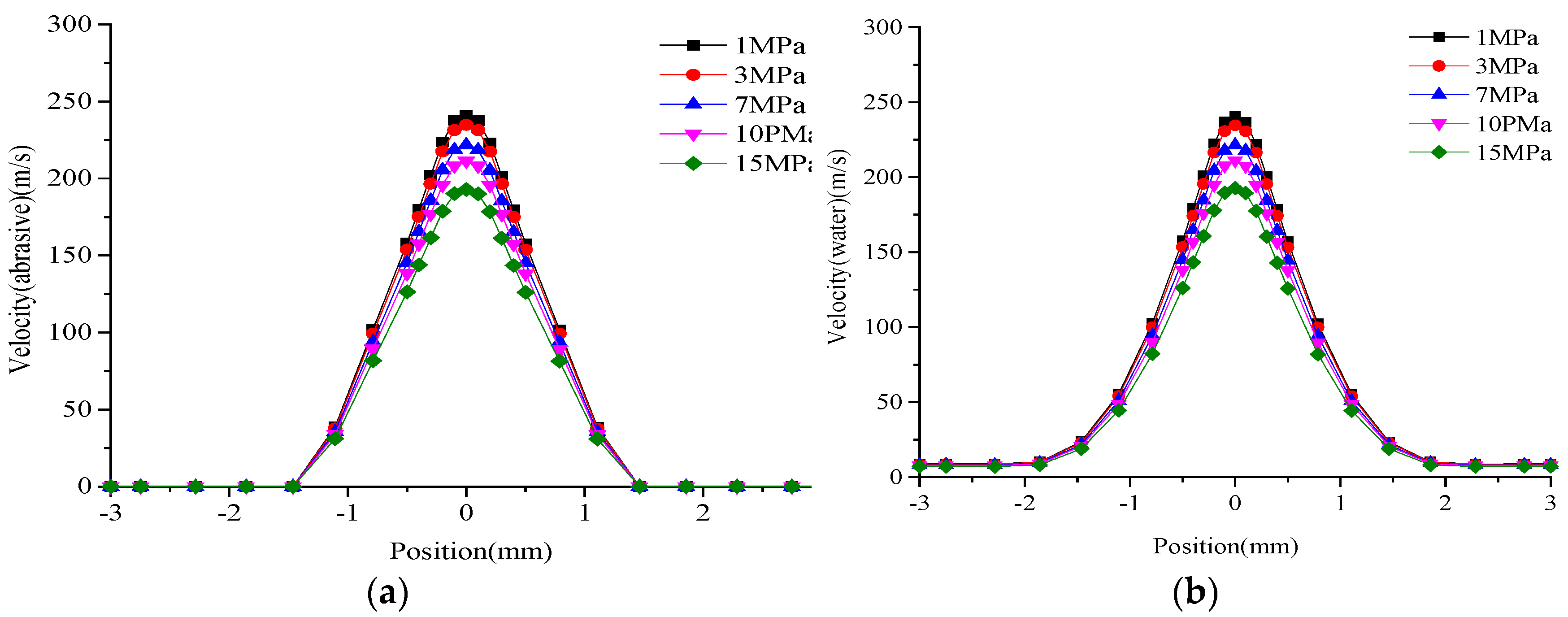

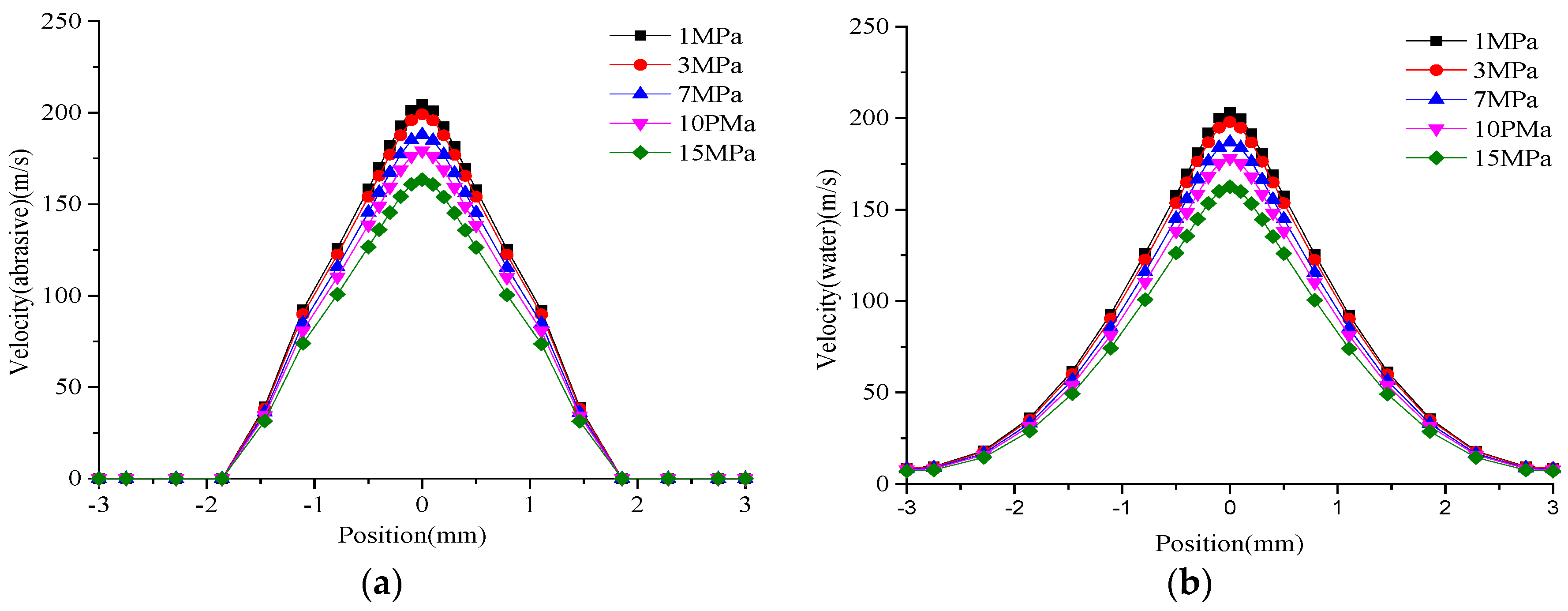

- Radial velocity distribution

4. Conclusions

- (1)

- In the convergence section, because of the geometrical structure, the velocity of the jet is increasing and the pressure energy of the abrasive is gradually converted into kinetic energy. After the ejection of the abrasive, the speed increases at the beginning and the maximum speed is 6 mm from the nozzle exit. After the speed reaches the maximum, it will decrease constantly because of the water resistance of the surrounding water zone. The entire jet section develops into a form of axial high speed, which then decreases along the radial direction at the nozzle exit.

- (2)

- The simulation calculation of two-phase flow with different sizes of abrasive particles has been carried out. As can be seen in the simulation results, the abrasive particle size has little effect on the velocity field outside the nozzle. The greater the particle size, the greater the kinetic energy and the greater the cutting ability. However, the diameter of the nozzle outlet is certain, so the abrasive particle size cannot be too large.

- (3)

