Efficient Antifungal and Flame-Retardant Properties of ZnO-TiO2-Layered Double-Nanostructures Coated on Bamboo Substrate

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Synthesis of TiO2 Thin Film on Bamboo Substrate

2.3. Synthesis of ZnO-TiO2-Layered Double-Nanostructures on Bamboo Substrate

2.4. Characterization

2.5. Antifungal Test

3. Results and Discussion

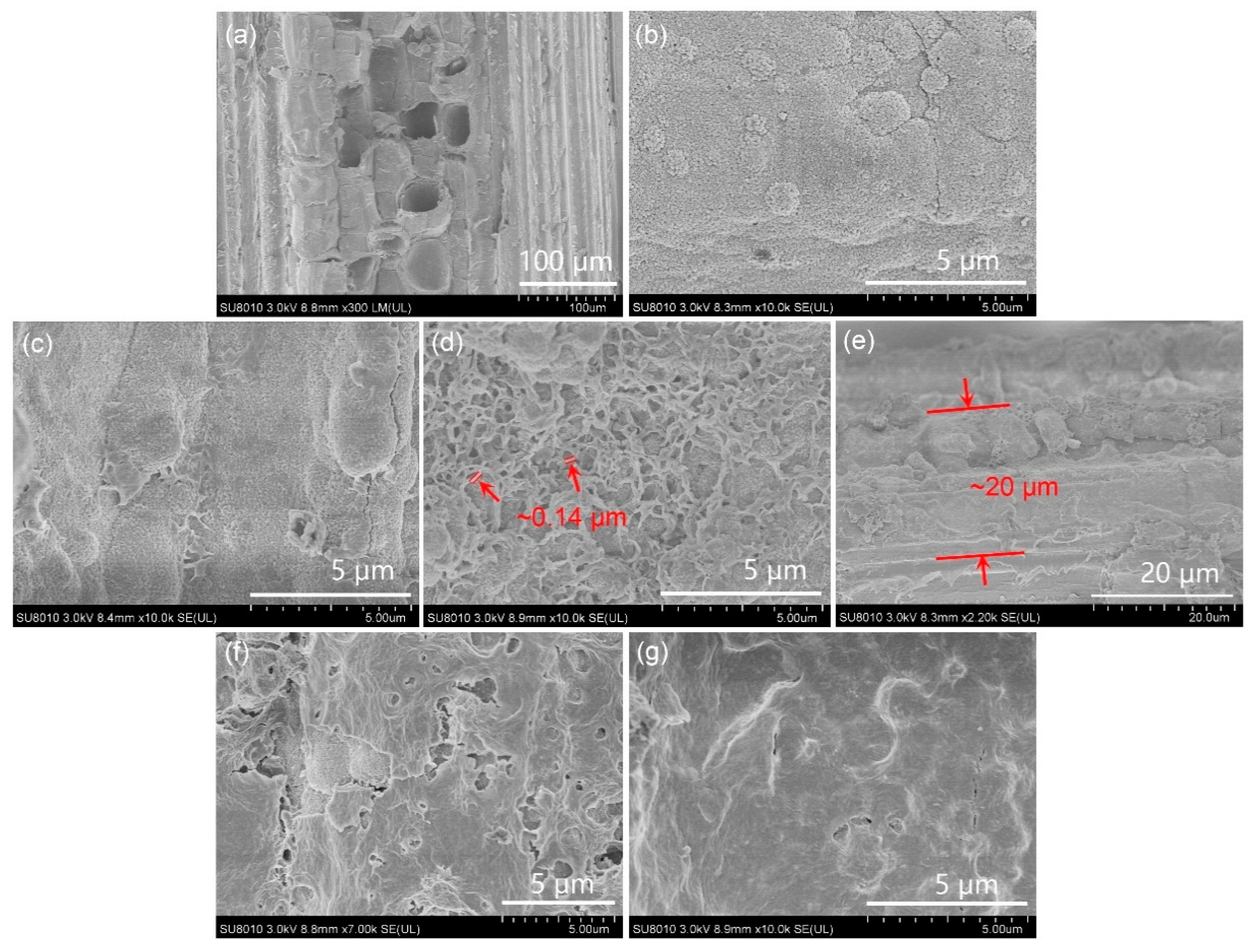

3.1. Morphological Observation

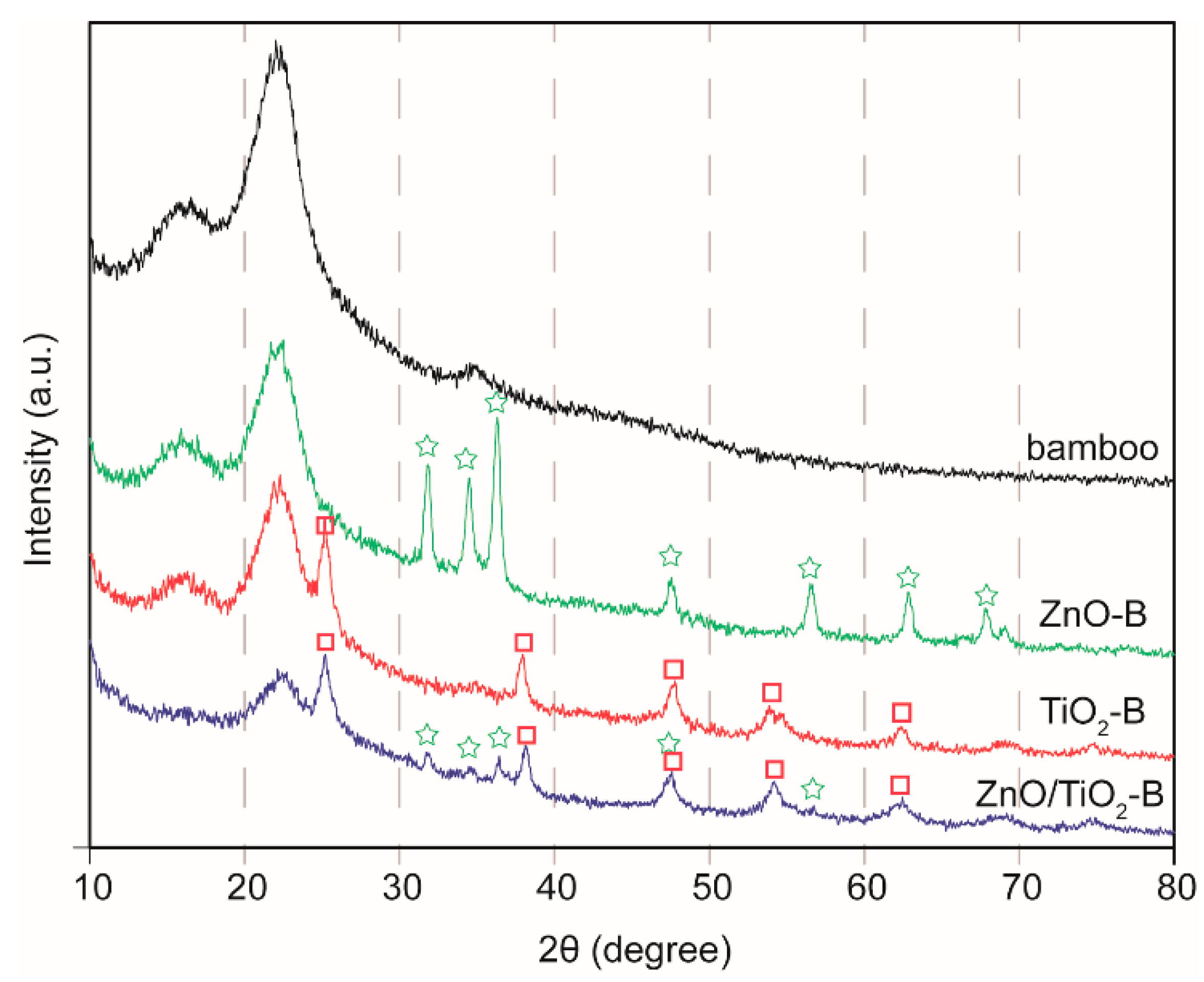

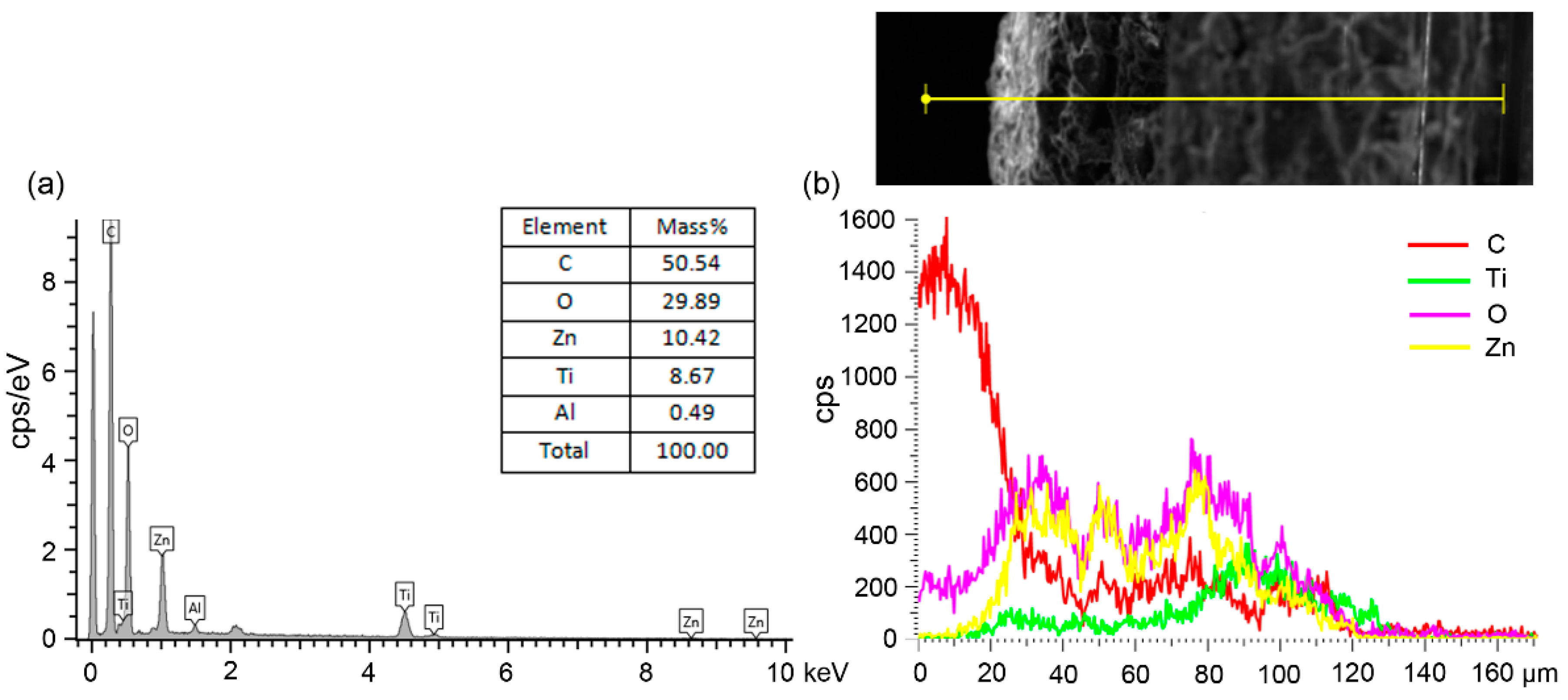

