2.1. Control Scheme

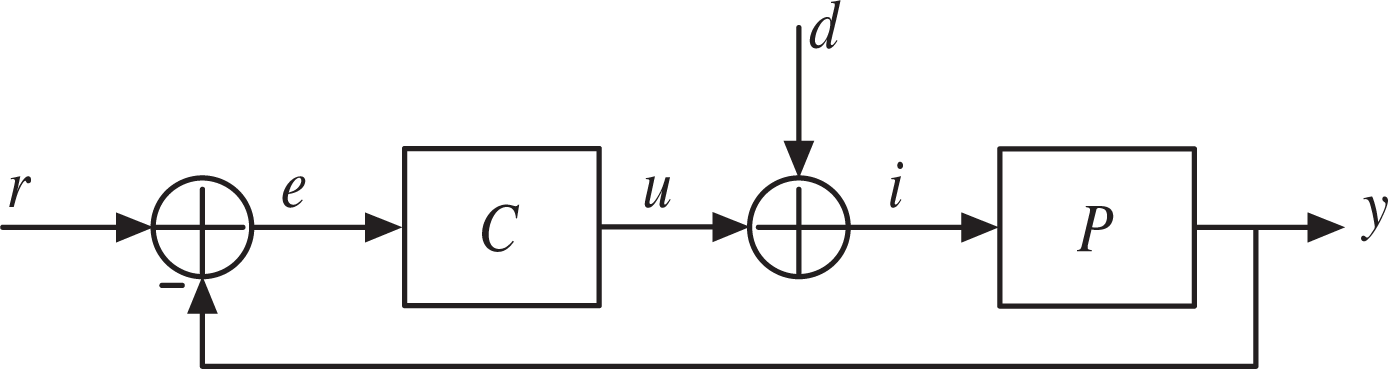

The unity-feedback control system shown in

Figure 1 is considered. The process

P is controlled by a PID controller whose transfer function can be either in series (“interacting”) form:

or in ideal (“non-interacting”) form:

The use of a (first- or second-order) noise filter [

17] is neglected for the sake of simplicity and without loss of generality, by taking into account that it can be designed so that it does not influence the PID controller dynamics significantly.

In order to evaluate the performance of the controller when either a set-point

r or a load disturbance d step signal is applied to the control system, an estimation of the process dynamics is performed (then, the current performance is compared with a selected benchmark one). In this context, it is worth recalling the so-called “half rule” [

18], as it provides a theoretical background for the proposed methods. The rule states that the largest neglected (denominator) time constant is distributed evenly to the effective dead time and the smallest retained time constant. Thus, for self-regulating processes, the following (possibly high-order) process transfer function can be considered:

where the time constants are ordered according to their magnitude (namely,

τ10 >

τ20 > ⋯). Then, Model

(3) can be approximated by a second order plus dead time (SOPDT) transfer function:

obtained by setting:

Alternatively, a simpler first order plus dead time (FOPDT) transfer function can be obtained as:

by setting:

It is worth noting that, defining as

T0 the sum of the time constants and of the dead time of the process, it results:

2.2. Set-Point Following Performance Assessment

Regarding the set-point following task, consider the PID controller

(1) and the process model

(4). Then, the Simple Internal Model Control (SIMC) tuning rules [

18], which are based on the well-known internal model control (IMC) concept, are selected as those that provide the benchmark performance. Based on them, the PID parameters are selected as:

As a consequence, it is easy to verify that:

and that, by approximating the delay term as

e−θs = 1 −

θs, the closed-loop transfer function is:

for which the resulting step response 2% settling time is:

and the step response integrated absolute error is:

where

e(

t) =

r(

t) −

y(

t) and

As is the amplitude of the set-point step.

It is therefore necessary to evaluate a closed-loop set-point step response and to verify that

Equations (10) and

(12) (or, alternatively,

Equation (13)) are satisfied, in principle, in order to establish that a PID controller is well tuned. Actually, it has to be pointed out that the use of the integrated absolute error is preferable, because, being based on the integral of a signal, it is more robust to the measurement noise. Then, an estimation

θm of the apparent dead time of the system can be performed by considering the time interval from the application of the step signal to the set-point and the time instant when the process output attains 2% of the new set-point value

As, namely, when the condition

y > 0.02

As occurs. In this context, in order to cope with the measurement noise, a simple sensible solution is to define a noise band

NB [

19] (whose amplitude should be equal to the amplitude of the measurement noise) and to rewrite the condition as

y >

NB. Then, Expression

(13) can be rewritten as:

With respect to

Equation (10), it is necessary to determine the process gain

µ and the sum of the lags and of the dead time of the process

T0 [

20]. The process gain

µ can be determined by considering the following trivial relations, which involve the final steady-state value of the control variable

u:

and, therefore, we have:

The determination of the sum of the lags and of the dead time of the process can be performed by considering the following variable:

By applying the Laplace transform to

Equation (17) and by expressing

u and

y in terms of

r, we have:

At this point, for the sake of clarity, it is convenient to write the controller and process transfer functions, respectively, as:

and:

Then, Expression

(18) can be rewritten as:

By applying the final value theorem to the integral of

v when a step is applied to the set-point signal, we finally obtain:

Thus, the sum of the lags and of the dead time of the process can be obtained by determining the integral of v(t) at the steady state when a step signal is applied to the set-point and by dividing it by the amplitude As of the step.