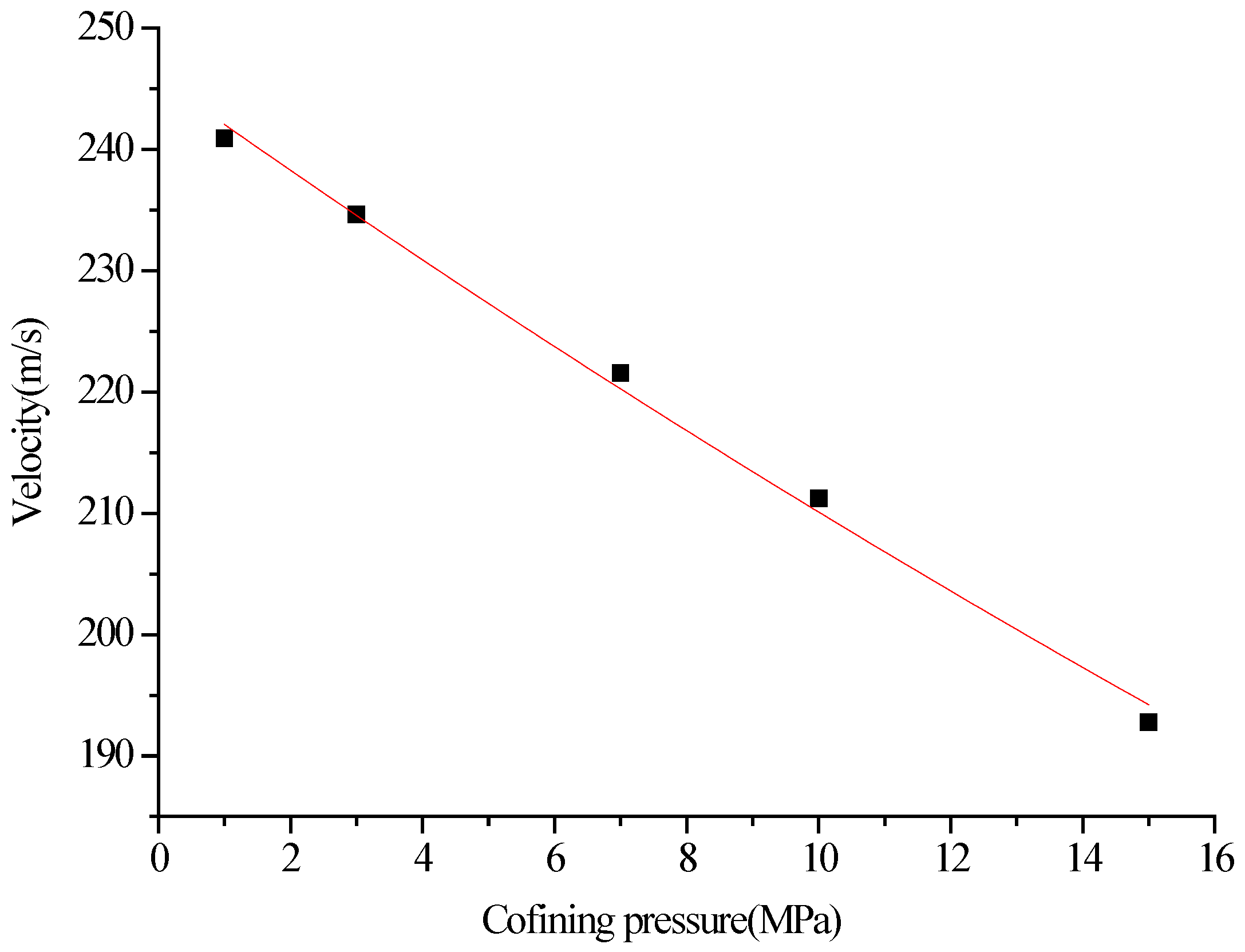

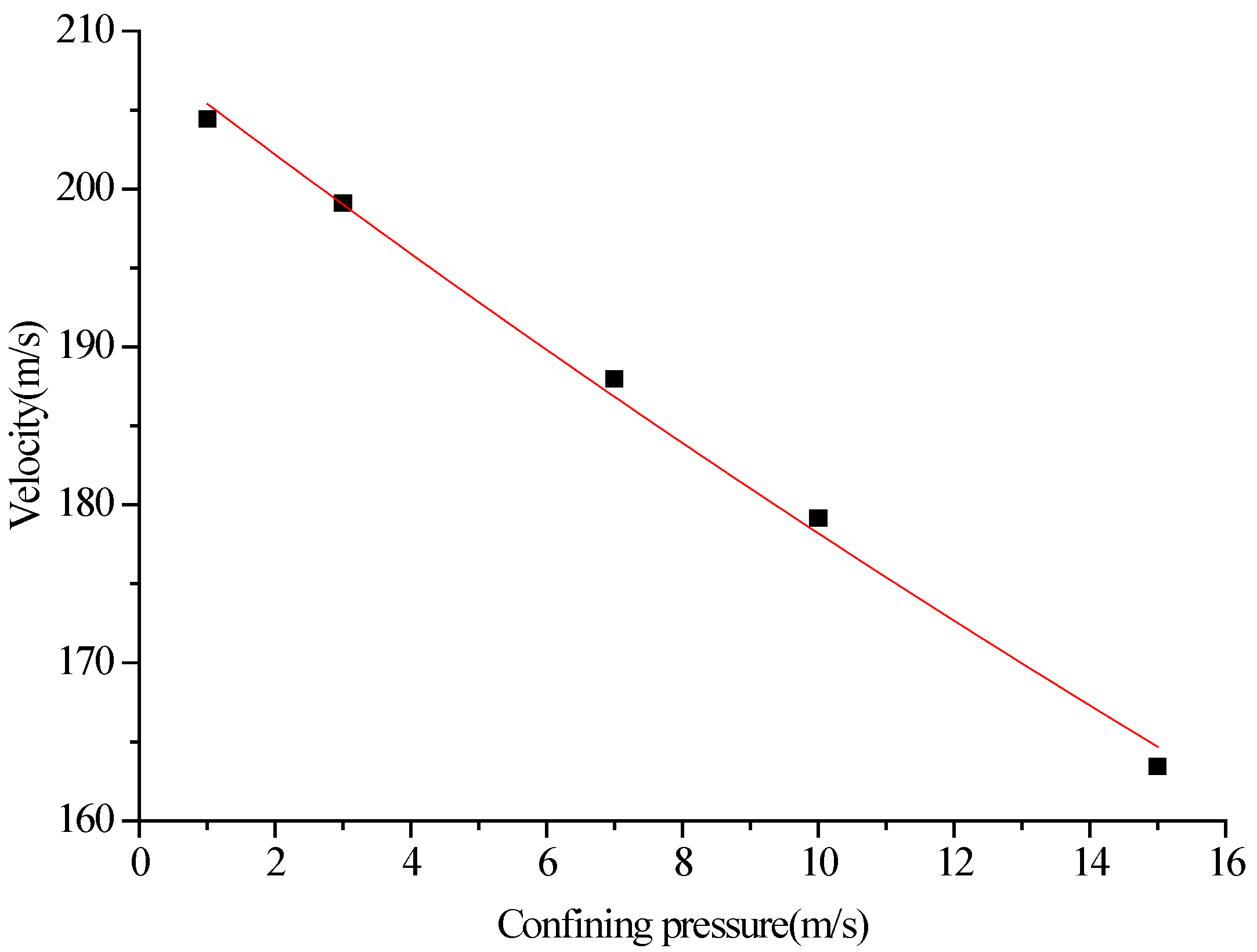

- The simulation calculation of two-phase flow with different confining pressures has been carried out. As can be seen in the simulation results, the jet velocity decreases constantly with the increase in confining pressure in the same place, and the relationship between the confining pressure and the axial velocity of the nozzle exit at different distances from the nozzle is in accordance with the exponential function.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Cui, M.; Li, C. Basic research on premixed abrasive water jet nozzle. China Saf. Sci. J. 1995, 5, 138–145. (In Chinese) [Google Scholar]

- Li, B.; Guo, C. Study on acceleration mechanism of abrasive particles of DIA jet in safe cutting. China Saf. Sci. J. 2005, 15, 52–55. (In Chinese) [Google Scholar]

- Li, X.; Sun, J.; Wang, J. Feasibility testing and investigation on a new technology for hard rock tunneling with a collimated abrasive water jet. Chin. J. Rock Mech. Eng. 2001, 20, 61–64. [Google Scholar] [CrossRef]

