The Circularity of Materials from the Perspective of a Product Life Cycle: A Life Cycle Assessment Case Study of Secondary Fence Boards—Part 1 (Baseline Scenario)

Abstract

:1. Introduction

2. Materials and Methods

- Impact categories, which are defined as “class representing environmental issues of concern to which life cycle inventory analysis results may be assigned” [29]. The impact categories represent specific environmental problems, such as climate change;

- Life cycle stages, which are defined as “consecutive and interlinked stages of a product system, from raw material acquisition or generation from natural resources to final disposal” [29]. These are the phases of the product life cycle that affect the environment;

- Processes, which are defined as “a set of interrelated or interacting activities that transforms inputs into outputs” [29]. These are smaller elements of the product life cycle for which data are quantified;

- Elementary flows, which are defined as “material or energy entering the system being studied that has been drawn from the environment without previous human transformation, or material or energy leaving the system being studied that is released into the environment without subsequent human transformation” [29]. These relate to material or energy directly derived from the environment or released directly into the environment, such as air emissions.

- The identification of the most relevant impact categories—all of the impact categories that together contribute to at least 80% of the single overall score (based on the normalised and weighted results);

- Th identification of the most relevant life cycle stages–all of the life cycle stages that together contribute more than 80% to the most relevant impact category (based on the characterised results),

- The identification of the most relevant processes–all of the processes that together contribute (along the entire life cycle) more than 80% to the most relevant impact category (based on the characterised results, considering absolute values);

- The identification of the most relevant elementary flows–all of the elementary flows that together contribute to at least 80% of the total impact of a most relevant impact category for each most relevant process (based on the characterised results)

- A—represents the allocation factor of burdens and credits between the supplier and the user of recycled materials;

- B—represents the allocation factor of energy recovery processes;

- QSin—represents the quality of the ingoing secondary material, i.e., the quality of the recycled material at the point of substitution;

- QSout—represents the quality of the outgoing secondary material, i.e., the quality of the recyclable material at the point of substitution;

- Qp—represents the quality of the primary material, i.e., the quality of the virgin material;

- R1—represents the recycled content, which is the proportion of material input to the production that has been recycled from a previous system;

- R2—represents the recycling rate, which is the proportion of the material in the product that will be recycled (or reused) in a subsequent system. R2 shall be measured at the output of the recycling plant;

- R3—represents the proportion of the material in the product that is used for energy recovery at EoL;

- Ev—represents the specific emissions and resources consumed arising from the acquisition and pre-processing of virgin material;

- E*v—represents the specific emissions and resources consumed arising from the acquisition and pre-processing of virgin material assumed to be substituted by recyclable materials;

- Erecycled—represents the specific emissions and resources consumed arising from the recycling process of the recycled (reused) material, including collection, sorting, and transportation processes;

- Erecycling_EoL—represents the specific emissions and resources consumed arising from the recycling process at EoL, including collection, sorting, and transportation processes;

- EER—represents the specific emissions and resources consumed arising from the energy recovery process (e.g., incineration with energy recovery, landfill with energy recovery, etc.);

- ESE elec ESE heat —represents the specific emissions and resources consumed that would have arisen from the specific substituted energy source: heat and electricity, respectively;

- ED—represents the specific emissions and resources consumed arising from the disposal of waste material at the EoL of the product being analysed, without energy recovery;

- XER elec XER heat—represents the efficiency of the energy recovery process for both heat and electricity;

- LHV—represents the lower heating value of the material in the product that is used for energy recovery.

3. Case Study

3.1. Goal and Scope Definition

- Materials and production—secondary fence board (manufacturing of secondary boards with Recycling process I);

- Materials—auxiliary materials (generation of raw materials to be included in auxiliary products used to install the secondary board, e.g., screws, bolts, wooden posts);

- Transport of the secondary board and auxiliary materials to the place of installation;

- Installation and use (assembly and maintenance);

- End of life (EoL)—secondary fence board (transport, landfilling, and incineration);

- End of life (EoL)—auxiliary materials.

3.2. Allocation

- For plastics, the allocation factor A equals 0.5; and for aluminium, it equals 0.2;

- The quality correction factors (QSin/Qp) for all plastics are assumed to be 0.9, and for aluminium, they are assumed to be 1.0.

