Industrial Process Monitoring in the Big Data/Industry 4.0 Era: from Detection, to Diagnosis, to Prognosis

Abstract

:1. Introduction: Old and New Trends in Industrial Process Monitoring

1.1. From Univariate, to Multivariate, to High-Dimensional (“Mega-Variate”)

1.2. From Homogeneous Data Tables to Heterogeneous Datasets

1.3. From Static, to Dynamic, to Non-Stationary

1.4. From Monitoring the Mean, to Dispersion, to Correlation

1.5. From Unstructured to Structured Process Monitoring

1.6. Summary of the Article Content and Contributions

2. Research Focus—The Past: Detection

3. Research Focus—The Present: Diagnosis

- Network inference structured approaches (NISA),

- Classification-based approaches (CBA).

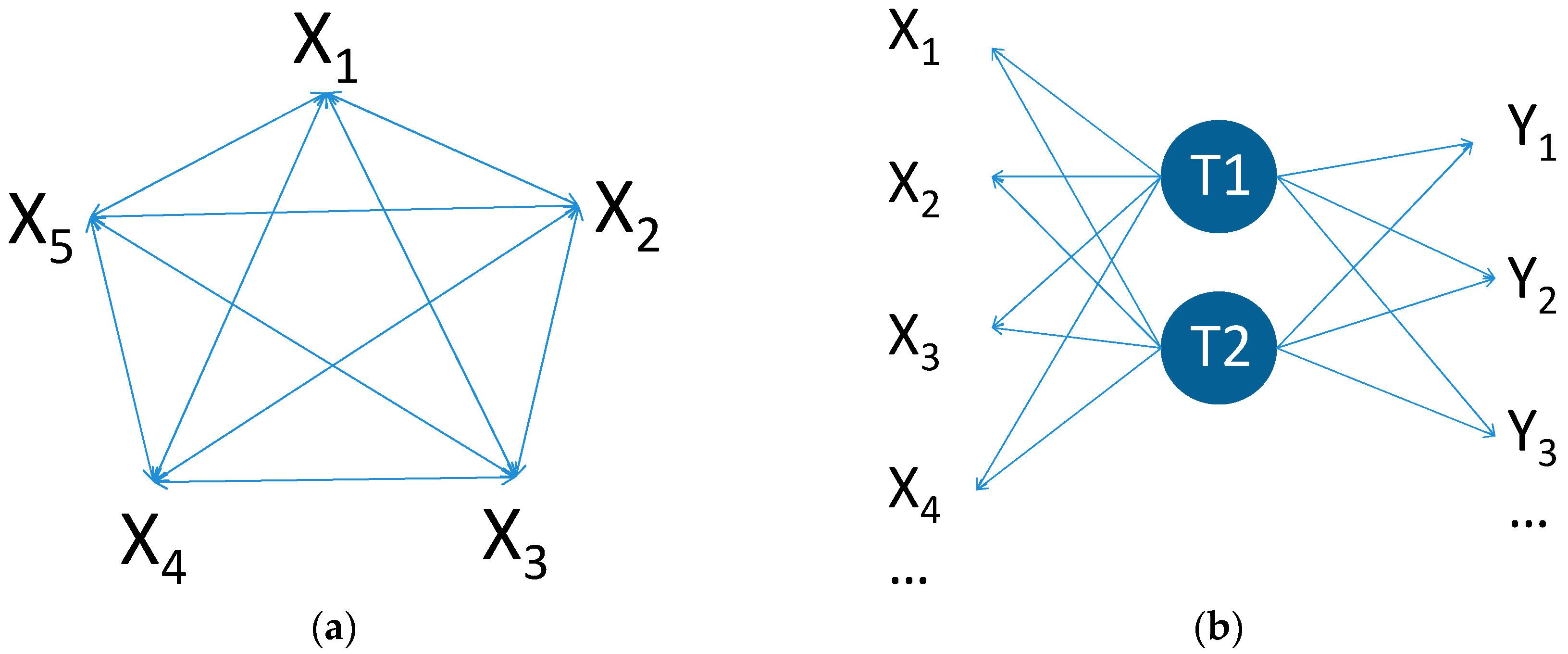

3.1. Data-Driven Structured Approaches for Process Diagnosis: Network Inference Structured Approaches (NISA)

3.2. Data-Driven Structured Approaches for Process Diagnosis: Classification-Based Approaches (CBA)

4. Research Focus—The Future: Prognosis

5. Discussion and Final Remarks

Acknowledgements

Author Contributions

Conflicts of Interest

References

- Reis, M.S.; Braatz, R.D.; Chiang, L.H. Big data-challenges and future research directions. Chem. Eng. Prog. 2016, 46–50. [Google Scholar] [CrossRef]

- Ebbers, M. 5 Things to Know about Big Data in Motion. Available online: https://www.ibm.com/developerworks/community/blogs/5things/entry/5_things_to_know_about_big_data_in_motion?lang=en (accessed on 1 May 2017).

