Effect of Particle Size on Microstructure and Mechanical Properties of Al-Based Composite Reinforced with 10 Vol.% Mechanically Alloyed Mg-7.4%Al Particles

Abstract

:1. Introduction

2. Experimental Section

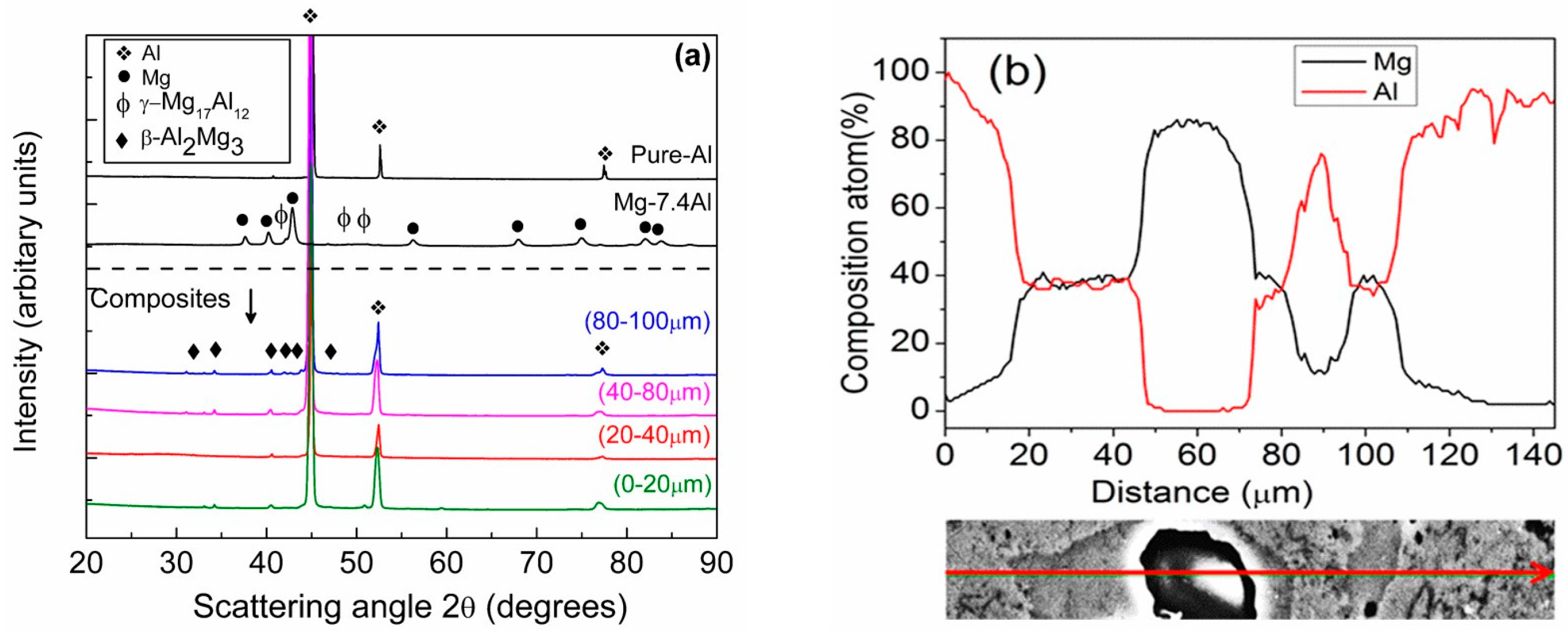

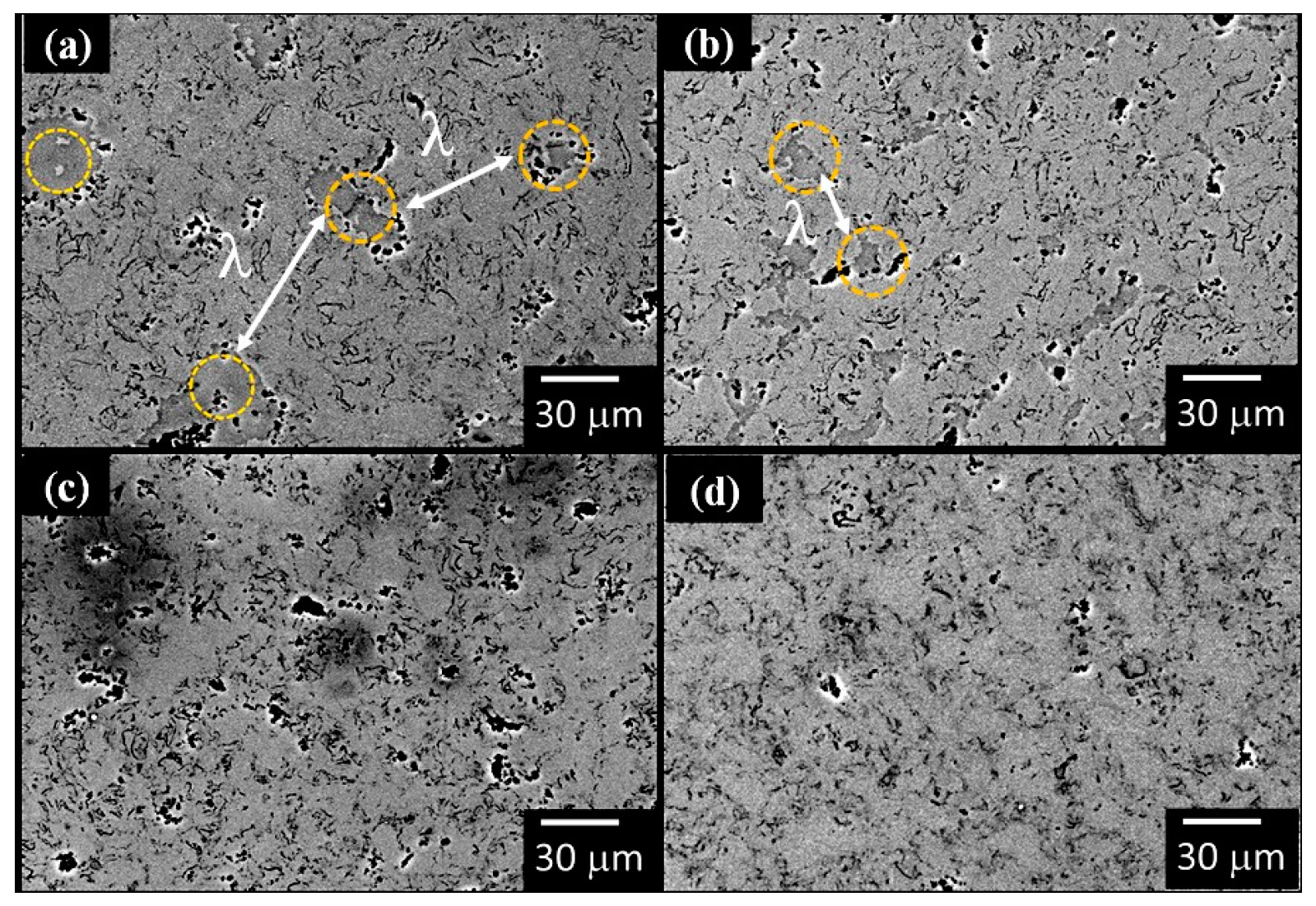

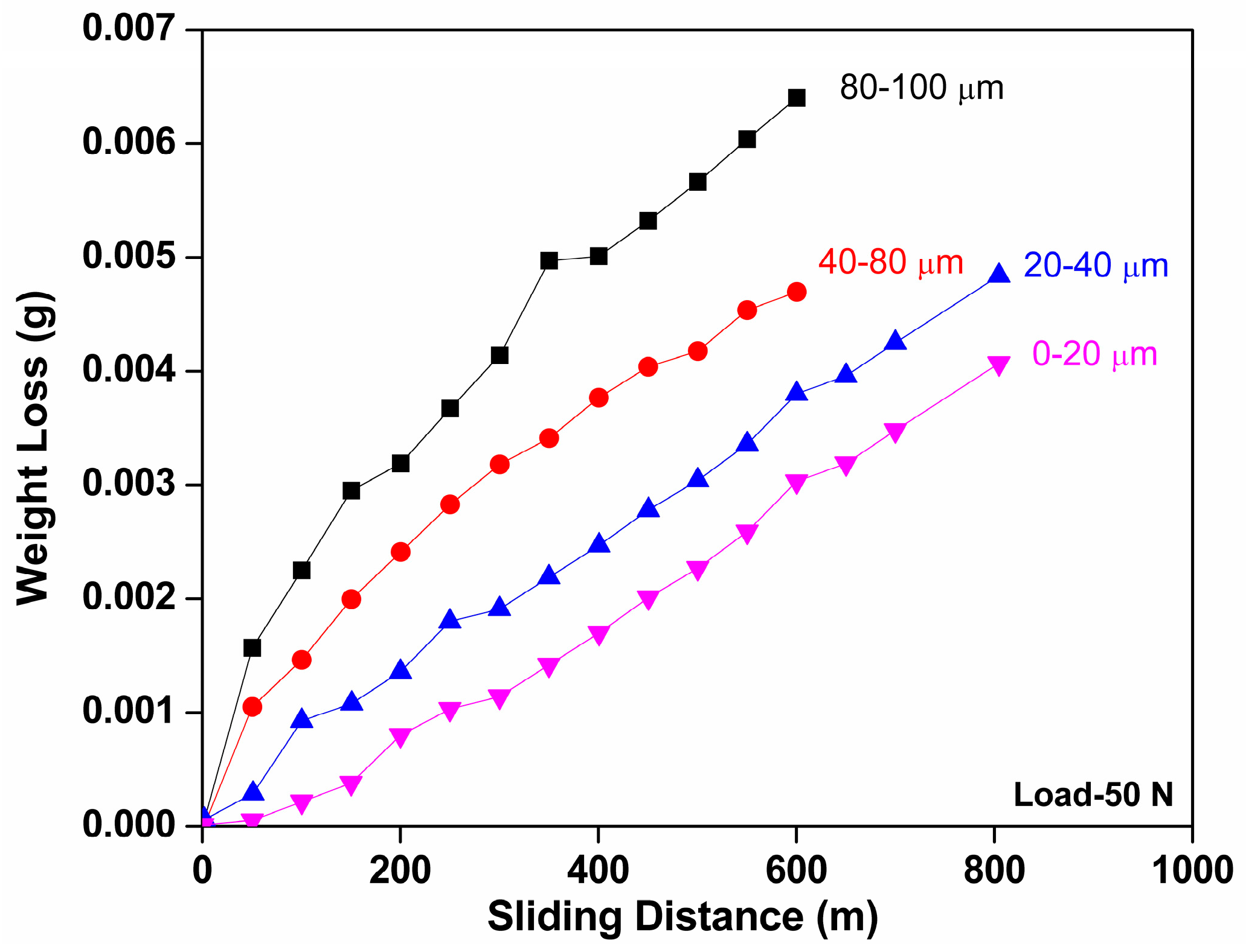

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Scudino, S.; Liu, G.; Prashanth, K.G.; Bartusch, B.; Surreddi, K.B.; Murty, B.S.; Eckert, J. Mechanical properties of Al-based metal matrix composites reinforced with Zr-based glassy particles produced by powder metallurgy. Acta Mater. 2009, 57, 2029–2039. [Google Scholar] [CrossRef]

