Graded Bandgap Ultrathin CIGS Solar Cells

Abstract

:1. Introduction

2. Device Architecture

3. Device Validation

4. Results and Discussion

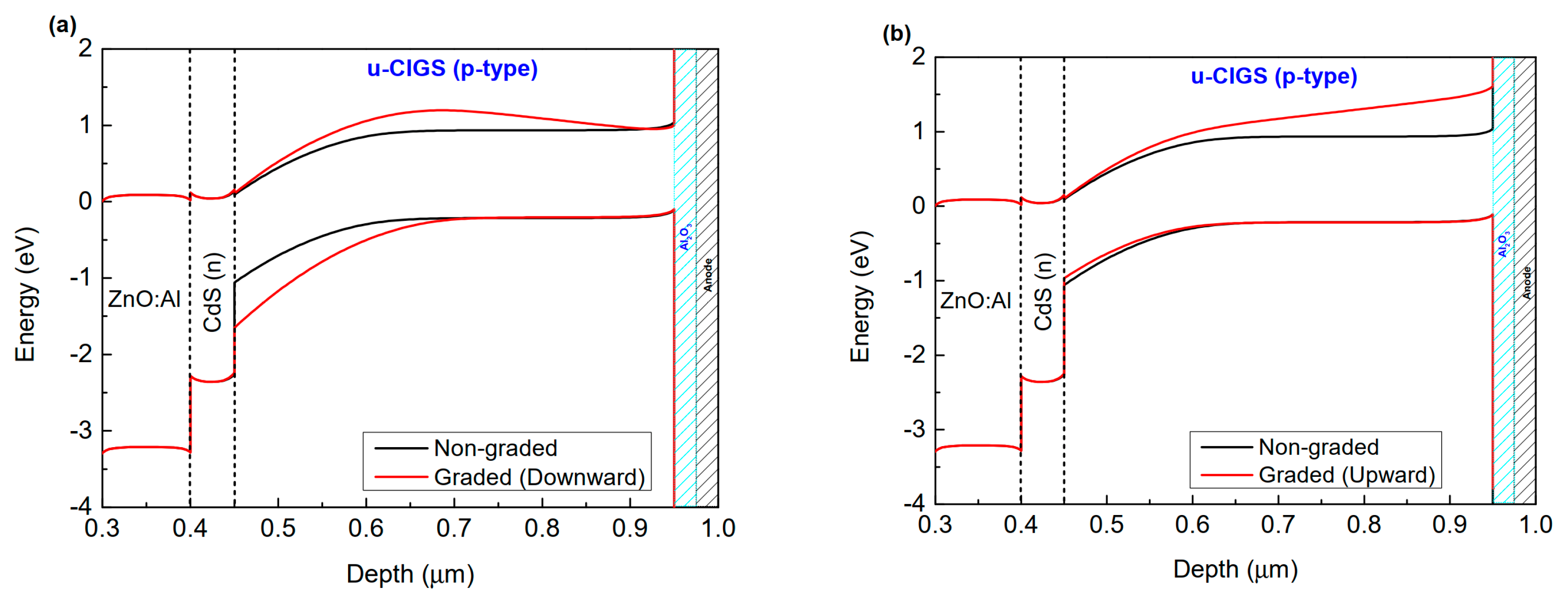

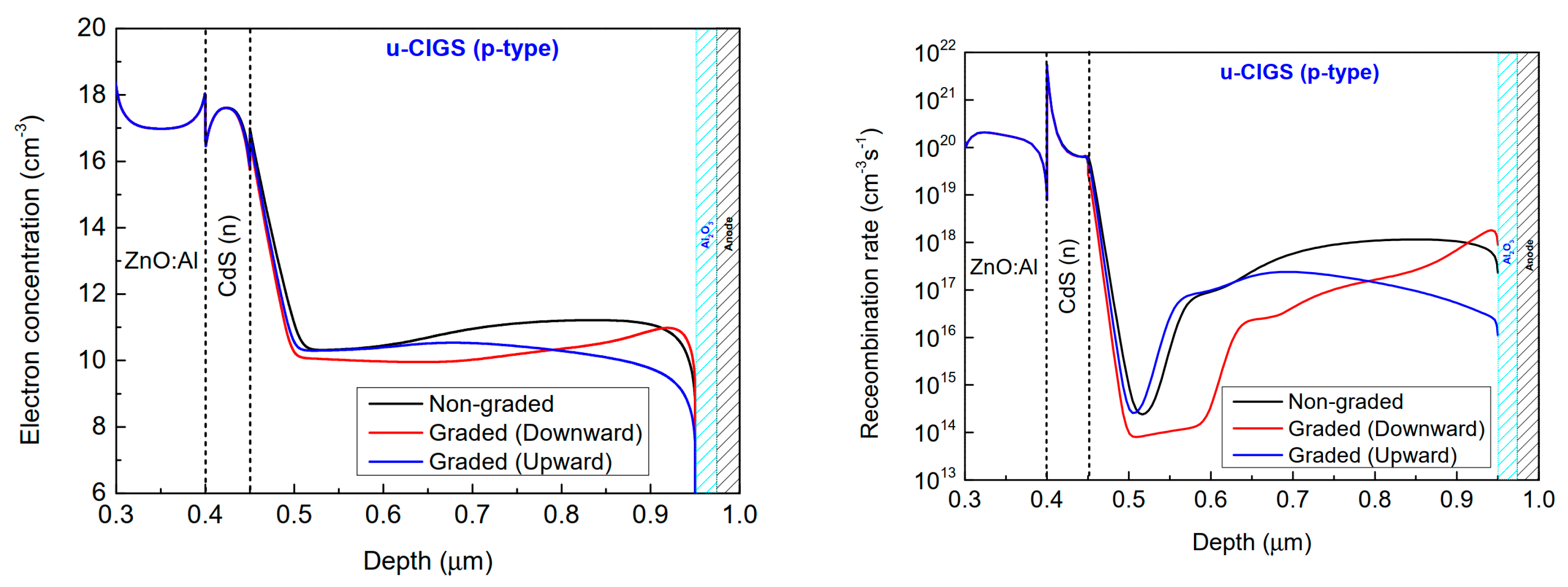

4.1. Impact of Graded Bandgap of the Absorber Layer