- White, D. Big data-what is it? Chem. Eng. Prog. 2016, 32–35. Available online: https://www.aiche.org/resources/publications/cep/2016/march/big-data-what-it (accessed on 30 June 2017).

- Colegrove, L.F.; Seasholtz, M.B.; Khare, C. Big data-getting started on the journey. Chem. Eng. Prog. 2016, 41–45. Available online: https://www.aiche.org/resources/publications/cep/2016/march/big-data-getting-started-on-journey (accessed on 30 June 2017).

- Manco, G.; Coleman, S.; Goeb, R.; Pievatolo, A.; Tort-Martorell, X.; Reis, M.S. How can smes benefit from big data? Challenges and a path forward. Qual. Reliab. Eng. Int. 2016, 32, 2151–2164. [Google Scholar]

- Shewhart, W.A. Economic Control of Quality of Manufactured Product; D. Van Nostrand Company, Inc.: New York, NY, USA, 1931. [Google Scholar]

- Weese, M.; Martinez, W.; Megahed, F.M.; Jones-Farmer, L.A. Statistical learning methods applied to process monitoring: An overview and perspective. J. Qual. Technol. 2016, 48, 4–27. [Google Scholar]

- Qin, S.J. Survey on data-driven industrial process monitoring and diagnosis. Annu. Rev. Control 2012, 36, 220–234. [Google Scholar] [CrossRef]

- Ge, Z.; Song, Z.; Gao, F. Review of recent research on data-based process monitoring. Ind. Eng. Chem. Res. 2013, 52, 3543–3562. [Google Scholar] [CrossRef]

- Page, E.S. Continuous inspection schemes. Biometrics 1954, 41, 100–115. [Google Scholar] [CrossRef]

- Roberts, S.W. Control charts tests based on geometric moving averages. Technometrics 1959, 1, 239–250. [Google Scholar] [CrossRef]

- Hotelling, H. Multivariate quality control, illustrated by the air testing of sample bombsights. In Selected Techniques of Statistical Analysis; Eisenhart, C., Hastay, M.W., Wallis, W.A., Eds.; McGraw-Hill: New York, NY, USA, 1947. [Google Scholar]

- Lowry, C.A.; Woodall, W.H.; Champ, C.W.; Rigdon, C.E. A multivariate exponentially weighted moving average control chart. Technometrics 1992, 34, 46–53. [Google Scholar] [CrossRef]

- Kresta, J.V.; MacGregor, J.F.; Marlin, T.E. Multivariate statistical monitoring of process operating performance. Can. J. Chem. Eng. 1991, 69, 35–47. [Google Scholar] [CrossRef]

- Kourti, T.; MacGregor, J.F. Process analysis, monitoring and diagnosis, using multivariate projection methods. Chemom. Intell. Lab. Syst. 1995, 28, 3–21. [Google Scholar] [CrossRef]

- Jackson, J.E. Quality control methods for several related variables. Technometrics 1959, 1, 359–377. [Google Scholar] [CrossRef]

- Jackson, J.E.; Mudholkar, G.S. Control procedures for residuals associated with principal component analysis. Technometrics 1979, 21, 341–349. [Google Scholar] [CrossRef]

- Kourti, T.; MacGregor, J.F. Multivariate SPC methods for process and product monitoring. J. Qual. Technol. 1996, 28, 409–428. [Google Scholar]

- Kourti, T. Application of latent variable methods to process control and multivariate statistical process control in industry. Int. J. Adapt. Control Signal Process. 2005, 19, 213–246. [Google Scholar] [CrossRef]

- MacGregor, J.F.; Jaeckle, C.; Kiparissides, C.; Koutoudi, M. Process monitoring and diagnosis by multiblock PLS methods. AIChE J. 1994, 40. [Google Scholar] [CrossRef]

- MacGregor, J.F.; Kourti, T. Statistical process control of multivariate processes. Control Eng. Pract. 1995, 3, 403–414. [Google Scholar] [CrossRef]

- Chen, Z.; Lovett, D.; Morris, J. Process analytical technologies and real time process control a review of some spectroscopic issues and challenges. J. Process Control 2011, 21, 1467–1482. [Google Scholar] [CrossRef]

- Reis, M.S.; Saraiva, P.M. Prediction of profiles in the process industries. Ind. Eng. Chem. Res. 2012, 51, 4254–4266. [Google Scholar] [CrossRef]

