1. Introduction

Although household-level distributed manufacturing in the U.S. resulted in the emergence of domestic commerce [

1,

2], standardized high-volume mass production has dominated domestic production since the industrial revolution [

3,

4,

5]. As even domestic production has given way to a global trend toward large-scale, globally centralized manufacturing and global shipping to feed world consumerism [

6,

7]. In the not so distant past economies of scale provided consumers with more convenient and lower-priced goods than what they could make themselves [

8]. However, starting in the early 2000’s a wave of publications have argued that distributed manufacturing with 3-D printing can reduce costs for consumers [

9,

10,

11,

12,

13]. The mainstream view of 3-D printing is that of a less centralized model of manufacturing, where 3-D printing businesses manufacture and sell products to consumers or other businesses [

14]. There is support that this model is indeed emerging in the business literature [

15,

16,

17].

The rapid growth of Internet sharing and open source hardware development [

18,

19], however, provide a more aggressive path to distributed at the consumer level by making use of self-replicating rapid prototyper (RepRap) 3-D printers [

20,

21,

22]. It is well established that RepRap-centered distributed digital production of high-end products (e.g., scientific tools) can significantly reduce costs [

23,

24,

25]. The savings for the distributed manufacturing of scientific tools [

26,

27,

28] provides unprecedentedly high return on investments (ROIs) for science funders [

29,

30] and the field is growing rapidly. However, recent studies have shown the number of free pre-designed 3-D products of all kinds is also growing rapidly [

31], and desktop open source RepRap 3-D printers are already economically beneficial for the average American consumer for both kits that consumers build themselves [

31] as well as plug-and-play commercial RepRap 3-D printers for less technically-sophisticated consumers [

32]. Most strikingly, a recent study showed commercial 3-D printers were economically viable even when used for only fabricating hard plastic toys [

33]. Furthermore, the study showed that the practice of DIY (do it yourself) home manufacturing with a 3-D printer was already in widespread use as only a single open source repository of 3-D printable designs (MyMiniFactory) was saving users over

$60 million/year in offset purchases of only 100 products [

33]. In addition, the latest data has shown an increased rate of users and downloads (from the paper published in early 2017) so those figures are now already over

$150 million/year for the same single database (of which there are dozens) [

34].

However, all of these previous studies of mass-distributed manufacturing only focused on hard thermoplastics (with the two most popular 3-D printing plastics polylactic acid (PLA) and acrylonitrile butadiene styrene (ABS) being the primary focus). To further enhance the use of distributed manufacturing using 3-D printing the materials selection must expand significantly to be able to cover the same variety of materials available in commercial products. Efforts have been made to ensure that body of natural and man-made materials are prevented from intellectual property lockdown with relation to applications in 3-D printing [

35] and significant efforts both in academia as well as industry have been made to develop new 3-D printing materials for RepRap technology. In particular, research on flexible filaments has been successful to expand distributed manufacturing into flexible objects. These objects which are traditionally made from vulcanized rubber or silicone can now be made from a recyclable thermoplastic elastomer (TPE) called thermoplastic polyurethane (TPU) [

36,

37]. For example, NinjaFlex filament, is an 85 Shore A Hardness TPU material [

38], which is readily available from a number of suppliers. However, as compared to more traditional filaments (e.g., PLA or ABS), which can be purchased for US

$20-30/kg [

39], NinjaFlex is expensive as it sells for

$64.99 for 750 grams [

40] or US

$86.65/kg.

With this higher price point, the positive economics of distributed manufacturing are not as clear for flexible products. To provide some insight into the potential for flexible filament to be both technically feasible and economically viable for distributed digital manufacturing at the consumer level this study investigates 20 common flexible household products fabricated with a single flexible material: NinjaFlex. The 3-D printed products were quantified by print time, electrical energy use and filament consumption by mass to determine the cost to fabricate with a commercial RepRap 3-D printer. Printed parts were inspected and when necessary tested for their targeted application to ensure technical feasibility. Then, the experimentally measured cost to DIY manufacturers was compared to low and high market prices for comparable commercially available products. The results of this techno-economic analysis are discussed. In addition, the mark-up and potential for long-term price declines was estimated for flexible filaments by converting TPE pellets into filament and reground TPE from a local recycling center into filament using an open source recyclebot [

41]. Finally, the implications of the results of these preliminary experiments at fabricating recycled TPE are discussed in detail in the context of distributed manufacturing, recycling and the circular economy.

