A Comprehensive Review of the Properties, Performance, Combustion, and Emissions of the Diesel Engine Fueled with Different Generations of Biodiesel

Abstract

:1. Introduction

2. Biodiesel Production Technology

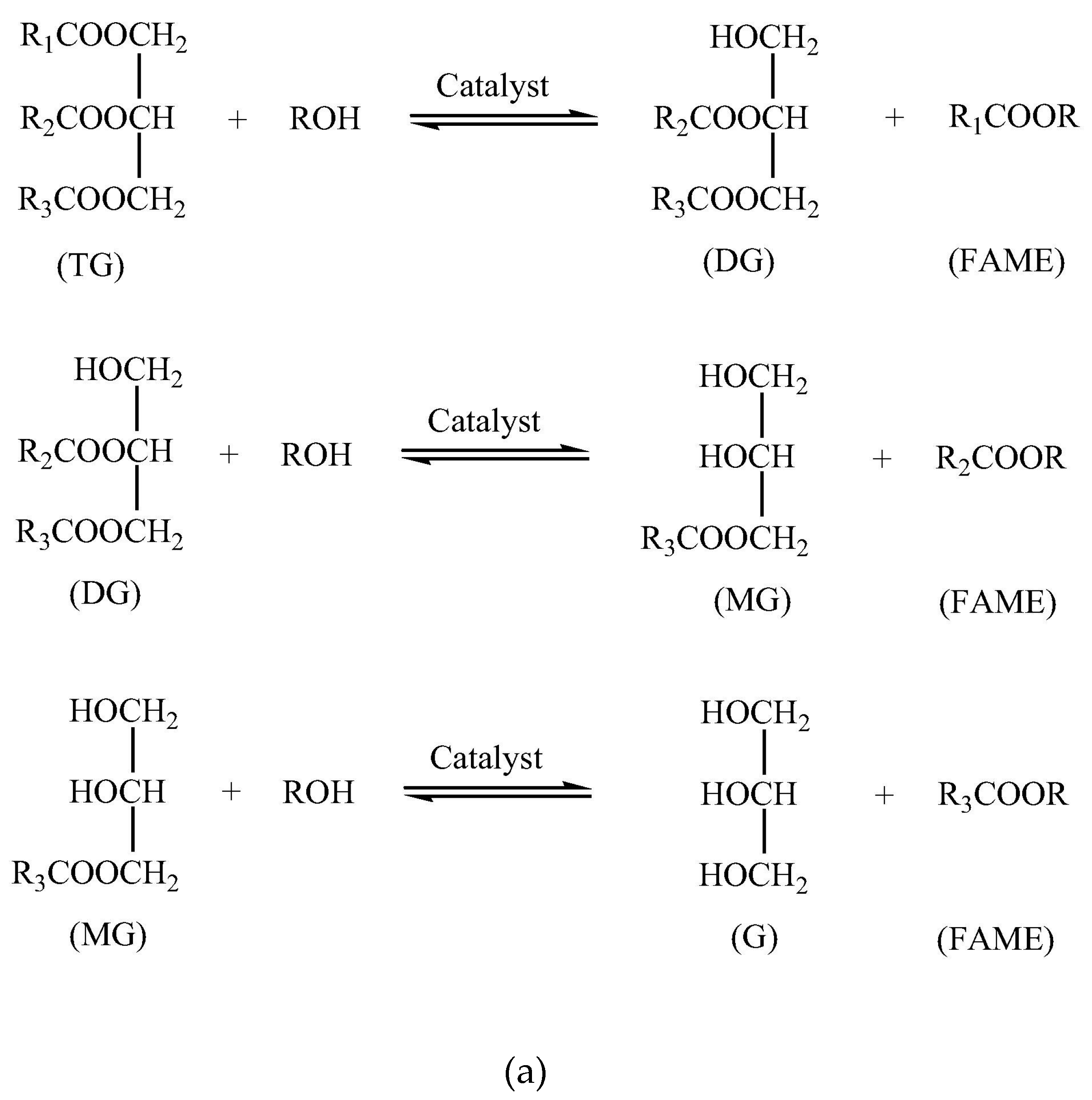

2.1. Transesterification

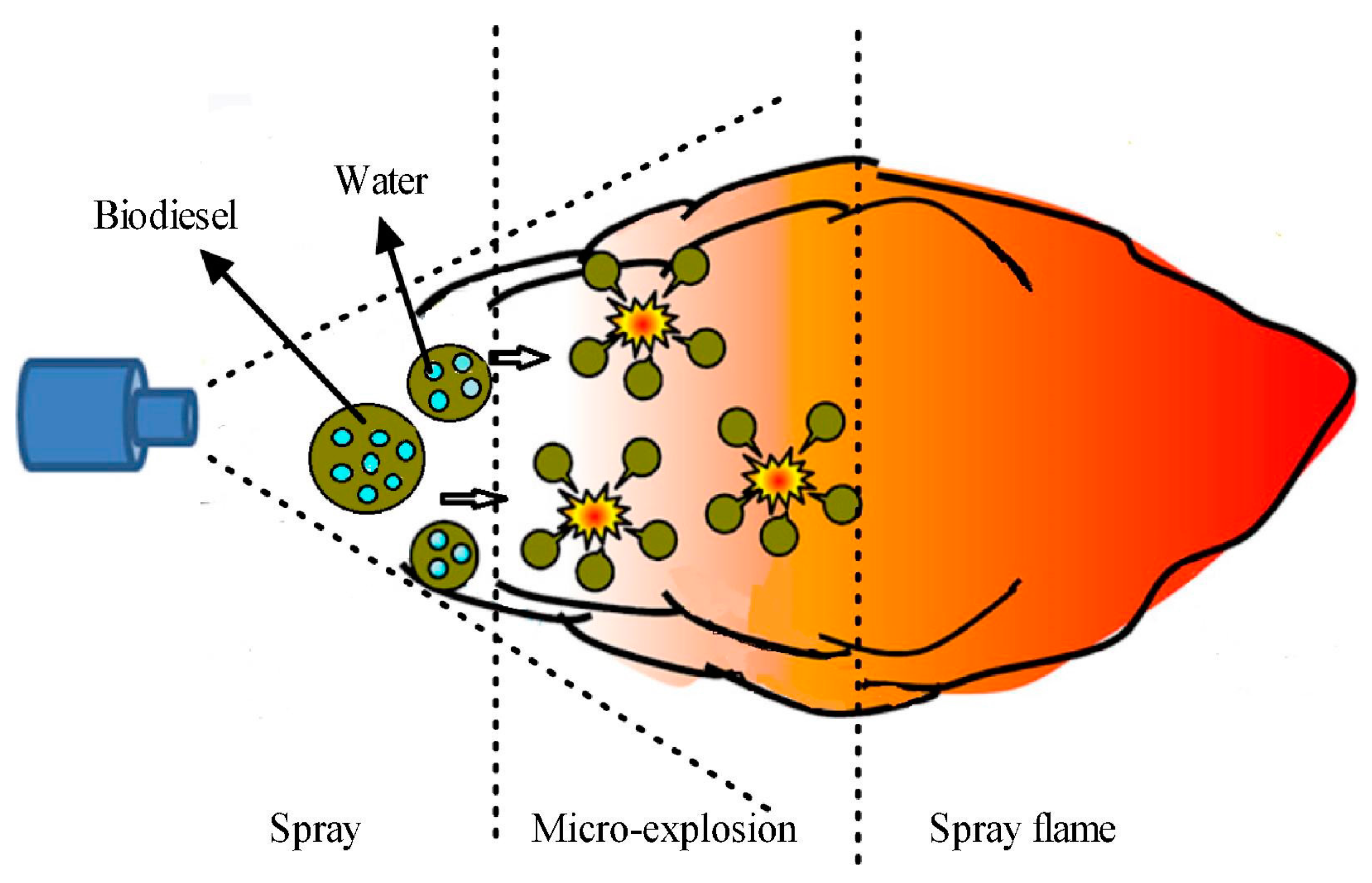

2.2. Micro-Emulsification Technology

2.3. Pyrolysis

| Pyrolysis Process | Residence Time (s) | Heating Rate (K/s) | Particle Size (mm) | Temp (K) |

|---|---|---|---|---|

| Slow | 450–550 | 0.1–1 | 5–50 | 550–950 |

| Fast | 0.5–10 | 10–200 | <1 | 850–1250 |

| Flash | <0.5 | >1000 | <0.2 | 1050–1300 |

2.4. Microwave/Ultrasonic-Assisted Production Technology

3. Feedstocks and Properties of Different Generations of Biodiesel

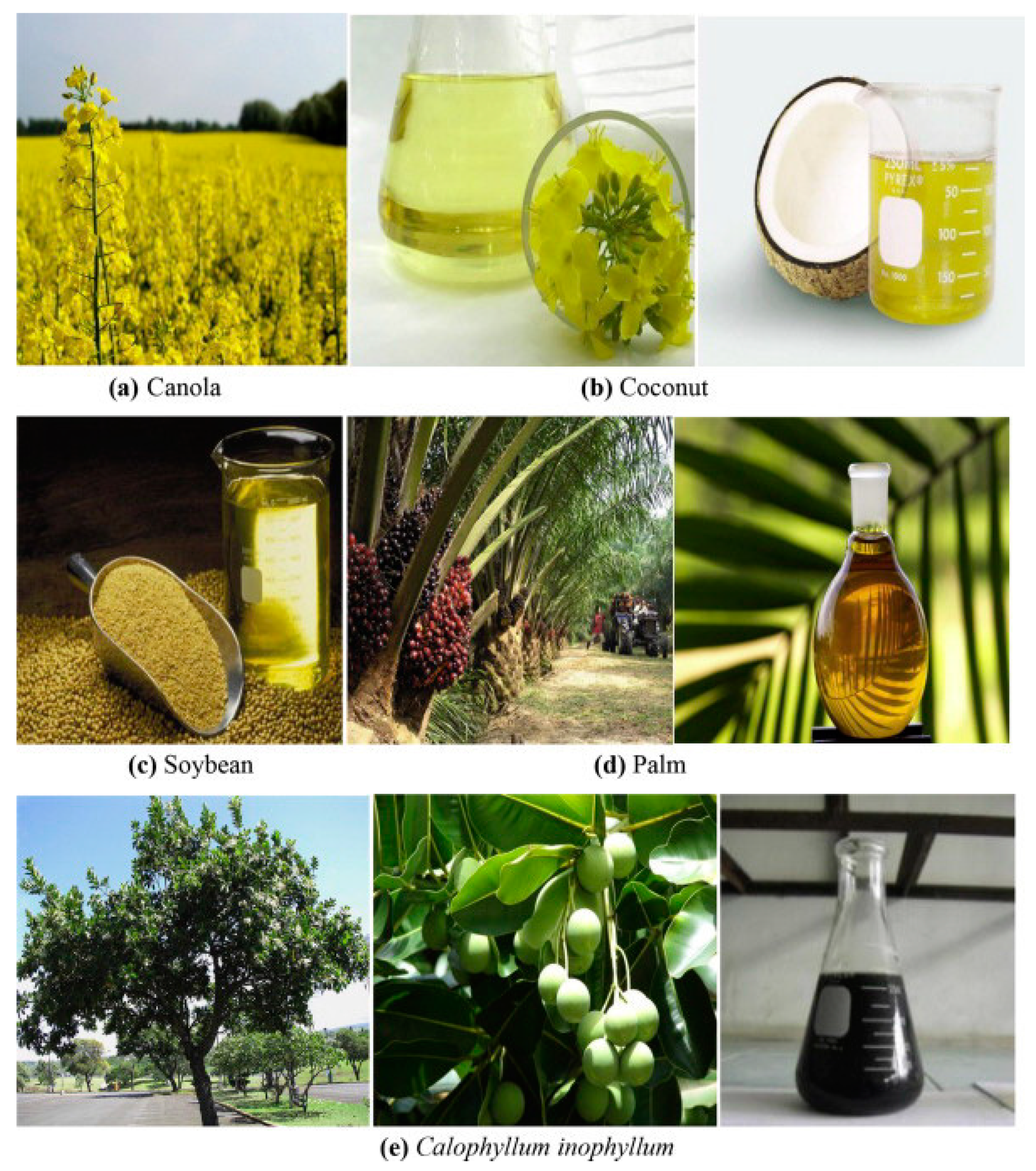

3.1. Feedstocks and Properties of First-Generation Biodiesel

| Edible Oil (1st Generation) | Non-Edible Oil (2nd Generation) | Waste Oils (3rd Generation) | Solar Biodiesel (4th Generation) |

|---|---|---|---|

| Almond | Babassu | Animal waste fat | Genetic algae |

| Canola | Carapa | Algae | Microorganisms |

| Cotton-seed | Castor | Chlorella | Solar fuels |

| Coconut | Camelina | Chicken waste fat | |

| Corn | Croton | Fish oil | |

| Groundnut | ETH-mustard | Grease-derived | |

| Hazelnut | Jatropha | Leather waste fat | |

| Moringa | Karanja | Lard | |

| Mustard | Linseed | Marginatum algae | |

| Olive-pomace | Mahua | Spirulina-platensis | |

| Palm | Meliaceae | Sheep fat raw oil | |

| Peanut | Merrill | Sheep skin oil | |

| Poppy-seed | Milkweed | Tallow oil | |

| Rapeseed | Nahar | Turkey render fat | |

| Rice-bran | Neem | Waste cooking oil | |

| Safflower | Papaya-seed | Waste fish oil | |

| Sal-seed | Polanga | ||

| Sesame | Poon | ||

| Soybean | Rubber | ||

| Sunflower | Stone-fruit-kernel | ||

| Tobacco | |||

| Terminalia-catappa | |||

| Terminalia-belerica |

| First Generation Biodiesel | Density (kg/m3) | Kinematic Viscosity (mm2/s) | Cetane Number | Cloud Point (°C) | Flash Point (°C) | Pour Point (°C) | Heating Value (MJ/kg) |