3.3. Life Cycle Inventory

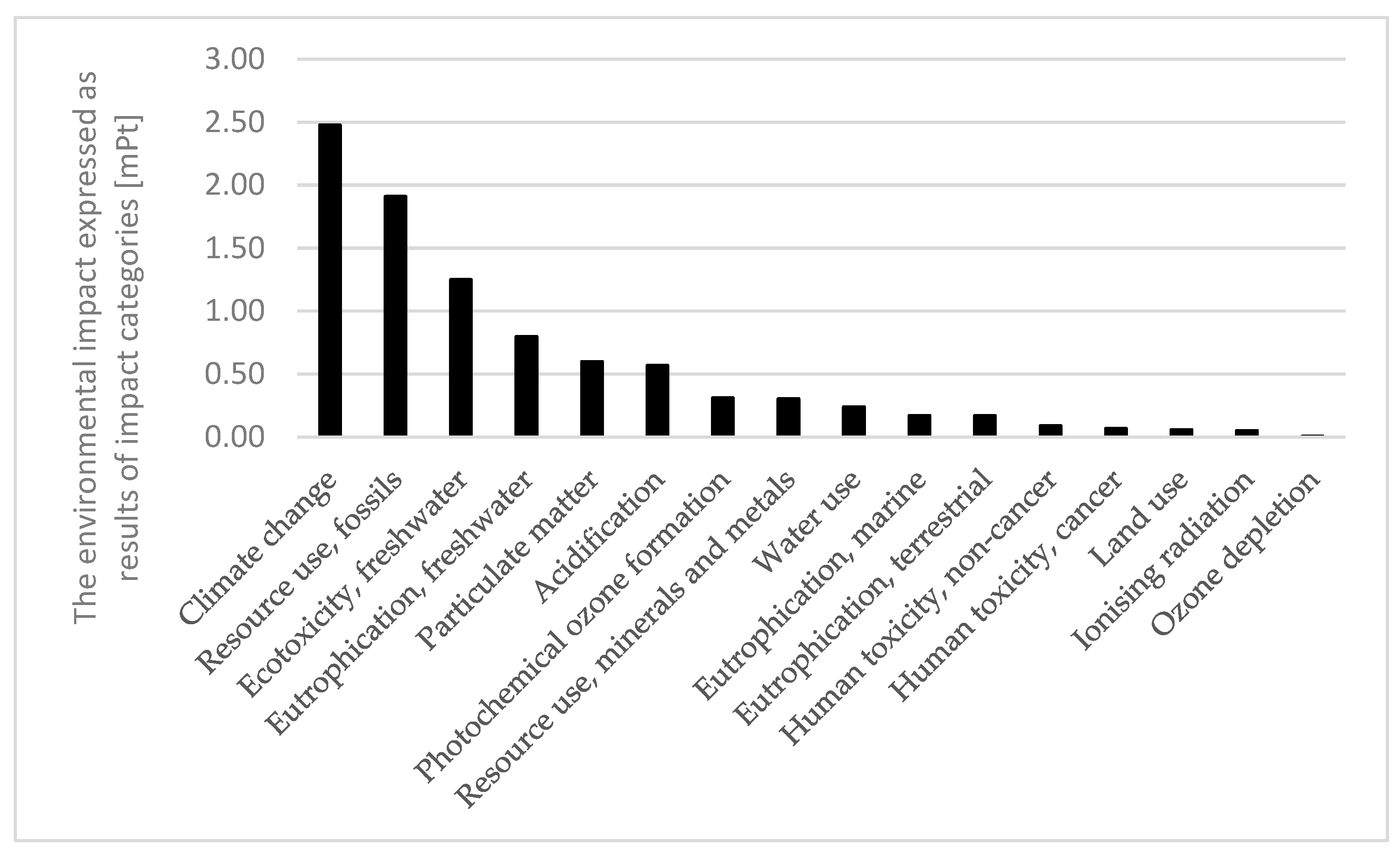

3.4. Results of the Life Cycle Impact Assessment (LCIA)

- Climate change—27.4% (2.48 mPt);

- Resource use, fossil fuels—21.1% (1.91 mPt);

- Ecotoxicity, freshwater—13.8% (1.25 mPt);

- Eutrophication, freshwater—8.8% (0.80 mPt);

- Particulate matter—6.6% (0.60 mPt);

- Acidification—6.3% (0.57 mPt).

