Organic Optical Sensor Based on Monolithic Integration of Organic Electronic Devices

Abstract

:1. Introduction

2. Experimental Section

3. Results and Discussion

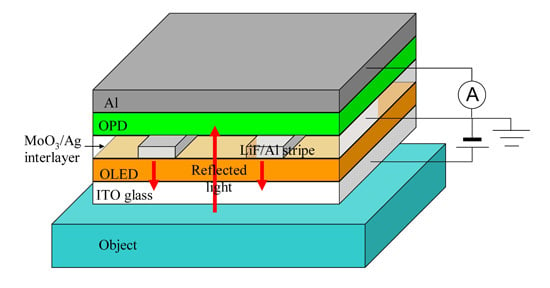

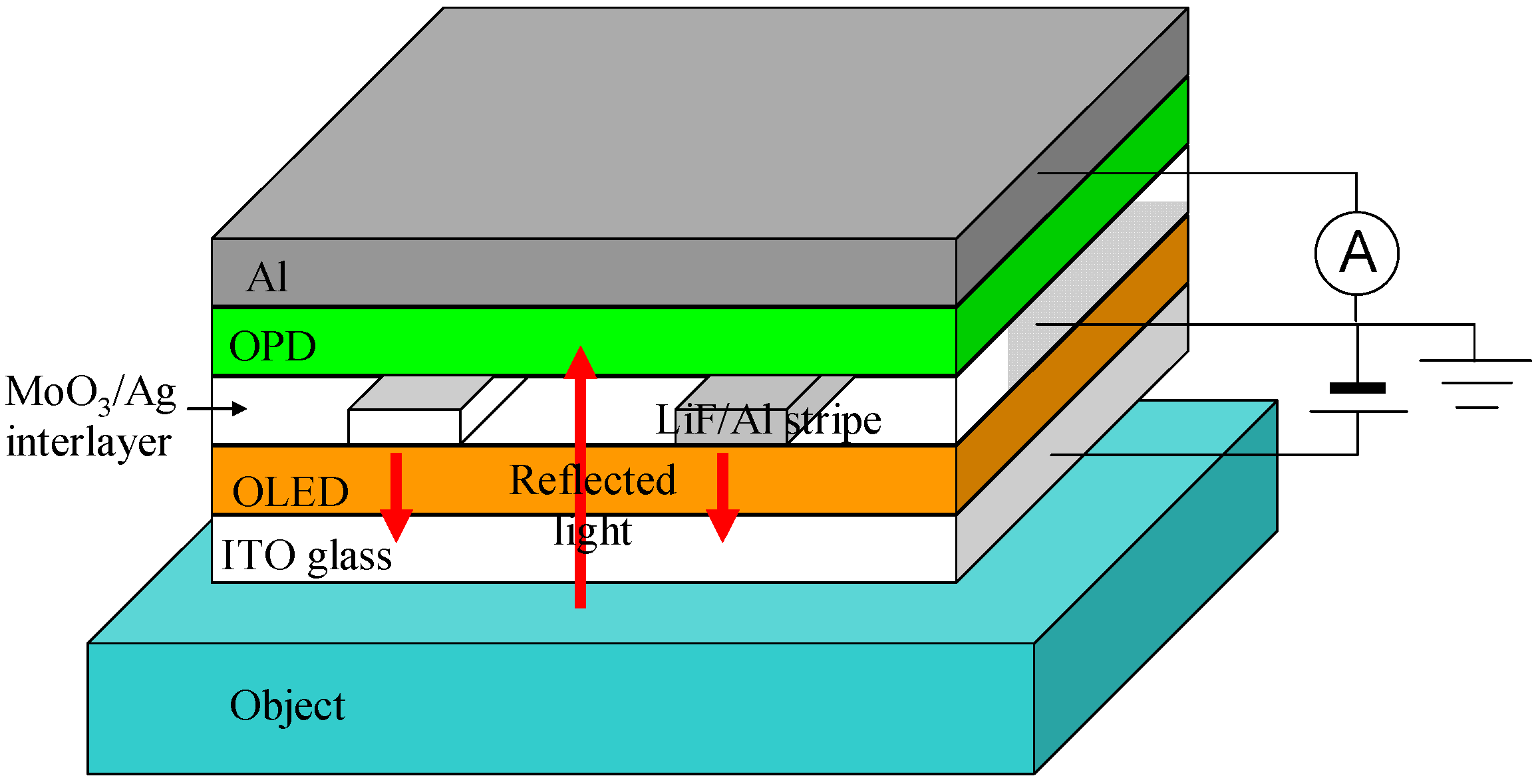

3.1. Operation Principle of the Organic Optical Sensor

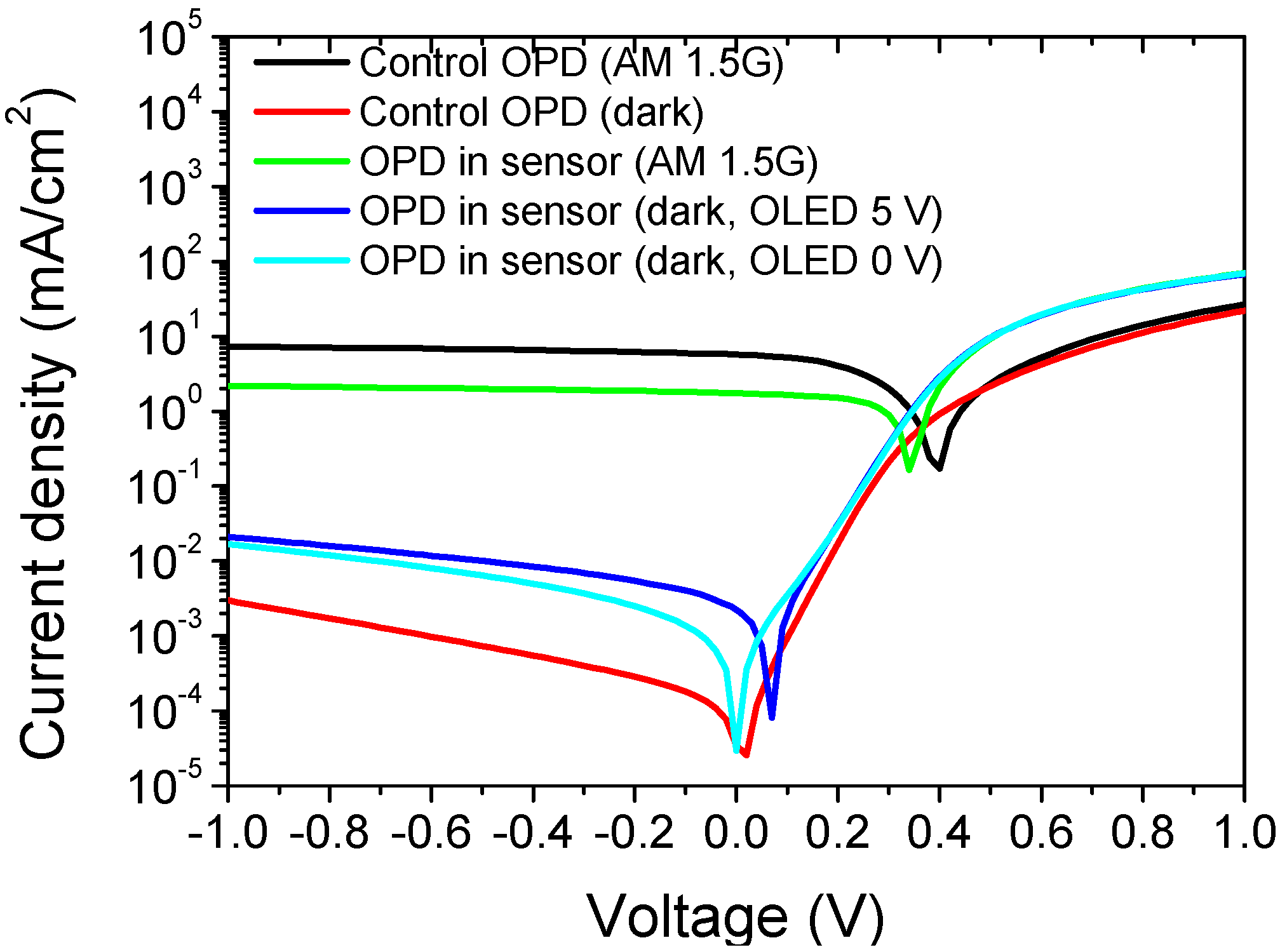

