Frequency Dependence of Electrical Parameters of an Organic-Inorganic Hybrid Composite Based Humidity Sensor

Abstract

:1. Introduction

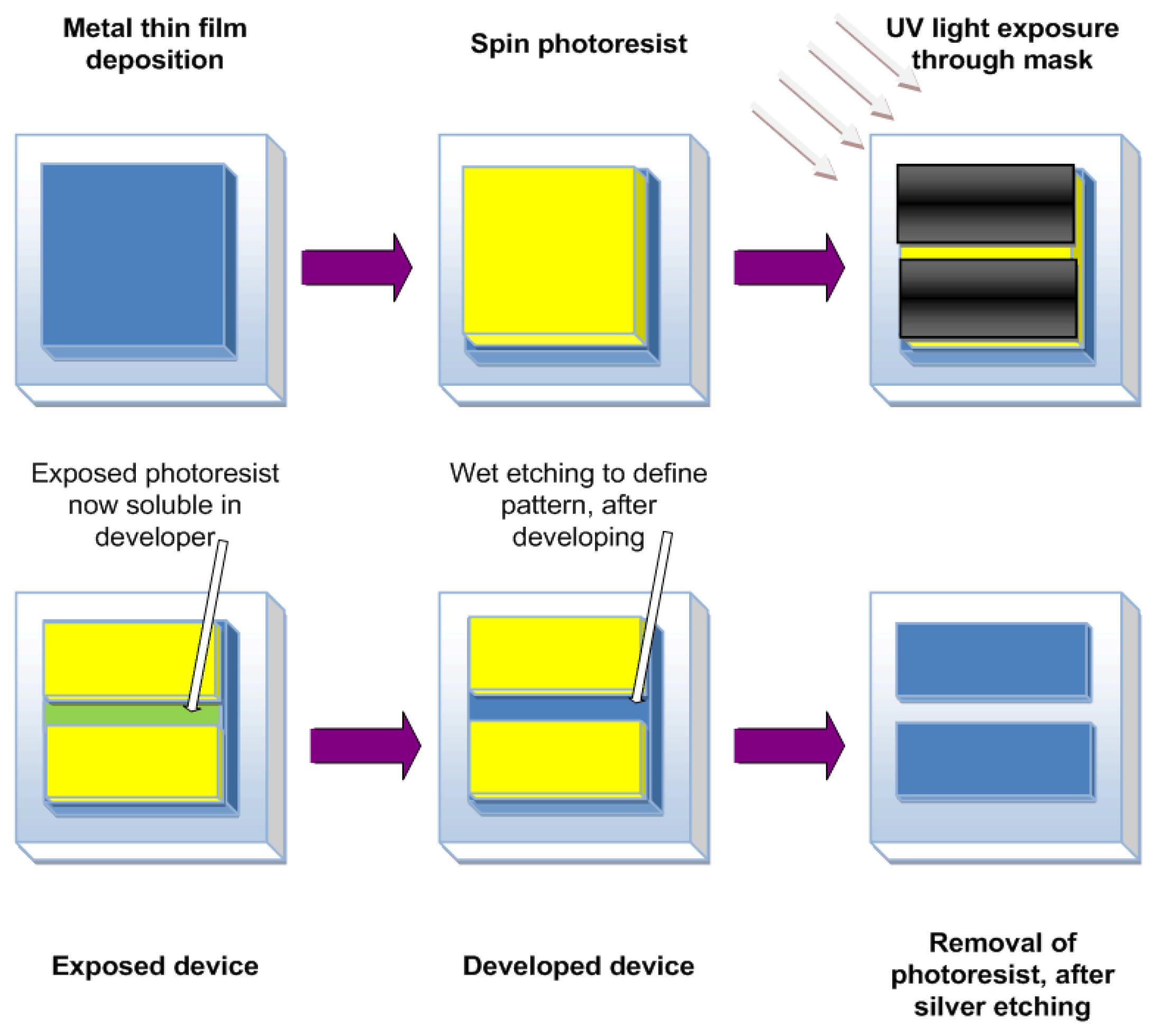

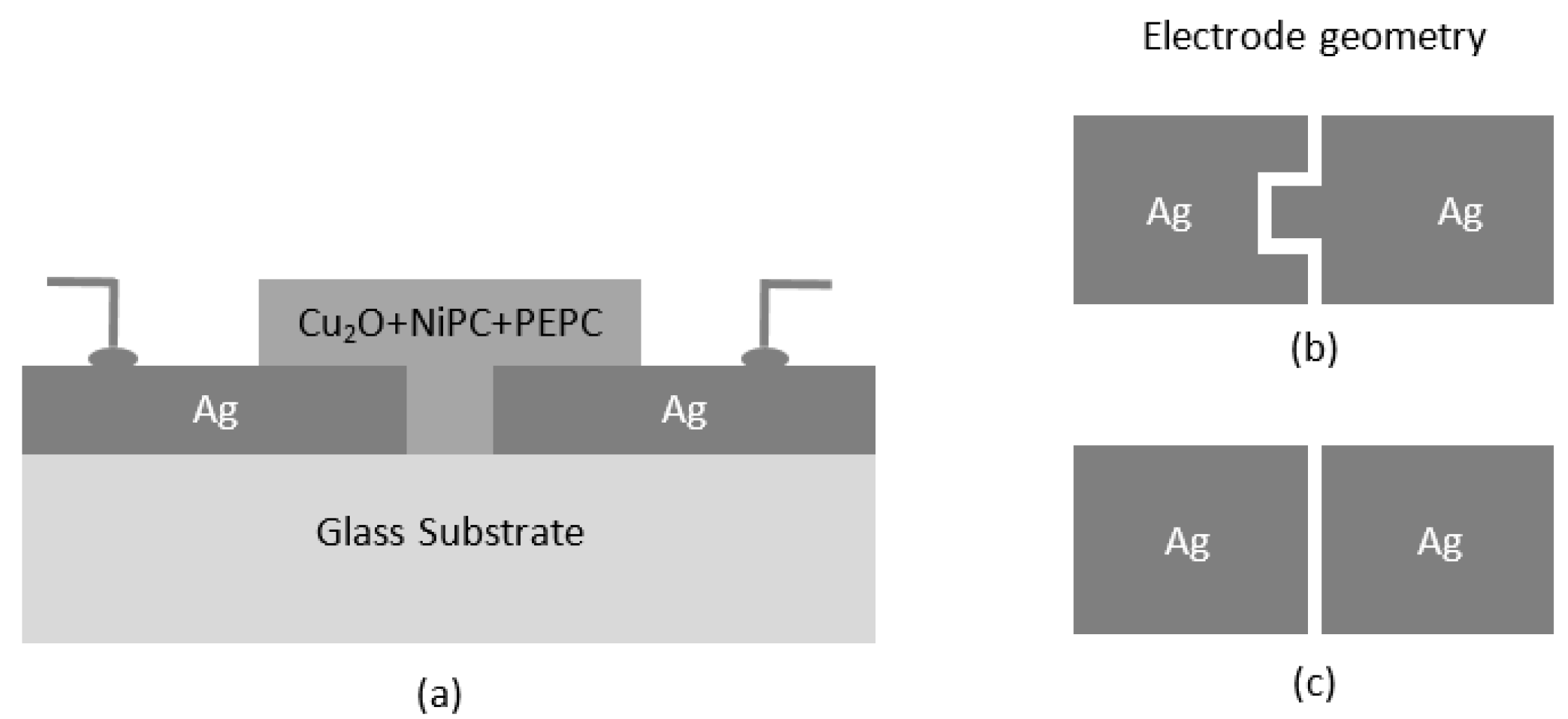

2. Experimental

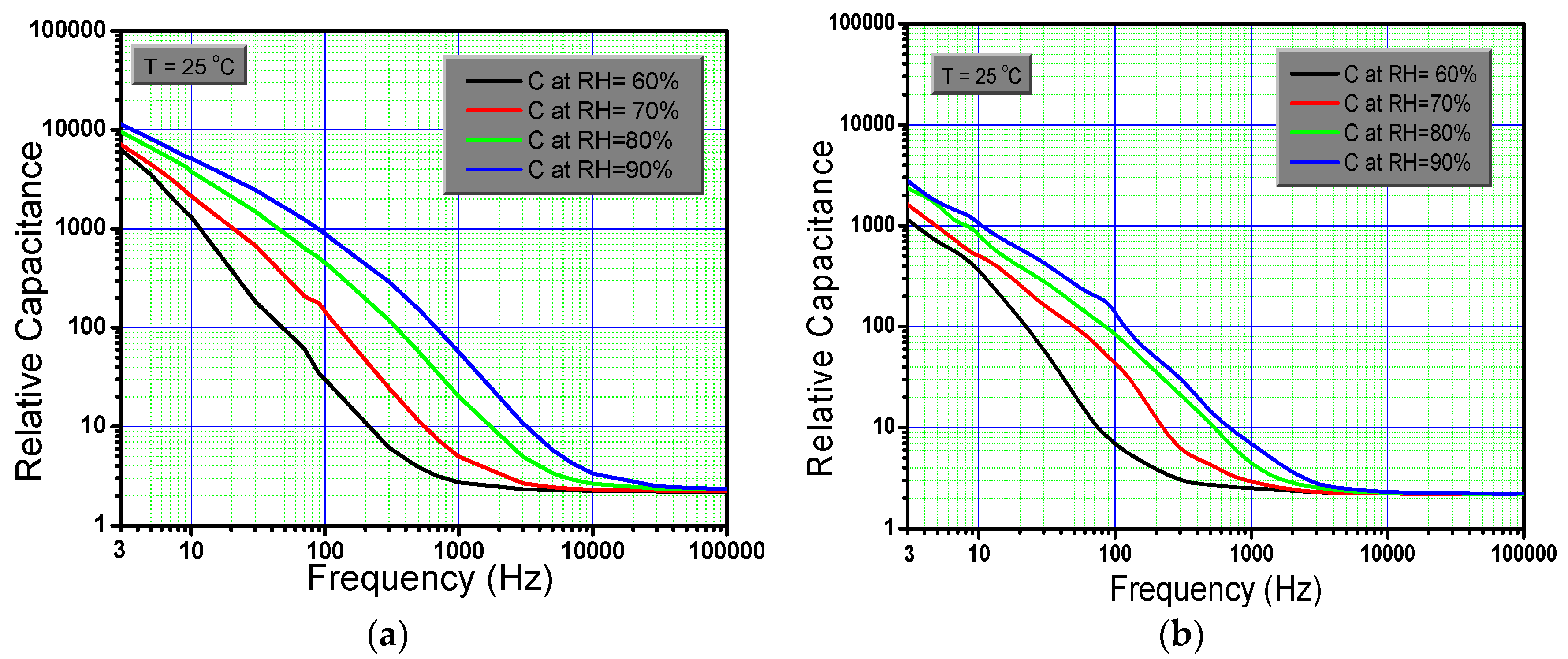

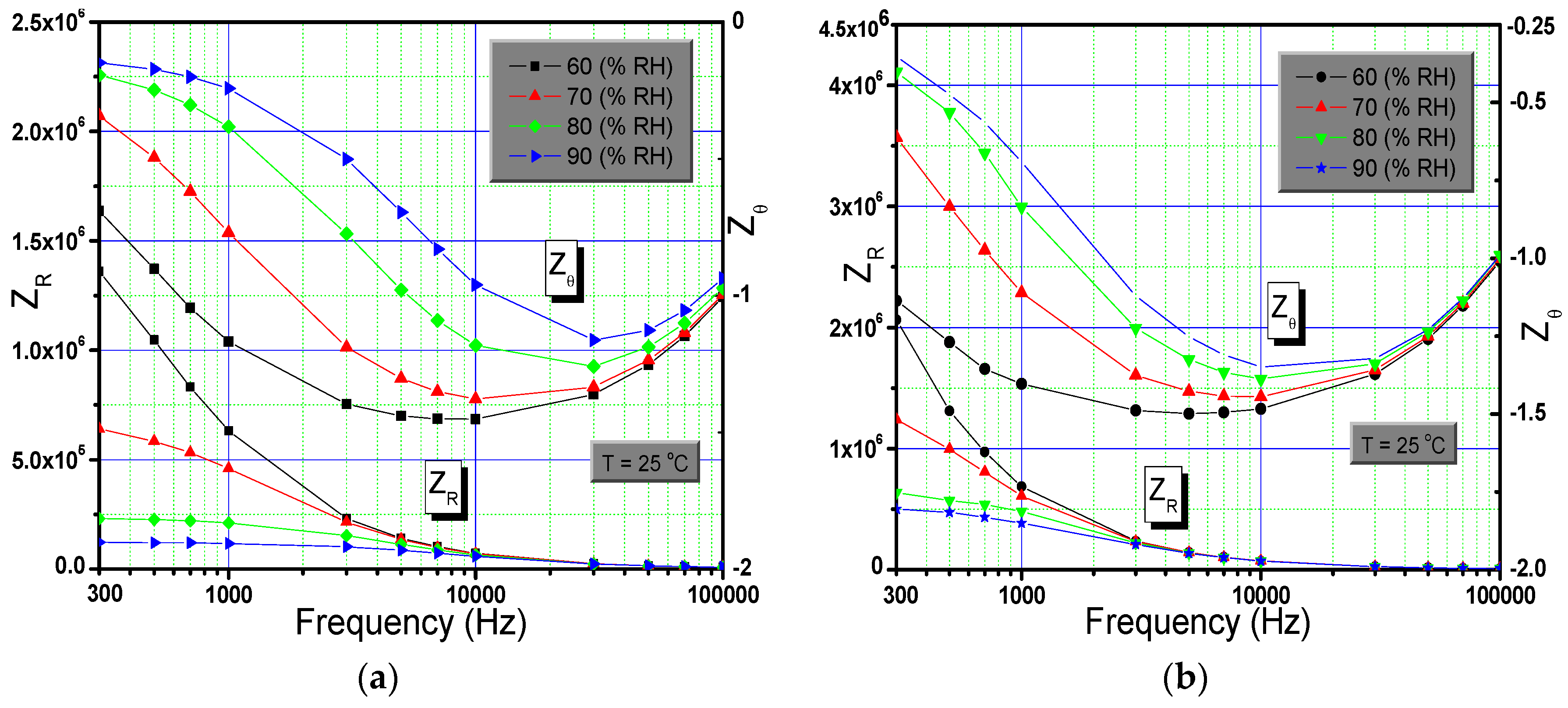

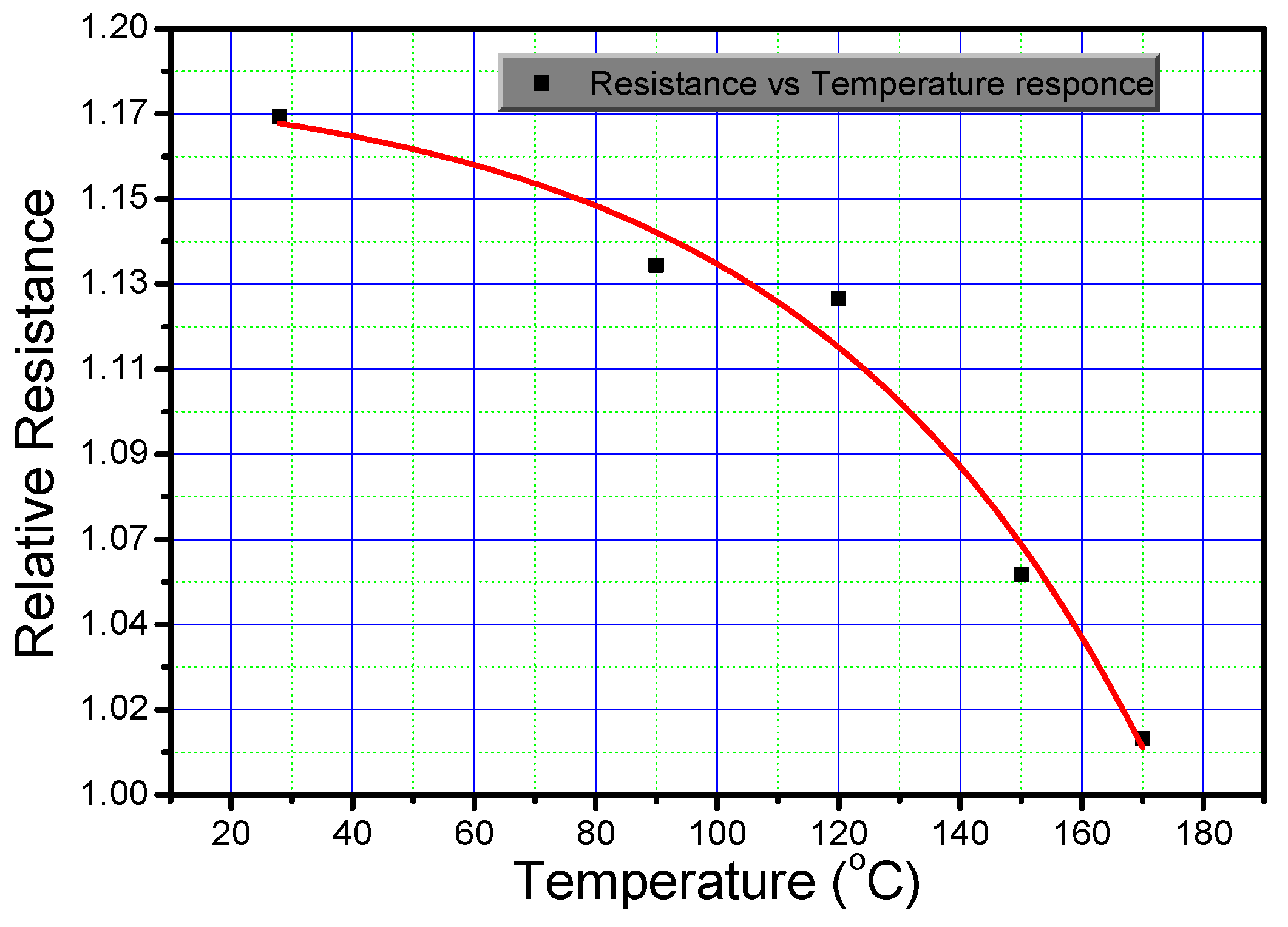

3. Results and Discussion

4. Conclusions

Acknowledgments

Conflicts of Interest

References