4. Discussion and Conclusions

- Electricity consumption—relating to the direct use of power during the production of the secondary boards in Recycling process I and consumption during the processing of debited primary packaging materials;

- Debited primary production of the packaging materials—relating to the direct consumption of resources and emission of pollutants in the supply chains of the primary packaging materials;

- The landfilling of waste aluminium included in the waste secondary fence boards—in the case of ecotoxicity in freshwater, the landfilling of waste aluminium during the end-of-life stage of the secondary boards has been found to be the most important issue.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Generation of Waste by Economic Activity. Eurostat Database. Available online: https://ec.europa.eu/eurostat/databrowser/view/ten00106/default/table?lang=en (accessed on 5 December 2023).

- Kaza, S.; Yao, L.; Bhada-Tata, P.; Van Woerden, F. What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050. Urban Development; World Bank: Washington, DC, USA, 2018; pp. 1–295. Available online: https://openknowledge.worldbank.org/entities/publication/d3f9d45e-115f-559b-b14f-28552410e90a (accessed on 5 December 2023).

- COM(2020) 98 Final Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. A New Circular Economy Action Plan for a Cleaner and More Competitive Europe. Brussels. Available online: https://eur-lex.europa.eu/resource.html?uri=cellar:9903b325-6388-11ea-b735-01aa75ed71a1.0017.02/DOC_1&format=PDF (accessed on 5 December 2023).

- Di Foggia, G.; Beccarello, M. An Overview of Packaging Waste Models in Some European Countries. Recycling 2022, 7, 38. [Google Scholar] [CrossRef]

- European Court of Auditors. Special Report 17/2023: Circular Economy—Slow Transition by Member States Despite EU Action. Available online: https://www.eca.europa.eu/en/publications/sr-2023-17 (accessed on 5 February 2024).

- Replies of the European Commission to the European Court of Auditors. Circular economy—Slow transition by member states despite EU action. Special Report. Available online: www.eca.europa.eu/Lists/ECAReplies/COM-Replies-SR-2023-17/COM-Replies-SR-2023-17_EN.pdf (accessed on 5 February 2024).

- Bajdur, W. Application of Environmental Assessment of Product Life Cycle in Shaping Waste Recycling. In The Role of Business in Achieving Sustainability, Part 2: Implication for Industry; Modrak, V., Ślusarczyk, B., Eds.; Published by Technical University Košice: Presov, Slovakia, 2010; pp. 175–192. [Google Scholar]

- Koci, V.; Trecakova, T. Mixed municipal waste management in the Czech Republic from the point of view of the LCA method. Int. J. Life Cycle Assess. 2011, 16, 113–124. [Google Scholar] [CrossRef]

- den Boer, J.; Obersteiner, G.; Gollnow, S.; den Boer, E.; Bodnárné Sándor, R. Enhancement of Food Waste Management and Its Environmental Consequences. Energies 2021, 14, 1790. [Google Scholar] [CrossRef]

- Kucukvar, M.; Egilmez, G.; Tatari, O. Life Cycle Assessment and Optimization-Based Decision Analysis of Construction Waste Recycling for a LEED-Certified University Building. Sustainability 2016, 8, 89. [Google Scholar] [CrossRef]

- Shen, L.; Worrell, E.; Patel, K.M. Open-loop recycling: A LCA case study of PET bottle-to-fibre recycling. Resour. Conserv. Recycl. 2010, 55, 34–52. [Google Scholar] [CrossRef]

- Rosenberg, S.; Kurz, L.; Huster, S.; Wehrstein, S.; Kiemel, S.; Schultmann, F.; Reichert, F.; Wörner, R.; Glöser-Chahoud, S. Combining dynamic material flow analysis and life cycle assessment to evaluate environmental benefits of recycling—A case study for direct and hydrometallurgical closed-loop recycling of electric vehicle battery systems. Resour. Conserv. Recycl. 2023, 198, 107145. [Google Scholar] [CrossRef]

