1. Introduction

In recent years, research in microelectronics mechanical systems, especially silicon base MEMS (Micro Electro Mechanical Systems), has been faced with reliability and service life problems. This is as a result of friction between surfaces such as the shafts, sleeves, pipes, gears, and the micro motor, which is in relative motion and also wears of parts under light load.

Nanometer super-hard film provides a new and effective solution for micro mechanical abrasion problems and is likely to be used as the next generation of sliding, speaking, reading, and writing disk protective film, it can also be used for print head of thermal printer, high fax machine head, and contact sensors because of its wear resistance properties.

Since the 1980s, mechanical properties of CrN

x coatings had been studied, and Cr

2N demonstrated predominant higher hardness and CrN were provided with better oxidation resistance and lower friction coefficient [

1]. Due to its excellent properties such as low friction coefficient, high corrosion resistance, wear resistance, high toughness, and low internal stress, transition metal nitrides CrN

x have been widely used as protective hard films to increase the lifetime and performance of cutting and wear proof tools today. While the main drawback of its hardness (20 GPa) [

2] restrict the use of CrN. A new generation of intelligent film, which can function very well under extreme conditions, such as high speed, dry cutting, high temperature, and surface oxidation is thus needed. Therefore, the study of friction and wear behavior of thin film over broad range of ambient conditions is of great significance. It has been reported that soft phases (Ag, Cu, Au, etc.) were effective to decrease the friction coefficient over broad working temperature range. Lihua Yu et al. [

3] synthesized the WCN-Ag film containing 6.6 at.% Ag has a low friction coefficient (<0.4) in the temperature range of 25–600 °C. The NbN-Ag composite films [

4] reported a decreased friction coefficient from 0.65 at 0 at.% Ag to 0.35 at 19.9 at.% Ag at room temperature. Shtansky et al. [

5] deposited MoCN-Ag films which maintained low friction coefficient over a wide temperature. Similarly, the role of V element working at high temperature as a result of the generation of V

2O

5 lubricating phase also has been studied extensively, such as CrV

xN [

6], TiAlVN [

7], TiAlN/VN [

8], NbVSiN [

9] etc. To further improve the properties of CrN, alloying with other element has been explored extensively [

10,

11,

12]. The superhardness of TiB

2 films has been detected [

13,

14,

15]. Many researchers studied the properties of Ti-Cr-B-N film [

16,

17]. However, there are few data on evaluating the performance of Cr based Cr-Ti-B-N thin film and no reports about the tribological properties at elevated temperature is available as of now.

In this work, the effects of the addition of Ti and B elements on the microstructure, mechanical, and tribological properties of such films were thoroughly investigated.

2. Experimental Details

Cr-Ti-B-N films with different Ti and B content were deposited on silicon wafer and AISI304 stainless steel plates (15 mm × 15 mm × 2 mm) using radio frequency reactive magnetron sputtering system with a pure Cr (99.95 at.%) and a TiB2 compound target (99.9 at.%). Prior to films deposition, the substrates (stainless steel AISI304) were polished with sandpaper and soft cloth used to clean the surface to removed residual scratches. The polished substrate was cleaned for 15 min ultrasonically in acetone and alcohol, then sent into the sputtering chamber. The base pressure of sputtering chamber was reduced to less than 6.0 × 10−4 Pa, and the pressure during deposition was set at 3.0 × 10−1 Pa. The distance between targets and substrates was 78 mm. A two hour deposition process was carried out in the presence of an Argon gas (Ar) and Nitrogen gas (N2) with constant Chromium target power and various TiB2 target power. Before the sputtering of Cr-Ti-B-N films, 10 min deposition of Cr (target power, 200 W) was conducted in a pure Argon atmosphere as the transition layer to confirm a good adhesion force of the films. The samples were located on a rotating plate which ensures homogeneous and uniform films deposited on the surface of the substrates.

The phase structures were evaluated with glancing incident X-ray diffraction with a Siemens X-ray diffractometer, with Cu Kα radiation, operated at 30 kV and 40 mA. The cross-sectional morphologies and component analysis of thin films were examined with a field emission scanning electron microscopy (FE-SEM, Merlin Compact-6170, ZEISS, Jena, Germany) which was operated at 20 kV and an Energy Disperse Spectroscopy (EDS Merlin Compact-6170, ZEISS, Germany) respectively.

