Electro- or Turbo-Driven?—Analysis of Different Blast Processes of Blast Furnace

Abstract

:1. Introduction

2. Background

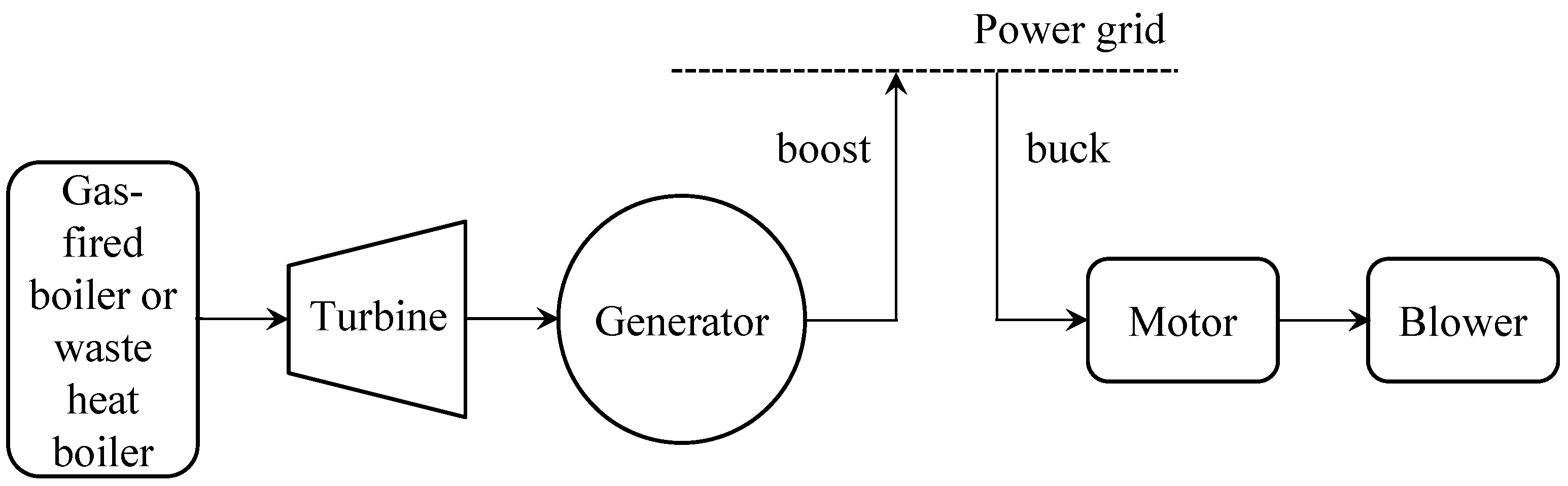

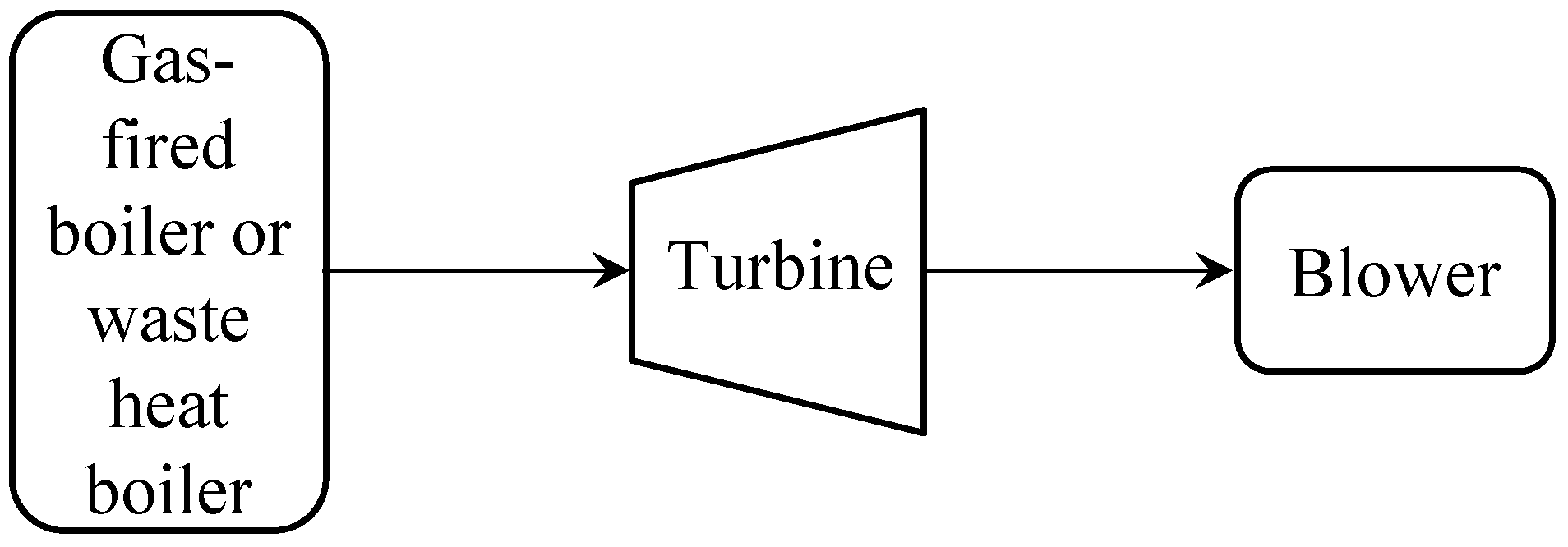

2.1. Description of Electro- and Turbo-Driven Blast Process

2.2. Turbo-Driven Blast Processes Survey

- SISCO: The company used both of the two driving modes; the turbo-driven mode was used for the blasting of large BFs with the volume of 2700 m3 and 3200 m3, and the electro-driven mode was used for the blasting of small BFs with the volume of 420 m3, 450 m3, and 750 m3. When designing large BFs, considering the insufficient electricity supplied by SISCO itself and the stability of the steam pipe network, SISCO originally adopted the turbo-driven mode. After years of operating practice, the company observed that the turbo-driven blast process has many auxiliary processes and a high failure rate, which are reflected in high energy consumption and high costs of turbo-driven blast. Therefore, in addition to improving the stability of the power grid, the company plans to convert the turbo-driven blast process of its BFs into the electro-driven one.

- XBISCO: The turbo-driven blast process was mainly used for BF blowers, air compressors in the oxygen-making plant and sintering drawing fans, while the electro-driven blast process is employed in all other cases. Among them, the steam generated by four 180 t/h boilers constituted the power source of four 40 MW BF blowers and two 10 MW sintering drawing fans; the steam generated by two 130 t/h boilers and one 220 t/h supplied two 20 MW air compressors in the oxygen plant. XBISCO believes that the turbo-driven blast process has low direct