Multi-Objective Disassembly Sequence Planning in Uncertain Industrial Settings: An Enhanced Water Wave Optimization Algorithm

Abstract

:1. Introduction

- In addressing the complexities of equipment maintenance in an industrial context, we introduce triangular fuzzy numbers to cope with uncertainty factors. This not only enhances decision accuracy but also demonstrates unique adaptability when facing uncertainty in practical operations.

- We integrate multi-objective optimization into industrial equipment maintenance within an uncertain environment, comprehensively considering complexities such as reducing disassembly time, minimizing tool and direction change frequency, and enhancing responsiveness to emergency maintenance components.

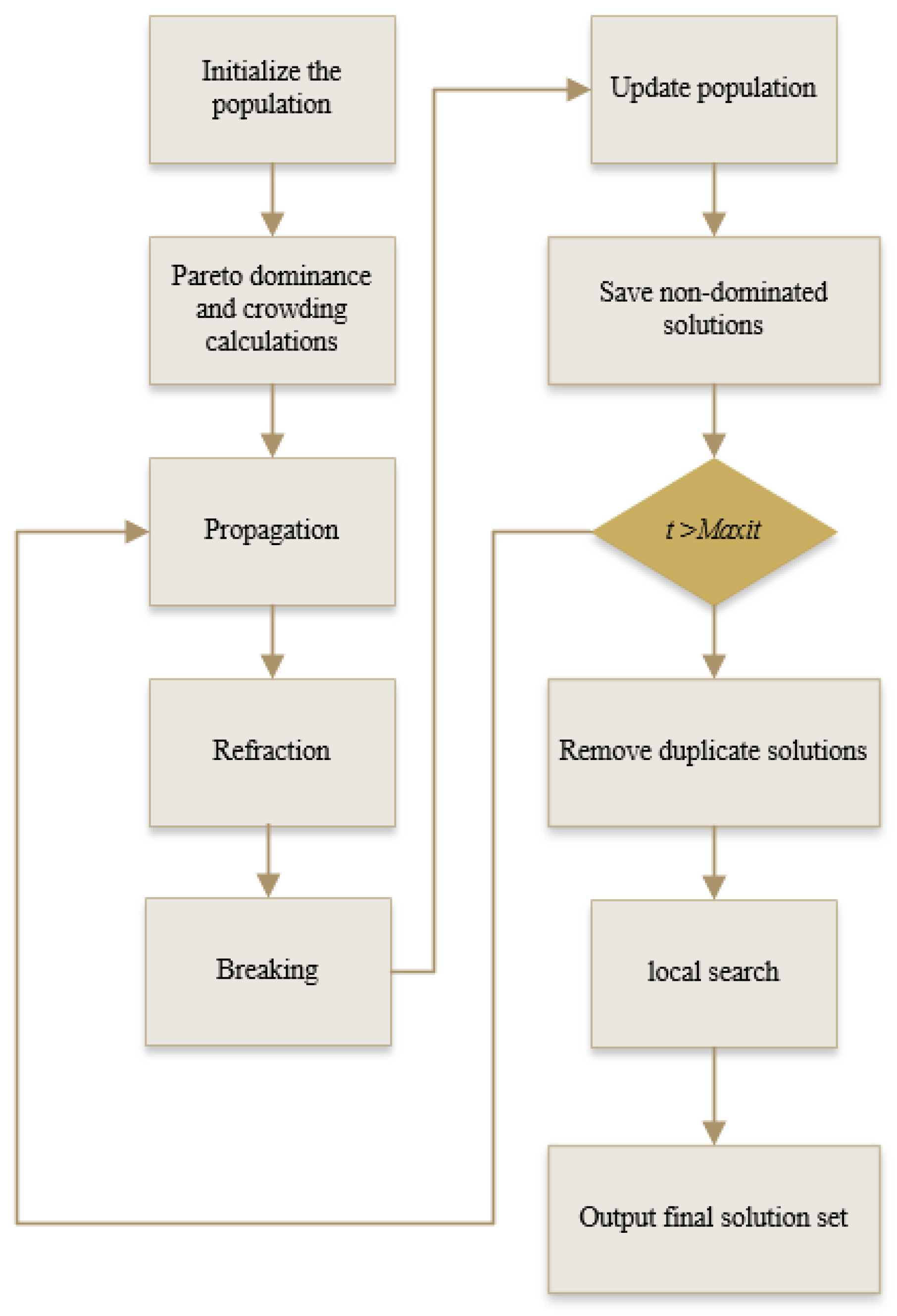

- We introduce the innovative EWWO algorithm, which, by redefining propagation, refraction, and breaking operators, extensively searches for solutions to the DSP problem, effectively addressing its complexities and NP-hard nature. This algorithm provides a powerful tool for addressing real-world industrial challenges.