|---|---|---|---|---|---|---|---|

| Diesel | 850 | 2.44–2.60 | 47–50 | - | 68–75 | −20 | 42–44.3 |

| Almond | 881 | 4.90 | 59 | - | 145 | - | 41.761 |

| Canola | 878 | 4.42 | 54 | −3.25 | 172.36 | −8 | 38.75–40.748 |

| Cotton-seed | 887 | 4.19 | 48.1 | 1.7 | 210 | −12.5 | 39.75 |

| Coconut | 867 | 3.20 | 64.65 | −1.6 | 113.83 | −8.3 | 35.2–38.2 |

| Corn | 883 | 4.19 | 55.4 | −3 | 171 | −2 | 39.9–43.1 |

| Groundnut | 920 | 4.40 | 59.85 | 8 | 132 | 3 | 39.8 |

| Hazelnut | 896 | 4.81 | 62.95 | −7.65 | 172.7 | −6 | 39.58 |

| Moringa | 873 | 4.92 | 64.57 | 18 | 173.3 | 16.5 | 40.89 |

| Mustard | 879 | 5.53 | 56 | 16 | 169.16 | −18 | 40.4 |

| Olive-pomace | 894 | 4.26 | 56.3 | 2 | 138 | 6 | 39.96 |

| Palm | 870 | 4.53 | 60.21 | 14.25 | 176.7 | 14.33 | 34.4–40.13 |

| Peanut | 878.5 | 4.69 | 58.24 | 12.6 | 176 | 11.5 | 35.33 |

| Poppy-seed | 889 | 4.37 | 58 | −8 | 175 | −18 | 42.085 |

| Rapeseed | 879 | 4.40 | 48.25 | −3.5 | 169.5 | −11 | 35.8–41.1 |

| Rice-bran | 881 | 4.40 | 51.15 | 5 | 175 | −11 | 40.87 |

| Safflower | 879 | 4.18 | 51.1 | −4 | 174 | −7 | 42.2 |

| Sal-seed | 879 | 5.44 | 52.5 | 18 | 143.5 | 12 | 39.96 |

| Sesame | 867 | 4.23 | 58.97 | 0.5 | 176.67 | −4 | 40.25 |

| Soybean | 882 | 4.15 | 44.7 | 0 | 140.1 | −3.2 | 35.74–39.84 |

| Sunflower | 869 | 4.26 | 45.7 | 1.33 | 180.33 | −2 | 34.71–40.6 |

3.2. Feedstocks and Properties of Second-Generation Biodiesel

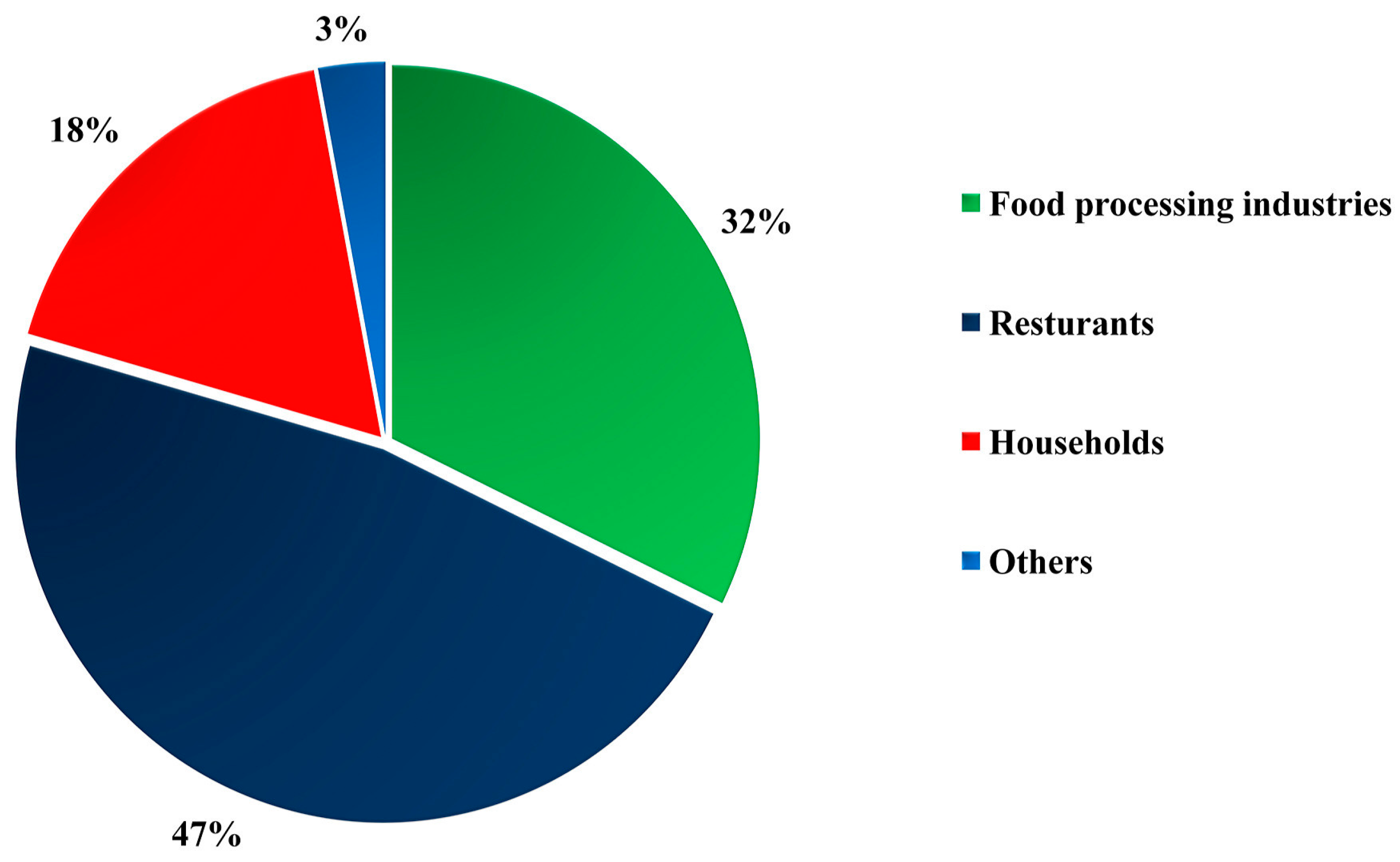

3.3. Feedstocks and Properties of Third-Generation Biodiesel

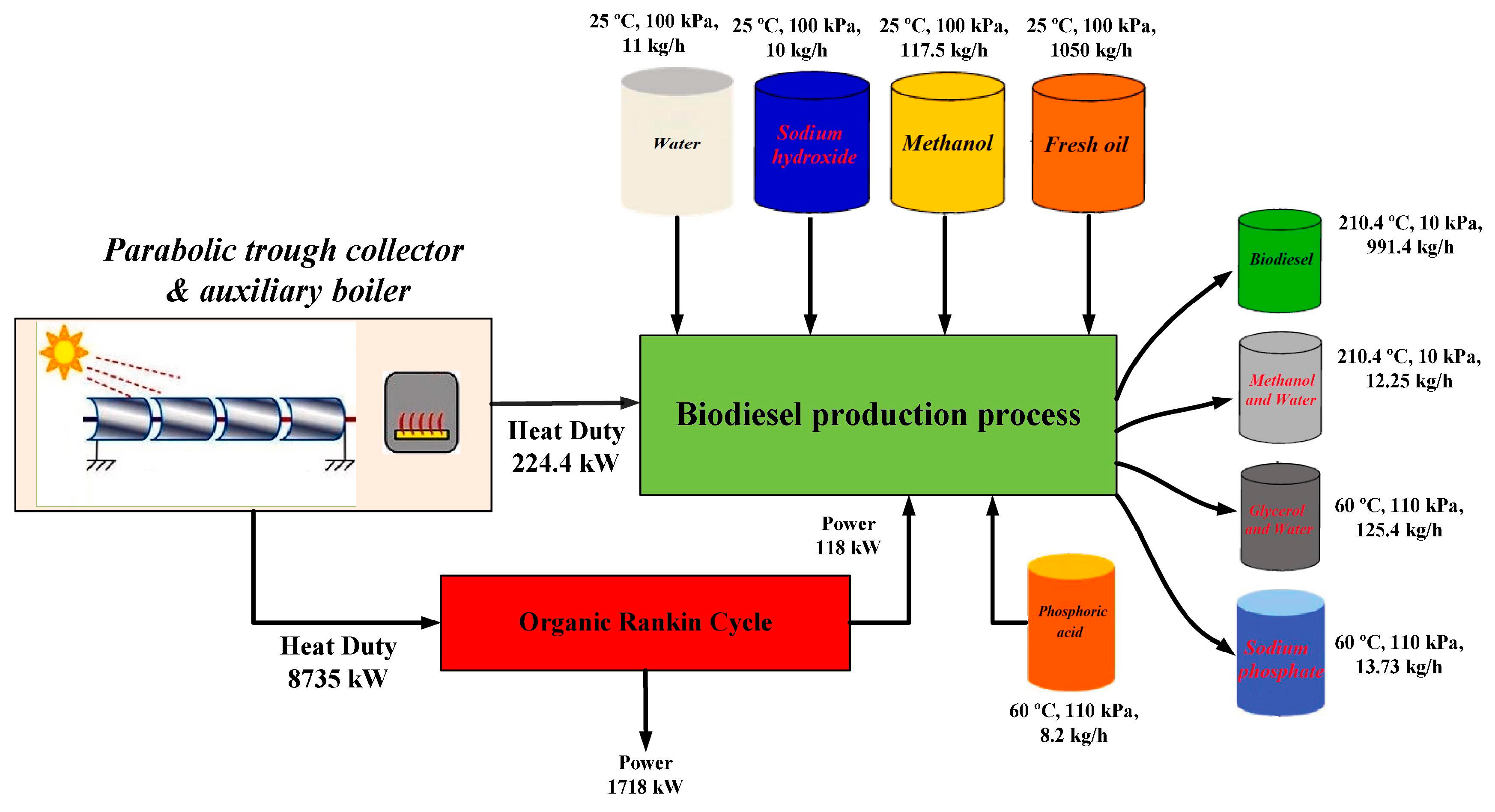

3.4. Research on the Fourth-Generation Biodiesel

4. Effects of Different Generations of Biodiesel on Engine Performance

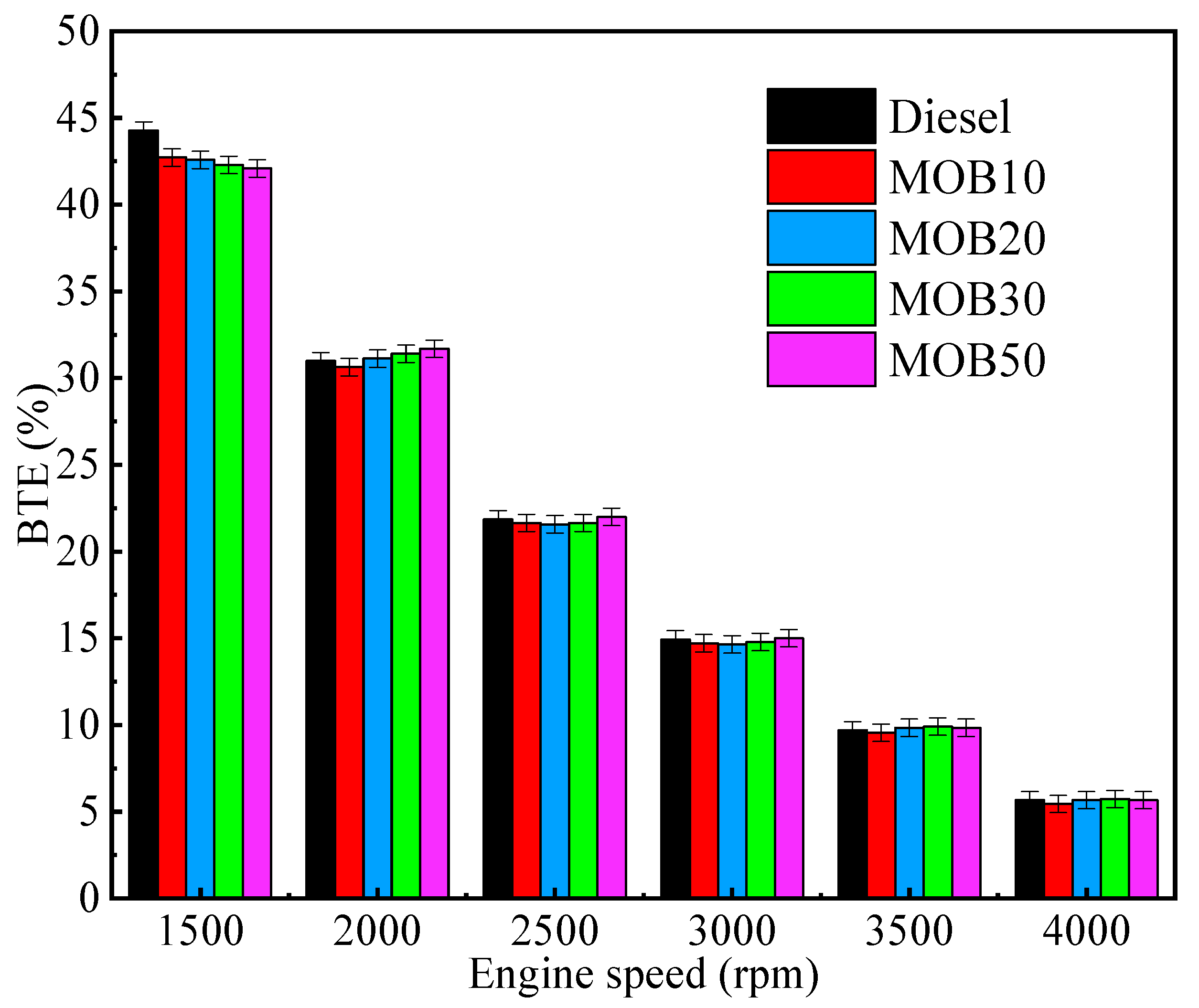

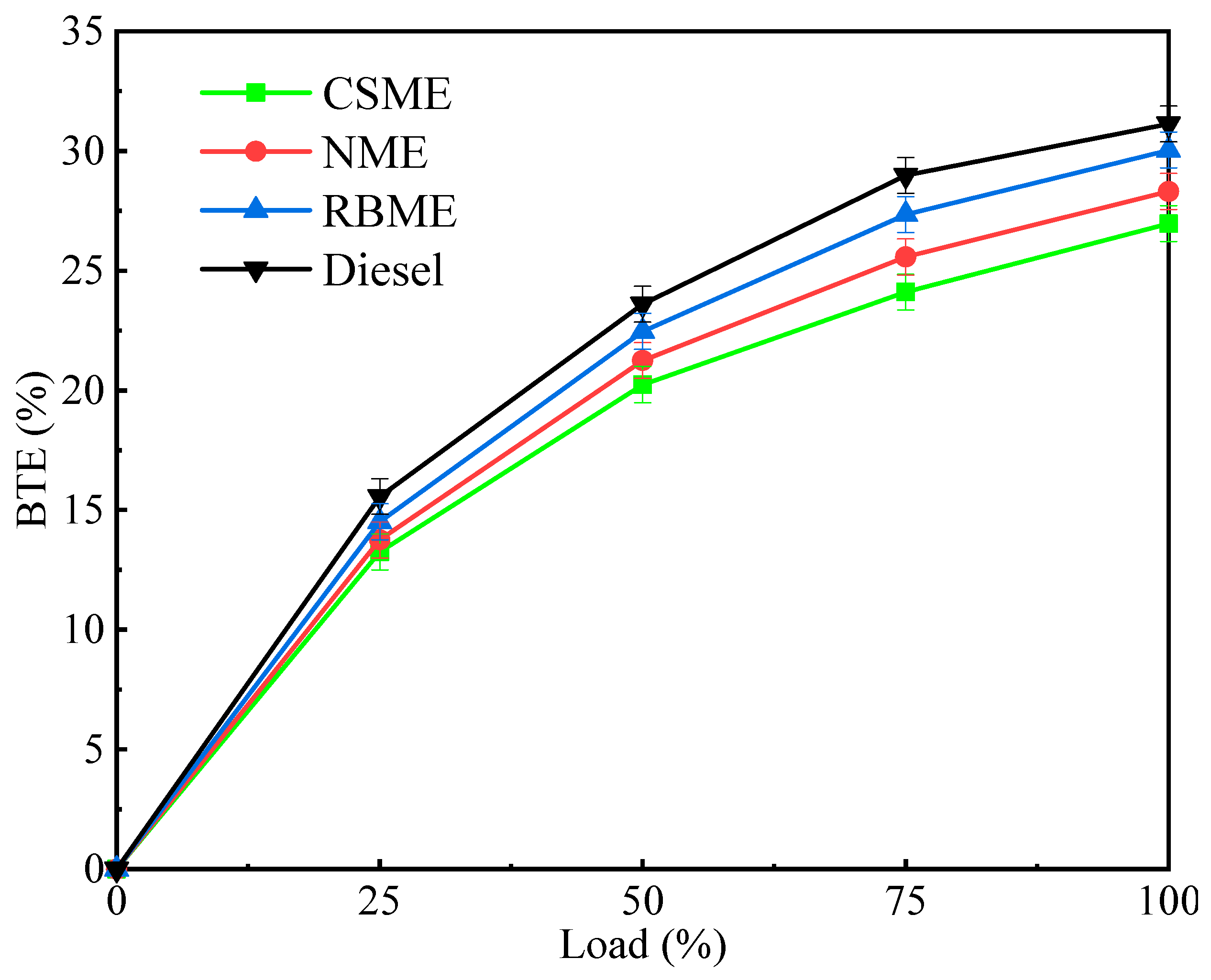