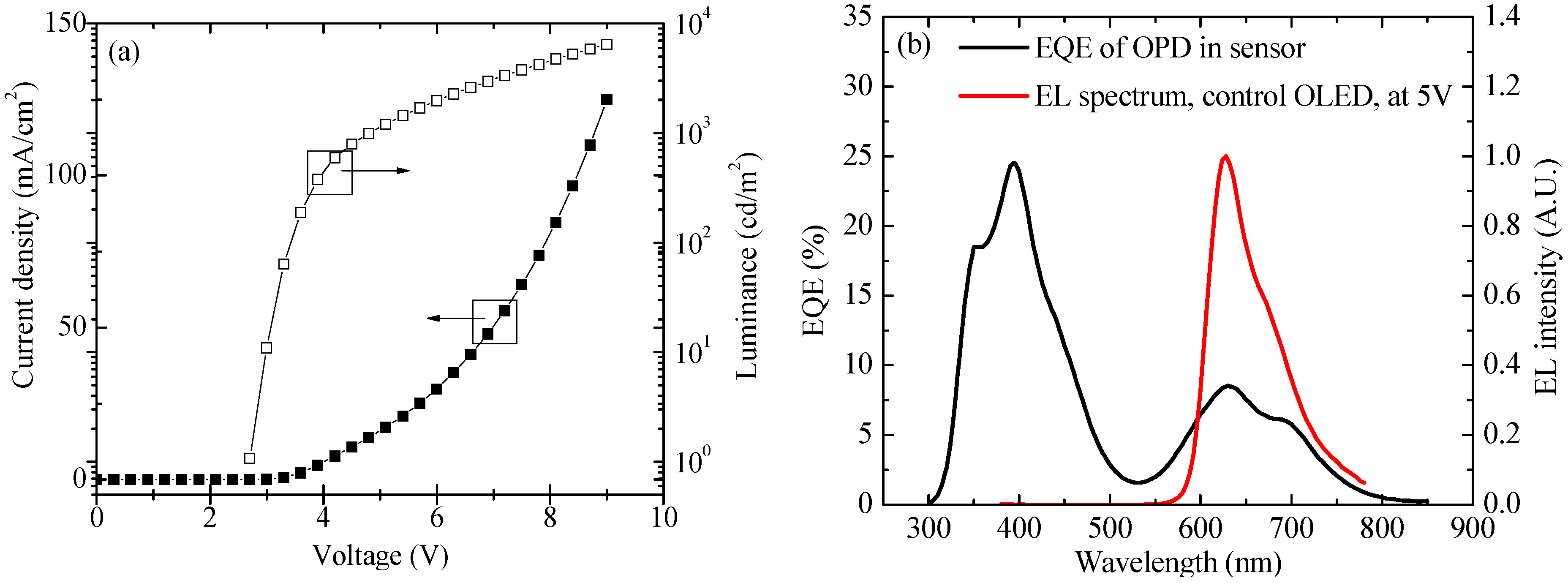

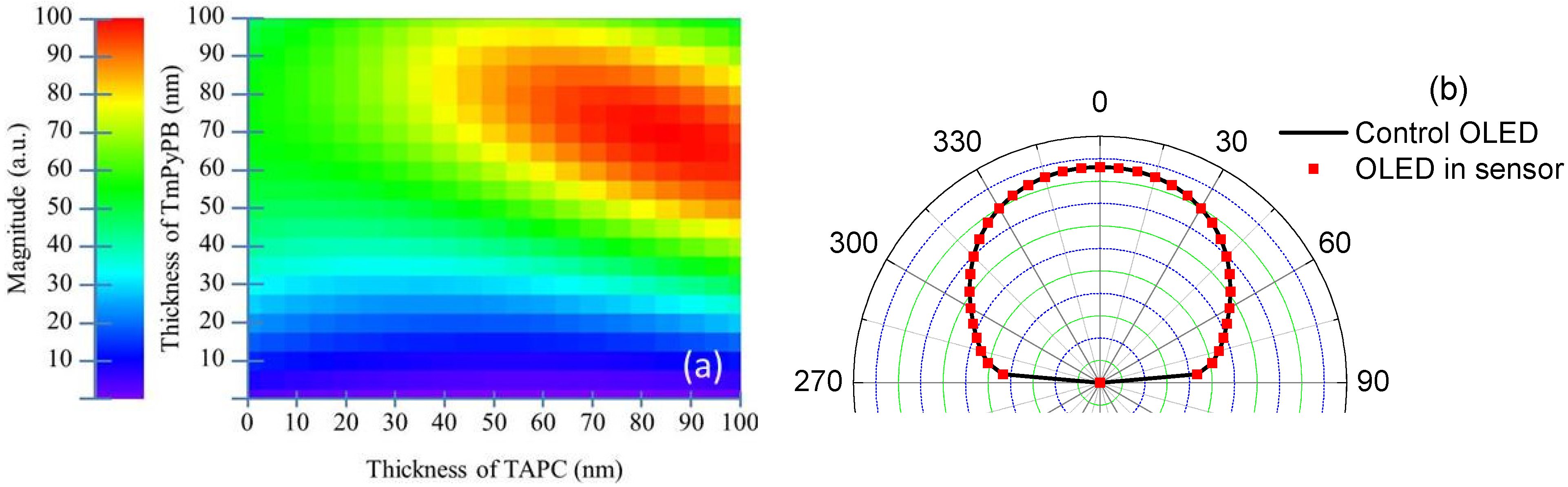

3.2. Characteristics of the OPD and OLED Units