2. Literature Review

2.1. Research on DSP

2.2. Research Gap and Contribution

3. Proposed Model

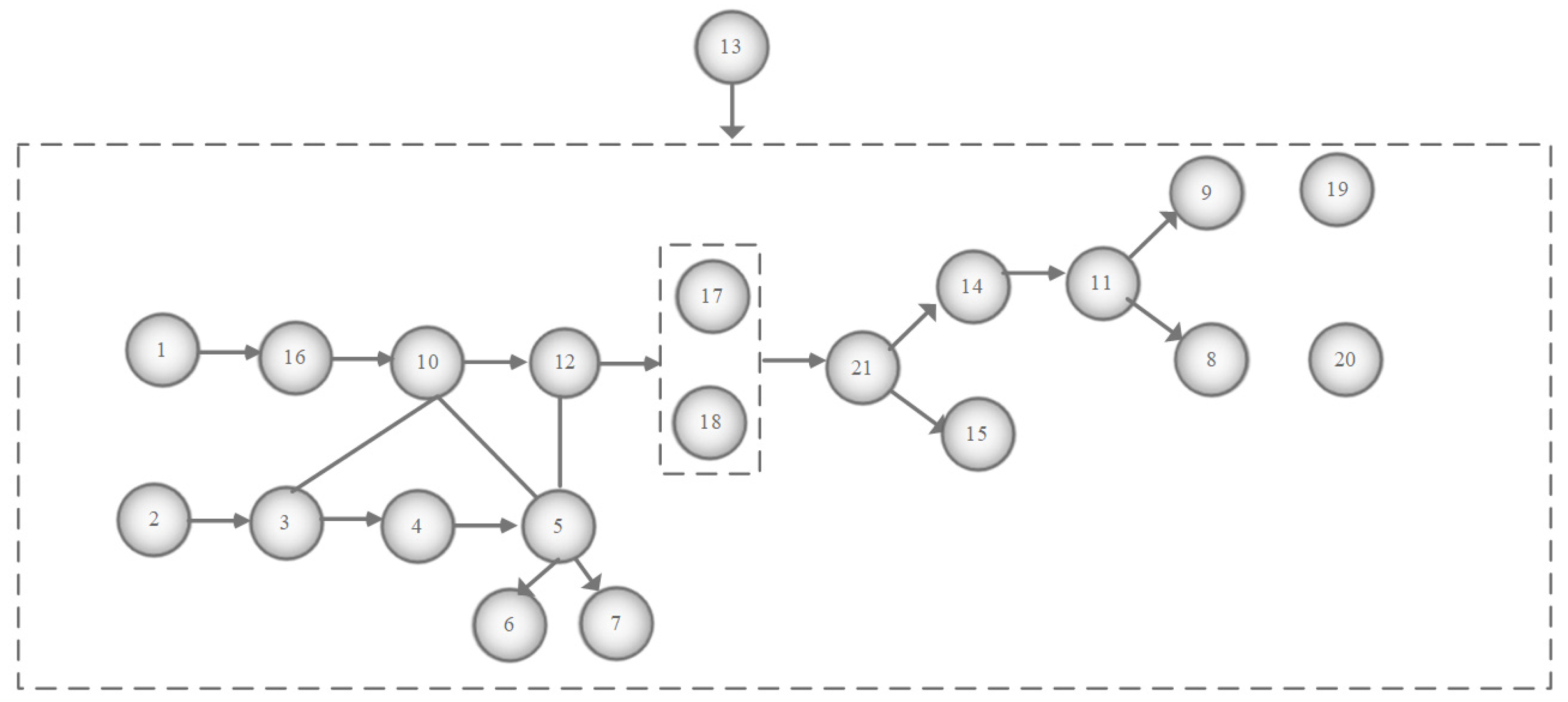

3.1. Disassembly Hybrid Graph

3.2. Triangular Fuzzy Numbers

3.3. Proposed Model

| Indices: | |

| m: | Index denoting the disassembly component, m 1, 2,…, M} |

| Parameters: | |

| M: | Total count of disassembly components |

| Fuzzy disassembly time associated with component m | |

| sm | Level of complexity for the removal of component m |

| Fuzzy time required for tool change | |

| Fuzzy time required for direction change | |

| Im | Position of component m in the disassembly sequence |

| dn | Number of direction changes in the disassembly sequence |

| tn | Number of tool changes in the disassembly sequence |

| Decision variables: | |

| hm | Priority indicator for component m, where hm = 1 if component m has priority; otherwise, hm = 0. |

- (1)

- Reducing disassembly time

- (2)

- Enhancing responsiveness to urgent maintenance components

- (3)

- Reducing tool and direction change frequency

4. Proposed Solution Method

4.1. Multi-Objective Handling Techniques

- Solution A is at least as good as Solution B in at least one objective.

- Solution A is strictly better than Solution B in at least one objective.

- If both of the above conditions are met, then Solution A Pareto dominates Solution B.

- Sort the solutions on the Pareto front for each objective based on their values.

- Calculate the distances of each solution on each objective.

- Sum the distances on each objective to obtain the crowding distance for each solution.

- A larger crowding distance indicates a lower crowding level of a solution on the front and is typically more worth retaining. This helps maintain diversity on the front while selecting solutions with higher performance.

