Composition and Structure Evolution of Bi2O3 Coatings as Efficient Photocatalysts

Abstract

:1. Introduction

2. Experimental

2.1. Preparation of Bi2O3 Photocatalyst Coatings

2.2. Characterization

2.3. Photocatalytic Activity

3. Results and Discussion

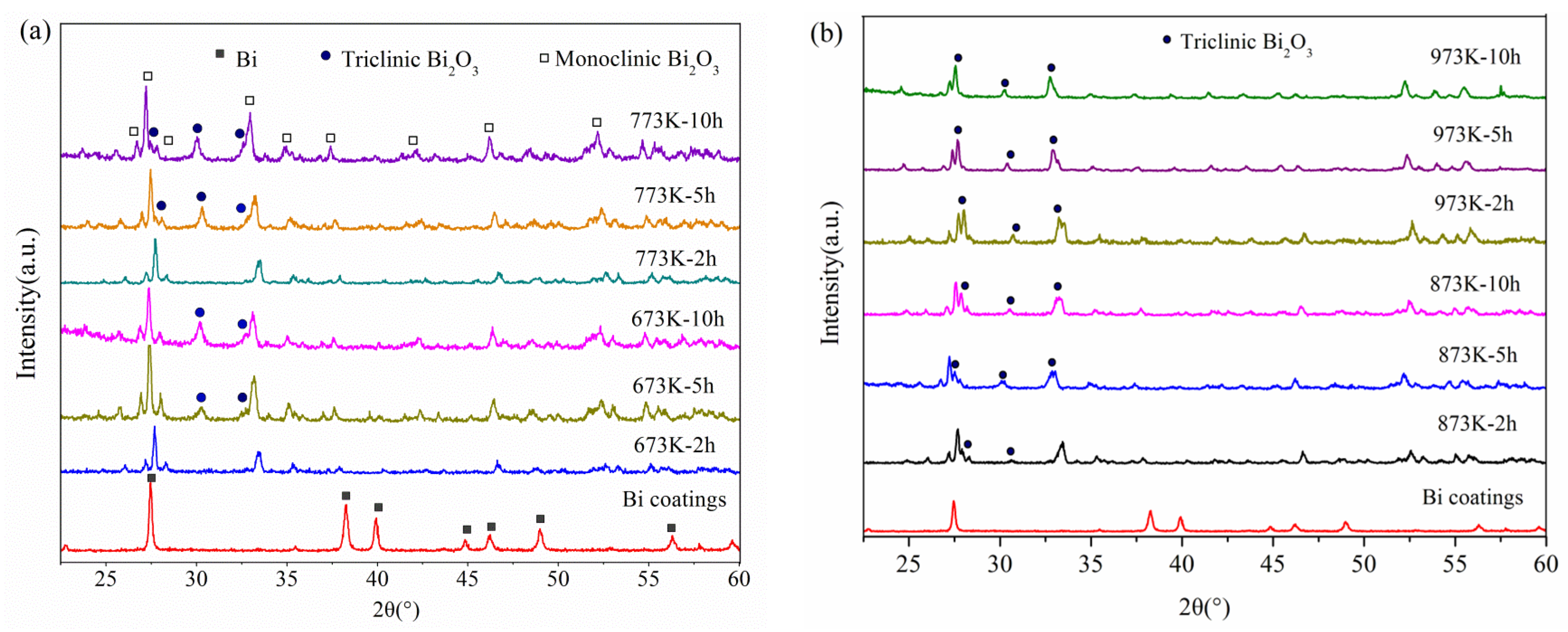

3.1. XRD Patterns

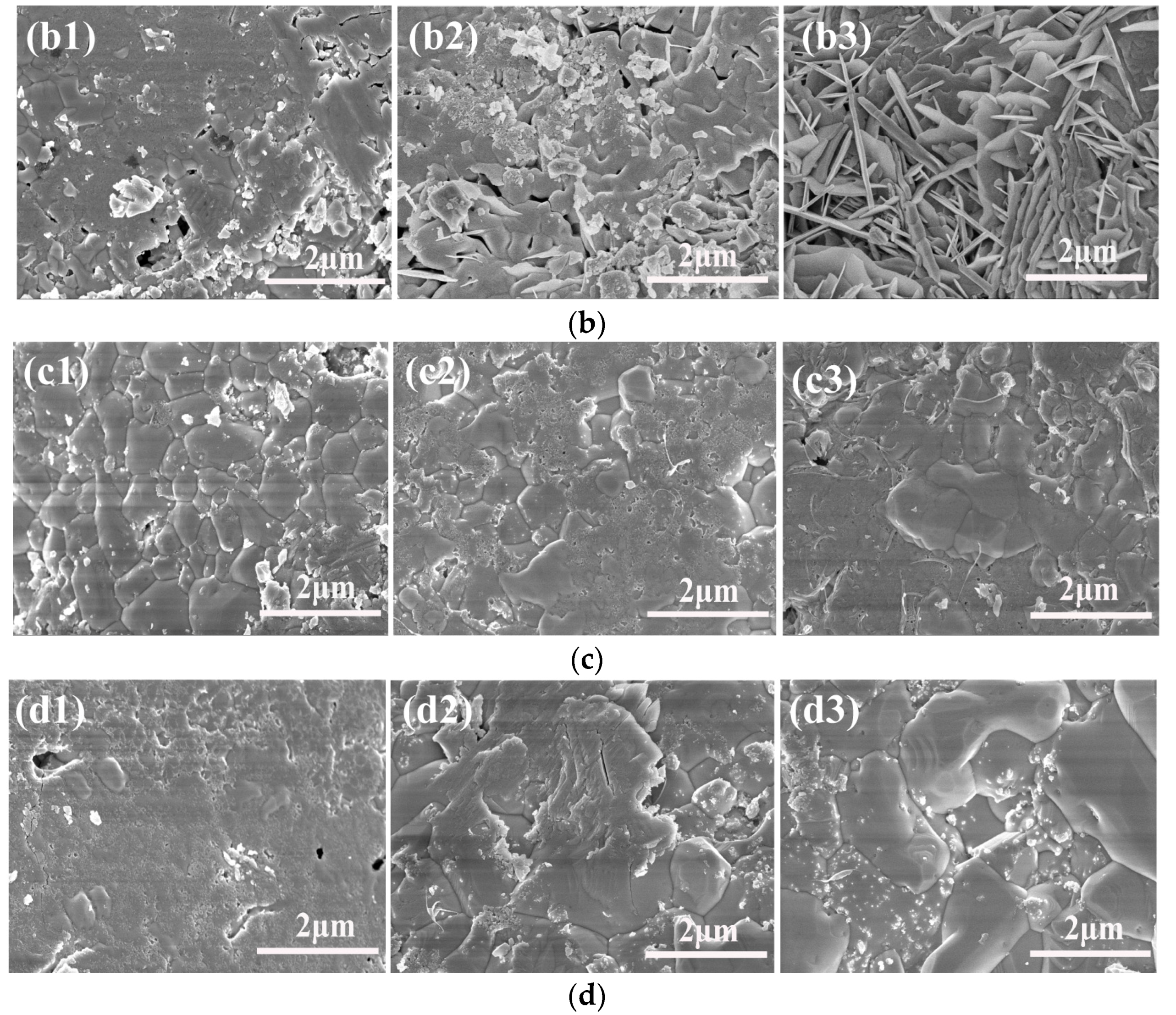

3.2. Microstructure Evolution of the Coatings

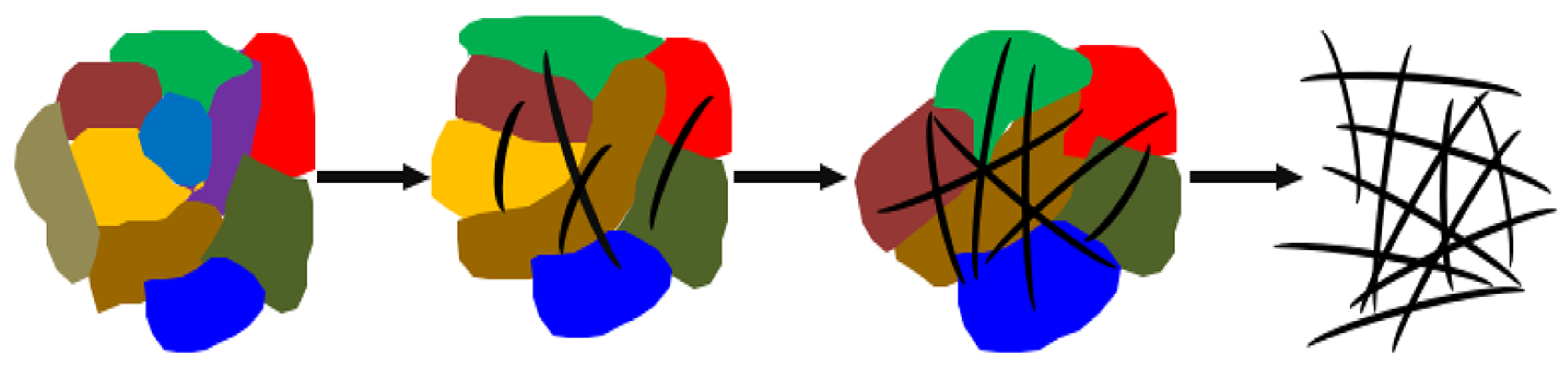

3.3. Structure Evolution Mechanism

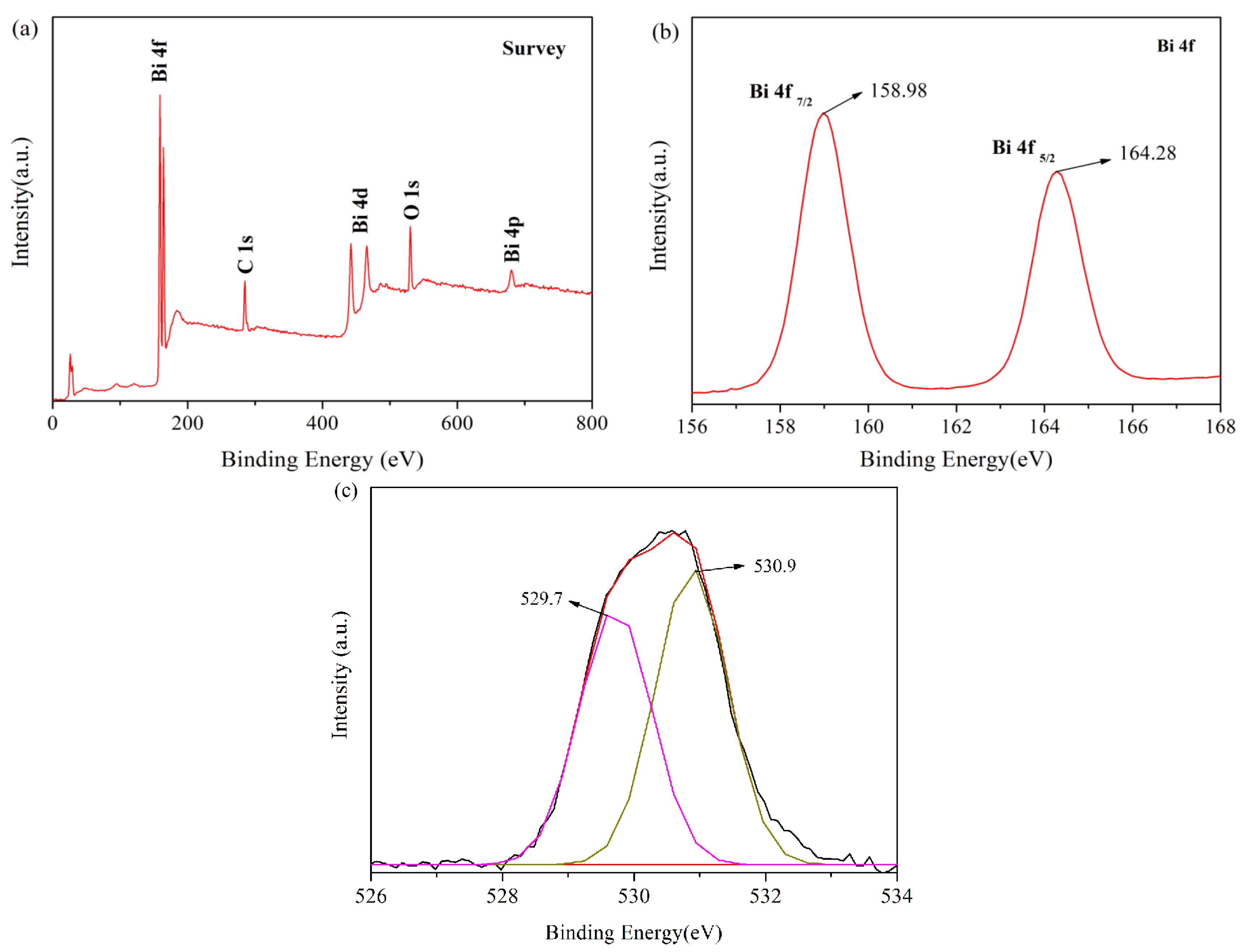