- Reis, M.S.; Saraiva, P.M. Multiscale statistical process control of paper surface profiles. Qual. Technol. Quant. Manag. 2006, 3, 263–282. [Google Scholar] [CrossRef]

- Woodall, W.H.; Spitzner, D.J.; Montgomery, D.C.; Gupta, S. Using control charts to monitor process and product quality profiles. J. Qual. Technol. 2004, 36, 309–320. [Google Scholar]

- Duchesne, C.; Liu, J.J.; MacGregor, J.F. Multivariate image analysis in the process industries: A review. Chemom. Intell. Lab. Syst. 2012, 117, 116–128. [Google Scholar] [CrossRef]

- Prats-Montalbán, J.M.; de Juan, A.; Ferrer, A. Multivariate image analysis: A review with applications. Chemom. Intell. Lab. Syst. 2011, 107, 1–23. [Google Scholar]

- Kim, K.; Mahmoud, M.A.; Woodall, W.H. On the monitoring of linear profiles. J. Qual. Technol. 2003, 35, 317–328. [Google Scholar]

- Reis, M.S.; Bauer, A. Wavelet texture analysis of on-line acquired images for paper formation assessment and monitoring. Chemom. Intell. Lab. Syst. 2009, 95, 129–137. [Google Scholar] [CrossRef]

- Montgomery, D.C.; Mastrangelo, C.M. Some statistical process control methods for autocorrelated data. J. Qual. Technol. 1991, 23, 179–193. [Google Scholar]

- Vasilopoulos, A.V.; Stamboulis, A.P. Modification of control chart limits in the presence of data correlation. J. Qual. Technol. 1978, 10, 20–30. [Google Scholar]

- Lu, C.-W.; Reynolds, M.R., Jr. Cusum charts for monitoring an autocorrelated process. J. Qual. Technol. 2001, 33, 316–334. [Google Scholar]

- Vermaat, M.B.; Does, R.J.M.M.; Bisgaard, S. EWMA control chart limits for first- and second-order autoregressive processes. Qual. Reliab. Eng. Int. 2008, 24, 573–584. [Google Scholar] [CrossRef]

- Harris, T.J.; Ross, W.H. Statistical process control procedures for correlated observations. Can. J. Chem. Eng. 1991, 69, 48–57. [Google Scholar] [CrossRef]

- Negiz, A.; Çinar, A. Statistical monitoring of multivariable dynamic processes with state-space models. AIChE J. 1997, 43, 2002–2020. [Google Scholar] [CrossRef]

- Simoglou, A.; Martin, E.B.; Morris, A.J. Dynamic multivariable statistical process control using partial least squares and canonical variate analysis. Comput. Chem. Eng. 1999, 23, S277–S280. [Google Scholar] [CrossRef]

- Treasure, R.J.; Kruger, U.; Cooper, J.E. Dynamic multivariate statistical process control using subspace identification. J. Process Control 2004, 14, 279–292. [Google Scholar] [CrossRef]

- Russell, E.L.; Chiang, L.H.; Braatz, R.D. Fault detection in industrial processes using canonical variate analysis and dynamic principal component analysis. Chemom. Intell. Lab. Syst. 2000, 51, 81–93. [Google Scholar] [CrossRef]

- Rato, T.J.; Reis, M.S. Fault detection in the Tennessee Eastman process using dynamic principal components analysis with decorrelated residuals (DPCA-dr). Chemom. Intell. Lab. Syst. 2013, 125, 101–108. [Google Scholar] [CrossRef]

- Rato, T.J.; Reis, M.S. Advantage of using decorrelated residuals in dynamic principal component analysis for monitoring large-scale systems. Ind. Eng. Chem. Res. 2013, 52, 13685–13698. [Google Scholar] [CrossRef]

- Ku, W.; Storer, R.H.; Georgakis, C. Disturbance detection and isolation by dynamic principal component analysis. Chemom. Intell. Lab. Syst. 1995, 30, 179–196. [Google Scholar] [CrossRef]

- Bakshi, B.R. Multiscale PCA with application to multivariate statistical process control. AIChE J. 1998, 44, 1596–1610. [Google Scholar] [CrossRef]

- Reis, M.S.; Bakshi, B.R.; Saraiva, P.M. Multiscale statistical process control using wavelet packets. AIChE J. 2008, 54, 2366–2378. [Google Scholar] [CrossRef]

- Reis, M.S.; Saraiva, P.M. Multiscale statistical process control with multiresolution data. AIChE J. 2006, 52, 2107–2119. [Google Scholar] [CrossRef]