The microstructure was analyzed by a high resolution transmission electron microscopy (HRTEM, JEOL, JEM-2100F, Tokyo, Japan) operated at 200 kV. The nanoindentation hardness and elastic modulus were all investigated by means of nanoindenter (CPX + NHT2 + MST), equipped with a diamond Berkovich indenter tip (3-side pyramid). An automatic indentation mode was programmed to place indentations with a 3 × 3 array, averaging data on the hardness of the film. The maximum load of 3 mN was used to meet the criterion of d/h < 0.1, averting the influence of the substrate during the hardness test, where d is the indenter penetration depth into the film, h is the film thickness. The ball-on-disc dry wear test was conducted on the stainless steel substrates at ambient conditions by using a UTM-2 CETR tribometer with an alumina ball as counterpart (diameter, 9.38 mm). The normal load, sliding speed, sliding time, and radius of wear track during the tests were 3 N, 50 r/min, 30 min and 4 mm, respectively. The wear tracks morphologies were examined with a 3D profilometer (Bruker DEKTAK-XT, Billerica, MA, USA) and wear rate (Ws) of the films were calculated using Equation (1).

where

C is the perimeter of the wear crack (mm),

S is the wear crack area (mm

2),

F is the normal load (N) and

L is the sliding length. The residual stress of the film was determined by means of the Stoney’s formula (Equation (2)).

where

Es is Young’s modulus,

Ts is thickness of substrate,

Rs is curvature radius of substrate, ν

s is Poisson’s ratio of silicon substrate,

Rf is curvature radius of film, and

Tf is thickness of the film. The curvature radii were also examined by the Bruker 3D Profiler.

3. Results and Discussion

3.1. Elemental Compositions and Microstructure of Cr-Ti-B-N Film

Table 1 shows the elemental compositions and film thickness of Cr-Ti-B-N films with various the powers of TiB

2 composite target. As shown in

Table 1, with the increase of the power of TiB

2 composite target, the Cr content in the films gradually decreases, with a corresponding increase of B and Ti content. In addition, the film thickness of the films increases with the increase of the power of TiB

2 composite target.