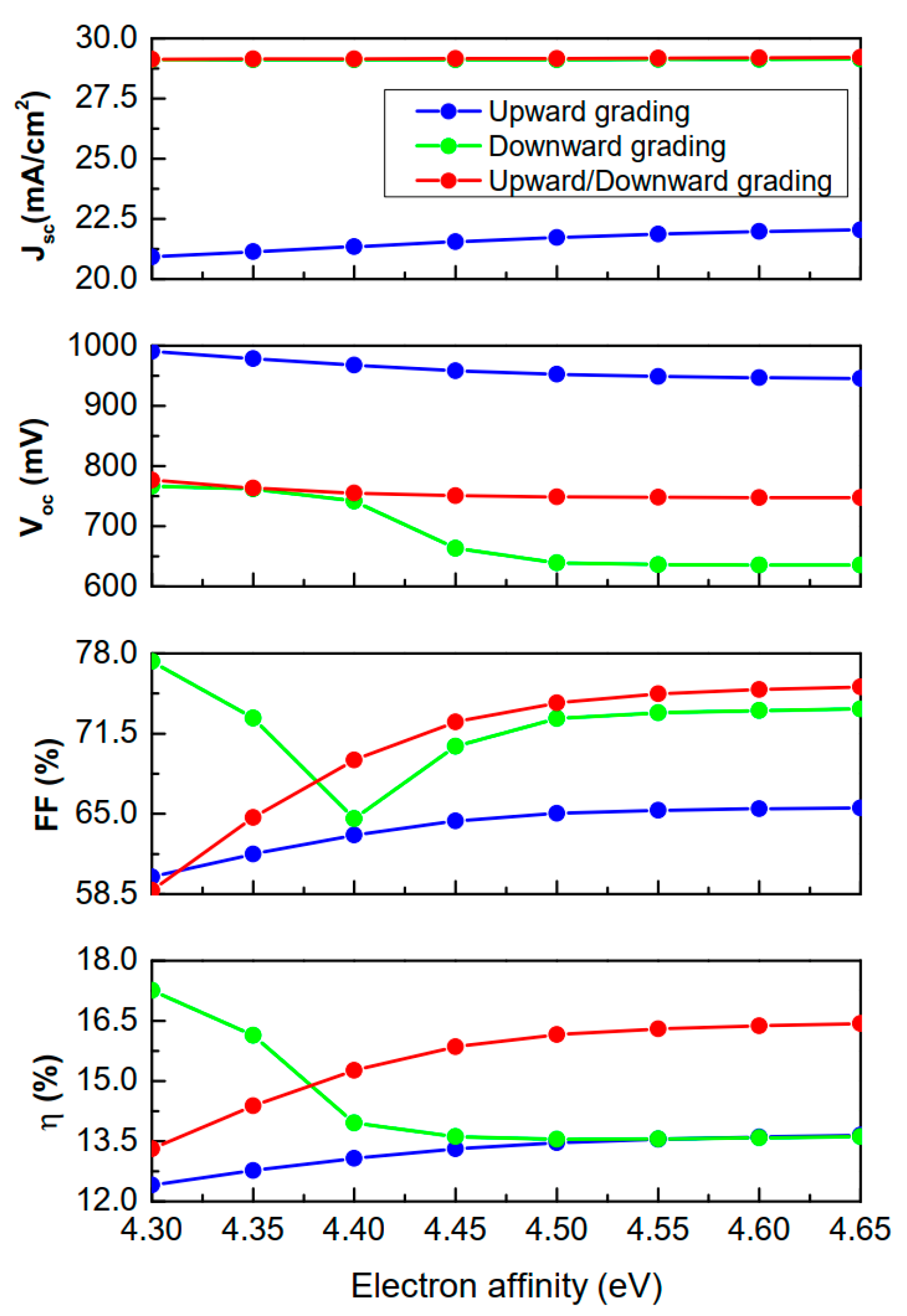

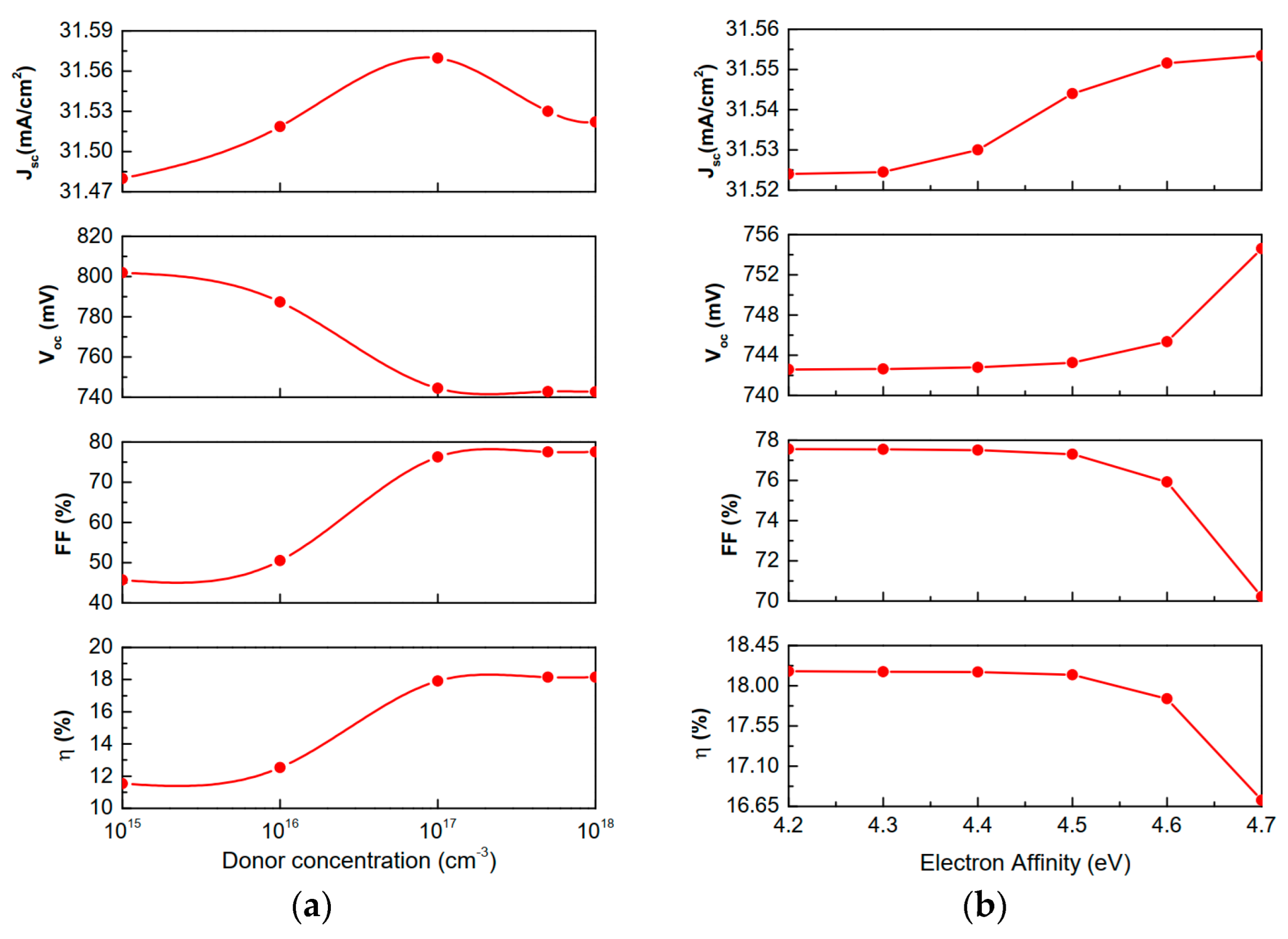

4.2. Impact of Varying Electron Affinities of the Absorber Layer

4.3. Impact of Varying Acceptor Doping Concentration of the Absorber Layer

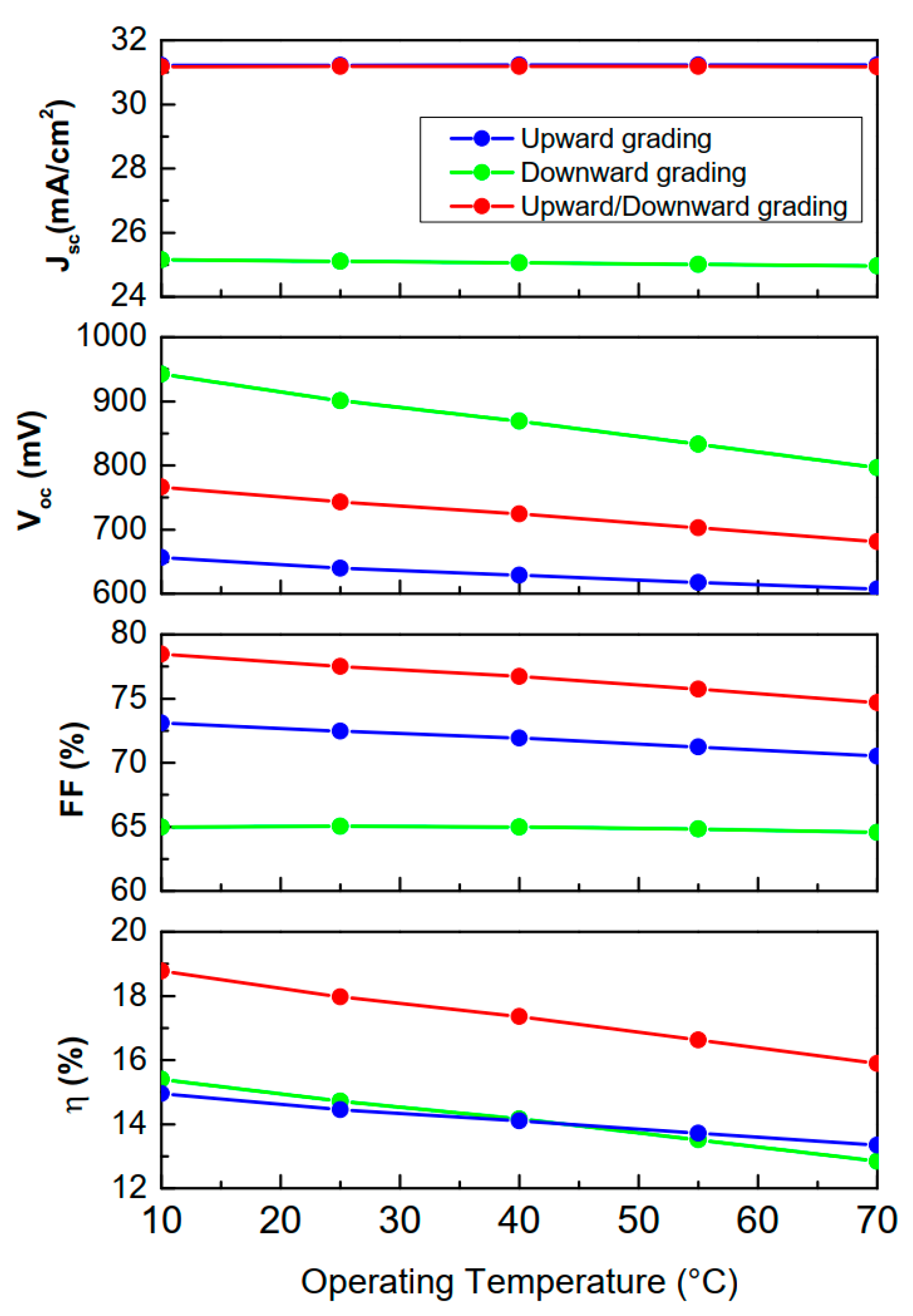

4.4. Temperature Dependence

4.5. Impact of ZnS Buffer Layer

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lontchi, J.; Zhukova, M.; Kovacic, M.; Krc, J.; Chen, W.C.; Edoff, M.; Bose, S.; Salomé, P.M.; Goffard, J.; Cattoni, A.; et al. Optimization of Back Contact Grid Size in Al2O3-Rear-Passivated Ultrathin CIGS PV Cells by 2-D Simulations. IEEE J. Photovolt. 2020, 10, 1908–1917. [Google Scholar] [CrossRef]

- Boukortt, N.E.I.; Adouane, M.; AlHammadi, R. High-performance ultrathin Cu (In, Ga) Se2 solar cell optimized by silvaco tools. Sol. Energy 2021, 228, 282–289. [Google Scholar] [CrossRef]