4.1. Effect on Brake Thermal Efficiency

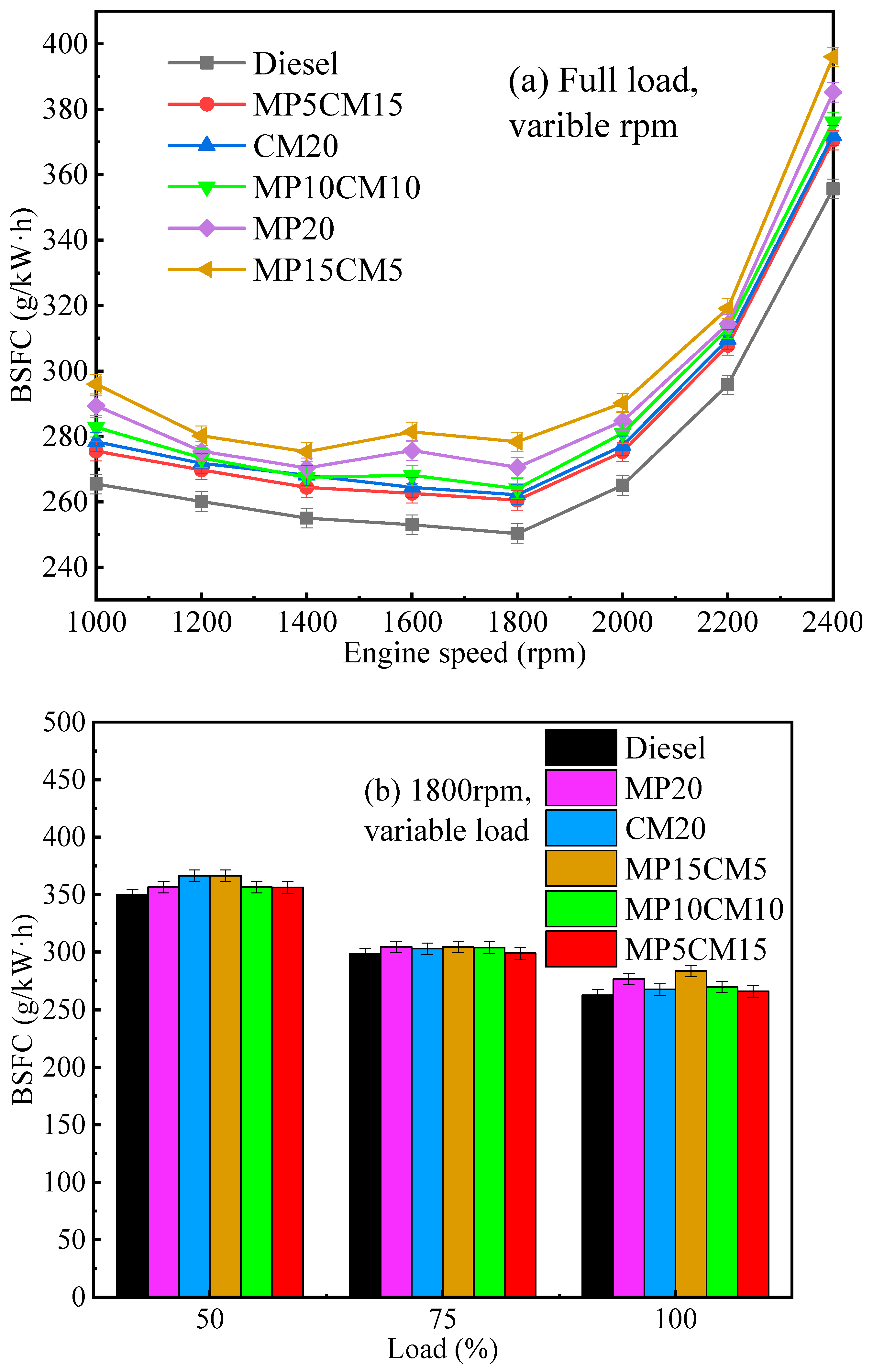

4.2. Effect on Brake Specific Fuel Consumption

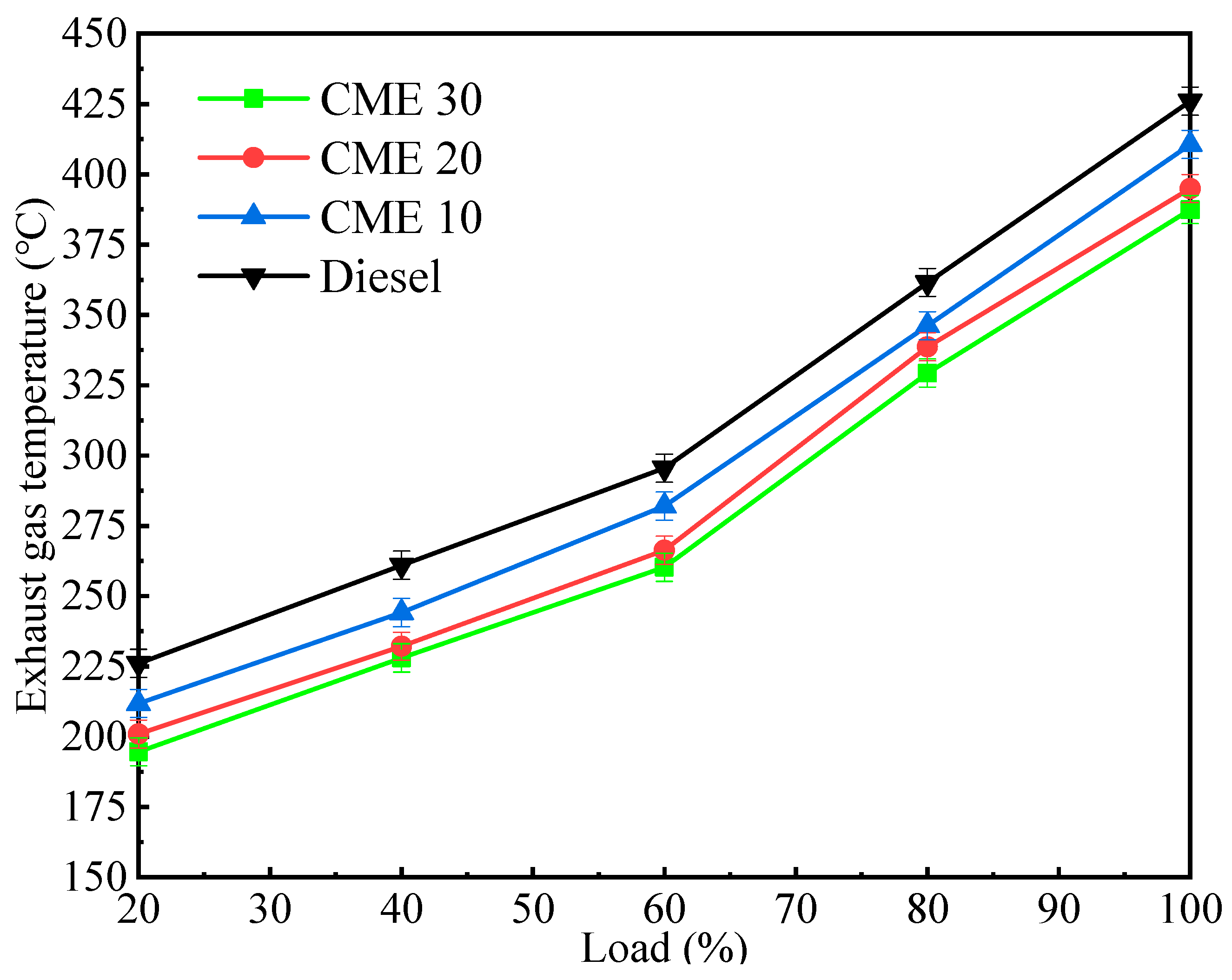

4.3. Effect on Exhaust Gas Temperature

4.4. Summary of Performance Analysis

5. Effects of Different Generations of Biodiesel on Engine Emissions

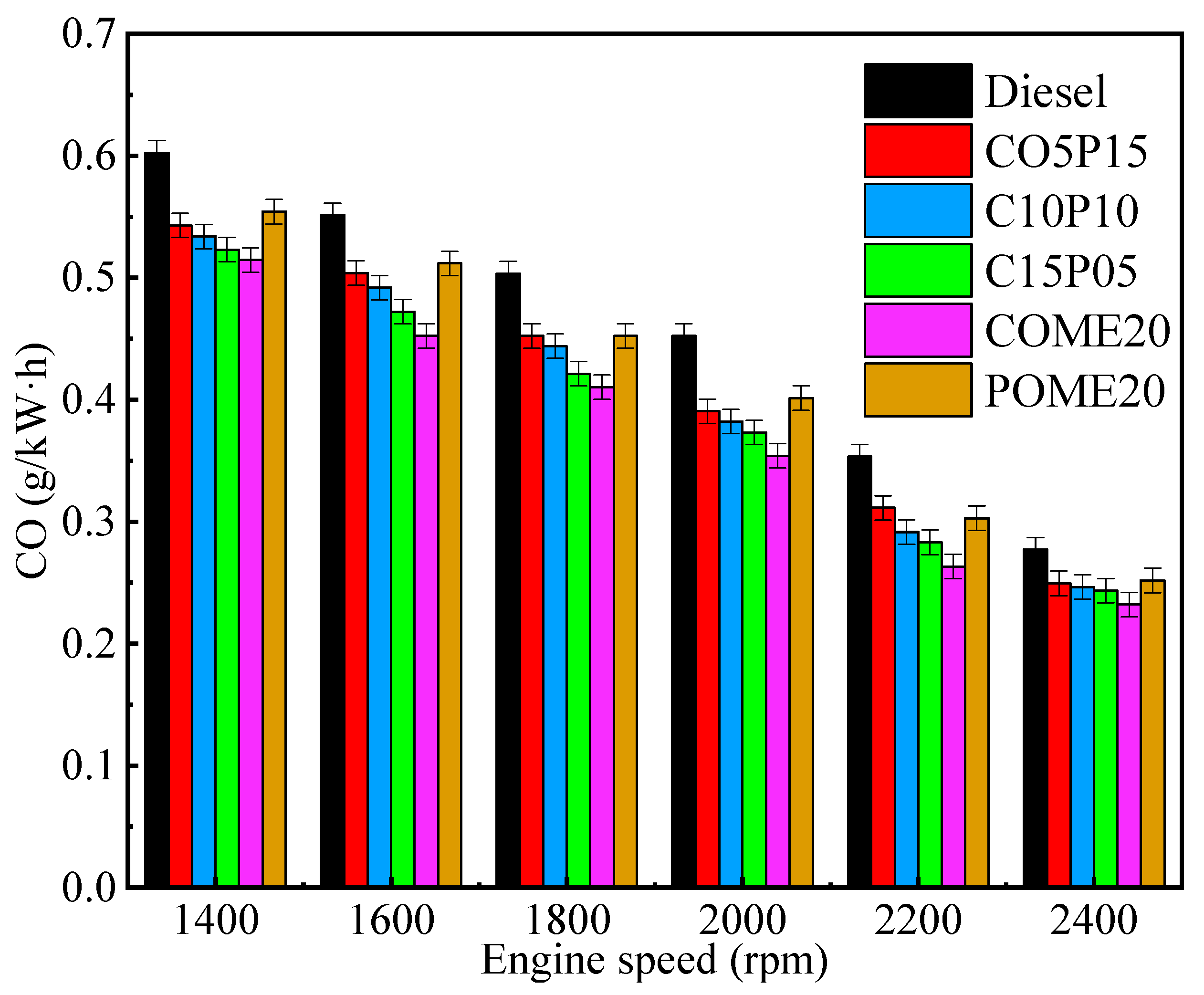

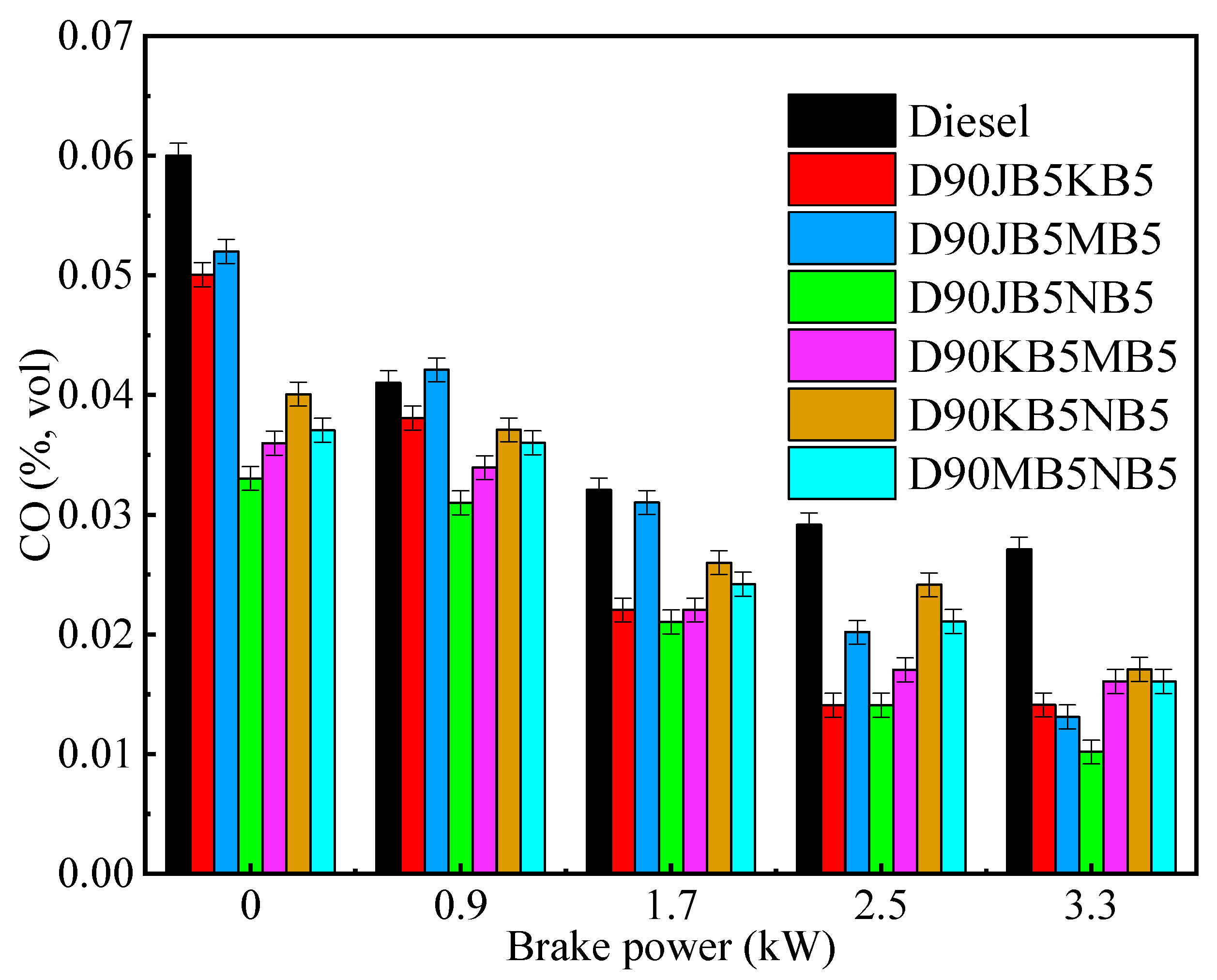

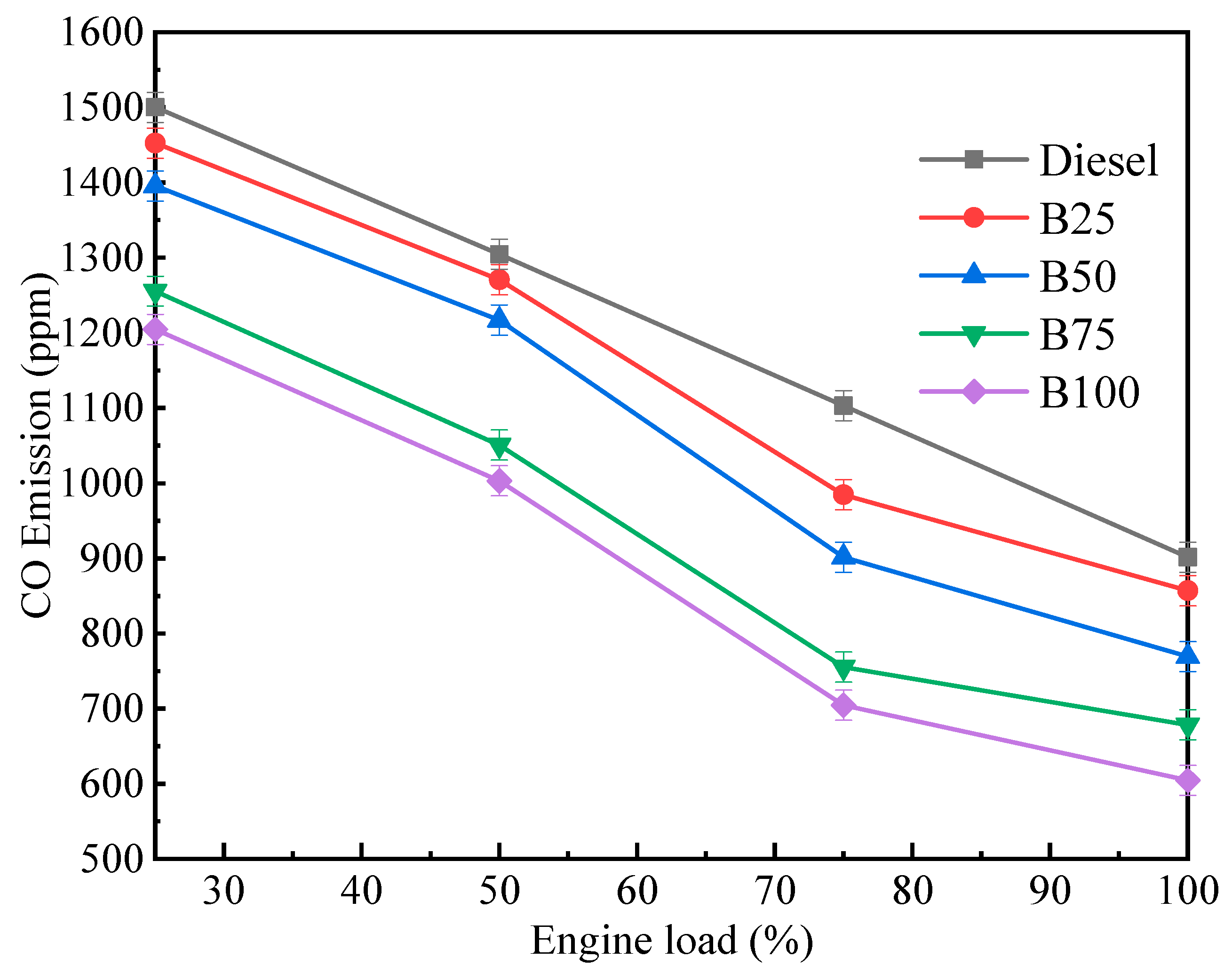

5.1. Effects on CO Emissions

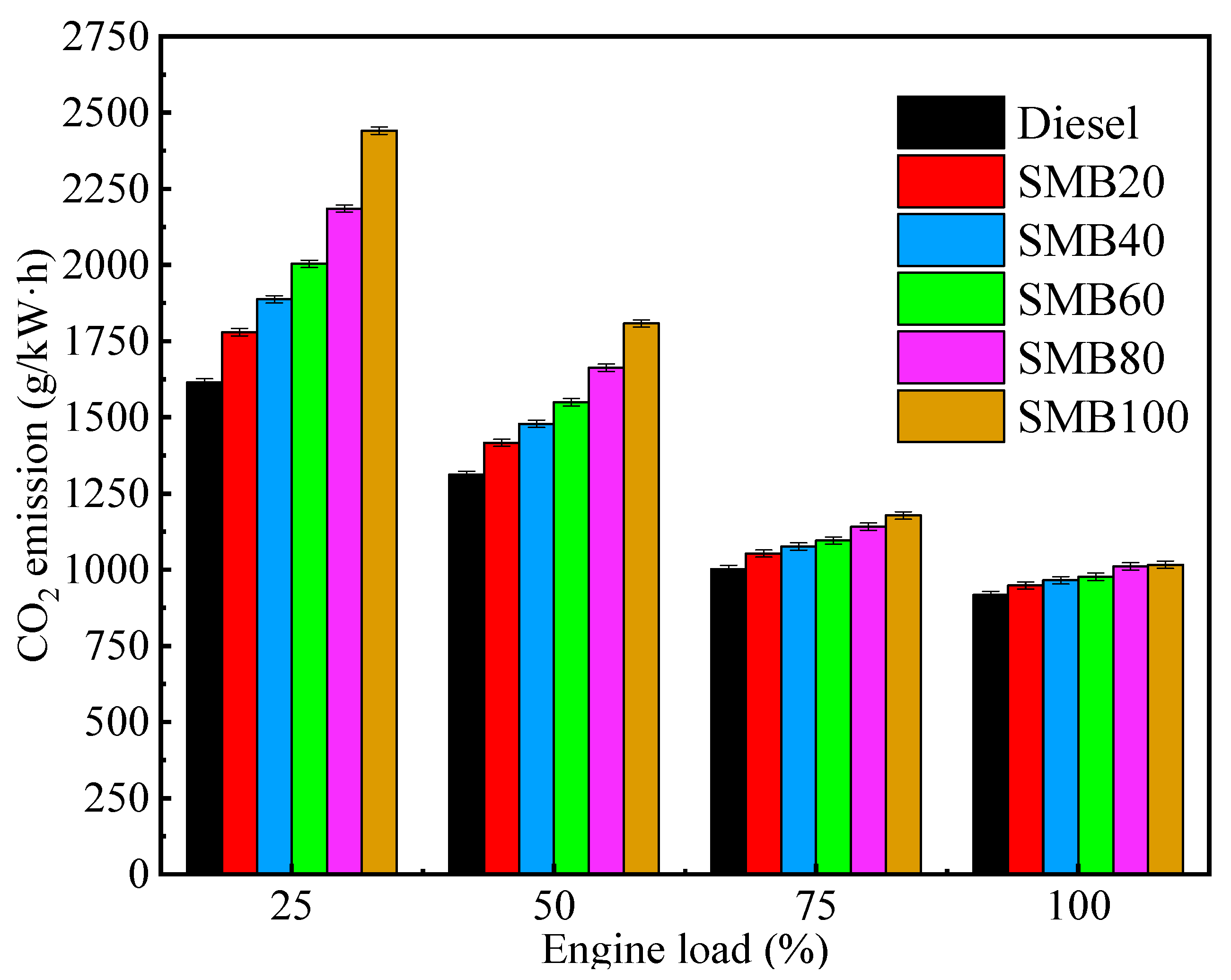

5.2. Effect on CO2 Emissions

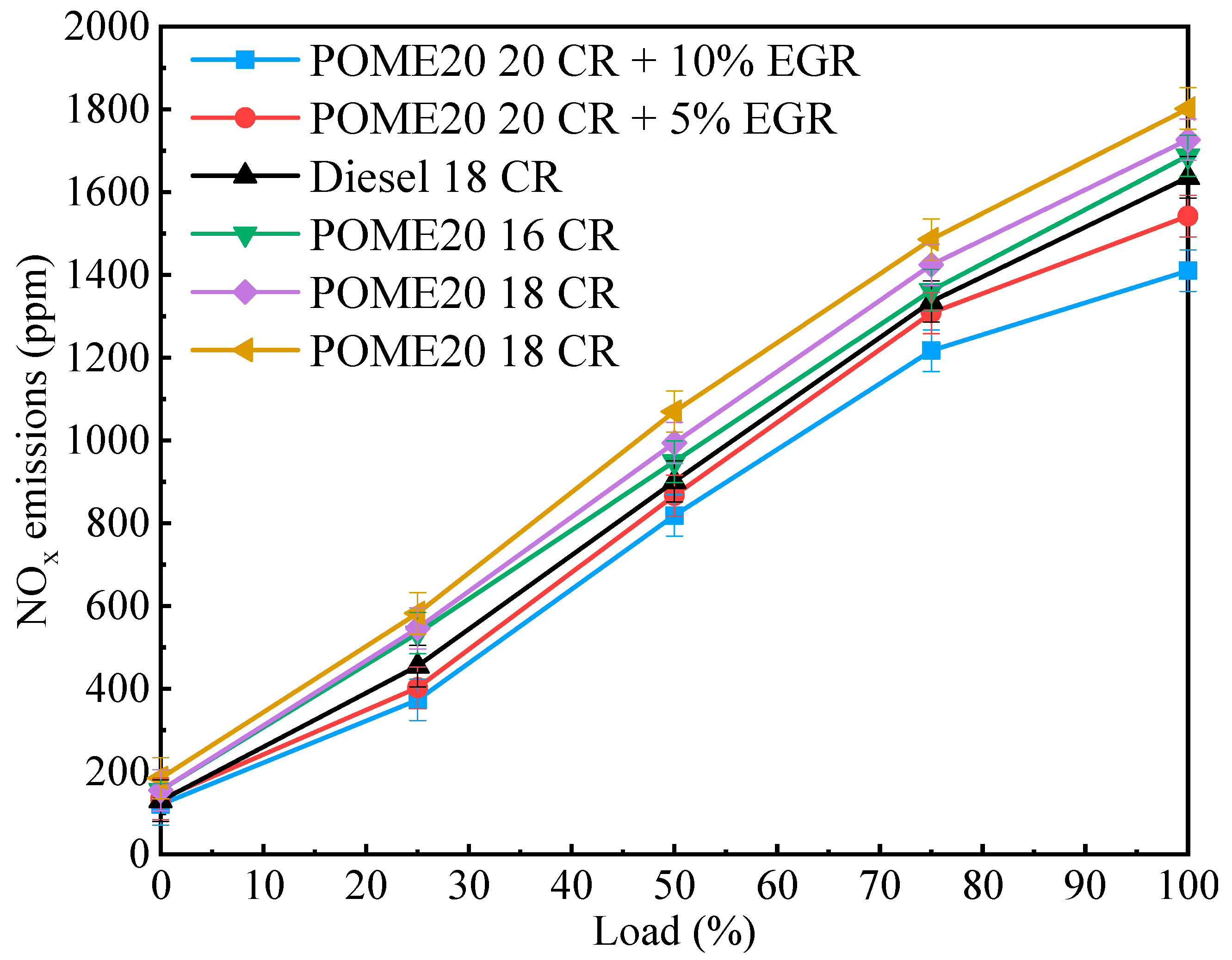

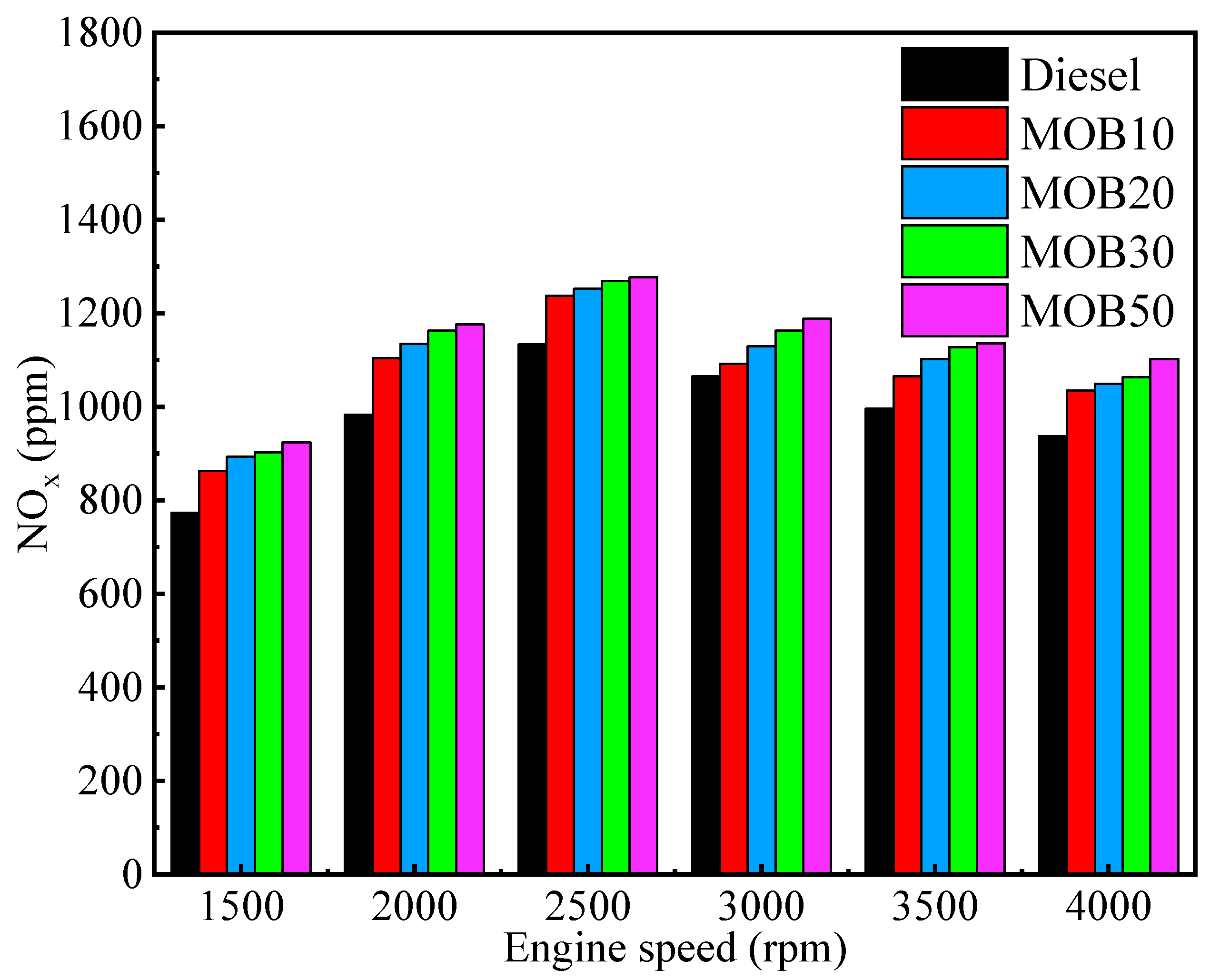

5.3. Effect on NOx Emissions

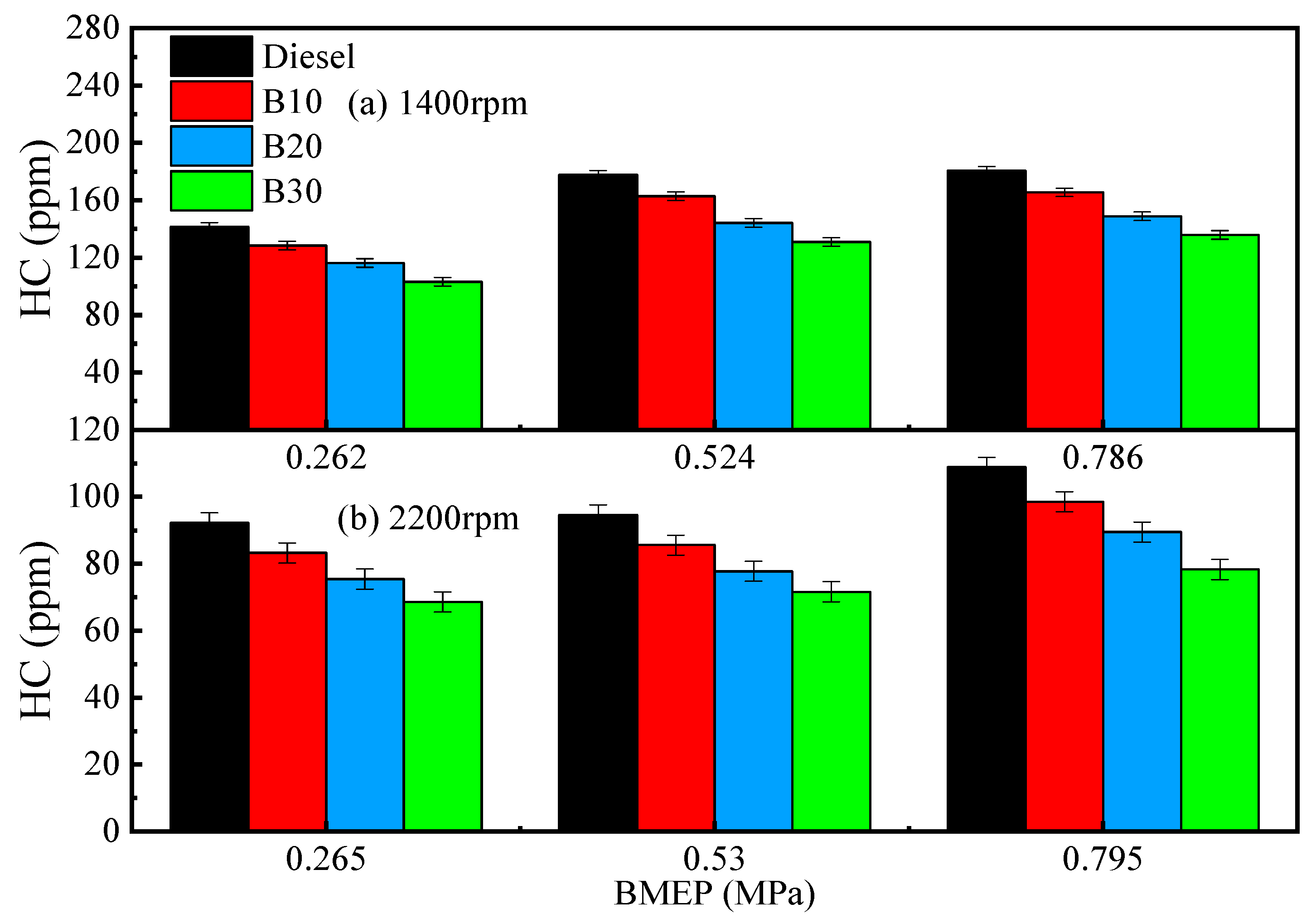

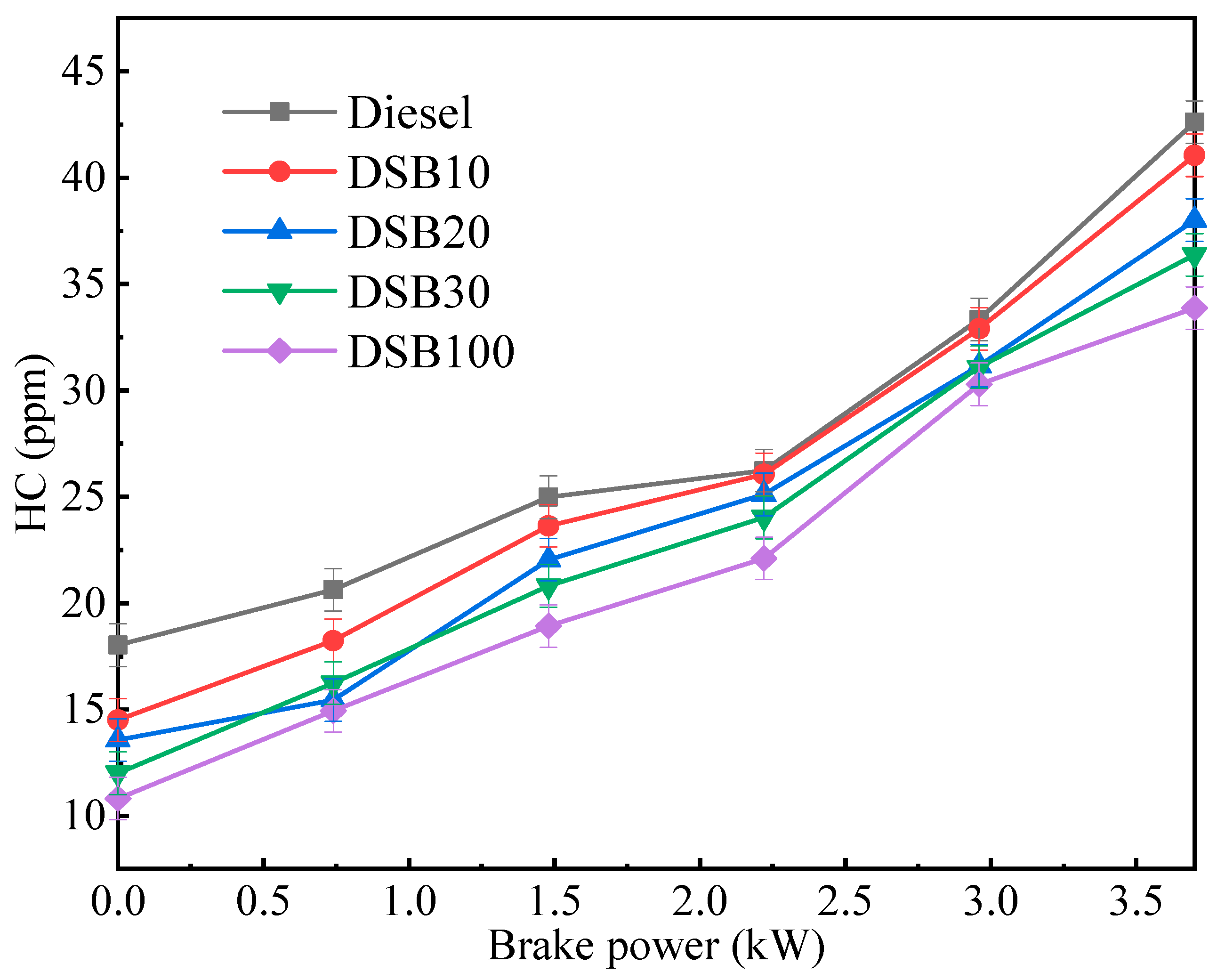

5.4. Effect on HC Emissions

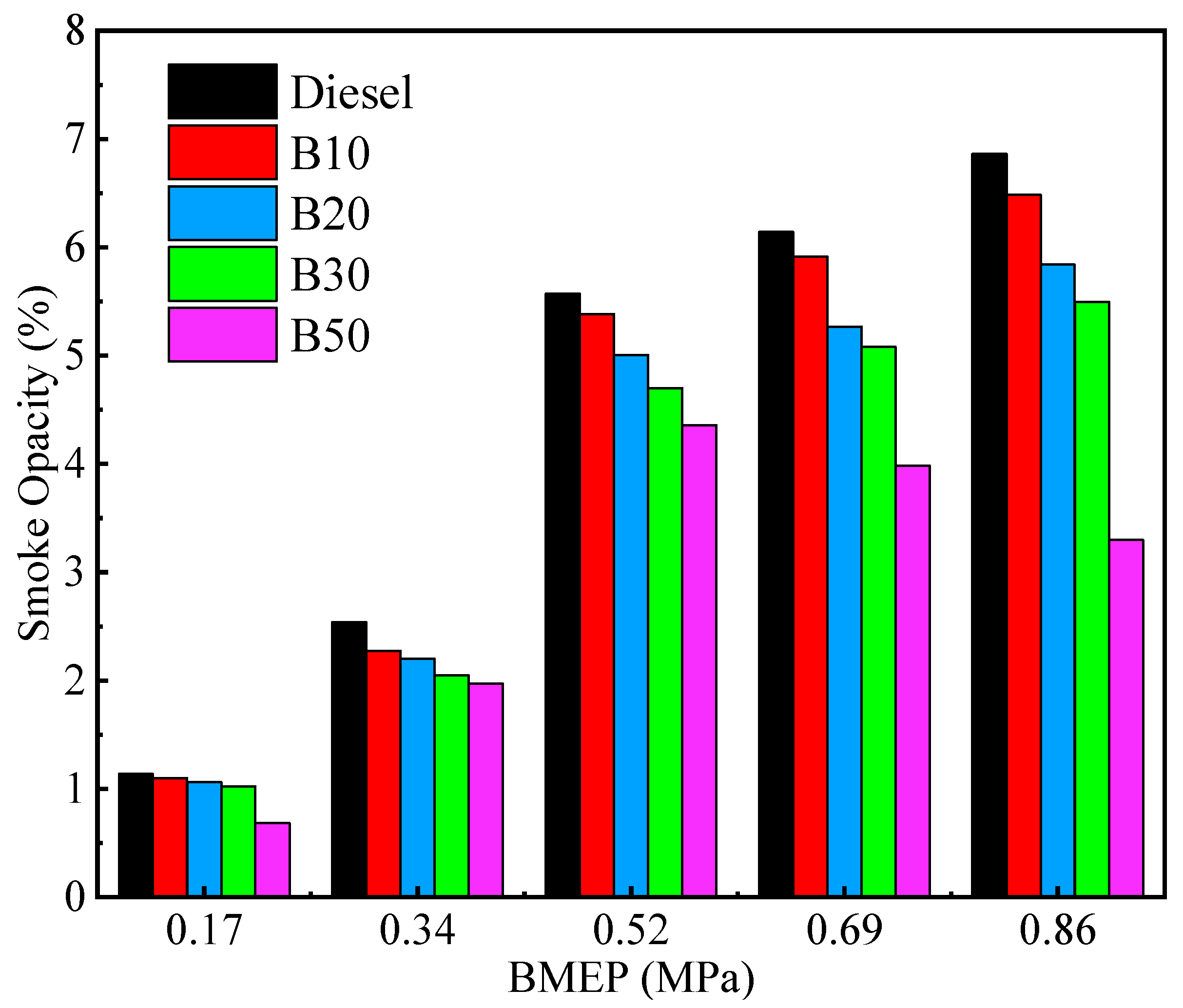

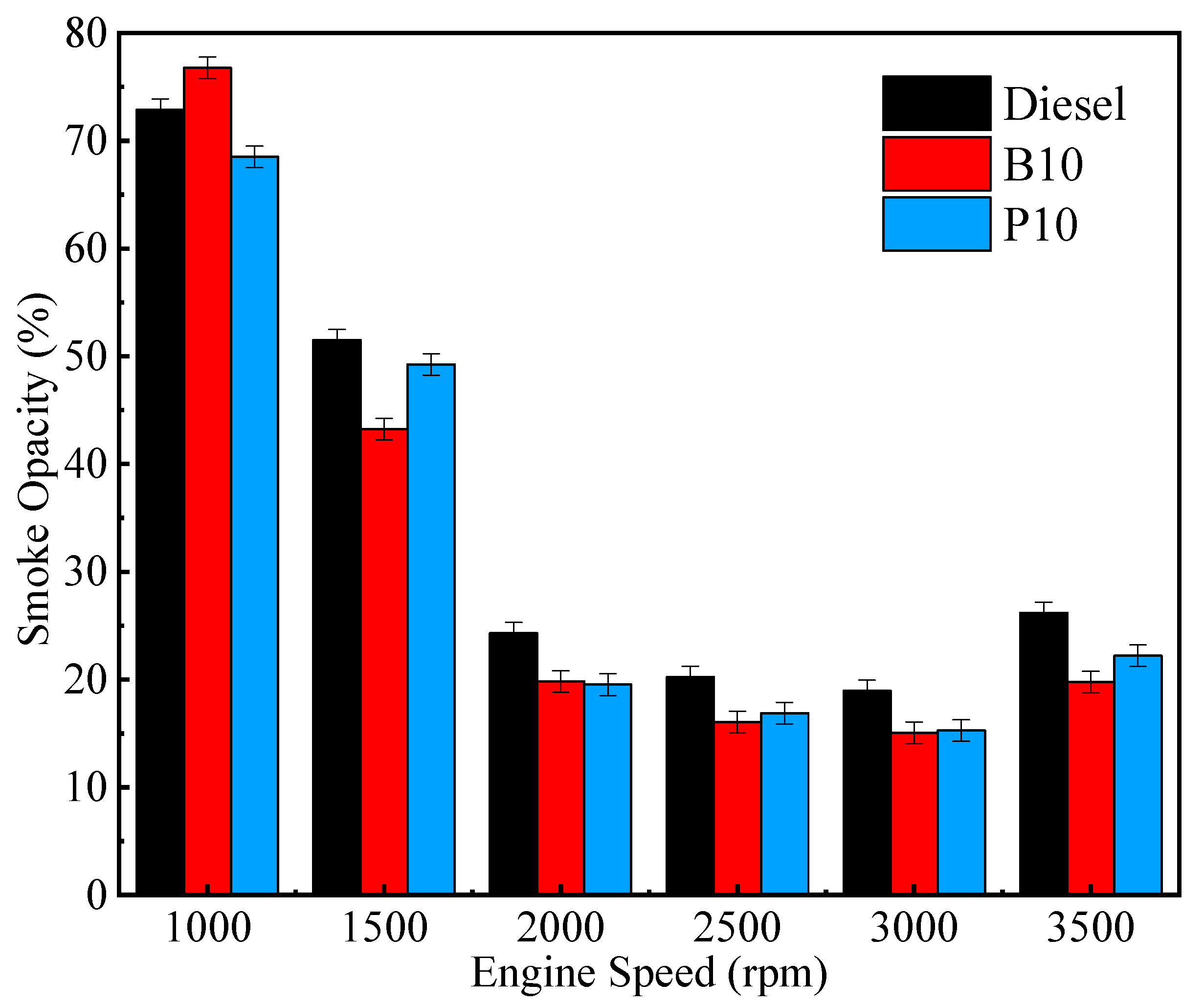

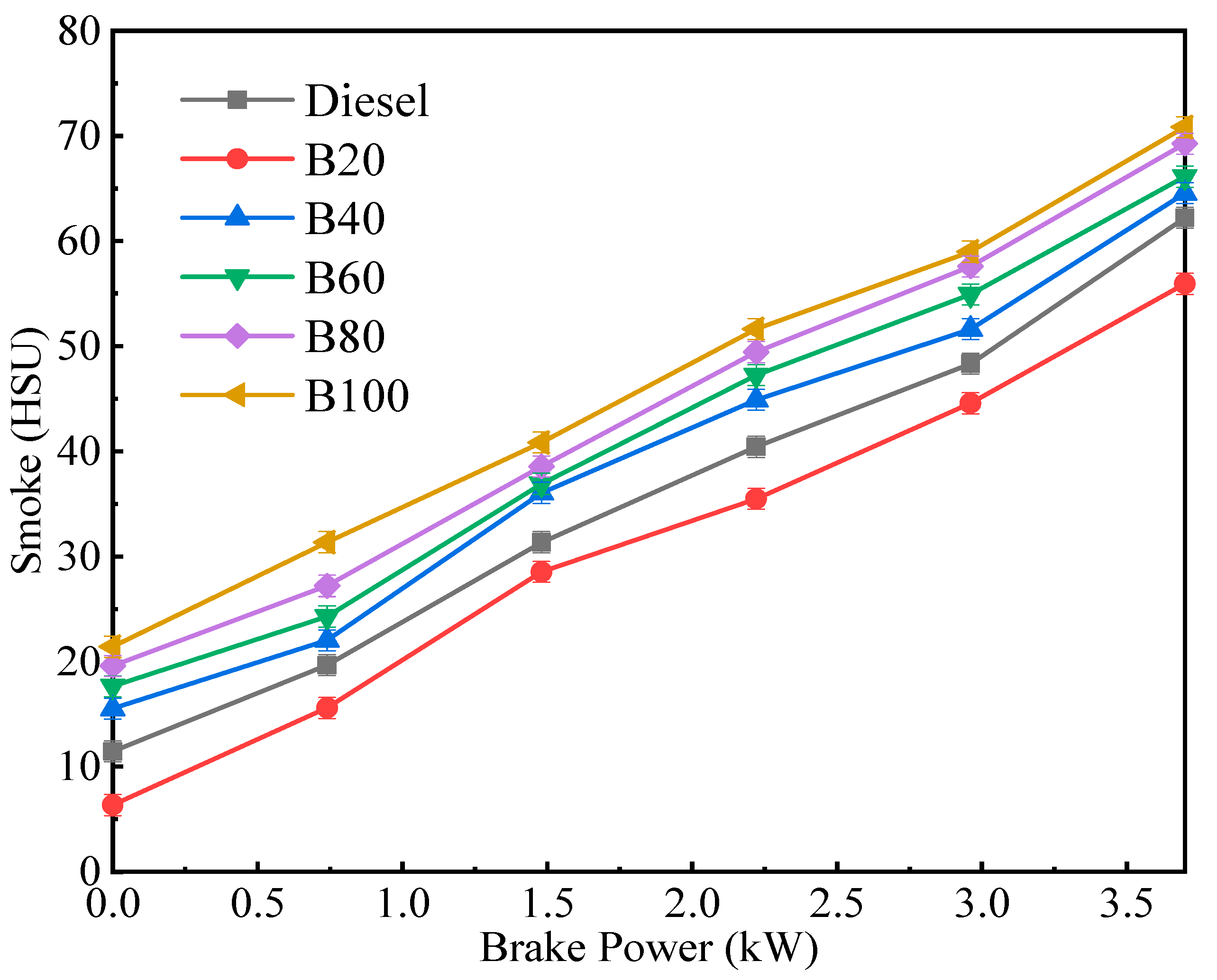

5.5. Effect on Smoke Emissions

5.6. Summary of Emission Analysis

6. Conclusions

- (1)

- The feedstocks and production technologies of different generations of biodiesel can affect the properties of different biodiesels. Specifically, according to different researchers, different biodiesel production technologies mainly affect the density, viscosity, and cetane number of the same biodiesel. Therefore, in the production process of biodiesel, the selection of appropriate production technology is of great significance to improve the properties of biodiesel and the use of biodiesel in diesel engines.

- (2)

- The 11–13% oxygen content in the biodiesel structure plays an important role in engine performance and emissions. Specifically, due to the additional oxygen content and higher cetane number, biodiesel has a better BTE compared with diesel, theoretically. However, due to