- Fugiel, A.; Śliwińska, A.; Burchart-Korol, D. Possibilities of Using Tools Supporting the Life Cycle Assessment of Multi-Functional Systems. Sci. Pap. Silesian Univ. Technol.—Organ. Manag. Ser. Organ. Manag. 2017, 100, 133–143. (In Polish) [Google Scholar] [CrossRef]

- Toniolo, S.; Mazzi, A.; Pieretto, C.; Scipioni, A. Allocation strategies in comparative life cycle assessment for recycling: Considerations from case studies. Resour. Conserv. Recycl. 2017, 117, 249–261. [Google Scholar] [CrossRef]

- Cherubini, E.; Franco, D.; Zanghelini, G.M.; Soares, S.R. Uncertainty in LCA case study due to allocation approaches and life cycle impact assessment methods. Int. J. Life Cycle Assess. 2018, 23, 2055–2070. [Google Scholar] [CrossRef]

- Aleisa, E.; Heijungs, R. Leveraging Life Cycle Assessment to Better Promote the Circular Economy: A First Step Using the Concept of Opportunity Cost. Sustainability 2022, 14, 3451. [Google Scholar] [CrossRef]

- Allacker, K.; Mathieux, F.; Pennington, D.; Pant, R. The search for an appropriate end-of-life formula for the purpose of the European Commission Environmental Footprint initiative. Int. J. Life Cycle Assess. 2017, 22, 1441–1458. [Google Scholar] [CrossRef]

- PAS 2050—Specification for the Assessment of the Life Cycle Greenhouse Gas Emissions of Goods and Services; The British Standards Institution: London, UK, 2008; pp. 1–43. Available online: http://www.carbonconstruct.com/pdf/pas_2050.pdf (accessed on 5 December 2023).

- Ekvall, T.; Björklund, A.; Sandin, G.; Jelse, K. Modeling recycling in life cycle Assessment. In Technical Report: Towards Sustainable Waste Management; The Swedish Life Cycle Centre: Gothenburg, Sweden, 2020; pp. 1–138. Available online: https://www.lifecyclecenter.se/wp-content/uploads/2020_05_Modeling-recyling-in-life-cycle-assessment-1.pdf (accessed on 6 December 2023).

- Farrapo, A.C., Jr.; Matheus, T.T.; Lagunes, R.M.; Filleti, R.; Yamaji, F.; Lopes Silva, D.A. The Application of Circular Footprint Formula in Bioenergy/Bioeconomy: Challenges, Case Study, and Comparison with Life Cycle Assessment Allocation Methods. Sustainability 2023, 15, 2339. [Google Scholar] [CrossRef]

- Krexner, T.; Kral, I.; Gronauer, A.; Medel-Jiménez, F.J.; Baue, A. Comparison of a system expansion and allocation approach for the handling of multi-output processes in life cycle assessment—A case study for nano-cellulose and biogas production from elephant manure. Special Issue. In Proceedings of the 48th International Symposium Actual Tasks on Agricultural Engineering (ATAE), Zagreb, Croatia, 2–4 March 2021; Available online: https://atae.agr.hr/ (accessed on 5 February 2024).

- Recommendation 2021/2279/EU Commission Recommendation (EU) of 15 December 2021 on the use of the Environmental Footprint Methods to Measure and Communicate the Life Cycle Environmental Performance of Products and Organisations. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32021H2279 (accessed on 5 December 2023).

- Commission Regulation (EU) 2022/1616 of 15 September 2022 on Recycled Plastic Materials and Articles Intended to Come into Contact with Foods, and Repealing Regulation (EC) No 282/2008. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32022R1616 (accessed on 7 February 2024).

- Commission Regulation (EU) No 10/2011 of 14 January 2011 on Plastic Materials and Articles Intended to Come into Contact with Food (Non-Legislative Acts). Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=CELEX%3A32011R0010 (accessed on 7 February 2024).

- Plastic—the Facts. The report. Available online: https://plasticseurope.org/pl/wp-content/uploads/sites/7/2021/11/Tworzywa-Fakty-2020_PL_do-pobrania.pdf (accessed on 7 February 2024).