investment costs. For the entire company, if CCPP projects are not considered, the boilers will be indispensable, and adopting the turbo-driven blast process can save the cost of one generator set. In fact, the adoption of an electro-driven blast process to increase the plant capacity would require an additional substation, leading to an extremely high fixed cost. Moreover, it is worth noting that a turbo-driven blast process is very reliable if properly maintained. XBISCO plans to continue the adoption of the turbo-driven mode for its newly built Corex utility energy area, in which two 240 t/h boilers drive two 20 MW air compressors in the oxygen plant.

- Xuanhua Steel: The company adopted the turbo-driven blast process on its four BFs in service (two 2500 m3 BFs, one 2000 m3 and one 1800 m3). Xuanhua Steel has two thermal workshops; the first workshop has two 160 t/h and a 180 t/h boilers that supply two 2500 m3 BF blowers; the second workshop has three 75 t/h, two 130 t/h and one 180 t/h boilers that supply a 2000 m3 BF and an 1800 m3 BF blower. Moreover, Xuanhua Steel also applied the turbo-driven blast technology to drive pumps and fans.

- Ansteel: The company has currently eight BFs and ten blowers. Among them, there are three electro-driven blowers for three 3200 m3 BFs, and five 2580 m3 BFs for seven turbo-driven blowers (plus two as backup). At present, three turbo-driven blowers are too old and need to be revamped and converted. According to conducted technical and economic analysis, Ansteel considered the electro-driven blast technology the most cost-effective solution, and converted the old three turbo-driven blowers into two new 6500 m3/min electro-driven blowers.

