Structural, Mechanical and Tribological Properties of NbCN-Ag Nanocomposite Films Deposited by Reactive Magnetron Sputtering

Abstract

:1. Introduction

2. Experimental Details

2.1. Preparation of Films

2.2. Characterization of the Films

3. Results and Discussion

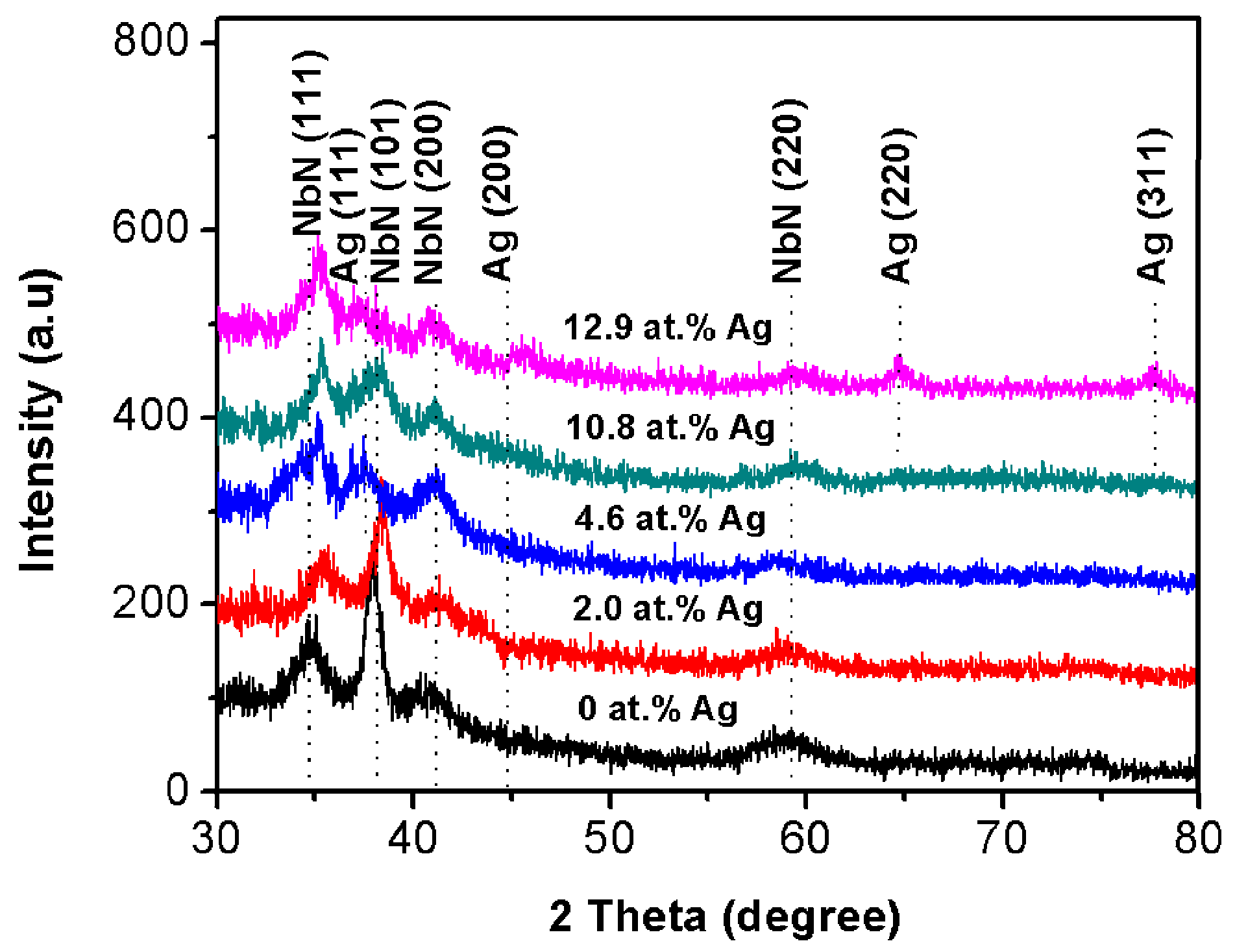

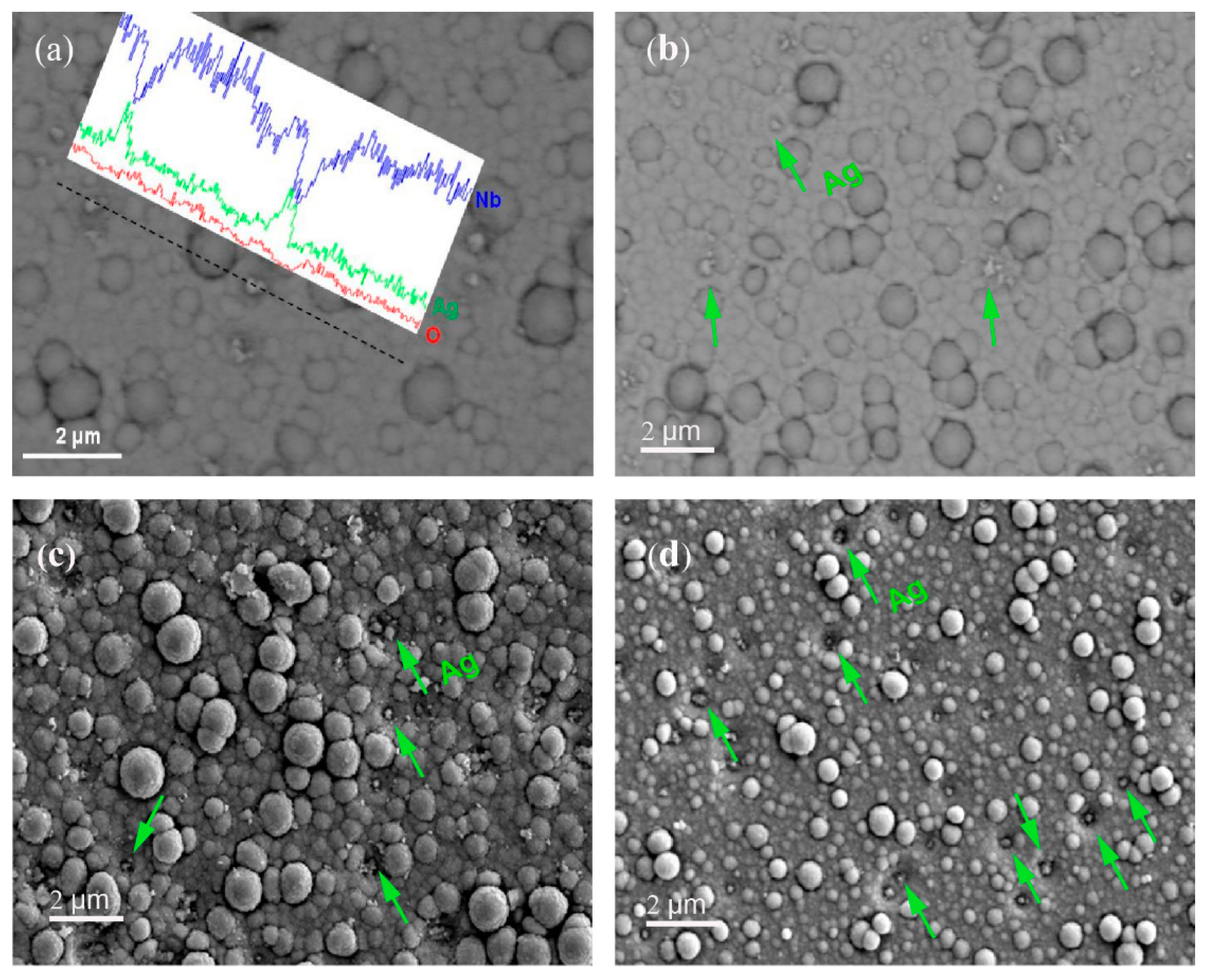

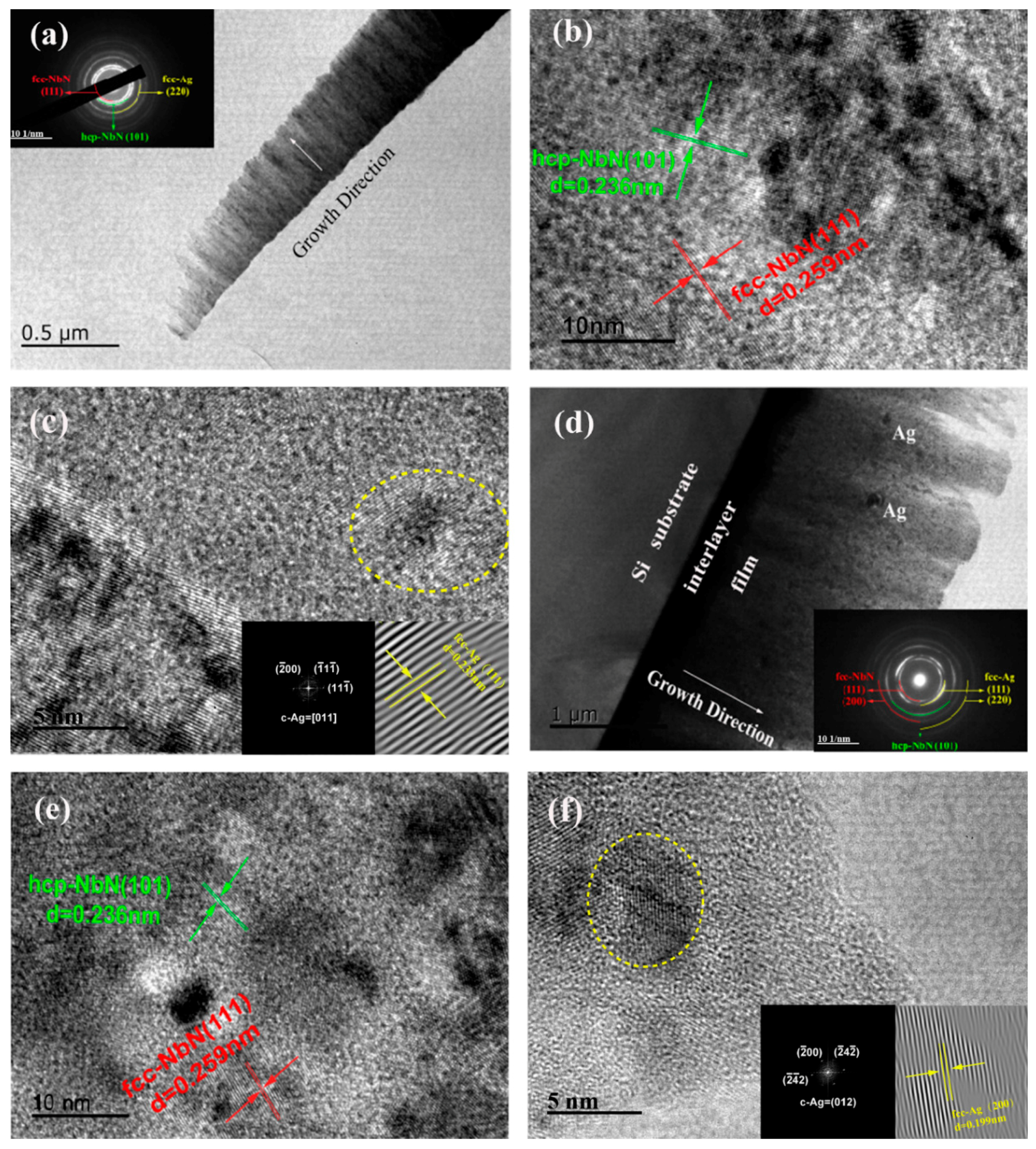

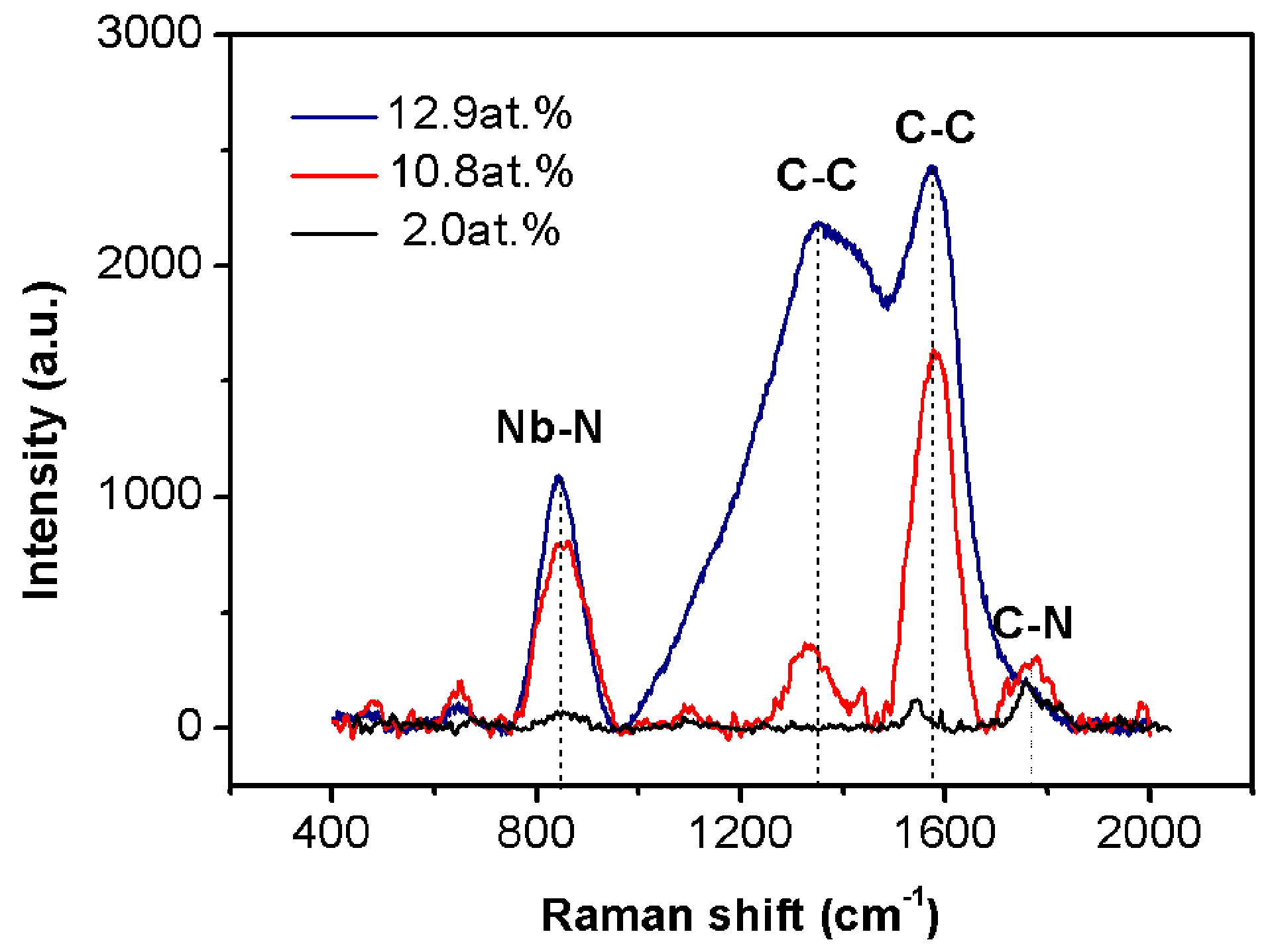

3.1. Composition and Phase Structure for NbCN-Ag Films