3.2. Elemental Composition and Crystalline Structure Analysis

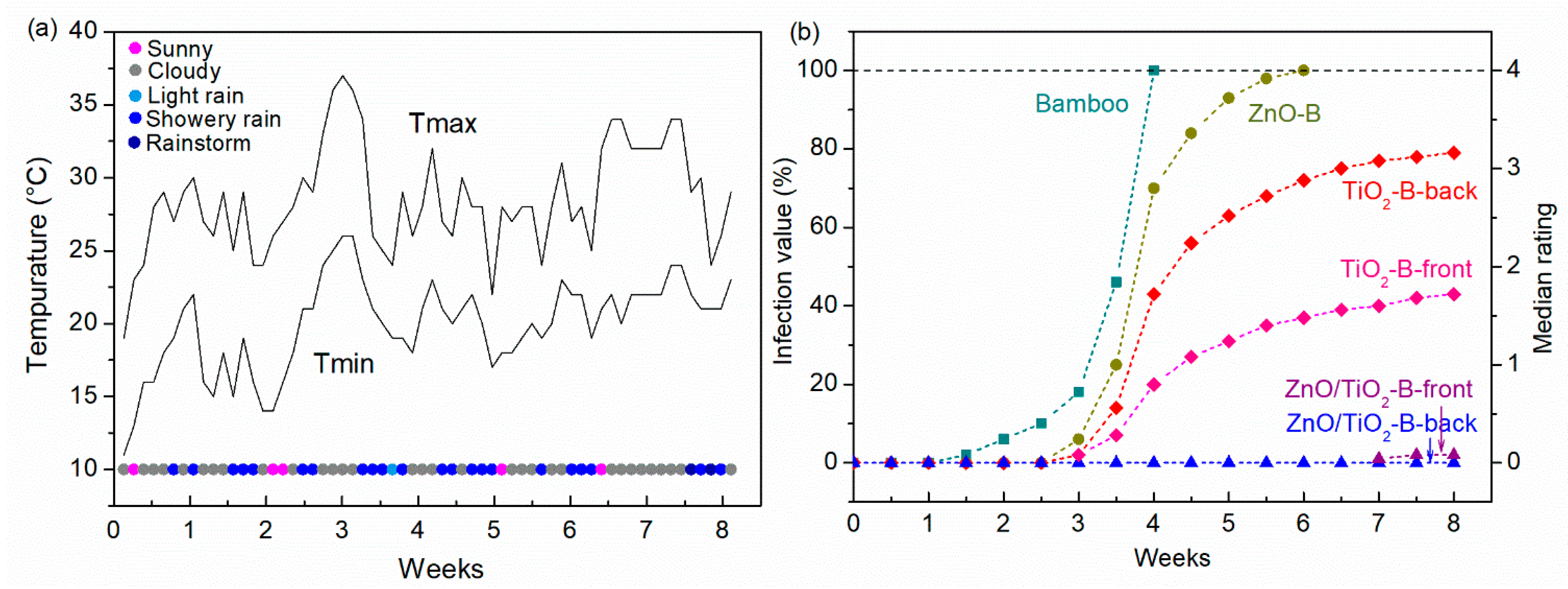

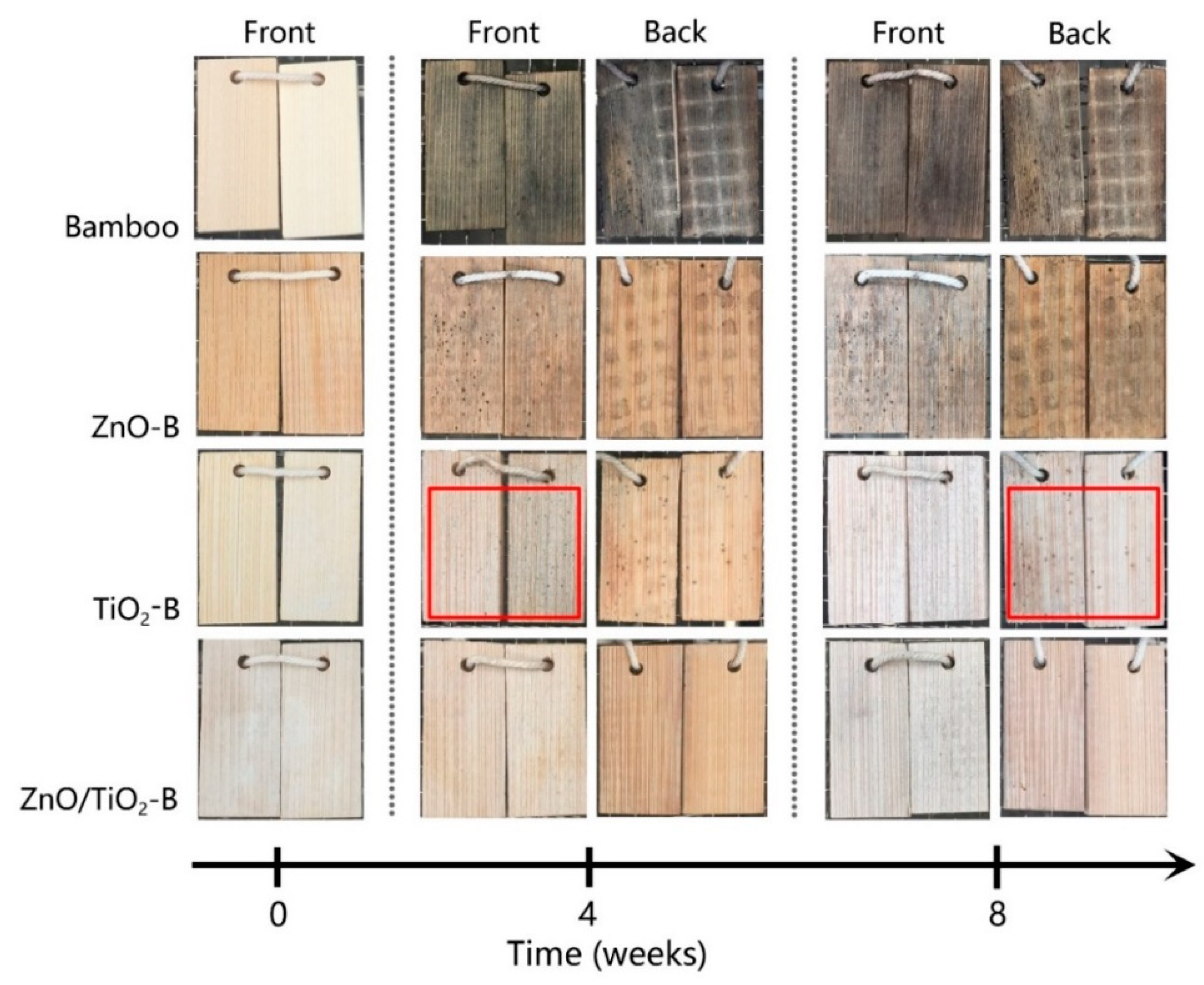

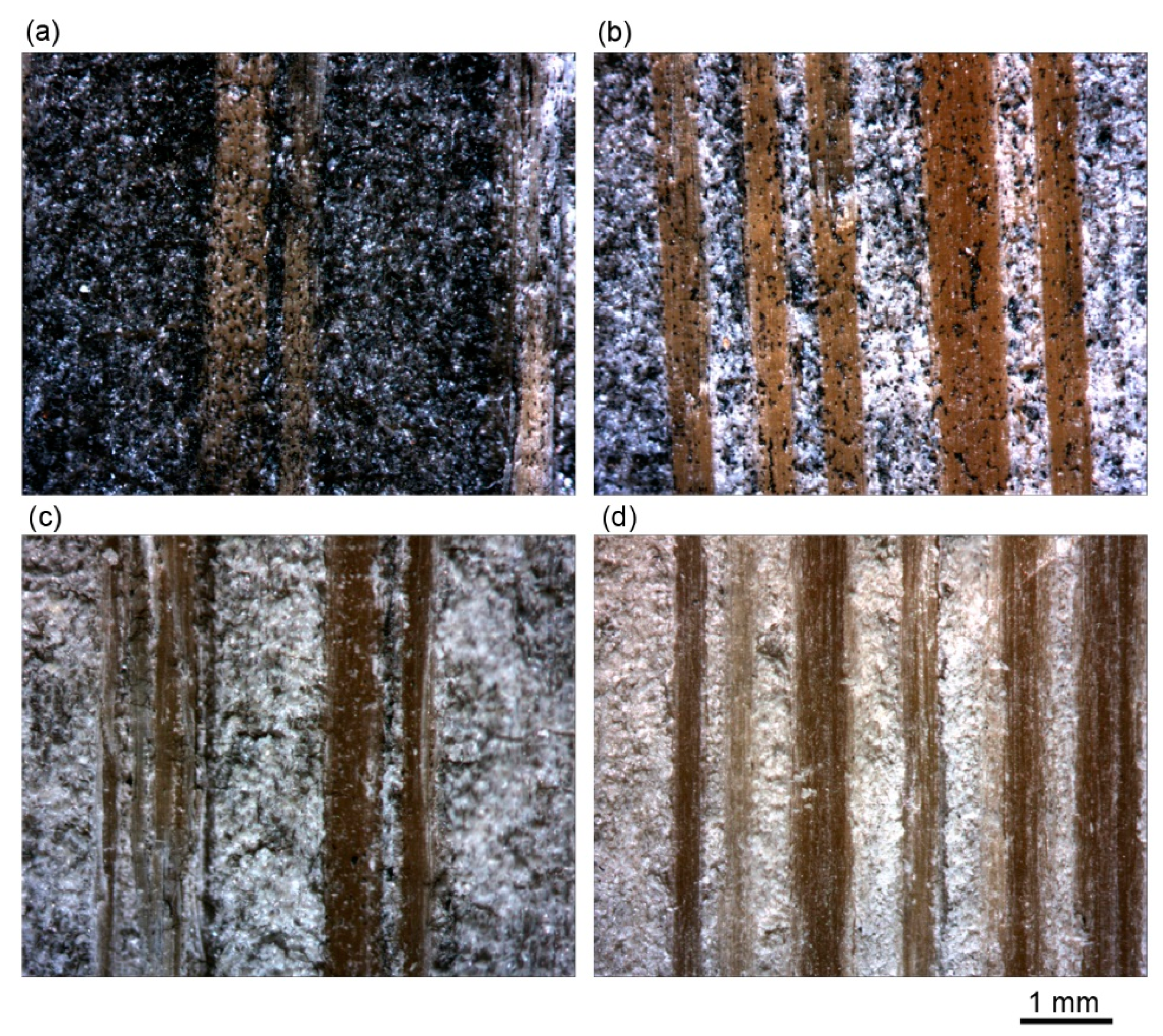

3.3. Antifungal Property

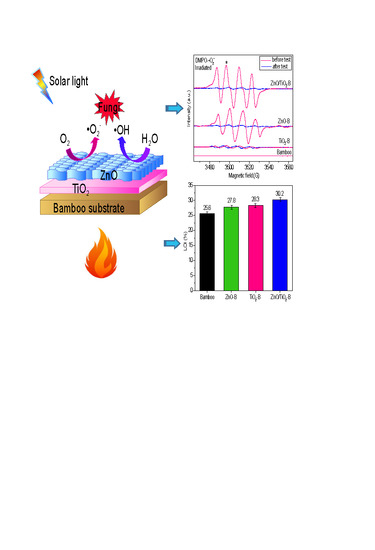

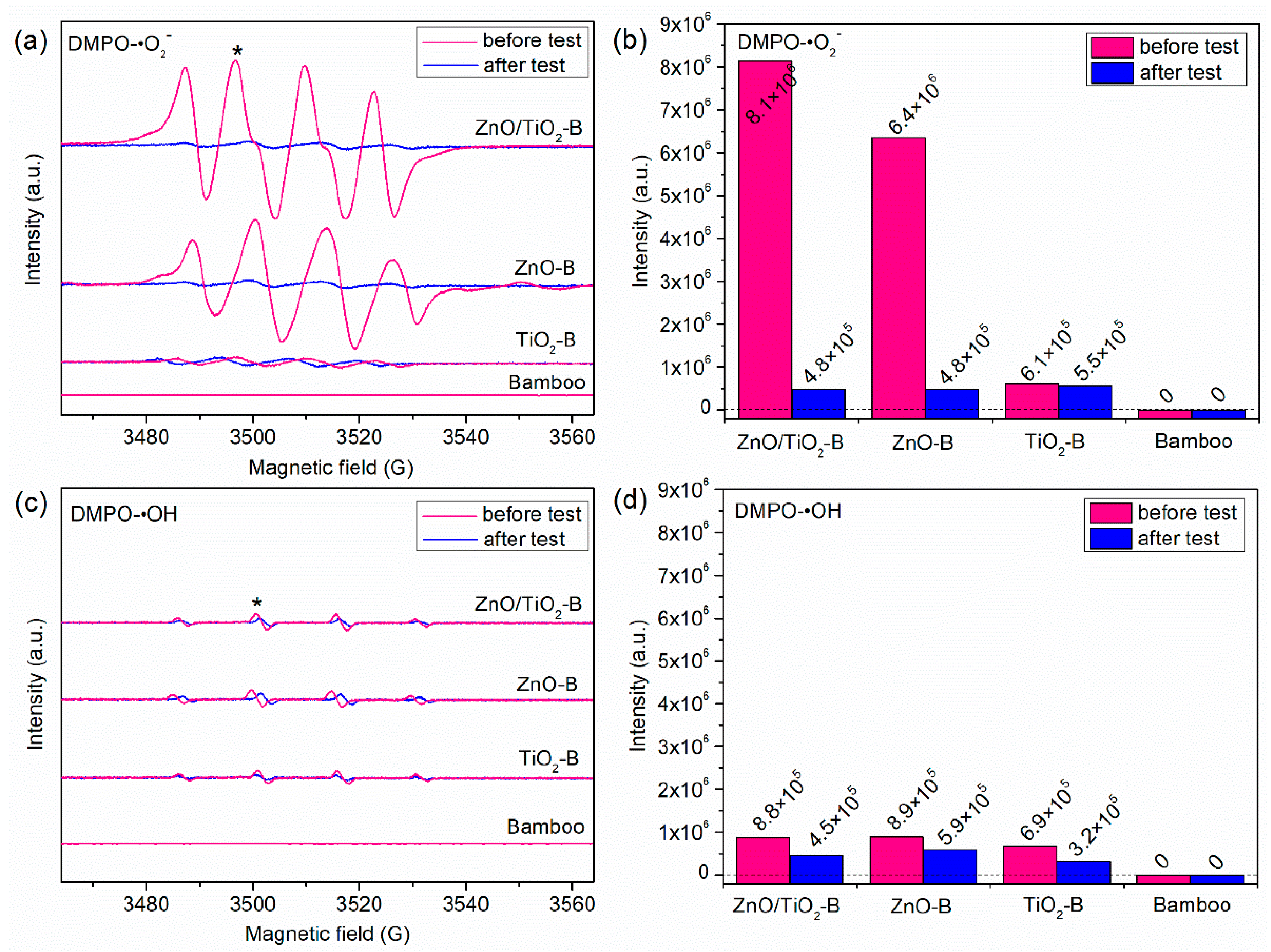

3.4. Mechanism of the Enhanced Antifungal Properties

3.5. Thermal Stability and Flame-Retardant Property

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sharma, B.; Gatóo, A.; Bock, M.; Ramage, M. Engineered bamboo for structural applications. Constr. Build. Mater. 