3. Analysis of Energy Efficiency of Blast Process

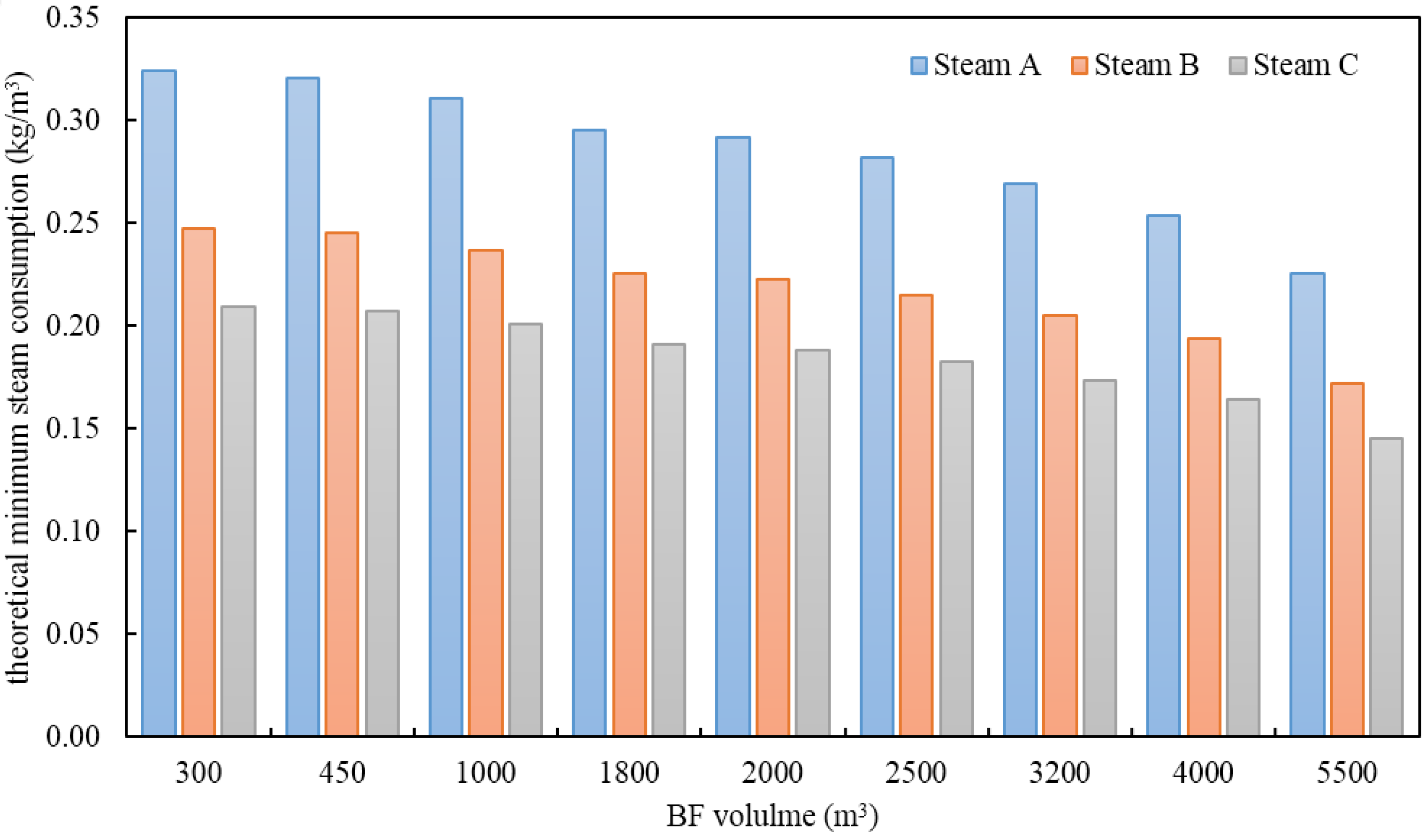

3.1. Theoretical Minimum Specific Steam Consumption of Blast Process

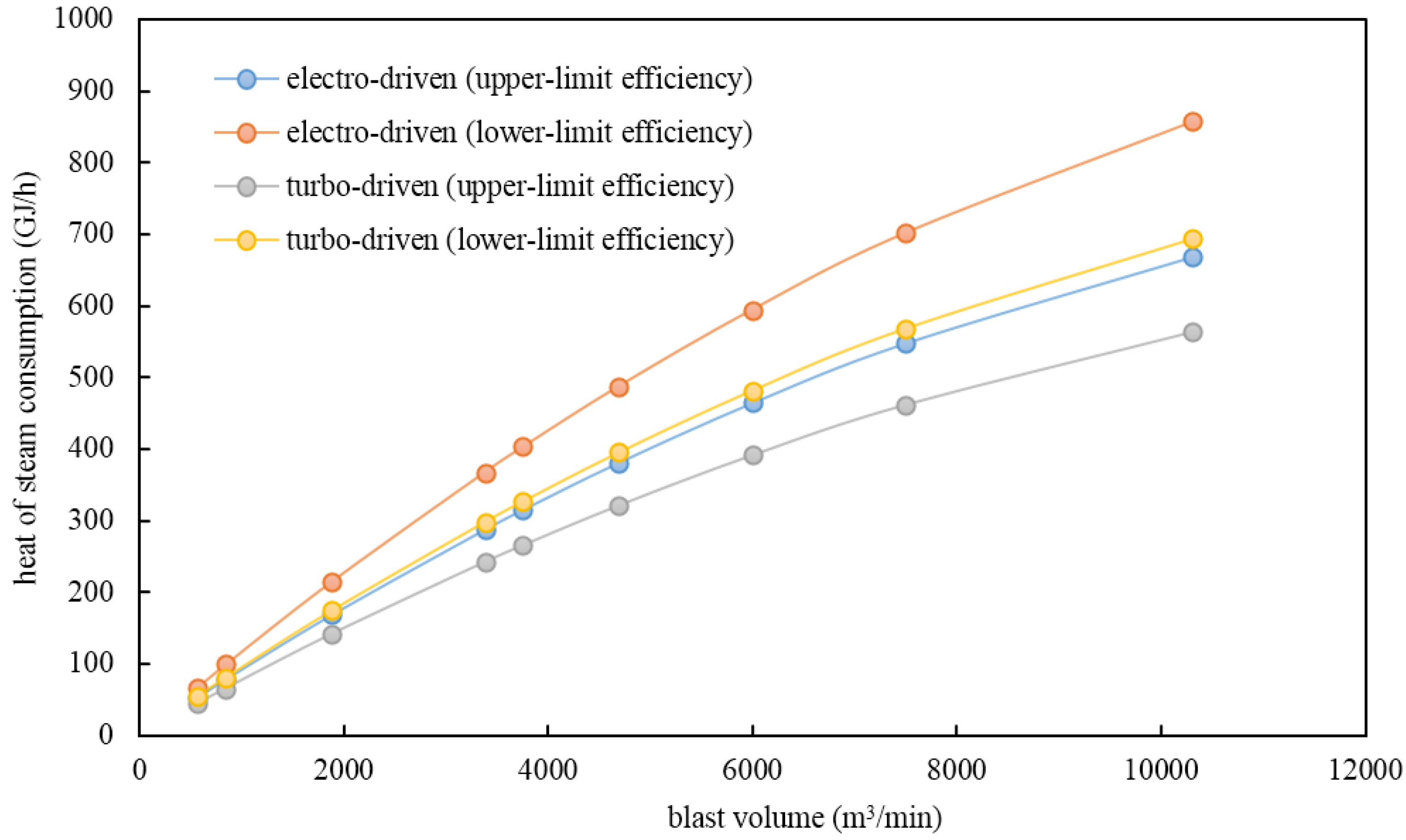

3.2. Energy Efficiency of Blast System

4. Analysis of Energy Consumption per Ton of Steel

4.1. Calculation Method of Energy Consumption

- x—Standard coal coefficient of steam, kgCE/kg;

- 0.34 × 10−4—Unit conversion coefficient of kJ and kgCE;

- R—Gas constant;

- H—Specific enthalpy of steam at temperature T and pressure p;

- s—Specific entropy of steam at temperature T and pressure p;

- h0—Specific enthalpy of steam at environmental temperature T0 and environmental pressure p0;

- s0—Specific entropy of steam at environmental temperature T0 and environmental pressure p0.