2. Materials and Methods

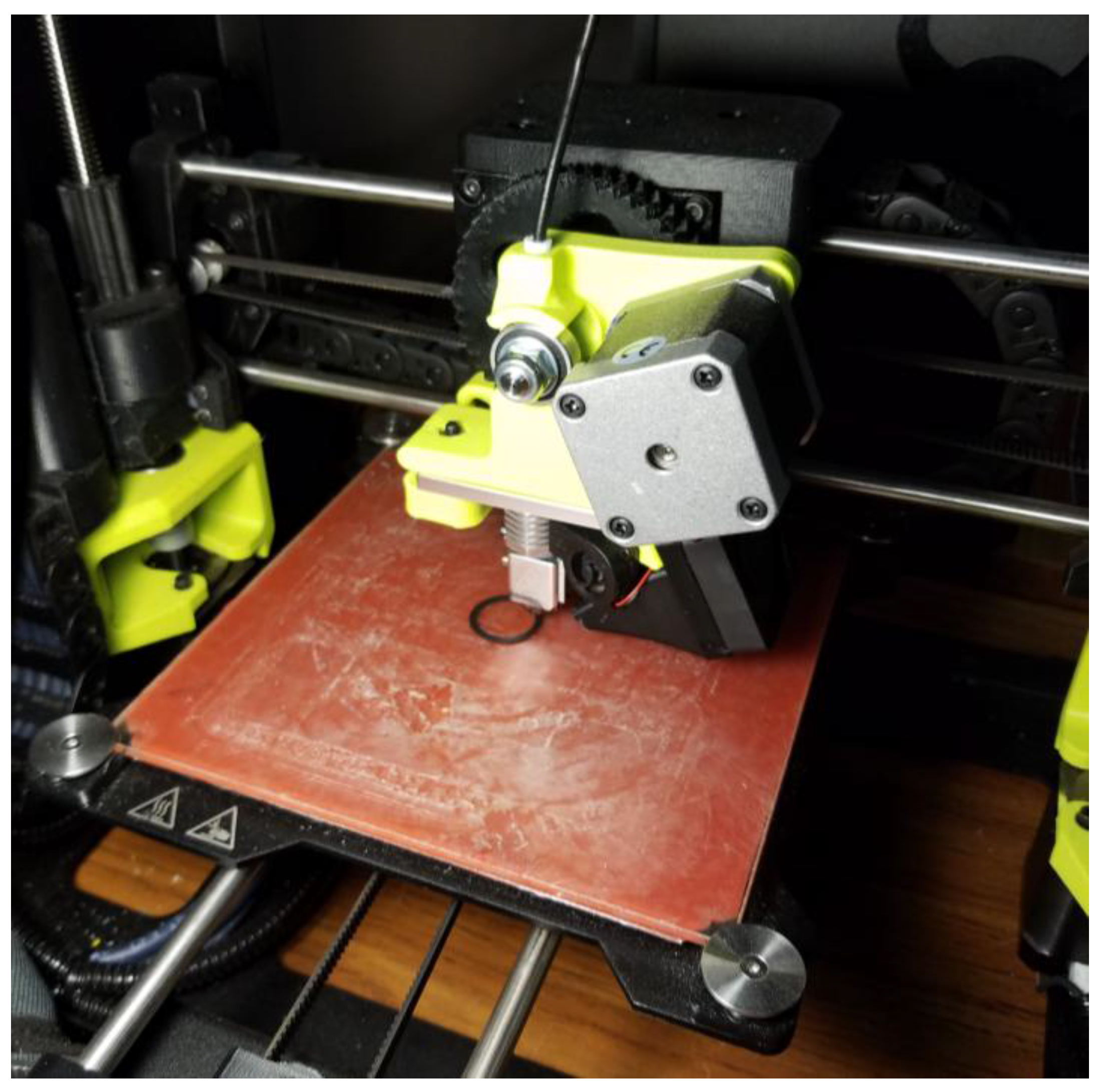

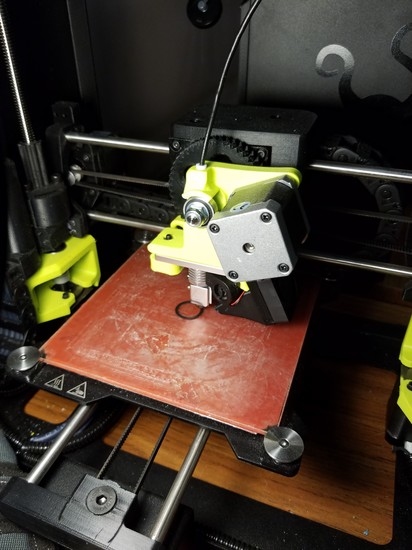

The use of flexible filaments requires special hardware to obtain successful 3-D prints. Extruders for flexible filament demand a direct path to the hot end with no open areas where the filament can kink. Several extruder options are available to buy or make, with the simplest option being to use a polytetrafluoroethylene (PTFE) tube the exact size of the filament (either 1.75 mm or 2.85 mm for the two most common filament diameters) to create a direct path from the drive gear to the hot end [

42]. This is the least expensive option, but also requires non-trivial technical knowledge. A more expensive solution is the Flexion Extruder [

43] for

$99.00 that fits on most fused filament fabricators (FFF)-class 3-D printers and is made for only flexible materials. Finally, for those using one of the open source Lulzbot line of 3-D printers, there is a drop-in replacement for the entire tool head. On a Lulzbot Mini [

44] the tool head is changed out for a FlexyStruder [

45] to print flexible filaments (e.g., Semiflex, NinjaFlex, etc.). This extruder costs

$295.00 and appears to be the easiest solution to printing with flexible materials for the average consumer. For this analysis, it was critical that the methods of manufacturing and materials were relevant and accessible to the average consumer and so this method was used here (

Figure 1).