- Clyne, T.W.; Withers, P.J. An Introduction to Metal Matrix Composites; Cambridge University Press: New York, NY, USA, 1993. [Google Scholar]

- Kainer, K.U. Metal Matrix Composites. Custom-Made Materials for Automotive and Aerospace Engineering; Wiley-VCH: Weinheim, Germany, 2006. [Google Scholar]

- Wang, Z.; Prashanth, K.G.; Scudino, S.; Chaubey, A.K.; Sordelet, D.J.; Zhang, W.W.; Li, Y.Y.; Eckert, J. Tensile properties of Al matrix composites reinforced with in situ Al84Gd6Ni7Co3 glassy particles. J. Alloy. Compd. 2014, 586, S419–S422. [Google Scholar] [CrossRef]

- Miracle, D.B. Metal matrix composites—From science to technological significance. Compos. Sci. Technol. 2005, 65, 2526–2540. [Google Scholar] [CrossRef]

- Torralba, J.M.; Da Costa, C.E.; Velascoa, F. P/M aluminum matrix composites: An overview. J. Mater. Process. Technol. 2003, 133, 203–206. [Google Scholar] [CrossRef]

- Liua, Y.Q.; Conga, H.T.; Wanga, W.; Sun, C.H.; Cheng, H.M. AlN nanoparticle-reinforced nanocrystalline Al matrix composites: Fabrication and mechanical properties. Mater. Sci. Eng. A 2009, 505, 151–156. [Google Scholar] [CrossRef]

- Wang, H.Y.; Jiang, Q.C.; Wang, Y.; Ma, B.X.; Zhao, F. Fabrication of TiB2 particulate reinforced magnesium matrix composites by powder metallurgy. Mater. Lett. 2004, 58, 3509–3513. [Google Scholar] [CrossRef]

- Kanga, Y.C.; Lap-Ip Chan, S. Tensile properties of nanometric Al2O3 particulate-reinforced aluminum matrix composites. Mater. Chem. Phys. 2004, 85, 438–443. [Google Scholar] [CrossRef]