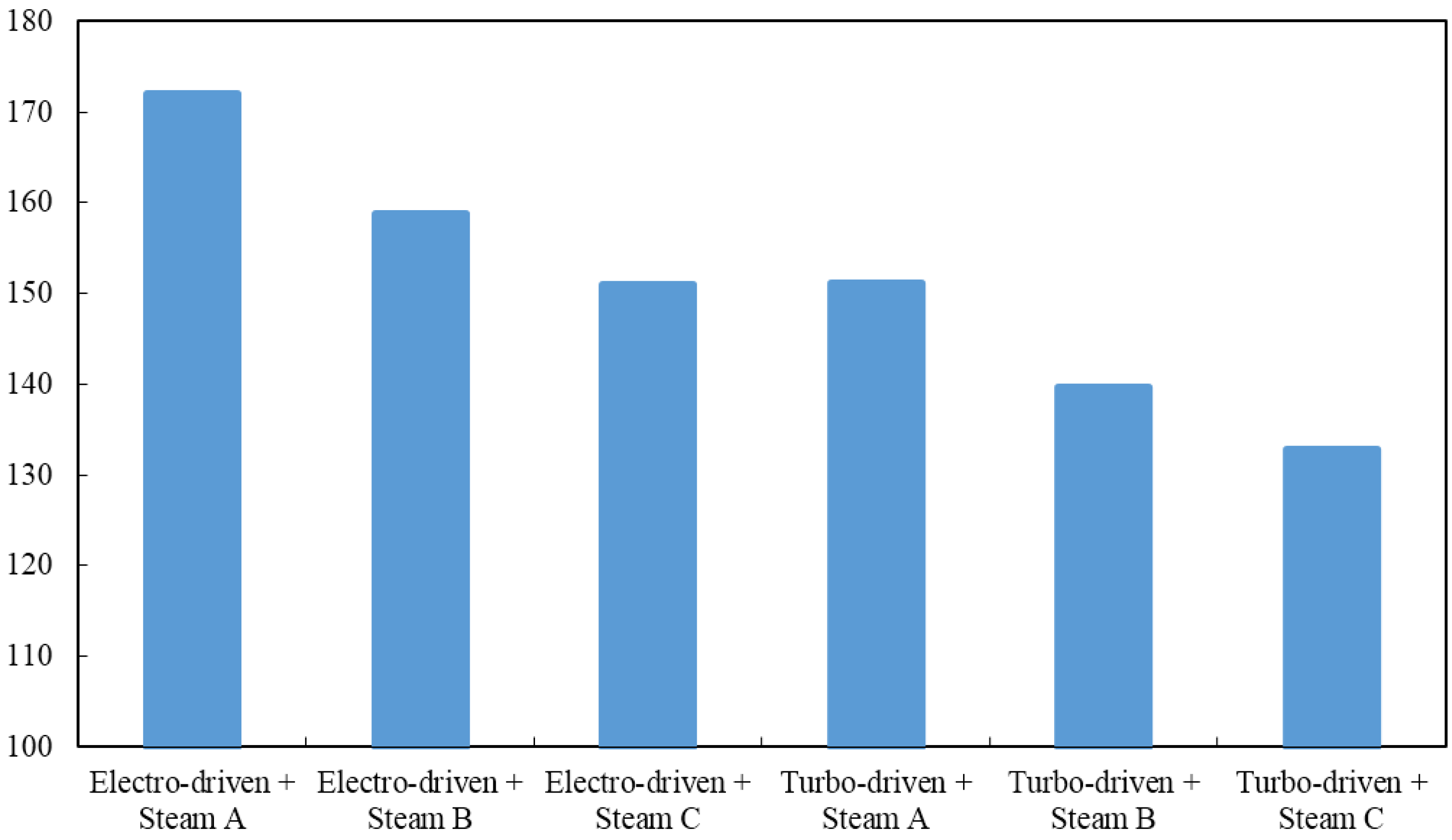

4.2. Influence of Driving Mode on Energy Consumption per Ton of Steel

- m—consumed steam by turbo-driven blast;

- n—consumed steam by electro-driven blast;

- xs—standard coal coefficient of steam;

- xe—standard coal coefficient of electricity;

- pHM—iron-to-steel ratio;

- ηe—generating efficiency of steam.