For the purpose of assessing the controller performance based on

Equations (10) and

(13), it is worth considering the following performance indices, named, respectively, the sigma index

SI and the set-point following performance index

SFPI (for a PID controller):

In principle, the performance obtained by the control system is considered to be satisfactory if

SFPIPID = 1. From a practical point of view, however, the controller is considered to be well tuned if the index is greater than a given threshold, which can be taken equal to 0.6. Note that this last value has been selected by considering the SIMC tuning rule applied to many different processes [

18], but in any case, another value of the threshold can be selected by the user depending on how tight its control specifications are. If the controller results in being badly tuned, then two cases might occur. If the value of

SI is less than one, this means that the current tuning is based on an underestimation of the process lags and/or of the dead time. Thus, an improvement of the performance can be achieved by decreasing the value of

Kp and/or by increasing the value of

Ti and/or

Td (see

Equation (10)). On the contrary, if the value of

SI is greater than one, this means that the current tuning is based on an overestimation of the process lags and/or of the dead time. Thus, an improvement of the performance can be achieved by increasing the value of

Kp and/or by decreasing the value of

Ti and/or

Td.

2.3. Retuning Algorithm

If the performance provided by the controller results in being unsatisfactory, the PID controller needs to be retuned. This can be done by exploiting the following procedure. The closed-loop step response is evaluated, and

θm and

T0 have to be calculated according to the technique described in Section 2.2 (see

Equation (22)). Then, if an overshoot occurs, the proportional gain

Kp is decreased, and the integral time constant

Ti and the derivative time constant

Td are subsequently calculated by means of Expressions

(9) and

(10). If the resulting value of

Ti is less than the value of

Td, then

Ti has to be decreased, and the values of

Kp and

Td are updated again according to

Equations (9) and

(10). The procedure is iterated until a value

Td > 0 is obtained. Conversely, if the closed-loop step response is overdamped (namely, there is no overshoot), the procedure starts by increasing the proportional gain

Kp, and then, the same steps of the case with overshoot are applied. By taking into account the considerations made in Section 2.2, a sound measure on how much to initially increase or decrease the parameters is given by the sigma index

SI.

Formally, starting from given values of

Kp,

Ti and

Td, the algorithm for retuning the PID controller is described as follows [

20].

Retuning algorithmEvaluate a closed-loop set-point step response y(t) and the corresponding control variable u(t), and determine µ, θm and T0.

Set Kpi = Kp (store the initial value of the proportional gain).

If max

t y(

t) >

As (namely, if there is overshoot), then:

If max

t y(

t) ≤

As (namely, if there is no overshoot), then:

End.

A simpler procedure can be performed by considering the FOPDT model

(6) and by directly applying the SIMC tuning rules devised for this kind of process, based on the estimated values,

θm and

τ =

T0 −

θm:

2.4. Experimental Results

The proposed algorithm has been applied to the temperature control loop shown in

Figure 2 as TIC3206. The plant is dedicated to the production of energy from renewable sources, in particular by using palm oil as a fuel. The control task consists of keeping the palm oil pipes at the required (warm) temperature to avoid its solidification, which would cause serious damage to the plant. During routine operations, the system has to keep the steady-state value, but during the start-up phase, the controller must follow a set-point step signal effectively. In the experiments performed on the plant, the controller was initially tuned with a proportional band

PB = 70% (note that the proportional band is equal to 100/

Kp) and an integral time constant equal to

Ti = 70 (s) (

Td = 0). After the application of the step signal to the set-point, the process parameters have been determined as

θm = 94 (s),

µ = 0.285 and

T0 = 184.3 (s). The corresponding values of

SI and

SFPIPID have been determined as 0.84 and 0.545, respectively, indicating the need for a retuning. By applying the retuning algorithm, the new values of the PID controller have been determined as