4.2. Population Initialization

4.3. Propagation Operator

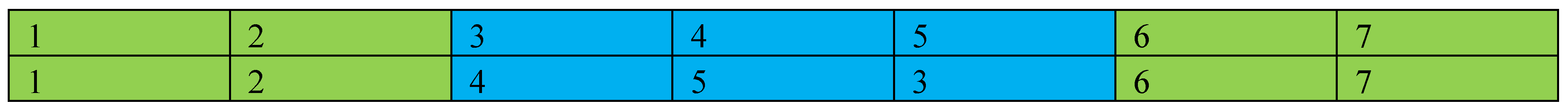

4.4. Refraction Operator

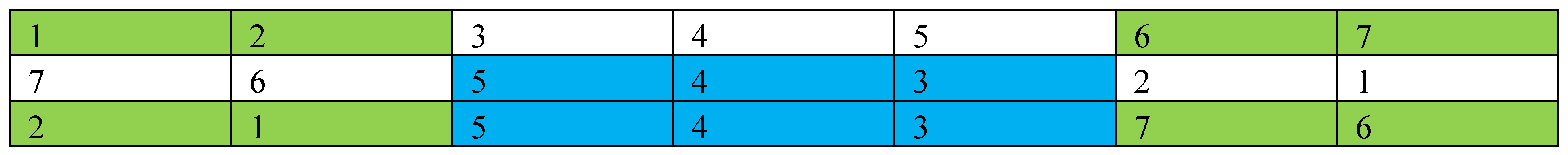

4.5. Breaking Operator

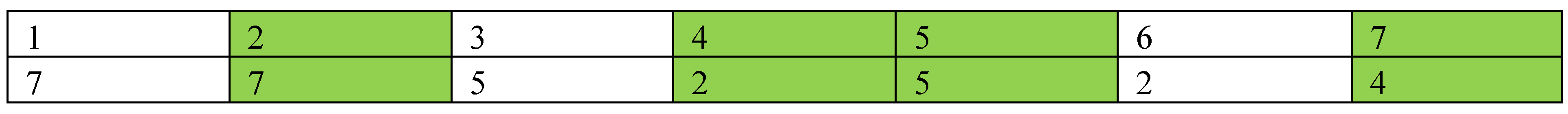

4.6. Local Search

4.7. EWWO Algorithm General Framework

5. Case Study

5.1. Case Study A

5.1.1. Case Description

5.1.2. Parameter Calibration

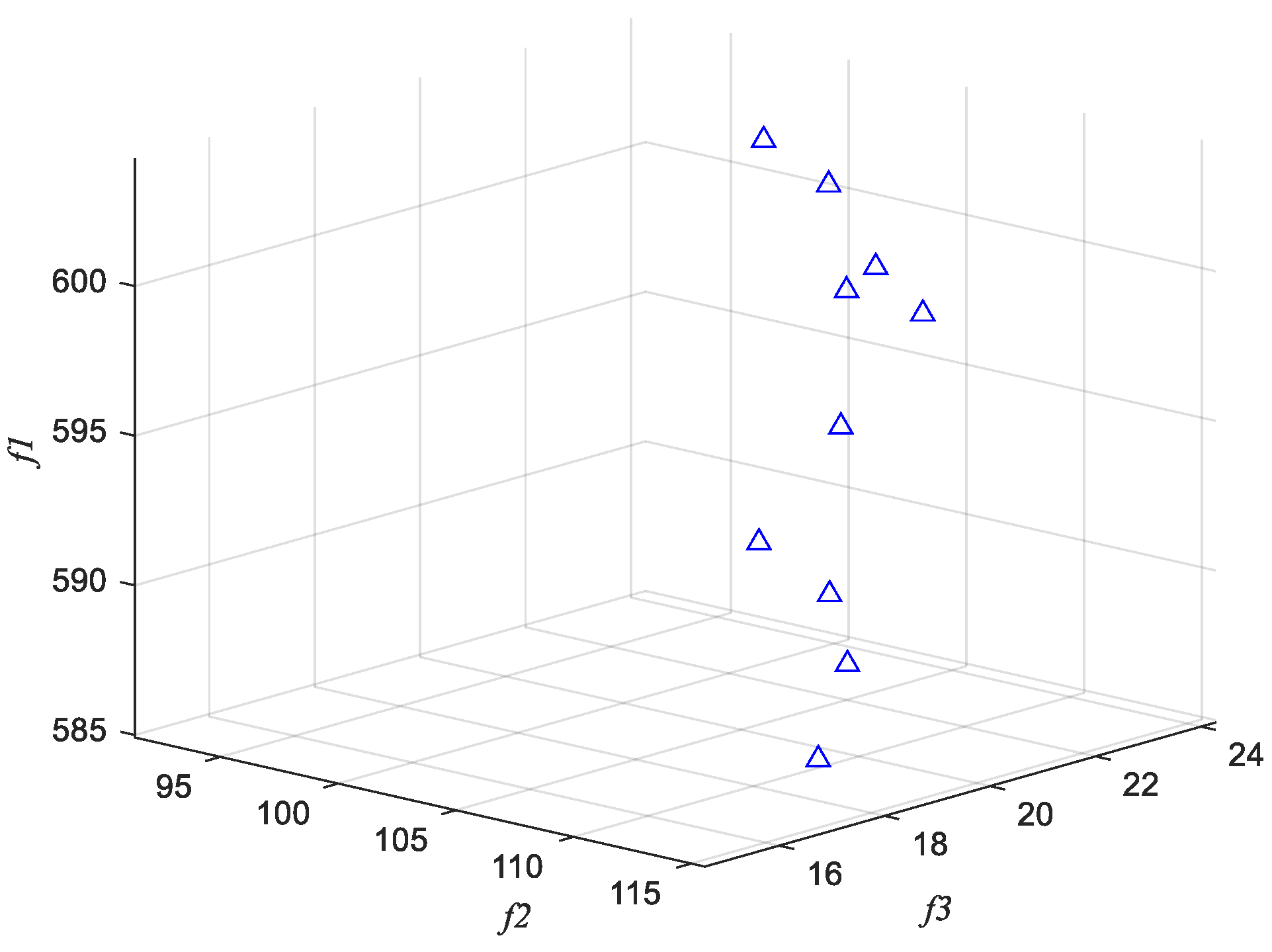

5.1.3. Computational Result

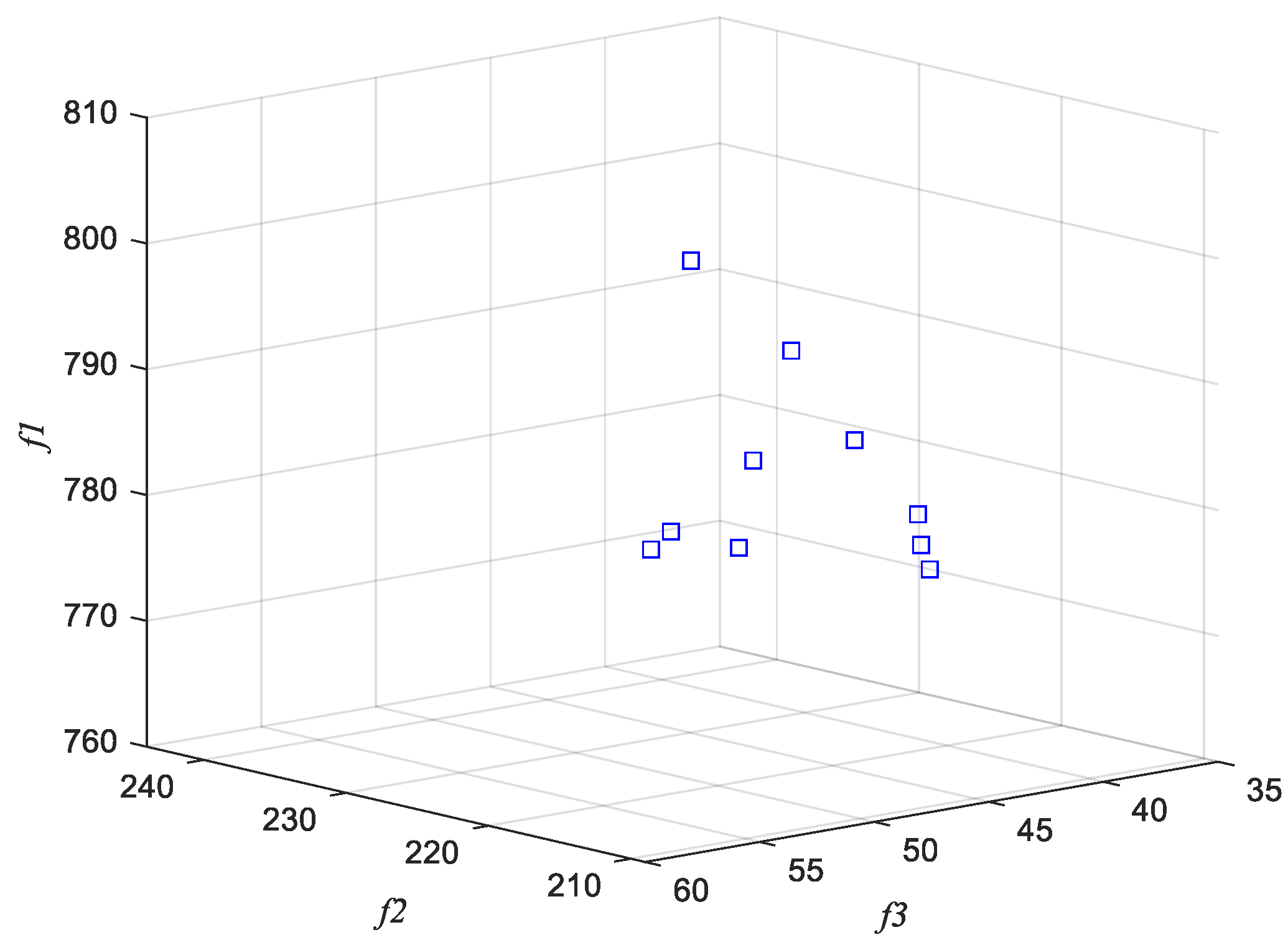

5.2. Case Study B

5.2.1. Case Description

5.2.2. Computational Result

6. Comparison with Other Algorithms

7. Conclusions and Future Work

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Tian, G.; Lu, W.; Zhang, X.; Zhan, M.; Dulebenets, M.A.; Aleksandrov, A.; Fathollahi-Fard, A.M.; Ivanov, M. A survey of multi-criteria decision-making techniques for green logistics and low-carbon transportation systems. Environ. Sci. Pollut. Res. 2023, 30, 57279–57301. [Google Scholar] [CrossRef] [PubMed]

- Du, N.; Fathollahi-Fard, A.M.; Wong, K.Y. Wildlife resource conservation and utilization for achieving sustainable development in China: Main barriers and problem identification. Environ. Sci. Pollut. Res. 2023. Epub ahead of print. [Google Scholar] [CrossRef] [PubMed]

- Tian, G.; Ren, Y.; Feng, Y.; Zhou, M.; Zhang, H.; Tan, J. Modeling and Planning for Dual-Objective Selective Disassembly Using and/or Graph and Discrete Artificial Bee Colony. IEEE Trans. Ind. Inform. 2018, 15, 2456–2468. [Google Scholar] [CrossRef]

- Meng, K.; Xu, G.; Peng, X.; Youcef-Toumi, K.; Li, J. Intelligent disassembly of electric-vehicle batteries: A forward-looking overview. Resour. Conserv. Recycl. 2022, 182, 106207. [Google Scholar] [CrossRef]

- Nikolaidis, P.; Poullikkas, A. Evolutionary priority-based dynamic programming for the adaptive integration of intermittent distributed energy resources in low-inertia power systems. Eng 2022, 2, 643–660. [Google Scholar] [CrossRef]

- Nikolaidis, P.; Poullikkas, A. Co-optimization of active power curtailment, load shedding and spinning reserve deficits through hybrid approach: Comparison of electrochemical storage technologies. IET Renew. Power Gener. 2021, 16, 92–104. [Google Scholar] [CrossRef]

- Wang, Y.; Gerchak, Y. Capacity games in assembly systems with uncertain demand. Manuf. Serv. Oper. Manag. 2003, 5, 252–267. [Google Scholar] [CrossRef]

