Recent Developments and Applications of Solid Phase Microextraction (SPME) in Food and Environmental Analysis—A Review

Abstract

:1. Introduction

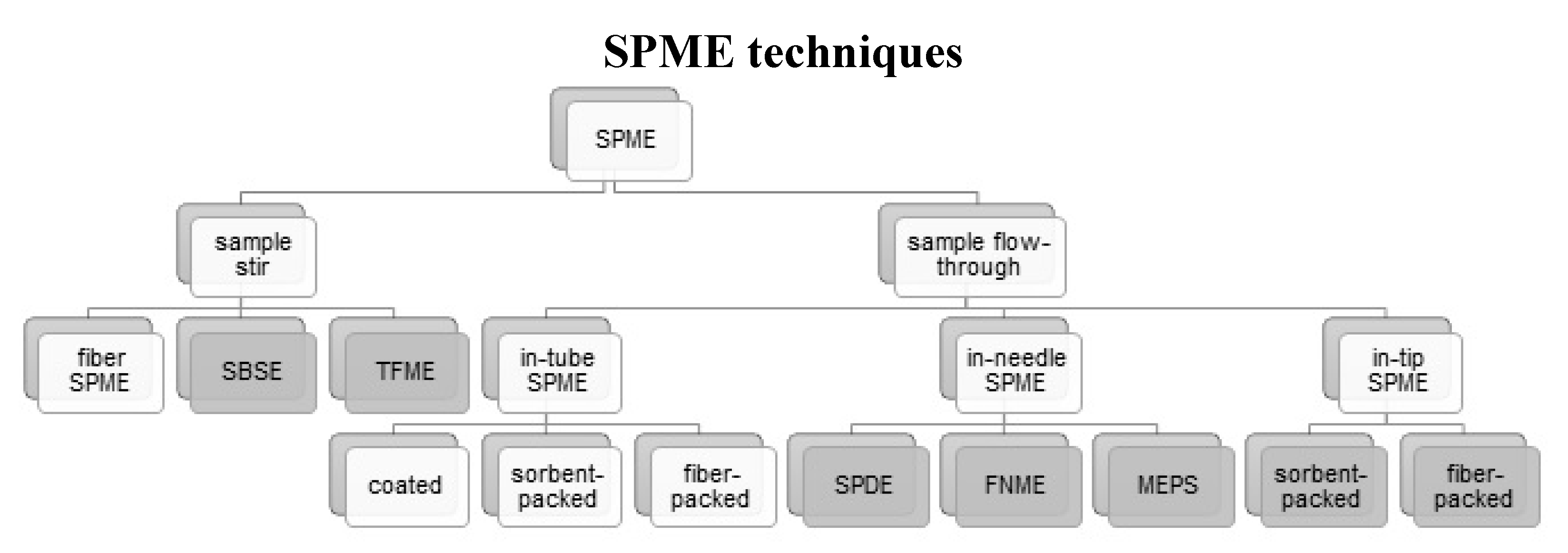

2. SPME Techniques

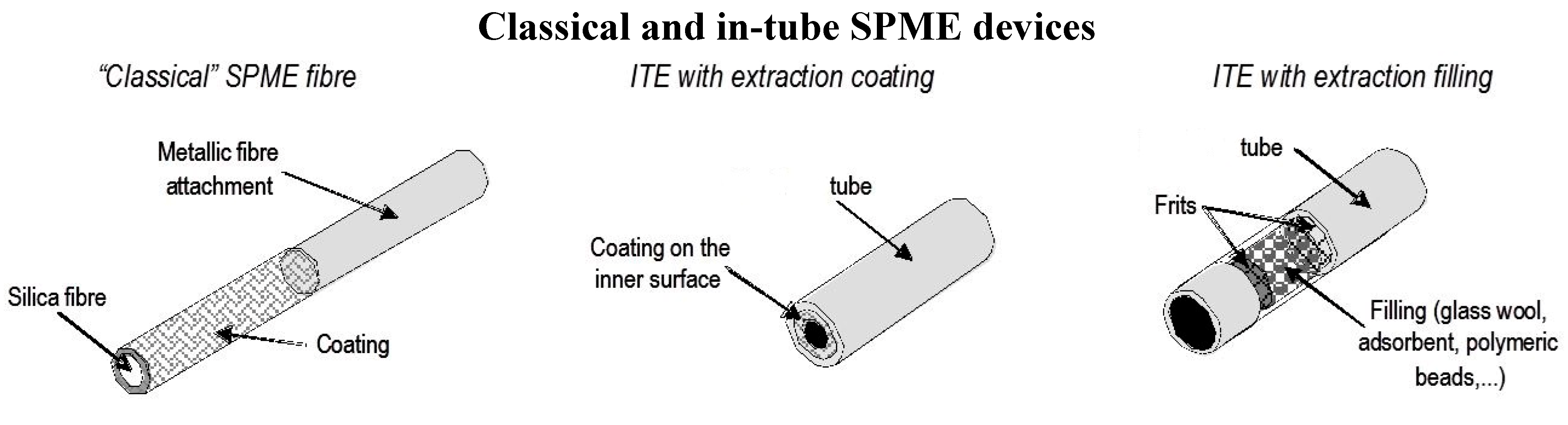

2.1. Fiber Solid-Phase Microextraction

2.2. In-tube Solid-Phase Microextraction

2.3. Cooled Coated Fiber Device

2.4. Non-fiber SPME Techniques

3. SPME Process

3.1. Extraction and Desorption Techniques

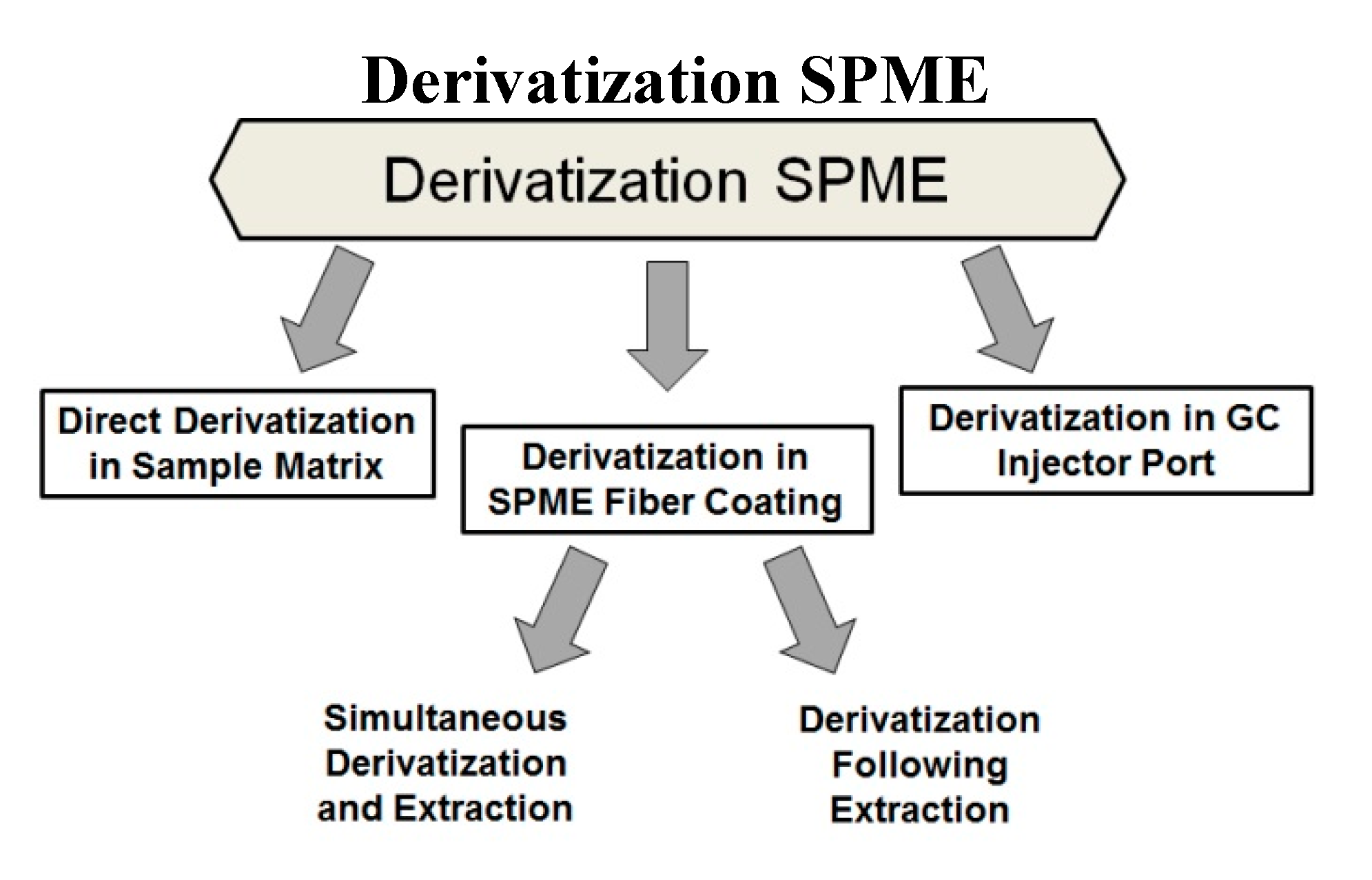

3.2. Derivatization

3.3. Salt-addition

3.4. Fiber Coatings

| Dipping and physical agglutinating methods | Sol-gel technology | Chemical grafting | Electrochemical methods | Electro-spinning | Liquid-phase deposition | Hydro-thermal methods |

|---|---|---|---|---|---|---|

| Carbon nanomaterials [26,120] Ordered mesoporous materials [121,122] Ionic liquids and polymeric ionic liquids [123,124] | Functionalized or polymer-functionalized carbon nanomaterials [125,126,127] Ionic liquid-mediated SPME coating [128,129] Sol-gel derived polymeric ionic liquid-based SPME coatings [130,131] Sol-gel ordered mesoporous silica SPME coating [132,133] Sol-gel coating on metal wires [134,135] Sol-gel molecularly imprinted polymer coatings [113,136] Aptamer Sol-gel SPME [137] | Nanomaterials [138,139] Immunoaffinity SPME [140] Molecularly imprinted polymers [141,142] Substrate-bonded ionic liquid coatings [143] Substrate-bonded polymeric ionic liquid coatings [144] | Electrodeposition Electropolymerized conductive polymers [88,145,146,147] Electropolymerized conductive polymers nanocomposite [148,149] Conductive polymer-ionic liquid composites [150,151] Metal oxides [152,153] Anodized metal wires Metal oxides [154,155] Electrophoretic deposition Carbon nanotubes (CNTs) [112,113,114,115] | Electrospun epoxide polymer Carbon nanofiber-based SPME [116,156,157] | SiO2, TiO2, SnO2, ZrO2 [117] Three dimensional transition metal oxides (V, Cr, Mn, Fe, Co, Ni, Cu, Zn, In, individually or combined) [158] | ZnO nanoparticles Organic frameworks (MOFs) [118,119] |

3.5. Quantitation

3.5.1. Traditional Calibration Methods

| Calibration method | Advantages | Disadvantages | Applications | |

|---|---|---|---|---|

| Traditional | External standard Standard addition Internal standard | No extensive sample preparation Correction of sample matrix effects Compensation of matrix effects and losses of analytes during sample preparation and irreproducibility in parameters (injection in GC/LC) | Need for availability of blank sample matrices Need for stable sampling procedure and chromatographic conditions Extensive sample preparation and analysis Limited availability of suitable internal standards High cost and limited availability of isotope-labelled standards | [176,177,178] [169,170] [165,166,167,168,171,172] |

| Equilibrium extraction | Possibility to calculate concentration of analytes by amount of extracted analytes Independence of amount of extracted analytes of sample volume | Need for knowledge about distribution coefficients | [181,182] | |

| Exhaustive extraction | Possibility to calculate concentration of analytes by amound of extracted analytes and sample volume | Suitable only for small sample volumes and large distribution coefficients or need for special devices | [56,183] | |

| Diffusion-based | Fick’s first law of diffusion Interface model and cross-flow mode Kinetic calibration with standard Standard-free kinetic calibration | Suitability for TWA sampling Independency of sampling rate of face velocity Minimizing of competitive effects for solid coating through high sampling rate and short time Suitability for on-site sampling Suitability for TWA sampling No need for standard loading Possibility to calculate concentrations of all extracted analytes in sample | Sorbent should be zero sink for target analytes Very low sample rate for water sampling Need for controlled or determined flow velocity of sampling matrix Application limited to linear sampling regime Need for determination of standard loading Need for stable sampling conditions Unsuitability for long-term monitoring | [184,185] [186,187] [188,189] [190] |