Ninja Flex (NinjaTek, Manheim, PA, USA) [

40] was 3-D printed on a commercial RepRap, the Lulzbot Mini [

44,

45] with a FlexyStruder Extruder [

46,

47] (Aleph Objects, Loveland, CO, USA). The Lulzbot Mini is a commercialized and fully assembled plug-and-play derivative of the RepRap, which can be used by a consumer with no training and modest technical familiarity (e.g., how to operate a desktop computer) [

47,

48].

3-D printing was monitored with a multimeter with an energy (kWh) reading accuracy of 0.5% [

49]. A digital scale with an error of ±0.05 g was used to mass each item after it was 3-D printed. To get the best prints of the Lulzbot Mini, the settings shown in

Table 1 in the open source slicing program, Cura 21.03 [

50], were used.

Twenty household items made from flexible materials were selected for fabrication and are shown in

Table 2. They 3-D printable products or components represent four primary classes: automotive parts, accessories, home goods and medical equipment. Some design files were free to download online when this study began and some had to be designed using FreeCAD [

51] and Autodesk Inventor 2017 and were subsequently released with open source licenses [

52].

Products to be used in this study were down selected based on the following criteria: (1) the objects needed to be of value so that prices could be found and savings could be calculated; (2) the objects needed to be functional, i.e., serve a purpose rather than be a decoration; (3) the original consumer item needed to have a hardness of 85 Shore A to be close to the properties of the widest available flexible filament (NinjaFlex); (4) the objects needed to fit on the Lulzbot Mini build plate and be printable within the build volume; and (5) the object needed to possess a geometry amenable to FFF 3-D printing (e.g., overhangs less than 45 degrees, low number and size of bridges, and surface features smaller than the print nozzle. The household products selected represent a diverse set of objects that home users would find the need to print to increase the livability of their home. For example, by manufacturing their own hinges for cabinets and chests people could fix old or broken furniture instead of throwing it away. Similarly, home users could also fix the rubber feet on their washing machine or make it so their furniture does not slip on a smooth floor. Finally, the tools around the house could become easier to use by printing custom handle grips. All these devices represent just a small number of possibilities that could be of value to consumers. Thus, these objects represented some of the most common flexible items that would normally be found at consumers’ home or in their garage that most likely would wear out over time and be expensive to replace. Products such as rubber gaskets and O-rings have known lifespans and average consumers do not stock spare parts. Similarly, custom products like a custom shoe insole or orthotic need replacement on the order of months or years. All of the printed products are subjected to basic tests of their functional units (function shown in

Table 2), which describe those properties of the product that must be present for the studied substitution to take place. These properties are in some cases appearance and aesthetic, but in general are based upon functionality or chemical stability and durability.

High and low commercial prices for each product was found on Google Shopping [

58]. A spreadsheet (

Table S1) of all links to where each item can be purchased is in

Supplementary Materials. Associated shipping costs were excluded from the analysis for both purchasing and distributed manufacturing (e.g., no shipping charges included for plastic filament) as free shipping is common with many online vendors in the U.S. The operating cost (

OL) for the Lulzbot Mini was calculated using electricity and filament consumption during printing. The average residential electricity rate for the United States in June 2017 was

$0.1322 [

59] and

$64.99 is the price for a full spool of NinjaFlex filament from the NinjaTek website [

40]; 750 g being the net amount purchased on the spool and the cost per gram equaling

$0.086. This operating cost was calculated as follows:

where

E is the energy consumed in kWh,

CE is the average rate of electricity in the United States in USD/kWh,

CF is the average cost of NinjaFlex filament in USD/kg, and

mf is the mass of the filament in grams consumed during printing. The marginal savings on each product,

Cs, is given by:

where

CC is the cost of the commercially available product (which is calculated for both low and high online prices from Google Shopper) and the marginal percent change,

P, between the cost to print a product and the commercially available product was calculated as follows:

where

CC is the cost for the commercial product at either the high or low price.

The previous calculations are all shown for each printed part in

Table 3. Each printed part is labeled in the item description column with calculations following in the subsequent columns.