- Chen, Z.; Zou, J.; Wang, W. Digital twin-oriented collaborative optimization of fuzzy flexible job shop scheduling under multiple uncertainties. Sadhana 2023, 48, 78. [Google Scholar] [CrossRef]

- Bentaha, M.L.; Dolgui, A.; Battaïa, O.; Riggs, R.J. Profit-oriented partial disassembly line design: Dealing with hazardous parts and task processingtimes uncertainty. Int. J. Prod. Res. 2018, 56, 7220–7242. [Google Scholar] [CrossRef]

- Ren, Y.; Zhang, C.; Zhao, F.; Xiao, H.; Tian, G. An asynchronous parallel disassembly planning based on genetic algorithm. Eur. J. Oper. Res. 2018, 269, 647–660. [Google Scholar] [CrossRef]

- Baghizadeh, K.; Ebadi, N.; Zimon, D.; Jum’a, L. Using Four Metaheuristic Algorithms to Reduce Supplier Disruption Risk in a Mathematical Inventory Model for Supplying Spare Parts. Mathematics 2022, 11, 42. [Google Scholar] [CrossRef]

- Zhang, C.; Fathollahi-Fard, A.M.; Li, J.; Tian, G.; Zhang, T. Disassembly sequence planning for intelligent manufacturing using social engineering optimizer. Symmetry 2021, 13, 663. [Google Scholar] [CrossRef]

- Ren, Y.; Tian, G.; Zhao, F.; Yu, D.; Zhang, C. Selective cooperative disassembly planning based on multi-objective discrete artificial bee colony algorithm. Eng. Appl. Artif. Intell. 2017, 64, 415–431. [Google Scholar] [CrossRef]

- Wu, P.; Wang, H.; Li, B.; Fu, W.; Ren, J.; He, Q. Disassembly sequence planning and application using simplified discrete gravitational search algorithm for equipment maintenance in hydropower station. Expert Syst. Appl. 2022, 208, 118046. [Google Scholar] [CrossRef]

- Motahar, M.M.; Nourzad, S.H.H. A hybrid method for optimizing selective disassembly sequence planning in adaptive reuse of buildings. Eng. Constr. Arch. Manag. 2022, 29, 307–332. [Google Scholar] [CrossRef]

- Fang, Y.; Ming, H.; Li, M.; Liu, Q.; Pham, D.T. Multi-objective evolutionary simulated annealing optimisation for mixed-model multi-robotic disassembly line balancing with interval processing time. Int. J. Prod. Res. 2020, 58, 846–862. [Google Scholar] [CrossRef]

- Chen, Z.; Li, L.; Zhao, F.; Sutherland, J.W.; Yin, F. Disassembly sequence planning for target parts of end-of-life smartphones using Q-learning algorithm. Procedia CIRP 2023, 116, 684–689. [Google Scholar] [CrossRef]

- Sun, X.; Guo, S.; Guo, J.; Du, B. A two-stage interactive evolutionary algorithm for multi-objective asynchronous parallel selective disassembly sequence planning problem. Comput. Ind. Eng. 2023, 175, 108855. [Google Scholar] [CrossRef]