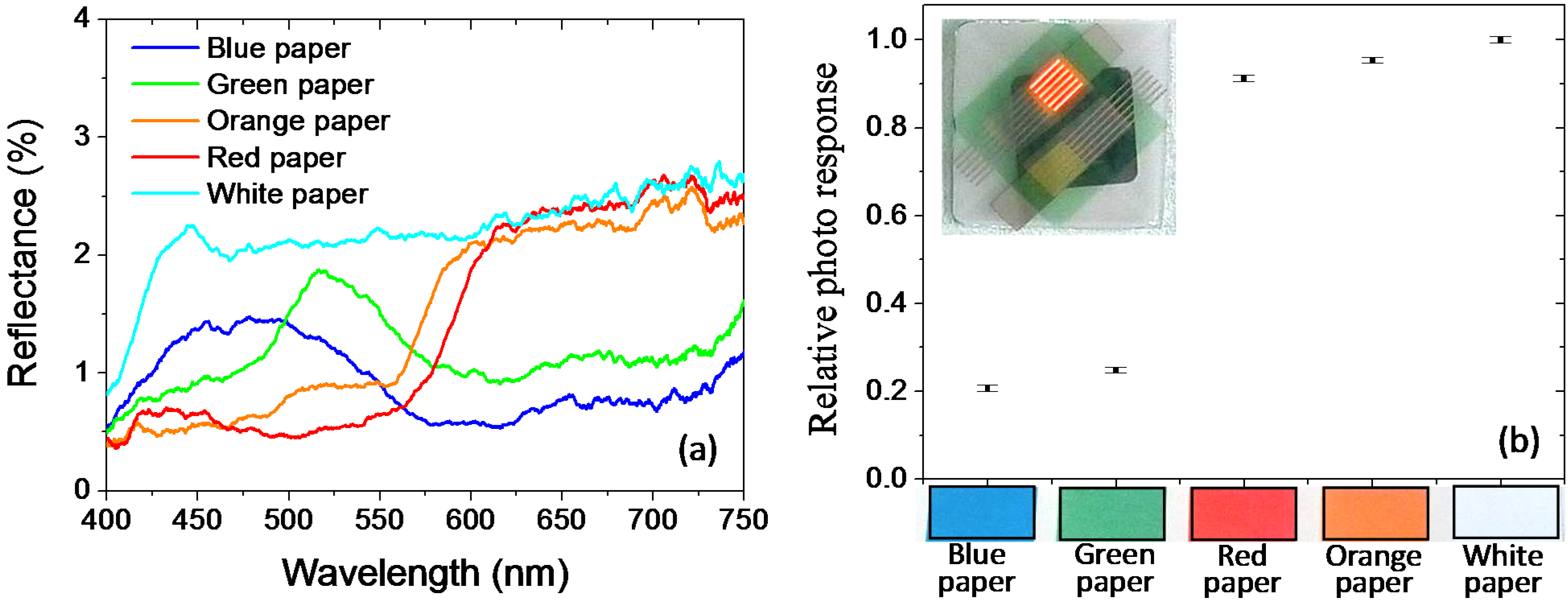

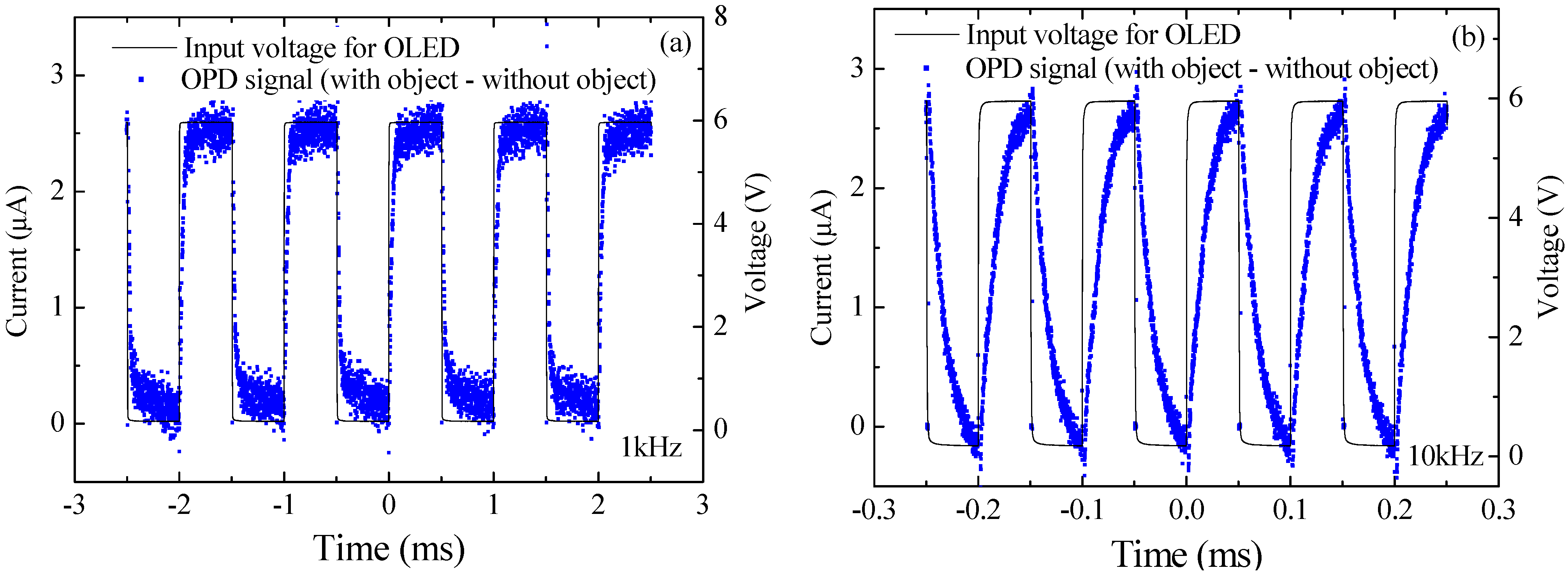

3.3. Photo Responses and Frequency Responses of the Organic Optical Sensor

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Tang, C.W.; VanSlyke, S.A. Organic electroluminescent diodes. Appl. Phys. Lett. 1987, 51, 913–915. [Google Scholar] [CrossRef]