3.5.2. Equilibrium Extraction

3.5.3. Exhaustive Extraction

3.5.4. Diffusion-based Calibration

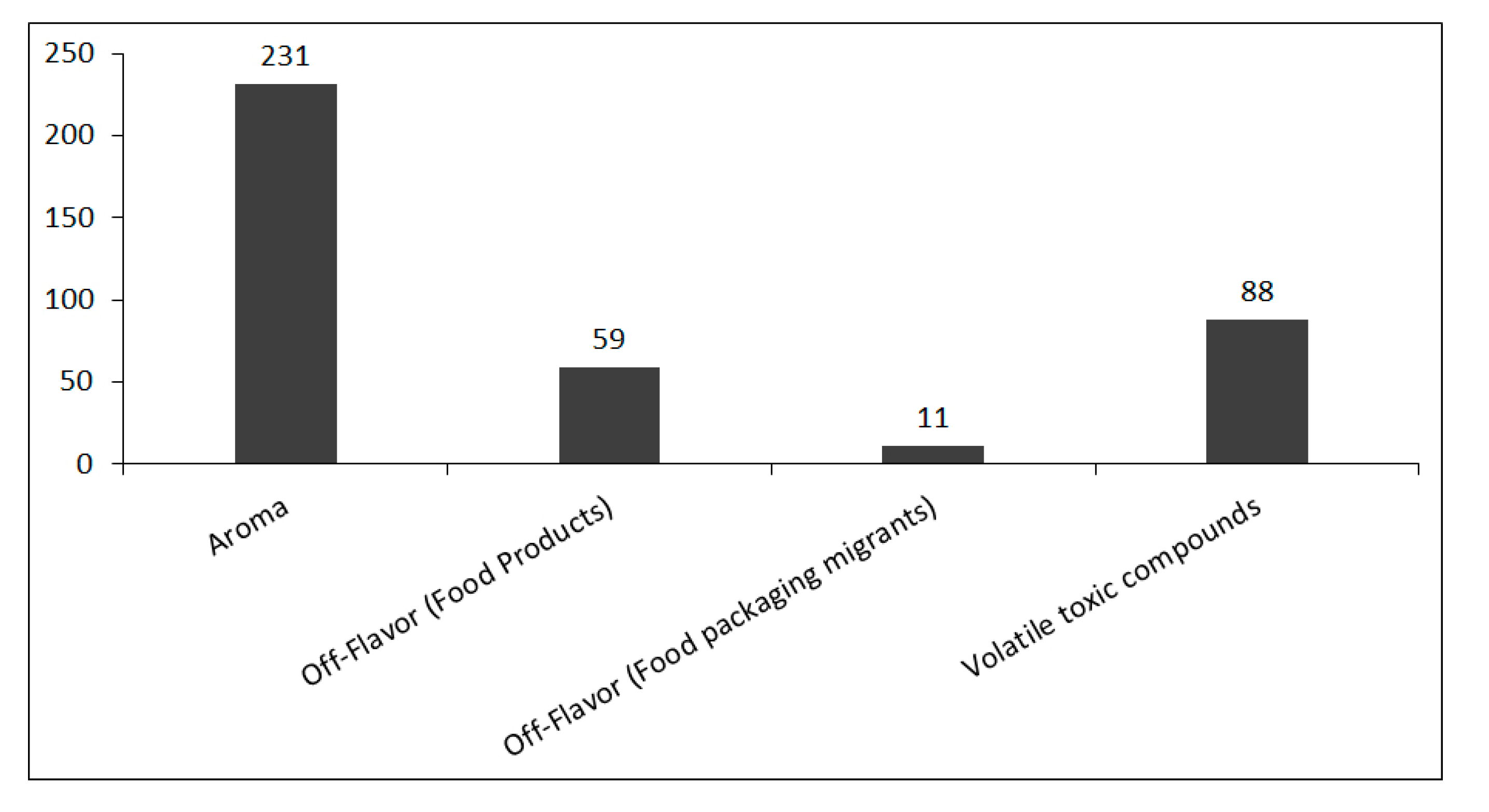

4. Applications in Food Analysis

| Extraction conditions | Desorption conditions | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Food Sample | Analyte | Technique | Fiber | Time [min] | Temp. [°C] | Salt addition | Deriv. | Time [min] | Temp. [°C] | Detection | LOD | Recovery | Ref. |

| Aroma | |||||||||||||

| Dairy products | |||||||||||||

| Butter | diacetyl | - | PDMS-DVB | 5 | 37 | - | - | 1 | 250 | GC-MS-MS | 0.0078 ppm | - | [200] |

| European PDO hard cheeses | VVC | HS-SPME | DVB-CAR-PDMS | 60 | 45 | - | - | 10 | 260 | GC-MS / GC-FID | - | - | [201] |

| PDO Cheese, Oscypek | VVC | HS-SPME | CAR-PDMS | 15 | 50 | - | - | 5 | 260 | GC-MS | - | - | [202] |

| Van Herby Cheeses | esters, ketones, alde-hydes, acids, alcohols, hydrocarbons, terpenes | HS-SPME | DVB-CAR-PDMS | 30 | 40 | - | - | 5 | 250 | GC-MS / GC-FID | - | - | [203] |

| Milk, cheese and whey powder | VVC | HS-SPME | DVB-CAR-PDMS | 30 | 40 | 4 g NaCl | - | 5 | 250 | GC-MS | - | - | [204] |

| Meat and meat products | |||||||||||||

| Roasted pork of mini-pig | VVC | DI-SPME | CAR-PDMS | 60 | 80 | 0.22 g salt | - | 4 | 280 | GC-MS / GO-O / GC-FID | - | - | [205] |

| Traditional smoke-cured bacon (CSCB) | alkane, aldehydes, ketones, alcohols, thioethers, thiols, furans, phenols | - | CAR-PDMS / DVB-CAR-PDMS | 30 | 60 | - | - | 5 | 280 | GC-MS | - | - | [206] |

| Minced beef | VVC | HS-SPME | DVB-CAR-PDMS | 30 | 40 | 25% NaCl | - | 1 | 250 | GC-MS | - | - | [207] |

| Cooked, cured pork ham | VVC | HS-SPME / SBSE | CAR-PDB-DVB / 0.5mm PDMS phase thickness stir bars | 30 / 90 | 40 / RT | - | - | 10 | 250 / 30 | GC-MS | - | - | [208] |

| Slow fermented sausages | dimethyl trisulfide, 3-methyl thiophene, 2,3-butanedione, 2-nonanoneacetic acid | HS-SPME | CAR-PDMS | 180 | 37 | - | - | 5 | 240 | GC-MS / GC-O | - | - | [209] |

| Cooked, fermented sausage | VVC | SPME | CAR-PDMS | 40 | 47 | - | - | 10 | 250 | GC-MS | - | - | [210] |

| Cooked beef | VVC | HS-SPME | DVB–CAR–PDMS | 25 | 40 | 6% NaCl | - | 3 | 250 | GC-MS | - | - | [211] |

| Juice and alcoholic beverages | |||||||||||||

| Whisky | fatty acid ethyl esters, higher alcohols, fatty acids, carbonyl com-pounds, monoterpenols, C13 norisoprenoids, volatile phenols | HS-SPME | CAR-PDMS | 60 | 40 | 30% NaCl | - | 6 | 220 | GC-MS | - | - | [212] |

| Banana Terra spirit | 3-methylbutan-1-ol, 3-methylbutan-1-ol acetate, 2-phenylethylacetate, phenylethyl alcohol | HS-SPME | PDMS-CAR-DVB | 25 | 60 | - | - | 2 | 240 | GC-MS / GC-O | - | - | [213] |

| Chinese Laobaigan liquor | VVC | HS-SPME | DVB-CAR-PDMS / CAR-PDMS | 40 | 60 | 3 g NaCl | - | 5 | 250 | GC-MS | - | - | [214] |

| Ice wine | aroma compounds | HS-SPME | DVB-CAR-PDMS | 5 | 45 | 1 g NaCl | - | 2 | 260 | GC-TOF-MS | trans-OL: 0.015 g/mL; cis-OL: 0.01 g/mL | - | [215,216] |

| Wine | 2-methyl-3-furanthiol, 4-mercapto-4-methyl-2-pentanone, 3-mercaptohexanol, 2-furanmethane-thiol, 3-mercaptohexyl acetate | HS-SPME | PDMS–DVB | 10 | 55 | - | on-fiber deri-vatization | 2 | 250 | GC-NCI-MS | 0.03–0.8 fg | - | [85] |

| Spanish white wines | VVC | HS-SPME | CAR-PDMS | 60 | 46 | - | - | 2 | 280 | GC-MS / GC-FID | 0.1–900 ng/mL | 97–110% | [217] |

| Cherry wines | VVC | HS-SPME | DVB-CAR-PDMS | 45 | 50 | 2 g NaCl | - | 5 | 230 | GC-MS | 0.03–7.27 µg/L | 60.7–125.6% | [218] |

| China gingko wine | VVC | HS-SPME | CAR-PDMS | 45 | 50 | saturated NaCl solution | - | 4 | 250 | GC-MS | - | - | [219] |

| Black raspberry wines | VVC | HS-SPME | PDMS-DVB | 30 | 60 | - | - | 5 | 230 | GC-MS | - | - | [220] |

| Beer | alcohols, esters, organic acids, aldehydes, ketones, terpenes, sulfur com-pounds, amines, phenols | HS-SPME | TMSPMA-OH-TSO prepared by sol-gel technology | 30 | 40 | 2 g NaCl | - | 5 | 300 | GC | 0.01–35.2 µg/L | 92.8–105.8% | [221] |

| Yellow passion fruit juice | VVC | HS-SPME | PDMS-DVB | 20 | 50 | 17% NaCl | - | 6 | 250 | GC-MS | - | - | [222] |

| Grape juice | aroma compounds | HS-SBSE | PDMS | 120 | RT | - | - | 5 | -50 | GC-MS | - | 28.4% | [223] |

| Orange beverage emulsion | VVC | HS-SPME | CAR-PDMS | 15 | 45 | 15% NaCl | - | 8 | 250 | GC-MS | 0.06–2.27 mg/L | 88.3–121.7% | [224] |

| Coffee | aroma compounds | HS-SPME | PDMS-DVB | 20 | 60 | - | - | 1 | 270 | GC-MS | - | - | [225] |

| Coffee | VVC | HS-SPME | PDMS | 5 | 30 | - | - | - | 220 | SAW | - | - | [226] |

| Coffee | VVC | HS-SPME | DVB-CAR-PDMS | 30 | 60 | - | - | 5 | 230 | GC | - | - | [227] |

| Coffee | furans, methoxyphenols, pyrazines, and ketones | HS-SPME | poly [VC16Im][NTf2] with 50% [VBIm2C12]2[Ntf2] | 30 | RT | - | - | 5 | 175 | GC-MS / GC-FID | - | - | [123] |

| Fruits and vegetables | |||||||||||||

| Various apricot varieties | ethyl acetate, hexyl acetate, limonene, b-cyclocitral, c-decalactone, 6-methyl-5-hepten-2-one, linalool, b-ionone, menthone and (E)-hexen-2-al | HS-SPME | CAR-PDMS | 20 | 40 | - | - | 4 | 250 | GC-MS / GC-O | - | - | [228] |

| Apricot varieties | linalool, a-terpineol, b-ionone and c-decalactone | HS-SPME | CAR-PDMS | 20 | 40 | saturated NaCl solution | - | 4 | 250 | GC-MS | - | - | [229] |

| Apricot varieties | aldehydes, alcohols, acetates, esters, terpenes and acids | HS-SPME | CAR-PDMS | 30 | 40 | - | - | 2 | 250 | GC-MS | - | - | [230] |

| Jackfruit | ethyl isovalerate, 3-methylbutyl acetate, 1-butanol, propyl isovalerate, isobutyl isovalerate, 2-methyl-butanol, butyl isovalerate | HS-SPME | DVB-CAR-PDMS | 30 | 10 | - | - | 5 | 250 | GC-TOF-MS | - | - | [231] |

| Cooked peaches | VVC | HS-SPME | DVB-CAR-PDMS | 20 | 40 | - | - | 10 | 270 | GC-MS | - | - | [232] |

| Monstera deliciosa fruit | VVC | HS-SPME | PDMS-DVB | 60 | 40 | 15% NaCl | - | 6 | 250 | GC–qMS | - | - | [233] |

| Pineapple fruit | VVC | HS-SPME | PDMS-DVB | 30 | 40 | - | - | 2 | 240 | GC×GC-qMS | - | - | [234] |

| Sweet cherry cultivars | VVC | HS-SPME | CAR-PDMS | 20 | 45 | 0.2 g NaCl | - | 10 | 260 | GC-MS | - | - | [235] |

| Air-dried raisins | free and glycosidically bound volatile compounds | HS-SPME | CAR-PDMS-DVB | 40 | 60 | 1.3 g NaCl | - | 8 | - | GC-MS | - | - | [236] |

| Table grapes | alcohols, carbonyls, C6 compounds, terpenoids, esters | HS-SPME | PDMS-DVB | 30 | 40 | 2 g CaCl2, 20 g NaCl | - | 3 | 220 | GC-MS | - | - | [237] |

| Tomato | VVC | HS-SPME | DVB-CAR-PDMS | 15 | 50 | saturated CaCl2 solution | - | 10 | 250 | GC-MS | - | - | [238] |

| Miscellaneous | |||||||||||||

| Thistle honey | VVC | HS-SPME | DVB-CAR-PDMS | 40 | 60 | 30% NaCl | - | 2 | 250 | GC-MS | - | - | [239] |

| Croatian lime tree, fir honey-dew, sage honey | VVC | HS-SPME | DVB-CAR-PDMS | 20 | 40 | 0.5 g an-hydrous Na2SO4 | - | 3 | 250 | GC-MS | - | - | [240] |

| Honey | VVC | HS-SPME | PDMS-DVB | 40 | 50 | - | - | 2 | 250 | GC-QTOF-MS | - | - | [241] |

| Extra virgin olive oils | VVC | HS-SPME | DVB-CAR-PDMS | 10 | 40 | - | - | 5 | 260 | GC-FID | - | - | [242] |

| Extra virgin olive oils | VVC | HS-SPME | DVB-CAR-PDMS | 360 | 30 | - | - | 4 | 270 | GC-MS | - | - | [243] |

| Virgin olive oil | VVC | HS-SPME | DVB-CAR-PDMS | 40 | 40 | - | - | 5 | 300 | GC-MS | 0.1–2.54 mg/kg | - | [244] |

| Black and white rice bran | terpenoid flavor odorants | HS-SPME | PDMS | 30 | 100 | - | - | 0.2 | 250 | GCxGC-MS | - | - | [245] |

| Italian rice cultivars | VVC | HS-SPME | DVB-CAR-PDMS | 60 | 60 | - | - | 5 | 250 | GC-MS | - | - | [246] |

| Palm sugar | N-heterocyclic and O-heterocyclic compounds | HS-SPME | DVB-CAR-PDMS | 10 | 50 | - | - | 5 | 240 | GC-MS | - | - | [247] |

| Almond cultivars | VVC | HS-SPME | DVB-CAR-PDMS | 60 | 60 | - | - | 10 | 270 | GC-MS | - | - | [248] |

| Saffron | VVC | HS-SPME | PDMS | 20 | 36 | - | - | 0.4 | 250 | GC-MS | - | - | [249] |

| Garlic | VVC | HS-SPME | CAR-PDMS | 30 | 30 | - | - | 3 | 220 | GC-MS | - | - | [250] |

| Atlantic shellfish species | VVC | HS-SPME | CAR-PDMS | 30 | 80 | 10 mL saturated NaCl solution | - | 10 | 260 | GC-MS | 0.12–1.19 ppb | 59.3–119.6% | [251] |

| Off-Flavor | |||||||||||||

| Food products | |||||||||||||

| Beer and beverage | sulfur compounds | HS-SDME / DI-SPME / HS-SDME | PDMS | 5 | 25 | 2.0 g NaCl / 20% NaCl solution | - | 5 | 250 | GC-FPD | 0.5 ng/mL for DPrDS -208.1 ng/mL | beer: 85.5–106.9%; bevera-ges: 95.2–110.8% | [252] |

| Beer | esters and vicinal diketones | HS-SPME | DVB-CAR-PDMS | 30 | 60 | 3.0 g NaCl | - | - | 260 | GC-MS | - | - | [253] |