- Qiu, L.; Dong, L.; Wang, Z.; Zhang, S.; Xu, P. Asynchronous parallel disassembly sequence planning method of complex products using discrete multi-objective optimization. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2022, 236, 1466–1482. [Google Scholar] [CrossRef]

- Ji, J.; Wang, Y. Selective disassembly sequence optimization based on the improved immune algorithm. Robot. Intell. Autom. 2023, 43, 96–108. [Google Scholar] [CrossRef]

- Fu, Y.; Zhou, M.; Guo, X.; Qi, L.; Sedraoui, K. Multiverse optimization algorithm for stochastic biobjective disassembly sequence planning subject to operation failures. IEEE Trans. Syst. Man Cybern. Syst. 2021, 52, 1041–1051. [Google Scholar] [CrossRef]

- Liang, P.; Fu, Y.; Ni, S.; Zheng, B. Modeling and optimization for noise-aversion and energy-awareness disassembly sequence planning problems in reverse supply chain. Environ. Sci. Pollut. Res. 2021. Online ahead of print. [Google Scholar] [CrossRef]

- Tian, G.; Zhou, M.; Li, P. Disassembly sequence planning considering fuzzy component quality and varying operational cost. IEEE Trans. Autom. Sci. Eng. 2017, 15, 748–760. [Google Scholar] [CrossRef]

- Kim, H.-W.; Park, C.; Lee, D.-H. Selective disassembly sequencing with random operation times in parallel disassembly environment. Int. J. Prod. Res. 2018, 56, 7243–7257. [Google Scholar] [CrossRef]

- Yeh, W.-C. Simplified swarm optimization in disassembly sequencing problems with learning effects. Comput. Oper. Res. 2012, 39, 2168–2177. [Google Scholar] [CrossRef]

- Zhang, X.; Zhou, H.; Fu, C.; Mi, M.; Zhan, C.; Pham, D.T.; Fathollahi-Fard, A.M. Application and planning of an energy-oriented stochastic disassembly line balancing problem. Environ. Sci. Pollut. Res. 2023. Online ahead of print. [Google Scholar] [CrossRef]

- Guo, H.; Zhang, L.; Ren, Y.; Li, Y.; Zhou, Z.; Wu, J. Optimizing a stochastic disassembly line balancing problem with task failure via a hybrid variable neighborhood descent-artificial bee colony algorithm. Int. J. Prod. Res. 2023, 61, 2307–2321. [Google Scholar] [CrossRef]

- Tian, G.; Zhang, X.; Fathollahi-Fard, A.M.; Jiang, Z.; Zhang, C.; Yuan, G.; Pham, D.T. Hybrid evolutionary algorithm for stochastic multiobjective disassembly line balancing problem in remanufacturing. Environ. Sci. Pollut. Res. 2023. Online ahead of print. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, K.; Zhu, L.; Wang, Y. A Pareto improved artificial fish swarm algorithm for solving a multi-objective fuzzy disassembly line balancing problem. Expert Syst. Appl. 2017, 86, 165–176. [Google Scholar] [CrossRef]

- Akyar, E.; Akyar, H.; Düzce, S.A. A new method for ranking triangular fuzzy numbers. Int. J. Uncertain. Fuzziness Knowl. Based Syst. 2012, 20, 729–740. [Google Scholar] [CrossRef]

- Zhan, J.; Deng, J.; Xu, Z.; Martínez, L. A three-way decision methodology with regret theory via triangular fuzzy numbers in incomplete multi-scale decision information systems. IEEE Trans. Fuzzy Syst. 2023, 31, 2773–2787. [Google Scholar] [CrossRef]

- Gao, Y.; Lou, S.; Zheng, H.; Tan, J. A data-driven method of selective disassembly planning at end-of-life under uncertainty. J. Intell. Manuf. 2021, 34, 565–585. [Google Scholar] [CrossRef]

- Georgiou, G.S.; Nikolaidis, P.; Lazari, L.; Christodoulides, P. A genetic algorithm driven linear programming for battery optimal scheduling in nearly zero energy buildings. In Proceedings of the 2019 54th International Universities Power Engineering Conference (UPEC), Bucharest, Romania, 3–6 September 2019; pp. 1–6. [Google Scholar]

- Zheng, Y.-J. Water wave optimization: A new nature-inspired metaheuristic. Comput. Oper. Res. 2015, 55, 1–11. [Google Scholar] [CrossRef]

- Zhan, C.; Zhang, X.; Tian, G.; Pham, D.T.; Ivanov, M.; Aleksandrov, A.; Fu, C.; Zhang, J.; Wu, Z. Environment-oriented disassembly planning for end-of-life vehicle batteries based on an improved northern goshawk optimisation algorithm. Environ. Sci. Pollut. Res. 2023, 30, 47956–47971. [Google Scholar] [CrossRef]

- Fathollahi-Fard, A.M.; Tian, G.; Ke, H.; Fu, Y.; Wong, K.Y. Efficient Multi-Objective Metaheuristic Algorithm For Sustainable Harvest Planning Problem. Comput. Oper. Res. 2023, 158, 106304. [Google Scholar] [CrossRef]

- Wang, S.; Guo, X.; Zhou, Y. Improved artificial bee colony algorithm for solving stochastic demolition line balancing problems. Ind. Eng. Manag. 2018, 2, 16–22+32. [Google Scholar] [CrossRef]

- Wang, D.; Liu, G.; Li, R.; Sun, D.; Fu, G.; Li, L. Research on target disassembly sequence planning of discarded mobile phones based on ant colony algorithm. Home Appl. Technol. 2021, 4, 34–38. [Google Scholar]

- Huang, J.; Pham, D.T.; Li, R.; Qu, M.; Wang, Y.; Kerin, M.; Su, S.; Ji, C.; Mahomed, O.; Khalil, R.; et al. An experimental human-robot collaborative disassembly cell. Comput. Ind. Eng. 2021, 155, 107189. [Google Scholar] [CrossRef]

- Nikolaidis, P.; Chatzis, S. Gaussian process-based Bayesian optimization for data-driven unit commitment. Int. J. Electr. Power Energy Syst. 2021, 130, 106930. [Google Scholar] [CrossRef]

- Liu, Q.; Li, X.; Liu, H.; Guo, Z. Multi-objective metaheuristics for discrete optimization problems: A review of the state-of-the-art. Appl. Soft Comput. 2020, 93, 106382. [Google Scholar] [CrossRef]