the average 3.13% and 89.56% respective higher viscosity and density, while having a 7.96% lower heating value compared with biodiesel, the BTE of biodiesel was lower than 2–5% on average in most literature reported by different researchers. This decrease in BTE can be significantly improved by using Metal-based and oxygenated additives such as cerium dioxide and n-butanol.

- (3)

- Because of the lower calorific value, higher density, and viscosity of biodiesel compared with diesel, which results in poor atomization and evaporation of the fuel in the cylinder, the BSFC of biodiesel is approximately 13% higher than that of diesel. Additionally, a nearly 10% higher average EGT was observed in biodiesel due to higher BSFC resulting in more fuel energy in the combustion chamber. Moreover, with the increase in engine load, due to the larger mass quantity of biodiesel injected into the cylinder, the BSFC and EGT difference decreased compared with diesel. Therefore, preheated biodiesel is recommended to decrease BSFC at low load conditions.

- (4)

- The 11–13% oxygen content in the biodiesel structure plays an important role in emission characteristics. Specifically, due to the higher oxygen content in biodiesel than in diesel and more fuel injection in the cylinder, the oxygen in the biodiesel structure reduces nearly 30% CO emissions, 50% HC emissions, and 70% smoke emissions. On the other hand, higher cylinder temperature and EGT were observed because the higher oxygen content of biodiesel improved combustion efficiency, and the NOx emissions of biodiesel were 12–14% higher than that of diesel. Since the CO in biodiesel is oxidized to CO2 by the additional oxygen content, the CO emissions of biodiesel are also 11–13% higher than that of diesel.