| Wine | volatile sulfur compouds | HS-SPME | CAR-PDMS | 20 | 35 | - | - | 7 | 300 | GC-pFPD | 0.5 µg/L | 0–100% | [254] |

| Chardonnay and Pinot gris wines | 2-aminoacetophenone | DI-SPME | DVB-CAR-PDMS | 30 | 30 | - | - | - | 250 | GC-MS | - | 70–80% | [255] |

| Orange juice | guaiacol and halogenated phenol | HS-SPME | DVB-CAR-PDMS | 30 | 40 | - | - | 5 | 220 | GC-MS / GC-O | - | - | [256] |

| Water and apple juice | geosmin | HS-SPME | PDMS synthesized as coated fiber by sol-gel technology | 25 | 40 | 37% NaCl | - | 4 | 250 | GC-MS | 1–1.000 ng/L | 95–102% | [257] |

| Coffee beverage | volatile compounds produced by fungi | HS-SPME | DVB-CAR | 30 | 65 | - | - | 0.7 | 270 | GC-MS | - | - | [258] |

| Rapeseed oil | hexanal, 2,4-heptadienal, 2-heptenal and 1-pentene-3-ol | HS-SPME | CAR-DVB-PDMS | 35 | 50 | - | - | - | 150 | MS | - | - | [259] |

| Conventional and high-oleic sunflower oil | hexanal, (E)-2-heptenal, (E)-2-decenal, (E,E)-2,4-nonadienal | HS-SPME | CAR-DVB-PDMS | 60 / 90 / 120 | 40 / 60 / 80 | - | - | 5 | 270 | MS | 0.4–4.3 mg/L | - | [260] |

| Conventional and high-oleic rapeseed oil | octanal, 3-octanone, propanal, (E,E)-2,4-hexa-dienal, (E)-2-heptenal | HS-SPME | CAR-DVB-PDMS | 90 | 40 | - | - | 5 | 270 | MS | 3.7–816.5 µg/L | - | [261] |

| Various frying oils | (E,E)-2,4-decadienal, heptanal, (E,E)-2,4-heptadienal, (E)-2-decenal | HS-SPME | CAR-DVB-PDMS | 90 | 40 | - | - | 5 | 270 | MS | 0.03–47.2 µg/L | - | [262] |

| Almond oils | hexanal, (E)-2-heptenal, (E)-2-octenal, nonanal, (E)-2-nonenal, (E,E)-2,4-nonadienal, (E,E)-2,4-decadienal | HS-SPME | DVB-CAR-PDMS | 60 | 60 | - | - | 10 | 270 | GC-MS | - | - | [263] |

| Butter | hexanal | HS-SPME | CAR-PDMS | 180 | 4 | - | - | 5 | 250 | GC-MS | - | 97.37% | [264] |

| Soymilk | aldehydes, alcohols, ketones, aromatic compounds, esters, furans | HS-SPME | CAR-PDMS | 20 | 40 | - | - | 3 | 300 | GC-MS | - | - | [265] |

| Fresh chilled pasteurised milk | microbially induced changes in volatile constituents | HS-SPME | CAR-PDMS | 30 | 40 | - | - | 2 | 240 | GC-MS / PTR-MS | - | - | [266] |

| Full fat bovine milk | volatile compounds (pentanal, pentanol, hexanal) produced by photooxidation | HS-SPME | CAR-PDMS | 30 | 50 | - | - | 0.02 | 250 | GC-MS | - | - | [267] |

| Chicken breast | sulfides methanethiol, dimethyl disulfide, di-methyl trisulfide, ethanol, 1- and 2-butanol, 1-butanol isomers, free fatty acids | HS-SPME | PDMS | 15 | 50 | - | - | 3 | 200 | GC-MS-FASST | - | - | [268] |

| Whiting | trimethylamine, 3-methyl-butanal, 2-methyl-butanal, 3-hydroxy-2-butanone, 3-methyl-1-butanol, 2-methyl-1-butanol | HS-SPME | CAR-PDMS | 40 | 50 | saturated NaCl solution | - | 0.16 | 250 | GC-MS | - | - | [269] |

| Rainbow trout | geosmin | HS-SPME | DVB-PDMS | 20 | 65 | 3.0 g NaCl | - | 3 | 270 | GC-MS | - | - | [270] |

| Potato crisps | VVC | HS-SPME | CAR-PDMS | 20 | 50 | - | - | 3 | 300 | MS e-nose / GS e-nose | - | - | [271] |

| Food packaging migrants | |||||||||||||

| Cork | chloroanisoles | CF-HS-SPME | PDMS | 10 | 130 / 10 | - | - | 3 | 260 | GC-TOF-MS | - | >90% | [56] |

| Wine | chlorophenols and chloroanisoles | MHS-SPME | DVB-CAR-PDMS | 60 | 70 | - | KHCO3 and acetic acid anhy-dride | 5 | 280 | GC-MS-MS | 0.004–0.077 ng | - | [80] |

| Wine | 4-ethylphenol, 4-ethylguaiacol | SPME | PDMS-CAR | 30 | 60 | - | - | 15 | 220 | GC-MS | - | - | [272] |

| Wine | 2,4,6-trichloroanisole, 2,3,4,6-tetrachloroani-sole, pentachloroanisole, 2,4,6-tribromoanisole, 4-ethylphenol (4-EP), 4-ethylguaiacol, 4-vinyl-phenol, 4-vinylguaiacol | MHS-SPME | DVB-CAR-PDMS | 60 | 70 | - | - | 5 | 270 | GC-MS-MS | 4-EP: 1800 g/L; others: 1000 g/L | 93.85–101.27% | [273] |

| Wine | haloanisoles | MHS-SPME | DVB-CAR-PDMS | 35 | 60 | 99.8% NaCl | - | 4 | 250 | GC-ion-trap MS | 120.70–150 pg | 88.8% | [274] |

| Water and honey | chlorophenols | DMSPE-HS-SPME | PVC/MWCNTs nanocomposite | 15 | 60 | 5 mol/L NaCl solution | - | 4 | 215 | GC-ECD | 0.08–0.6 ng/mL | 91–109% | [120] |

| Volatlile toxic compounds | |||||||||||||

| Contaminants | |||||||||||||

| Milk | diethylstilbestrol | DI-SPME | CNT reinforced hollow fiber | 30 | 60 | - | - | 10 | - | HPLC | 5.1 mg/L | 57.50%–120.42% | [125] |

| Milk | enzyme-generated volatile organic com-pounds associated with Listeria monocytogenes | HS-SPME | PA | 10 | 37 | - | - | 2 | 230 | GC-MS | - | - | [275] |

| Milk | PAHs | DI-SPME | diethoxydiphenyl-silane prepared by sol-gel technology | 60 | 60 | - | - | 2 | 330 | GC-MS | 0.01–0.08 µg/L | - | [276] |

| Milk and honey | benzimidazole | DI-SPME | MEMF | 70 | - | - | - | 20 | - | HPLC-DAD | 0.11–0.30 μg/L | 72.3–121%; 83.1–119% | [277] |

| Chicken muscle and milk | tetracyclines (antibiotic) | SPME | molecularly imprinted polymer | 30 | - | - | - | 10 | - | HPLC | 1.0 - 2.3 µg/L | - | [141] |

| Baby formula | furfural and hydroxymethylfurfural | HS-SPME | dodecylbenzene-sulfonate-doped polypyrrole | 30 | 50 | 2 mol/L NaCl | - | - | 200 | IMS | 6 ng/g; 5 ng/g | 95% / 92% | [278] |

| Baby food and fruit juice | furan | HS-SPME | PEG and PEG/CNTs fibers prepared by sol-gel technology | 25 / 30 | 3 g NaCl | - | 0.25 | 230 | GC-FID | 0.001 ng/mL; 0.00025 ng/mL | 92–98.5% | [126] | |

| Fruit juices | carbamate and phenylurea pesticide residues | DI-SPME | PDMS-DVB and CW-TPR | 90 | 20 | 0.3 g 30% NaCl | - | 15 | 250 | LC/QIT-MS | 0.001–0.01 mg/kg | 0–82% | [279] |

| Soft drinks | 4-methylimidazole | HS-SPME | PDMS-DVB | 50 | 110 | saturated NaCl solution | - | - | 270 | GC-MS / LC-MS/MS | 1.9 µg/L | - | [280] |

| Brazilian sugarcane juice | pesticideand benzo[a]pyrene | SBSE andMASE | - | 180 / 30 | 280 / 45 | saturated NaCl solution | - | 11 | 250 | TD-GC-MS / LVI-GC-MS | 0.002–0.4 µg/L; 0.004 - 0.56 µg/L | 0.2–55.3%; 13.6–103.1% | [281] |

| Carbonated drink, juice drink, sauce, jam, succade | benzoic and sorbic acids | in-tube SPME | diethylamine-modified poly(GMA-co-EDMA) monolithic capillary | 5 | - | - | - | 7 | - | HPLC-UV | 1.2; 0.9 ng/mL | 84.4–106% | [282] |

| Water and juice | benzoylurea insecticides | MMF-SPME | MMF/MAED | 70 | - | - | - | - | - | HPLC-DAD | water: 0.026–0.075 mg/L; juice: 0.053–0.29 mg/L | 65.1–118% | [283] |

| Drinking water | organic micro-pollutants | DI-SPME | PDMS-DVB | 30 | 60 | - | - | - | 280 | GC-MS | 0.5–10 µg/L | - | [284] |

| Apple, apple juice, tomato | organophosphorus pesticides | HS-SPME | PDMS-DVB including B15C5 prepared by sol-gel technology | 45 | 70 | 5 g NaCl | - | 5 | 270 | GC-FPD | 0.003–0.09 ng/g | apple juice: 71.5 –01.6% apple: 83.3–97.7% tomato: 55.3–105.3% (spiked 5 ng/g) | [285] |

| Apples | polycyclic aromatic hydrocarbons, benzene, toluene, ethylbenzene, xylene | HS-SPME | CAR-PDMS | 45 | 60 | - | - | 5 | 250 | GC-MS | 0.02 mg < LOD < 0.26 mg | 0.012–0.140 µg | [286] |

| Fruit and vegetables | pesticide residues | HS-SPME | PDMS | 34 | 62 | 10% NaCl | - | 7 | 270 | GC-MS | 0.35–8.33 µg/kg | 73–118% | [287] |

| Packaged fresh vegetables | volatiles derived from Salmonella typhimurium | HS-SPME | CAR-PDMS | 15 | 20 | - | - | 3 | - | GC-MS | - | - | [288] |

| Vegetables | PAHs | HS-SPME | benzoxy-C[6]/OH-TSO prepared by sol-gel technology | 40 | 60 | NaCl | - | 10 | 280 | GC-FID | 0.04–2.32 ng/g | 81.07–107.5% | [289] |

| Vegetables | organophosphorus pesticide residues | DI-SPME | PA | 30 | RT | 10% NaCl | - | 11 | 260 | GC-FPD | 0.01–0.14 µg/L | - | [290] |

| Radish | organochlorine pesticides | HS-SPME | calix[4]arene/hy-droxy-terminated silicone oil prepared by sol-gel technology | 30 | 70 | 1.0 g K2SO4 | - | 2 | 270 | GC-ECD | 1.27–174 ng/kg | 83.05–119.3% | [291] |

| Roasted coffee | furan | HS-SPME | CAR-PDMS | 30 | 35 | - | - | - | - | GC-MS | 3–10 μg/kg | 76–101% | [292] |

| Wine | 2,4,6-trichloroanisole, dibutyl phthalate | SR-SPME | graphene and graphene oxide prepared by sol-gel technology | 20 | 45 | 20% NaCl | - | 5 | 250 | GC-MS | 0.3 ng/L | 96.96% / 98.20% | [293] |

| Still and fortified wines | fungicides captan, chlorthalonil, folpet, iprodione, procymidone and vinclozolin, acaricide dicofol | DI-SPME | PDMS | 60 | 35 | - | - | 3 | 250 | GC-MS/MS | - | 70–120% | [294] |

| Breaded fish products | furanic compounds | HS-SPME | CAR-PDMS | 40 | 37 ± 1 | 3 g NaCl | - | 10 | 280 | GC-MS | - | - | [295] |

| Fresh, deep frozen, canned, boiled, roasted fish | formaldehyde | HS-SPME | CAR-PDMS | 30 | 80 | - | PFBHA | 3 | 310 | GC-MS | 17 µg/kg | 94.8 ± 1.7% | [81] |

| Cooked, peeled tropical shrimps | 3-methyl-1-butanal, 2,3-butanedione, 2-methyl-1-butanal, 2,3-heptanedione and trimethylamine induced by isolated bacteria | HS-SPME | CAR-PDMS | 25 | 40 | - | - | 5 | 280 | GC-MS | - | - | [296] |

| Packaged, aged, fresh beef | VOCs associated with Salmonella | HS-SPME | CAR-PDMS | 30 | 23 ± 2 °C | - | - | 10 | 270 | GC-MS | - | - | [297] |

| Smoked meat products | PAHs | DI-SPME | PDMS | 60 | 25 | - | - | 30 | 250 | GC-MS | 0.008–0.138 ng/mL | - | [298] |

| Meat roasted in plastic bags | plasticisers (phthalates) | DI-CF-SPME | PA | 30 | 45 | - | - | 0.02 | 250 | GC-MS | 0.01–0.18 µg/kg | - | [134] |

| Fruit leathers | carbonyl compounds generated from ozone-based food colorants decomposition | HS-SPME | PDMS-DVB | 15 | 60 | - | PFBHA methanol | - | 250 | GC-MS | 0.016–0.030 μg/L | - | [86] |