3. Results

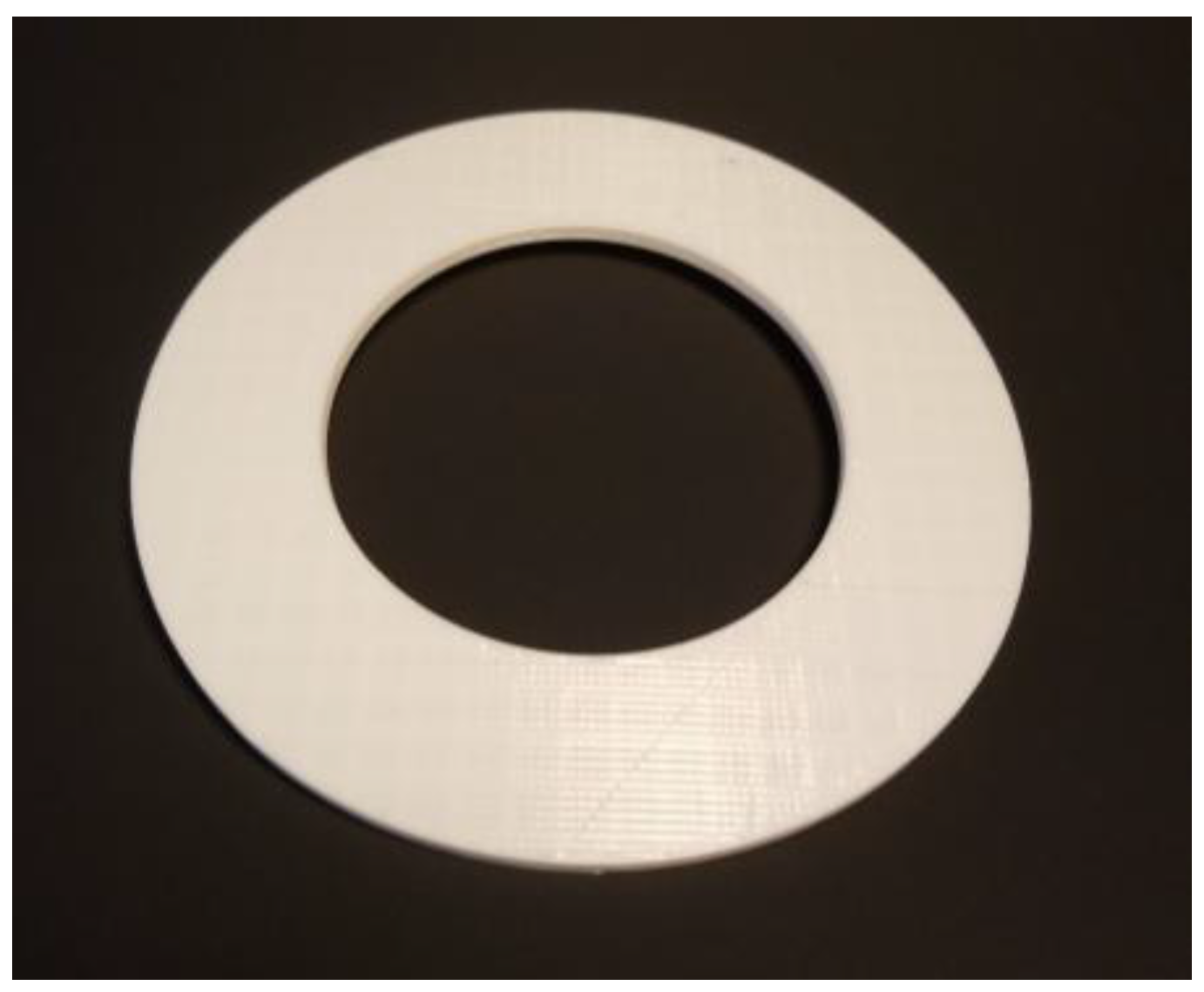

The results of the 3-D prints with flexible filament were tolerable with a standard successful print for each print job as judged by function. Cura Lulzbot edition has predefined settings for NinjaFlex and these presets were used in order to represent the mostly likely printing settings by inexperienced consumers. The use of presets makes it straight forward for beginners to get started printing flexible objects. With the “quick print” settings enabled, users select the quality to be either high detail, normal or high speed. These selections mostly effect layer height and was altered on larger items like the hammer ergonomic grip, which was made with large layers to reduce printing time. The printing parameters that had a large effect on the end part was shell thickness and infill percentage. For the automotive related parts like the O-rings, gaskets and belts, the parts were printed with thick shells (1.2 mm) and low infill (20%). This provided an overall strong part with more flexibility. Shown in

Figure 2, as a representative print, the average visual quality of the part was excellent.

For household parts like the hammer ergonomic grip, thinner shells and less infill gave parts a soft and comfortable feel. Shown in

Figure 3, the overhangs in the finger grips printed perfectly. This is an example of a large part with large layers (0.4 mm) to reduce printing time. Even with the visible layers, the part appears aesthetically acceptable.

The product accessory category was primarily printed with 100% infill, which would provide protection against falls and repeated use. This category included rather intricate prints like the iPhone 5 case and the GoPro Session Camera Case shown in

Figure 4. This prints turned out well, especially with the overhangs although there was a small amount of stringing. The layers are still visible but do not take away from the detail of the part itself. This part is a representative example at some of the detail users can still maintain, which is similar to harder thermoplastics when printing with flexible filament.

Finally, the medical device in

Figure 5 was printed at 50% infill with thinner shells because it needed to be robust and strong, but still flexible and light. This is another large print that was printed at a slightly lower layer height (0.25 mm). The print worked well and had only a light amount of stringing on the inside of the part itself that did not interfere with the functioning of the component nor impact in aesthetically.