3.4. XPS

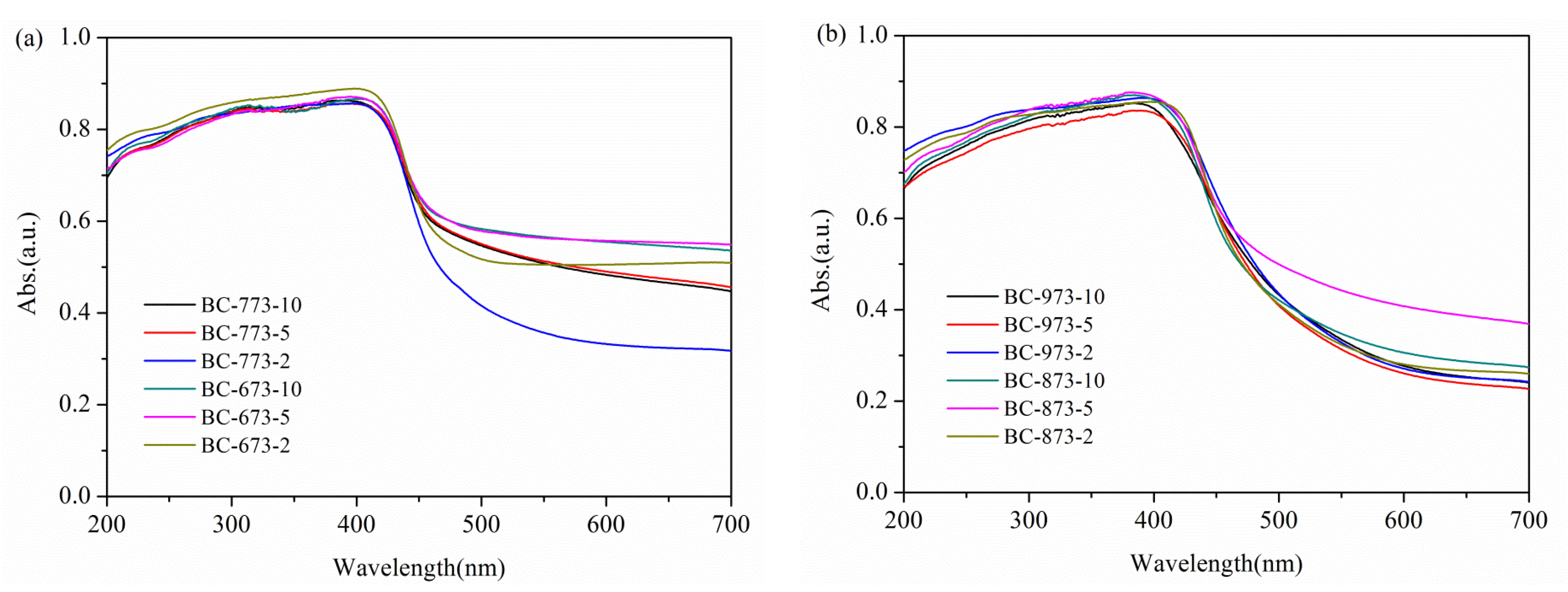

3.5. UV-Vis Diffuse Reflectance Spectra

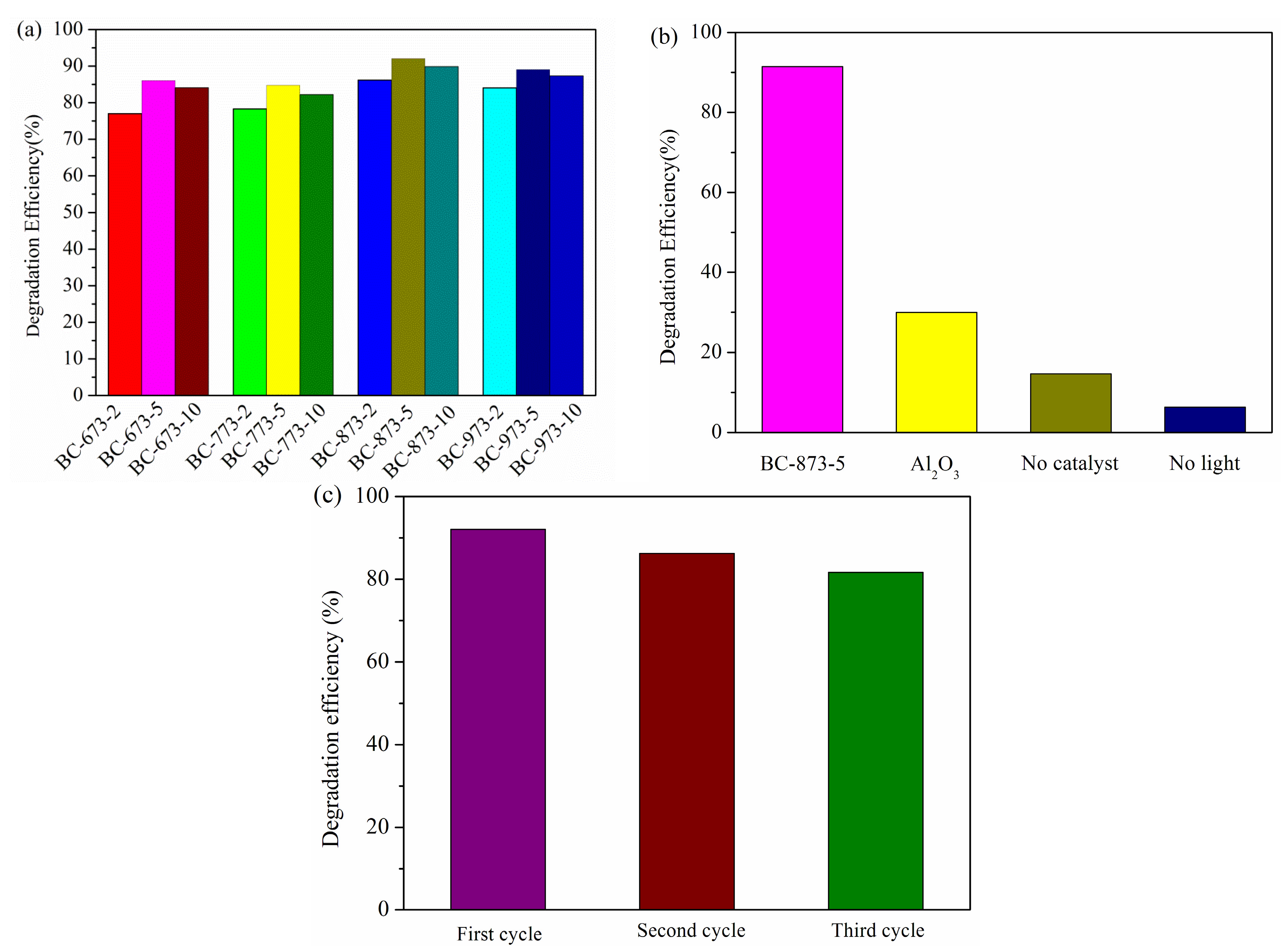

3.6. Photocatalytic Activities for Organic Dye

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Cheng, L.; Kang, Y. Synthesis and characterization of Bi2O3/NaBiO3 composite visible light-driven photocatalyst. Mater. Lett. 2013, 97, 125–128. [Google Scholar] [CrossRef]

- Cao, S.; Huang, Q.; Zhu, B.; Yu, J. Trace-level phosphorus and sodium co-doping of g-C3N4 for enhanced photocatalytic H2 production. J. Power Sources 2017, 351, 151–159. [Google Scholar] [CrossRef]

- Navabpour, P.; Cooke, K.; Sun, H.L. Photocatalytic properties of doped TiO2 coatings deposited using reactive magnetron sputtering. Coatings 2017, 7, 10. [Google Scholar] [CrossRef]