4.1. Aroma

4.2. Off-Flavors

4.3. Volatile Toxic Compounds

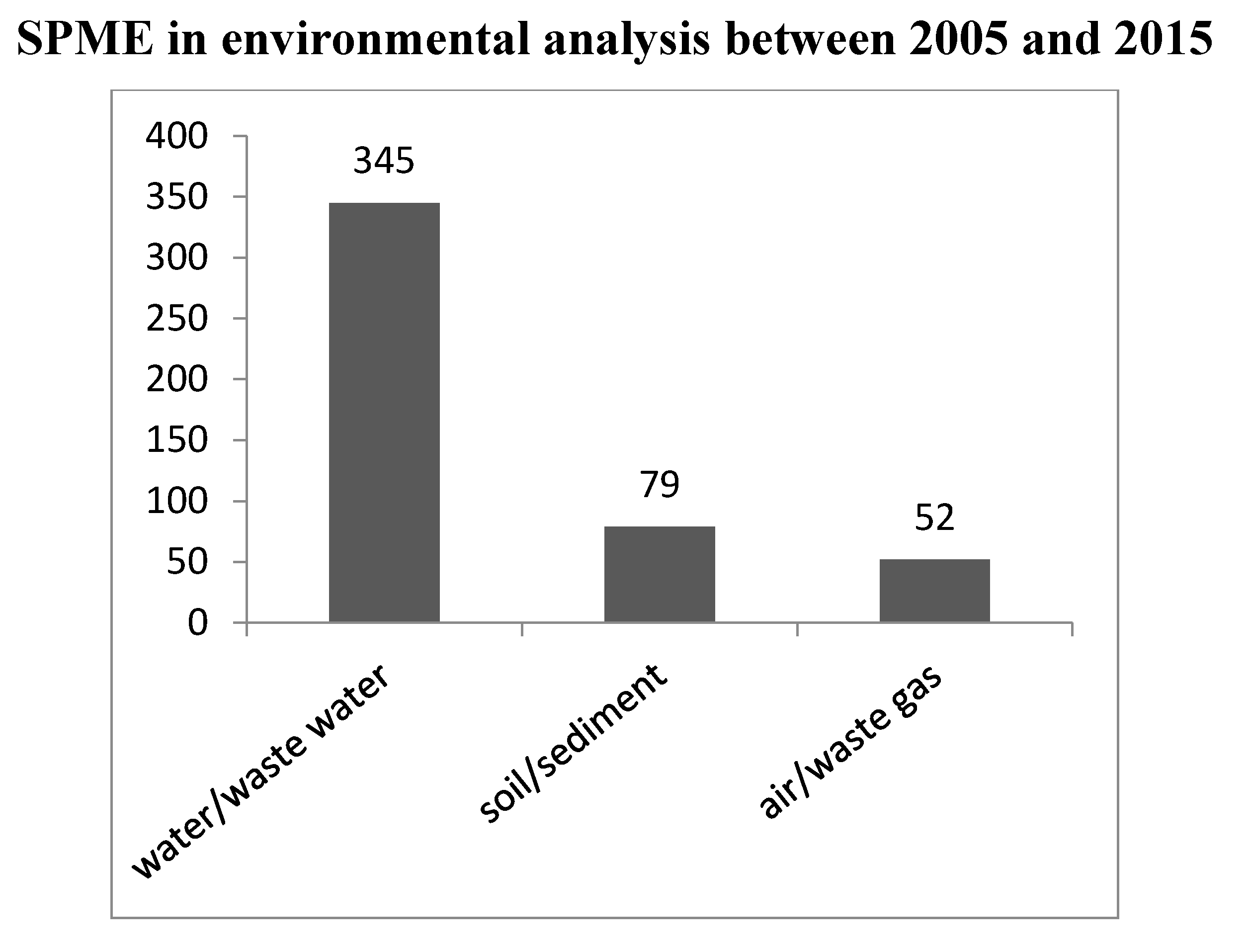

5. Environmental Applications

5.1. Air Samples

| Extraction conditions | Desorption conditions | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Analyte | Environmental Sample | Technique | Fiber | Time [min] | Temp. [°C] | (Salt) Addition | Deriv. | Time [min] | Temp. [°C] | Detection | LOD | Recovery [%] | Ref. |

| Air | |||||||||||||

| Pollutants | |||||||||||||

| Volatile organohalogen compounds | workplace air | SPME | sol-gel SWCNT / silica | 15 | RT | - | - | 3 | 280 | GC-MS | 0.09–0.2 ng/mL | - | [127] |

| Formaldehyde and other carbonyl compounds | indoor air | SPME | PDMS-DVB | 15 | RT | - | PFBHA | 4 | 250 | GC-MS | 0.002–0.032 µg/m³ | - | [82] |

| Acetaldehyde, acetone, BTX, pinene, trichloroethylene, alkanes | indoor air (classrooms) | SPME | PDMS-CAR | 240 | RT | - | - | 2.5 | 320 | GC-MS | 0.05–5.9 µg/m³ | 79–120 | [181] |

| BTEX | indoor and outdoor air | SPME | PDMS-CAR | 30 | 14–24 | - | - | 2 | 260 | GC-MS | 0.05–0.1 µg/m³ (benzene) | - | [319] |

| PAH | ambient air particulate matter (PM10, TPS), sampling on quarz filter disks and extraction with water/methylene chloride/acetone | DI-CF-SPME | PDMS | 60 | 70 | - | - | 1 | 270 | GC-MS | 0.02–1.16 ng | 88–98 | [330] |

| Alkyl- and methoxy-phenolic compounds | biomass smoke, absorption in aqueous NaOH prior to SPME | HS-SPME | CW-DVB | 90 | - | 35% NaCl, pH 2 | - | 3 | 250 | GC-MS | 1.13–4.60 ng/mL | - | [324] |

| Organophosphate triesters | indoor air (lecture room, office) | dynamic SPME | PDMS | 40–90 min / >18 h; air flow rate 10–35 cm/s | 22 | - | - | 2 | 280 | GC-NPD | - | - | [327] |

| Volatile organic compounds | |||||||||||||

| VOC | indoor air | SPME | PDMS-CAR | 10 | RT | - | - | 10 | 300 | GC-MS / GC-FID | - | 122 ± 24 | [331] |

| VOC | indoor air | SPME | PDMS-CAR | 1–45 | - | - | - | 2.5 | 320 | GC-MS | - | - | [332] |

| VOC | air from volcanic and geothermal areas, landfill gas | SPME | PDMS-DVB-CAR | 30 | 20 | - | - | 2 | 230 | GC-MS | - | 78–84 | [323] |

| Odorous compounds | |||||||||||||

| VOC and odorous compounds | air from swine barn, cattle feedlots | SPME | PDMS-CAR | 60 | RT | - | - | 5 | 260 | GC-MS-O | - | - | [320] |

| Volatile carbon, sulfur and nitrogen compounds | air from livestock operations | dynamic SPME | PDMS-DVB-CAR | 5 min / air flow rate 16 cm/s | 20 | - | - | - | 300 | GC-MS | - | - | [328] |

| VOC and odorous compounds | swine barn particulate matter (TPS, PM10, PM2.5, PM1), adsorption on TEOM filters prior to SPME | HS-SPME | PDMS-CAR | 180 | 25 | - | - | 40 | 260 | GC-MS-O | - | - | [333] |

| Odorous compounds | waste gas from fat refinery | SPME | PDMS-CAR | 30 | RT | - | - | 5 | 290 | GC-MS / GC-FID-O | - | - | [102] |

| Odorous compounds | gaseous effluents from production of poultry feather and viscera meal, condensed prior to SPME | HS-SPME | PDMS-DVB-CAR | 20 | 50 | - | - | 4 | 250 | GC-MS | - | - | [325] |

| Volatile organic sulfur compounds | air from different areas of sewage treatment plant | SPME | PDMS-CAR | 45 | 22 /RT | - | - | 2 | 200 | GC-MS | 0.01–0.08 µg/m³ | 75–96 | [322] |

| Synthetic musks | indoor air, adsorption on Tenax TA prior to SPME | HS-SPME | DVB-CAR-PDMS | 20 | 100 | 100 µL acetone | - | 5 | 270 | GC-MS | 0.029–0.380 ng/m³ | 85–103 | [326] |

| Trimethylamine | ambient air | SPME | PDMS-DVB | 10 | 22 / RT | - | - | 3 | 210 | GC-FID | [321] | ||

| Diacetyl | air | SPME | PDMS | 2 | RT | - | - | 1 | 250 | GC-MS | 0.05 ppm | - | [200] |

| Monoterpenes | plant emissions, ambient air | SPME | PDMS-DVB | 20 | 25 / RT | - | - | 5 | 250 | GC-MS | 4–20 ppt | - | [329] |

| Water | |||||||||||||

| Odorous compounds | |||||||||||||

| Earthy-musty odorants | source, product, and tap water from different waterworks | HS-SPME | PDMS-DVB-CAR | 30 | 60 | 25% NaCl | - | 5 | 230 | GC-MS | 0.1–1.3 ng/L | 83–112 | [334] |

| Earthy-musty odorants | tap water, river water, lake water | HS-SPME | PDMS-DVB-CAR | 30 | 90 | - | - | - | - | GC-MS | 0.25–0.61 ng/L | 65–92 | [335] |

| Earthy-musty odorants | tap water, lake water | HS-SPME | PDMS-DVB-CAR | 30 | 50 | 30% NaCl | - | 3 | 265 | GC-MS | 0.32–0.66 ng/L | 86–113 | [336] |

| Odorous trichlorobromo- phenols | tap water, river water | HS-SPME | PDMS-DVB-CAR | 90 | 60 | NaCl 6.5 g/30 mL | di-methyl sulfate / NaOH | 1 | 270 | GC-MS | 0.22–0.95 ng/L | - | [337] |

| Algal taste and odor compounds | lake water | HS-SPME | PDMS-DVB-CAR | 30 | 65 | NaCl | - | 3 | 250 | GC-MS-O | sub to low ppt range | 80–115 | [87] |

| Volatile sulfur compounds | odorous freshwater lakes | HS-SPME | PDMS-CAR | 30 | 45 | - | - | 3 | 250 | GC-FPD | 1.6–93.5 ng/L | 87–112 | [338] |

| Nitro musk fragrances | tap water, wastewater | HS-SPME | PDMS-CAR, PDMS-DVB | 25 | 100 | - | - | 2 | 300 / 270 | GC-μECD | 0.25–3.6 ng/L | 96–108 | [339] |

| Volatile and semivolatile organic compounds | |||||||||||||

| VOC | surface water, wastewater from wastewater treatment plant and from municipal solid-waste treatment plant | HS-SPME | PDMS-CAR | 30 | 50 | 10% NaCl | - | 5 | 280 | GC-MS-MS | 0.005–2 µg/L | 70–120 | [340] |

| Volatile and semivolatile organic compounds | landfill leachate | SBSE | PDMS | 60–120 | RT | - | none, acetate or BSTFA | 30 °C to 280 °C at 60 °C/min, 5 min hold at 280 °C | GC-MS | - | - | [341] | |

| Volatile and semivolatile organic compounds | snow | Di-SPME/HS-SPME | PDMS-DVB | 40 / 180 | RT | - | - | 5 | 250 | GC-MS | 0.11–1.93 µg/L | - | [342] |

| Pesticides | |||||||||||||

| Pyrethroid pesticides | tap water, waste water from sewage treatment plant, run-off water, water from container used for washing oranges | DI-SPME | PDMS | 20 | 50 | 0.02% Na2S2O3, 2% acetone | - | 3 | 280 | GC-MS | 0.9–35 pg/mL | - | [343] |

| Pyrethroid pesticides | groundwater | DI-SPME | PDMS/DVB | 30 | 65 | - | - | 5 | - | LC-PIF-FD | 0.003–0.009 µg/L | 92–109 | [344] |

| Benzimidazole fungicides | seawater, ground water, sewage | DI-SPME | PDMS-CAR | 40 | 60 | 15% NaCl | - | 10 (in metha-nol) | - | HPLC-FD | 0.03–1.30 ng/mL | 81–120 | [345] |

| Organochlorine pesticides | lake water | HS-SPME | PMPVS | 30 | 80 | - | - | 2 | 270 | GC-ECD | 0.84–13.0 ng/L | 72–116 | [346] |

| Organochlorine pesticides | groundwater | DI-SPME | PDMS-DVB-CAR | 45 | RT | - | - | 2 | 260 | GC-ECD | 0.0013–0.45 ng/L | 92–105 | [347] |

| Organochlorine pesticides | seawater | HS-SPME | poly(3,4-ethylene dioxythio-phene) | 15 | 70 | - | - | 2 | 270 | GC-µECD | 0.16–0.84 ng/L | 63–127 | [146] |

| Organochlorine pesticides and metabolites | seawater, sewage, groundwater | DI-SPME | PDMS-DVB, CW/TPR | 40 | 50 /45 | - | - | 8 / 10 | - | HPLC-UV-DAD | 0.3–3.6 ng/mL | 90–104 | [348] |

| Pesticides tebuthiuron and diuron | water | DI-SPME | PA | 50 | - | - | - | 15 | - | LC-DAD | 10–50 µg/L | - | [349] |

| Pesticides | surface and groundwater | DI-SPME | PA | 30 | 50 | - | - | 5 | 280 | GC-MS | 0.02–0.3 ng/mL | 78–109 | [350] |

| Organo-phosphorus pesticides | river water | DI-SPME | sol-gel based amino fiber | 40 | 30 | 20% NaCl | - | 4 | 250 | GC-MS | 0.05–1.0 ng/L | 80–115 | [351] |

| Organochlorine (OCP), organo-phosphorus (OPP), triazine, pyrethroid, and miscellaneous pesticides | groundwater | HS-SPME | PDMS-DVB | 60 | 60 | - | - | - | - | GC-ECD- TSD / GC-MS / GC-MS-MS | <0.1 µg/L | - | [352] |

| PAH and related compounds | |||||||||||||

| PAH | tap water, surface water, underground water, rainwater | HS-SPME | PDMS | 30 | 60 | 10% NaCl | - | 2 | 280 | GC-FID | 0.06–0.5 μg/L | 71–109 | [353] |

| PAH | rainwater, strom water | DI-SPME | PDMS | 60 | 65 | 0.5 M sodium mono-chloro-acetate | - | - | - | GC-MS | 0.001–0.041 µg/L | 72–111 | [354] |

| PAH | wastewater from scrubber of pilot-scale fluidized bed incinerator system | MA-HS-SPME | PDMS-DVB | 30 | 20 | - | - | 5 | 290 | GC-FID | 0.3–1.0 µg/L | 88–103 | [355] |

| PAH | surface waters, leaching waters of contaminated soils | HS-SPME | PA | 60 | 50 | - | - | 2 | 250 | GC-FID | 0.08–0.20 µg/L | - | [356] |

| Hydroxy metabolites of PAH | mini pore water, minimal salts medium, soil extract culture medium | DI-SPME | PA | 40 | 40 | 8% NaCl | BSTFA | 3 | 280 | GC-MS | 0.002–0.134 µg/L | - | [357] |

| Phenols | |||||||||||||

| Volatile phenols | well water, drinking water | HS-SPME | PANI | 60 | 80 | 30% NaCl, pH 2 | - | 5 | 275 | GC-FID | 1.3–12.8 ng/mL | 88–103 | [88] |

| Phenols | real-life water samples | HS-SPME | PANI | 50 | 50 | NaCl, pH 2 | - | 5 | 200 | GC-FID | 0.69–3.7 ng/mL | 69–112 | [147] |