In addition, to the flexible 3-D prints being both functional and aesthetically acceptable the results also indicate there was a distinct economic advantage to 3-D printing with flexible filament. These results are summarized in

Table 3 for the Ninjaflex prints.

Table 3 shows the material cost, print time, energy cost market value and absolute savings in USD as well as percent change as compared to high and low costs of market available equivalent products. The print time ranged by a factor of 100X from 2 min for the small O ring to 225 min (3.75 h.) for the hammer grip. In all cases the energy costs for the printing was 3 US cents or less. The price of the products ranged from a few tens of cents to a few tens of dollars. The average of the percent savings compared to the low market value equivlant products was 75% with a standard deviation of 0.15. This is substantial, but as the potentially bespoke 3-D printed parts are more appropriately compared to the high market value items the latter comparison is even more important. For these high market value comparisons, the average percent savings was 92% with a standard deviation of 0.08.

For recycled TPE filament, the same tests were conducted on a selection of three products and the results are shown in

Table 4. The results show that savings increased and percent change for both high and low increased dramtically compared to the Ninjaflex shown in

Table 3. For the recycled TPE filament the average for all the low market values was 89% with a standard deviation of 0.08. For the high market values the average was 99% with a standard deviation of 0.005.

4. Discussion

4.1. Technical Quality and 3-D Printing Challenges with Flexible Material

As can be seen in

Figure 2,

Figure 3,

Figure 4 and

Figure 5, the quality of the 3-D printed parts is acceptable when comparing these parts to mass-manufactured products. The form and function of each of the 3-D printed parts matched the traditionally manufactured ones in most cases. The biggest difference was that NinjaFlex is harder than some of the traditional items. For example, when the traditional item is made from a soft silicone, trying to replicate that feeling would be difficult with NinjaFlex. Secondly the layer lines are noticeable in a lot of the larger parts, which could be unfavorable aesthetically to some consumers. The functional units of the tested products are summarized in

Table 5. As can be seen in

Table 5 many of the functional unit tests were under a short duration of time. For example, although the phone case was tested over a year of normal usage, a commercial phone case would be expected to last over the lifetime of the average phone, which is now approaching 5 years. Thus, this preliminary data can be built upon in future work covering the complete life cycle and durability tests of each printed product class.

NinjaFlex is generally more challenging to 3-D print with than hard thermoplastic polymers. The print speed is roughly 3.5 times slower, which makes all prints significantly more time consuming when compared to more traditional FFF printing. Support material is challenging to cleanly remove so using it can be detrimental to the finish of the part. This limits the geometries available and indicates a rich area of future work to develop compatible support materials. Also unlike the more conventional hard thermoplastics, there is not as readily available consumer-safe way of smoothing the layer lines. NinjaFlex can be smoothed by using careful application of heat or by using aggressive lab grade chemicals including: concentrated hydrochloric acid (HCl), concentrated sulfuric acid (H

2SO

4), concentrated nitric acid (HNO

3), tetrahydrofurane (THF), dimethyl formamide (DMF), dimethyl acetamide (DMA), N-methyl pyrrolidone (NMP), and pyridine [

60]. However, the use of these chemicals without appropriate safety facilities and equipment is not recommended. Due to this fact, from a distributed manufacturing perspective, what comes off the printer is essentially the finished product. Finally, stringing is also a problem while printing with NinjaFlex, stringing occurs when excess molten material is pulled between empty spaces in the part and can usually be solved by either lowering printing temperature or increasing retraction settings. However, retraction settings must be very low or turned off to prevent jamming of the tool head when printing with NinjaFlex. Small strings can usually be cut off manually or melted with a heat gun, soldering iron or torch so this aesthetic challenge was not found to be a significant issue.

4.2. Economic Analysis of Distributed Manufacturing with Flexible Materials

The results from

Table 3 show that while energy cost is a contributing factor to the overall operating cost, it is a very small percentage (roughly 1%). As flexible materials are currently costlier than hard plastic filament, the relative value of the material cost is even more dominant. Comparing NinjaFlex to traditional printing filaments, every gram of plastic used is about 3 times more expensive [

39]. Overall, distributed manufacturing with flexible filaments provides a substantial savings over purchasing as the results in

Table 3 show the average savings of 75–92% with every 3-D printed object providing at least a 44% savings or more on the low end, and at least 75% savings on the high end compared to buying the same product on the market.

To start printing with flexible filament requires an upfront investment, with the tools used in this studying being $1250 for the 3-D printer, a $295 add on tool head and $65 filament for a total of US$1610 and only USD$1545 in capital costs. Less expensive options are available, but require a significant technical competence and time investment that are not available in most households. The average savings per product for the 20 items was US$9.87, so 164 average products would need to be printed to recoup the initial investment for all the equipment and supplies (or only 157 to cover the capital costs). As the average filament use per product was 12.7 g the material cost is US$1.10 per item. Thus, roughly 2 kg of material would be needed to print the items necessary to recoup the cost of the system.