- Ruiz-Garcia, L.; Lunadei, L.; Barreiro, P.; Robla, I. A review of wireless sensor technologies and applications in agriculture and food industry: state of the art and current trends. Sensors 2009, 9, 4728–4750. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Laville, C.; Pellet, C. Comparison of three humidity sensors for a pulmonary function diagnosis microsystem. Sens. J. IEEE 2002, 2, 96–101. [Google Scholar] [CrossRef]

- Ahmad, Z.; Shuhail, M.; Ibrahim, I.; Al-Rawi, W.K.; Sulaiman, K.; Zafar, Q.; Sazal, A.H.; Shaameri, Z. MEH-PPV/Alq3 donor-acceptor blend as a photodetector. Chin. Phys. B 2013, 22, 100701–100705. [Google Scholar] [CrossRef]

- Karimov, K.; Moiz, S.; Tahir, M.M.; Ahmed, N.; Tariq, R.; Abbas, S.; Zafar, Q. Nickel phthalocynanine-metal Schottky diode as photodetector. J. Optoelectron. Adv. Mater. 2014, 16, 1430–1435. [Google Scholar]

- Bouattoura, D.; Villon, P.; Farges, G. Dynamic programming approach for newborn’s incubator humidity control. IEEE Trans. Biomed. Eng. 1998, 45, 48–55. [Google Scholar] [CrossRef] [PubMed]