- Morris, J. Multiscale multivariate statistical process control. In Encyclopedia of Systems and Control; Baillieul, J., Samad, T., Eds.; Springer: London, UK, 2014; pp. 1–7. [Google Scholar]

- Nomikos, P.; MacGregor, J.F. Monitoring batch processes using multiway principal component analysis. AIChE J. 1994, 40, 1361–1375. [Google Scholar] [CrossRef]

- Nomikos, P.; MacGregor, J.F. Multivariate SPC charts for monitoring batch processes. Technometrics 1995, 37, 41–59. [Google Scholar] [CrossRef]

- Westerhuis, J.A.; Kourti, T.; MacGregor, J.F. Analysis of multiblock and hierarchical PCA and PLS models. J. Chemom. 1998, 12, 301–321. [Google Scholar] [CrossRef]

- Westerhuis, J.A.; Kourti, T.; MacGregor, J.F. Comparing alternative approaches for multivariate statistical analysis of batch process data. J. Chemom. 1999, 13, 397–413. [Google Scholar] [CrossRef]

- Meng, X.; Morris, A.J.; Martin, E.B. On-line monitoring of batch processes using a parafac representation. J. Chemom. 2003, 17, 65–81. [Google Scholar] [CrossRef]

- Van den Kerkhof, P.; Vanlaer, J.; Gins, G.; Van Impe, J.F.M. Dynamic model-based fault diagnosis for (bio)chemical batch processes. Comput. Chem. Eng. 2012, 40, 12–21. [Google Scholar] [CrossRef]

- Chen, J.; Yen, J.-H. Three-way data analysis with time lagged window for on-line batch process monitoring. Korean J. Chem. Eng. 2003, 20, 1000–1011. [Google Scholar] [CrossRef]

- Choi, S.W.; Morris, J.; Lee, I.-B. Dynamic model-based batch process monitoring. Chem. Eng. Sci. 2008, 63, 622–636. [Google Scholar] [CrossRef]

- He, Q.P.; Wang, J. Statistics pattern analysis: A new process monitoring framework and its application to semiconductor batch processes. AIChE J. 2011, 57, 107–121. [Google Scholar] [CrossRef]

- Rato, T.J.; Blue, J.; Pinaton, J.; Reis, M.S. Translation invariant multiscale energy-based PCA (TIME-PCA) for monitoring batch processes in semiconductor manufacturing. IEEE Trans. Autom. Sci. Eng. 2017, 14, 894–904. [Google Scholar] [CrossRef]

- Rato, T.J.; Reis, M.S. Non-causal data-driven monitoring of the process correlation structure: A comparison study with new methods. Comput. Chem. Eng. 2014, 71, 307–322. [Google Scholar] [CrossRef]

- Rato, T.J.; Reis, M.S. On-line process monitoring using local measures of association. Part I: Detection performance. Chemom. Intell. Lab. Syst. 2015, 142, 255–264. [Google Scholar] [CrossRef]

- Wang, J.; He, Q.P. Multivariate statistical process monitoring based on statistics pattern analysis. Ind. Eng. Chem. Res. 2010, 49, 7858–7869. [Google Scholar] [CrossRef]

- Rato, T.J.; Reis, M.S. On-line process monitoring using local measures of association. Part II: Design issues and fault diagnosis. Chemom. Intell. Lab. Syst. 2015, 142, 265–275. [Google Scholar] [CrossRef]

- Huwang, L.; Yeh, A.B.; Wu, C. Monitoring multivariate process variability for individual observations. J. Qual. Technol. 2007, 39, 258–278. [Google Scholar]

- Sullivan, J.H.; Stoumbos, Z.G.; Mason, R.L.; Young, J.C. Step-down analysis for changes in the covariance matrix and other parameters. J. Qual. Technol. 2007, 39, 66–84. [Google Scholar]

- Qiu, P. Distribition-free multivariate process control based on log-linear modeling. IIE Trans. 2008, 40, 664–677. [Google Scholar] [CrossRef]

- Zou, C.; Tsung, F. Likelihood ratio-based distribution-free EWMA control charts. J. Qual. Technol. 2010, 42, 174–196. [Google Scholar]

- Chakraborti, S.; Van der Lan, P.; Bakir, S.T. Nonparametric control charts: An overview and some results. J. Qual. Technol. 2001, 33, 304–315. [Google Scholar]

- Martin, E.B.; Morris, A.J. Non-parametric confidence bounds for process performance monitoring charts. J. Process Control 1996, 6, 349–358. [Google Scholar] [CrossRef]