- Boukortt, N.; Patanè, S.; Hadri, B. Electrical characterization of n-ZnO/c-Si 2D heterojunction solar cell by using TCAD tools. Silicon 2018, 10, 2193–2199. [Google Scholar] [CrossRef]

- Dhere, N.G. Toward GW/year of CIGS production within the next decade. Sol. Energy Mater. Sol. Cells 2007, 91, 1376–1382. [Google Scholar] [CrossRef]

- Edoff, M.; Schleussner, S.; Wallin, E.; Lundberg, O. Technological and economical aspects on the influence of reduced Cu (In, Ga) Se2 thickness and Ga grading for co-evaporated Cu (In, Ga) Se2 modules. Thin Solid Film. 2011, 519, 7530–7533. [Google Scholar] [CrossRef]

- Ochoa, M.; Buecheler, S.; Tiwari, A.N.; Carron, R. Challenges and opportunities for an efficiency boost of next generation Cu (In, Ga) Se 2 solar cells: Prospects for a paradigm shift. Energy Environ. Sci. 2020, 13, 2047–2055. [Google Scholar] [CrossRef]

- Sravani, L.; Routray, S.; Courel, M.; Pradhan, K.P. Loss mechanisms in CZTS and CZTSe Kesterite thin-film solar cells: Understanding the complexity of defect density. Sol. Energy 2021, 227, 56–66. [Google Scholar] [CrossRef]

- Boukortt, N.E.I.; Hadri, B. Simulation of electrical characteristics of PERC solar cells. J. Electron. Mater. 2018, 47, 5825–5832. [Google Scholar] [CrossRef]

- Joel, J. Characterization of Al2O3 as CIGS Surface Passivation Layer in High-Efficiency CIGS Solar Cells; Uppsala University: Uppsala, Sweden, 2014. [Google Scholar]

- Boukortt, N.E.I.; Patanè, S.; Adouane, M.; AlHammadi, R. Numerical optimization of ultrathin CIGS solar cells with rear surface passivation. Sol. Energy 2021, 220, 590–597. [Google Scholar] [CrossRef]

- Kotipalli, R.; Vermang, B.; Fjällström, V.; Edoff, M.; Delamare, R.; Flandre, D. Influence of Ga/(Ga+ In) grading on deep-defect states of Cu (In, Ga) Se2 solar cells. Phys. Status Solidi (RRL)—Rapid Res. Lett. 2015, 9, 157–160. [Google Scholar] [CrossRef]

- Kotipalli, R.; Vermang, B.; Joel, J.; Rajkumar, R.; Edoff, M.; Flandre, D. Investigating the electronic properties of Al2O3/Cu (In Ga) Se2 interface. AIP Adv. 2015, 5, 107101. [Google Scholar] [CrossRef]

- Birant, G.; Mafalda, J.; Scaffidi, R.; De Wild, J.; Buldu, D.; Kohl, T.; Brammertz, G.; Meuris, M.; Poortmans, J.; Vermang, B. Rear surface passivation of ultra-thin CIGS solar cells using atomic layer deposited HfOx. EPJ Photovolt. 2020, 11, 10. [Google Scholar] [CrossRef]

- Vermang, B.; Wätjen, J.T.; Frisk, C.; Fjällström, V.; Rostvall, F.; Edoff, M.; Salomé, P.; Borme, J.; Nicoara, N.; Sadewasser, S. Introduction of Si PERC Rear Contacting Design to Boost Efficiency of Cu (In, Ga) Se $_{\bf 2}$ Solar Cells. IEEE J. Photovolt. 2014, 4, 1644–1649. [Google Scholar] [CrossRef]

- Vermang, B.; Rostvall, F.; Fjällström, V.; Edoff, M. Potential-induced optimization of ultra-thin rear surface passivated CIGS solar cells. Phys. Status Solidi (RRL)—Rapid Res. Lett. 2014, 8, 908–911. [Google Scholar] [CrossRef]

- Boukortt, N.E.I.; Patanè, S. Single junction-based thin-film CIGS solar cells optimization with efficiencies approaching 24.5%. Optik 2020, 218, 165240. [Google Scholar] [CrossRef]

- Cunha, J.M.; Rocha, C.; Vinhais, C.; Fernandes, P.A.; Salomé, P.M. Understanding the AC Equivalent Circuit Response of Ultrathin Cu (In, Ga) Se 2 Solar Cells. IEEE J. Photovolt. 2019, 9, 1442–1448. [Google Scholar] [CrossRef]