- Choi, W.H.; Tam, H.L.; Zhu, F.R.; Ma, D.G.; Sasabe, H.; Kido, J. High performance semitransparent phosphorescent white organic light emitting diodes with bi-directional and symmetrical illumination. Appl. Phys. Lett. 2013, 102, 153308. [Google Scholar] [CrossRef]

- Choi, W.H.; Tam, H.L.; Ma, D.G.; Zhu, F.R. Emission behavior of dual-side emissive transparent white organic light-emitting diodes. Opt. Express 2015, 23, A471–A479. [Google Scholar] [CrossRef] [PubMed]

- Tan, H.S.; Kulkarni, S.R.; Cahyadi, T.; Lee, P.S.; Mhaisalkar, S.G.; Kasim, J.; Shen, Z.X.; Zhu, F.R. Solution-processed trilayer inorganic dielectric for high performance flexible organic field effect transistors. Appl. Phys. Lett. 2008, 93, 183503. [Google Scholar] [CrossRef]

- Liu, H.X.; Wu, Z.H.; Hu, J.Q.; Song, Q.L.; Wu, B.; Tam, H.L.; Yang, Q.Y.; Choi, W.H.; Zhu, F.R. Efficient and ultraviolet durable inverted organic solar cells based on an aluminum-doped zinc oxide transparent cathode. Appl. Phys. Lett. 2013, 103, 043309. [Google Scholar] [CrossRef]

- Clark, J.; Lanzani, G. Organic photonics for communications. Nat. Photonics 2010, 4, 438–446. [Google Scholar] [CrossRef]

- Yao, Y.; Chen, H.Y.; Huang, H.; Yang, Y. Low voltage and fast speed all-polymeric optocouplers. Appl. Phys. Lett. 2007, 90, 053509. [Google Scholar] [CrossRef]

- Dong, G.; Zheng, H.; Jiang, C.; Duan, L.; Wang, L.; Qiu, Y. High-Performance Organic Optocouplers Based on a Photosensitive Interfacial C60/NPB Heterojunction. Adv. Mater. 2009, 21, 2501. [Google Scholar]

- Stathopoulos, N.A.; Palilis, L.C.; Vasilopoulou, M.; Botsialas, A.; Falaras, P.; Argitis, P. All-organic optocouplers based on polymer light-emitting diodes and photodetectors. Phys. Stat. Sol. 2008, 205, 2522–2525. [Google Scholar] [CrossRef]

- Hofmann, O.; Miller, P.; Sullivan, P.; Jones, T.S.; de Mello, J.C.; Bradley, D.D.C.; de Mello, A.J. Thin-film organic photodiodes as integrated detectors for microscale chemiluminescence assays. Sens. Actuators B 2005, 106, 878–884. [Google Scholar]

- Shinar, J.; Shinar, R. Organic light-emitting devices (OLEDs) and OLED-based chemical and biological sensors: An overview. J. Phys. D 2008, 41, 133001. [Google Scholar] [CrossRef]

- Choudhury, B.; Shinar, R.; Shinar, J. Glucose biosensors based on organic light-emitting devices structurally integrated with a luminescent sensing element. J. Appl. Phys. 2004, 96, 2949–2954. [Google Scholar] [CrossRef]

- Ratcliff, E.L.; Veneman, P.A.; Simmonds, A.; Zacher, B.; Huebner, D.; Saavedra, S.S.; Armstrong, N.R. A planar, chip-based, dual-beam refractometer using an integrated organic light-emitting diode (OLED) light source and organic photovoltaic (OPV) detectors. Anal. Chem. 2010, 82, 2734–2742. [Google Scholar] [CrossRef] [PubMed]