- Van den Kerkhof, P.; Vanlaer, J.; Gins, G.; Van Impe, J.F.M. Analysis of smearing-out in contribution plot based fault isolation for statistical process control. Chem. Eng. Sci. 2013, 104, 285–293. [Google Scholar] [CrossRef]

- Westerhuis, J.A.; Gurden, S.P.; Smilde, A.K. Generalized contribution plots in multivariate statistical process monitoring. Chemom. Intell. Lab. Syst. 2000, 51, 95–114. [Google Scholar] [CrossRef]

- Yue, H.H.; Qin, S.J. Reconstruction-based fault identification using a combined index. Ind. Eng. Chem. Res. 2001, 40, 4403–4414. [Google Scholar] [CrossRef]

- Kuang, T.-H.; Yan, Z.; Yao, Y. Multivariate fault isolation via variable selection in discriminant analysis. J. Process Control 2015, 35, 30–40. [Google Scholar] [CrossRef]

- Yan, Z.; Yao, Y. Variable selection method for fault isolation using least absolute shrinkage and selection operator (LASSO). Chemom. Intell. Lab. Syst. 2015, 146, 136–146. [Google Scholar] [CrossRef]

- Montgomery, D.C. Introduction to Statistical Quality Control, 4th ed.; Wiley: New York, NY, USA, 2001. [Google Scholar]

- Woodall, W.H.; Montgomery, D.C. Some current directions in the theory and application of statistical process monitoring. J. Qual. Technol. 2014, 46, 78–94. [Google Scholar]

- Crosier, R.B. Multivariate generalizations of cumulative sum quality-control schemes. Technometrics 1988, 30, 291–303. [Google Scholar] [CrossRef]

- Kenett, R.S.; Zacks, S. Modern Industrial Statistics: With Applications in R, Minitab and JMP, 2nd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2014. [Google Scholar]

- Woodall, W.H. Control charts based o attribute data: Bibliography and review. J. Qual. Technol. 1997, 29, 172–183. [Google Scholar]

- Grant, E.L.; Leavenworth, R.S. Statistical Quality Control, 7th ed.; McGraw-Hill: Boston, MA, USA, 1999. [Google Scholar]

- Komulainen, T.; Sourander, M.; Jämsä-Jounela, S.L. An online application of dynamical PLS to a dearomatization process. Comput. Chem. Eng. 2004, 28, 2611–2619. [Google Scholar] [CrossRef]

- Alawi, A.; Morris, A.J.; Martin, E.B. ESCAPE-15, European Symposium on Computer Aided Process Engineering. In Statistical Performance Monitoring Using State Space Modelling and Wavelet Analysis; Puigjaner, L., Espuña, A., Eds.; Elsevier: Barcelona, Spain, 2005; pp. 1459–1464. [Google Scholar]

- Tian, X.M.; Zhang, X.L.; Deng, X.G.; Chen, S. Multiway kernel independent component analysis based on feature samples for batch process monitoring. Neurocomputing 2009, 72, 1584–1596. [Google Scholar] [CrossRef]

- Yoo, C.K.; Lee, J.-M.; Vanrolleghem, P.A.; Lee, I.-B. On-line monitoring of batch processes using multiway independent component analysis. Chemom. Intell. Lab. Syst. 2004, 71, 151–163. [Google Scholar] [CrossRef]

- Zhang, Y.W.; Qin, S.J. Fault detection of non-linear processes using multiway kernel independent analysis. Ind. Eng. Chem. Res. 2007, 46, 7780–7787. [Google Scholar] [CrossRef]

- Zhao, C.H.; Gao, F.R.; Wang, F.L. Nonlinear batch process monitoring using phase-based kernel independent component analysis-principal component analysis. Ind. Eng. Chem. Res. 2009, 48, 9163–9174. [Google Scholar] [CrossRef]

- Choi, S.W.; Lee, I.-B. Nonlinear dynamic process monitoring based on dynamic kernel PCA. Chem. Eng. Sci. 2004, 59, 5897–5908. [Google Scholar] [CrossRef]

- Lee, J.-M.; Yoo, C.; Lee, I.-B. Fault detection of batch processes using multiway kernel principal component analysis. Comput. Chem. Eng. 2004, 28, 1837–1847. [Google Scholar] [CrossRef]

- Venkatasubramanian, V.; Yin, R.R.K.; Kavuri, S.N. A review of process fault detection and diagnosis. Part I–III. Comput. Chem. Eng. 2003, 27, 293–311, 313–326, 327–346. [Google Scholar] [CrossRef]

- Woodall, W.H. Controversies and contradictions in statistical process control. J. Qual. Technol. 2000, 32, 341–350. [Google Scholar]