PB = 82.78%,

Ti = 64.82 (s) and

Td = 24.45 (s), with a corresponding value of

SFPIPID = 0.973 (obviously, it is

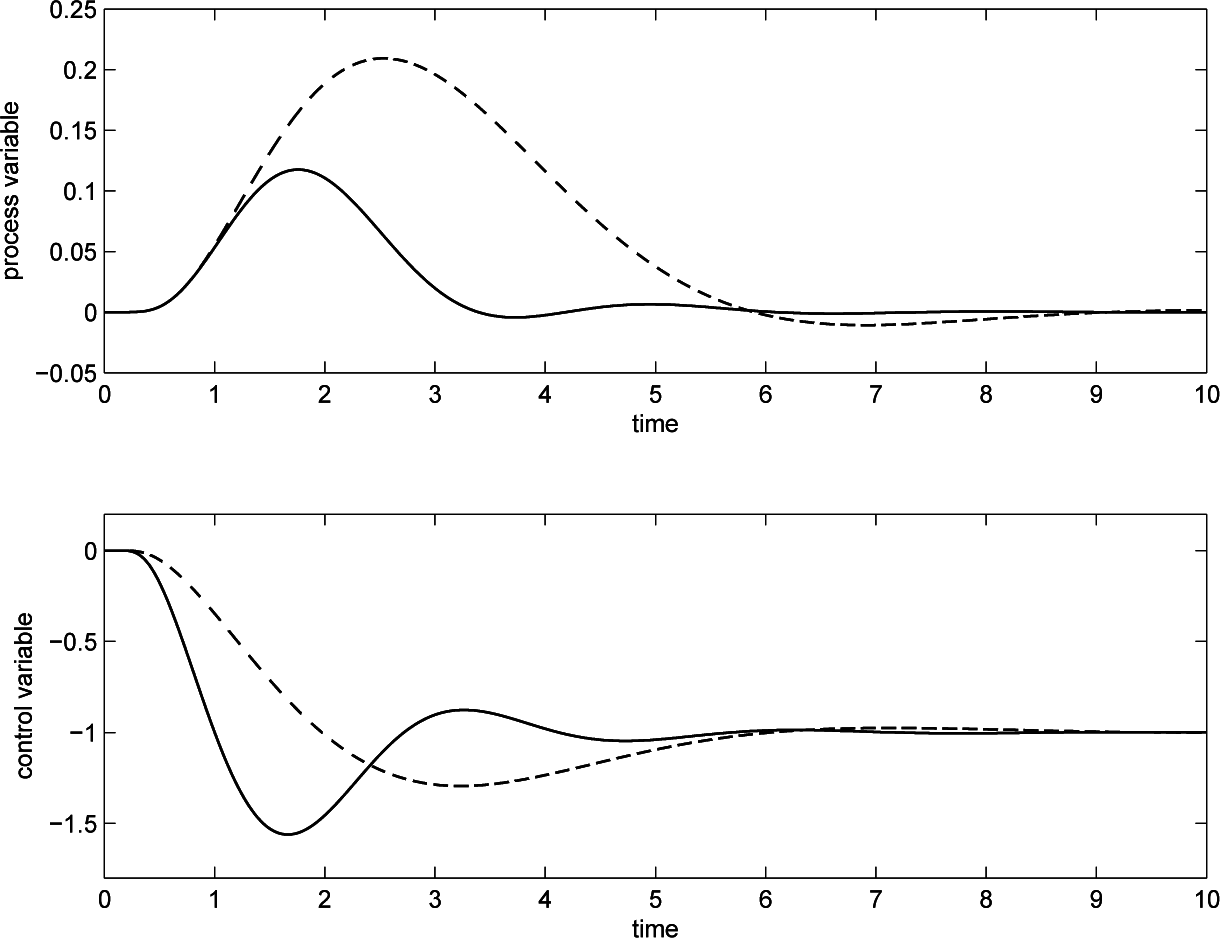

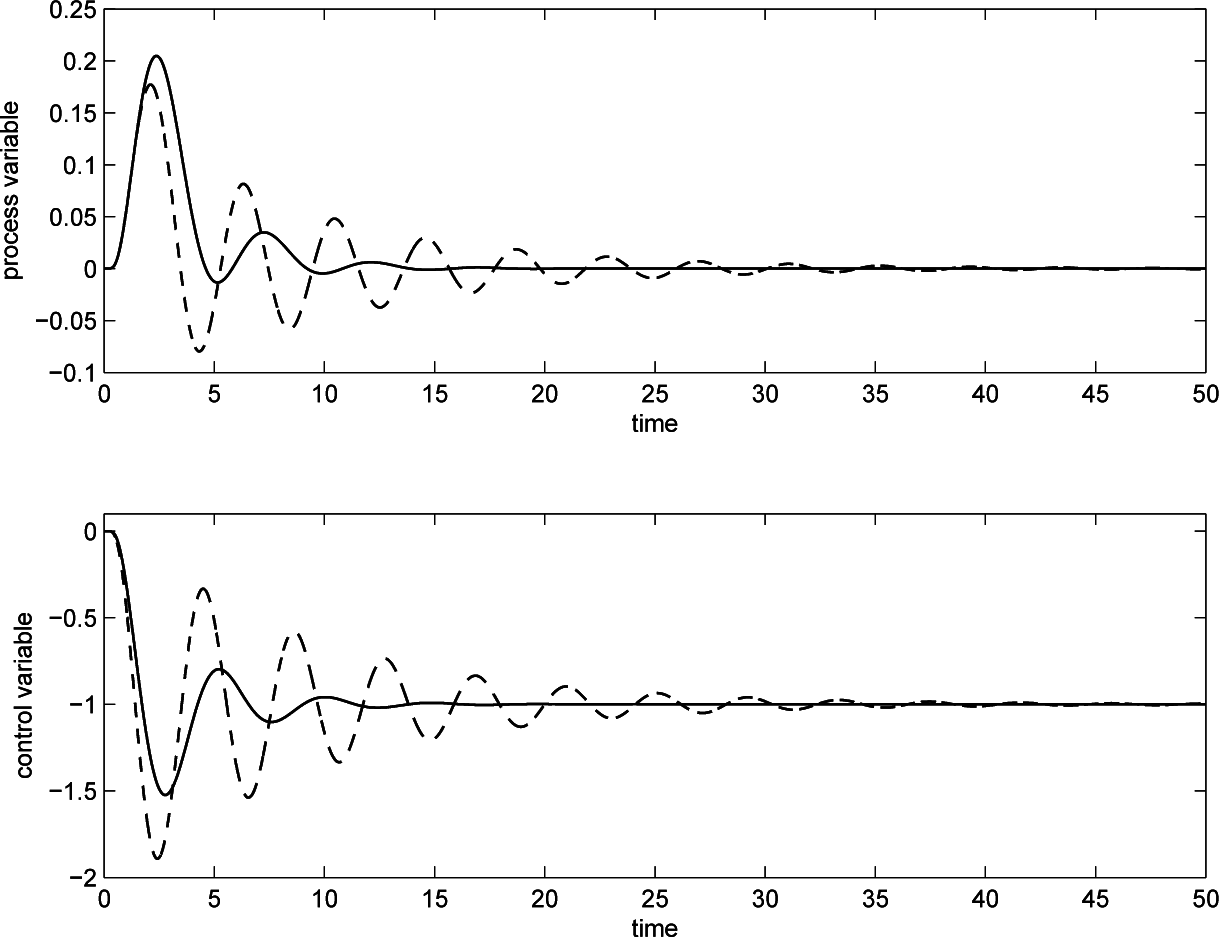

SI = 1). The set-point step responses before and after the retuning procedure are shown in

Figures 3 and

4, respectively, where a clear improvement in the performance appears (note the different time range in the two figures). In particular, the settling time has been considerably reduced, which is obviously appreciated in the start-up phase.

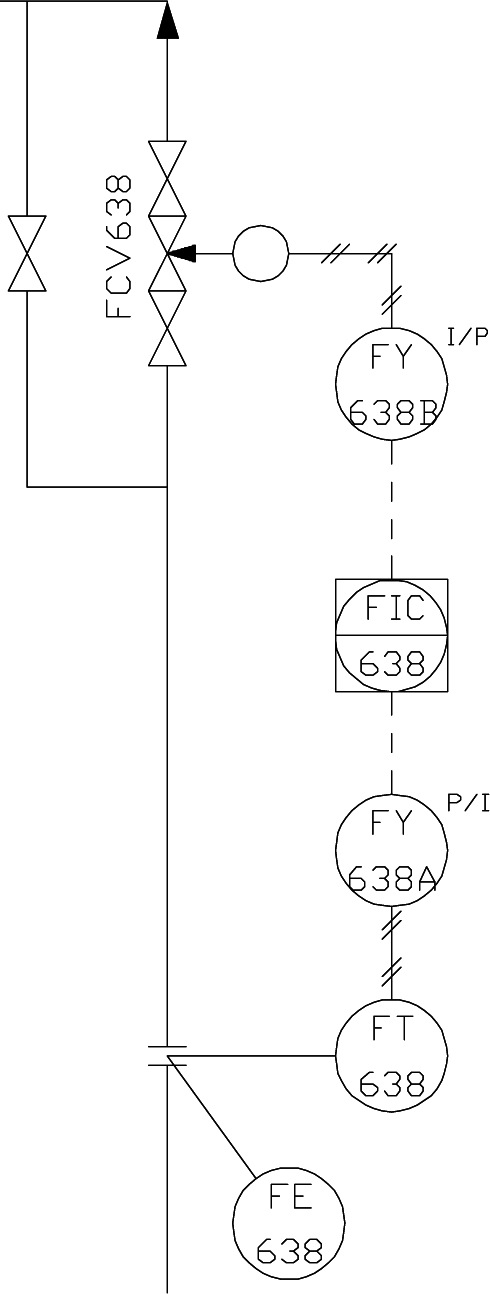

Another experiment has been performed in a chemical plant and, in particular, in a flow control loop denoted as FIC638 in the P&Idiagram shown in

Figure 5 [

21]. The PI controller controls the flow of hydrochloric acid (HCL), which comes from a tank and is sent to a neutralization column, where it reacts with anhydride-trimethylamine to generate trimethylamine hydrochloride (TMAHCL 56). The FIC638’s performance significantly affects the quality of TMAHCL. Indeed, by providing a fast, but accurate, set-point following, it is possible to avoid the pH correction of the raw product, because the hydrochloride would already be within the designed range.