- Forrest, S.R. The path to ubiquitous and low-cost organic electronic appliances on plastic. Nature 2004, 428, 911–918. [Google Scholar] [CrossRef] [PubMed]

- Ramuz, M.; Bürgi, L.; Stanley, R.; Winnewisser, C. Coupling light from an organic light emitting diode (OLED) into a single-mode waveguide: Toward monolithically integrated optical sensors. J. Appl. Phys. 2009, 105, 084508. [Google Scholar] [CrossRef]

- Ali, F.; Periasamy, N.; Patankar, M.P.; Narasimhan, K.L. Integrated Organic Blue LED and Visible-Blind UV Photodetector. J. Phys. Chem. C 2011, 115, 2462–2469. [Google Scholar] [CrossRef]

- Lee, T.W.; Noh, T.Y.; Choi, B.K.; Kim, M.S.; Shin, D.W.; Kido, J. High-efficiency stacked white organic light-emitting diodes. Appl. Phys. Lett. 2008, 92, 043301. [Google Scholar] [CrossRef]

- Liao, L.S.; Klubek, K.P.; Tang, C.W. High-efficiency tandem organic light-emitting diodes. Appl. Phys. Lett. 2004, 84, 167. [Google Scholar] [CrossRef]

- Yakimov, A.; Forrest, S.R. High photovoltage multiple-heterojunction organic solar cells incorporating interfacial metallic nanoclusters. Appl. Phys. Lett. 2002, 80, 1667. [Google Scholar] [CrossRef]

- Peumans, P.; Forrest, S.R. Efficient, high-bandwidth organic multilayer photodetectors. Appl. Phys. Lett. 2000, 76, 3855. [Google Scholar] [CrossRef]

- Tam, H.L.; Wang, X.Z.; Zhu, F.R. Integration of transmissible organic electronic devices for sensor application. Proc. SPIE 2013, 8831, 883121. [Google Scholar]

- Wang, X.Z.; Tam, H.L.; Yong, K.S.; Chen, Z.K.; Zhu, F.R. High performance optoelectronic device based on semitransparent organic photovoltaic cell integrated with organic light-emitting diode. Org. Electron. 2011, 12, 1429–1433. [Google Scholar] [CrossRef]

- Matsushita, Y.; Shimada, H.; Miyashita, T.; Shibata, M.; Naka, S.; Okada, H.; Onnagawa, H. Organic bi-function matrix array. Jpn. J. Appl. Phys. 2005, 44, 2526–2829. [Google Scholar] [CrossRef]

- Xue, J.G.; Forrest, S.R. Organic optical bistable switch. Appl. Phys. Lett. 2003, 82, 136. [Google Scholar] [CrossRef]

- Ohmori, Y.; Kajii, H.; Kaneko, M.; Yoshino, K.; Ozaki, M.; Fujii, A.; Hikita, M.; Takenaka, H.; Taneda, T. Realization of polymeric optical integrated devices utilizing organic light-emitting diodes and photodetectors fabricated on a polymeric waveguide. IEEE J. Sel. Top. Quantum Electron. 2004, 10, 70–78. [Google Scholar] [CrossRef]

- Low, B.L.; Zhu, F.R.; Zhang, K.R.; Chua, S.J. An in situ sheet resistance study of oxidative-treated indium tin oxide substrates for organic light emitting display applications. Thin Solid Films. 2002, 417, 116. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tam, H.L.; Choi, W.H.; Zhu, F. Organic Optical Sensor Based on Monolithic Integration of Organic Electronic Devices. Electronics 2015, 4, 623-632. https://doi.org/10.3390/electronics4030623

Tam HL, Choi WH, Zhu F. Organic Optical Sensor Based on Monolithic Integration of Organic Electronic Devices. Electronics. 2015; 4(3):623-632. https://doi.org/10.3390/electronics4030623

Chicago/Turabian StyleTam, Hoi Lam, Wing Hong Choi, and Furong Zhu. 2015. "Organic Optical Sensor Based on Monolithic Integration of Organic Electronic Devices" Electronics 4, no. 3: 623-632. https://doi.org/10.3390/electronics4030623