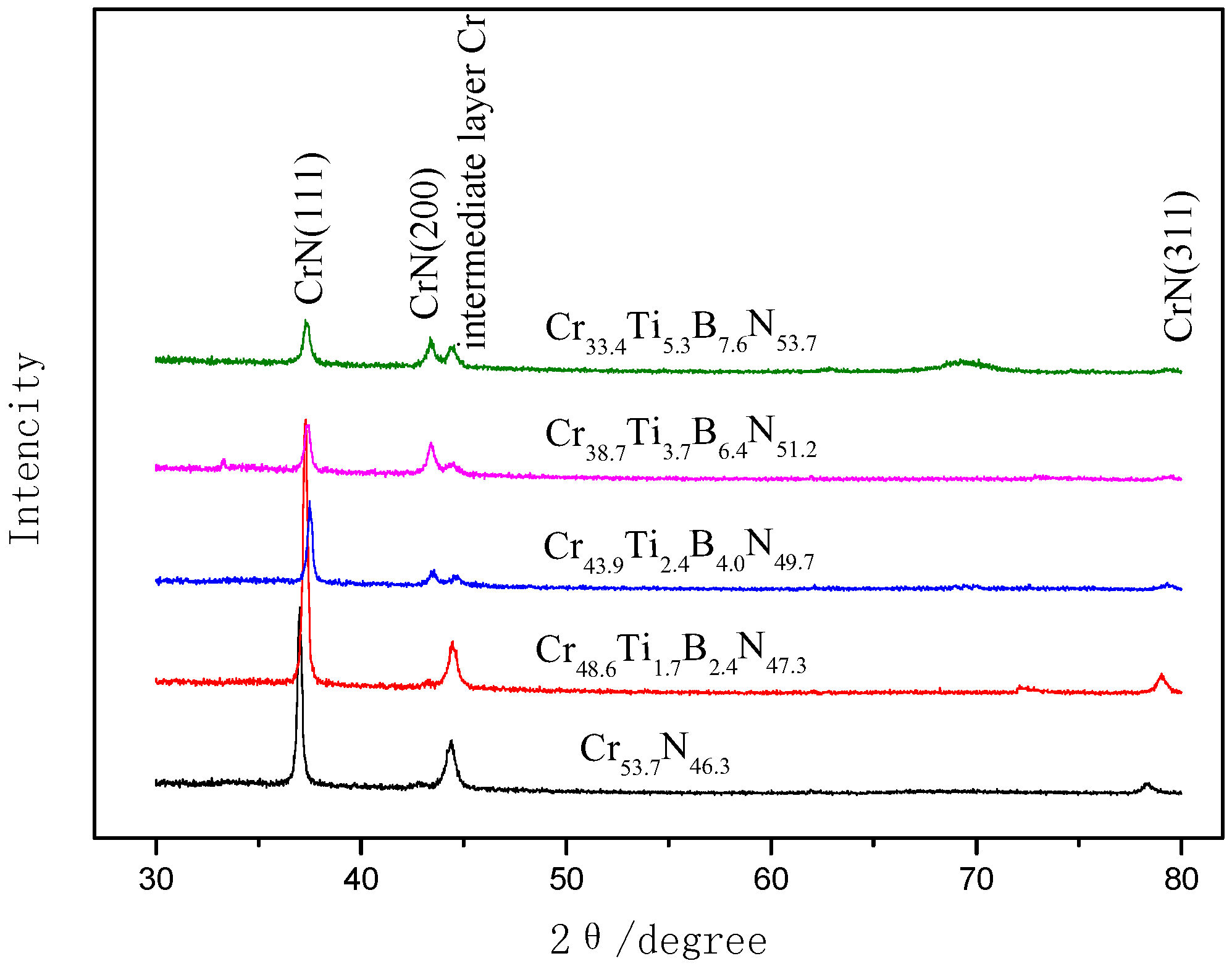

Figure 1 shows the X-ray diffraction patterns of Cr-Ti-B-N films with various Ti and B contents. As shown in

Figure 1, for the binary CrN film, three diffraction peaks at ~36°, ~44° and ~78° are detected, which are corresponding to the face-centered cubic (fcc) CrN (111), Cr interlayer and fcc-CrN (311) repectively, based on the ICCD card 11-0065. For each pattern of quaternary Cr-Ti-B-N films, the diffraction peaks of the films are similar to that of the binary CrN film, and no other diffraction peaks corresponding to the crystalline phases such as TiB

2 and CrB

2 are not observed. Besides this, the diffraction peaks of Cr-Ti-B-N films gradually shift to higher angle, this suggests that the combination of Ti and B elements into the Cr-Ti-B-N films leads to the decrease of the lattice constant. The grain size of the films was calculated by the Scherrer’s equation and the results show that the grain size of the films decreases gradually from about 33 nm for binary CrN film to 15 nm for quaternary Cr

33.4Ti

5.3B

7.6N

53.7 film.

Figure 2 illustrates the cross-sectional SEM images of Cr-Ti-B-N films with various Ti and B contents. As illustrated in the

Figure 2a, the binary CrN film exhibits a columnar-growth and dense structure. As the increase of the Ti and B contents in the films, as shown in

Figure 2b, the columnar-growth and dense structure disappears and the Cr

33.4Ti

5.3B

7.6N

53.7 film shows an isometric structure.