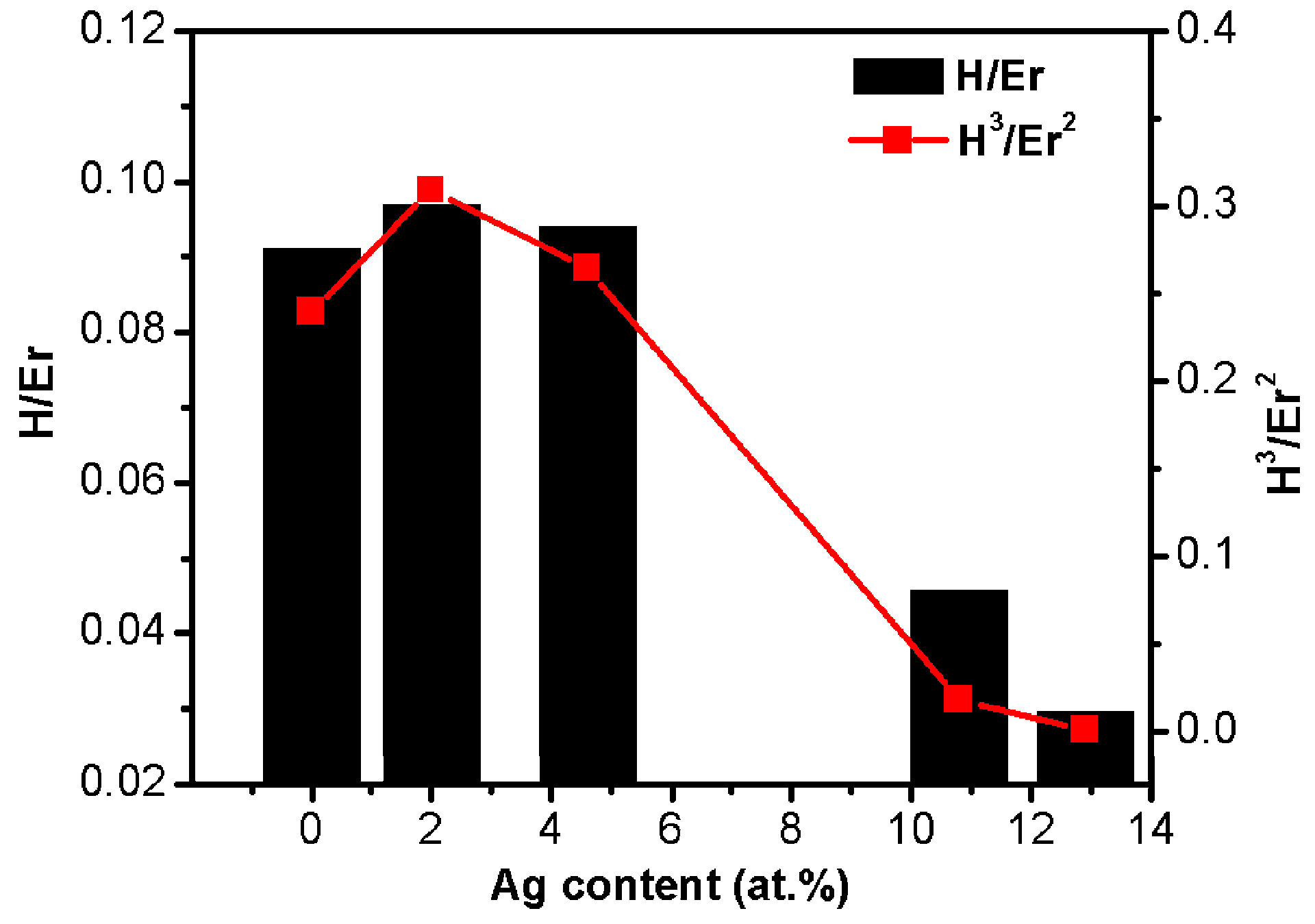

3.2. Mechanical Properties

3.3. Tribological Properties

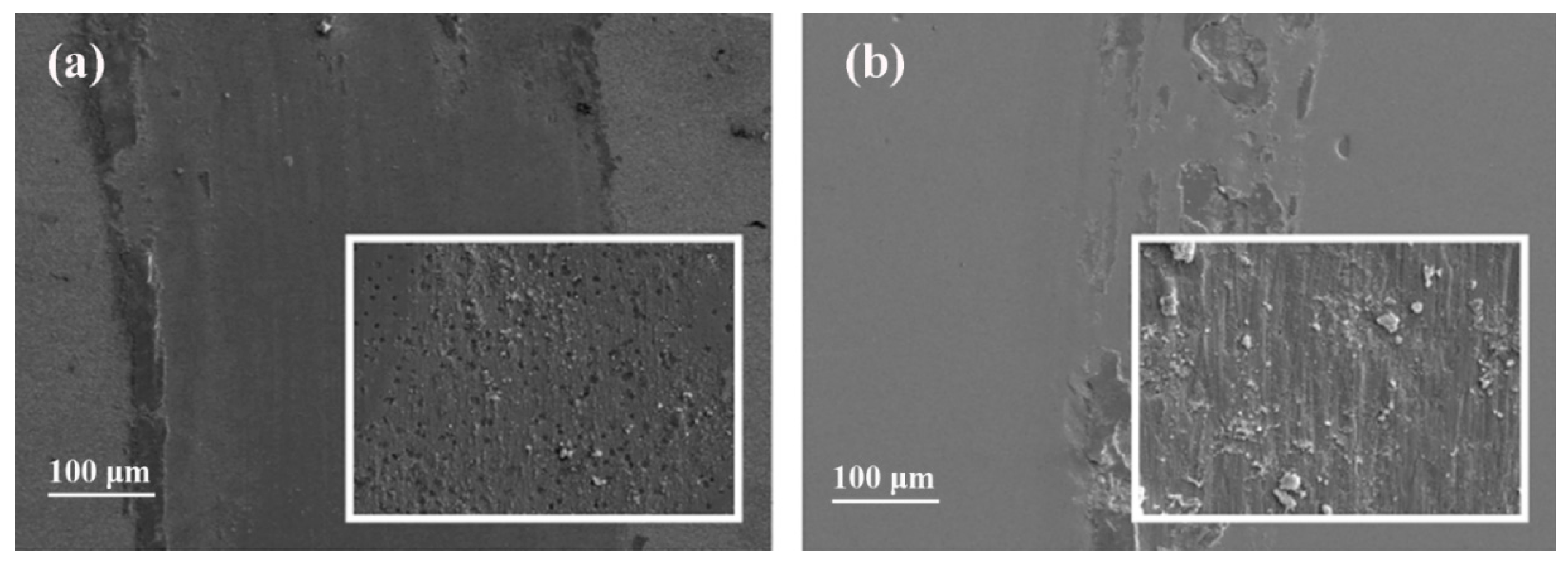

3.3.1. Tribological Properties at Room Temperature

3.3.2. Tribological Properties at Elevated Temperature

- The oxidation of the films became serious due to the increasing in temperature. Nb2O5 had a layered structure [10], which was highly diffusible and easily worn.

- The oxidation of C would also increase the wear rates at high temperature. When the