- Baghizadeh, K.; Zimon, D.; Jum’a, L. Modeling and optimization sustainable forest supply chain considering discount in transportation system and supplier selection under uncertainty. Forests 2021, 12, 964. [Google Scholar] [CrossRef]

- Lee, M.-L.; Behdad, S.; Liang, X.; Zheng, M. Task allocation and planning for product disassembly with human–robot collaboration. Robot. Comput. Manuf. 2022, 76, 102306. [Google Scholar] [CrossRef]

- Wei, T.; Guo, X.; Wang, J.; Qi, L.; Qin, S.; Xu, G. Multi-objective discrete harmony search algorithm for disassembly line balance problems considering human body posture change. In Proceedings of the 4th International Conference on Informatics Engineering & Information Science, Tianjin, China, 19–21 November 2021. [Google Scholar]

- Tian, G.; Zhang, L.; Fathollahi-Fard, A.M.; Kang, Q.; Li, Z.; Wong, K.Y. Addressing a collaborative maintenance planning using multiple operators by a multi-objective metaheuristic algorithm. IEEE Trans. Autom. Sci. Eng. 2023, 1–13. [Google Scholar] [CrossRef]

- Fathollahi-Fard, A.M.; Hajiaghaei-Keshteli, M.; Tavakkoli-Moghaddam, R.; Smith, N.R. Bi-level programming for home health care supply chain considering outsourcing. J. Ind. Inf. Integr. 2022, 25, 100246. [Google Scholar] [CrossRef]

| Order | Name | Tool | Direction | Disassembly Time/s | Priority | Difficulty |

|---|---|---|---|---|---|---|

| 1 | Platen | 1 | +y | 16.83, 17.64, 18.50 | 0 | 0.25 |

| 2 | Electric motor | 1 | +y | 37.35, 40.15, 41.92 | 0 | 0.1 |

| 3 | Coupling | 1 | +y | 22.99, 23.85, 24.07 | 0 | 0.0 |

| 4 | Gearbox | 2 | +y | 41.06, 41.57, 43.20 | 1 | 0 |

| 5 | Machine base | 2 | −x | 28.13, 29.00, 30.01 | 0 | 0 |

| 6 | Slag discharge box | 1 | −x | 10.78, 11.68, 12.22 | 0 | 0.2 |

| 7 | Machine base sealing device | 2 | −x | 21.59, 22.45, 23.53 | 1 | 0.2 |

| 8 | Drive plate and scraper device | 3 | −x | 24.48, 25.39, 25.83 | 1 | 0.15 |

| 9 | Grinding ring and nozzle ring | 3 | +x | 28.08, 28.87, 29.77 | 1 | 0 |

| 10 | Grinding roller assembly | 2 | +x | 11.82, 12.81, 13.95 | 0 | 0.1 |

| 11 | Press frame assembly | 3 | +x | 10.94, 11.66, 12.57 | 1 | 0.2 |

| 12 | Articulated shaft assembly | 1 | +z | 11.78, 12.72, 13.34 | 0 | 0.1 |

| 13 | Machine casing | 2 | +z | 25.65, 26.43, 27.02 | 0 | 0.1 |

| 14 | Rod loading device | 2 | +z | 10.54, 11.26, 12.13 | 0 | 0.25 |

| 15 | Loading oil cylinder | 3 | +y | 27.84, 29.06, 29.41 | 1 | 0 |

| 16 | Separator | 3 | +y | 27.94, 29.06, 29.33 | 1 | 0 |

| 17 | Sealing manifold | 3 | −x | 26.06, 27.08, 28.08 | 0 | 0 |

| 18 | Fire suppression gas piping | 1 | −x | 22.52, 23.54, 24.33 | 0 | 0.15 |

| 19 | High-pressure oil station and low-pressure oil station | 2 | −y | 37.25, 37.91, 39.25 | 0 | 0.1 |

| 20 | Oil–water piping | 2 | −y | 28.10, 28.70, 30.29 | 0 | 0 |

| 21 | Disc drive device | 2 | +z | 28.08, 28.83, 30.14 | 1 | 0 |

| Parameters | Level 1 | Level 2 | Level 3 |

|---|---|---|---|

| N | 30 | 40 | 50 |

| Maxit | 100 | 150 | 200 |

| hmax | 3 | 4 | 5 |

| λ | 1 | 2 | 3 |

| α | 1.3 | 1.5 | 1.8 |

| β | 0.01 | 0.02 | 0.03 |

| Numbers | N | Maxit | hmax | λ | α | β | RPD |

|---|---|---|---|---|---|---|---|

| 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0.1168 |

| 2 | 1 | 1 | 2 | 2 | 3 | 3 | 0.1340 |

| 3 | 1 | 2 | 1 | 3 | 3 | 2 | 0.1665 |

| 4 | 1 | 2 | 3 | 1 | 2 | 3 | 0.1339 |

| 5 | 1 | 3 | 2 | 3 | 2 | 1 | 0.0526 |

| 6 | 1 | 3 | 3 | 2 | 1 | 2 | 0.1446 |

| 7 | 2 | 1 | 1 | 3 | 2 | 3 | 0.0886 |

| 8 | 2 | 1 | 3 | 1 | 3 | 2 | 0.0809 |

| 9 | 2 | 2 | 2 | 2 | 2 | 2 | 0.1320 |

| 10 | 2 | 2 | 3 | 3 | 1 | 1 | 0.1056 |

| 11 | 2 | 3 | 1 | 2 | 3 | 1 | 0.1201 |

| 12 | 2 | 3 | 2 | 1 | 1 | 3 | 0.0969 |

| 13 | 3 | 1 | 2 | 3 | 1 | 2 | 0.1412 |

| 14 | 3 | 1 | 3 | 2 | 2 | 1 | 0.0558 |

| 15 | 3 | 2 | 1 | 2 | 1 | 3 | 0.0495 |

| 16 | 3 | 2 | 2 | 1 | 3 | 1 | 0.0713 |

| 17 | 3 | 3 | 1 | 1 | 2 | 2 | 0.0025 |

| 18 | 3 | 3 | 3 | 3 | 3 | 3 | 0 |

| Level | N | Maxit | hmax | λ | α | β |

|---|---|---|---|---|---|---|

| 1 | 0.249 | 0.206 | 0.181 | 0.167 | 0.218 | 0.174 |

| 2 | 0.208 | 0.220 | 0.209 | 0.212 | 0.155 | 0.223 |

| 3 | 0.107 | 0.139 | 0.174 | 0.185 | 0.191 | 0.168 |

| Order | Scheme | f2 | f3 | |

|---|---|---|---|---|

| 1 | 13, 2, 3, 4, 1, 16, 5, 7, 6, 10, 12, 18, 17, 21, 14, 15, 11, 8, 9, 19, 20 | 575.6, 600.7, 627.4 | 102 | 23 |