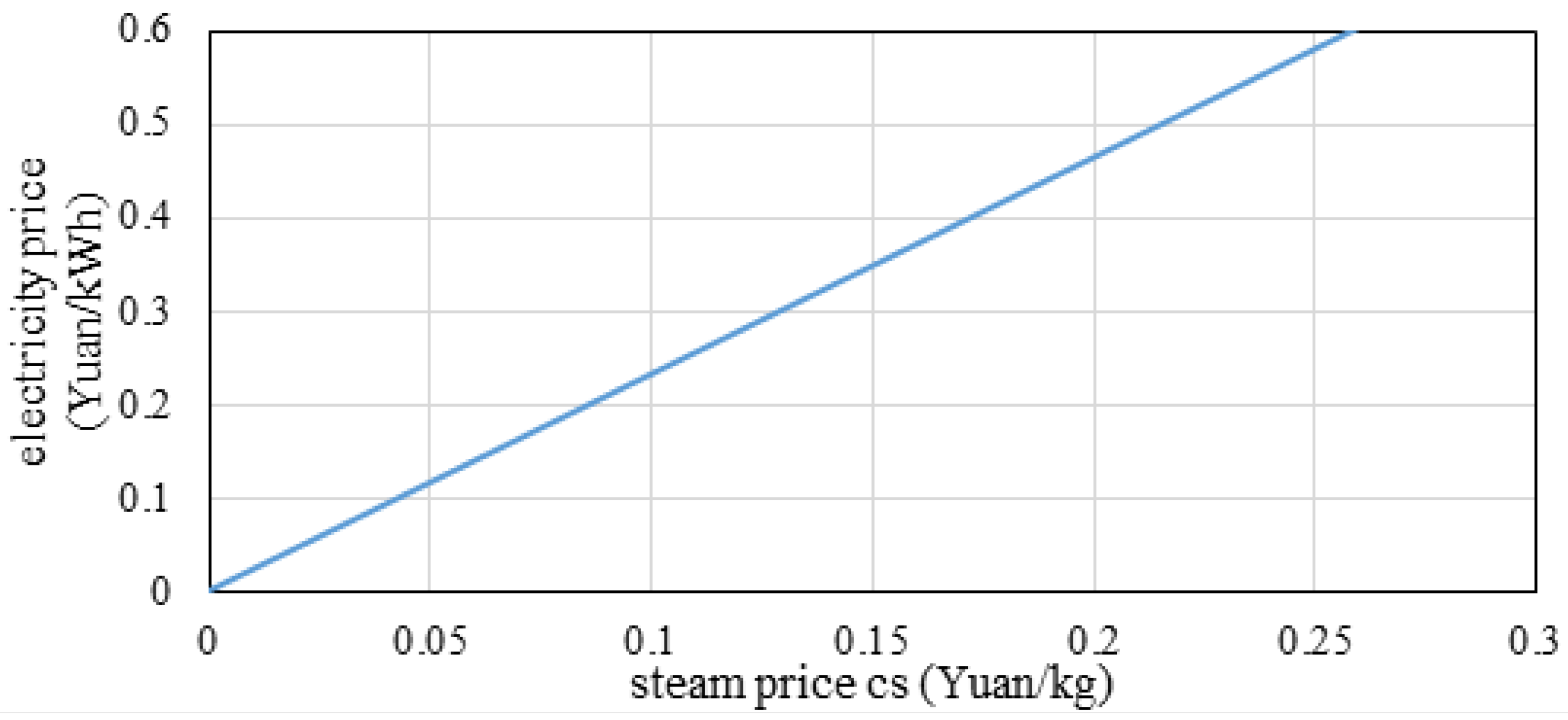

5. Analysis of Energy Cost

5.1. Energy Cost of Blast Process

5.2. Influence of Driving Mode on Total Energy Cost per Ton of Steel

6. Case Study

6.1. Case 1: Company A

6.2. Case 2: Company B

7. Conclusions and Recommendations

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| BF | blast furnace |

| CCPP | combined cycle of power plant |

| CE | coal equivalent |

References

- Aghaali, H.; Ångström, H.E. A review of turbocompounding as a waste heat recovery system for internal combustion engines. Renew. Sustain. Energy Rev. 2015, 49, 813–824. [Google Scholar] [CrossRef]