2015, 81, 66–73. [Google Scholar] [CrossRef]

- Verma, C.S.; Chariar, V.M. Development of layered laminate bamboo composite and their mechanical properties. Compos. Part B Eng. 2012, 43, 1063–1069. [Google Scholar] [CrossRef]

- Yu, Y.; Huang, X.; Yu, W. A novel process to improve yield and mechanical performance of bamboo fiber reinforced composite via mechanical treatments. Compos. Part B Eng. 2014, 56, 48–53. [Google Scholar] [CrossRef]

- Yu, Y.; Liu, R.; Huang, Y.; Meng, F.; Yu, W. Preparation, physical, mechanical, and interfacial morphological properties of engineered bamboo scrimber. Constr. Build. Mater. 2017, 157, 1032–1039. [Google Scholar] [CrossRef]

- Flynn, A.; Chan, K.W.; Zhu, Z.H.; Yu, L. Sustainability, space and supply chains: The role of bamboo in Anji County, China. J. Rural Stud. 2017, 49, 128–139. [Google Scholar] [CrossRef] [Green Version]

- Darbari, S.; Abdi, Y.; Haghighi, F.; Mohajerzadeh, S.; Haghighi, N. Investigating the antifungal activity of TiO2 nanoparticles deposited on branched carbon nanotube arrays. J. Phys. D Appl. Phys. 2011, 44, 245401–245410. [Google Scholar] [CrossRef]

- Hou, X.; Ma, H.; Liu, F.; Deng, J.; Ai, Y.; Zhao, X.; Mao, D.; Li, D.; Liao, B. Synthesis of Ag ion-implanted TiO2 thin films for antibacterial application and photocatalytic performance. J. Hazard. Mater. 2015, 299, 59–66. [Google Scholar] [CrossRef] [PubMed]

- Akhavan, O. Lasting antibacterial activities of Ag-TiO2/Ag/a-TiO2 nanocomposite thin film photocatalysts under solar light irradiation. J. Colloid Interface Sci. 2009, 336, 117–124. [Google Scholar] [CrossRef] [PubMed]

- Chauhan, I.; Aggrawal, S.; Mohanty, P. ZnO nanowire-immobilized paper matrices for visible light-induced antibacterial activity against Escherichia coli. Environ. Sci. Nano 2015, 2, 273–279. [Google Scholar] [CrossRef]

- Lipovsky, A.; Nitzan, Y.; Gedanken, A.; Lubart, R. Antifungal activity of ZnO nanoparticles–the role of ROS mediated cell injury. Nanotechnology 2011, 22, 105101–105105. [Google Scholar] [CrossRef] [PubMed]