- Schurack, F.; Eckert, J.; Schultz, L. Synthesis and mechanical properties of high strength aluminium-based quasicrystalline composites. Philos. Mag. 2003, 83, 1287–1305. [Google Scholar] [CrossRef]

- El Kabir, T.; Joulain, A.; Gauthier, V.; Dubois, S.; Bonneville, J.; Bertheau, D. Hot isostatic pressing synthesis and mechanical properties of Al/Al–Cu–Fe composite materials. J. Mater. Res. 2008, 23, 904–910. [Google Scholar] [CrossRef]

- Scudino, S.; Liu, G.; Sakaliyska, M.; Surreddi, K.B.; Eckert, J. Powder metallurgy of Al-based metal matrix composites reinforced with β-Al3Mg2 intermetallic particles: Analysis and modeling of mechanical properties. Acta Mater. 2009, 57, 4529–4538. [Google Scholar] [CrossRef]

- Inoue, A. Amorphous: Nanoquasicrystalline and nanocrystalline alloys in Al-based systems. Prog. Mater. Sci. 1998, 43, 365–520. [Google Scholar] [CrossRef]

- Inoue, A.; Kimura, H. Fabrications and mechanical properties of bulk amorphous, nanocrystalline, nanoquasicrystalline alloys in aluminum-based system. J. Light Mater. 2001, 1, 31–41. [Google Scholar] [CrossRef]

- Chaubey, A.K.; Scudino, S.; Samadi Khoshkhoo, M.; Prashanth, K.G.; Mukhopadhyay, N.K.; Mishra, B.K.; Eckert, J. High-strength ultrafine grain Mg-7.4%Al alloy synthesized by consolidation of mechanically alloyed powders. J. Alloy. Compd. 2014, 610, 446–461. [Google Scholar] [CrossRef]

- Omyma, E.-K.; Fathy, A. Effect of SiC particle size on the physical and mechanical properties of extruded Al matrix nanocomposites. Mater. Des. 2014, 54, 348–353. [Google Scholar]

- Smagorinski, M.E.; Tsantrizos, P.G.; Grenier, S.; Cavasin, A.; Brzezinski, T.; Kim, G. The properties and microstructure of Al-based composites reinforced with ceramic particles. Mater. Sci. Eng. A 1998, 244, 86–90. [Google Scholar] [CrossRef]

- Scudino, S.; Bartusch, B.; Eckert, J. Viscosity of the supercooled liquid in multi-component Zr-based metallic glasses. J. Phys. Conf. Ser. 2009, 144. [Google Scholar] [CrossRef]

- Erich, D.L. Metal-matrix composites: Problems, applications and potential in P/M industry. Prog. Powder Metall. 1986, 46, 45–65. [Google Scholar]

- Ali, F.; Scudino, S.; Liu, G.; Srivastava, V.C.; Mukhopadhyay, N.K.; Khoshkhoo, M.S.; Prashanth, K.G.; Uhlenwinkel, V.; Calin, M.; Eckert, J. Modeling the strengthening effect of Al-Cu-Fe quasicrystalline particles in Al-based metal matrix composites. J. Alloy. Compd. 2012, 536, S130–S133. [Google Scholar] [CrossRef]

- Chaubey, A.K.; Scudino, S.; Mukhopadhyay, N.K.; Mishra, B.K.; Eckert, J. Effect of particle dispersion on the mechanical behavior of Al-based metal matrix composites reinforced with nanocrystalline Al-Caintermetallics. J. Alloy. Compd. 2012, 536, S134–S137. [Google Scholar] [CrossRef]

- Slipenyuk, A.; Kuprin, V.; Milman, Yu.; Goncharuk, V.; Eckert, J. properties of P/M processed particle reinforced metal matrix composites specified by reinforcement concentration and matrix-to-reinforcement particle size ratio. Acta Mater. 2006, 54, 157–166. [Google Scholar] [CrossRef]

- Chaubey, A.K.; Scudino, S.; Khoshkhoo, M.S.; Prashanth, K.G.; Mukhopadhyay, N.K.; Mishra, B.K.; Eckert, J. Synthesis and characterization of nanocrystalline Mg-7.4%Al powders produced by mechanical alloying. Metals 2013, 3, 58–68. [Google Scholar] [CrossRef]

- ASTM-E8/E08M-08. Standard Test Methods for Tension Testing of Metallic Materials; ASTM International: West Conshohocken, PA, USA, 2008. [Google Scholar]

- Alloy phase diagrams. In ASM Handbook; ASM International: Materials Park, OH, USA, 1997.