- Saleem, M.; Karimov, K.S.; Karieva, Z.; Mateen, A. Humidity sensing properties of CNT–OD–VETP nanocomposite films. Phys. E 2010, 43, 28–32. [Google Scholar] [CrossRef]

- Chani, M.T.S.; Karimov, K.S.; Ahmad Khalid, F.; Raza, K.; Umer Farooq, M.; Zafar, Q. Humidity sensors based on aluminium phthalocyanine chloride thin films. Phys. E 2012, 45, 77–81. [Google Scholar] [CrossRef]

- Kim, S.-J.; Park, J.-Y.; Lee, S.-H.; Yi, S.-H. Humidity sensors using porous silicon layer with mesa structure. J. Phys. D Appl. Phys. 2000, 33, 1781–1784. [Google Scholar] [CrossRef]

- Mulla, I.; Chaudhary, V.; Vijayamohanan, K. Humidity sensing properties of boron phosphate. Sens. Actuators A 1998, 69, 72–76. [Google Scholar] [CrossRef]

- Buvailo, A.I.; Xing, Y.; Hines, J.; Dollahon, N.; Borguet, E. TiO2/LiCl-based nanostructured thin film for humidity sensor applications. ACS Appl. Mater. Interfaces 2011, 3, 528–533. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.-T.; Wu, C.-L.; Chen, I.; Huang, Y.-H. Humidity sensors based on silica nanoparticle aerogel thin films. Sens. Actuators B 2005, 107, 402–410. [Google Scholar] [CrossRef]