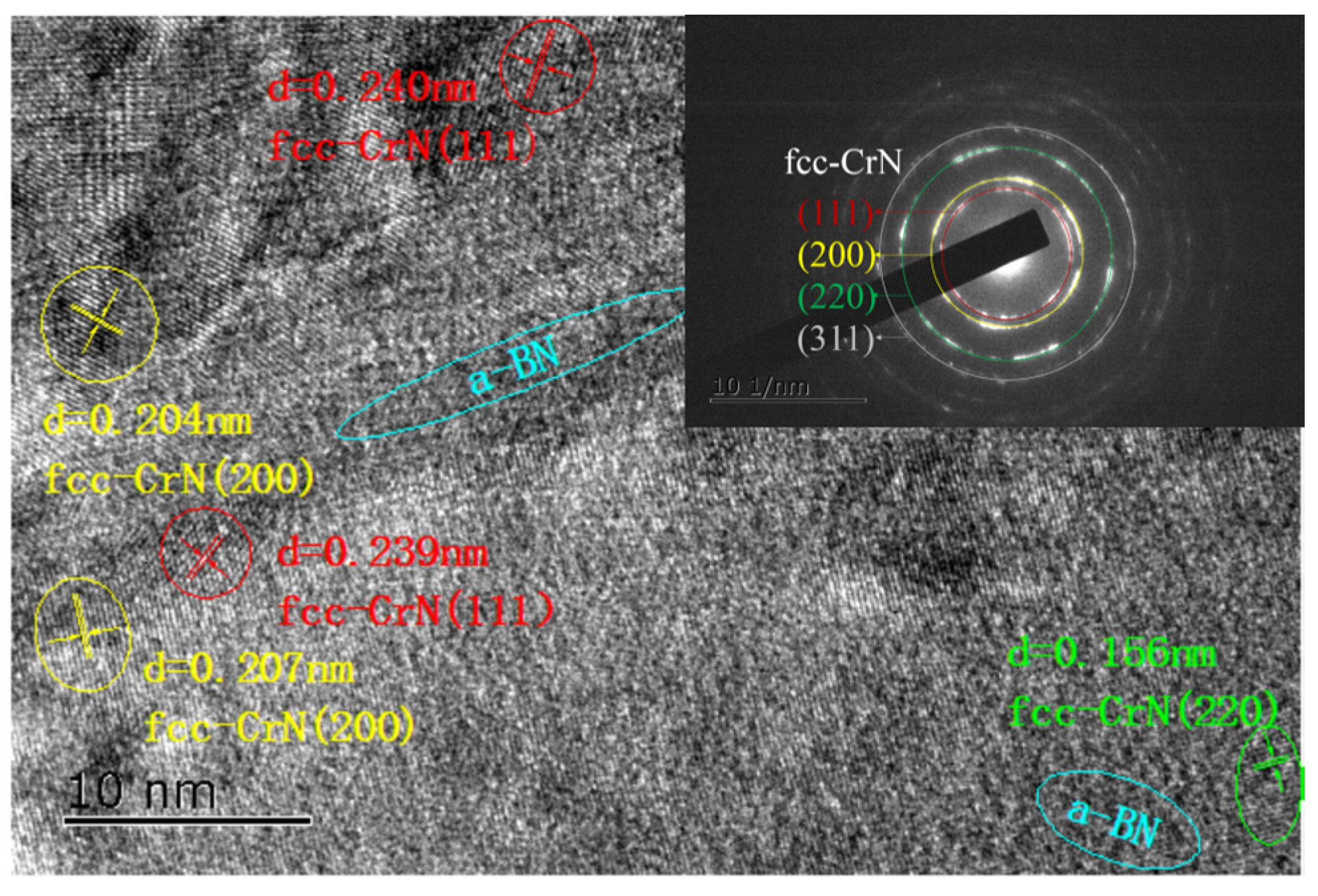

In order to further analyze the microstructure of Cr-Ti-B-N films, the microstructure of Cr

43.9Ti

2.4B

4.0N

49.7 film is investigated by high-resolution transmission electron microscope (HRTEM) and the results is shown in

Figure 3. As shown in

Figure 3, the Cr

43.9Ti

2.4B

4.0N

49.7 film exhibits a nano-composite microstructure and is consisted of nanocrystallites and amorphous phase. Besides this, three different lattice fringes with the lattice spacing of ~0.240 nm, ~0.204 nm, and ~0.156 nm are detected. Those lattice fringes are corresponding to the fcc-CrN (111), (200), and (220), since the values of lattice spacing of fcc-CrN (111), (200), and (220) (ICCD card 11-0065) are 0.2394 nm, 0.2068 nm, 0.1463 nm, and 0.1249 nm, respectively. The corresponding selected area electron diffraction (SEAD) pattern of Cr

43.9Ti

2.4B

4.0N

49.7 film is also shown in

Figure 3 as an inset. The diffraction rings can be referred to as the lattice planes of fcc-CrN (111), (200), (220), and (311). These results are in agreement with the XRD pattern. Similar studies [

18] also reported the existence of BN amorphous phase.