- Wenzel, H.; Hauschild, M.Z.; Alting, L. Environmental Assessment of Products: Volume 1: Methodology, Tools and Case Studies in Product Development, 1st ed.; Springer: New York, NY, USA, 2000; pp. 1–543. [Google Scholar]

- Guinée, J.B.; Gorrée, M.; Heijungs, R.; Huppes, G.; Kleijn, R.; Koning, A.; de Oers, L.; van Wegener Sleeswijk, A.; Suh, S.; Udo de Haes, H.A.; et al. Handbook on Life Cycle Assessment. Operational Guide to the ISO Standards. III: Scientific Background, 1st ed.; Kluwer Academic Publishers: Dordrech, The Netherlands, 2002; pp. 1–314. [Google Scholar]

- European Commission, Joint Research Centre, Institute for Environment and Sustainability. ILCD International Reference Life Cycle Data System (ILCD) Handbook—General Guide for Life Cycle Assessment—Detailed Guidance, 1st ed.; Office of the European Union: Luxembourg, 2010; pp. 1–417. Available online: https://eplca.jrc.ec.europa.eu/uploads/ILCD-Handbook-General-guide-for-LCA-DETAILED-GUIDANCE-12March2010-ISBN-fin-v1.0-EN.pdf (accessed on 5 December 2023).

- ISO 14040; Environmental Management—Life Cycle Assessment—Principles and Framework. The International Organisation for Standardization: Brussels, Belgium, 2006.

- Weidema, B.P.; Wesnaes, M.S. Data quality management for life cycle inventories-an example of using data quality indicators. J. Clean. Prod. 1996, 4, 167–174. [Google Scholar] [CrossRef]

- Lewandowska, A.; Foltynowicz, Z.; Podlesny, A. Comparative LCA of Industrial Objects Part 1: LCA Data Quality Assurance—Sensitivity Analysis and Pedigree Matrix. Int. J. Life Cycle Assess. 2004, 9, 86–89. [Google Scholar] [CrossRef]

- More Specific Rules for Defining the Electricity Market. Available online: https://www.environdec.com/news/more-specific-rules-for-defining-the-electricity-market (accessed on 6 December 2023).

- BRE Global Product Category Rules (PCR). Available online: https://www.greenbooklive.com/filelibrary/EN_15804/PN514-BRE-EN-15804-PCR.pdf (accessed on 6 December 2023).

- Association of Issuing Bodies. Available online: https://www.aib-net.org/facts/european-residual-mix/2018 (accessed on 6 December 2023).

- Corona, B.; Shen, L.; Reike, D.; Carreón, J.R.; Worrell, E. Towards sustainable development through the circular economy—A review and critical assessment on current circularity metrics. Resour. Conserv. Recycl. 2019, 151, 104498. [Google Scholar] [CrossRef]

| Production of Secondary Fence Boards (Recycling Process I) | ||

|---|---|---|

| Ecoinvent Dataset (https://ecoinvent.org/database/, accessed on 10 July 2023) | Amount | Unit |

| Inputs | ||

| Polypropylene, granulate {GLO}| market for|Cut-off, U | 0.06 | kg |

| Injection moulding {GLO}| market for|Cut-off, U | 0.06 | kg |

| Steel, chromium steel 18/8 {GLO}| market for|Cut-off, U | 1.89 | g |

| Silicone product {RER}| market for silicone product|Cut-off, U | 0.45 | g |

| Ethylene glycol {GLO}| market for|Cut-off, U | 0.4 | g |

| Lubricating oil {RER}| market for lubricating oil|Cut-off, U | 1.71 | g |

| Liquefied petroleum gas {GLO}| market group for liquefied petroleum gas|Cut-off, U | 0.08 | kg |

| Electricity, low voltage {PL}| market for|Cut-off, U | 48.65 | kWh |

| Outputs | ||

| Mixed plastics (waste treatment) {GLO}| recycling of mixed plastics|Cut-off, U | 0.06 | kg |

| Hazardous waste for incineration {Europe without Switzerland}| market for hazardous waste, for incineration|Cut-off, U | 2.11 | g |