- Li, B. Development of safe cutting device in inflammable and explosive place. Fluid Mach. 2005, 33, 42–44. [Google Scholar]

- Lin, B.; Lv, Y.; Li, B. High-pressure abrasive hydraulic cutting seam technology and its application in outbursts prevention. J. China Coal Soc. 2007, 32, 959–963. [Google Scholar]

- Li, X.; Lu, Y.; Zhao, Y. Study on improving the permeability of soft coal seam with high pressure pulsed water jet. J. China Coal Soc. 2008, 33, 1386–1390. [Google Scholar]

- Liu, L. Simulation and Experimental Validation on the Flow Field Inside and Outside the Nozzle of Non-Submersed Precision Micro Abrasive Waterjet; Shandong University: Jinan, China, 2008. [Google Scholar]

- W, D.; Wu, Y.; Luo, W.; Xiang, Y. Study of flow field on cutting with high pressure water jet. J. Wuhan Univ. Sci. Eng. 2005, 18, 15–18. [Google Scholar]

- Wang, M.; Wang, R. Numerical simulation on fluid-particle two-phase jet flow field in nozzle. J. Univ. Pet. China 2005, 29, 46–49. [Google Scholar]

- Chen, C.; Nie, S.; Wu, Z.; Li, Z. A study of high pressure water jet characteristics by CFD simulation. Mach. Tool Hydraul. 2006, 2, 103–105. [Google Scholar]