It has already been shown that the standard nozzle on the Lulzbot Mini provides an ROI of 108% after 5 years [

32]. Some prosumers (producing consumers) will use their 3-D printers considerably more than once per week and are thus able to recover their initial investment more rapidly by printing out the same types of items at a greater rate or in a few expensive substitution prints (e.g., custom orthotics). Thus, if it is assumed the prosumer primarily uses the 3-D printer to print hard plastic items at a rate of 1 time per week, the printer is paid for in the first year for custom items compared to high priced products available commercially and then only the

$360 for the flexible extruder upgrade and flexible filament are needed to be repaid. This can be done in 37 average items or less than a year if printing one item per week with flexible filament. In addition, as flexible 3-D printed capability is still somewhat novel prosumers could start their own small business and sell printing services to recoup the investment even more rapidly.

The accessibility of new lower cost open source 3-D printers such as the Lulzbot Mini that was used in this study has been steadily increasing to the benefit of consumers. The consumer now has an alternative to commercial purchasing for a rapidly growing list of consumer products using this type of machine. Based on the results of this study, for the use of distributed manufacturing on a regular basis the consumer would expect a high return on investment. In addition to the economic benefits, the consumer can now participate in a collaborative environment with other consumers that enjoy making their own items—the maker community [

61,

62,

63,

64,

65]. This community is also growing as a result of increased 3-D printer accessibility to makers [

66,

67,

68,

69]. This community is filled with makers and tinkerers that believe in fixing what is broken and reusing what they already have [

70,

71]. This is a mindset of a conscious consumer, one that understands the environmental impact of buying something and throwing it away [

71,

72,

73,

74,

75,

76,

77,

78].

Distributed manufacturing is the term used here to describe decentralized fabrication of parts in smaller factories or homes that are local to end-users [

12,

13,

69,

79,

80,

81,

82,

83]. This concept is ideal for additive manufacturing as 3-D printers located around the globe could be utilized to make a variety of parts for people that are geographically close to consumers. This reduces shipping time, packaging materials and emissions from the embodied energy of transportation as well as material savings [

79,

80]. If someone wanted to start up their own micro-factory at home as a source of income they could do so for a very low up-front investment in machinery [

17]. A laptop, Internet access, a 3-D printer and some filament is all someone would need to start designing parts for other people or companies and then printing the designs for them in their own residence (e.g., Make XYZ [

84] or 3D Hubs with over 5000 such small businesses already in operation [

85]). This business model is incredibly scalable with a very low risk due to its small initial investment. Once a 3-D printer is setup properly, it can run untouched, making build platforms full of parts. Someone that works during the day at another job could start a print before going to work and then have it done when they return home to take off the parts and begin a second print shift.

4.3. Recycling Flexible Materials

As the results of this study clearly show, the material cost is the biggest factor for operating expenses of a 3-D printer, particularly in regards to flexible materials. This is due to the high mark-up from filament manufacturers that convert pellets of polymer into a filament. The mark-up on PLA for example is more than 6X. PLA pellets can be bought for about US

$4.00 and PLA filament is sold for around US

$25 or more. Similarly, there appears to be a significant markup with flexible filaments, with virgin TPE pellets costing

$4.50 for 1 kg [

36]. The savings from printing with pellets or making filament could be up to 93%. Thus, a filament extruder or a recyclebot [

41] can be used minimize the cost of distributed manufacturing [

86]. Ideally a high volume fraction of recycled materials would be used which reduce embodied energy use and environmental impact [

87,

88,

89] and supporting the goals of the circular economy [

86]. Preliminary work on the mechanical properties of such recycling is promising [

90,

91]. A recyclebot can be made for under US

$600 [

92] and would need to make roughly 9 kg to offset the cost with savings on purchased filament when using flexible filament. As this could be accomplished in a week, the ROI for such a device is again greater than 100%. However, this is a substantial amount representing several years of printing only an object a week, which may indicate that recyclebots are appropriate for heavy-use makers, but may be more appropriately deployed at makerspaces, hackerspaces, libraries, design studios, community recycling centers as well as small filament-related businesses. There is also a clear need to improve the design of recyclebots to reduce their costs for developing world applications such as improving waste picker income [

93] as well as move to more appropriate and expansive recycling codes that cover 3-D printing polymers [

94].