- Lin, T.; Yang, C.; Wang, Z.; Yin, H.; Lü, X.; Huang, F.; Lin, J.; Xie, X.; Jiang, M. Effective nonmetal incorporation in black titania with enhanced solar energy utilization. Energy Environ. Sci. 2014, 7, 967–972. [Google Scholar] [CrossRef]

- Wu, J.; Lu, H.; Zhang, X.; Raziq, F.; Qu, Y.; Jing, L. Enhanced charge separation of rutile TiO2 nanorods by trapping holes and transferring electrons for efficient cocatalyst-free photocatalytic conversion of CO2 to fuels. Chem. Commun. 2016, 52, 5027–5029. [Google Scholar] [CrossRef] [PubMed]

- Ratova, M.; Kelly, P.J.; West, G.T.; Tosheva, L. A novel technique for the deposition of bismuth tungstate onto titania nanoparticulates for enhancing the visible light photocatalytic activity. Coatings 2016, 6, 29. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, Y.; Zhang, T.; Dong, F.; Huang, H. Readily attainable spongy foam photocatalyst for promising practical photocatalysis. Appl. Catal. B Environ. 2017, 208, 75–81. [Google Scholar] [CrossRef]

- Gadhi, T.A.; Hernandez-Gordillo, A.; Bizarro, M.; Jagdale, P.; Tagliaferro, A.; Rodil, S.E. Efficient alpha/beta-Bi2O3 composite for the sequential photodegradation of two-dyes mixture. Ceram. Int. 2016, 42, 13065–13073. [Google Scholar] [CrossRef]

- Cheng, L.; Kang, Y. Bi5O7I/Bi2O3 composite photocatalyst with enhanced visible light photocatalytic activity. Catal. Commun. 2015, 72, 16–19. [Google Scholar] [CrossRef]

- Medina, J.C.; Bizarro, M.; Silva-Bermudez, P.; Giorcelli, M.; Tagliaferro, A.; Rodil, S.E. Photocatalytic discoloration of methyl orange dye by delta-Bi2O3 thin films. Thin Solid Films 2016, 612, 72–81. [Google Scholar] [CrossRef]

- Yan, Y.; Zhou, Z.; Cheng, Y.; Qiu, L.; Gao, C.; Zhou, J. Template-free fabrication of α- and β-Bi2O3 hollow spheres and their visible light photocatalytic activity for water purification. J. Alloys Compd. 2016, 605, 102–108. [Google Scholar] [CrossRef]

- Wang, Y.; Zhao, J.; Zhou, B.; Zhao, X.; Wang, Z.; Zhu, Y. Three-dimensional hierarchical flowerlike microstructures of α-Bi2O3 constructed of decahedrons and rods. J. Alloys Compd. 2014, 592, 296–300. [Google Scholar] [CrossRef]

- Kıranşan, M.; Khataee, A.; Karaca, S.; Sheydaei, M. Artificial neural network modeling of photocatalytic removal of a disperse dye using synthesized of ZnO nanoparticles on montmorillonite. Spectrochim. Acta A 2015, 140, 465–473. [Google Scholar] [CrossRef] [PubMed]

- Tamilselvi, S.; Asaithambi, M.; Sivakumar, P. Nano-TiO2-loaded activated carbon fiber composite for photodegradation of a textile dye. Desalin. Water Treat. 2016, 57, 15495–15502. [Google Scholar] [CrossRef]

- Djellabi, R.; Ghorab, M.F.; Cerrato, G.; Morandi, S.; Gatto, S.; Oldani, V.; Di Michele, A.; Bianchi, C.L. Photoactive TiO2-montmorillonite composite for degradation of organic dyes in water. J. Photochem. Photobiol. A 2014, 295, 57–63. [Google Scholar] [CrossRef]

- Jin, L.; Dai, B. TiO2 activation using acid-treated vermiculite as a support: Characteristics and photoreactivity. Appl. Surf. Sci. 2012, 258, 3386–3392. [Google Scholar] [CrossRef]

- Wang, L.; Wang, X.; Cui, S.; Fan, X.; Zu, B.; Wang, C. TiO2 supported on silica nanolayers derived from vermiculite for efficient photocatalysis. Catal. Today 2013, 216, 95–103. [Google Scholar] [CrossRef]