| Phenols | river water, waste water | DI-SPME | oxidized MWCNTs | 30 | 20 | 36% NaCl | - | 3 (in ACN / water 70:30) | RT | HPLC-DAD | 0.25–3.67 ng/L | 86–119 | [138] |

| Phenols and nitrophenols | rainwater | SPME | PA | 40 | RT | NaCl, pH 3.0 | MDBSTFA | 5 | 280 | GC-MS | 0.2–99 μg/L | - | [358] |

| Chlorophenols | landfill leachate | IL-HS-SPME | 1-butyl-3-methylimida-zolium hexafluoro-phosphate | 4 | 25 | pH 2 | - | 4 | 240 | GC-MS | 0.008–0.026 µg/L | 87–99 | [124] |

| Chlorophenols | landfill leachate | purge-assisted HS-SPME | PA | 30 | 75 | - | - | 3 | 130 °C (0.05 min) to 300 °C at 8 °C/s, 4 min hold | GC-MS | 0.1–0.4 pg/mL | 83–114 | [359] |

| Miscellaneous | |||||||||||||

| Organometallic compounds (mercury, lead, tin) | river water, seawater | HS-SPME | PDMS-DVB-CAR | 15 | 40 | - | sodium tetra-ethyl-borate | 2 | 260 | GC-MS-MS | 4–33 ng/L | 50–109 | [360] |

| Organo-phosphorus fire retardants and plasticizers | wastewater, MAE prior to SPME | DI-SPME | PDMS | 30 | 65 | 10% NaCl | - | 0.5 | 250 | GC-ICP-MS / GC-TOF-MS | 29–50 ng/L | 38–43 | [83] |

| Non-halogenated solvents | textile wastewater | HS-SPME | PDMS | 10 | 35 | - | - | 5 | 240 | GC-MS | 0.1–300 µg/L | - | [361] |

| Acetone | seawater | SPME | PDMS-DVB | 30 | RT | NaCl, pH 3.7 | PFBHA | 5 | 250 | GC-MS | 3.0 nM | - | [362] |

| BTEX | waste water | HS-SPME | PDMS-DVB | 1 | RT | 35% NaCl | - | 0.16 | 200 | portable GC-µFID | 0.4–1.4 µg/L | 98–111 | [89] |

| BTEX | groundwater | HS-SPME | PDMS-CAR | 15 | 25 | 267 g/L NaCl | - | 2 | 290 | cryo-trap-GC-MS | 0.01–0.05 ng/L | - | [363] |

| Acrolein | surface water, drinking water | HS-SPME | PDMS-CAR | 50 | 60 | saturated NaCl solution | 2,2,2-trifluo-roethyl-hydra-zine | - | 220 | GC-MS | 0.06 µg/L | 91–104 | [364] |

| Pharmaceutical compounds | wastewater | dSPME | CW-TPR | 30 | 75 | 300 g/L NaCl, pH 3/11 | - | 10 | - | LC-MS-MS | LOQ: 0.005–0.05 µg/L | 89–110 | [90] |

| Endocrine disrupting chemicals and steroid hormones | river water | DI-SPME | PA | 90 | 45 | 10 g/L NaCl 10, pH 5 | BSTFA | 5 | 290 | GC-MS | 0.002–0.378 µg/L | - | [365] |

| Bisphenol A | landfill leachate | HS-SPME | PA | 60 | 25 | 100 g/L NaCl, pH 2 | BSTFA | 5 | 280 | GC-MS | 0.03 µg/L | - | [91] |

| Estrogens | surface water, wastewater | IT-SPME | DVB | 20 cycles à 40 µL (100 µL/min) | - | - | - | - | - | LC-MS-MS | 2.7–11.7 pg/mL | 86–107 | [92] |

| Organic pollutants (pesticides, octyl/nonyl phenols, pentachloro-benzene, PAHs) | wastewater, landfill leachate | DI-SPME | CW-DVB | 45 | RT | NaCl 10% | - | 5 | 250 | GC-TOF-MS | - | - | [366] |

| Organochlorine pesticides and polychlorinated bisphenyls | river water | HS-SPME | PDMS | 60 | 80 | - | - | 5 | 250 | GC-MS-MS | 0.4–26 pg/L | 75–105 | [367] |

| Volatile halogenated hydrocarbons, benzene | groundwater from waste-oil recycling facility | HS-SPDE | PDMS-AC | 15 cycles à 1 mL (50 µL/s) | 60 | 5% NaCl | - | 1 mL (10 µL/s) | 300 | GC-MS | 12–870 ng/L | - | [368] |

| BTEX and halocarbons | contaminated water | HS-SPME | PAC | 20 | 40–45 | 25% NaCl | - | 1 | 260 | GC-FID-ECD | LOQ: 0.01–0.94 µg/L | 88–113 | [369] |

| Chlorobenzene | tap water, river water | HS-SPME | nanofiber coated by electrospun PU | 5 | 30 | 25% NaCl | - | 2 | 200 | GC-MS | 10 ng/L | 94–102 | [370] |

| 1,2-cis-dichloroethylene, trichloroethylene | effluent from soil column experiments | HS-SPME | PDMS | 5 | 25 | - | - | 1 | 250 | GC-FID | 2.4–4.2 µg/L | - | [371] |

| 1,3-dichloro-2-propanol | tap water, river water, paper mill sewage | HS-SPME | PDMS-DVB-CAR | 30 | 25 | NaCl | BSTFA | 5 | 260 | GC-MS-MS | 0.4 ng/mL | 93–103 | [318] |

| Epichlorohydrin | water and sewage | HS-SPME | PDMS-CAR | 15 | 50 | - | - | 1 | 240 | GC-MS, GC-ECD | water: 1.0 ng/L | - | [93] |

| Polybrominated diphenyl ethers | river water, waste water | DI-SPME | MWCNT | 30 | RT | - | - | 2 | 295 | GC-ECD | 3.6–8.6 ng/L | 90–119 | [372] |

| Soil / Sediment and other Solid Matrices | |||||||||||||

| Odorous compounds | |||||||||||||

| VOC and odorous compounds | dairy manure | HS-SPME | PDMS-DVB-CAR | 30 | 30 | - | - | - | 230 | MD-GC-MS-O | - | - | [373] |

| Odorous volatile compounds | compost | HS-SPME | PDMS-CAR | 60 | 20 | - | - | 40 | 250 | GC-MS | 0.06–2.38 ppb | - | [374] |

| Volatile and semivolatile organic compounds | |||||||||||||

| VOC | soil, manure, compost, biochar | HS-SPME | PDMS-DVB-CAR | 20 | 20 | - | - | 5 | 230 | GC-MS | 0.01–310 ng/g | - | [375] |

| VOC | cow slurry | HS-SPME | PDMS-DVB-CAR / PDMS-CAR | 15 | 35 | NaCl | - | 3 | 300 | GC-MS | 0.02–1441 µg/L | - | [376] |

| Volatile and semivolatile organic compounds | urban landfill soil | HS-SPME | PDMS-DVB | 30 | 50 | NaCl | - | - | 250 | GC-MS | - | - | [377] |

| Pesticides | |||||||||||||

| Pyrethroids, organochlorine pesticides | agricultural soils | HS-SPME | PA | 30 | 100 | - | - | 5 | 290 | GC-µECD | 0.004–1.2 ng/g | 71–147 | [378] |

| Pyrethroids | sediment pore water | SPME | PDMS | 20 | - | - | - | 3 | 260 | GC-ECD | - | - | [379] |

| PAH and related compounds | |||||||||||||

| PAH | sediment pore water, sediments | SPME | PDMS | 500 h | 18 | 1 mL 10 mM NaN3 | - | 15 | 50 °C to 250 °C at 200 °C/min | - | - | [380] | |

| PAH | coastal sediments, MAE with acetone prior to SPME | DI-SPME | PDMS | 60 | 60 | - | - | - | 270 | GC-MS | 0.07–0.76 µg/kg | 70–110 | [381] |

| PAH | sand, sediment | CF-HS-SPME | PDMS | 40 | 150 (fiber: 5) | - | - | 2 | 300 | GC-FID | 0.3–3 pg/g | - | [54] |

| Parent and alkyl PAH | sediment pore water | HS-SPME | PDMS | 30 | - | - | - | 5 | 320 | GC-MS | 0.002–0.6 ng/mL | - | [382] |

| Miscellaneous | |||||||||||||

| 4-t-octylphenol, nonylphenol, bisphenol A | activated sludge | nd-SPME | PA | - | 20 | - | - | 5 | 2800 | GC-MS | - | - | [383] |

| Phenols and indoles | cow slurry | HS-SPME | PDMS-DVB-CAR | 15 | 35 | NaCl | MTBSTFA | 9 | 300 | GC-MS | 0.004–707 µg/L | >64 | [94] |

| Polybrominated diphenyl ethers | soil | HS-SPME | sol-gel M-β-CD-OH-TSO | 60 | 95 | methanol | - | 12 | 300 | GC-MS | 13.0–78.3 pg/g | 78–99 | [384] |

| Perfluoro-carboxylic acids | harbour sediments, PFE prior to SPME | HS-SPME | PDMS | 30 | 30 | saturated NaCl solution | boron trifluo-ride | 3 | 300 | GC-MS | 0.5–0.8 ng/g | 99–103 | [95] |

| Organotin compounds | sediment | HS-SPME | PDMS | 30 | 80 | ethanol, pH 5.3 | sodium tetra-ethyl-borate | 1 | 250 | GC-MS | 1.0–6.3 µg/kg | 98–117 | [84] |

| Mono-, di- and tri-butyltin | sediment, extraction with hydrochloric acid/ethanol prior to SPME | HS-SPME | PDMS | 30 | 40 | pH 4 | sodium tetra-ethyl-borate | 2 | 250 | GC-MS-MS | 0.03–1.0 pg/g | - | [96] |

| Cyclopentadienyl-manganese tricarbonyl, (methylcyclo-penta-di-enyl)manganese tricarbonyl | seawater, soil | HS-SPME | PDMS-DVB | 20 | 60 | 5% NaCl | - | 0,25 | 250 | GC-MIP-AED | 0.62–0.65 pg Mn/g | 76–113 | [385] |

| Nitrous oxide | estuarine soils and sediments | HS-SPME | PDMS-CAR | 2 | 50 | - | - | 1 | 200 | GC-MS | 18 ppb | - | 386] |

5.2. Aqueous Samples

5.3. Solid Samples

6. Prospects and Trends

7. Conclusions

Author Contributions

Conflicts of Interest

References

- Nerín, C. Focus on sample handling. Anal. Bioanal. Chem. 2007, 388, 1001–1002. [Google Scholar] [CrossRef] [PubMed]

- Nerín, C.; Salafranca, J.; Aznar, M.; Batlle, R. Critical review on recent developments in solventless techniques for extraction of analytes. Anal. Bioanal. Chem. 2009, 393, 809–833. [Google Scholar] [CrossRef] [PubMed]

- Mondello, L.; Costa, R.; Tranchida, P.Q.; Dugo, P.; Presti, M.L.; Festa, S.; Fazio, A.; Dugo, G. Reliable characterization of coffee bean aroma profiles by automated headspace solid phase microextraction-gas chromatography-mass spectrometry with the support of a dual-filter mass spectra library. J. Sep. Sci. 2005, 28, 1101–1109. [Google Scholar] [CrossRef] [PubMed]

- Arthur, C.L.; Pawliszyn, J. Solid Phase Microextraction with Thermal Desorption Using Fused Silica Optical Fibers. Anal. Chem. 1990, 62, 2145–2148. [Google Scholar] [CrossRef]

- Pawliszyn, J. Solid Phase Microextraction: Theory and Practice; Wiley, VCH: New York, NY, USA, 1997. [Google Scholar]

- Lord, H.; Pawliszyn, J. Evolution of solid-phase microextraction technology. J. Chromatogr. A 2000, 885, 153–193. [Google Scholar] [CrossRef]

- Adahchour, M.; Beens, J.; Vreuls, R.J.J.; Batenburg, A.M.; Rosing, E.A.E.; Brinkman, U.A.T. Application of Solid-Phase Micro-Extraction and Comprehensive Two-Dimensional Gas Chromatography (GC x GC) for Flavour Analysis. Chromatographia 2002, 55, 361–367. [Google Scholar] [CrossRef]

- Chai, M.; Pawliszyn, J. Analysis of Environmental Air Samples by Solid-Phase Microextraction and Gas Chromatography/lon Trap Mass Spectrometry. Environ. Sci. Technol. 1995, 29, 693–701. [Google Scholar] [CrossRef] [PubMed]

- Kleeberg, K.K.; Dobberstein, D.; Hinrichsen, N.; Müller, A.; Weber, P.; Steinhart, H. Sampling Procedures with Special Focus on Automatization. In Advances in Food Diagnostics, 1st ed.; Nollet, L.M.L., Toldrá, F., Eds.; Blackwell Publishing: Ames, IA, USA, 2007; pp. 253–293. [Google Scholar]

- Pawliszyn, J. Method and Device for Solid Phase Microextraction and Desorption. US Patent 1997. [Google Scholar]

- Dietz, C.; Sanz, J.; Cámara, C. Recent developments in solid-phase microextraction coatings and related techniques. J. Chromatogr. A 2006, 1103, 183–192. [Google Scholar] [CrossRef] [PubMed]

- Kataoka, H.; Lord, H.L.; Pawliszyn, J. Applications of solid-phase microextraction in food analysis. J. Chromatogr. A 2000, 880, 35–62. [Google Scholar] [CrossRef]

- Jeleń, H.H.; Majcher, M.; Dziadas, M. Microextraction techniques in the analysis of food flavor compounds: A review. Anal. Chim. Acta 2012, 738, 13–26. [Google Scholar] [CrossRef] [PubMed]

- Pillonel, L.; Bosset, J.O.; Tabacchi, R. Rapid Preconcentration and Enrichment Techniques for the Analysis of Food Volatile. A Review. Lebensm.-Wiss. Technol. 2002, 35, 1–14. [Google Scholar] [CrossRef]

- Wardencki, W.; Michulec, M.; Curylo, J. A review of theoretical and practical aspects of solid-phase microextraction in food analysis. Int. J. Food Sci. Technol. 2004, 39, 703–717. [Google Scholar] [CrossRef]

- Alpendurada, M.F. Solid-phase microextraction: A promising technique for sample preparation in environmental analysis. J. Chromatogr. A 2000, 889, 3–14. [Google Scholar] [PubMed]