To analyze the potential to radically reduce the material cost, recycled TPE was manufactured and tested. A recyclebot filament extruder was used to create filament from the pellets and successfully printed the designs listed in

Table 4. This recycled TPE cost

$1.10 for 1 kg [

95]. Using recycled plastic instead of NinjaFlex could thus potentially save 98% on material cost. The recycled TPE did come with a few interesting challenges, however. As the material was reground material, it was not as consistent as virgin TPE, meaning that each batch could potentially be a different composition, which would make some form of testing during printing necessary as has been developed for PLA [

96]. This again would open up a new market tying recycling to environmentally responsible consumerism as has been done previously in other contexts [

97]. A second problem was that the melting point was rather high compared to other 3-D printing materials, with the best settings for 3-D printing found to be at 290 °C. Most low-cost 3-D printers max out at 300 °C, so it could be potentially harmful to run in some machines. Finally, there was an issue with getting bed adhesion. The PVA glue stick that was used when printing NinjaFlex did not work when printing the recycled TPE. Turning the build plate temperature up to 100 °C solved this problem, but then also increased the embodied energy of the prints (and the cost from electricity per printed part) again as shown in

Table 4.

4.4. Labor Costs in a Distributed Manufacturing Context

The cost savings detailed in

Section 4.2 and 4.3 do not include any labor costs and may at first appear biased against the conventional centralized manufacturing model of product distribution. This is an important assumption that needs to be further explained as in many cases it may be a conservative assumption undervaluing the savings from distributed manufacturing. This assumption is valid when there is not an opportunity cost (positive or negative) for the prosumer to use distributed manufacturing to produce a product for self-consumption. For pre-designed flexible products using the 3-D printer in this study (or equivalent) this situation occurs. The time it takes to search for the design of a product is approximately equivalent to the time needed for shopping for a product on line. The time it takes to order a product (i.e., input credit card information and shipping address) is about the same time it takes to download an stl (including any form of customization), choose printer settings and start the print job. The actual print time is not necessarily a factor as the printers can be comfortably operated without observation. The one exception for this is when the print jobs extend past the available print area on the bed. So for example, as shown in

Figure 6 if printing out more than four 2 1/2″ oil resistant gaskets multiple print runs will need to be started and the print bed cleared between each run for the bed size shown. As noted earlier, there essentially no post processing of flexible products and the user simply has to remove them from the print bed. This step can be looked at as a time investment less than that needed for unpacking a shipped online order. Thus, it is perhaps instructive to compare distributed manufacturing of a single gasket and a dozen gaskets to the best case scenario for conventional manufacturing and shipping. The best case scenario for traditional manufacturing would use an online digital shopping experience equivalent to Amazon with Prime (all shipping and credit card information pre input so that an order can be placed with a single click and free 2-day delivery). Ordering a single gasket takes only a minute to find and order but involves 2 days generally or 1 day to only several hours for shipping in optimal geographic location (e.g., New York City) or of very limited product selection with Prime Now in 2 h. Whereas for the distributed manufacturing case setting up the print only takes a few minutes and is ready in less than an hour. As there is a significant cost advantage as shown in

Table 3 and

Table 4 as well as time savings for access to the product, it is clear that using distributed manufacturing is in the best interest of consumers for single simple pre-designed products. If a consumer needs a dozen 2 1/2″ oil resistant gaskets, however, the analysis becomes slightly more complex. Again in the Amazon case ordering a dozen gaskets and having them shipped takes approximately the same amount of time (only a few minutes of consumer time to order and unpack the shipment but 2 days for shipping). However, in the distributed manufacturing case as shown in

Figure 6 only 4 gaskets can be printed at a time over a time period of more than 3 h. Thus, it would take the consumer 4 trips to the 3-D printer (1 to set up the first print, 2 to get the first two batches and set up the next print, and a final trip to get the last batch of 4 gaskets) where a few minutes for each trip, which would be primarily composed of the time to remove printed products. Again using distributed manufacturing would be justified by the economic savings. However, as there is more than 9 h of printing time and 4 trips to the printer the actual working time for the prosumer extends past an 8 h work day (even though only a few actual minutes of “work” are required by the prosumer). This could expand the completion of the print job to 2 days, possibly negating the secondary advantage of faster product availability. It is straight forward to imagine an even larger order where the economic benefits of the manufacturing with a 3-D printer would be eroded by the hassle of removing printed products and setting up the printer again (e.g., hundreds of gaskets). Thus, with low cost open source technology available today there is still an advantage for centralized manufacturing of large orders of identical products for a single consumer. However, as this study has shown in most cases where only a single product or a few are needed by the consumer there is both an economic as well as a time advantage to using a 3-D printer to produce one´s own products even with commercial flexible filament.

It should also be pointed out that this advantage is magnified considerably when considering traditional brick and mortar store shopping. Printing 3-D at home involves significantly less time invested than physically going to a brick and mortar shop and finding a product and bringing it back to a home or business until the print job itself is substantially large.

Setting labor costs estimates to zero is not generally valid for a business if there is paid employee doing the printing and would need to be taken into account for financial analysis. There are, however, several exceptions to this as well. Zero labor costs are relevant in the following situations: (1) where the 3-D printing is used as a learning tool in order to provide employees with experience in the fabrication of products; (2) where the labor is provided by unpaid interns or volunteers; or, (3) where there is no opportunity cost to using existing salaried employee (e.g., a receptionists are paid a fixed cost in $/h, and for which there is no opportunity cost for them to operate the 3-D printer in between their other tasks such as greeting customers, etc.). This last example, may provide the best opportunity for some businesses to take advantage of the economic benefits of 3-D printing for distributed manufacturing as operating the 3-D printer could be seen as equivalent to operating a 2-D printer or copying machine, which is already often under the job description of secretaries and receptionists. As this article has shown even printing with advanced materials such as flexible materials of pre-designed products is now within the reach of low-skilled workers such as receptionists after minimal training.