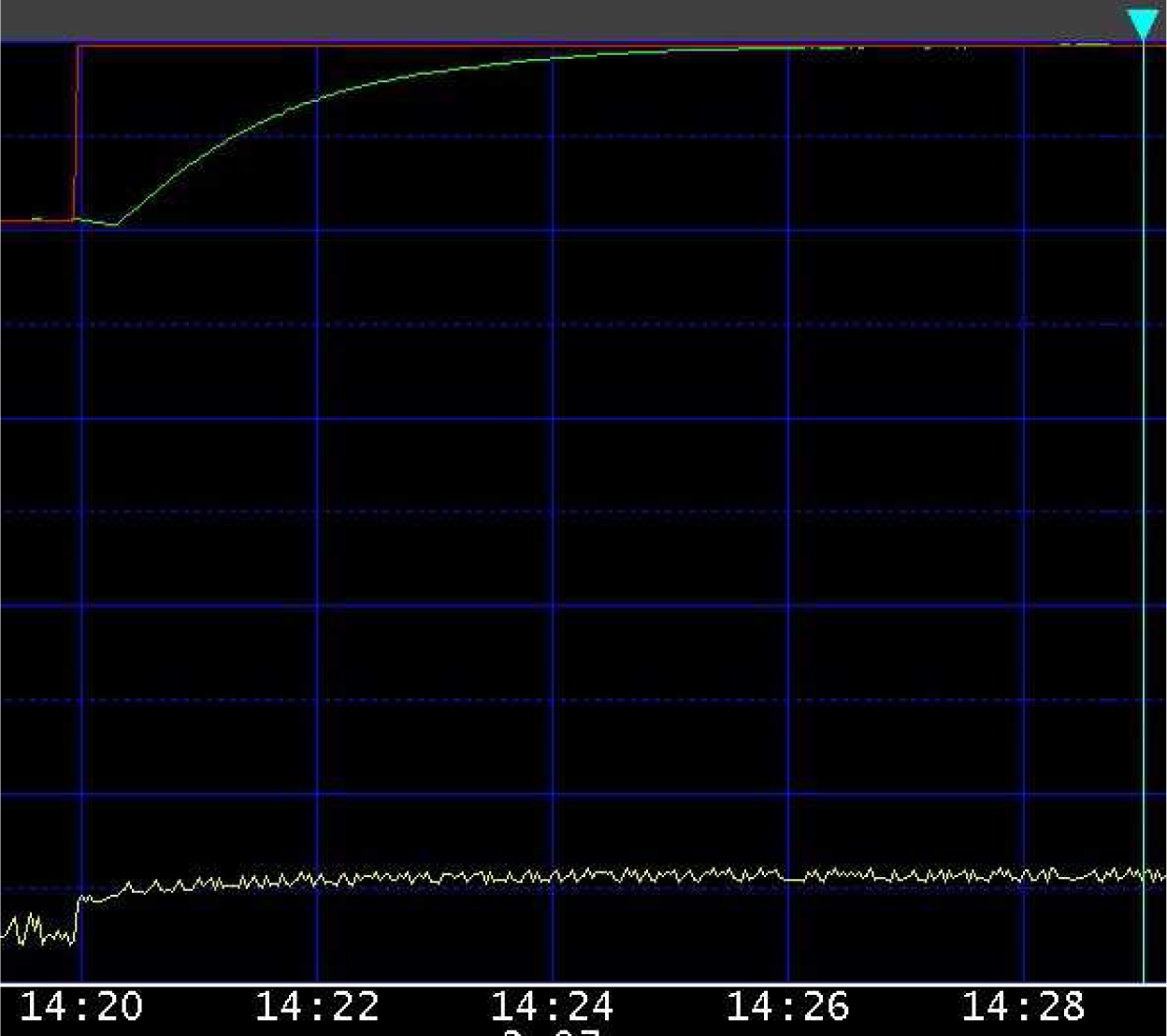

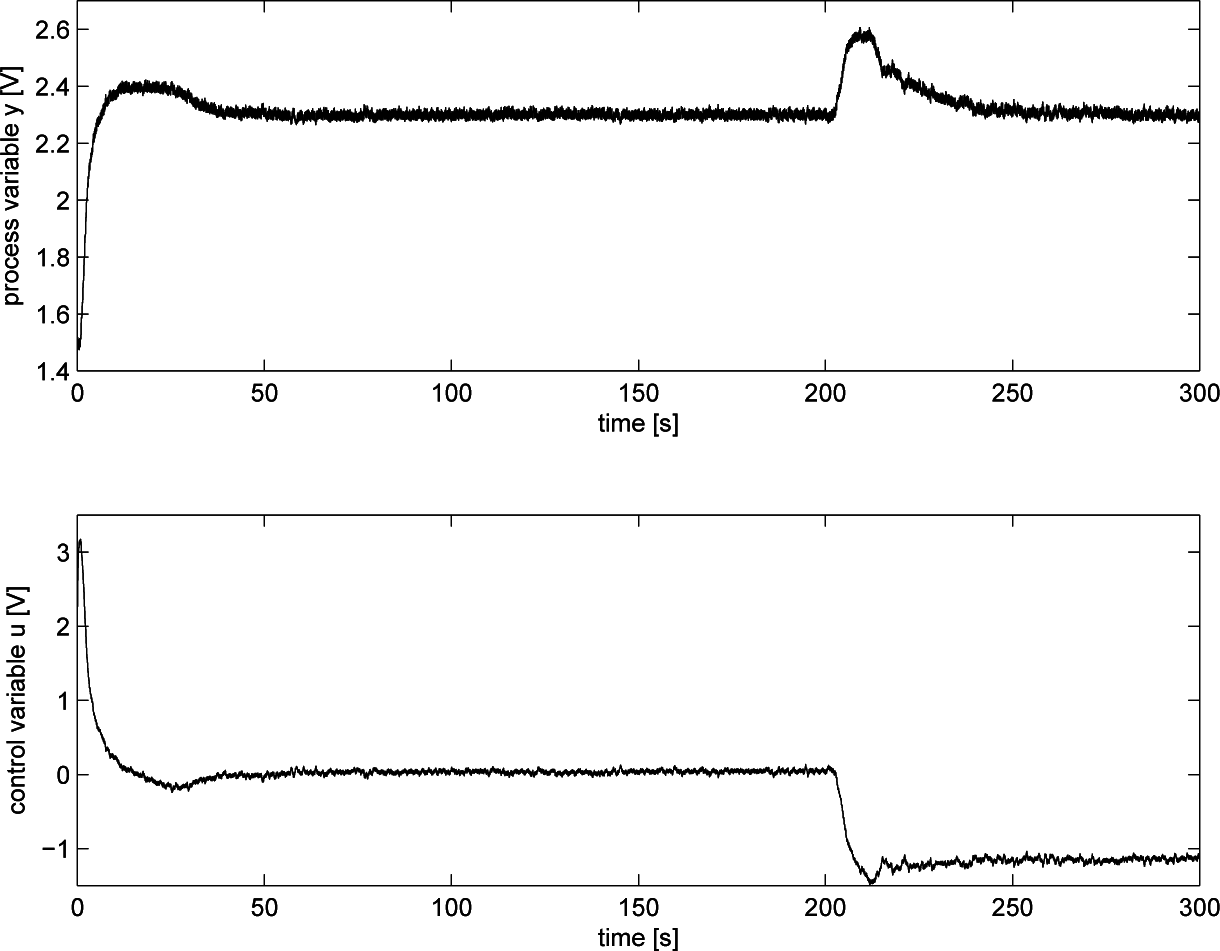

During the commissioning phase, the FIC638 was manually tuned with

PB = 500 and

Ti = 60 (s), and the resulting response to a set-point step change from 1500 (kg/h) to 1750 (kg/h) was the one shown in

Figure 6. The corresponding value of the integrated absolute error (IAE) was 7.585 (kg) (the flow is measured in (kg/h), but the values are stored at each second). When the system attained its steady-state value, the following values of the process parameters were estimated:

θm = 19 (s),

µ = 3.125 and

T0 = 58 (s). The value of the sigma index

SI resulted in being 1.86, while the value of the closed-loop index

SFPIPID resulted in being equal to 0.35, which means that both indices indicate that the controller had to be retuned. The PI controller has then to be retuned by applying Formula