- Innocenzi, P.; Zub, I.L.; Kessler, V.G. Sol-gel Methods for Materials Processing: Focusing on Materials for Pollution Control, Water Purification, and Soil Remediation; Springer: Dordrecht, Netherlands, 2008. [Google Scholar]

- Ahmad, Z.; Zafar, Q.; Touati, F.; Shakoor, R.; Al-Thani, N. Study of π-conjugation effect of organic semiconductors on their optical parameters. Opt. Mater. 2016, 54, 94–97. [Google Scholar] [CrossRef]

- Zafar, Q.; Aziz, F.; Sulaiman, K. Eco-benign visible wavelength photodetector based on phthalocyanine-low bandgap copolymer composite blend. RSC Adv. 2016, 6, 13101–13109. [Google Scholar] [CrossRef]

- Zafar, Q.; Ahmad, Z.; Sulaiman, K. PFO-DBT: MEH-PPV: PC71BM ternary blend assisted platform as a photodetector. Sensors 2015, 15, 965–978. [Google Scholar] [CrossRef] [PubMed]

- Azmer, M.I.; Zafar, Q.; Ahmad, Z.; Sulaiman, K.; Karimov, K.S. VOPcPhO based organic pressure sensor and displacement transducer. Synth. Met. 2014, 191, 120–125. [Google Scholar] [CrossRef]

- Zafar, Q.; Najeeb, M.A.; Ahmad, Z.; Sulaiman, K. Organic–inorganic hybrid nanocomposite for enhanced photo-sensing of PFO-DBT: MEH-PPV: PC71BM blend-based photodetector. J. Nanopart. Res. 2015, 17, 1–10. [Google Scholar] [CrossRef]

- Ahmad, Z.; Abdullah, S.M.; Zafar, Q.; Sulaiman, K. Investigation of charge transport in organic polymer donor/acceptor photovoltaic materials. J. Mod. Opt. 2014, 61, 1730–1734. [Google Scholar] [CrossRef]

- Azmer, M.I.; Zafar, Q.; Ahmad, Z.; Sulaiman, K. Humidity sensor based on electrospun MEH-PPV: PVP microstructured composite. RSC Adv. 2016, 6, 35387–35393. [Google Scholar] [CrossRef]

- Zafar, Q.; Ahmad, Z.; Sulaiman, K.; Hamzah, A.S.; Rahman, Z.A. A MEHPPV/VOPcPhO composite based diode as a photodetector. Sens. Actuators A 2014, 206, 138–143. [Google Scholar] [CrossRef]

- Ahmad, Z.; Sayyad, M.H.; Karimov, K.S. Bi-layer capacitive type light and humidity sensors. J. Ovonic Res. 2008, 5, 91–95. [Google Scholar]

- Ahmad, Z.; Sayyad, M.H.; Karimov, K.S. Capacitive hygrometers based on natural organic compound. J. Optoelectron. Adv. Mater. 2008, 2, 507–510. [Google Scholar]

- Ahmad, Z.; Sayyad, M.H.; Saleem, M.; Karimov, K.S.; Shah, M. Humidity-dependent characteristics of methyl-red thin film-based Ag/methyl-red/Ag surface-type cell. Phys. E Low-Dimens. Syst. Nanostruct. 2008, 41, 18–22. [Google Scholar] [CrossRef]

- Ahmad, Z.; Sayyad, M.H.; Yaseen, M.; Aw, K.C.; M-Tahir, M.; Ali, M. Potential of 5,10,15,20-Tetrakis(3′,5′-di-tertbutylphenyl)porphyrinatocopper(II) for a multifunctional sensor. Sens. Actuators B 2011, 155, 81–85. [Google Scholar] [CrossRef]

- Murtaza, I.; Karimov, K.S.; Ahmad, Z.; Qazi, I.; Mahroof-Tahir, M.; Khan, T.; Amin, T. Humidity sensitive organic field effect transistor. J. Semicond. 2010, 31. [Google Scholar] [CrossRef]

- Aziz, F.; Hassan Sayyad, M.; Sulaiman, K.; Majlis, B.; Karimov, K.S.; Ahmad, Z.; Sugandi, G. IOPscience-Influence of humidity conditions on the capacitive and resistive response of an Al/VOPc/Pt co-planar humidity sensor. Meas. Sci. Technol. 2012, 23. [Google Scholar] [CrossRef]