| 2 | 13, 2, 3, 1, 16, 19, 10, 4, 12, 18, 17, 21, 14, 11, 15, 8, 9, 5, 7, 20, 6 | 572.3, 597.1, 623.5 | 106 | 23 |

| 3 | 13, 19, 1, 16, 2, 3, 4, 10, 12, 18, 17, 21, 14, 15, 11, 8, 9, 5, 7, 20, 6 | 573.4, 598.3, 624.8 | 104 | 23 |

| 4 | 13, 2, 3, 4, 5, 7, 1, 16, 10, 12, 18, 17, 21, 14, 11, 15, 8, 9, 6, 19, 20 | 575.7, 600.8, 627.6 | 97 | 24 |

| 5 | 13, 1, 16, 2, 3, 4, 19, 20, 5, 7, 10, 12, 18, 17, 21, 14, 15, 11, 9, 8, 6 | 567.5, 591.9, 617.5 | 108 | 19 |

| 6 | 13, 2, 3, 1, 16, 4, 20, 19, 5, 7, 10, 12, 18, 6, 17, 21, 14, 11, 9, 8, 15 | 562.9, 586.9, 611.9 | 115 | 17 |

| 7 | 13, 1, 16, 2, 3, 4, 19, 20, 10, 5, 7, 12, 18, 6, 17, 21, 14, 15, 11, 9, 8 | 565.2, 589.4, 614.7 | 114 | 18 |

| 8 | 13, 1, 16, 2, 3, 4, 5, 7, 19, 20, 10, 6, 12, 18, 17, 21, 14, 11, 9, 8, 15 | 566.4, 590.7, 616.2 | 111 | 19 |

| 9 | 13, 1, 2, 16, 3, 4, 5, 7, 10, 20, 6, 12, 18, 17, 21, 14, 15, 11, 9, 8, 19 | 569.9, 594.5, 620.5 | 107 | 21 |

| 10 | 13, 19, 1, 16, 2, 3, 4, 10, 5, 7, 12, 17, 18, 21, 14, 15, 11, 9, 8, 6, 20 | 573.3, 598.2, 624.6 | 105 | 22 |