- Kairyte, K.; Kadys, A.; Luksiene, Z. Antibacterial and antifungal activity of photoactivated ZnO nanoparticles in suspension. J. Photochem. Photobiol. B 2013, 128, 78–84. [Google Scholar] [CrossRef] [PubMed]

- Sharma, D.; Rajput, J.; Kaith, B.S.; Kaur, M.; Sharma, S. Synthesis of ZnO nanoparticles and study of their antibacterial and antifungal properties. Thin Solid Films 2010, 519, 1224–1229. [Google Scholar] [CrossRef]

- Chen, X.; Ku, S.; Weibel, J.A.; Ximenes, E.; Liu, X.; Ladisch, M.R.; Garimella, S.V. Enhanced antimicrobial efficacy of bimetallic porous CuO microspheres decorated with Ag nanoparticles. ACS Appl. Mater. Interfaces 2017, 9, 39165–39173. [Google Scholar] [CrossRef] [PubMed]

- Lu, Z.; Mao, C.; Meng, M.; Liu, S.; Tian, Y.; Yu, L.; Sun, B.; Li, C.M. Fabrication of CeO2 nanoparticle-modified silk for UV protection and antibacterial applications. J. Colloid Interface Sci. 2014, 435, 8–14. [Google Scholar] [CrossRef] [PubMed]

- Jing, L.; Xu, Y.; Huang, S.; Xie, M.; He, M.; Xu, H.; Li, H.; Zhang, Q. Novel magnetic CoFe2O4/Ag/Ag3VO4 composites: Highly efficient visible light photocatalytic and antibacterial activity. Appl. Catal. B Environ. 2016, 199, 11–22. [Google Scholar] [CrossRef]

- Xu, Y.; Liu, Q.; Liu, C.; Zhai, Y.; Xie, M.; Huang, L.; Xu, H.; Li, H.; Jing, J. Visible-light-driven Ag/AgBr/ZnFe2O4 composites with excellent photocatalytic activity for E. coli disinfection and organic pollutant degradation. J. Colloid Interface Sci. 2018, 512, 555–566. [Google Scholar] [CrossRef] [PubMed]

- Yin, Z.; Li, C.; Liu, X.; Feng, G.; Du, H.L.; Shi, L. Zn-doped TiO2 nanoparticles with high photocatalytic activity synthesized by hydrogen–oxygen diffusion flame. Appl. Catal. B Environ. 2008, 79, 208–215. [Google Scholar] [CrossRef]

- Lin, L.; Yang, Y.; Men, L.; Wang, X.; He, D.; Chai, Y.; Zhao, B.; Ghoshroy, S.; Tang, Q. A highly efficient TiO2@ZnO n-p-n heterojunction nanorod photocatalyst. Nanoscale 2012, 5, 588–593. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Zheng, Y.Z.; Lu, S.; Tao, X.; Che, Y.; Chen, J.F. Visible-light-responsive TiO2-coated ZnO:I nanorod array films with enhanced photoelectrochemical and photocatalytic performance. ACS Appl. Mater. Interfaces 2015, 7, 6093–6101. [Google Scholar] [CrossRef] [PubMed]

- Yuan, S.; Mu, J.; Mao, R.; Li, Y.; Zhang, Q.; Wang, H. All-nanoparticle self-assembly ZnO/TiO2; heterojunction thin films with remarkably enhanced photoelectrochemical activity. ACS Appl. Mater. Interfaces 2014, 6, 5719–5725. [Google Scholar] [CrossRef] [PubMed]

- Sun, W.; Meng, S.; Zhang, S.; Zheng, X.; Ye, X.; Fu, X.; Chen, S. Insight into the transfer mechanisms of photogenerated carriers for heterojunction photocatalysts with analogous positions of valence band and conduction band: A case study of ZnO/TiO2. J. Phys. Chem. C 2018, 122, 15409–15420. [Google Scholar] [CrossRef]

- Cheng, P.; Wang, Y.; Xu, L.; Sun, P.; Su, Z.; Jin, F.; Liu, F.; Sun, Y.; Lu, G. High specific surface area urchin-like hierarchical ZnO-TiO2 architectures: Hydrothermal synthesis and photocatalytic properties. Mater. Lett. 2016, 175, 52–55. [Google Scholar] [CrossRef]

- GB/T 18261-2013 Test Method for Anti-Mildew Agents in Controlling Wood Mould and Stain Fungi; Standardization Administration of China: Beijing, China, 2013. (In Chinese)

- Liu, B.; Sun, Y.; Wang, D.; Wang, L.; Zhang, L.; Zhang, X.; Lin, Y.; Xie, T. Construction of a branched ZnO-TiO2 nanorod array heterostructure for enhancing the photovoltaic properties in quantum dot-sensitized solar cells. RSC Adv. 2014, 4, 32773–32780. [Google Scholar] [CrossRef]