temperature reached 300 °C, the wear rates of NbCN-Ag composite films were higher than that of NbCN film, which was due to the formation of a large amount of AgNbO3 and Ag2O. This could aggravate the wear rates of the NbCN-Ag films.

- During the testing of friction, wear and deformation occurred on the Ag lubrication films. Due to the small surface strength of the films, the worn Ag chip had a tendency of dual disc adhesion, and the friction heating intensified the transfer of Ag [30]. The friction surface favored forming metal adhesion to aggravate the rate of wear, resulting in the severely deeper abrasive grooves on the worn tracks for NbCN film. (4) As the temperature increased from 300 °C to 500 °C, more Ag atoms diffused to the surface, which made the film hollow and easy to wear [14,31].

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ezirmik, K.V.; Rouhi, S. Influence of Cu additions on the mechanical and wear properties of NbN coatings. Surf. Coat. Technol. 2014, 260, 179–185. [Google Scholar] [CrossRef]

- Cansever, N.; Danışman, M.; Kazmanlı, K. The effect of nitrogen pressure on cathodic arc deposited NbN thin films. Surf. Coat. Technol. 2008, 202, 5919–5923. [Google Scholar] [CrossRef]

- Zhang, K.; Balasubramanian, K.; Ozsdolay, B.D.; Mulligan, C.P.; Khare, S.V.; Zheng, W.T.; Gall, D. Epitaxial NbCxN1−x(001) layers: Growth, mechanical properties, and electrical resistivity. Surf. Coat. Technol. 2015, 277, 136–143. [Google Scholar] [CrossRef]

- Cheng, Y.H.; Browne, T.; Heckerman, B.; Meletis, E.I. Influence of the C content on the mechanical and tribological properties of the TiCN coatings deposited by LAFAD technique. Surf. Coat. Technol. 2011, 205, 4024–4029. [Google Scholar] [CrossRef]

- Zhang, K.; Wen, M.; Wang, S.; Deng, R.P.; Gall, D.; Zheng, W.T. Sputter deposited NbCxNy films: Effect of nitrogen content on structure and mechanical and tribological properties. Surf. Coat. Technol. 2014, 258, 746–753. [Google Scholar] [CrossRef]