- Aziz, F.; Sayyad, M.; Karimov, K.S.; Saleem, M.; Ahmad, Z.; Khan, S.M. Characterization of vanadyl phthalocyanine based surface-type capacitive humidity sensors. J. Semicond. 2010, 31. [Google Scholar] [CrossRef]

- Shah, M.; Ahmad, Z.; Sulaiman, K.; Karimov, K.S.; Sayyad, M. Carbon nanotubes’ nanocomposite in humidity sensors. Solid-State Electron. 2012, 69, 18–21. [Google Scholar] [CrossRef]

- Shamala, K.; Murthy, L.; Radhakrishna, M.; Rao, K.N. Characterization of Al2O3 thin films prepared by spray pyrolysis method for humidity sensor. Sens. Actuators A 2007, 135, 552–557. [Google Scholar] [CrossRef]

- Parvatikar, N.; Jain, S.; Khasim, S.; Revansiddappa, M.; Bhoraskar, S.; Prasad, M. Electrical and humidity sensing properties of polyaniline/WO3 composites. Sens. Actuators B 2006, 114, 599–603. [Google Scholar] [CrossRef]

- Suri, K.; Annapoorni, S.; Sarkar, A.; Tandon, R. Gas and humidity sensors based on iron oxide–polypyrrole nanocomposites. Sens. Actuators B 2002, 81, 277–282. [Google Scholar] [CrossRef]

- Karimov, K.S.; Saleem, M.; Karieva, Z.; Mateen, A.; Chani, M.T.S.; Zafar, Q. Humidity sensing properties of Cu2O-PEPC nanocomposite films. J. Semicond. 2012, 33. [Google Scholar] [CrossRef]

- Ahmad, Z.; Zafar, Q.; Sulaiman, K.; Akram, R.; Karimov, K.S. A humidity sensing organic-inorganic composite for environmental monitoring. Sensors 2013, 13, 3615–3624. [Google Scholar] [CrossRef] [PubMed]

- Al-Sehemi, A.G.; Al-Assiri, M.S.; Kalam, A.; Zafar, Q.; Azmer, M.I.; Sulaiman, K.; Ahmad, Z. Sensing performance optimization by tuning surface morphology of organic (D-π-A) dye based humidity sensor. Sens. Actuators B 2016, 231, 30–37. [Google Scholar] [CrossRef]

- Chani, M.T.S.; Karimov, K.S.; Khalid, F.A.; Moiz, S.A. Polyaniline based impedance humidity sensors. Solid State Sci. 2013, 18, 78–82. [Google Scholar] [CrossRef]

- Ahmad, Z.; Abdullah, S.M.; Sulaiman, K. Temperature-sensitive chemical cell based on Nickel (II) phthalocyanine-tetrasulfonic acid tetrasodium salt. Sens. Actuators A 2012, 179, 146–150. [Google Scholar] [CrossRef]

- Gabriel, G.; Illa, X.; Guimera, A.; Rebollo, B.; Hernández-Ferrer, J.; Martin-Fernandez, I.; Martínez, M.T.; Godignon, P.; Sanchez-Vives, M.V.; Villa, R. Carbon Nanotubes as Suitable Interface for Improving Neural Recordings; INTECH Open Access Publisher: Rijeka, Croatia - EUROPEAN UNION, 2013. [Google Scholar]

- Lin, Q.; Li, Y.; Yang, M. Investigations on the sensing mechanism of humidity sensors based on electrospun polymer nanofibers. Sens. Actuators B 2012, 171, 309–314. [Google Scholar] [CrossRef]

© 2016 by the author; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Akram, R. Frequency Dependence of Electrical Parameters of an Organic-Inorganic Hybrid Composite Based Humidity Sensor. Electronics 2016, 5, 23. https://doi.org/10.3390/electronics5020023

Akram R. Frequency Dependence of Electrical Parameters of an Organic-Inorganic Hybrid Composite Based Humidity Sensor. Electronics. 2016; 5(2):23. https://doi.org/10.3390/electronics5020023

Chicago/Turabian StyleAkram, Rizwan. 2016. "Frequency Dependence of Electrical Parameters of an Organic-Inorganic Hybrid Composite Based Humidity Sensor" Electronics 5, no. 2: 23. https://doi.org/10.3390/electronics5020023