- Zhang, W.; Bi, F.; Yu, Y.; He, H. Phosphoric acid treating of ZSM-5 zeolite for the enhanced photocatalytic activity of TiO2/HZSM-5. J. Mol. Catal. A Chem. 2013, 372, 6–12. [Google Scholar] [CrossRef]

- Pham, T.D.; Lee, B.K. Feasibility of silver doped TiO2 glass fiber photocatalyst under visible irradiation as an indoor air germicide. Int. J. Environ. Res. Public Health 2014, 11, 3271–3288. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.Z.; Hui, J.; Yang, L.; Huang, H.H.; Cai, Y.X.; Yin, S.Q.; Ding, Y.M. Enhanced photocatalytic performance of Bi2O3/H-ZSM-5 composite for rhodamine B degradation under UV light irradiation. Appl. Surf. Sci. 2014, 289, 224–229. [Google Scholar] [CrossRef]

- Zhang, F.; Wang, Z.; Wang, T.; Jia, L.; Wang, C.; Zhang, S. Facile synthesis of Bi2WO6/Bi2O3-loaded polyurethane sponge with enhanced visible light photocatalytic activity. Funct. Mater. Lett. 2016, 9, 1650026. [Google Scholar] [CrossRef]

- Zhou, Y.; Shuai, L.; Jiang, X.; Jiao, F.; Yu, J. Visible-light-driven photocatalytic properties of layered double hydroxide supported-Bi2O3 modified by Pd(II) for methylene blue. Adv. Powder Technol. 2015, 26, 439–447. [Google Scholar] [CrossRef]

- Cheng, L.; Hu, X.; Hao, L. Easily recycled Bi2O3 photocatalyst coatings prepared via ball milling followed by calcination. Appl. Phys. A 2017, 123, 443. [Google Scholar] [CrossRef]

- Liu, G.; Li, S.; Lu, Y.; Zhang, J.; Feng, Z.; Li, C. Controllable synthesis of α-Bi2O3 and γ-Bi2O3 with high photocatalytic activity by α-Bi2O3→γ-Bi2O3→α-Bi2O3 transformation in a facile precipitation method. J. Alloys Compd. 2016, 689, 787–799. [Google Scholar] [CrossRef]

- Zou, H.; Song, M.; Yi, F.; Bian, L.; Liu, P.; Zhang, S. Simulated-sunlight-activated photocatalysis of Methyl Orange using carbon and lanthanum co-doped Bi2O3–TiO2 composite. J. Alloys Compd. 2016, 680, 54–59. [Google Scholar] [CrossRef]

- Huang, J.; Chen, H.; Pang, S.; Liu, G.; Cui, H.; Dong, L.; Liu, X. Preparation and electrocatalytic performance of Bi-modified quartz column particle electrode for phenol degradation. J. Chem. 2015, 2015, 812752. [Google Scholar] [CrossRef]

| Samples | Rate Constants (min−1) |

|---|---|

| BC-673-2 | 0.0091 |

| BC-673-5 | 0.0115 |

| BC-673-10 | 0.0109 |

| BC-773-2 | 0.0092 |

| BC-773-5 | 0.0113 |

| BC-773-10 | 0.0104 |

| BC-873-2 | 0.0125 |

| BC-873-5 | 0.0150 |

| BC-873-10 | 0.0137 |

| BC-973-2 | 0.0109 |

| BC-973-5 | 0.0125 |

| BC-973-10 | 0.0117 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, L.; Hao, L.; Lu, Y. Composition and Structure Evolution of Bi2O3 Coatings as Efficient Photocatalysts. Coatings 2018, 8, 14. https://doi.org/10.3390/coatings8010014

Cheng L, Hao L, Lu Y. Composition and Structure Evolution of Bi2O3 Coatings as Efficient Photocatalysts. Coatings. 2018; 8(1):14. https://doi.org/10.3390/coatings8010014

Chicago/Turabian StyleCheng, Lijun, Liang Hao, and Yun Lu. 2018. "Composition and Structure Evolution of Bi2O3 Coatings as Efficient Photocatalysts" Coatings 8, no. 1: 14. https://doi.org/10.3390/coatings8010014