- Tong, C.Y.; Lee, J.W.; Kuo, C.C.; Huang, S.H.; Chan, Y.C.; Chen, H.W.; Duh, J.G. Effects of carbon content on the microstructure and mechanical property of cathodic arc evaporation deposited CrCN thin films. Surf. Coat. Technol. 2013, 231, 482–486. [Google Scholar] [CrossRef]

- Velasco, S.C.; Cavaleiro, A.; Carvalho, S. Functional properties of ceramic-Ag nanocomposite coatings produced by magnetron sputtering. Prog. Mater. Sci. 2016, 84, 158–191. [Google Scholar] [CrossRef] [Green Version]

- Kelly, P.J.; Li, H.; Benson, P.S.; Whitehead, K.A.; Verran, J.; Arnell, R.D.; Iordanova, I. Comparison of the tribological and antimicrobial properties of CrN/Ag, ZrN/Ag, TiN/Ag, and TiN/Cu nanocomposite coatings. Surf. Coat. Technol. 2010, 205, 1606–1610. [Google Scholar] [CrossRef]

- Ju, H.; Xu, J. Microstructure and tribological properties of NbN-Ag composite films by reactive magnetron sputtering. Appl. Surf. Sci. 2015, 355, 878–883. [Google Scholar] [CrossRef]

- Mulligan, C.P.; Blanchet, T.A.; Gall, D. CrN–Ag nanocomposite coatings: Tribology at room temperature and during a temperature ramp. Surf. Coat. Technol. 2010, 204, 1388–1394. [Google Scholar] [CrossRef]

- Kiryu, S.; Shoji, A.; Kohjiro, S.; Kodaira, S. Stress in NbCxN1−x films prepared by reactive RF magnetron sputtering. Jpn. J. Appl. Phys. 1993, 32, L834–L836. [Google Scholar] [CrossRef]

- Sánchez-López, J.C.; Abad, M.D.; Carvalho, I.; Galindo, R.E.; Benito, N.; Ribeiro, S.; Henriques, M.; Cavaleiro, A.; Carvalho, S. Influence of silver content on the tribomechanical behavior on Ag-TiCN bioactive coatings. Surf. Coat. Technol. 2012, 206, 2192–2198. [Google Scholar] [CrossRef] [Green Version]

- Ferreri, I.; Lopes, V.; Calderon, V.S. Study of the effect of the silver content on the structure and mechanical behavior of Ag-ZrCN coatings for orthopedic prostheses. Mater. Sci. Eng. C 2014, 42, 782–790. [Google Scholar] [CrossRef] [PubMed]

- Shtansky, D.V.; Bondarev, A.V.; Kiryukhantsev-Korneev, P.V. Structure and tribological properties of MoCN-Ag coatings in the temperature range of 25–700 °C. Appl. Surf. Sci. 2013, 273, 408–414. [Google Scholar] [CrossRef]

- Yu, L.; Zhao, H.; Xu, J. Influence of silver content on structure, mechanical and tribological properties of WCN–Ag films. Mater. Charact. 2016, 114, 136–145. [Google Scholar] [CrossRef]

- Xu, J.; Chen, J.; Yu, L. Influence of Si content on the microstructure and mechanical properties of VSiN films deposited by reactive magnetron sputtering. Vacuum 2016, 131, 51–57. [Google Scholar] [CrossRef]

- Shi, J.; Muders, C.M.; Kumar, A.; Jiang, X.; Pei, Z.L.; Gong, J.; Sun, C. Study on nanocomposite Ti–Al–Si–Cu–N films with various Si contents deposited by cathodic vacuum arc ion plating. Appl. Surf. Sci. 2012, 258, 9642–9649. [Google Scholar] [CrossRef]

- Singh, K.; Bidaye, A.C.; Suri, A.K. Magnetron sputtered NbN films with electroplated Cr interlayer. Vacuum 2011, 86, 267–274. [Google Scholar] [CrossRef]

- Wang, J.; Song, Z.; Xu, K. Influence of sputtering bias on the microstructure and properties of Nb-Si-N films. Surf. Coat. Technol. 2007, 201, 4931–4934. [Google Scholar] [CrossRef]