- Qu, Y.; Chen, S.; Wang, X.; Teng, S. Discussion of the numerical simulation of ax-symmetric jet with different turbulent model. J. Eng. Thermophys. 2008, 6, 957–959. [Google Scholar]

- Gao, J.; Hu, S.; Ning, Y. The study of numerical simulation and flow characteristics of submerged abrasive jet based on CFD. China Mech. Eng. 2003, 14, 1188–1191. [Google Scholar]

- Dong, X. Numerical simulation study of the nozzle inside-flow of premixed abrasive water jet. Mach. Design Res. 2005, 21, 87–91. (In Chinese) [Google Scholar]

- Hou, R.G.; Huang, C.Z.; Wang, J.; Lu, X.Y.; Feng, Y.X. Simulation of solid-liquid two-phase flow inside and outside the abrasive water jet nozzle. Key Eng. Mater. 2007, 339, 453–457. [Google Scholar] [CrossRef]

- Su, M.; Huang, S. Foundation of Computational Fluid Dynamics; Tsinghua University Press: Beijing, China, 1997. (In Chinese) [Google Scholar]

- Hu, G.; Yu, T.; Liu, X. The numerical simulation of two phase flow about the liquid and solid in nozzle of DIA jet. Mechatronics 2005, 16, 20–23. (In Chinese) [Google Scholar]

- Saxena, A.; Paul, S. Numerical modelling of kerf geometry in abrasive water jet machining. Int. J. Abras. Technol. 2007, 1, 208–230. [Google Scholar] [CrossRef]

- Nie, B.; Meng, J.; Ji, Z. Numerical simulation research of liquid-solid two-phase flow in abrasive water jet nozzle. J. Beijing Inst. Technol. 2009, 18, 157–161. [Google Scholar]

- Meng, J.; Nie, B.; Ma, Y. Study on abrasive mixing chamber of pre-mixed water jet. Gazi Univ. J. Sci. 2015, 28, 425–431. [Google Scholar]

- Liu, G.; Wang, K.; Chen, X. Numerical simulation of internal flow field for post-mixed abrasive water jet descaling nozzle. Gongcheng Kexue Xuebao/Chin. J. Eng. 2015, 37, 29–34. [Google Scholar] [CrossRef]

| Abrasive Particle Size (mm) | The Axis Velocity of the Abrasive (m/s) | |||

|---|---|---|---|---|

| Nozzle Exit | 3 mm from the Nozzle Exit | 6 mm from the Nozzle Exit | 12 mm from the Nozzle Exit | |

| 0.18 | 242.147 | 244.374 | 244.447 | 207.116 |

| 0.2 | 241.526 | 243.857 | 243.981 | 206.916 |

| 0.28 | 241.433 | 243.765 | 243.883 | 206.844 |

| Confining Pressure (MPa) | The Axis Velocity of the Abrasive (m/s) | |||

|---|---|---|---|---|

| Nozzle Exit | 3 mm from the Nozzle Exit | 6 mm from the Nozzle Exit | 12 mm from the Nozzle Exit | |

| 1 | 238.629 | 240.933 | 241.053 | 204.431 |

| 3 | 232.415 | 234.659 | 234.776 | 199.088 |

| 7 | 219.458 | 221.578 | 221.684 | 187.957 |

| 10 | 209.215 | 211.237 | 211.335 | 179.156 |

| 15 | 190.924 | 192.771 | 192.854 | 163.446 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meng, J.; Wei, Q.; Ma, Y. Numerical Simulation Study on the Flow Field Out of a Submerged Abrasive Water Jet Nozzle. Math. Comput. Appl. 2016, 21, 2. https://doi.org/10.3390/mca21010002

Meng J, Wei Q, Ma Y. Numerical Simulation Study on the Flow Field Out of a Submerged Abrasive Water Jet Nozzle. Mathematical and Computational Applications. 2016; 21(1):2. https://doi.org/10.3390/mca21010002

Chicago/Turabian StyleMeng, Junqing, Qingen Wei, and Yechao Ma. 2016. "Numerical Simulation Study on the Flow Field Out of a Submerged Abrasive Water Jet Nozzle" Mathematical and Computational Applications 21, no. 1: 2. https://doi.org/10.3390/mca21010002