- Standard terminology relating to methods of mechanical testing. In ASTM Annual Book; ASTM: West Conshohocken, PA, USA, 2003.

- Manoharan, M.; Lewandowski, J.J. Effect of reinforcement size and matrix microstructure on the fracture properties of an aluminum metal matrix composite. Mater. Sci. Eng. A 1992, 150, 179–186. [Google Scholar] [CrossRef]

- Lewandowski, J.J.; Liu, D.S.; Liu, C. Observations on the effects of particle size and superposed pressure in deformation of metal matrix composites. Scr. Metall. 1991, 25, 21–26. [Google Scholar] [CrossRef]

- Kamat, S.; Hirth, J.P.; Mehrabian, R. Mechanical properties of particle-reinforced aluminum-matrix composites. Acta Metall. 1989, 37, 2395–2402. [Google Scholar] [CrossRef]

- Gustafson, T.W.; Panda, P.C.; Song, G.; Raj, R. Influence of microstructural scale on plastic flow behavior of metal matrix composites. Acta Mater. 1997, 45, 1633–1643. [Google Scholar] [CrossRef]

- Llorca, J. An analysis of the influence of reinforcement fracture on the strength of discontinuously-reinforced metal-matrix composites. Acta Metall. 1995, 43, 181–192. [Google Scholar] [CrossRef]

- Kumai, S.; King, J.E.; Knott, J.F. Short and long fatigue crack growth in a SiC reinforced aluminium alloy. Fatigue Fract. Eng. Mater. Struct. 1990, 13, 511–524. [Google Scholar] [CrossRef]

- Ehtemam-Haghighi, S.; Prashanth, K.G.; Attar, H.; Chaubey, A.K.; Cao, G.H.; Zhang, L.C. Evaluation of mechanical and wear properties of Ti-xNb-7Fe alloys designed for biomedical applications. Mater. Des. 2016, 111, 592–599. [Google Scholar]

- Prashanth, K.G.; Debalina, B.; Wang, Z.; Gostin, P.F.; Gebert, A.; Calin, M.; Kühn, U.; Kamaraj, M.; Scudino, S.; Eckert, J. Tribological and corrosion properties of Al-12Si produced by selective laser melting. J. Mater. Res. 2014, 29, 2044–2054. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Scudino, S.; Chaubey, A.K.; Löber, L.; Wang, P.; Attar, H.; Schimansky, F.P.; Pyczak, F.; Eckert, J. Processing of Al–12Si–TNM composites by selective laser melting and evaluation of compressive and wear properties. J. Mater. Res. 2016, 31, 55–65. [Google Scholar] [CrossRef]

| Samples | Density (gm/cm3) | Hardness (Hv) |

|---|---|---|

| Al pure | 2.71 ± 0.15 | 42 ± 4 |

| Al-10AlMg (80–100 µm) | 2.61 ± 0.25 | 85 ± 7 |

| Al-10AlMg (40–80 µm) | 2.63 ± 0.24 | 87 ± 6 |

| Al-10AlMg (20–40 µm) | 2.64 ± 0.22 | 88 ± 5 |

| Al-10AlMg (0–20 µm) | 2.65 ± 0.18 | 89 ± 4 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chaubey, A.K.; Konda Gokuldoss, P.; Wang, Z.; Scudino, S.; Mukhopadhyay, N.K.; Eckert, J. Effect of Particle Size on Microstructure and Mechanical Properties of Al-Based Composite Reinforced with 10 Vol.% Mechanically Alloyed Mg-7.4%Al Particles. Technologies 2016, 4, 37. https://doi.org/10.3390/technologies4040037

Chaubey AK, Konda Gokuldoss P, Wang Z, Scudino S, Mukhopadhyay NK, Eckert J. Effect of Particle Size on Microstructure and Mechanical Properties of Al-Based Composite Reinforced with 10 Vol.% Mechanically Alloyed Mg-7.4%Al Particles. Technologies. 2016; 4(4):37. https://doi.org/10.3390/technologies4040037

Chicago/Turabian StyleChaubey, Anil K., Prashanth Konda Gokuldoss, Zhi Wang, Sergio Scudino, Nilay K. Mukhopadhyay, and Jürgen Eckert. 2016. "Effect of Particle Size on Microstructure and Mechanical Properties of Al-Based Composite Reinforced with 10 Vol.% Mechanically Alloyed Mg-7.4%Al Particles" Technologies 4, no. 4: 37. https://doi.org/10.3390/technologies4040037