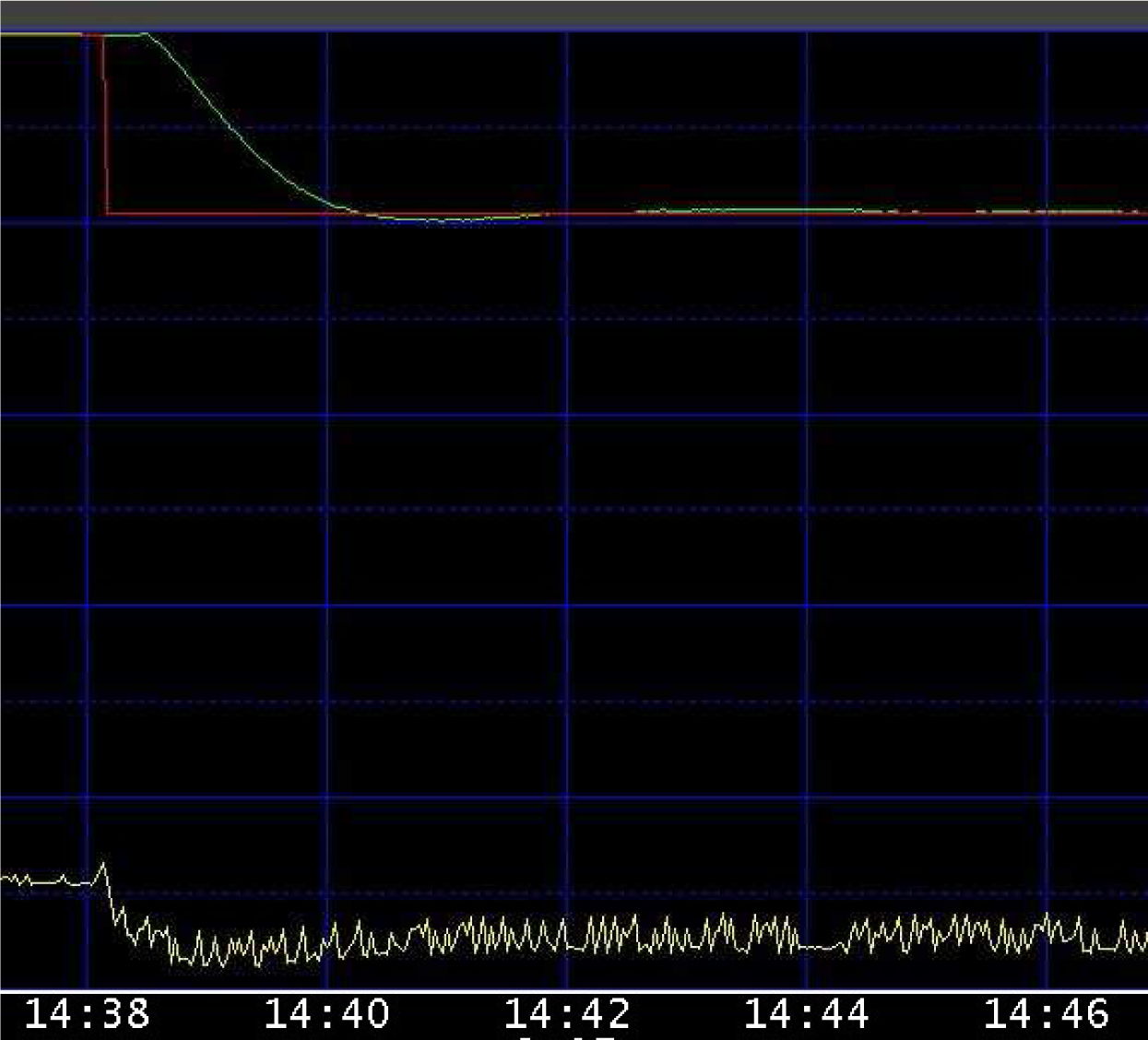

(25), which yielded

PB = 304.5 and

Ti = 39 (s). These values were applied to the PI controller before changing the set-point value from 1750 (kg/h) back to the value it had previously (1,500 (kg/h)). The step response obtained is shown in

Figure 7. It can be seen that, although a small overshoot appeared, the settling time was shorter. The value of the integrated absolute error

IAE decreased to 4.01 (kg), and the set-point following performance index increased to 0.66.

2.5. Load Disturbance Rejection Performance Assessment

The same reasoning made for the set-point following performance can be done also for the load disturbance rejection one [

22]. Consider the control scheme of

Figure 1, where the PID controller has transfer function

(2) and the FOPDT process has transfer function

(3). A load disturbance step

d of amplitude

Ad is assumed to enter into the process at a known time instant, which is taken as

t = 0 without loss of generality. The disturbance amplitude

Ad can be estimated by considering the final value of the integral of the control error:

Once the amplitude of the step disturbance has been determined, the process gain

µ can be determined, by considering the integral of process input

i =

u +

d (where

d =

Ad) as:

Finally, the value of the sum of the time constants of the process can be determined by considering the variable:

and by calculating

T0 as:

Finally, in order to obtain a FOPDT model of the process, the apparent dead time θm of the system can be estimated by considering the time interval from the occurrence of the load disturbance and the time instant when the absolute value of the difference between the process output and its previous steady-state value exceed the noise band threshold.

It is worth stressing that the method works well when an abrupt (namely, step-like) load disturbance occurs. Thus, the performance assessment technique has to be implemented together with a procedure for the detection of abrupt load disturbances, such as, for instance, the one proposed in [

23].

Once the process parameters have been estimated, the Chen–Seborg tuning rule proposed in [

24] can be used to provide the benchmark performance in terms of integrated absolute error. Indeed, this tuning rule aims at achieving the following closed-loop transfer function (this can be easily ascertained by approximating the delay term as

:

where

τc is a design parameter, which can be selected as

τc =

θ in order to provide a satisfactory robustness.

Thus, by considering

τ =

T0 −

θm, the PID controller parameters can be calculated as:

As the desired closed-loop transfer function

(30) has only real poles, the desired integrated absolute error

IAE is equal to the integrated error, that is (see

Equation (26)):

Thus, a performance index for the load rejection task (called

LRPI, load disturbance rejection performance index) for a PID controller is defined by comparing the obtained integrated absolute error with the desired one, that is:

A similar reasoning can be applied if a PI controller is selected. In this case, the target closed-loop transfer function between the process variable and the load disturbance is:

where

τc =

θ to achieve a satisfactory robustness. Correspondingly, by considering the estimated apparent dead time, the tuning formulas are:

and the performance index is:

As for the set-point following performance, even if the ideal LRPI index is equal to one, from a practical point of view, a sensible default value of 0.6 can be imposed, but in any case, the value of the threshold can be selected by the user depending on how tight the required performance in a given application is.