- Buchberger, W.; Zaborsky, P. Sorptive Extraction Techniques for Trace Analysis of Organic Pollutants in the Aquatic Environment. Acta Chim. Slov. 2007, 54, 1–13. [Google Scholar] [CrossRef]

- Ouyang, G.; Pawliszyn, J. Recent developments in SPME for on-site analysis and monitoring. TrAC Trends Anal. Chem. 2006, 25, 692–703. [Google Scholar] [CrossRef]

- Ribeiro, C.; Ribeiro, A.R.; Maia, A.S.; Gonçalves, V.M.; Tiritan, M.E. New Trends in Sample Preparation Techniques for Environmental Analysis. Crit. Rev. Anal. Chem. 2014, 44, 142–185. [Google Scholar] [CrossRef] [PubMed]

- Wardencki, W.; Curyło, J.; Namieśnik, J. Trends in solventless sample preparation techniques for environmental analysis. J. Biochem. Biophys. Methods 2007, 70, 275–288. [Google Scholar] [CrossRef] [PubMed]

- Padrón, M.E.; Afonso-Olivares, C.; Sosa-Ferrera, Z.; Santana-Rodríguez, J.J. Microextraction Techniques Coupled to Liquid Chromatography with Mass Spectrometry for the Determination of Organic Micropollutants in Environmental Water Samples. Molecules 2014, 19, 10320–10349. [Google Scholar] [CrossRef] [PubMed]

- Ouyang, G.; Pawliszyn, J. A critical review in calibration methods for solid-phase microextraction. Anal. Chim. Acta 2008, 627, 184–197. [Google Scholar] [CrossRef] [PubMed]

- Aziz-Zanjani, M.O.; Mehdinia, A. Electrochemically prepared solid-phase microextraction coatings—A review. Anal. Chim. Acta 2013, 781, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Aziz-Zanjani, M.O.; Mehdinia, A. A review on procedures for the preparation of coatings for solid phase microextraction. Microchim. Acta 2014, 181, 1169–1190. [Google Scholar] [CrossRef]

- Kumar, A.; Gaurav; Malik, A.K.; Tewary, D.K.; Singh, B. A review on development of solid phase Microextraction fibers by sol–gel methods and their applications. Anal. Chim. Acta 2008, 610, 1–14. [Google Scholar] [CrossRef] [PubMed]

- Luo, J.; Wu, Y.; Lin, S. Review: Recent developments of carbon nanotubes hybrid assemblies for sensing. Am. J. Nano Res. Appl. 2015, 3, 23–28. [Google Scholar]

- Moein, M.M.; Said, R.; Bassyouni, F.; Abdel-Rehim, M. Solid Phase Microextraction and Related Techniques for Drugs in Biological Samples. J. Anal. Methods Chem. 2014. [Google Scholar] [CrossRef] [PubMed]

- Aulakh, J.S.; Malik, A.K.; Kaur, V.; Schmitt-Kopplin, P. A Review on Solid Phase Micro Extraction—High Performance Liquid Chromatography (SPME-HPLC) Analysis of Pesticides. Crit. Rev. Anal. Chem. 2005, 35, 71–85. [Google Scholar] [CrossRef]

- Turner, N.W.; Subrahmanyam, S.; Piletsky, S.A. Analytical methods for determination of mycotoxins: A review. Anal. Chim. Acta 2009, 632, 168–180. [Google Scholar] [CrossRef] [PubMed]

- Kataoka, H. Automated sample preparation using in-tube solid-phase microextraction and its application—A review. Anal. Bioanal. Chem. 2002, 373, 31–45. [Google Scholar] [CrossRef] [PubMed]

- Smith, R.M. Before the injection—Modern methods of sample preparation for separation techniques. J. Chromatogr. A 2003, 1000, 3–27. [Google Scholar] [CrossRef]

- Nerín, C.; Philo, M.R.; Salafranca, J.; Castle, L. Determination of bisphenol-type contaminants from food packaging materials in aqueous foods by solid-phase microextraction–high-performance liquid chromatography. J. Chromatogr. A 2002, 963, 375–380. [Google Scholar] [CrossRef]

- Zhang, Z.; Pawliszyn, J. Headspace solid-phase microextraction. Anal. Chem. 1993, 65, 1843–1852. [Google Scholar] [CrossRef]

- Tuduri, L.; Desauziers, V.; Fanlo, J.L. A simple calibration procedure for volatile organic compounds sampling in air with adsorptive solid-phase microextraction fibers. Analyst 2003, 128, 1028–1032. [Google Scholar] [CrossRef] [PubMed]

- Spietelun, A.; Pilarczyk, M.; Kloskowski, A.; Namieśnik, J. Current trends in solid-phase microextraction (SPME) fibre coatings. Chem. Soc. Rev. 2010, 39, 4524. [Google Scholar] [CrossRef] [PubMed]

- Namieśnik, J.; Zygmunt, B.; Jastrzebska, A. Application of solid-phase microextraction for determination of organic vapours in gaseous matrices. J. Chromatogr. A 2000, 885, 405–418. [Google Scholar] [CrossRef]

- Souza-Silva, E.A.; Pawliszyn, J. Direct Immersion Solid-Phase Microextraction with Matrix-Compatible Fiber Coating for Multiresidue Pesticide Analysis of Grapes by Gas Chromatography-Time-of-Flight Mass Spectrometry (DI-SPME-GC-ToFMS). J. Agric. Food Chem. 2015, 63, 4464–4477. [Google Scholar] [CrossRef] [PubMed]

- Aulakh, J.S.; Malik, A.K.; Kaur, V.; Schmitt-Kopplin, P. A Review on Solid Phase Micro Extraction—High Performance Liquid Chromatography (SPME-HPLC) Analysis of Pesticides. Crit. Rev. Anal. Chem. 2005, 35, 71–85. [Google Scholar] [CrossRef]

- Spietelun, A.; Marcinkowski, Ł.; Kloskowski, A.; Namieśnik, J. Application of green sample preparation techniques for the isolation, preconcentration and gas chromatographic determination of organic environmental pollutants. In Proceeedings of the 6th Shanghai International Symposium on Analytical Chemistry, Shanghai, China, 16–18 October 2012.

- Gan, J.; Bondarenko, S. Determination of Pesticides in Water. In Analysis of Pesticides in Food and Enviromental Samples; Tadeo, J.L., Ed.; CRC Press: Boca Raton, FL, USA, 2008; Volume 3, pp. 231–256. [Google Scholar]

- Vas, G.; Vékey, K. Solid-phase microextraction: A powerful sample preparation tool prior to mass spectrometric analysis. J. Mass Spectrom. 2004, 39, 233–254. [Google Scholar] [CrossRef] [PubMed]

- Prosen, H.; Zupančič-Kralj, L. Solid-phase microextraction. TrAC Trends Anal. Chem. 1999, 18, 272–282. [Google Scholar] [CrossRef]

- Ai, J. Solid Phase Microextraction for Quantitative Analysis in Nonequilibrium Situations. Anal. Chem. 1997, 69, 1230–1236. [Google Scholar] [CrossRef]

- Ai, J. Headspace Solid Phase Microextraction. Dynamics and Quantitative Analysis before Reaching a Partition Equilibrium. Anal. Chem. 1997, 69, 3260–3266. [Google Scholar] [CrossRef]

- Eisert, P.; Pawliszyn, J. Automated In-Tube Solid-Phase Microextraction Coupled to High-Performance Liquid Chromatography. Anal. Chem. 1997, 69, 3140–3147. [Google Scholar] [CrossRef]

- Globig, D.; Weickhardt, C. Fully automated in-tube solid-phase microextraction for liquid samples coupled to gas chromatography. Anal. Bioanal. Chem. 2005, 381, 656–659. [Google Scholar] [CrossRef] [PubMed]

- Silva, C.; Cavaco, C.; Perestrelo, R.; Pereira, J.; Câmara, J.S. Microextraction by Packed Sorbent (MEPS) and Solid-Phase Microextraction (SPME) as Sample Preparation Procedures for the Metabolomic Profiling of Urine. Metabolites 2014, 4, 71–97. [Google Scholar] [CrossRef] [PubMed]

- Kubinec, R.; Berezkin, V.G.; Górová, R.; Addová, G.; Mracnová, H.; Soják, L. Needle concentrator for gas chromatographic determination of BTEX in aqueous samples. J. Chromatogr. B 2004, 800, 295–301. [Google Scholar] [CrossRef]

- Jochmann, M.A. Solventless extraction and enrichment methods for compound-specific isotope analysis. Ph.D. Thesis, University of Tubingen, Germany, 19 December 2006. [Google Scholar]

- Kataoka, H. Recent developments and applications of microextraction techniques in drug analysis. Anal. Bioanal. Chem. 2010, 396, 339–364. [Google Scholar] [CrossRef] [PubMed]

- Saito, Y.; Jinno, K. Miniaturized sample preparation combined with liquid phase Separations. J. Chromatogr. A 2003, 1000, 53–67. [Google Scholar] [CrossRef]

- Zhang, Z.; Pawliszyn, J. Quantitative Extraction Using an Internally Cooled Solid Phase Microextraction Device. Anal. Chem. 1995, 67, 34–43. [Google Scholar] [CrossRef]

- Chen, Y.; Pawliszyn, J. Miniaturization and Automation of an Internally Cooled Coated Fiber Device. Anal. Chem. 2006, 78, 5222–5226. [Google Scholar] [CrossRef] [PubMed]

- Ghiasvand, A.R.; Hosseinzadeh, S.; Pawliszyn, J. New cold-fiber headspace solid-phase microextraction device for quantitative extraction of polycyclic aromatic hydrocarbons in sediment. J. Chromatogr. A 2006, 1124, 35–42. [Google Scholar] [CrossRef] [PubMed]

- Carasek, E.; Pawliszyn, J. Screening of Tropical Fruit Volatile Compounds Using Solid-Phase Microextraction (SPME) Fibers and Internally Cooled SPME Fiber. J. Agric. Food Chem. 2006, 54, 8688–8696. [Google Scholar] [CrossRef] [PubMed]

- Carasek, E.; Cudjoe, E.; Pawliszyn, J. Fast and sensitive method to determine chloroanisoles in cork using an internally cooled solid-phase microextraction fiber. J. Chromatogr. A 2007, 1138, 10–17. [Google Scholar] [CrossRef] [PubMed]

- Mirnaghi, F.S.; Hein, D.; Pawliszyn, J. Thin-Film Microextraction Coupled with Mass Spectrometry and Liquid Chromatography–Mass Spectrometry. Chromatographia 2013, 76, 1215–1223. [Google Scholar] [CrossRef]

- Jiang, R.; Pawliszyn, J. Thin-film microextraction offers another geometry for solid-phase microextraction. TrAC Trends Anal. Chem. 2012, 39, 245–253. [Google Scholar] [CrossRef]

- Koziel, J.A.; Odziemkowski, M.; Pawliszyn, J. Sampling and Analysis of Airborne Particulate Matter and Aerosols Using In-Needle Trap and SPME Fiber Devices. Anal. Chem. 2001, 73, 47–54. [Google Scholar] [CrossRef] [PubMed]

- Wang, A.; Fang, F.; Pawliszyn, J. Sampling and determination of volatile organic compounds with needle trap devices. J. Chromatogr. A 2005, 1072, 127–135. [Google Scholar] [CrossRef] [PubMed]

- Saito, Y.; Ueta, I.; Kotera, K.; Ogawa, M.; Wada, H.; Jinno, K. In-needle extraction device designed for gas chromatographic analysis of volatile organic compounds. J. Chromatogr. A 2006, 1106, 190–195. [Google Scholar] [CrossRef] [PubMed]

- SPDETM: The Magic Needle. flyer; CHROMTECH GmbH: Idstein, Germany, 2006. Available online: http://www.chromtech.de/download/20130130160105/CT-ProduktblattSPDE-231205.pdf (accessed on 31 March 2015).

- Ampuero, S.; Bogdanov, S.; Bosset, J.O. Classification of unifloral honeys with an MS-based electronic nose using different sampling modes: SHS, SPME and INDEX. Eur. Food Res. Technol. 2004, 218, 198–207. [Google Scholar] [CrossRef]

- Lipinski, J. Automated solid phase dynamic extraction—Extraction of organics using a wall coated syringe needle. Fresenius. J. Anal. Chem. 2001, 369, 57–62. [Google Scholar] [CrossRef] [PubMed]

- Balasubramanian, S.; Panigrahi, S. Solid-Phase Microextraction (SPME) Techniques for Quality Characterization of Food Products: A Review. Food Bioprocess Technol. 2011, 4, 1–26. [Google Scholar] [CrossRef]

- Nilsson, T.; Ferrari, R.; Facchetti, S. Inter-laboratory studies for the validation of solid-phase microextraction for the quantitative analysis of volatile organic compounds in aqueous samples. Anal. Chim. Acta 1997, 356, 113–123. [Google Scholar] [CrossRef]

- Bene, A.; Luisier, J.L.; Fornage, A. Applicability of a SPME method for the rapid determination of VOCs. Chimia 2002, 56, 289–291. [Google Scholar] [CrossRef]

- Basheer, C.; Lee, H.K. Hollow fiber membrane-protected solid phase microextraction of triazine herbicides in bovine milk and sewage sludge samples. J. Chromatogr. A 2004, 1047, 189–194. [Google Scholar] [CrossRef]

- Razote, E.; Jeon, I.; Maghirang, R.; Chobpattana, W. Dynamic air sampling of volatile organic compounds using solid phase microextraction. J. Environ. Sci. Health Part B 2002, 37, 365–378. [Google Scholar] [CrossRef] [PubMed]

- Razote, E.B.; Maghirang, R.G.; Seitz, L.M.; Jeon, I.J. Characterization of volatile organic compounds on airborne dust in a swine finishing barn. Transac. ASAE 2004, 47, 1231–1238. [Google Scholar] [CrossRef]

- Parreira, F.V.; de Carvalho, C.R.; Cardeal, Z.L. Evaluation of indoor exposition to benzene, toluene, ethylbenzene, xylene and styrene by passive sampling with a solid-phase microextraction device. J. Chromatogr. Sci. 2002, 40, 122–126. [Google Scholar] [CrossRef] [PubMed]

- Jung, D.M.; Ebeler, S.E. Headspace solid-phase microextraction method for the study of the volatility of selected flavor compounds. J. Agric. Food Chem. 2003, 51, 200–205. [Google Scholar] [CrossRef] [PubMed]

- Pawliszyn, J. Solid phase Microextraction. In A century of Separation Science; Issaq, H.J., Ed.; Marcel Dekker, Inc: New York, NY, USA, 2002; pp. 399–419. [Google Scholar]