- Li, W.; Zhao, J.; Fu, L.; Yuan, W.; Zheng, Z.; Li, Y. Energy efficiency analysis of condensed waste heat recovery ways in cogeneration plant. Energy Convers. Manag. 2015, 101, 616–625. [Google Scholar] [CrossRef]

- Van de Bor, D.M.; Ferreira, C.A.I.; Kiss, A.A. Low grade waste heat recovery using heat pumps and power cycles. Energy 2015, 89, 864–873. [Google Scholar] [CrossRef]

- Brücknera, S.; Liu, S.; Miró, L.; Radspieler, M.; Cabeza, L.F.; Lävemann, E. Industrial waste heat recovery technologies: An economic analysis of heat transformation technologies. Appl. Energy 2015, 151, 157–167. [Google Scholar] [CrossRef]

- Ajimotokan, H.A.; Sher, I. Thermodynamic performance simulation and design optimisation of trilateral-cycle engines for waste heat recovery-to-power generation. Appl. Energy 2015, 154, 26–34. [Google Scholar] [CrossRef]

- Remeli, M.F.; Kiatbodin, L.; Singh, B.; Verojporn, K.; Date, A.; Akbarzadeh, A. Power generation from waste heat using heat pipe and thermoelectric generator. Energy Procedia 2015, 75, 645–650. [Google Scholar] [CrossRef]

- Ma, G.; Cai, J.; Zhang, L.; Sun, W. Influence of steam recovery and consumption on energy consumption per ton of steel. Energy Procedia 2012, 14, 566–571. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, Q.; Wang, W.; Zhao, J.; Leung, H. Data-driven based model for flow prediction of steam system in steel industry. Inf. Sci. 2012, 193, 104–114. [Google Scholar] [CrossRef]

- Niu, L.; Hou, Y.; Sun, W.; Chen, S. The measurement of thermodynamic performance in cryogenic two-phase turbo-expander. Cryogenics 2015, 70, 76–84. [Google Scholar] [CrossRef]

- Geng, P.; Yao, C.; Wang, Q.; Wei, L.; Liu, J.; Pan, W.; Han, G. Effect of DMDF on the PM emission from a turbo-charged diesel engine with DDOC and DPOC. Appl. Energy 2015, 148, 449–455. [Google Scholar] [CrossRef]

- Höfert, R. Variable speed turbo couplings used as pump drive in desalination plants. Desalination 1999, 125, 181–189. [Google Scholar] [CrossRef]

- Yan, J.; Shao, S.F.; Liu, J.P.; Zhang, Z. Experiment and analysis on performance of steam-driven jet injector for district-heating system. Appl. Therm. Eng. 2005, 25, 1153–1167. [Google Scholar] [CrossRef]

- Minav, T.A.; Laurila, L.I.E.; Pyrhönen, J.J. Analysis of electro-hydraulic lifting system’s energy efficiency with direct electric drive pump control. Autom. Constr. 2013, 30, 144–150. [Google Scholar] [CrossRef]

- Safaiy, M.R.; Maghmoumi, Y.; Karimipour, A. Economic Evaluation Utilization of Electro-Feed Water Pump and Turbo-Feed Water Pump and Compare Them in a 12.5-Megawatts Steam Unit Thermal Cycle and Provide the Optimum Solution. In Proceedings of the 4th International Meeting of Advances in Thermofluids, Melaka, Malaysia, 3–4 October 2011.