Author Contributions

Funding

Conflicts of Interest

References

- Tan, D.; Chen, Z.; Li, J.; Luo, J.; Yang, D.; Cui, S.; Zhang, Z. Effects of Swirl and Boiling Heat Transfer on the Performance Enhancement and Emission Reduction for a Medium Diesel Engine Fueled with Biodiesel. Processes 2021, 9, 568. [Google Scholar] [CrossRef]

- Van Fan, Y.; Perry, S.; Klemeš, J.J.; Lee, C.T. A review on air emissions assessment: Transportation. J. Clean. Prod. 2018, 194, 673–684. [Google Scholar] [CrossRef]

- Zhang, Z.; Tian, J.; Li, J.; Lv, J.; Wang, S.; Zhong, Y.; Dong, R.; Gao, S.; Cao, C.; Tan, D. Investigation on combustion, performance and emission characteristics of a diesel engine fueled with diesel/alcohol/n-butanol blended fuels. Fuel 2022, 320, 123975. [Google Scholar] [CrossRef]

- E, J.; Pham, M.; Zhao, D.; Deng, Y.; Le, D.; Zuo, W.; Zhu, H.; Liu, T.; Peng, Q.; Zhang, Z. Effect of different technologies on combustion and emissions of the diesel engine fueled with biodiesel: A review. Renew. Sustain. Energy Rev. 2017, 80, 620–647. [Google Scholar] [CrossRef]

- Feng, C.; Deng, Y.; Tan, Y.; Han, W.; E, J.; Chen, L.; Han, D. Experimental and simulation study on the effect of ZSM-5 hydrocarbon catcher on the emission of gasoline engine during cold start. Fuel 2022, 313, 122661. [Google Scholar] [CrossRef]

- Chen, S.; Tian, J.; Li, J.; Li, W.; Zhang, Z. Investigation of the Performance and Emission Characteristics of a Diesel Engine with Different Diesel-Methanol Dual-Fuel Ratios. Processes 2021, 9, 1944. [Google Scholar] [CrossRef]

- Abdellatief, T.M.; Ershov, M.A.; Kapustin, V.M. New recipes for producing a high-octane gasoline based on naphtha from natural gas condensate. Fuel 2020, 276, 118075. [Google Scholar] [CrossRef]

- Zhang, Z.; Ye, J.; Tan, D.; Feng, Z.; Luo, J.; Tan, Y.; Huang, Y. The effects of Fe2O3 based DOC and SCR catalyst on the combustion and emission characteristics of a diesel engine fueled with biodiesel. Fuel 2021, 290, 120039. [Google Scholar] [CrossRef]

- Zhang, Z.; Tian, J.; Xie, G.; Li, J.; Xu, W.; Jiang, F.; Huang, Y.; Tan, D. Investigation on the combustion and emission characteristics of diesel engine fueled with diesel/methanol/n-butanol blends. Fuel 2022, 314, 123088. [Google Scholar] [CrossRef]

- Mohr, S.H.; Wang, J.; Ellem, G.; Ward, J.; Giurco, D. Projection of world fossil fuels by country. Fuel 2015, 141, 120–135. [Google Scholar] [CrossRef]

- Fan, L.; Cheng, F.; Zhang, T.; Liu, G.; Yuan, J.; Mao, P. Visible-light photoredox-promoted desilylative allylation of α-silylamines: An efficient route to synthesis of homoallylic amines. Tetrahedron Lett. 2021, 81, 153357. [Google Scholar] [CrossRef]

- Han, D.; E, J.; Deng, Y.; Zhao, X.; Feng, C.; Chen, J.; Leng, E.; Liao, G.; Zhang, F. A review of studies using hydrocarbon reduction measures for reducing hydrocarbon emissions from cold start of gasoline engine. Renew. Sustain. Energy Rev. 2021, 135, 110079. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, J.; Tian, J.; Dong, R.; Zou, Z.; Gao, S.; Tan, D. Performance, combustion and emission characteristics investigations on a diesel engine fueled with diesel/ethanol/n-butanol blends. Energy 2022, 249, 123733. [Google Scholar] [CrossRef]

- Gainey, B.; Yan, Z.; Lawler, B. Autoignition characterization of methanol, ethanol, propanol, and butanol over a wide range of operating conditions in LTC/HCCI. Fuel 2021, 287, 119495. [Google Scholar] [CrossRef]

- Cai, T.; Becker, S.M.; Cao, F.; Wang, B.; Tang, A.; Fu, J.; Han, L.; Sun, Y.; Zhao, D. NOx emission performance assess-ment on a perforated plate-implemented premixed ammonia-oxygen micro-combustion system. Chem. Eng. J. 2021, 417, 128033. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, J.; Tian, J.; Zhong, Y.; Zou, Z.; Dong, R.; Gao, S.; Xu, W.; Tan, D. The effects of Mn-based catalysts on the selective catalytic reduction of NOx with NH3 at low temperature: A review. Fuel Process. Technol. 2022, 230, 107213. [Google Scholar] [CrossRef]

- Hu, L.; Bao, X.; Lin, M.; Yu, C.; Wang, F. Research on risky driving behavior evaluation model based on CIDAS real data. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2021, 235, 2176–2187. [Google Scholar] [CrossRef]

- Zhao, D.; Guan, Y.; Reinecke, A. Characterizing hydrogen-fuelled pulsating combustion on thermodynamic properties of a combustor. Commun. Phys. 2019, 2, 44. [Google Scholar] [CrossRef]

- Cai, T.; Zhao, D.; Sun, Y.; Ni, S.; Li, W.; Guan, D.; Wang, B. Evaluation of NOx emissions characteristics in a CO2-Free micro-power system by implementing a perforated plate. Renew. Sustain. Energy Rev. 2021, 145, 111150. [Google Scholar] [CrossRef]

- Hu, L.; Hu, X.; Kuang, A.; Lin, M.; Wang, J. Casualty risk of e-bike rider struck by passenger vehicle using China In- depth accident data. Traffic Inj. Prev. 2020, 21, 283–287. [Google Scholar] [CrossRef]

- Tan, Y.; E, J.; Chen, J.; Liao, G.; Zhang, F.; Li, J. Investigation on combustion characteristics and thermal performance of a three rearward-step structure micro combustor fueled by premixed hydrogen/air. Renew. Energy 2022, 186, 486–504. [Google Scholar] [CrossRef]

- Li, Y.; Chen, Y.; Wu, G.; Liu, J. Experimental evaluation of water-containing isopropanol-n-butanol-ethanol and gasoline blend as a fuel candidate in spark-ignition engine. Appl. Energy 2018, 219, 42–52. [Google Scholar] [CrossRef]

- Zuo, H.; Zhu, Y.; Abubakar, S.; Li, Y. Effect of a crossed-semicircular-plate on thermal performance of micro-combustor fueled by premixed hydrogen-air mixture. Int. J. Hydrogen Energy 2022, 47, 17442–17453. [Google Scholar] [CrossRef]

- Vijay Kumar, M.; Veeresh Babu, A.; Ravi Kumar, P. The impacts on combustion, performance and emissions of biodiesel by using additives in direct injection diesel engine. Alex. Eng. J. 2018, 57, 509–516. [Google Scholar] [CrossRef]

- Liu, J.; Yang, F.; Wang, H.; Ouyang, M.; Hao, S. Effects of pilot fuel quantity on the emissions characteristics of a CNG/diesel dual fuel engine with optimized pilot injection timing. Appl. Energy 2013, 110, 201–206. [Google Scholar] [CrossRef]

- Hu, L.; Hu, X.; Wan, J.; Lin, M.; Huang, J. The injury epidemiology of adult riders in vehicle-two-wheeler crashes in China, Ningbo, 2011–2015. J. Saf. Res. 2019, 72, 21–28. [Google Scholar] [CrossRef]

- Sakthivel, R.; Ramesh, K.; Purnachandran, R.; Mohamed Shameer, P. A review on the properties, performance and emission aspects of the third generation biodiesels. Renew. Sustain. Energy Rev. 2018, 82, 2970–2992. [Google Scholar] [CrossRef]

- Liu, J.; Ulishney, C.J.; Dumitrescu, C.E. Effect of spark timing on the combustion stages seen in a heavy-duty compression-ignition engine retrofitted to natural gas spark-ignition operation. SAE Int. J. Engines 2021, 14, 335. [Google Scholar] [CrossRef]

- Peng, Q.; Xie, B.; Yang, W.; Tang, S.; Li, Z.; Zhou, P.; Luo, N. Effects of porosity and multilayers of porous medium on the hydrogen-fueled combustion and micro-thermophotovoltaic. Renew. Energy 2021, 174, 391–402. [Google Scholar] [CrossRef]

- Han, J.; Somers, L.M.T.; Cracknell, R.; Joedicke, A.; Wardle, R.; Mohan, V.R.R. Experimental investigation of ethanol/diesel dual-fuel combustion in a heavy-duty diesel engine. Fuel 2020, 275, 117867. [Google Scholar] [CrossRef]

- Li, Z.; Wang, Y.; Yin, Z.; Geng, H.; Zhu, R.; Zhen, X. Effect of injection strategy on a diesel/methanol dual-fuel direct-injection engine. Appl. Therm. Eng. 2021, 189, 116691. [Google Scholar] [CrossRef]

- Cai, T.; Zhao, D. Enhancing and assessing ammonia-air combustion performance by blending with dimethyl ether. Renew. Sustain. Energy Rev. 2022, 156, 112003. [Google Scholar] [CrossRef]

- Yan, Z.M.; Gainey, B.; Lawler, B. A parametric modeling study of thermal barrier coatings in low-temperature combustion engines. Appl. Therm. Eng. 2022, 200, 117687. [Google Scholar] [CrossRef]

- E, J.; Liu, T.; Yang, W.; Deng, Y.; Gong, J. A skeletal mechanism modeling on soot emission characteristics for bio-diesel surrogates with varying fatty acid methyl esters proportion. Appl. Energy 2016, 181, 322–331. [Google Scholar] [CrossRef]

- E, J.; Liu, T.; Yang, W.M.; Li, J.; Gong, J.; Deng, Y. Effects of fatty acid methyl esters proportion on combustion and emission characteristics of a biodiesel fueled diesel engine. Energy Convers. Manag. 2016, 117, 410–419. [Google Scholar] [CrossRef]

- Zhang, Z.; E, J.; Deng, Y.; Pham, M.; Zuo, W.; Peng, Q.; Yin, Z. Effects of fatty acid methyl esters proportion on combustion and emission characteristics of a biodiesel fueled marine diesel engine. Energy Convers. Manag. 2018, 159, 244–253. [Google Scholar] [CrossRef]

- Zhang, Z.; Tian, J.; Li, J.; Cao, C.; Wang, S.; Lv, J.; Zheng, W.; Tan, D. The development of diesel oxidation catalysts and the effect of sulfur dioxide on catalysts of metal-based diesel oxidation catalysts: A review. Fuel Process. Technol. 2022, 233, 107317. [Google Scholar] [CrossRef]

- Tamilselvan, P.; Nallusamy, N.; Rajkumar, S. A comprehensive review on performance, combustion and emission characteristics of biodiesel fuelled diesel engines. Renew. Sustain. Energy Rev. 2017, 79, 1134–1159. [Google Scholar] [CrossRef]

- Mohd Noor, C.W.; Noor, M.M.; Mamat, R. Biodiesel as alternative fuel for marine diesel engine applications: A review. Renew. Sustain. Energy Rev. 2018, 94, 127–142. [Google Scholar] [CrossRef]

- Zhang, B.; E, J.; Gong, J.; Yuan, W.; Zhao, X.; Hu, W. Influence of structural and operating factors on performance degradation of the diesel particulate filter based on composite regeneration. Appl. Therm. Eng. 2017, 121, 838–852. [Google Scholar] [CrossRef]

- Zhong, C.; Tan, J.; Zuo, H.; Wu, X.; Wang, S.; Liu, J. Synergy effects analysis on CDPF regeneration performance enhancement and NOx concentration reduction of NH3–SCR over Cu–ZSM–5. Energy 2021, 230, 120814. [Google Scholar] [CrossRef]

- Zuo, H.; Zhang, B.; Huang, Z.; Wei, K.; Zhu, H.; Tan, J. Effect analysis on SOC values of the power lithium manganate battery during discharging process and its intelligent estimation. Energy 2022, 238, 121854. [Google Scholar] [CrossRef]

- Sathyamurthy, R.; Balaji, D.; Gorjian, S.; Muthiya, S.J.; Bharathwaaj, R.; Vasanthaseelan, S.; Essa, F.A. Performance, combustion and emission characteristics of a DI-CI diesel engine fueled with corn oil methyl ester biodiesel blends. Sustain. Energy Technol. Assess. 2021, 43, 100981. [Google Scholar] [CrossRef]

- Ong, H.C.; Masjuki, H.H.; Mahlia, T.M.I.; Silitonga, A.S.; Chong, W.T.; Yusaf, T. Engine performance and emissions using Jatropha curcas, Ceiba pentandra and Calophyllum inophyllum biodiesel in a CI diesel engine. Energy 2014, 69, 427–445. [Google Scholar] [CrossRef]

- Gonca, G.; Dobrucali, E. Theoretical and experimental study on the performance of a diesel engine fueled with diesel–biodiesel blends. Renew. Energy 2016, 93, 658–666. [Google Scholar] [CrossRef]

- Xue, J.; Grift, T.E.; Hansen, A.C. Effect of biodiesel on engine performances and emissions. Renew. Sustain. Energy Rev. 2011, 15, 1098–1116. [Google Scholar] [CrossRef]

- Kant Bhatia, S.; Kant Bhatia, R.; Jeon, J.-M.; Pugazhendhi, A.; Kumar Awasthi, M.; Kumar, D.; Kumar, G.; Yoon, J.-J.; Yang, Y.-H. An overview on advancements in biobased transesterification methods for biodiesel production: Oil resources, extraction, biocatalysts, and process intensification technologies. Fuel 2021, 285, 119117. [Google Scholar] [CrossRef]

- Ahmed, R.; Huddersman, K. Review of biodiesel production by the esterification of wastewater containing fats oils and grease (FOGs). J. Ind. Eng. Chem. 2022, 110, 1–14. [Google Scholar] [CrossRef]

- Javed, F.; Shamair, Z.; Hafeez, A.; Fazal, T.; Aslam, R.; Akram, S.; Rashid, N.; Zimmerman, W.B.; Rehman, F. Conversion of poultry-fat waste to a sustainable feedstock for biodiesel production via microbubble injection of reagent vapor. J. Clean. Prod. 2021, 311, 127525. [Google Scholar] [CrossRef]

- Cavalett, O.; Ortega, E. Integrated environmental assessment of biodiesel production from soybean in Brazil. J. Clean. Prod. 2010, 18, 55–70. [Google Scholar] [CrossRef]

- Zhang, Z.; Ye, J.; Lv, J.; Xu, W.; Tan, D.; Jiang, F.; Huang, H. Investigation on the effects of non-uniform porosity catalyst on SCR characteristic based on the field synergy analysis. J. Environ. Chem. Eng. 2022, 10, 107056. [Google Scholar] [CrossRef]

- Szulczyk, K.R.; Atiqur Rahman Khan, M. The potential and environmental ramifications of palm biodiesel: Evidence from Malaysia. J. Clean. Prod. 2018, 203, 260–272. [Google Scholar] [CrossRef]

- Arbab, M.I.; Varman, M.; Masjuki, H.H.; Kalam, M.A.; Imtenan, S.; Sajjad, H.; Rizwanul Fattah, I.M. Evaluation of combustion, performance, and emissions of optimum palm–coconut blend in turbocharged and non-turbocharged conditions of a diesel engine. Energy Convers. Manag. 2015, 90, 111–120. [Google Scholar] [CrossRef]

- Kumar, S.; Chaube, A.; Jain, S.K. Sustainability issues for promotion of Jatropha biodiesel in Indian scenario: A review. Renew. Sustain. Energy Rev. 2012, 16, 1089–1098. [Google Scholar] [CrossRef]

- Saravanan, N.; Nagarajan, G.; Puhan, S. Experimental investigation on a DI diesel engine fuelled with Madhuca Indica ester and diesel blend. Biomass Bioenergy 2010, 34, 838–843. [Google Scholar] [CrossRef]

- Wu, G.; Ge, J.C.; Choi, N.J. A Comprehensive Review of the Application Characteristics of Biodiesel Blends in Diesel Engines. Appl. Sci. 2020, 10, 8015. [Google Scholar] [CrossRef]

- Agarwal, A.K. Biofuels (alcohols and biodiesel) applications as fuels for internal combustion engines. Prog. Energy Combust. Sci. 2007, 33, 233–271. [Google Scholar] [CrossRef]

- Ahmad, T.; Danish, M.; Kale, P.; Geremew, B.; Adeloju, S.B.; Nizami, M.; Ayoub, M. Optimization of process variables for biodiesel production by transesterification of flaxseed oil and produced biodiesel characterizations. Renew. Energy 2019, 139, 1272–1280. [Google Scholar] [CrossRef]

- Kumar, H.; Sarma, A.K.; Kumar, P. A comprehensive review on preparation, characterization, and combustion characteristics of microemulsion based hybrid biofuels. Renew. Sustain. Energy Rev. 2020, 117, 109498. [Google Scholar] [CrossRef]

- Zhang, Z.; Lv, J.; Xie, G.; Wang, S.; Ye, Y.; Huang, G.; Tan, D. Effect of assisted hydrogen on combustion and emission characteristics of a diesel engine fueled with biodiesel. Energy 2022, 254, 124269. [Google Scholar] [CrossRef]

- Hu, L.; Zhong, Y.; Hao, W.; Moghimi, B.; Huang, J.; Zhang, X.; Du, R. Optimal route algorithm considering traffic light and energy consumption. IEEE Access 2018, 6, 59695–59704. [Google Scholar] [CrossRef]

- Hu, Y.; Sun, Y.; He, J.; Fang, D.; Zhu, J.; Meng, X. Effect of friction stir processing parameters on the microstructure and properties of ZK60 magnesium alloy. Mater. Res. Express 2022, 8, 016508. [Google Scholar] [CrossRef]

- Adewale, P.; Dumont, M.-J.; Ngadi, M. Recent trends of biodiesel production from animal fat wastes and associated production techniques. Renew. Sustain. Energy Rev. 2015, 45, 574–588. [Google Scholar] [CrossRef]

- Tran, D.-T.; Chang, J.-S.; Lee, D.-J. Recent insights into continuous-flow biodiesel production via catalytic and non-catalytic transesterification processes. Appl. Energy 2017, 185, 376–409. [Google Scholar] [CrossRef]

- Abrar, I.; Bhaskarwar, A.N. Microemulsion fuels for compression ignition engines: A review on engine performance and emission characteristics. Fuel 2019, 257, 115944. [Google Scholar] [CrossRef]

- Leng, L.; Li, H.; Yuan, X.; Zhou, W.; Huang, H. Bio-oil upgrading by emulsification/microemulsification: A review. Energy 2018, 161, 214–232. [Google Scholar] [CrossRef]

- Rajesh Kumar, B.; Saravanan, S. Use of higher alcohol biofuels in diesel engines: A review. Renew. Sustain. Energy Rev. 2016, 60, 84–115. [Google Scholar] [CrossRef]

- Arpornpong, N.; Attaphong, C.; Charoensaeng, A.; Sabatini, D.A.; Khaodhiar, S. Ethanol-in-palm oil/diesel microemulsion-based biofuel: Phase behavior, viscosity, and droplet size. Fuel 2014, 132, 101–106. [Google Scholar] [CrossRef]

- Bora, P.; Boro, J.; Konwar, L.J.; Deka, D. Formulation of microemulsion based hybrid biofuel from waste cooking oil—A comparative study with biodiesel. J. Energy Inst. 2016, 89, 560–568. [Google Scholar] [CrossRef]

- Zhang, Z.; E, J.; Chen, J.; Zhu, H.; Zhao, X.; Han, D.; Zuo, W.; Peng, Q.; Gong, J.; Yin, Z. Effects of low-level water addition on spray, combustion and emission characteristics of a medium speed diesel engine fueled with bio-diesel fuel. Fuel 2019, 239, 245–262. [Google Scholar] [CrossRef]

- Alvarez-Chavez, B.J.; Godbout, S.; Palacios-Rios, J.H.; Le Roux, É.; Raghavan, V. Physical, chemical, thermal and biological pre-treatment technologies in fast pyrolysis to maximize bio-oil quality: A critical review. Biomass Bioenergy 2019, 128, 105333. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, Q.; Ke, L.; Peng, Y.; Liu, Y.; Wu, Q.; Tian, X.; Dai, L.; Ruan, R.; Jiang, L. Review on the catalytic pyrolysis of waste oil for the production of renewable hydrocarbon fuels. Fuel 2021, 283, 119170. [Google Scholar] [CrossRef]

- Chiaramonti, D.; Prussi, M.; Buffi, M.; Rizzo, A.M.; Pari, L. Review and experimental study on pyrolysis and hydrothermal liquefaction of microalgae for biofuel production. Appl. Energy 2017, 185, 963–972. [Google Scholar] [CrossRef]

- Jung, J.-M.; Oh, J.-I.; Baek, K.; Lee, J.; Kwon, E.E. Biodiesel production from waste cooking oil using biochar de-rived from chicken manure as a porous media and catalyst. Energy Convers. Manag. 2018, 165, 628–633. [Google Scholar] [CrossRef]

- Auti, S.M.; Rathod, W.S. Effect of hybrid blends of raw tyre pyrolysis oil, karanja biodiesel and diesel fuel on single cylinder four stokes diesel engine. Energy Rep. 2021, 7, 2214–2220. [Google Scholar] [CrossRef]

- Laesecke, J.; Ellis, N.; Kirchen, P. Production, analysis and combustion characterization of biomass fast pyrolysis oil—Biodiesel blends for use in diesel engines. Fuel 2017, 199, 346–357. [Google Scholar] [CrossRef]

- Vihar, R.; Seljak, T.; Rodman Oprešnik, S.; Katrašnik, T. Combustion characteristics of tire pyrolysis oil in turbo charged compression ignition engine. Fuel 2015, 150, 226–235. [Google Scholar] [CrossRef]