| Order | Name | Tool | Direction | Disassembly Time/s | Priority | Difficulty |

|---|---|---|---|---|---|---|

| 1 | Oil inlet plug | 1 | z | 3.12, 4.08, 4.99 | 0 | 0 |

| 2 | Rear bearing cover | 3 | z | 5.78, 6.54, 7.17 | 0 | 0.25 |

| 3 | Speed sensors | 3 | −y | 8.70, 8.97, 9.70 | 0 | 0.15 |

| 4 | Transmission cover | 2 | y | 5.97, 6.14, 6.88 | 0 | 0 |

| 5 | Snap Ring | 4 | y | 12.35, 13.21, 13.82 | 1 | 0 |

| 6 | Front bearing cover | 1 | −y | 45.42, 46.64, 47.75 | 1 | 0 |

| 7 | Transmission rear housing | 5 | y | 33.73, 33.93, 34.66 | 1 | 0.15 |

| 8 | Transmission front housing | 3 | y | 10.14, 10.37, 10.97 | 0 | 0.25 |

| 9 | Intermediate shaft | 1 | −y | 18.59, 19.07, 19.31 | 0 | 0.1 |

| 10 | Fork pulling | 3 | −y | 11.65, 12.38, 12.75 | 0 | 0.12 |

| 11 | Input shaft | 2 | −y | 7.62, 8.03, 8.58 | 1 | 0 |

| 12 | Output shaft | 3 | y | 7.54, 8.72, 9.26 | 0 | 0 |

| 13 | Fastener 1 | 5 | −y | 15.92, 16.48, 16.79 | 0 | 1 |

| 14 | Fastener 2 | 5 | −y | 35.76, 36.62, 38.85 | 0 | 0 |

| 15 | Fastener 3 | 4 | −y | 24.80, 25.53, 26.19 | 0 | 0.15 |

| 16 | Fastener 4 | 4 | −y | 23.49, 24.10, 25.06 | 1 | 0.25 |

| 17 | Fastener 5 | 5 | y | 28.07, 28.60, 29.60 | 1 | 0.2 |

| 18 | Fastener 6 | 5 | −y | 32.43, 33.47, 34.30 | 0 | 0.1 |

| 19 | Fastener 7 | 3 | −y | 10.34, 10.81, 12.05 | 0 | 0.15 |

| 20 | Fastener 8 | 2 | −y | 4.69, 4.98, 5.09 | 0 | 1 |

| 21 | Fastener 9 | 2 | y | 3.98, 4.49, 4.68 | 0 | 1 |

| 22 | Fastener 10 | 5 | y | 15.68, 16.37, 16.99 | 1 | 0 |

| 23 | Fastener 11 | 4 | −y | 5.64, 6.43, 6.51 | 0 | 1 |

| 24 | Fastener 12 | 4 | y | 7.73, 8.37, 8.77 | 0 | 0.15 |

| 25 | Fastener 13 | 5 | y | 10.74, 11.25, 11.91 | 0 | 0.25 |

| 26 | Fastener 14 | 3 | y | 7.05, 7.68, 7.89 | 0 | 0 |

| 27 | Fastener 15 | 4 | −y | 19.05, 19.38, 20.34 | 1 | 0.1 |

| 28 | Fastener 16 | 5 | y | 23.44, 24.11, 24.68 | 0 | 0.1 |

| 29 | Fastener 17 | 4 | −y | 15.22, 15.62, 16.18 | 0 | 0.25 |

| 30 | Fastener 18 | 4 | y | 15.29, 15.93, 16.24 | 0 | 0.15 |

| 31 | Fastener 19 | 3 | −y | 6.01, 6.39, 6.63 | 0 | 1 |

| 32 | Fastener 20 | 3 | x | 4.03, 4.29, 4.52 | 1 | 1 |

| 33 | Fastener 21 | 3 | x | 5.38, 5.64, 6.08 | 0 | 1 |

| 34 | Fastener 22 | 3 | x | 11.55, 12.08, 12.20 | 0 | 0.15 |

| 35 | Fastener 23 | 2 | −x | 7.52, 7.78, 8.20 | 1 | 0 |

| 36 | Fastener 24 | 4 | −x | 16.73, 17.02, 17.36 | 0 | 0 |

| 37 | Fastener 25 | 3 | x | 9.53, 10.05, 11.55 | 1 | 0.15 |

| 38 | Fastener 26 | 4 | −x | 12.62, 12.86, 13.10 | 0 | 0.25 |

| 39 | Fastener 27 | 3 | −x | 8.71, 9.88, 10.42 | 0 | 0.15 |

| 40 | Fastener 28 | 3 | −x | 10.86, 11.17, 11.34 | 0 | 0.25 |

| Order | Scheme | f2 | f3 | |

|---|---|---|---|---|

| 1 | 22, 17, 25, 13, 19, 20, 21, 4, 15, 16, 18, 3, 2, 26, 24, 23, 5, 35, 39, 40, 34, 33, 32, 37, 31, 38, 36, 7, 9, 28, 14, 29, 1, 30, 27, 6, 10, 8, 11, 12 | 737.8, 771.5, 809.6 | 234 | 41 |

| 2 | 20, 21, 17, 25, 22, 14, 19, 3, 15, 16, 18, 13, 4, 1, 2, 26, 24, 23, 5, 36, 32, 37, 34, 35, 38, 40, 39, 31, 33, 7, 9, 28, 30, 27, 29, 6, 10, 8, 12, 11 | 734.2, 767.6, 805.1 | 244 | 38 |

| 3 | 17, 22, 14, 18, 25, 13, 16, 15, 2, 20, 21, 24, 26, 23, 5, 32, 35, 37, 38, 31, 19, 34, 36, 39, 33, 40, 1, 7, 4, 3, 9, 27, 29, 30, 28, 6, 10, 8, 12, 11 | 752.9, 787.9, 828.1 | 212 | 49 |

| 4 | 18, 17, 22, 15, 16, 20, 14, 19, 3, 13, 1, 2, 21, 4, 24, 23, 26, 25, 5, 37, 32, 34, 33, 35, 38, 39, 36, 40, 31, 7, 9, 27, 29, 30, 28, 6, 10, 8, 12, 11 | 744.4, 778.7, 817.4 | 231 | 41 |

| 5 | 13, 16, 15, 18, 17, 22, 25, 20, 2, 21, 24, 26, 23, 5, 32, 35, 37, 38, 31, 3, 14, 34, 36, 19, 33, 40, 39, 7, 1, 4, 9, 27, 29, 30, 28, 6, 10, 8, 11, 12 | 761.0, 796.7, 838.0 | 210 | 53 |

| 6 | 16, 20, 18, 25, 22, 17, 14, 13, 15, 19, 3, 2, 23, 26, 24, 5, 37, 32, 35, 34, 31, 33, 36, 38, 40, 39, 7, 1, 21, 4, 9, 30, 27, 29, 28, 6, 10, 8, 12, 11 | 740.1, 774.04, 812.4 | 218 | 42 |

| 7 | 18, 17, 16, 22, 21, 14, 15, 20, 3, 2, 26, 25, 24, 23, 5, 35, 39, 40, 34, 33, 32, 37, 31, 38, 36, 7, 13, 19, 4, 1, 9, 27, 29, 30, 28, 6, 10, 8, 12, 11 | 742.4, 776.5, 815.2 | 217 | 43 |

| 8 | 16, 22, 18, 17, 3, 19, 15, 13, 20, 2, 26, 25, 24, 23, 5, 35, 39, 40, 34, 33, 32, 37, 31, 38, 36, 7, 14, 1, 21, 4, 9, 27, 29, 28, 30, 6, 10, 8, 11, 12 | 745.9, 780.3, 819.5 | 214 | 45 |

| 9 | 22, 17, 14, 18, 25, 21, 13, 3, 19, 1, 20, 16, 15, 2, 26, 24, 23, 5, 34, 33, 32, 37, 31, 38, 36, 39, 40, 35, 7, 4, 9, 27, 29, 28, 30, 6, 10, 8, 12, 11 | 736.5, 770.1, 807.9 | 241 | 39 |

| 10 | 22, 16, 17, 14, 19, 21, 25, 15, 3, 18, 2, 23, 26, 24, 5, 37, 32, 35, 20, 39, 4, 40, 33, 13, 34, 38, 36, 31, 7, 9, 28, 30, 27, 29, 1, 6, 10, 8, 11, 12 | 769.2, 805.6, 848.1 | 209 | 58 |

| Case study A | |||

| Algorithms | HV | Spread | CPU (based on s) |

| NSGA-II | 0.73 | 0.79 | 12.91 |

| MODABC | 0.75 | 0.73 | 14.61 |

| ACO | 0.70 | 0.77 | 14.32 |

| EWWO | 0.82 | 0.69 | 13.15 |

| Case study B | |||

| Algorithms | HV | Spread | CPU (based on s) |

| NSGA-II | 0.69 | 0.82 | 46.29 |

| MODABC | 0.72 | 0.75 | 47.58 |

| ACO | 0.65 | 0.80 | 53.34 |

| EWWO | 0.78 | 0.73 | 45.57 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, Y.; Zhan, C.; Aljuaid, M. Multi-Objective Disassembly Sequence Planning in Uncertain Industrial Settings: An Enhanced Water Wave Optimization Algorithm. Processes 2023, 11, 3057. https://doi.org/10.3390/pr11113057

Fan Y, Zhan C, Aljuaid M. Multi-Objective Disassembly Sequence Planning in Uncertain Industrial Settings: An Enhanced Water Wave Optimization Algorithm. Processes. 2023; 11(11):3057. https://doi.org/10.3390/pr11113057

Chicago/Turabian StyleFan, Yongsheng, Changshu Zhan, and Mohammed Aljuaid. 2023. "Multi-Objective Disassembly Sequence Planning in Uncertain Industrial Settings: An Enhanced Water Wave Optimization Algorithm" Processes 11, no. 11: 3057. https://doi.org/10.3390/pr11113057