It is worth noting at this point that, despite the tuning of the PID controller taking into account the load disturbance rejection task, the set-point following performance can be in any case recovered by considering that, for PID controllers, the transfer function from the reference signal to the process variable is:

Thus, by adopting a two degrees of freedom PID controller, a set-point filter equal to:

can be designed by placing both zeros at −1/

θ, so that the overall transfer function between the set-point and the process variable now results:

This is achieved by setting:

By following a similar reasoning for the PI controller case, the set-point filter has to be designed as:

Thus, in this context, as the overall transfer function is of the FOPDT type, the set-point following performance can be assessed by using the performance index of

Equation (24).

As an illustrative example, consider the process:

A PID controller is initially employed with the parameters selected as

Kp = 1,

Ti = 10 and

Td = 1. After the load disturbance occurs on the process, the gain

µ is correctly determined by means of

Equation (72), while the computation

(73) gives exactly

T0 = 20; finally, the dead time is estimated to be

θm = 6.27. The performance indices related to this initial manual tuning are

LRPIPID = 0.582 and

SFPIPID = 0.642, which indicates a quite poor behavior of the controller. Hence, the PID parameters are retuned by using

Equation (36), resulting in

Kp = 1.785,

Ti = 14.06,

Td = 2.087.

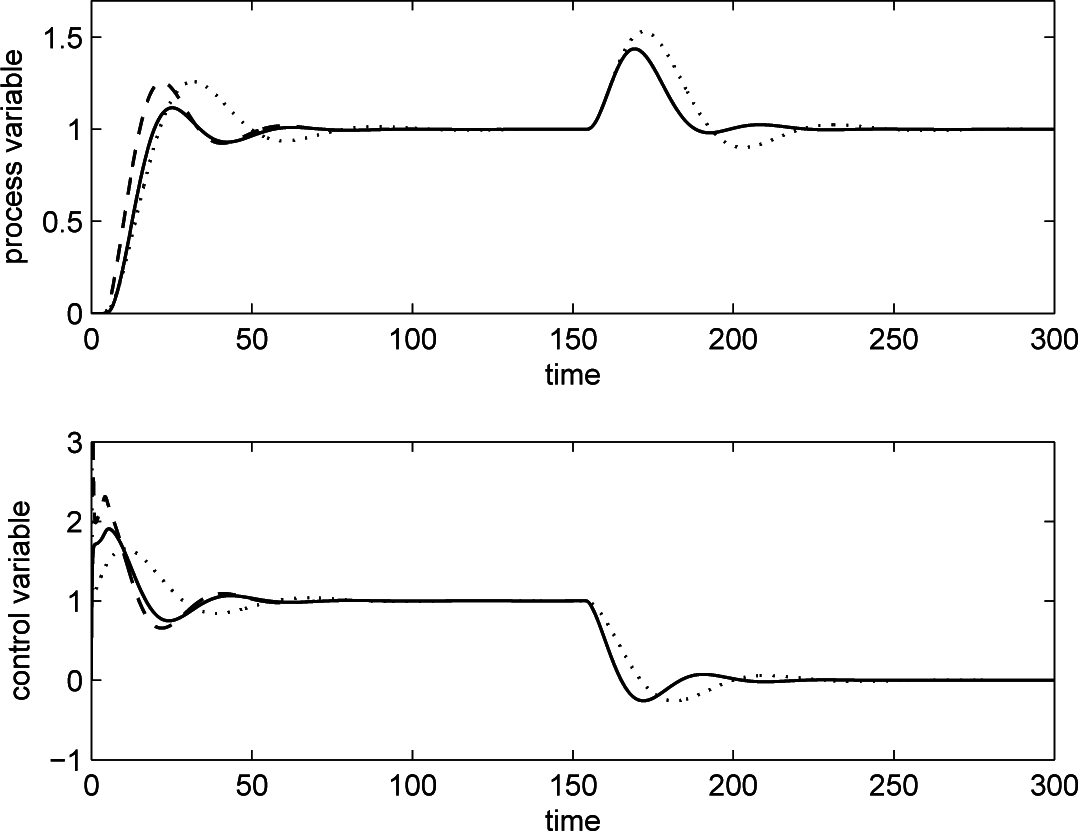

Figure 8 shows the performance improvement that results from the retuning; of course, when the set-point filter of

Equation (42) is applied, the typical aggressiveness in the load disturbance rejection task does not have to be paid by a high overshoot in the set-point following, like happens if the filter is not used. In fact, in both cases, it is

LRPIPID = 0.877, but by filtering the set-point, it is

SFPIPID = 0.849.