- Pradhan, D.; Bendu, H.; Singh, R.K.; Murugan, S. Mahua seed pyrolysis oil blends as an alternative fuel for light-duty diesel engines. Energy 2017, 118, 600–612. [Google Scholar] [CrossRef]

- Jahirul, M.; Rasul, M.; Chowdhury, A.; Ashwath, N. Biofuels Production through Biomass Pyrolysis—A Technological Review. Energies 2012, 5, 4952–5001. [Google Scholar] [CrossRef]

- Mellouk, H.; Meullemiestre, A.; Maache-Rezzoug, Z.; Bejjani, B.; Dani, A.; Rezzoug, S.-A. Valorization of industrial wastes from French maritime pine bark by solvent free microwave extraction of volatiles. J. Clean. Prod. 2016, 112, 4398–4405. [Google Scholar] [CrossRef]

- Chuah, L.F.; Klemeš, J.J.; Yusup, S.; Bokhari, A.; Akbar, M.M. A review of cleaner intensification technologies in biodiesel production. J. Clean. Prod. 2017, 146, 181–193. [Google Scholar] [CrossRef]

- Zhang, X.; Yan, S.; Tyagi, R.D.; Drogui, P.; Surampalli, R.Y. Ultrasonication aided biodiesel production from one-step and two-step transesterification of sludge derived lipid. Energy 2016, 94, 401–408. [Google Scholar] [CrossRef]

- Yu, G.W.; Nie, J.; Lu, L.G.; Wang, S.P.; Li, Z.G.; Lee, M.R. Transesterification of soybean oil by using the synergistic microwave-ultrasonic irradiation. Ultrason Sonochem. 2017, 39, 28–290. [Google Scholar] [CrossRef] [PubMed]

- Aghbashlo, M.; Tabatabaei, M.; Hosseinpour, S. On the exergoeconomic and exergoenvironmental evaluation and optimization of biodiesel synthesis from waste cooking oil (WCO) using a low power, high frequency ultrasonic reactor. Energy Convers. Manag. 2018, 164, 385–398. [Google Scholar] [CrossRef]

- Ho, W.W.S.; Ng, H.K.; Gan, S. Advances in ultrasound-assisted transesterification for biodiesel production. Appl. Therm. Eng. 2016, 100, 553–563. [Google Scholar] [CrossRef]

- Koberg, M.; Cohen, M.; Ben-Amotz, A.; Gedanken, A. Bio-diesel production directly from the microalgae biomass of Nannochloropsis by microwave and ultrasound radiation. Bioresour. Technol. 2011, 102, 4265–4269. [Google Scholar] [CrossRef]

- Mazubert, A.; Taylor, C.; Aubin, J.; Poux, M. Key role of temperature monitoring in interpretation of microwave effect on transesterification and esterification reactions for biodiesel production. Bioresour. Technol. 2014, 161, 270–279. [Google Scholar] [CrossRef]

- Yan, J.; Zhao, Y.; Li, K.; Zhang, H.; Fan, L.; Lu, Z. Efficient production of biodiesel from ionic liquid catalyzed esterification using ultrasonic-microwave combined intensification. Chem. Eng. Process.-Process Intensif. 2020, 149, 107870. [Google Scholar] [CrossRef]

- Singh, D.; Sharma, D.; Soni, S.L.; Sharma, S.; Kumar Sharma, P.; Jhalani, A. A review on feedstocks, production processes, and yield for different generations of biodiesel. Fuel 2020, 262, 116553. [Google Scholar] [CrossRef]

- Ashraful, A.M.; Masjuki, H.H.; Kalam, M.A.; Rizwanul Fattah, I.M.; Imtenan, S.; Shahir, S.A.; Mobarak, H.M. Production and comparison of fuel properties, engine performance, and emission characteristics of biodiesel from various non-edible vegetable oils: A review. Energy Convers. Manag. 2014, 80, 202–228. [Google Scholar] [CrossRef]

- Singh, D.; Sharma, D.; Soni, S.L.; Sharma, S.; Kumari, D. Chemical compositions, properties, and standards for different generation biodiesels: A review. Fuel 2019, 253, 60–71. [Google Scholar] [CrossRef]

- Hou, J.; Zhang, P.; Yuan, X.; Zheng, Y. Life cycle assessment of biodiesel from soybean, jatropha and microalgae in China conditions. Renew. Sustain. Energy Rev. 2011, 15, 5081–5091. [Google Scholar] [CrossRef]

- Johari, A.; Nyakuma, B.B.; Mohd Nor, S.H.; Mat, R.; Hashim, H.; Ahmad, A.; Yamani Zakaria, Z.; Tuan Abdullah, T.A. The challenges and prospects of palm oil based biodiesel in Malaysia. Energy 2015, 81, 255–261. [Google Scholar] [CrossRef]

- Klepacka, A.M.; Florkowski, W.J.; Revoredo-Giha, C. The expansion and changing cropping pattern of rapeseed production and biodiesel manufacturing in Poland. Renew. Energy 2019, 133, 156–165. [Google Scholar] [CrossRef]

- Kumar, D.; Kumar, G.; Singh, C.P. Fast, easy ethanolysis of coconut oil for biodiesel production assisted by ultrasonication. Ultrason Sonochem. 2010, 17, 555–559. [Google Scholar] [CrossRef]

- E, J.; Liu, G.; Zhang, Z.; Han, D.; Chen, J.; Wei, K.; Gong, J.; Yin, Z. Effect analysis on cold starting performance enhancement of a diesel engine fueled with biodiesel fuel based on an improved thermodynamic model. Appl. Energy 2019, 243, 321–335. [Google Scholar] [CrossRef]

- Acaroglu, M.; Demirbas, A. Relationships between Viscosity and Density Measurements of Biodiesel Fuels. Energy Sources Part A Recovery Util. Environ. Eff. 2007, 29, 705–712. [Google Scholar] [CrossRef]

- Sarin, A.; Sharma, N.; Devgan, K.; Singh, M. Study of kinematic viscosity and density of biodiesels exposed to radiations. Mater. Today Proc. 2021, 46, 5516–5522. [Google Scholar] [CrossRef]

- Sia, C.B.; Kansedo, J.; Tan, Y.H.; Lee, K.T. Evaluation on biodiesel cold flow properties, oxidative stability and enhancement strategies: A review. Biocatal. Agric. Biotechnol. 2020, 24, 101514. [Google Scholar] [CrossRef]

- Gülüm, M.; Bilgin, A. Density, flash point and heating value variations of corn oil biodiesel–diesel fuel blends. Fuel Process. Technol. 2015, 134, 456–464. [Google Scholar] [CrossRef]

- Ziyad, B.A.; Yousfi, M.; Vander Heyden, Y. Effects of growing region and maturity stages on oil yield, fatty acid profile and tocopherols of Pistacia atlantica Desf. fruit and their implications on resulting biodiesel. Renew. Energy 2022, 181, 167–181. [Google Scholar] [CrossRef]

- Mostafaei, M. ANFIS models for prediction of biodiesel fuels cetane number using desirability function. Fuel 2018, 216, 665–672. [Google Scholar] [CrossRef]

- Ramírez-Verduzco, L.F.; Rodríguez-Rodríguez, J.E.; Jaramillo-Jacob, A.D.R. Predicting cetane number, kinematic viscosity, density and higher heating value of biodiesel from its fatty acid methyl ester composition. Fuel 2012, 91, 102–111. [Google Scholar] [CrossRef]

- Lapuerta, M.; Rodríguez-Fernández, J.; de Mora, E.F. Correlation for the estimation of the cetane number of biodiesel fuels and implications on the iodine number. Energy Policy 2009, 37, 4337–4344. [Google Scholar] [CrossRef]

- Santos, S.M.; Nascimento, D.C.; Costa, M.C.; Neto, A.M.B.; Fregolente, L.V. Flash point prediction: Reviewing empirical models for hydrocarbons, petroleum fraction, biodiesel, and blends. Fuel 2020, 263, 116375. [Google Scholar] [CrossRef]

- Boog, J.H.F.; Silveira, E.L.C.; de Caland, L.B.; Tubino, M. Determining the residual alcohol in biodiesel through its flash point. Fuel 2011, 90, 905–907. [Google Scholar] [CrossRef]

- Cernoch, M.; Hajek, M.; Skopal, F. Relationships among flash point, carbon residue, viscosity and some impuri-ties in biodiesel after ethanolysis of rapeseed oil. Bioresour. Technol. 2010, 101, 7397–7401. [Google Scholar] [CrossRef]

- Rahman, S.M.A.; Fattah, I.M.R.; Maitra, S.; Mahlia, T.M.I. A ranking scheme for biodiesel underpinned by critical physicochemical properties. Energy Convers. Manag. 2021, 229, 113742. [Google Scholar] [CrossRef]

- Yao, J.; Qi, R.; Pan, Y.; He, H.; Fan, Y.; Jiang, J.; Jiang, J. Prediction of the flash points of binary biodiesel mixtures from molecular structures. J. Loss Prev. Process Ind. 2020, 65, 104137. [Google Scholar] [CrossRef]

- Datta, A.; Mandal, B.K. A comprehensive review of biodiesel as an alternative fuel for compression ignition engine. Renew. Sustain. Energy Rev. 2016, 57, 799–821. [Google Scholar] [CrossRef]

- Fadhil, A.B.; Abdulahad, W.S. Transesterification of mustard (Brassica nigra) seed oil with ethanol: Purification of the crude ethyl ester with activated carbon produced from de-oiled cake. Energy Convers. Manag. 2014, 77, 495–503. [Google Scholar] [CrossRef]

- Bhale, P.V.; Deshpande, N.V.; Thombre, S.B. Improving the low temperature properties of biodiesel fuel. Renew. Energy 2009, 34, 794–800. [Google Scholar] [CrossRef]

- Fassinou, W.F.; Steene, L.V.D.; Toure, S.; Martin, E. What correlation is appropriate to evaluate biodiesels and vegetable oils higher heating value (HHV)? Fuel 2011, 90, 3398–3403. [Google Scholar] [CrossRef]

- Sanli, H.; Canakci, M.; Alptekin, E. Predicting the higher heating values of waste frying oils as potential bio-diesel feedstock. Fuel 2014, 115, 850–854. [Google Scholar] [CrossRef]

- Hong, I.K.; Lee, J.R.; Lee, S.B. Fuel properties of canola oil and lard biodiesel blends: Higher heating value, oxidative stability, and kinematic viscosity. J. Ind. Eng. Chem. 2015, 22, 335–340. [Google Scholar] [CrossRef]

- Silitonga, A.S.; Masjuki, H.H.; Mahlia, T.M.I.; Ong, H.C.; Chong, W.T.; Boosroh, M.H. Overview properties of biodiesel diesel blends from edible and non-edible feedstock. Renew. Sustain. Energy Rev. 2013, 22, 346–360. [Google Scholar] [CrossRef]

- Bhuiya, M.M.K.; Rasul, M.G.; Khan, M.M.K.; Ashwath, N.; Azad, A.K. Prospects of 2nd generation biodiesel as a sustainable fuel—Part: 1 selection of feedstocks, oil extraction techniques and conversion technologies. Renew. Sustain. Energy Rev. 2016, 55, 1109–1128. [Google Scholar] [CrossRef]

- Atabani, A.E.; Mahlia, T.M.I.; Masjuki, H.H.; Badruddin, I.A.; Yussof, H.W.; Chong, W.T.; Lee, K.T. A comparative evaluation of physical and chemical properties of biodiesel synthesized from edible and non-edible oils and study on the effect of biodiesel blending. Energy 2013, 58, 296–304. [Google Scholar] [CrossRef]

- Hoang, A.T.; Tabatabaei, M.; Aghbashlo, M.; Carlucci, A.P.; Ölçer, A.I.; Le, A.T.; Ghassemi, A. Rice bran oil-based biodiesel as a promising renewable fuel alternative to petrodiesel: A review. Renew. Sustain. Energy Rev. 2021, 135, 110204. [Google Scholar] [CrossRef]

- Devarajan, Y. Experimental evaluation of combustion, emission and performance of research diesel engine fuelled di-methyl- carbonate and biodiesel blends. Atmos. Pollut. Res. 2019, 10, 795–801. [Google Scholar] [CrossRef]

- Sajjadi, B.; Raman, A.A.A.; Arandiyan, H. A comprehensive review on properties of edible and non-edible vegetable oil-based biodiesel: Composition, specifications and prediction models. Renew. Sustain. Energy Rev. 2016, 63, 62–92. [Google Scholar] [CrossRef]

- Aransiola, E.F.; Ojumu, T.V.; Oyekola, O.O.; Madzimbamuto, T.F.; Ikhu-Omoregbe, D.I.O. A review of current technology for biodiesel production: State of the art. Biomass Bioenergy 2014, 61, 276–297. [Google Scholar] [CrossRef]

- Shelke, P.S.; Sakhare, N.M.; Lahane, S. Investigation of Combustion Characteristics of a Cottonseed Biodiesel Fuelled Diesel Engine. Procedia Technol. 2016, 25, 1049–1055. [Google Scholar] [CrossRef]

- Lee, R.A.; Lavoie, J.-M. From first- to third-generation biofuels: Challenges of producing a commodity from a biomass of increasing complexity. Anim. Front. 2013, 3, 6–11. [Google Scholar] [CrossRef]

- Rozina; Asif, S.; Ahmad, M.; Zafar, M.; Ali, N. Prospects and potential of fatty acid methyl esters of some non-edible seed oils for use as biodiesel in Pakistan. Renew. Sustain. Energy Rev. 2017, 74, 687–702. [Google Scholar] [CrossRef]

- Yang, L.; Takase, M.; Zhang, M.; Zhao, T.; Wu, X. Potential non-edible oil feedstock for biodiesel production in Africa: A survey. Renew. Sustain. Energy Rev. 2014, 38, 461–477. [Google Scholar] [CrossRef]

- Kumar, A.; Sharma, S. Potential non-edible oil resources as biodiesel feedstock: An Indian perspective. Renewable Sustain. Energy Rev. 2011, 15, 1791–1800. [Google Scholar] [CrossRef]

- Anwar, M.; Rasul, M.G.; Ashwath, N.; Nabi, M.D.N. The potential of utilising papaya seed oil and stone fruit kernel oil as non-edible feedstock for biodiesel production in Australia—A review. Energy Rep. 2019, 5, 280–297. [Google Scholar] [CrossRef]

- Anwar, M.; Rasul, M.G.; Ashwath, N. Production optimization and quality assessment of papaya (Carica papaya) biodiesel with response surface methodology. Energy Convers. Manag. 2018, 156, 103–112. [Google Scholar] [CrossRef]

- Anwar, M.; Rasul, M.; Ashwath, N.; Rahman, M. Optimisation of Second-Generation Biodiesel Production from Australian Native Stone Fruit Oil Using Response Surface Method. Energies 2018, 11, 2566. [Google Scholar] [CrossRef]

- Dash, S.K.; Elumalai, P.V.; Ranjit, P.S.; Das, P.K.; Kumar, R.; Kunar, S.; Papu, N.H. Experimental investigation on synthesis of biodiesel from non-edible Neem seed oil: Production optimization and evaluation of fuel properties. Mater. Today Proc. 2021, 47, 2463–2466. [Google Scholar] [CrossRef]

- Anwar, M.; Rasul, M.; Ashwath, N. Optimization of biodiesel production from stone fruit kernel oil. Energy Procedia 2019, 160, 268–276. [Google Scholar] [CrossRef]

- Zare, A.; Stevanovic, S.; Jafari, M.; Verma, P.; Babaie, M.; Yang, L.; Rahman, M.M.; Ristovski, Z.D.; Brown, R.J.; Bodisco, T.A. Analysis of cold-start NO2 and NOx emissions, and the NO2/NOx ratio in a diesel engine powered with different diesel-biodiesel blends. Environ. Pollut. 2021, 290, 118052. [Google Scholar] [CrossRef]

- Arumugam, A.; Ponnusami, V. Biodiesel production from Calophyllum inophyllum oil a potential non-edible feedstock: An overview. Renew. Energy 2019, 131, 459–471. [Google Scholar] [CrossRef]

- Akintunde, S.B.; Obayopo, S.O.; Adekunle, A.S.; Obisesan, O.R.; Olaoye, O.S. Combustion and emission study of sandbox seed oil biodiesel performance in a compression ignition (CI) engine. Energy Rep. 2021, 7, 3869–3876. [Google Scholar] [CrossRef]

- Oni, B.A.; Oluwatosin, D. Emission characteristics and performance of neem seed (Azadirachta indica) and Camelina (Camelina sativa) based biodiesel in diesel engine. Renew. Energy 2020, 149, 725–734. [Google Scholar] [CrossRef]

- Chhandama, M.V.L.; Satyan, K.B.; Changmai, B.; Vanlalveni, C.; Rokhum, S.L. Microalgae as a feedstock for the production of biodiesel: A review. Bioresour. Technol. Rep. 2021, 15, 100771. [Google Scholar] [CrossRef]

- Singh, D.; Sharma, D.; Soni, S.L.; Inda, C.S.; Sharma, S.; Sharma, P.K.; Jhalani, A. A comprehensive review of biodiesel production from waste cooking oil and its use as fuel in compression ignition engines: 3rd generation cleaner feedstock. J. Clean. Prod. 2021, 307, 127299. [Google Scholar] [CrossRef]

- Khan, S.; Siddique, R.; Sajjad, W.; Nabi, G.; Hayat, K.M.; Duan, P.; Yao, L. Biodiesel Production from Algae to Overcome the Energy Crisis. HAYATI J. Biosci. 2017, 24, 163–167. [Google Scholar] [CrossRef]

- Banković-Ilić, I.B.; Stojković, I.J.; Stamenković, O.S.; Veljkovic, V.B.; Hung, Y.-T. Waste animal fats as feed-stocks for biodiesel production. Renew. Sustain. Energy Rev. 2014, 32, 238–254. [Google Scholar] [CrossRef]

- Alptekin, E.; Canakci, M.; Sanli, H. Biodiesel production from vegetable oil and waste animal fats in a pilot plant. Waste Manag. 2014, 34, 2146–2154. [Google Scholar] [CrossRef] [PubMed]

- Ballesteros, R.; Monedero, E.; Guillén-Flores, J. Determination of aldehydes and ketones with high atmospheric reactivity on diesel exhaust using a biofuel from animal fats. Atmos. Environ. 2011, 45, 2690–2698. [Google Scholar] [CrossRef]

- Jacob, A.; Ashok, B.; Alagumalai, A.; Chyuan, O.H.; Le, P.T.K. Critical review on third generation micro algae biodiesel production and its feasibility as future bioenergy for IC engine applications. Energy Convers. Manag. 2021, 228, 113655. [Google Scholar] [CrossRef]

- Nautiyal, P.; Subramanian, K.A.; Dastidar, M.G.; Kumar, A. Experimental assessment of performance, combustion and emissions of a compression ignition engine fuelled with Spirulina platensis biodiesel. Energy 2020, 193, 116861. [Google Scholar] [CrossRef]

- Nagarajan, R.; Dharmaraja, J.; Shobana, S.; Sermarajan, A.; Nguyen, D.D.; Murugavelh, S. A comprehensive investigation on Spirulina platensis—Part I: Cultivation of biomass, thermo–kinetic modelling, physico–chemical, combustion and emission analyses of bio–oil blends in compression ignition engine. J. Environ. Chem. Eng. 2021, 9, 105231. [Google Scholar] [CrossRef]

- Gad, M.S.; El-Seesy, A.I.; Abu Hashish, H.M.; He, Z.; Alshaer, W.G. Combustion and emissions aspects of a diesel engine working with sheep fat oil biodiesel-diesel blends. Case Stud. Therm. Eng. 2021, 26, 101162. [Google Scholar] [CrossRef]

- Jayaprabakar, J.; Dawn, S.S.; Ranjan, A.; Priyadharsini, P.; George, R.J.; Sadaf, S.; Rajha, C.R. Process optimization for biodiesel production from sheep skin and its performance, emission and combustion characterization in CI engine. Energy 2019, 174, 54–68. [Google Scholar] [CrossRef]

- Keskin, A.; Şen, M.; Emiroğlu, A.O. Experimental studies on biodiesel production from leather industry waste fat and its effect on diesel engine characteristics. Fuel 2020, 276, 118000. [Google Scholar] [CrossRef]

- Ge, S.; Brindhadevi, K.; Xia, C.; Elesawy, B.H.; Elfasakhany, A.; Unpaprom, Y.; Doan, H.V. Egg shell catalyst and chicken waste biodiesel blends for improved performance, combustion and emission characteristics. Fuel 2021, 306, 121633. [Google Scholar] [CrossRef]

- Du, E.; Cai, L.; Huang, K.; Tang, H.; Xu, X.; Tao, R. Reducing viscosity to promote biodiesel for energy security and improve combustion efficiency. Fuel 2018, 211, 194–196. [Google Scholar] [CrossRef]

- Daridon, J.-L. Predicting the effect of pressure on biodiesel density at pressures of up to 200 MPa based on fatty acid alkyl ester profiles and density values at atmospheric pressure. Fuel 2020, 281, 118767. [Google Scholar] [CrossRef]