- Ramaker, H.-J.; van Sprang, E.N.; Westerhuis, J.A.; Smilde, A.K. Fault detection properties of global, local and time evolving models for batch process monitoring. J. Process Control 2005, 15, 799–805. [Google Scholar] [CrossRef]

- Kenett, R.S.; Pollak, M. On assessing the performance of sequential procedures for detecting a change. Qual. Reliab. Eng. Int. 2012, 28, 500–507. [Google Scholar] [CrossRef]

- Frisén, M. On multivariate control charts. Production 2011, 21, 235–241. [Google Scholar]

- Rato, T.J.; Rendall, R.; Gomes, V.; Chin, S.-T.; Chiang, A.P.; Saraiva, P.; Reis, M.S. A systematic methodology for comparing batch process monitoring methods: Part I—Assessing detection strength. Ind. Eng. Chem. Res. 2016, 55, 5342–5358. [Google Scholar] [CrossRef]

- Yin, S.; Ding, S.X.; Haghani, A.; Hao, H.; Zhang, P. A comparison study of basic data-driven fault diagnosis and process monitoring methods on the benchmark Tennessee Eastman process. J. Process Control 2012, 22, 1567–1581. [Google Scholar] [CrossRef]

- Chiang, L.H.; Russel, E.L.; Braatz, R.D. Fault Detection and Diagnosis in Industrial Systems; Springer-Verlag: London, UK, 2001. [Google Scholar]

- Green, D.W.; Perry, R.H. Perry’s Chemical Engineerings’ Handbook, 8th ed.; McGraw-Hill: New York, NY, USA, 2008. [Google Scholar]

- Chiang, L.H.; Braatz, R.D. Process monitoring using causal map and multivariate statistics: Fault detection and identification. Chemom. Intell. Lab. Syst. 2003, 65, 159–178. [Google Scholar] [CrossRef]

- Thambirajah, J.; Benabbas, L.; Bauer, M.; Thornhill, N.F. Cause-and-effect analysis in chemical processes utilizing XML, plant connectivity and quantitative process history. Comput. Chem. Eng. 2009, 33, 503–512. [Google Scholar] [CrossRef]

- Cheng, H.; Nikus, M.; Jämsä-Jounela, S.-L. Fault diagnosis of the paper machine short circulation process using novel dynamic causal digraph reasoning. J. Process Control 2008, 18, 676–691. [Google Scholar] [CrossRef]

- Chiang, L.H.; Jiang, B.; Zhu, X.; Huang, D.; Braatz, R.D. Diagnosis of multiple and unknown faults using the causal map and multivariate statistics. J. Process Control 2015, 28, 27–39. [Google Scholar] [CrossRef]

- Zhang, X.; Hoo, K.A. Effective fault detection an isolation using the bond graph-based domain decomposition. Comput. Chem. Eng. 2011, 35, 132–148. [Google Scholar] [CrossRef]

- Ould-Bouamama, B.; El Harabi, R.; Abdelkrim, M.N.; Ben Gayed, M.K. Bond graphs for the diagnosis of chemical processes. Comput. Chem. Eng. 2012, 36, 301–324. [Google Scholar] [CrossRef]

- Vedam, H.; Venkatasubramanian, V. PCA-SDG based process monitoring and fault diagnosis. Control Eng. Pract. 1999, 7, 903–917. [Google Scholar] [CrossRef]

- He, B.; Chen, T.; Yang, X. Root cause analysis in multivariate statistical process monitoring: Integrating reconstruction-based multivariate contribution analysis with fuzzy-signed directed graphs. Comput. Chem. Eng. 2014, 64, 167–177. [Google Scholar] [CrossRef]

- Wan, Y.; Yang, F.; Lu, N.; Xu, H.; Ye, H.; Li, W.; Xu, P.; Song, L.; Usadi, A.K. Statistical root cause analysis of novel faults based on digraph models. Chem. Eng. Res. Des. 2013, 91, 89–99. [Google Scholar] [CrossRef]

- Venkatasubramanian, V.; Rengaswamy, R.; Kavuri, S.N. A review of process fault detection and diagnosis. Part II: Qualitative models and search strategies. Comput. Chem. Eng. 2003, 27, 313–326. [Google Scholar] [CrossRef]

- Yoon, S.; MacGregor, J.F. Statistical and causal model-based approaches to fault detection and isolation. AIChE J. 2000, 46, 1813–1824. [Google Scholar] [CrossRef]

- Van Sprang, E.N.M.; Ramaker, H.-J.; Westerhuis, J.A.; Smilde, A.K. Statistical batch process monitoring using gray models. AIChE J. 2005, 51, 931–945. [Google Scholar] [CrossRef]