- Costas-Rodriguez, M.; Pena-Pereira, F. Method Development with Miniaturized Sample Preparation Techniques. In Miniaturization in Sample Preparation; Pena-Pereira, F., Ed.; De Gruyter Open: Warsaw, Poland, 2014; pp. 276–307. [Google Scholar]

- Pawliszyn, J. Handbook of solid phase Microextraction, 1st ed.; Elsevier Inc: Waltham, MA, USA, 2012. [Google Scholar]

- Lord, H.L. Strategies for interfacing solid-phase microextraction with liquid chromatography. J. Chromatogr. A 2008, 1152, 2–13. [Google Scholar] [CrossRef] [PubMed]

- Tong, H.; Sze, N.; Thomson, B.; Nacson, S.; Pawliszyn, J. Solid phase microextraction with matrix assisted laser desorption/ionization introduction to mass spectrometry and ion mobility spectrometry. Analyst 2002, 127, 1207–1210. [Google Scholar] [CrossRef] [PubMed]

- Stalikas, C.D.; Fiamegos, Y.C. Microextraction combined with derivatization. TrAC Trends Anal. Chem. 2008, 27, 533–542. [Google Scholar] [CrossRef]

- Pan, L.; Pawliszyn, J. Derivatization/Solid-Phase Microextraction: New Approach to Polar Analytes. Anal. Chem. 1997, 69, 196–205. [Google Scholar] [CrossRef]

- Martínez-Uruñuela, A.; González-Sáiz, J.M.; Pizarro, C. Multiple solid-phase microextraction in a non-equilibrium situation Application in quantitative analysis of chlorophenols and chloroanisoles related to cork taint in wine. J. Chromatogr. A 2005, 1089, 31–38. [Google Scholar] [CrossRef] [PubMed]

- Bianchi, F.; Careri, M.; Musci, M.; Mangia, A. Fish and food safety: Determination of formaldehyde in 12 fish species by SPME extraction and GC–MS analysis. Food Chem. 2007, 100, 1049–1053. [Google Scholar] [CrossRef]

- Bourdin, D.; Desauziers, V. Development of SPME on-fiber derivatization for the sampling of formaldehyde and other carbonyl compounds in indoor air. Anal. Bioanal. Chem. 2014, 406, 317–328. [Google Scholar] [CrossRef] [PubMed]

- Ellis, J.; Shah, M.; Kubachka, K.M.; Caruso, J.A. Determination of organophosphorus fire retardants and plasticizers in wastewater samples using MAE-SPME with GC-ICPMS and GC-TOFMS detection. J. Environ. Monit. 2007, 9, 1329–1336. [Google Scholar] [CrossRef] [PubMed]

- Devos, C.; Vliegen, M.; Willaert, B.; David, F.; Moens, L.; Sandra, P. Automated headspace-solid-phase micro extraction–retention time locked-isotope dilution gas chromatography–mass spectrometry for the analysis of organotin compounds in water and sediment samples. J. Chromatogr. A 2005, 1079, 408–414. [Google Scholar] [CrossRef]

- Mateo-Vivaracho, L.; Ferreira, V.; Cacho, J. Automated analysis of 2-methyl-3-furanthiol and 3-mercaptohexyl acetate at ng L−1 level by headspace solid-phase microextracion with on-fibre derivatisation and gas chromatography–negative chemical ionization mass spectrometric determination. J. Chromatogr. A 2006, 1121, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Zhu, W.; Koziel, J.A.; Cai, L.; Özsoy, D.H.; Leeuwen, J.H. Quantification of Carbonyl Compounds Generated from Ozone-Based Food Colorants Decomposition Using On-Fiber Derivatization-SPME-GC-MS. Chromatography 2015, 2, 1–18. [Google Scholar] [CrossRef]

- Peter, A.; Köster, O.; Schildknecht, A.; Gunten, U. Occurrence of dissolved and particle-bound taste and odor compounds in Swiss lake waters. Water Res. 2009, 43, 2191–2200. [Google Scholar] [CrossRef] [PubMed]

- Mousavi, M.; Noroozian, E.; Jalali-Heravi, M.; Mollahosseini, A. Optimization of solid-phase microextraction of volatile phenols in water by a polyaniline-coated Pt-fiber using experimental design. Anal. Chim. Acta 2007, 581, 71–77. [Google Scholar] [CrossRef] [PubMed]

- Ji, J.; Deng, C.; Shen, W.; Zhang, X. Field analysis of benzene, toluene, ethylbenzene and xylene in water by portable gas chromatography–microflame ionization detector combined with headspace solid-phase microextraction. Talanta 2006, 69, 894–899. [Google Scholar] [CrossRef] [PubMed]

- Unceta, N.; Sampedro, M.C.; Bakar, N.K.A.; Gómez-Caballero, A.; Goicolea, M.A.; Barrio, R.J. Multi-residue analysis of pharmaceutical compounds in wastewaters by dual solid-phase microextraction coupled to liquid chromatography electrospray ionization ion trap mass spectrometry. J. Chromatogr. A 2010, 1217, 3392–3399. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Lin, L.; Zou, S.; Lan, C.; Luan, T. Determination of bisphenol A in landfill leachate by solid phase microextraction with headspace derivatization and gas chromatography-mass spectrophotometry. Chin. J. Anal. Chem. 2006, 34, 325–328. [Google Scholar] [CrossRef]

- Mitani, K.; Fujioka, M.; Kataoka, H. Fully automated analysis of estrogens in environmental waters by in-tube solid-phase microextraction coupled with liquid chromatography–tandem mass spectrometry. J. Chromatogr. A 2005, 1081, 218–224. [Google Scholar] [CrossRef] [PubMed]

- Gaca, J.; Wejnerowska, G. Determination of epichlorohydrin in water and sewage samples. Talanta 2006, 70, 1044–1050. [Google Scholar] [CrossRef] [PubMed]

- Larreta, J.; Usobiaga, A.; Etxebarria, N.; Arana, G.; Zuloaga, O. Optimisation of the on-fibre derivatisation of volatile fatty acids in the simultaneous determination together with phenols and indoles in cow slurries. Anal. Bioanal. Chem. 2007, 389, 1603–1609. [Google Scholar] [CrossRef] [PubMed]

- Alzaga, R.; Salgado-Petinal, C.; Jover, E.; Bayona, J.M. Development of a procedure for the determination of perfluorocarboxylic acids in sediments by pressurised fluid extraction, headspace solid-phase microextraction followed by gas chromatographic–mass spectrometric determination. J. Chromatogr. A 2006, 1083, 1–6. [Google Scholar] [CrossRef]

- Carvalho, P.N.; Pinto, L.F.; Clara, M.; Basto, P.; Teresa, M.; Vasconcelos, S.D. Headspace solid-phase micro-extraction and gas chromatography-ion trap tandem mass spectrometry method for butyltin analysis in sediments: Optimization and validation. Microchem. J. 2007, 87, 147–153. [Google Scholar] [CrossRef]

- Quintana, J.B.; Rodriguez, I. Strategies for the microextraction of polar organic contaminants in water samples. Anal. Bioanal. Chem. 2006, 384, 1447–1461. [Google Scholar] [CrossRef] [PubMed]

- Gałuszka, A.; Migaszewski, Z.; Namieśnik, J. The 12 principles of green analytical chemistry and the SIGNIFICANCE mnemonic of green analytical practices. TrAC Trends Anal. Chem. 2013, 50, 78–84. [Google Scholar] [CrossRef]

- Wu, J.; Xie, W.; Pawliszyn, J. Automated in tube solid-phase microextraction coupled with HPLC–ES–MS for the determination of catechins and caffeine in tea. Analyst 2000, 125, 2216–2222. [Google Scholar] [CrossRef] [PubMed]

- Górecki, T.; Yu, X.; Pawliszyn, J. Theory of analyte extraction by selected porous polymer SPME fibres. Analyst 1999, 124, 643–649. [Google Scholar] [CrossRef]

- Cai, J.; Liu, B.; Su, Q. Comparison of simultaneous distillation extraction and solid-phase microextraction for the determination of volatile flavor components. J. Chromatogr. A 2001, 930, 1–7. [Google Scholar] [CrossRef]

- Kleeberg, K.K.; Liu, Y.; Jans, M.; Schlegelmilch, M.; Streese, J.; Stegrnann, R. Development of a simple and sensitive method for the characterization of odorous waste gas emissions by means of solid-phase microextraction (SPME) and GC MS/olfactometry. Waste Manage. 2005, 25, 872–879. [Google Scholar] [CrossRef] [PubMed]

- Huang, K.P.; Wang, G.R.; Huang, B.Y.; Liu, C.Y. Preparation and application of ionic liquid-coated fused-silica capillary fibers for solid-phase microextraction. Anal. Chim. Acta 2009, 645, 42–47. [Google Scholar] [CrossRef] [PubMed]

- He, Y.; Pohl, J.; Engel, R.; Rothman, L.; Thomas, M. Preparation of ionic liquid based solid-phase microextraction fiber and its application to forensic determination of methamphetamine and amphetamine in human urine. J. Chromatogr. A 2009, 1216, 4824–4830. [Google Scholar] [CrossRef] [PubMed]

- Mullett, W.M.; Martin, P.; Pawliszyn, J. In-Tube Molecularly Imprinted Polymer Solid-Phase Microextraction for the Selective Determination of Propranolol. Anal. Chem. 2001, 73, 2383–2389. [Google Scholar] [CrossRef] [PubMed]

- Hofacker, S.; Mechtel, M.; Mager, M.; Kraus, H. Sol–gel: A new tool for coatings chemistry. Prog. Org. Coat. 2002, 45, 159–164. [Google Scholar] [CrossRef]

- Mullett, W.M.; Levsen, K.; Lubda, D.; Pawliszyn, J. Bio-compatible in-tube solid-phase microextraction capillary for the direct extraction and high-performance liquid chromatographic determination of drugs in human serum. J. Chromatogr. A 2002, 963, 325–334. [Google Scholar] [CrossRef]

- Chong, S.; Wang, D.; Hayes, J.; Wilhite, B.; Malik, A. Sol-gel coating technology for the preparation of solid-phase microextraction fibers of enhanced thermal stability. Anal. Chem. 1997, 69, 3889–3898. [Google Scholar] [CrossRef] [PubMed]

- Young, S.K. Sol-Gel Science for Ceramic Materials. Mater. Matt. 2006, 1, 8. [Google Scholar]

- Hu, B.; He, M.; Chen, B. Novel Materials in Solid-Phase Microextraction and Related Sample Preparation Approaches. In Miniaturization in Sample Preparation; Pereira, F.P., Ed.; De Gruyter Open Ltd: Warsaw, Poland; Berlin, Germany, 2014; pp. 88–190. [Google Scholar]

- Djozan, D.; Assadi, Y.; Haddadi, S.H. Anodized Aluminum Wire as a Solid-Phase Microextraction Fiber. Anal. Chem. 2001, 73, 4054–4058. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.; Ding, Y.; Yuan, D. Electrosorption-enhanced solid-phase microextraction of trace anions using a platinum plate coated with single-walled carbon nanotubes. Talanta 2011, 85, 1148–1153. [Google Scholar] [CrossRef] [PubMed]

- Li, M.K.; Lei, N.; Gong, C.; Yu, Y.; Lam, K.; Lam, M.H.; Yu, H.; Lam, P.K. An organically modified silicate molecularly imprinted solid-phase microextraction device for the determination of polybrominated diphenyl ethers. Anal. Chim. Acta 2009, 633, 197–203. [Google Scholar] [CrossRef] [PubMed]

- Ma, X.; Li, Q.; Yuan, D. Determination of endocrine-disrupting compounds in water by carbon nanotubes solid-phase microextraction fiber coupled online with high performance liquid chromatography. Talanta 2011, 85, 2212–2217. [Google Scholar] [CrossRef] [PubMed]

- Maghsoudi, S.; Noroozian, E. HP-SPME of Volatile Polycyclic Aromatic Hydrocarbons from Water Using Multiwalled Carbon Nanotubes Coated on a Steel Fiber through Electrophoretic Deposition. Chromatographia 2012, 75, 913–921. [Google Scholar] [CrossRef]

- Zewe, J.W.; Steach, J.K.; Olesik, S.V. Electrospun fibers for solid-phase microextraction. Anal. Chem. 2010, 82, 5341–5348. [Google Scholar] [CrossRef] [PubMed]

- Lin, B.; Li, T.; Zhao, Y.; Huang, F.-K.; Guo, L.; Feng, Y.-Q. Preparation of a TiO2 nanoparticle-deposited capillary column by liquid phase deposition and its application in phosphopeptide analysis. J. Chromatogr. A 2008, 1192, 95–102. [Google Scholar] [CrossRef] [PubMed]

- Alizadeh, R.; Najafi, N.M.; Kharrazi, S. A new solid phase micro extraction for simultaneous head space extraction of ultra traces of polar and non-polar compounds. Anal. Chim. Acta 2011, 689, 117–121. [Google Scholar] [CrossRef] [PubMed]

- Ji, J.; Liu, H.; Chen, J.; Zeng, J.; Huang, J.; Gao, L.; Wang, Y.; Chen, X. ZnO nanorod coating for solid phase microextraction and its applications for the analysis of aldehydes in instant noodle samples. J. Chromatogr. A 2012, 1246, 22–27. [Google Scholar] [CrossRef] [PubMed]

- Farhadi, K.; Matin, A.A.; Amanzadeh, H.; Biparva, P.; Tajik, H.; Farshid, A.A.; Pirkharrati, H. A novel dispersive micro solid phase extraction using zein nanoparticles as the sorbent combined with headspace solid phase micro-extraction to determine chlorophenols in water and honey samples by GC–ECD. Talanta 2014, 128, 493–499. [Google Scholar] [CrossRef] [PubMed]

- Anbia, M.; Khazaei, M. Ordered nanoporous carbon-based SPME and determination by GC. Chromatographia 2011, 73, 379–384. [Google Scholar] [CrossRef]

- Rahimi, A.; Hashemi, P.; Badiei, A.; Arab, P.; Ghiasvand, A.R. CMK-3 nanoporous carbon as a new fiber coating for solid-phase microextraction coupled to gas chromatography–mass spectrometry. Anal. Chim. Acta 2011, 695, 58–62. [Google Scholar] [CrossRef] [PubMed]