- Chacko, N.; Johnson, C.; Varadarajan, P.; Sai Srinivas, S.; Jeyaseelan, T. A comparative evaluation of cetane enhancing techniques for improving the smoke, NOx and BSFC trade-off in an automotive diesel engine. Fuel 2021, 289, 119918. [Google Scholar] [CrossRef]

- Musthafa, M.M. Development of performance and emission characteristics on coated diesel engine fuelled by biodiesel with cetane number enhancing additive. Energy 2017, 134, 234–239. [Google Scholar] [CrossRef]

- E, J.; Zhang, Z.; Tu, Z.; Zuo, W.; Hu, W.; Han, D.; Jin, Y. Effect analysis on flow and boiling heat transfer performance of cooling water-jacket of bearing in the gasoline engine turbocharger. Appl. Therm. Eng. 2018, 130, 754–766. [Google Scholar] [CrossRef]

- Giakoumis, E.G.; Sarakatsanis, C.K. Estimation of biodiesel cetane number, density, kinematic viscosity and heating values from its fatty acid weight composition. Fuel 2018, 222, 574–585. [Google Scholar] [CrossRef]

- Erdoğan, S. LHV and HHV prediction model using regression analysis with the help of bond energies for bio-diesel. Fuel 2021, 301, 121065. [Google Scholar] [CrossRef]

- Zhu, B.; Chen, G.; Cao, X.; Wei, D. Molecular characterization of CO2 sequestration and assimilation in micro-algae and its biotechnological applications. Bioresour. Technol. 2017, 244, 1207–1215. [Google Scholar] [CrossRef]

- Shokravi, H.; Shokravi, Z.; Heidarrezaei, M.; Ong, H.C.; Rahimian Koloor, S.S.; Petru, M.; Lau, W.J.; Ismail, A.F. Fourth generation biofuel from genetically modified algal biomass: Challenges and future directions. Chemosphere 2021, 285, 131535. [Google Scholar] [CrossRef]

- Mehrpooya, M.; Ghorbani, B.; Bahnamiri, F.K.; Marefati, M. Solar fuel production by developing an integrated biodiesel production process and solar thermal energy system. Appl. Therm. Eng. 2020, 167, 114701. [Google Scholar] [CrossRef]

- Zahedi, A.; Timasi, H.; Kasaeian, A.; Mirnezami, S.A. Design and construction of a new dual CHP-type renew-able energy power plant based on an improved parabolic trough solar collector and a biofuel generator. Renew. Energy 2019, 135, 485–495. [Google Scholar] [CrossRef]

- Malik, S.; Shahid, A.; Liu, C.-G.; Zafar Khan, A.; Nawaz, M.Z.; Zhu, H.; Mehmood, M.A. Developing fourth-generation biofuels secreting microbial cell factories for enhanced productivity and efficient product recovery; a review. Fuel 2021, 298, 120858. [Google Scholar] [CrossRef]

- Wang, H.; Peng, X.; Zhang, H.; Yang, S.; Li, H. Microorganisms-promoted biodiesel production from biomass: A review. Energy Convers. Manag. 2021, 12, 100137. [Google Scholar] [CrossRef]

- Dey, S.; Reang, N.M.; Das, P.K.; Deb, M. A comprehensive study on prospects of economy, environment, and efficiency of palm oil biodiesel as a renewable fuel. J. Clean. Prod. 2021, 286, 124981. [Google Scholar] [CrossRef]

- He, B.-Q. Advances in emission characteristics of diesel engines using different biodiesel fuels. Renew. Sustain. Energy Rev. 2016, 60, 570–586. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhong, Y.; Wang, J.; Tan, D.; Zhang, Z.; Yang, D. Effects of Different Biodiesel-Diesel Blend Fuel on Combustion and Emission Characteristics of a Diesel Engine. Processes 2021, 9, 1984. [Google Scholar] [CrossRef]

- Silitonga, A.S.; Masjuki, H.H.; Ong, H.C.; Sebayang, A.H.; Dharma, S.; Kusumo, F.; Siswantoro, J.; Milano, J.; Daud, K.; Mahlia, T.M.I.; et al. Evaluation of the engine performance and exhaust emissions of biodiesel-bioethanol-diesel blends using kernel-based extreme learning machine. Energy 2018, 159, 1075–1087. [Google Scholar] [CrossRef]

- Abu-Hamdeh, N.H.; Alnefaie, K.A. A comparative study of almond and palm oils as two bio-diesel fuels for diesel engine in terms of emissions and performance. Fuel 2015, 150, 318–324. [Google Scholar] [CrossRef]

- Ztürk, E.; Can, Ö.; Usta, N.; Yücesu, H.S. Effects of retarded fuel injection timing on combustion and emissions of a diesel engine fueled with canola biodiesel. Eng. Sci. Technol. Int. J. 2020, 23, 1466–1475. [Google Scholar] [CrossRef]

- How, H.G.; Masjuki, H.H.; Kalam, M.A.; Teoh, Y.H. An investigation of the engine performance, emissions and combustion characteristics of coconut biodiesel in a high-pressure common-rail diesel engine. Energy 2014, 69, 749–759. [Google Scholar] [CrossRef]

- Deivajothi, P.; Manieniyan, V.; Sivaprakasam, S. An impact of ethyl esters of groundnut acid oil (vegetable oil refinery waste) used as emerging fuel in DI diesel engine. Alex. Eng. J. 2018, 57, 2215–2223. [Google Scholar] [CrossRef]

- Gumus, M. A comprehensive experimental investigation of combustion and heat release characteristics of a biodiesel (hazelnut kernel oil methyl ester) fueled direct injection compression ignition engine. Fuel 2010, 89, 2802–2814. [Google Scholar] [CrossRef]

- Teoh, Y.H.; How, H.G.; Masjuki, H.H.; Nguyen, H.T.; Kalam, M.A.; Alabdulkarem, A. Investigation on particulate emissions and combustion characteristics of a common-rail diesel engine fueled with Moringa oleifera biodiesel-diesel blends. Renew. Energy 2019, 136, 521–534. [Google Scholar] [CrossRef]

- Satyanarayana, P.A.; Kanth Oleti, R.; Uppalapati, S.; Sridevi, V. A Comparative Study on Characterization of Used Cooking Oil and Mustard Oil for Biodiesel Production: Engine Performance. Mater. Today Proc. 2018, 5, 18187–18201. [Google Scholar] [CrossRef]

- Rosha, P.; Mohapatra, S.K.; Mahla, S.K.; Cho, H.; Chauhan, B.S.; Dhir, A. Effect of compression ratio on combustion, performance, and emission characteristics of compression ignition engine fueled with palm (B20) bio-diesel blend. Energy 2019, 178, 676–684. [Google Scholar] [CrossRef]

- Raman, L.A.; Deepanraj, B.; Rajakumar, S.; Sivasubramanian, V. Experimental investigation on performance, combustion and emission analysis of a direct injection diesel engine fuelled with rapeseed oil biodiesel. Fuel 2019, 246, 69–74. [Google Scholar] [CrossRef]

- Asokan, M.A.; Senthur Prabu, S.; Prathiba, S.; Mishra, S.; Mittal, H.; Verma, V. Emission and performance behavior of safflower oil biodiesel/diesel blends in DI diesel engine. Mater. Today Proc. 2021, 46, 8266–8270. [Google Scholar] [CrossRef]

- Pali, H.S.; Kumar, N.; Alhassan, Y. Performance and emission characteristics of an agricultural diesel engine fueled with blends of Sal methyl esters and diesel. Energy Convers. Manag. 2015, 90, 146–153. [Google Scholar] [CrossRef]

- Dhar, A.; Agarwal, A.K. Performance, emissions and combustion characteristics of Karanja biodiesel in a transportation engine. Fuel 2014, 119, 70–80. [Google Scholar] [CrossRef]

- Gad, M.S.; El-Shafay, A.S.; Abu Hashish, H.M. Assessment of diesel engine performance, emissions and combustion characteristics burning biodiesel blends from jatropha seeds. Process Saf. Environ. Prot. 2021, 147, 518–526. [Google Scholar] [CrossRef]

- Nguyen, T.; Pham, M.; Anh, T.L. Spray, combustion, performance and emission characteristics of a common rail diesel engine fueled by fish-oil biodiesel blends. Fuel 2020, 269, 117108. [Google Scholar] [CrossRef]

- Patel, C.; Chandra, K.; Hwang, J.; Agarwal, R.A.; Gupta, N.; Bae, C.; Gupta, T.; Agarwal, A.K. Comparative compression ignition engine performance, combustion, and emission characteristics, and trace metals in particulates from Waste cooking oil, Jatropha and Karanja oil derived biodiesels. Fuel 2019, 236, 1366–1376. [Google Scholar] [CrossRef]

- Subramaniam, M.; Solomon, J.M.; Nadanakumar, V.; Anaimuthu, S.; Sathyamurthy, R. Experimental investigation on performance, combustion and emission characteristics of DI diesel engine using algae as a biodiesel. Energy Rep. 2020, 6, 1382–1392. [Google Scholar] [CrossRef]

- Dhamodaran, G.; Krishnan, R.; Pochareddy, Y.K.; Pyarelal, H.M.; Sivasubramanian, H.; Ganeshram, A.K. A comparative study of combustion, emission, and performance characteristics of rice-bran-, neem-, and cottonseed-oil biodiesels with varying degree of unsaturation. Fuel 2017, 187, 296–305. [Google Scholar] [CrossRef]

- Mathimani, T.; Kumar, T.S.; Chandrasekar, M.; Uma, L.; Prabaharan, D. Assessment of fuel properties, engine performance and emission characteristics of outdoor grown marine Chlorella vulgaris BDUG 91771 bio-diesel. Renew. Energy 2017, 105, 637–646. [Google Scholar] [CrossRef]

- Arunkumar, M.; Kannan, M.; Murali, G. Experimental studies on engine performance and emission characteristics using castor biodiesel as fuel in CI engine. Renew. Energy 2019, 131, 737–744. [Google Scholar] [CrossRef]

- Yesilyurt, M.K.; Aydin, M. Experimental investigation on the performance, combustion and exhaust emission characteristics of a compression-ignition engine fueled with cottonseed oil biodiesel/diethyl ether/diesel fuel blends. Energy Convers. Manag. 2020, 205, 112355. [Google Scholar] [CrossRef]

- Zener, O.; Yüksek, L.; Ergenç, A.T.; Özkan, M. Effects of soybean biodiesel on a DI diesel engine performance, emission and combustion characteristics. Fuel 2014, 115, 875–883. [Google Scholar]

- Asokan, M.A.; Senthur Prabu, S.; Bade, P.K.K.; Nekkanti, V.M.; Gutta, S.S.G. Performance, combustion and emission characteristics of juliflora biodiesel fuelled DI diesel engine. Energy 2019, 173, 883–892. [Google Scholar] [CrossRef]

- How, H.G.; Masjuki, H.H.; Kalam, M.A.; Teoh, Y.H.; Chuah, H.G. Effect of Calophyllum Inophyllum bio-diesel-diesel blends on combustion, performance, exhaust particulate matter and gaseous emissions in a multicylinder diesel engine. Fuel 2018, 227, 154–164. [Google Scholar] [CrossRef]

- Mubarak, M.; Shaija, A.; Suchithra, T.V. Experimental evaluation of Salvinia molesta oil biodiesel/diesel blends fuel on combustion, performance and emission analysis of diesel engine. Fuel 2021, 287, 119526. [Google Scholar] [CrossRef]

- Shareef, S.M.; Mohanty, D.K. Experimental investigations of dairy scum biodiesel in a diesel engine with variable injection timing for performance, emission and combustion. Fuel 2020, 280, 118647. [Google Scholar] [CrossRef]

- Sathiyamoorthi, R.; Sankaranarayanan, G.; Adhith Kumaar, S.B.; Chiranjeevi, T.; Dilip Kumar, D. Experimental investigation on performance, combustion and emission characteristics of a single cylinder diesel engine fuelled by biodiesel derived from Cymbopogon Martinii. Renew. Energy 2019, 132, 394–415. [Google Scholar] [CrossRef]

- Ruhul, A.M.; Kalam, M.A.; Masjuki, H.H.; Shahir, S.A.; Alabdulkarem, A.; Teoh, Y.H.; How, H.G.; Reham, S.S. Evaluating combustion, performance and emission characteristics of Millettia pinnata and Croton megalo-carpus biodiesel blends in a diesel engine. Energy 2017, 141, 2362–2376. [Google Scholar] [CrossRef]

- Perumal, V.; Ilangkumaran, M. Experimental analysis of engine performance, combustion and emission using pongamia biodiesel as fuel in CI engine. Energy 2017, 129, 228–236. [Google Scholar] [CrossRef]

- Ogunkunle, O.; Ahmed, N.A. Exhaust emissions and engine performance analysis of a marine diesel engine fuelledwith Parinari polyandra biodiesel–diesel blends. Energy Rep. 2020, 6, 2999–3007. [Google Scholar] [CrossRef]

- Viswanathan, V.K.; Thomai, P. Performance and emission characteristics analysis of Elaeocarpus Ganitrus biodiesel blend using CI engine. Fuel 2021, 288, 119611. [Google Scholar] [CrossRef]

- Tizvir, A.; Shojaeefard, M.H.; Zahedi, A.; Molaeimanesh, G.R. Performance and emission characteristics of bio-diesel fuel from Dunaliella tertiolecta microalgae. Renew. Energy 2022, 182, 552–561. [Google Scholar] [CrossRef]

- Gowda, S.H.; Avinash, A.; Raju, K. Production optimization of Vateria Indica biodiesel and performance evaluation of its blends on compression ignition engine. Sustain. Chem. Pharm. 2021, 22, 100475. [Google Scholar] [CrossRef]

- Parthiban, K.S.; Pandian, S.; Subramanian, D. Conventional and in-situ transesterification of Annona squamosa seed oil for biodiesel production: Performance and emission analysis. Environ. Technol. Innov. 2021, 23, 101593. [Google Scholar] [CrossRef]

- Azad, K.; Rasul, M. Performance and combustion analysis of diesel engine fueled with grape seed and waste cooking biodiesel. Energy Procedia 2019, 160, 340–347. [Google Scholar] [CrossRef]

- Tayari, S.; Abedi, R.; Rahi, A. Comparative assessment of engine performance and emissions fueled with three different biodiesel generations. Renew. Energy 2020, 147, 1058–1069. [Google Scholar] [CrossRef]

- A.V.S.L, S.B.; Subramaniapillai, N.; Khadhar Mohamed, M.S.B.; Narayanan, A. Effect of rubber seed oil biodiesel on engine performance and emission analysis. Fuel 2021, 296, 120708. [Google Scholar] [CrossRef]

- Baweja, S.; Trehan, A.; Kumar, R. Combustion, performance, and emission analysis of a CI engine fueled with mustard oil biodiesel blended in diesel fuel. Fuel 2021, 292, 120346. [Google Scholar] [CrossRef]

- Ellappan, S.; Rajendran, S. A comparative review of performance and emission characteristics of diesel engine using eucalyptus-biodiesel blend. Fuel 2021, 284, 118925. [Google Scholar] [CrossRef]

- Rai, R.K.; Sahoo, R.R. Engine performance, emission, and sustainability analysis with diesel fuel-based Shorea robusta methyl ester biodiesel blends. Fuel 2021, 292, 120234. [Google Scholar] [CrossRef]

- Liu, J.; Huang, Q.; Ulishney, C.; Dumitrescu, C.E. Machine learning assisted prediction of exhaust gas temperature of a heavy-duty natural gas spark ignition engine. Appl. Energy 2021, 300, 117413. [Google Scholar] [CrossRef]

- Kalghatgi, G. Is it really the end of internal combustion engines and petroleum in transport? Appl. Energy 2018, 225, 965–974. [Google Scholar] [CrossRef]

- Rahman, M.A.; Aziz, M.A. Biodiesel from water hyacinth biomass and its influence on CI engine performance, emission, combustion and heat loss characteristics with the induction of hydroxy. Energy 2021, 224, 120151. [Google Scholar] [CrossRef]

- Rajak, U.; Nashine, P.; Verma, T.N. Effect of spirulina microalgae biodiesel enriched with diesel fuel on performance and emission characteristics of CI engine. Fuel 2020, 268, 117305. [Google Scholar] [CrossRef]

- Balamurugan, T.; Arun, A.; Sathishkumar, G.B. Biodiesel derived from corn oil—A fuel substitute for diesel. Renew. Sustain. Energy Rev. 2018, 94, 772–778. [Google Scholar] [CrossRef]

- Dhar, A.; Kevin, R.; Agarwal, A.K. Production of biodiesel from high-FFA neem oil and its performance, emission and combustion characterization in a single cylinder DICI engine. Fuel Process. Technol. 2012, 97, 118–129. [Google Scholar] [CrossRef]

- Chandra Sekhar, S.; Karuppasamy, K.; Vedaraman, N.; Kabeel, A.E.; Sathyamurthy, R.; Elkelawy, M.; Alm ElDin Bastawissi, H. Biodiesel production process optimization from Pithecellobium dulce seed oil: Performance, combustion, and emission analysis on compression ignition engine fuelled with diesel/biodiesel blends. Energy Convers. Manag. 2018, 161, 141–154. [Google Scholar] [CrossRef]

- Anawe, P.A.L.; Adewale, F.J. Data on physico-chemical, performance, combustion and emission characteristics of Persea Americana Biodiesel and its blends on direct-injection, compression-ignition engines. Data Brief 2018, 21, 1533–1540. [Google Scholar] [CrossRef]

- Erdoğan, S.; Balki, M.K.; Aydın, S.; Sayın, C. Performance, emission and combustion characteristic assessment of biodiesels derived from beef bone marrow in a diesel generator. Energy 2020, 207, 118300. [Google Scholar] [CrossRef]

- Sakthivel, G. Prediction of CI engine performance, emission and combustion characteristics using fish oil as a biodiesel at different injection timing using fuzzy logic. Fuel 2016, 183, 214–229. [Google Scholar] [CrossRef]

- Singh, M.; Sandhu, S.S. Performance, emission and combustion characteristics of multi-cylinder CRDI engine fueled with argemone biodiesel/diesel blends. Fuel 2020, 265, 117024. [Google Scholar] [CrossRef]

- Sayyed, S.; Das, R.K.; Kulkarni, K. Experimental investigation for evaluating the performance and emission characteristics of DICI engine fueled with dual biodiesel-diesel blends of Jatropha, Karanja, Mahua, and Neem. Energy 2022, 238, 121787. [Google Scholar] [CrossRef]

- Yesilyurt, M.K. The effects of the fuel injection pressure on the performance and emission characteristics of a diesel engine fuelled with waste cooking oil biodiesel-diesel blends. Renew. Energy 2019, 132, 649–666. [Google Scholar] [CrossRef]

- Dharmaraja, J.; Nguyen, D.D.; Shobana, S.; Saratale, G.D.; Arvindnarayan, S.; Atabani, A.E.; Chang, S.W.; Kumar, G. Engine performance, emission and bio characteristics of rice bran oil derived biodiesel blends. Fuel 2019, 239, 153–161. [Google Scholar] [CrossRef]

- Yildiz, I.; Caliskan, H.; Mori, K. Effects of cordierite particulate filters on diesel engine exhaust emissions in terms of pollution prevention approaches for better environmental management. J. Environ. Manag. 2021, 293, 112873. [Google Scholar] [CrossRef]

- Abdellatief, T.M.M.; Ershov, M.A.; Kapustin, V.M.; Chernysheva, E.A.; Savelenko, V.D.; Salameh, T.; Abdel-Kareem, M.A.; Olabi, A.G. Novel promising octane hyperboosting using isoolefinic gasoline additives and its application on fuzzy modeling. Int. J. Hydrog. Energy 2022, 47, 4932–4942. [Google Scholar] [CrossRef]

- Jamshaid, M.; Masjuki, H.H.; Kalam, M.A.; Zulkifli, N.W.M.; Arslan, A.; Qureshi, A.A. Experimental investigation of performance, emissions and tribological characteristics of B20 blend from cottonseed and palm oil bio-diesels. Energy 2022, 239, 121894. [Google Scholar] [CrossRef]

- Uyumaz, A.; Aydoğan, B.; Yılmaz, E.; Solmaz, H.; Aksoy, F.; Mutlu, İ.; İpci, D.; Calam, A. Experimental investigation on the combustion, performance and exhaust emission characteristics of poppy oil biodiesel-diesel dual fuel combustion in a CI engine. Fuel 2020, 280, 118588. [Google Scholar] [CrossRef]

- Sun, C.; Liu, Y.; Qiao, X.; Ju, D.; Tang, Q.; Fang, X.; Zhou, F. Experimental study of effects of exhaust gas recirculation on combustion, performance, and emissions of DME-biodiesel fueled engine. Energy 2020, 197, 117233. [Google Scholar] [CrossRef]

- Alagu, K.; Venu, H.; Jayaraman, J.; Raju, V.D.; Subramani, L.; Appavu, P.; Dhanasekar, S. Novel water hyacinth biodiesel as a potential alternative fuel for existing unmodified diesel engine: Performance, combustion and emission characteristics. Energy 2019, 179, 295–305. [Google Scholar] [CrossRef]