- Weidl, G.; Madsen, A.L.; Israelson, S. Applications of object-oriented bayesian networks for condition monitoring, root cause analysis and decision support on operation of complex continuous processes. Comput. Chem. Eng. 2005, 29, 1996–2009. [Google Scholar] [CrossRef]

- Yu, J.; Rashid, M.M. A novel dynamic bayesian network-based networked process monitoring approach for fault detection, propagation, identification, and root cause diagnosis. AIChE J. 2013, 59, 2348–2365. [Google Scholar] [CrossRef]

- Bauer, M.; Cox, J.W.; Caveness, M.H.; Downs, J.J.; Thornhill, N.F. Finding the direction of disturbance propagation in a chemical process using transfer entropy. IEEE Trans. Control Syst. Technol. 2007, 15, 12–21. [Google Scholar] [CrossRef]

- Bauer, M.; Thornhill, N.F. A practical method for identifying the propagation path of plant-wide disturbances. J. Process Control 2008, 18, 707–719. [Google Scholar] [CrossRef]

- Yuan, T.; Qin, S.J. International Symposium on Advanced Control of Chemical Processes. In Root Cause Diagnosis of Plant-Wide Oscillations Using Granger Causality, 8th ed.; IFAC: Singapore, 2012; pp. 160–165. [Google Scholar]

- Pellet, J.-P.; Elisseeff, A.A. Partial correlation-based algorithm for causal structure discovery with continuous variables. In Proceedings of the 7th International Conference on Intelligent Data Analysis, Ljubljana, Slovenia, 6–8 September 2007; Springer-Verlag: Ljubljana, Slovenia, 2007; pp. 229–239. [Google Scholar]

- Fuente, A.D.L.; Bing, N.; Hoeschele, I.; Mendes, P. Discovery of meaningful associations in genomic data using partial correlation coefficients. Bioinformatics 2004, 20, 3565–3574. [Google Scholar] [CrossRef] [PubMed]

- Kalisch, M.; Bühlmann, P. Robustification of the PC-algorithm for directed acyclic graphs. J. Comput. Graph. Stat. 2008, 17, 773–789. [Google Scholar] [CrossRef]

- Rato, T.J.; Reis, M.S. Sensitivity enhancing transformations for monitoring the process correlation structure. J. Process Control 2014, 24, 905–915. [Google Scholar] [CrossRef]

- Rato, T.J.; Reis, M.S. Multiscale and megavariate monitoring of the process networked structure: M2NET. J. Chemom. 2015, 29, 309–322. [Google Scholar] [CrossRef]

- Rato, T.J.; Reis, M.S. Markovian and non-markovian sensitivity enhancing transformations for process monitoring. Chem. Eng. Sci. 2017, 163, 223–233. [Google Scholar] [CrossRef]

- Alcala, C.F.; Qin, S.J. Reconstruction-based contribution for process monitoring. Automatica 2009, 45, 1593–1600. [Google Scholar] [CrossRef]

- MacGregor, J.; Cinar, A. Monitoring, fault diagnosis, fault-tolerant control and optimization: Data driven methods. Comput. Chem. Eng. 2012, 47, 111–120. [Google Scholar] [CrossRef]

- Cinar, A.; Palazoglu, A.; Kayihan, F. Chemical Process Performance Evaluation; CRC Press: Boca Raton, FL, USA, 2007. [Google Scholar]

- Yu, J. Localized fisher discriminant analysis based complex chemical process monitoring. AIChE J. 2011, 57, 1817–1828. [Google Scholar] [CrossRef]

- Lazzaretti, A.E.; Ferreira, V.H.; Neto, H.V.; Toledo, L.F.R.B.; Pinto, C.L.S. A New Approach for Event Classification and Novelty Detection in Power Distribution Networks. In Proceedings of the 2013 IEEE Power and Energy Society General Meeting (PES), Vancouver, BC, Canada, 21–25 July 2013; pp. 1–5. [Google Scholar]

- Jing, C.; Hou, J. SVM and PCA based fault classification approaches for complicated industrial processes. Neurocomputing 2015, 167, 636–642. [Google Scholar] [CrossRef]

- Monroy, I.; Villez, K.; Graells, M.; Venkatasubramanian, V. Fault diagnosis of a benchmark fermentation process: A comparative study of feature extraction and classification techniques. Bioprocess Biosyst. Eng. 2012, 35, 689–704. [Google Scholar] [CrossRef] [PubMed]

- Ding, S.X. Data-driven design of monitoring and diagnosis systems for dynamic processes: A review of subspace technique based schemes and some recent results. J. Process Control 2014, 24, 431–449. [Google Scholar] [CrossRef]