- Toledo, B.R.; Hantao, L.W.; Ho, T.D.; Augusto, F.; Anderson, J.L. A chemometric approach toward the detection and quantification of coffee adulteration by solid-phase microextraction using polymericionic liquid sorbent coatings. J. Chomatogr. A 2014, 1346, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Ho, T.T.; Chen, C.Y.; Li, Z.G.; Yang, T.C.C.; Lee, M.R. Determination of chlorophenols in landfill leachate using headspace sampling with ionic liquid-coated solid-phase microextraction fibers combined with gas chromatography–mass spectrometry. Anal. Chim. Acta 2012, 712, 72–77. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Chen, J.; Shi, J.P. Determination of diethylstilbestrol in milk using carbon nanotube-reinforced hollow fiber solid-phase microextraction combined with high-performance liquid chromatography. Talanta 2012, 97, 222–228. [Google Scholar] [CrossRef] [PubMed]

- Sarafraz-Yazdi, A.; Abbasian, M.; Amiri, A. Determination of furan in food samples using two solid phase microextraction fibers based on sol–gel technique with gas chromatography–flame ionization detector. Food Chem. 2012, 131, 698–704. [Google Scholar] [CrossRef]

- Attari, S.G.; Bahrami, A.; Shahna, F.G.; Heidari, M. Solid-phase microextraction fiber development for sampling and analysis of volatile organohalogen compounds in air. J. Environ. Health Sci. Eng. 2014, 12, 123–130. [Google Scholar] [CrossRef] [PubMed]

- Shearrow, A.M.; Harris, G.A.; Fang, L.; Sekhar, P.K.; Nguyen, L.T.; Turner, E.B.; Bhansali, S.; Malik, A. Ionic liquid-mediated Sol-gel coatings for capillary microextraction. J. Chomatogr. A 2009, 1216, 5449–5458. [Google Scholar] [CrossRef] [PubMed]

- Shearrow, A.M.; Bhansali, S.; Malik, A. Ionic liquid-mediated bis(3-methyldimethoxysilyl)propyl. polypropylene oxide-based polar Sol-gel coatings for capillary microextraction. J. Chromatogr. A 2009, 1216, 6349–6355. [Google Scholar] [CrossRef] [PubMed]

- Zhou, X.; Shao, X.; Shu, J.J.; Liu, M.M.; Liu, H.L.; Feng, X.H.; Liu, F. Thermally stable ionic liquid-based Sol-gel coating for ultrasonic extraction–solid-phase microextraction–gas chromatography determination of phthalate esters in agricultural plastic films. Talanta 2012, 89, 129–135. [Google Scholar] [CrossRef] [PubMed]

- Liu, M.; Zhou, X.; Chen, Y.; Liu, H.; Feng, X.; Qiu, G.; Liu, F.; Zeng, Z. Innovative chemically bonded ionic liquids-based Sol-gel coatings as highly porous, stable and selective stationary phases for solid phase microextraction. Anal. Chim. Acta 2010, 683, 96–106. [Google Scholar] [CrossRef] [PubMed]

- Fan, Y.; Feng, Y.Q.; Shi, Z.G.; Wang, J.B. Ordered mesoporous silica coated capillary for in-tube solid phase microextraction coupled to high performance liquid chromatography. Anal. Chim. Acta 2005, 543, 1–8. [Google Scholar] [CrossRef]

- Zhu, F.; Liang, Y.; Xia, L.; Rong, M.; Su, C.; Lai, R.; Li, R.; Ouyang, G. Preparation and characterization of vinyl-functionalized mesoporous organosilica-coated solid-phase microextraction fiber. J. Chromatogr. A 2012, 1247, 42–48. [Google Scholar] [CrossRef] [PubMed]

- Moreira, M.A.; André, L.C.; Cardeal, Z.L. Analysis of plasticiser migration to meat roasted in plastic bags by SPME–GC/MS. Food Chem. 2015, 178, 195–200. [Google Scholar] [CrossRef] [PubMed]

- Es-Haghi, A.; Hosseini, S.M.; Khoshhesab, Z.M. Development and application of a new solid-phase microextraction fiber by Solgel technology on titanium wire. Anal. Chim. Acta 2012, 742, 74–79. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.L.; Gao, Y.L.; Wang, P.P.; Shang, H.; Pan, S.Y.; Li, X.J. Sol-gel molecularly imprinted polymer for selective solid phase microextraction of organophosphorous pesticides. Talanta 2013, 115, 920–927. [Google Scholar] [CrossRef] [PubMed]

- Mu, L.; Hu, X.; Wen, J.; Zhou, Q. Robust aptamer Sol-gel solid phase microextraction of very polar adenosine from human plasma. J. Chromatogr. A 2013, 1279, 7–12. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Ji, Y.; Zhang, Y.; Zhang, H.; Liu, M. Oxidized multiwalled carbon nanotubes as a novel solid-phase microextraction fiber for determination of phenols in aqueous samples. J. Chromatogr. A 2007, 1165, 10–17. [Google Scholar] [CrossRef] [PubMed]

- Bagheri, H.; Ayazi, Z.; Sistani, H. Chemically bonded carbon nanotubes on modified gold substrate as novel unbreakable solid phase microextraction fiber. Microchim. Acta 2011, 174, 295–301. [Google Scholar] [CrossRef]

- Queiroz, M.E.C.; Oliveira, E.B.; Breton, F.; Pawliszyn, J. Immunoaffinity in-tube solid phase microextraction coupled with liquid chromatography–mass spectrometry for analysis of fluoxetine in serum samples. J. Chromatogr. A 2007, 1174, 72–77. [Google Scholar] [CrossRef] [PubMed]

- Hu, X.; Pan, J.; Hu, Y.; Huo, Y.; Li, G. Preparation and evaluation of solid-phase microextraction fiber based on molecularly imprinted polymers for trace analysis of tetracyclines in complicated samples. J. Chromatogr. A 2008, 1188, 97–107. [Google Scholar] [CrossRef] [PubMed]

- Djozan, D.; Farajzadeh, M.A.; Sorouraddin, S.M.; Baheri, T. Determination of methamphetamine, amphetamine and ecstasy by inside-needle adsorption trap based on molecularly imprinted polymer followed by GC-FID determination. Microchim. Acta 2012, 179, 209–217. [Google Scholar] [CrossRef]

- Amini, R.; Rouhollahi, A.; Adibi, M.; Mehdinia, A. A novel reusable ionic liquid chemically bonded fused-silica fiber for headspace solid-phase microextraction/gas chromatography-flame ionization detection of methyl tert-butyl ether in a gasoline sample. J. Chromatogr. A 2011, 1218, 130–136. [Google Scholar] [CrossRef] [PubMed]

- Pang, L.; Liu, J.F. Development of a solid-phase microextraction fiber by chemical binding of polymeric ionic liquid on a silica coated stainless steel wire. J. Chromatogr. A 2012, 1230, 8–14. [Google Scholar] [CrossRef] [PubMed]

- Tamer, U.; Ertas, N.; Udum, Y.A.; Sahin, Y.; Pekmez, K.; Yıldız, A. Electrochemically controlled solid-phase microextraction (EC-SPME) based on overoxidized sulfonated polypyrrole. Talanta 2005, 67, 245–251. [Google Scholar] [CrossRef] [PubMed]

- Banitaba, M.H.; Mohammadi, A.A.; Davarani, S.S.H.; Mehdinia, A. Preparation and evaluation of a novel solid-phase microextraction fiber based on poly(3,4-ethylenedioxythiophene) for the analysis of OCPs in water. Anal. Methods 2011, 3, 2061–2067. [Google Scholar] [CrossRef]

- Bagheri, H.; Babanezhad, A.M.E. An electropolymerized aniline-based fiber coating for solid phase microextraction of phenols from water. Anal. Chim. Acta 2005, 532, 89–95. [Google Scholar] [CrossRef]

- Chen, L.; Chen, W.; Ma, C.; Du, D.; Chen, X. Electropolymerized multiwalled carbon nanotubes/polypyrrole fiber for solid-phase microextraction and its applications in the determination of pyrethroids. Talanta 2011, 84, 104–108. [Google Scholar] [CrossRef] [PubMed]

- Mehdinia, A.; Khani, H.; Mozaffari, S. Fibers coated with a graphene-polyaniline nanocomposite for the headspace solid-phase microextraction of organochlorine pesticides from seawater samples. Microchim. Acta 2014, 181, 89–95. [Google Scholar] [CrossRef]

- Zhao, F.; Wang, M.; Ma, Y.; Zeng, B. Electrochemical preparation of polyaniline–ionic liquid based solid phase microextraction fiber and its application in the determination of benzene derivatives. J. Chromatogr. A 2011, 1218, 387–391. [Google Scholar] [CrossRef] [PubMed]

- Gao, Z.; Li, W.; Liu, B.; Liang, F.; He, H.; Yang, S.; Sun, C. Nanostructured polyaniline-ionic liquid composite film coated steel wire for headspace solid-phase microextraction of organochlorine pesticides in water. J. Chromatogr. A 2011, 1218, 6285–6291. [Google Scholar] [CrossRef] [PubMed]

- Mehdinia, A.; Mousavi, M.F.; Shamsipur, M. Nano-structured lead dioxide as a novel stationary phase for solid-phase microextraction. J. Chromatogr. A 2006, 1134, 24–31. [Google Scholar] [CrossRef] [PubMed]

- Budziak, D.; Martendal, E.; Carasek, E. Application of an NiTi alloy coated with ZrO2 solid-phase microextraction fiber for determination of haloanisoles in red wine samples. Microchim. Acta 2009, 164, 197–202. [Google Scholar] [CrossRef]

- Liu, H.; Wang, D.; Ji, L.; Li, J.; Liu, S.; Liu, X.; Jiang, S. A novel TiO2 nanotube array/Ti wire incorporated solid-phase microextraction fiber with high strength, efficiency and selectivity. J. Chromatogr. A 2010, 1217, 1898–1903. [Google Scholar] [CrossRef] [PubMed]

- Cao, D.; Lü, J.; Liu, J.; Jiang, G. In situ fabrication of nanostructured titania coating on the surface of titaniumwire: A new approach for preparation of solid-phase microextraction fiber. Anal. Chim. Acta 2008, 611, 56–61. [Google Scholar] [CrossRef] [PubMed]

- Bagheri, H.; Aghakhani, A.; Baghernejad, M.; Akbarinejad, A. Novel polyamide-based nanofibers prepared by electrospinning technique for headspace solid-phase microextraction of phenol and chlorophenols from environmental samples. Anal. Chim. Acta 2012, 716, 34–39. [Google Scholar] [CrossRef] [PubMed]

- Newsome, T.E.; Zewe, J.W.; Olesik, S.V. Electrospun nanofibrous solid-phase microextraction coatings for preconcentration of pharmaceuticals prior to liquid chromatographic separations. J. Chromatogr. A 2012, 1262, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Yu, Q.W.; Ma, Q.; Feng, Y. Temperature-response polymer coating for in-tube solid-phase microextraction coupled to highperformance. Talanta 2011, 84, 1019–1025. [Google Scholar] [CrossRef] [PubMed]

- International Organization for Standardization. Water Quality–Determination of Selected Plant Treatment Agents and Biocide Products–Method Using Solid-Phase Microextraction (SPME) Followed by Gas Chromatography-Mass Spectrometry (GC-MS); International Organization for Standardization: Genf, Switzerland, ISO 27108:2010.

- Deutsches Institut für Normung. German Standard Methods for the Examination of Water, Waste Water and Sludge–Jointly Determinable Substances (group F)–Part 34: Determination of Selected Plant Treatment Agents, Biocides and Break-Down Products; Method Using Gas Chromatography (GC-MS) after Solid-Phase Micro Extraction (SPME) (F 34); Deutsches Institut für Normung: Berlin, Germany, DIN 38407-34:2006-05.

- Deutsches Institut für Normung. German Standard Methods for the Examination of Water, Waste Water and Sludge–Jointly Determinable Substances (group F)–Part 41: Determination of Selected Easily Volatile Organic Compounds in Water–Method Using Gas Chromatography (GC-MS) after Headspace Solid-Phase Micro Extraction (HS-SPME) (F 41); Deutsches Institut für Normung: Berlin, Germany, DIN 38407-41:2011-06.

- International Organization for Standardization. Water Quality–Determination of Volatile Organic Compounds in Water–Method Using Headspace Solid-Phase Micro-Extraction (HS-SPME) Followed by Gas Chromatography-Mass Spectrometry (GC-MS); International Organization for Standardization: Genf, Switzerland, ISO/DIS 17943:2014-07.

- Austrian Standards Institute. Determination of Volatile Compounds in Cellulose-based Materials by Solid Phase Micro Extraction (SPME); Austrian Standards Insitute: Vienna, Austria, OENORM A 1117: 2004-05-01.

- ASTM International. Standard Test Method for Determination of Parent and Alkyl Polycyclic Aromatics in Sediment Pore Water Using Solid-Phase Microextraction and Gas Chromatography/Mass Spectrometry in Selected Ion Monitoring Mode; ASTM International: West Conshohocken, PA, USA, ASTM D 7363a:2013.

- Bagheri, H.; Babanezhad, E.; Khalilian, F. A novel sol–gel-based amino-functionalized fiber for headspace solid-phase microextraction of phenol and chlorophenols from environmental samples. Anal. Chim. Acta 2008, 616, 49–55. [Google Scholar] [CrossRef] [PubMed]

- Zeng, J.; Yu, B.; Chen, W.; Lin, Z.; Zhang, L.; Lin, Z.; Chen, X.; Wang, X. Application of ceramic/carbon composite as a novel coating for solid-phase Microextraction. J. Chromatogr. A 2008, 1188, 26–33. [Google Scholar] [CrossRef] [PubMed]

- Januszkiewicz, J.; Sabik, H.; Azarnia, S.; Lee, B. Optimization of headspace solid-phase microextraction for the analysis of specific flavors in enzyme modified and natural Cheddar cheese using factorial design and response surface methodology. J. Chromatogr. A 2008, 1195, 16–24. [Google Scholar] [CrossRef] [PubMed]

- Ravelo-Perez, L.M.; Hernandez-Borges, J.; Borges-Miquel, T.M.; Rodriguez Delgado, M.A. Multiple pesticide analysis in wine by MEKC combined with solid-phase microextraction and sample stacking. Electrophoresis 2007, 28, 4072–4081. [Google Scholar] [CrossRef] [PubMed]

- De Jager, L.S.; Perfetti, G.A.; Diachenko, G.W. Analysis of tetramethylene disulfotetramine in foods using solid-phase microextraction–gas chromatography–mass spectrometry. J. Chromatogr. A 2008, 1192, 36–40. [Google Scholar] [CrossRef] [PubMed]