- Bose, S.; Cunha, J.M.; Suresh, S.; De Wild, J.; Lopes, T.S.; Barbosa, J.R.; Silva, R.; Borme, J.; Fernandes, P.A.; Vermang, B.; et al. Optical lithography patterning of SiO2 layers for interface passivation of thin film solar cells. Sol. RRL 2018, 2, 1800212. [Google Scholar] [CrossRef]

- Cunha, J.M.V.; Fernandes, P.A.; Hultqvist, A.; Teixeira, J.P.; Bose, S.; Vermang, B.; Garud, S.; Buldu, D.; Gaspar, J.; Edoff, M.; et al. Insulator Materials for Interface Passivation of Cu (In, Ga) Se 2 Thin Films. IEEE J. Photovolt. 2018, 8, 1313–1319. [Google Scholar] [CrossRef]

- Ledinek, D.; Salome, P.; Hägglund, C.; Zimmermann, U.; Edoff, M. Rear Contact Passivation for High Bandgap Cu (In, Ga) Se 2 Solar Cells with a Flat Ga profile. IEEE J. Photovolt. 2018, 8, 864–870. [Google Scholar]

- Salome, P.M.; Vermang, B.; Ribeiro-Andrade, R.; Teixeira, J.P.; Cunha, J.M.; Mendes, M.J.; Haque, S.; Borme, J.; Aguas, H.; Fortunato, E.; et al. Passivation of interfaces in thin film solar cells: Understanding the effects of a nanostructured rear point contact layer. Adv. Mater. Interfaces 2018, 5, 1701101. [Google Scholar] [CrossRef]

- Goffard, J.; Colin, C.; Mollica, F.; Cattoni, A.; Sauvan, C.; Lalanne, P.; Guillemoles, J.F.; Naghavi, N.; Collin, S. Light trapping in ultrathin CIGS solar cells with nanostructured back mirrors. IEEE J. Photovolt. 2017, 7, 1433–1441. [Google Scholar] [CrossRef]

- Boukortt, N.E.I.; AlAmri, A.M.; Bouhjar, F.; Bouhadiba, K. Investigation and optimization of ultrathin Cu (In, Ga) Se2 solar cells by using silvaco-TCAD tools. J. Mater. Sci. Mater. Electron. 2021, 32, 21525–21538. [Google Scholar] [CrossRef]

- Yun, S.; Qin, Y.; Uhl, A.R.; Vlachopoulos, N.; Yin, M.; Li, D.; Han, X.; Hagfeldt, A. New-generation integrated devices based on dye-sensitized and perovskite solar cells. Energy Environ. Sci. 2018, 11, 476–526. [Google Scholar] [CrossRef]

- Jacobsson, T.J.; Hultqvist, A.; Svanström, S.; Riekehr, L.; Cappel, U.B.; Unger, E.; Rensmo, H.; Johansson, E.M.; Edoff, M.; Boschloo, G. 2-Terminal CIGS-perovskite tandem cells: A layer by layer exploration. Sol. Energy 2020, 207, 270–288. [Google Scholar] [CrossRef]

- Boukortt, N.E.I.; Patanè, S.; Loureiro, A.G.; AlAmri, A.M.; Abdulraheem, Y.M.; Lenka, T.R.; Paul, R.; Abushattal, A. Electrical and Optical Investigation of 2T-Perovskite/u-CIGS Tandem Solar Cells with ~30% Efficiency. IEEE Trans. Electron. Devices 2022, 69, 3798–3806. [Google Scholar] [CrossRef]

- Benick, J.; Steinhauser, B.; Müller, R.; Bartsch, J.; Kamp, M.; Mondon, A.; Richter, A.; Hermle, M.; Glunz, S. High efficiency n-type PERT and PERL solar cells. In Proceedings of the 2014 IEEE 40th Photovoltaic Specialist Conference (PVSC), Denver, CO, USA, 8–13 June 2014; pp. 3637–3640. [Google Scholar]

- User Guide Manual, ATLAS; Version 5.28.1.R; Silvaco Inc.: Santa Clara, CA, USA, 2019.

- Chirilă, A.; Buecheler, S.; Pianezzi, F.; Bloesch, P.; Gretener, C.; Uhl, A.R.; Fella, C.; Kranz, L.; Perrenoud, J.; Seyrling, S.; et al. Highly efficient Cu(In, Ga)Se2 solar cells grown on flexible polymer films. Nat. Mater. 2011, 10, 857–861. [Google Scholar] [CrossRef]

- Dietrich, J.; Abou-Ras, D.; Rissom, T.; Unold, T.; Schock, H.W.; Boit, C. Compositional Gradients in Cu (In, Ga) Se2 Thin Films for Solar Cells and Their Effects on Structural Defects. IEEE J. Photovolt. 2012, 2, 364–370. [Google Scholar] [CrossRef]