| Waste plastic, mixture {RoW}| treatment of waste plastic, mixture, municipal incineration | Cut-off, U | 0.45 | g |

| Steel and iron (waste treatment) {GLO}| recycling of steel and iron|Cut-off, U | 1.89 | g |

| Mixed plastics (waste treatment) {GLO}| recycling of mixed plastics|Cut-off, U | 0.06 | g |

| Hazardous waste for incineration {Europe without Switzerland}| market for hazardous waste, for incineration|Cut-off, U | 2.11 | g |

| Materials and Production—Secondary Fence Board—Baseline Scenario 1a (Primary Production of Packaging Debited) | ||

|---|---|---|

| Ecoinvent Dataset (https://ecoinvent.org/database/, accessed on 10 July 2023) | Amount | Unit |

| Inputs | ||

| Production of secondary fence board (Recycling process I) | 3.75 | kg |

| Polyethylene, high density, granulate {GLO}| market for|Cut-off, U (debit) | 3.375 | kg |

| Injection moulding {GLO}| market for|Cut-off, U (debit) | 3.375 | kg |

| Production of secondary fence board (Recycling process I) | 3.75 | kg |

| Polypropylene, granulate {GLO}| market for|Cut-off, U (debit) | 3.375 | kg |

| Injection moulding {GLO}| market for|Cut-off, U (debit) | 3.375 | kg |

| Production of secondary fence board (Recycling process 1) | 1.25 | kg |

| Polycarbonate {GLO}| market for|Cut-off, U (debit) | 1.125 | kg |

| Injection moulding {GLO}| market for|Cut-off, U (debit) | 1.125 | kg |

| Production of secondary fence board (Recycling process I) | 1.25 | kg |

| Nylon 6-6 {RER}| market for nylon 6-6|Cut-off, U (debit) | 1.125 | kg |

| Injection moulding {GLO}| market for|Cut-off, U (debit) | 1.125 | kg |

| Production of secondary fence board (Recycling process 1) | 1.25 | kg |

| Acrylonitrile-butadiene-styrene copolymer {GLO}| market for|Cut-off, U (debit) | 1.125 | kg |

| Injection moulding {GLO}| market for|Cut-off, U (debit) | 1.125 | kg |

| Production of secondary fence board (Recycling process I) | 0.5 | kg |

| Aluminium, primary, liquid {GLO}| market for|Cut-off, U (debit) | 0.5 | kg |

| Total Production of secondary fence board (Recycling process I): | 11.75 | kg |

| Total debited primary production: | 10.625 | kg |

| The Most Relevant Impact Categories | The Most Relevant Life Cycle Stages | |||

|---|---|---|---|---|

| Life Cycle Stage | Environmental Impact (Characterised Results) | Share | ||

| Climate change | Materials and production of secondary fence boards | 88.40 | kg CO2 eq | 93% |

| Resource use of fossil fuels | Materials and production of secondary fence boards | 1437.65 | MJ | 96% |

| Ecotoxicity in freshwater | End of life of secondary fence boards | 1553.53 | CTUe | 56% |

| Materials and production of secondary fence boards | 1165.15 | CTUe | 42% | |

| Eutrophication in freshwater | Materials and production of secondary fence boards | 0.04 | kg P eq | 98% |

| Particulate matter | Materials and production of secondary fence boards | 3.58 × 10−6 | disease inc. | 90% |

| Acidification | Materials and production of secondary fence boards | 0.49 | mol H+ eq | 97% |

| The Most Relevant Impact Categories | The Most Relevant Processes (Only Processes with the Highest Contribution are Listed) | |

|---|---|---|

| Ecoinvent dataset (https://ecoinvent.org/database/, accessed on 10 July 2023) | Share (Based on Characterised Results, Recalculated by Considering Absolute Values) | |

| Climate change | Electricity, high voltage {PL}|heat and power co-generation, hard coal|Cut-off, U | 12% |

| Nylon 6-6 {RER}| production|Cut-off, U | 10% | |

| Electricity, high voltage {PL}|heat and power co-generation, lignite|Cut-off, U | 8% | |