- Carvalho, I.; Henriques, M.; Oliveira, J.C.; Alves, C.F.A.A.; Piedade, P.; Carvalho, S. Influence of surface features on the adhesion of Staphylococcus epidermidis to Ag–TiCN thin films. Sci. Technol. Adv. Mater. 2013, 14, 35009–35018. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kaiser, R.; Spengler, W.; Schicktanz, S.; Politis, C. Raman Spectra and Superconductivity of Various Phases of a High-Tc Superconductor: NbN. Phys. Status Solidi 1978, 87, 565–573. [Google Scholar] [CrossRef]

- Stone, D.S.; Migas, J.; Martini, A. Adaptive NbN/Ag coatings for high temperature tribological applications. Surf. Coat. Technol. 2012, 206, 4316–4321. [Google Scholar] [CrossRef]

- Prabhakaran, V.; Talke, F.E. Wear and hardness of carbon overcoats on magnetic recording sliders. Wear 2000, 243, 18–24. [Google Scholar] [CrossRef]

- Qi, J.; Luo, J.; Wen, S. Structure, mechanical and tribological properties of carbon nitride thin films. Vac. Sci. Technol. 2000, 6, 381–384. (In Chinese) [Google Scholar]

- Erdemir, A. A crystal-chemical approach to lubrication by solid oxides. Tribol. Lett. 2000, 8, 97–102. [Google Scholar] [CrossRef]

- Jouve, G.; Severac, C.; Cantacuzene, S. XPS study of NbN and (Nb Ti)N superconducting coatings. Thin Solid Films 1996, 28, 146–153. [Google Scholar] [CrossRef]

- Yu, K.Y.; Liu, Y.; Rios, S.; Wang, H.; Zhang, X. Strengthening mechanisms of Ag/Ni immiscible multilayers with fcc/fcc interface. Surf. Coat. Technol. 2013, 237, 269–275. [Google Scholar] [CrossRef]

- Waterhouse, G.I.N.; Bowmaker, G.A.; Metson, J.B. The thermal decomposition of silver (I, III) oxide: A combined XRD, FT-IR and Raman spectroscopic study. Phys. Chem. Che. Phys. 2001, 3, 3838–3845. [Google Scholar] [CrossRef]

- Mulligana, C.P.; Blanchetb, T.A.; Galla, D. CrN-Ag nanocomposite coatings: High-temperature tribological response. Wear 2010, 269, 125–131. [Google Scholar] [CrossRef]

- Erdemir, A. A crystal chemical approach to the formulation of self-lubricating composite coatings. Surf. Coat. Technol. 2005, 200, 1792–1796. [Google Scholar] [CrossRef]

- Bondarev, A.V.; Kiryukhantsev-Korneev, P.V.; Sidorenko, D.A.; Shtansky, D.V. A new insight into hard low friction MoCN-Ag coatings intended for applications in wide temperature range. Mater. Des. 2015, 93, 63–72. [Google Scholar] [CrossRef]

- Ju, H.; Xu, J.; Yu, L. Effects of Mo content on the microstructure and friction and wear properties of TiMoN films. Acta. Metall. Sin. 2012, 48, 1132–1138. [Google Scholar]

| Ag Content (at.%) | λ (nm) | BNbN(101) (°) |

|---|---|---|

| 0 | 0.154 | 0.462 ± 0.002 |

| 2.0 | 0.504 ± 0.003 | |

| 4.6 | 0.515 ± 0.002 | |

| 10.8 | 0.534 ± 0.001 | |

| 12.9 | 0.673 ± 0.002 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, F.; Yu, L.; Ju, H.; Asempah, I.; Xu, J. Structural, Mechanical and Tribological Properties of NbCN-Ag Nanocomposite Films Deposited by Reactive Magnetron Sputtering. Coatings 2018, 8, 50. https://doi.org/10.3390/coatings8020050

Wu F, Yu L, Ju H, Asempah I, Xu J. Structural, Mechanical and Tribological Properties of NbCN-Ag Nanocomposite Films Deposited by Reactive Magnetron Sputtering. Coatings. 2018; 8(2):50. https://doi.org/10.3390/coatings8020050

Chicago/Turabian StyleWu, Fanjing, Lihua Yu, Hongbo Ju, Isaac Asempah, and Junhua Xu. 2018. "Structural, Mechanical and Tribological Properties of NbCN-Ag Nanocomposite Films Deposited by Reactive Magnetron Sputtering" Coatings 8, no. 2: 50. https://doi.org/10.3390/coatings8020050