- Witte, W.; Abou-Ras, D.; Albe, K.; Bauer, G.H.; Bertram, F.; Boit, C.; Brüggemann, R.; Christen, J.; Dietrich, J.; Eicke, A.; et al. Gallium gradients in Cu (In, Ga) Se2 thin-film solar cells. Prog. Photovolt. Res. Appl. 2015, 23, 717–733. [Google Scholar] [CrossRef]

- Singh, P.; Ravindra, N.M. Temperature dependence of solar cell performance—An analysis. Sol. Energy Mater. Sol. Cells 2012, 101, 36–45. [Google Scholar] [CrossRef]

- Prasad, R.; Das, A.K.; Singh, U.P. Impact of buffer layers on the performance of graded CIGS solar cells: A numerical approach. Appl. Phys. A 2021, 127, 816. [Google Scholar] [CrossRef]

- de Wild, J.; Scaffidi, R.; Brammertz, G.; Birant, G.; Vermang, B. Dielectric Front Passivation for Cu (In, Ga) Se2 Solar Cells: Status and Prospect. Adv. Energy Sustain. Res. 2022, 2200132. [Google Scholar] [CrossRef]

- Shin, S.S.; Kim, K.; Yoo, J.; Kim, J.H.; Ahn, S.; Cho, A.; Kim, D.; Jo, Y.; Jeong, I.; Shin, D.; et al. Heterojunction interface passivation strategy for Cu (In1-x, Gax) Se2 solar cell with nano-level engineering of Zn-based buffer structure via atomic layer deposition method. Sol. Energy Mater. Sol. Cells 2021, 224, 111010. [Google Scholar] [CrossRef]

- Persson, C.; Zhao, Y.J.; Lany, S.; Zunger, A. n-type doping of CuIn Se 2 and CuGa Se 2. Phys. Rev. B 2005, 72, 035211. [Google Scholar] [CrossRef]

- Werner, F.; Veith-Wolf, B.; Spindler, C.; Barget, M.R.; Babbe, F.; Guillot, J.; Schmidt, J.; Siebentritt, S. Oxidation as key mechanism for efficient interface passivation in Cu (In, Ga) Se 2 thin-film solar cells. Phys. Rev. Appl. 2020, 13, 054004. [Google Scholar] [CrossRef]

- Salome, P.M.; Ribeiro-Andrade, R.; Teixeira, J.P.; Keller, J.; Törndahl, T.; Nicoara, N.; Edoff, M.; Gonzalez, J.C.; Leitao, J.P.; Sadewasser, S. Cd and Cu interdiffusion in Cu (In, Ga) Se 2/CdS hetero-interfaces. IEEE J. Photovolt. 2017, 7, 858–863. [Google Scholar] [CrossRef]

- Weiss, T.P.; Bissig, B.; Feurer, T.; Carron, R.; Buecheler, S.; Tiwari, A.N. Bulk and surface recombination properties in thin film semiconductors with different surface treatments from time-resolved photoluminescence measurements. Sci. Rep. 2019, 9, 5385. [Google Scholar] [CrossRef]

- Weiss, T.P.; Carron, R.; Wolter, M.H.; Löckinger, J.; Avancini, E.; Siebentritt, S.; Buecheler, S.; Tiwari, A.N. Time-resolved photoluminescence on double graded Cu (In, Ga) Se2–Impact of front surface recombination and its temperature dependence. Sci. Technol. Adv. Mater. 2019, 20, 313–323. [Google Scholar] [CrossRef]

- Alkhayat, R.B.; Sapkota, D.R. Study of Degradation of Cu (In, Ga) Se 2 Solar Cell Parameters due to Temperature. In Proceedings of the 2022 IEEE 49th Photovoltaics Specialists Conference (PVSC), Philadelphia, PA, USA, 5–10 June 2022; pp. 1252–1256. [Google Scholar]

- Bengas, R.; Lahmar, H.; Redha, K.M.; Mentar, L.; Azizi, A.; Schmerber, G.; Dinia, A. Electrochemical synthesis of n-type ZnS layers on p-Cu2O/n-ZnO heterojunctions with different deposition temperatures. RSC Adv. 2019, 9, 29056–29069. [Google Scholar] [CrossRef]

- Ramanathan, K.M.; Glynn, J.S.; Christensen, S.; Pankow, J.; Li, J.; Scharf, J.; Mansfield, L.; Contreras, M.; Noufi, R. A Comparative Study of Zn(O,S) Buffer Layers and CIGS Solar Cells Fabricated by CBD, ALD, and Sputtering. In Proceedings of the 38th IEEE Photovoltaic Specialist Conference, Austin, TX, USA, 3–8 June 2012; pp. 1101–1104. [Google Scholar]