| Polycarbonate {RoW}|production|Cut-off, U | 7% | |

| Electricity, high voltage {RoW}|electricity production, hard coal|Cut-off, U | 6% | |

| Ethylene {RoW}|ethylene production, average|Cut-off, U | 5% | |

| Propylene {RoW}|production|Cut-off, U | 4% | |

| Polycarbonate {RER}|production|Cut-off, U | 3% | |

| Acrylonitrile-butadiene-styrene copolymer {RoW}|production|Cut-off, U | 3% | |

| Heat, district or industrial, other than natural gas {RoW}|heat production, at hard coal industrial furnace 1–10 MW|Cut-off, U | 2% | |

| Acrylonitrile-butadiene-styrene copolymer {RER}|production|Cut-off, U | 2% | |

| Heat, district or industrial, other than natural gas {RoW}|heat production, at hard coal industrial furnace 1–10 MW|Cut-off, U | 2% | |

| Acrylonitrile-butadiene-styrene copolymer {RER}|production|Cut-off, U | 2% | |

| +32 other processes with very low individual contribution (0.2–1%) | ||

| Resource use, fossil fuels | Ethylene {RoW}|ethylene production, average|Cut-off, U | 12% |

| Propylene {RoW}|production|Cut-off, U | 11% | |

| Nylon 6-6 {RER}|production|Cut-off, U | 9% | |

| Lignite {RER}|mine operation|Cut-off, U | 6% | |

| Polycarbonate {RoW}|production|Cut-off, U | 5% | |

| Acrylonitrile-butadiene-styrene copolymer {RoW}|production|Cut-off, U | 4% | |

| Hard coal {CN}|hard coal mine operation and hard coal preparation|Cut-off, U | 4% | |

| Hard coal {Europe, without Russia and Turkey}|hard coal mine operation and hard coal preparation|Cut-off, U | 3% | |

| Hard coal {ID}|hard coal mine operation and hard coal preparation|Cut-off, U | 3% | |

| Ethylene {RER}|ethylene production, average|Cut-off, U | 3% | |

| Propylene {RER}|production|Cut-off, U | 3% | |

| +9 other processes with low individual contributions (1–2%) | ||

| The Most Relevant Impact Categories | The Most Relevant Elementary Flows | ||

|---|---|---|---|

| Name of Elementary Flow | Compartment | Share | |

| Climate change | Carbon dioxide, fossil fuel | Output to air | 83% |

| Resource use of fossil fuels | Oil, crude | Input of raw material | 34% |

| Gas, natural/m3 | Input of raw material | 28% | |

| Coal, hard | Input of raw material | 24% | |

| Ecotoxicity in freshwater | Aluminium | Output to water | 57% |

| Aluminium | Output to air | 23% | |

| Chloride | Output to water | 9% | |

| Eutrophication in freshwater | Phosphate | Output to water | 99% |

| Particulate matter | Particulates < 2.5 μm | Output to air | 59% |

| Sulfur dioxide | Output to air | 23% | |

| Acidification | Sulfur dioxide | Output to air | 72% |

| Nitrogen oxides | Output to air | 26% | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kulczycka, J.; Lewandowska, A.; Joachimiak-Lechman, K.; Kurczewski, P. The Circularity of Materials from the Perspective of a Product Life Cycle: A Life Cycle Assessment Case Study of Secondary Fence Boards—Part 1 (Baseline Scenario). Resources 2024, 13, 50. https://doi.org/10.3390/resources13040050

Kulczycka J, Lewandowska A, Joachimiak-Lechman K, Kurczewski P. The Circularity of Materials from the Perspective of a Product Life Cycle: A Life Cycle Assessment Case Study of Secondary Fence Boards—Part 1 (Baseline Scenario). Resources. 2024; 13(4):50. https://doi.org/10.3390/resources13040050

Chicago/Turabian StyleKulczycka, Joanna, Anna Lewandowska, Katarzyna Joachimiak-Lechman, and Przemysław Kurczewski. 2024. "The Circularity of Materials from the Perspective of a Product Life Cycle: A Life Cycle Assessment Case Study of Secondary Fence Boards—Part 1 (Baseline Scenario)" Resources 13, no. 4: 50. https://doi.org/10.3390/resources13040050