- Gins, G.; Van den Kerkhof, P.; Vanlaer, J.; Van Impe, J. Improving classification-based diagnosis of batch processes through data selection and appropriate pretreatment. J. Process Control 2015, 26, 90–101. [Google Scholar] [CrossRef]

- Bishop, C.M. Pattern Recognition and Machine Learning; Springer: Berlin, Germany, 2006. [Google Scholar]

- Chandola, V.; Banerjee, A.; Kumar, V. Anomaly detection: A survey. ACM Comput. Surv. 2009, 41. [Google Scholar] [CrossRef]

- Ganganwar, V. An overview of classification algorithms for imbalanced dataset. Int. J. Emerg. Technol. Adv. Eng. 2012, 2, 42–47. [Google Scholar]

- Liu, Y.; Pan, Y.; Wang, Q.; Huang, D. Statistical process monitoring with integration of data projection and one-class classification. Chemom. Intell. Lab. Syst. 2015, 149, 1–11. [Google Scholar] [CrossRef]

- Lazzaretti, A.E.; Tax, D.M.J.; Neto, H.V.; Ferreira, V.H. Novelty detection and multi-class classification in power distribution voltage waveforms. Expert Syst. Appl. 2016, 45, 322–330. [Google Scholar] [CrossRef]

- Pooyan, N.; Shahbazian, M.; Salahshoor, K.; Hadian, M. Simultaneous fault diagnosis using multi-class support vector machine in a dew point process. J. Nat. Gas Sci. Eng. 2015, 23, 373–379. [Google Scholar] [CrossRef]

- Gins, G.; Wuyts, S.; Van den Zegel, S.; Van Impe, J. Extending process monitoring to simultaneous false alarm rejection and fault identification (FARFI). Lect. Notes Comput. Sci. 2016. [Google Scholar] [CrossRef]

- Wang, K.; Jiang, W. High-dimensional process monitoring and fault isolation via variable selection. J. Qual. Technol. 2009, 41, 247–258. [Google Scholar]

- Zou, C.; Jiang, W.; Tsung, F. A LASSO-based diagnostic framework for multivariate statistical process control. Technometrics 2011, 53, 297–309. [Google Scholar] [CrossRef]

- Kadlec, P.; Gabrys, B.; Strandt, S. Data-driven soft sensors in the process industry. Comput. Chem. Eng. 2009, 33, 795–814. [Google Scholar] [CrossRef]

- Kaneko, H.; Funatsu, K. A soft sensor method based on values predicted from multiple intervals of time difference for improvement and estimation of prediction accuracy. Chemom. Intell. Lab. Syst. 2011, 109, 197–206. [Google Scholar] [CrossRef]

- Lin, B.; Jørgensen, S.B. Soft sensor design by multivariate fusion of image features and process measurements. J. Process Control 2011, 21, 547–553. [Google Scholar] [CrossRef]

- Shang, C.; Huang, X.; Suykens, J.A.K.; Huang, D. Enhancing dynamic soft sensors based on DPLS: A temporal smoothness regularization approach. J. Process Control 2015, 28, 17–26. [Google Scholar] [CrossRef]

- Sharmin, R.; Sundararaj, U.; Shah, S.; Griend, L.V.; Sun, Y.J. Inferential sensors for estimation of polymer quality parameters: Industrial application of a PLS-based soft-sensor for a ldpe plant. Chem. Eng. Sci. 2006, 61, 6372–6384. [Google Scholar] [CrossRef]

- Rato, T.J.; Reis, M.S. Multiresolution soft sensors (MR-SS): A new class of model structures for handling multiresolution data. Ind. Eng. Chem. Res. 2017, 56, 3640–3654. [Google Scholar] [CrossRef]

- Mason, R.L.; Tracy, N.D.; Young, J.C. Decomposition of T2 for multivariate control chart interpretation. J. Qual. Technol. 1995, 27, 99–108. [Google Scholar]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Reis, M.S.; Gins, G. Industrial Process Monitoring in the Big Data/Industry 4.0 Era: from Detection, to Diagnosis, to Prognosis. Processes 2017, 5, 35. https://doi.org/10.3390/pr5030035

Reis MS, Gins G. Industrial Process Monitoring in the Big Data/Industry 4.0 Era: from Detection, to Diagnosis, to Prognosis. Processes. 2017; 5(3):35. https://doi.org/10.3390/pr5030035

Chicago/Turabian StyleReis, Marco S., and Geert Gins. 2017. "Industrial Process Monitoring in the Big Data/Industry 4.0 Era: from Detection, to Diagnosis, to Prognosis" Processes 5, no. 3: 35. https://doi.org/10.3390/pr5030035