- Simandan, I.-D.; Sava, F.; Buruiana, A.-T.; Burducea, I.; Becherescu, N.; Mihai, C.; Velea, A.; Galca, A.-C. The Effect of the Deposition Method on the Structural and Optical Properties of ZnS Thin Films. Coatings 2021, 11, 1064. [Google Scholar] [CrossRef]

| Device Characteristics | Symbol | Al:ZnO | ZnO | CdS | ZnS [33] | CIGS |

|---|---|---|---|---|---|---|

| Thickness (nm) | d | 300 | 100 | 50 | 50 | 500 |

| Bandgap (eV) | Eg | 3.3 | 3.3 | 2.4 | 3.6 | 1.15 |

| Affinity (eV) | χe | 4.55 | 4.55 | 4.45 | 4.4 | 4.5 |

| Permitivity | εr | 9 | 9 | 10 | 8.32 | 13.6 |

| CB density of state (cm−3) | Nc | 3.1 × 1018 | 3.1 × 1018 | 1.3 × 1018 | 2.2 × 1018 | 3.1 × 1018 |

| VB density of state (cm−3) | Nv | 1.8 × 1019 | 1.8 × 1019 | 9.1 × 1018 | 1.8 × 1019 | 1.8 × 1019 |

| Electron thermal velocity (cm/s) | Vtn | 2.4 × 107 | 2.4 × 107 | 3.1 × 107 | 3.1 × 107 | 3.9 × 107 |

| Hole thermal velocity (cm/s) | Vtp | 1.3 × 107 | 1.3 × 107 | 1.6 × 107 | 1.6 × 107 | 1.4 × 107 |

| Mobility of electrons (cm2/V.s) | μn | 100 | 100 | 72 | 250 | 100 |

| Mobility of holes (cm2/V.s) | μp | 31 | 31 | 20 | 40 | 12.5 |

| Donor concentration, ND (cm−3) | Nd | 5 × 1018 | 1 × 1017 | 5 × 1017 | 5 × 1017 | - |

| Acceptor concentration, NA (cm−3) | Na | - | - | - | - | 3 × 1016 |

| Defect density (cm3) | Nt | 1 × 1016 | 1 × 1016 | 1 × 1016 | 1 × 1016 | 1 × 1014 |

| Cell Parameters | This Work | Ref. [1] | Ref. [2] |

|---|---|---|---|

| Jsc (mA/cm2) | 26.93 | 26.79 | 26.70 |

| Voc (mV) | 629.175 | 661.58 | 621.27 |

| FF (%) | 72.92 | 71.54 | 74.85 |

| Pmax (W/m2) | 247.148 | - | - |

| η (%) | 12.35 | 12.68 | 12.41 |

| Device Characteristics | Standard (1.15 eV) | Graded Bandgap (Downward) | Graded Bandgap (Upward) | Double-Graded Bandgap (Downward/Upward) |

|---|---|---|---|---|

| J0 (mA/cm2) | 3.17 × 10−7 | 3.25 × 10−7 | 3.23 × 10−7 | 3.18 × 10−7 |

| Jsc (mA/cm2) | 26.93 | 21.72 | 29.12 | 29.16 |

| Voc (mV) | 629.175 | 952.252 | 639.544 | 748.778 |

| FF (%) | 72.92 | 65.04 | 72.71 | 73.98 |

| Pmax (W/m2) | 247.148 | 269.16 | 270.86 | 323.11 |

| η (%) | 12.35 | 13.45 | 13.54 | 16.15 |

| u-CIGS Devices (25 °C) | Jsc (mA/cm2) | Voc (mv) | FF (%) | η (%) |

|---|---|---|---|---|

| Eg downward graded (ZnS buffer layer) | 25.10 | 901.01 | 65.04 | 14.71 |

| Eg upward graded (ZnS buffer layer) | 31.18 | 639.52 | 72.45 | 14.44 |

| Eg double-graded (CdS buffer layer) | 31.22 | 742.66 | 77.50 | 17.97 |

| Eg double-graded (ZnS buffer layer) | 31.53 | 742.78 | 77.50 | 18.15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Boukortt, N.E.I.; Patanè, S.; Hadri, B.; Crupi, G.

Graded Bandgap Ultrathin CIGS Solar Cells

. Electronics 2023, 12, 393.

https://doi.org/10.3390/electronics12020393

Boukortt NEI, Patanè S, Hadri B, Crupi G.

Graded Bandgap Ultrathin CIGS Solar Cells

. Electronics. 2023; 12(2):393.

https://doi.org/10.3390/electronics12020393

Boukortt, Nour El I., Salvatore Patanè, Baghdad Hadri, and Giovanni Crupi.

2023. "Graded Bandgap Ultrathin CIGS Solar Cells

" Electronics 12, no. 2: 393.

https://doi.org/10.3390/electronics12020393