4.5. Limitations and Future Work

This study had several limitations. One of the fundamental weaknesses of scaling the results of this study as was done with former studies on hard plastic distributed manufacturing is the flexible filament design community is new and there is not a large quantity of designs specifically made to be printed in flexible materials. Another limitation of this study was that NinjaFlex was the only filament that was tested. Using other brands could may have given a different part quality or surface finish. Future work in this area can complete an analysis for all commercially available flexible filaments.

Another limitation of this study is that it is a specific snap shot on the economic viability in time using highly contextualized data (e.g., prices of specific filaments, 3-D printers and printer parts as well as electricity prices). However, based on current trends the results of this study can be generalized (i.e., the economic benefits of distributed manufacturing with flexible filament will expand). The price of the 3-D printers and the 3-D printer parts is likely only to continue to decline following current trends [

14]. In addition, as discussed above, the current markup for 3-D printing flexible filament is unlikely to continue into the future as competition (even possibly with recycled materials) reduces margins and overall cost for consumers. A similar trend has already taken place with PLA and the price has dropped by more than 50% in the last 5 years. The only cost for distributed manufacturing that is likely to increase is that of electricity costs. For example, the real electricity price escalation for residential electricity consumers (prosumers here) has been on average 3.6% p.a. in the years 2000–2006 in the U.S. [

98] and 4.3% p.a. in the years 2000–2007 in the EU [

99]. These increases are likely to continue in the medium-term future, but as shown here the electrical portion of the total cost of distributed manufacturing is minor. In addition, several solar-powered 3-D printing systems have been developed [

100,

101] that would eliminate that price increase directly.

There are several areas of technical and social science study that would improve the viability and feasibility of distributed manufacturing of products made with flexible materials with 3-D printers including: (1) materials selection; (2) reliability; (3) material costs and (4) social acceptability that are summarized in

Table 6.

Unlike hard plastics in FFF 3-D printing, which now possess a significant diversity, there are only a few types of commercial flexible filament [

102,

103,

104]. As the preliminary technical work in this study showed there is significant promise for using recyclebots to research opportunities for new flexible filaments from recycled flexible polymers. This trend could be further supported by adopting new far more diverse polymer recycling codes to further expand the materials selection while reducing costs [

94]. In addition, there is a large potential for research into new composite filaments with TPE as the matrix and carbon or steel fiber as reinforcement [

105,

106,

107,

108,

109]. This could open new possibilities for 3-D printing belts that do not stretch and deform (while enabling the RepRap community one step closer to complete self-replication). Research can also continue with TPU filaments and how they compare to TPE with price point, hardness, strength and ease of use. Finally, continuing to design flexible parts that could be used in the household would improve the economics of this approach further for more consumers. Potential devices could be new wearable technology, custom tools or new types of hardware. Furthermore, the lifetime of 3-D printed products must be evaluated.

The reliability of prosumer 3-D printers can be below experiences consumers are accustomed to with more mature products and this is an even greater factor than normal with the use of flexible filament. One of the largest problems is that flexible filament can jam more easily than hard plastics as if the flexible filament has any room between the extrusion gear and the nozzle, it will get stuck and jam. Similarly, correctly calibrated temperature at the hot end is important if too low, flexible filament will jam. Wittbrodt et al. estimated that print errors represented 20% for new users with a self-built RepRap 3-D printer printing hard plastic [

31]—with flexible filament, the error would be higher than that percentage due to likelihood of jamming for novice users. However, new automated systems for bed leveling and nozzle cleaning (as used in the Lulzbot Mini and other commercialized open source 3-D printers) reduces this error. To correct all of these errors an automated system of quality assurance is needed. Research has just begun in this area using machine vision and inexpensive webcams to find faults and halt prints [

110,

111] as well as laser scanning [

112]. Finally, if using a build plate with a PEI sheet like on the stock Lulzbot mini, a PVA glue stick must be used because NinjaFlex will stick too well to it and the part will not be able to be removed.

Based on the results of this study future work should be done to analyze how likely a consumer is to buy a 3-D printer as a way of saving money—particularly with the use of specialty materials such as flexible filaments. The value for producing simple single material products has been expanded in this study, but for the full potential of distributed manufacturing to be reached prosumers must be enabled to fabricate complex multi-material products. Future research is needed to determine the disruptive potential of distributed 3-D printing both on enabling such 3-D printing on the technical front, as well as detailed life cycled analysis on the economic side. This should include an extensive survey about the likeliness of prosumers using their printers for personal gain as well. For such a study, the goal would be to determine how often prosumers use their 3-D printer and where their designs come from, i.e., downloaded or designed themselves.