- Astvatsaturova, A.A.; Zorin, V.M.; Trukhnii, A.D. Assessment of steam work efficiency as applied to a turbine being designed. Therm. Eng. 2015, 1, 26–33. [Google Scholar] [CrossRef]

- Shi, Y.Z. Energy efficiency analyses of steam-driving and electricity-driving. Chem. Eng. Des. 1993, 3, 33–34. (In Chinese) [Google Scholar]

- Han, X.Y.; Ma, Q.T. Energy consumption and economic operation analysis of blast blowers under different driving modes. GM Metall. Mine Ind. 2014, 10, 72–75. (In Chinese) [Google Scholar]

- Ma, G.; Cai, J.; Xie, G. Performance analysis on different driving style of Ansteel blast furnace blower. Energy Metall. 2012, 3, 53–55. (In Chinese) [Google Scholar]

- Song, Z.P. Total energy system analysis of heating. Energy 2000, 25, 807–822. [Google Scholar] [CrossRef]

- How a Blast Furnace Works? Available online: https://www.steel.org/Making Steel/How Its Made/Processes/How a Blast Furnace Works.aspx (accessed on 1 April 2016).

- Liu, J.X. Energy saving analysis by comparing trubo-driven BF blast system with electro-driven one. Iron Steel Technol. 2008, 5, 53–54. (In Chinese) [Google Scholar]

- Sun, W.Q.; Cai, J.J.; Du, T.; Zhang, D.W. Specific energy consumption analysis model and its application in typical steel manufacturing process. J. Iron Steel Res. Int. 2010, 10, 33–37. [Google Scholar] [CrossRef]

- Zarnikau, J.; Guermouche, S.; Schmidt, P. Can different energy resources be added or compared? Energy 1996, 21, 483–491. [Google Scholar] [CrossRef]

- Zhang, G.G.; Sun, W.Q.; Cai, J.J. Research on Energy Consumption Index and Energy Conversion Coefficients for Iron and Steel Enterprise. In Proceedings of the Asia Steel Conference 2012, Beijing, China, 23–27 September 2012.

- General Principles for Calculation of the Comprehensive Energy Consumption. Available online: http://www.sac.gov.cn/SACSearch/search?channelid=97779&templet=gjcxjg_detail.jsp&searchword=STANDARD_CODE=%27GB/T%202589–2008%27&XZ=T (accessed on 1 April 2016).

| Steam | Temperature (°C) | Pressure (MPa) |

|---|---|---|

| A | 300 | 0.98 |

| B | 435 | 3.4 |

| C | 535 | 8.8 |

| Drive Mode | Variables | () | () | () | () | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Electro-driven | Upper-limit efficiency (%) | 99.5 | 37.90 | 98.5 | 94 | 98 | 99 | 97 | 95 | 99 | 30.90 |

| Lower-limit efficiency (%) | 98.5 | 35.34 | 98.0 | 92 | 98 | 98 | 97 | 85 | 97 | 24.11 | |

| Turbo-driven | Upper-limit efficiency (%) | 99.0 | 37.03 | − | − | − | − | − | − | 100 | 36.66 |

| Lower-limit efficiency (%) | 97.0 | 30.70 | − | − | − | − | − | − | 100 | 29.78 |

| BF | Productivity | Blast Flow Rate | Steam Consumption | ||

|---|---|---|---|---|---|

| (t/d) | (m3/min) | (t/h) | (kg/m3) | (kg/t) | |

| #1 | 5500 | 5633 | 114 | 0.3373 | 473 |

| #2 | 8100 | 8143 | 139.4 | 0.2853 | 413 |

| Productivity | Blast Flow Rate | Steam Consumption | ||

|---|---|---|---|---|

| (t/d) | (m3/min) | (t/h) | (kg/m3) | (kg/t) |

| 4950 | 4450 | 90 | 0.3371 | 436 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, W.; Zhao, Y.; Wang, Y. Electro- or Turbo-Driven?—Analysis of Different Blast Processes of Blast Furnace. Processes 2016, 4, 28. https://doi.org/10.3390/pr4030028

Sun W, Zhao Y, Wang Y. Electro- or Turbo-Driven?—Analysis of Different Blast Processes of Blast Furnace. Processes. 2016; 4(3):28. https://doi.org/10.3390/pr4030028

Chicago/Turabian StyleSun, Wenqiang, Yueqiang Zhao, and Yunchun Wang. 2016. "Electro- or Turbo-Driven?—Analysis of Different Blast Processes of Blast Furnace" Processes 4, no. 3: 28. https://doi.org/10.3390/pr4030028