- Lachom, V.; Poolcharuansin, P.; Laokul, P. Preparation, characterizations and photocatalytic activity of a ZnO/TiO2 nanocomposite. Mater. Res. Express 2017, 4, 035006. [Google Scholar] [CrossRef]

- Li, J.; Yu, H.; Wu, Z.; Wang, J.; He, S.; Ji, J.; Li, N.; Bao, Y.; Huang, C.; Chen, Z. Room temperature synthesis of crystalline anatase TiO2 on bamboo timber surface and their short-term antifungal capability under natural weather conditions. Colloids Surf. A 2016, 508, 117–123. [Google Scholar] [CrossRef]

- Goffredo, G.B.; Citterio, B.; Biavasco, F.; Stazi, F.; Barcelli, S.; Munafò, P. Nanotechnology on wood: The effect of photocatalytic nanocoatings against Aspergillus niger. J. Cult. Herit. 2017, 27, 125–136. [Google Scholar] [CrossRef]

- Velasco, L.F.; Carmona, R.J.; Matos, J.; Ania, C.O. Performance of activated carbons in consecutive phenol photooxidation cycles. Carbon 2014, 73, 206–215. [Google Scholar] [CrossRef] [Green Version]

- Teng, W.; Li, X.; Zhao, Q.; Chen, G. Fabrication of Ag/Ag3PO4/TiO2 heterostructure photoelectrodes for efficient decomposition of 2-chlorophenol under visible light irradiation. J. Mater. Chem. A 2013, 1, 9060–9068. [Google Scholar] [CrossRef]

- Zhao, D.; Sheng, G.; Chen, C.; Wang, X. Enhanced photocatalytic degradation of methylene blue under visible irradiation on graphene@TiO2 dyade structure. Appl. Catal. B Environ. 2012, 111, 303–308. [Google Scholar] [CrossRef]

- Zheng, X.; Li, D.; Li, X.; Chen, J.; Cao, C.; Fang, J.; Wang, J.; He, Y.; Zheng, Y. Construction of ZnO/TiO2 photonic crystal heterostructures for enhanced photocatalytic properties. Appl. Catal. B Environ. 2015, 168–169, 408–415. [Google Scholar] [CrossRef]

- Xiao, F.X. Construction of highly ordered ZnO-TiO2 nanotube arrays (ZnO/TNTs) heterostructure for photocatalytic application. ACS Appl. Mater. Interfaces 2012, 4, 7055–7063. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Zheng, H.; Sun, Q.; Han, S.; Fan, B.; Yao, Q.; Yan, C.; Jin, C. Fabrication of superhydrophobic bamboo timber based on an anatase TiO2 film for acid rain protection and flame retardancy. RSC Adv. 2015, 5, 62265–62272. [Google Scholar] [CrossRef]

- Gao, L.; Lu, Y.; Li, J.; Sun, Q. Superhydrophobic conductive wood with oil repellency obtained by coating with silver nanoparticles modified by fluoroalkyl silane. Holzforschung 2016, 70, 63–68. [Google Scholar] [CrossRef]

- Gao, L.; Lu, Y.; Zhan, X.; Li, J.; Sun, Q. A robust, anti-acid, and high-temperature–humidity-resistant superhydrophobic surface of wood based on a modified TiO2 film by fluoroalkyl silane. Surf. Coat. Technol. 2015, 262, 33–39. [Google Scholar] [CrossRef]

- Wang, J.; Jin, C.; Sun, Q.; Zhang, Q. Fabrication of nanocrystalline anatase TiO2 in a graphene network as a bamboo coating material with enhanced photocatalytic activity and fire resistance. J. Alloys Compd. 2017, 702, 418–426. [Google Scholar] [CrossRef]

| Rating | Description |

|---|---|

| 0 | No fungal growth |

| 1 | The area of fungal infection is <25% |

| 2 | The area of fungal infection is 25%–50% |

| 3 | The area of fungal infection is 50%–75% |

| 4 | The area of fungal infection is >75% |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ren, D.; Li, J.; Xu, J.; Wu, Z.; Bao, Y.; Li, N.; Chen, Y. Efficient Antifungal and Flame-Retardant Properties of ZnO-TiO2-Layered Double-Nanostructures Coated on Bamboo Substrate. Coatings 2018, 8, 341. https://doi.org/10.3390/coatings8100341

Ren D, Li J, Xu J, Wu Z, Bao Y, Li N, Chen Y. Efficient Antifungal and Flame-Retardant Properties of ZnO-TiO2-Layered Double-Nanostructures Coated on Bamboo Substrate. Coatings. 2018; 8(10):341. https://doi.org/10.3390/coatings8100341

Chicago/Turabian StyleRen, Danjing, Jingpeng Li, Jun Xu, Zaixing Wu, Yongjie Bao, Neng Li, and Yuhe Chen. 2018. "Efficient Antifungal and Flame-Retardant Properties of ZnO-TiO2-Layered Double-Nanostructures Coated on Bamboo Substrate" Coatings 8, no. 10: 341. https://doi.org/10.3390/coatings8100341