- Gharehghani, A.; Mirsalim, M.; Hosseini, R. Effects of waste fish oil biodiesel on diesel engine combustion characteristics and emission. Renew. Energy 2017, 101, 930–936. [Google Scholar] [CrossRef]

- Kodate, S.V.; Satyanarayana Raju, P.; Yadav, A.K.; Kumar, G.N. Investigation of preheated Dhupa seed oil bio-diesel as an alternative fuel on the performance, emission and combustion in a CI engine. Energy 2021, 231, 120874. [Google Scholar] [CrossRef]

- Omidvarborna, H.; Kumar, A.; Kim, D.-S. A laboratory investigation on the effects of unsaturated bonds and chain lengths of different biodiesel feedstocks on carbon dioxide, carbon monoxide, and methane emissions under low-temperature combustion. J. Environ. Chem. Eng. 2016, 4, 4769–4775. [Google Scholar] [CrossRef]

- Mourad, M.; Mahmoud, K.R.M.; NourEldeen, E.-S.H. Improving diesel engine performance and emissions characteristics fuelled with biodiesel. Fuel 2021, 302, 121097. [Google Scholar] [CrossRef]

- Shrivastava, P.; Verma, T.N. Effect of fuel injection pressure on the characteristics of CI engine fuelled with biodiesel from Roselle oil. Fuel 2020, 265, 117005. [Google Scholar] [CrossRef]

- Rajak, U.; Nashine, P.; Dasore, A.; Verma, T.N. Utilization of renewable and sustainable microalgae biodiesel for reducing the engine emissions in a diesel engine. Fuel 2022, 311, 122498. [Google Scholar] [CrossRef]

- Anwar, M.; Rasul, M.G.; Ashwath, N. A pragmatic and critical analysis of engine emissions for biodiesel blended fuels. Fuel 2020, 270, 117513. [Google Scholar] [CrossRef]

- Simsek, S. Effects of biodiesel obtained from Canola, sefflower oils and waste oils on the engine performance and exhaust emissions. Fuel 2020, 265, 117026. [Google Scholar] [CrossRef]

- IŞIk, M.Z. Comparative experimental investigation on the effects of heavy alcohols- safflower biodiesel blends on combustion, performance and emissions in a power generator diesel engine. Appl. Therm. Eng. 2021, 184, 116142. [Google Scholar] [CrossRef]

- Valente, O.S.; Pasa, V.M.; Belchior, C.R.; Sodre, J.R. Exhaust emissions from a diesel power generator fuelled by waste cooking oil biodiesel. Sci. Total Environ. 2012, 431, 57–61. [Google Scholar] [CrossRef] [PubMed]

- Krishania, N.; Rajak, U.; Chaurasiya, P.K.; Singh, T.S.; Birru, A.K.; Verma, T.N. Investigations of spirulina, waste cooking and animal fats blended biodiesel fuel on auto-ignition diesel engine performance, emission characteristics. Fuel 2020, 276, 118123. [Google Scholar] [CrossRef]

- Hoang, A.T. Experimental study on spray and emission characteristics of a diesel engine fueled with pre-heated bio-oils and diesel fuel. Energy 2019, 171, 795–808. [Google Scholar] [CrossRef]

- Lozhkina, O.V.; Lozhkin, V.N. Estimation of nitrogen oxides emissions from petrol and diesel passenger cars by means of on-board monitoring: Effect of vehicle speed, vehicle technology, engine type on emission rates. Transp. Res. Part D Transp. Environ. 2016, 47, 251–264. [Google Scholar] [CrossRef]

- Sun, J.; Caton, J.A.; Jacobs, T.J. Oxides of nitrogen emissions from biodiesel-fuelled diesel engines. Prog. Energy Combust. Sci. 2010, 36, 677–695. [Google Scholar] [CrossRef]

- Rajendran, S. Effect of antioxidant additives on oxides of nitrogen (NOx) emission reduction from Annona biodiesel operated diesel engine. Renew. Energy 2019, 148, 1321–1326. [Google Scholar] [CrossRef]

- Prasada Rao, G.; Sathya Vara Prasad, L. Combined influence of compression ratio and exhaust gas recirculation on the diverse characteristics of the diesel engine fueled with novel palmyra biodiesel blend. Energy Convers. Manag. 2022, 14, 100185. [Google Scholar] [CrossRef]

- Krishania, N.; Rajak, U.; Nath Verma, T.; Kumar Birru, A.; Pugazhendhi, A. Effect of microalgae, tyre pyrolysis oil and Jatropha biodiesel enriched with diesel fuel on performance and emission characteristics of CI engine. Fuel 2020, 278, 118252. [Google Scholar] [CrossRef]

- Can, Ö.; Öztürk, E.; Solmaz, H.; Aksoy, F.; Çinar, C.; Yücesu, H.S. Combined effects of soybean biodiesel fuel addition and EGR application on the combustion and exhaust emissions in a diesel engine. Appl. Therm. Eng. 2016, 95, 115–124. [Google Scholar] [CrossRef]

- Gürü, M.; Koca, A.; Can, Ö.; Çınar, C.; Şahin, F. Biodiesel production from waste chicken fat based sources and evaluation with Mg based additive in a diesel engine. Renew. Energy 2010, 35, 637–643. [Google Scholar] [CrossRef]

- Badawy, T.; Mansour, M.S.; Daabo, A.M.; Abdel Aziz, M.M.; Othman, A.A.; Barsoum, F.; Basouni, M.; Hussien, M.; Ghareeb, M.; Hamza, M.; et al. Selection of second-generation crop for biodiesel extraction and testing its impact with nano additives on diesel engine performance and emissions. Energy 2021, 237, 121605. [Google Scholar] [CrossRef]

- Uyumaz, A. Combustion, performance and emission characteristics of a DI diesel engine fueled with mustard oil biodiesel fuel blends at different engine loads. Fuel 2018, 212, 256–267. [Google Scholar] [CrossRef]

- Ershov, M.A.; Potanin, D.A.; Tarazanov, S.V.; Abdellatief, T.M.M.; Kapustin, V.M. Blending Characteristics of Isooctene, MTBE, and TAME as Gasoline Components. Energy Fuels 2020, 34, 2816–2823. [Google Scholar] [CrossRef]

- Ershov, M.A.; Abdellatief, T.M.M.; Potanin, D.A.; Klimov, N.A.; Chernysheva, E.A.; Kapustin, V.M. Characteristics of Isohexene as a Novel Promising High-Octane Gasoline Booster. Energy Fuels 2020, 34, 8139–8149. [Google Scholar] [CrossRef]

- Kanimozhi, B.; Kumar, G.; Alsehli, M.; Elfasakhany, A.; Veeman, D.; Balaji, S.; Thiran, T.; Kumar, T.P.; Sekar, M. Effects of oxyhydrogen on the CI engine fueled with the biodiesel blends: A performance, combustion and emission characteristics study. Int. J. Hydrog. Energy 2021. [Google Scholar] [CrossRef]

- Rajesh, K.; Natarajan, M.P.; Devan, P.K.; Ponnuvel, S. Coconut fatty acid distillate as novel feedstock for bio-diesel production and its characterization as a fuel for diesel engine. Renew. Energy 2021, 164, 1424–1435. [Google Scholar] [CrossRef]

- E, J.; Pham, M.; Deng, Y.; Nguyen, T.; Duy, V.; Le, D.; Zuo, W.; Peng, Q.; Zhang, Z. Effects of injection timing and injection pressure on performance and exhaust emissions of a common rail diesel engine fueled by various concentrations of fish-oil biodiesel blends. Energy 2018, 149, 979–989. [Google Scholar]

- Wei, L.; Cheung, C.S.; Huang, Z. Effect of n-pentanol addition on the combustion, performance and emission characteristics of a direct-injection diesel engine. Energy 2014, 70, 172–180. [Google Scholar] [CrossRef]

- Cai, T.; Zhao, D. Temperature Dependence of Laminar Burning Velocity in Ammonia/Dimethyl Ether-air Pre-mixed Flames. J. Therm. Sci. 2022, 31, 189–197. [Google Scholar] [CrossRef]

- Xie, B.; Peng, Q.; Yang, W.; Li, S.; E, J.; Li, Z.; Tao, M.; Zhang, A. Effect of pins and exit-step on thermal performance and energy effi-ciency of hydrogen-fueled combustion for micro-thermophotovoltaic. Energy 2022, 239, 122341. [Google Scholar] [CrossRef]

- Hazar, H.; Telceken, T.; Sevinc, H. An experimental study on emission of a diesel engine fuelled with SME (saf-flower methyl ester) and diesel fuel. Energy 2022, 241, 122915. [Google Scholar] [CrossRef]

- Uyumaz, A. Experimental evaluation of linseed oil biodiesel/diesel fuel blends on combustion, performance and emission characteristics in a DI diesel engine. Fuel 2020, 267, 117150. [Google Scholar] [CrossRef]

- Elumalai, P.V.; Parthasarathy, M.; Lalvani, J.S.C.I.J.; Mehboob, H.; Samuel, O.D.; Enweremadu, C.C.; Saleel, C.A.; Afzal, A. Effect of injection timing in reducing the harmful pollutants emitted from CI engine using N-butanol antioxidant blended eco-friendly Mahua biodiesel. Energy Rep. 2021, 7, 6205–6221. [Google Scholar] [CrossRef]

- Teoh, Y.H.; Yaqoob, H.; How, H.G.; Le, T.D.; Nguyen, H.T. Comparative assessment of performance, emissions and combustion characteristics of tire pyrolysis oil-diesel and biodiesel-diesel blends in a common-rail direct injection engine. Fuel 2022, 313, 123058. [Google Scholar] [CrossRef]

- Banapurmath, N.R.; Tewari, P.G.; Hosmath, R.S. Performance and emission characteristics of a DI compression ignition engine operated on Honge, Jatropha and sesame oil methyl esters. Renew. Energy 2008, 33, 1982–1988. [Google Scholar] [CrossRef]

- Zhang, Z.; E, J.; Chen, J.; Zhao, X.; Zhang, B.; Deng, Y.; Peng, Q.; Yin, Z. Effects of boiling heat transfer on the performance enhancement of a medium speed diesel engine fueled with diesel and rapeseed methyl ester. Appl. Therm. Eng. 2020, 169, 114984. [Google Scholar] [CrossRef]

- E, J.; Zhang, Z.; Chen, J.; Pham, M.; Zhao, X.; Peng, Q.; Zhang, B.; Yin, Z. Performance and emission evaluation of a marine diesel engine fueled by water biodiesel-diesel emulsion blends with a fuel additive of a cerium oxide nanoparticle. Energy Convers. Manag. 2018, 169, 194–205. [Google Scholar] [CrossRef]

- E, J.; Zhao, X.; Qiu, L.; Wei, K.; Zhang, Z.; Deng, Y.; Han, D.; Liu, G. Experimental investigation on performance and economy characteristics of a diesel engine with variable nozzle turbocharger and its application in urban bus. Energy Convers. Manag. 2019, 193, 149–161. [Google Scholar] [CrossRef]

- Zuo, H.; Tan, J.; Wei, K.; Huang, Z.; Zhong, D.; Xie, F. Effects of different poses and wind speeds on wind-induced vibration characteristics of a dish solar concentrator system. Renew. Energy 2021, 168, 1308–1326. [Google Scholar] [CrossRef]

- Zuo, H.; Liu, G.; E, J.; Zuo, W.; Wei, K.; Hu, W.; Tan, J.; Zhong, D. Catastrophic analysis on the stability of a large dish solar thermal power generation system with wind-induced vibration. Sol. Energy 2019, 183, 40–49. [Google Scholar] [CrossRef]

- E, J.; Liu, G.; Liu, T.; Zhang, Z.; Zuo, H.; Hu, W.; Wei, K. Harmonic response analysis of a large dish solar thermal power generation system with wind-induced vibration. Sol. Energy 2019, 181, 116–129. [Google Scholar]

- E, J.; Zhang, B.; Zeng, Y.; Wen, M.; Huang, Z.; Wei, K.; Chen, J.; Zhu, H.; Deng, Y. Effects analysis on active equalization control of lithium-ion batteries based on intelligent estimation of the state-of-charge. Energy 2022, 238, 121822. [Google Scholar] [CrossRef]

- E, J.; Luo, B.; Han, D.; Chen, J.; Liao, G.; Zhang, F.; Ding, J. A comprehensive review on performance improvement of micro energy mechanical system: Heat transfer, micro combustion and energy conversion. Energy 2022, 240, 122509. [Google Scholar] [CrossRef]

- Yi, F.; E, J.; Zhang, B.; Zuo, H.; Wei, K.; Chen, J.; Zhu, H.; Zhu, H.; Deng, Y. Effects of coupling phase change material and liquid cooling on heat dissipation characteristics of Lithium-ion battery thermal management system. Renew Energy 2022, 181, 472–489. [Google Scholar] [CrossRef]

- E, J.; Meng, T.; Chen, J.; Zhao, X.; Zhang, B.; Peng, Q. Effect analysis on performance enhancement of a hydrogen/air non-premixed micro combustor with sudden expansion and contraction structure. Energy 2021, 230, 120727. [Google Scholar] [CrossRef]

- E, J.; Ding, J.; Chen, J.; Liao, G.; Zhang, F.; Luo, B. Process in micro-combustion and energy conversion of micro power system: A review. Energy Convers. Manag. 2021, 246, 114664. [Google Scholar] [CrossRef]

| Property Specification | Units | Biodiesel Standard | |||

|---|---|---|---|---|---|

| ASTM D6751 | EN 14214 | ||||

| Test-Method | Limits | Test-Method | Limits | ||

| Density at 15 °C | kg/m3 | ASTM D1298 | 880 | EN-ISO 3675/12185 | 860–900 |

| Kinematic viscosity at 40 °C | mm2/s | ASTM D445 | 1.9–6.0 | EN-ISO3104 | 3.5–5.0 |

| Cetane number | - | ASTM D613 | 47 minimum | EN-ISO5165 | 51 minimum |

| Cloud point | °C | ASTMD2500 | −3 to −12 | - | - |

| Flash point | °C | ASTMD93 | 130 minimum | ENISO3679 | 101 minimum |

| Pour point | °C | ASTMD97 | −15 to −16 | - | |

| Second Generation Biodiesel | Density (kg/m3) | Kinematic Viscosity (mm2/s) | Cetane Number | Cloud Point (°C) | Flash Point (°C) | Pour Point (°C) | Heating Value (MJ/kg) |

|---|---|---|---|---|---|---|---|

| Diesel | 850 | 2.44–2.60 | 47–50 | - | 68–75 | −20 | 42–44.3 |

| Babassu | 872.5 | 4.20 | 63.25 | 4 | 117 | - | 31.8 |

| Carapa | 871.4 | 4.75 | 42.6 | −10 | 70 | - | 38.55 |

| Castor | 922 | 17.14 | 37.55 | −11.16 | 178.56 | −20 | 38.09 |

| Camelina | 885 | 4.11 | 48.91 | 2.5 | 150 | −6.3 | 45.2 |

| Croton | 870 | 4.07 | 42.57 | −4 | 164 | −5 | 39.786 |

| ETH-mustard | 844.5 | 5.12 | 50.5 | 16 | 134.75 | 15 | 41.4 |

| Jatropha | 865 | 4.52 | 55.43 | 5.66 | 175.5 | 6 | 40.79 |

| Karanja | 889 | 4.79 | 56.55 | 13.3 | 157.4 | 6.4 | 36.56 |

| Linseed | 852 | 3.95 | 34.6 | 2.43 | 241 | −9.6 | 37.45–41.8 |

| Mahua | 895 | 4.77 | 55 | 4.33 | 129.5 | 4.33 | 36.9–39.4 |

| Meliaceae | 893 | 4.72 | 44 | 8 | 188.5 | 8 | 39.96 |

| Merrill | 876 | 5.14 | 76.74 | 7.66 | 148.66 | 0.67 | 44.986 |

| Milkweed | 870 | 4.6 | 50 | 2.23 | 128 | 2.23 | 39.7 |

| Nahar | 893 | 5.67 | 54.6 | 6.1 | 131.5 | −1.2 | 35 |

| Neem | 865 | 5.30 | 52 | 6.7 | 152 | 3.1 | 38.34 |

| Papaya-seed | 840 | 3.53 | 48.29 | - | 112 | - | 38.49 |

| Polanga | 878.6 | 4.75 | 56.8 | 11.73 | 151.66 | 8.43 | 39.39–41.3 |

| Poon | 876 | 5.82 | 54.83 | 1.6 | 153.75 | −0.2 | 40.09 |

| Rubber | 875 | 5.60 | 53 | 3.1 | 173.4 | −7 | 39.174 |

| Stone-fruit-kernel | 855 | 4.26 | 50.45 | −4 | 105 | −8 | 39.64 |

| Tobacco | 865 | 3.56 | 51.5 | - | 165 | −12 | 42.22 |

| Terminalia-catappa | 876 | 4.3 | 57.1 | - | 90 | 6 | 37.73 |

| Terminalia-belerica | 883 | 4.98 | 53.2 | 5 | 126 | 3 | 39.22 |

| Third Generation Biodiesel | Density (kg/m3) | Kinematic Viscosity (mm2/s) | Cetane Number | Cloud Point (°C) | Flash Point (°C) | Pour Point (°C) | Heating Value (MJ/kg) |

|---|---|---|---|---|---|---|---|

| Diesel | 850 | 2.44–2.60 | 47–50 | - | 68–75 | −20 | 42–44.3 |

| Animal waste fat | 882.04 | 4.92 | 58.7 | 11 | 170 | - | 37.327 |

| Algae | 880 | 5.58 | - | 6 | 46 | 3 | 30.881 |

| Chlorella | 900 | 4.22 | 52 | - | 124 | - | 40.04 |

| Chicken waste fat | 865 | 4.11 | 56 | −5 | 170 | - | 40.2 |

| Fish oil | 866 | 4.4 | 56 | - | 142 | - | 37.58 |

| Grease-derived | 886 | 4.75 | - | −5 | 140 | −10 | 41.28 |

| Leather waste fat | 875.5 | 4.636 | 58.8 | - | 173.5 | 9 | 39.7 |

| Lard | 877 | 4.84 | - | - | 143.5 | 7 | 36.5 |

| Marginatum algae | 830 | 5.0 | 50 | −4 | 181 | −4 | 42.861 |

| Spirulina-platensis | 860 | 5.66 | 56.22 | - | 130 | −18 | 41.36 |

| Sheep fat raw oil | 875 | 4.5 | 61 | - | 192 | - | 40.5 |

| Sheep skin | 875 | 3.73 | - | 15 | 178 | 11 | 35.769 |

| Tallow | 873.2 | 5.85 | 56 | - | 53 | - | 38.35 |

| Turkey render fat | 885.8 | 4.49 | 52.4 | 0 | 178.1 | 4 | 40.68 |

| Waste cooking oil | 876.08 | 3.658 | 50.54 | - | 160 | - | 39.767 |

| Waste fish oil | 875 | 4.14 | 41 | - | 169 | - | 51.5 |

| Generations | Benefits | Limitations |

|---|---|---|

| First generation | Accessible raw material for biodiesel production, easy availability of crops, and easy production processes. | Conflict with the food supply, lower crop yield, and less feedstock adaptability for the environment. |

| Second generation | No effect on food supply, fewer production costs, more getable feedstocks | Lower cost of conversion, and efficiency, lower crop yield for some feedstocks |

| Third generation | The feedstocks such as waste cooking oil can be produced from no land, have no effect on food supply, and have higher growth rates. | Higher costs for energy conversion and higher energy for algae culture, lower oil content in some feedstocks |

| Fourth generation | Higher energy conversion efficiency decreased the CO emissions, and carbon neutralization. | Higher cost in the production Infancy level in the research |

| CR | Diesel (ppm) | Generation | Biodiesel (ppm) | % (Lower) |

|---|---|---|---|---|

| 16.5 | 2998.2 | First | 2553.8 for soybean | 14.82 |

| Second | 2974.8 for Jatropha | 0.78 | ||

| Third | 2663 for spirulina | 11.18 | ||

| 17.5 | 3148.8 | First | 2668.7 for soybean | 15.24 |

| Second | 1900.8 for Jatropha | 39.63 | ||

| Third | 2668.5 for spirulina | 15.25 | ||

| 18.5 | 3388.8 | First | 2770.3 for soybean | 18.25 |

| Second | 1941.6 for Jatropha | 42.7 | ||

| Third | 2770.4 for spirulina | 18.24 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Zhong, Y.; Lu, S.; Zhang, Z.; Tan, D. A Comprehensive Review of the Properties, Performance, Combustion, and Emissions of the Diesel Engine Fueled with Different Generations of Biodiesel. Processes 2022, 10, 1178. https://doi.org/10.3390/pr10061178

Zhang Y, Zhong Y, Lu S, Zhang Z, Tan D. A Comprehensive Review of the Properties, Performance, Combustion, and Emissions of the Diesel Engine Fueled with Different Generations of Biodiesel. Processes. 2022; 10(6):1178. https://doi.org/10.3390/pr10061178