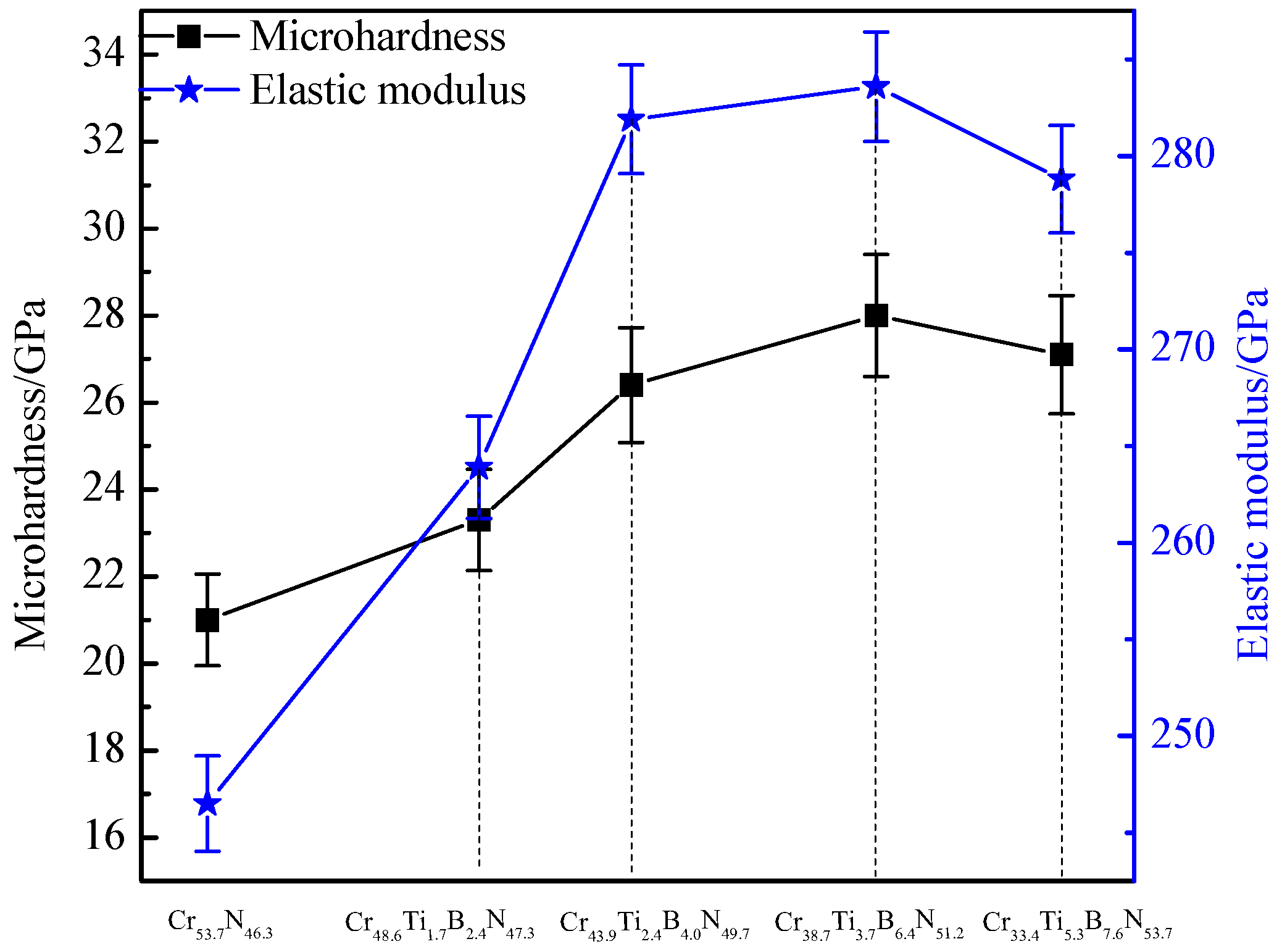

3.2. Mechanical Properties

Figure 4 shows the hardness and elastic modulus of Cr-Ti-B-N films with the increasing Ti and B contents. As the Ti and B elements were introduced, the hardness and elastic modulus of Cr-Ti-B-N films increased from 21 and 246.5 GPa to a maximum value of approximately 28 and 283.6 GPa for Cr

38.7Ti

3.7B

6.4N

51.2 film, and then decreased slightly with further increase of Ti and B contents.

The hardness enhancement might be attributed to the solution of Ti into the films due to the different of radius of Ti, Cr atoms. The radius Cr and Ti is 0.125 nm and 0.146 nm, respectively, with the replacement of Ti into the CrN film, a strong lattice distortion will emerge, thus generate large distortion energy. On the other way, CrN and TiN have the same crystal structure with a face-centered cubic lattice type of NaCl. According to the laws of Hume-Rothery, the smaller radius anion (N) occupied face-centered cubic lattice, while Cr and Ti cations were forced into the pores of octahedral; together with the similar crystal lattice parameters between CrN and TiN, it’s easy to form a continuous supersaturated solid solution. It can be concluded that the solid solution strengthening, the refined crystalline strengthening, and the increase of residual compressive stress all played a role in enhancing the hardness of the film [

19]. While the reduction in hardness with a further increase in Ti and B contents after maximum hardness is as a result of increase of amorphous BN phase [

20,

21,

22].

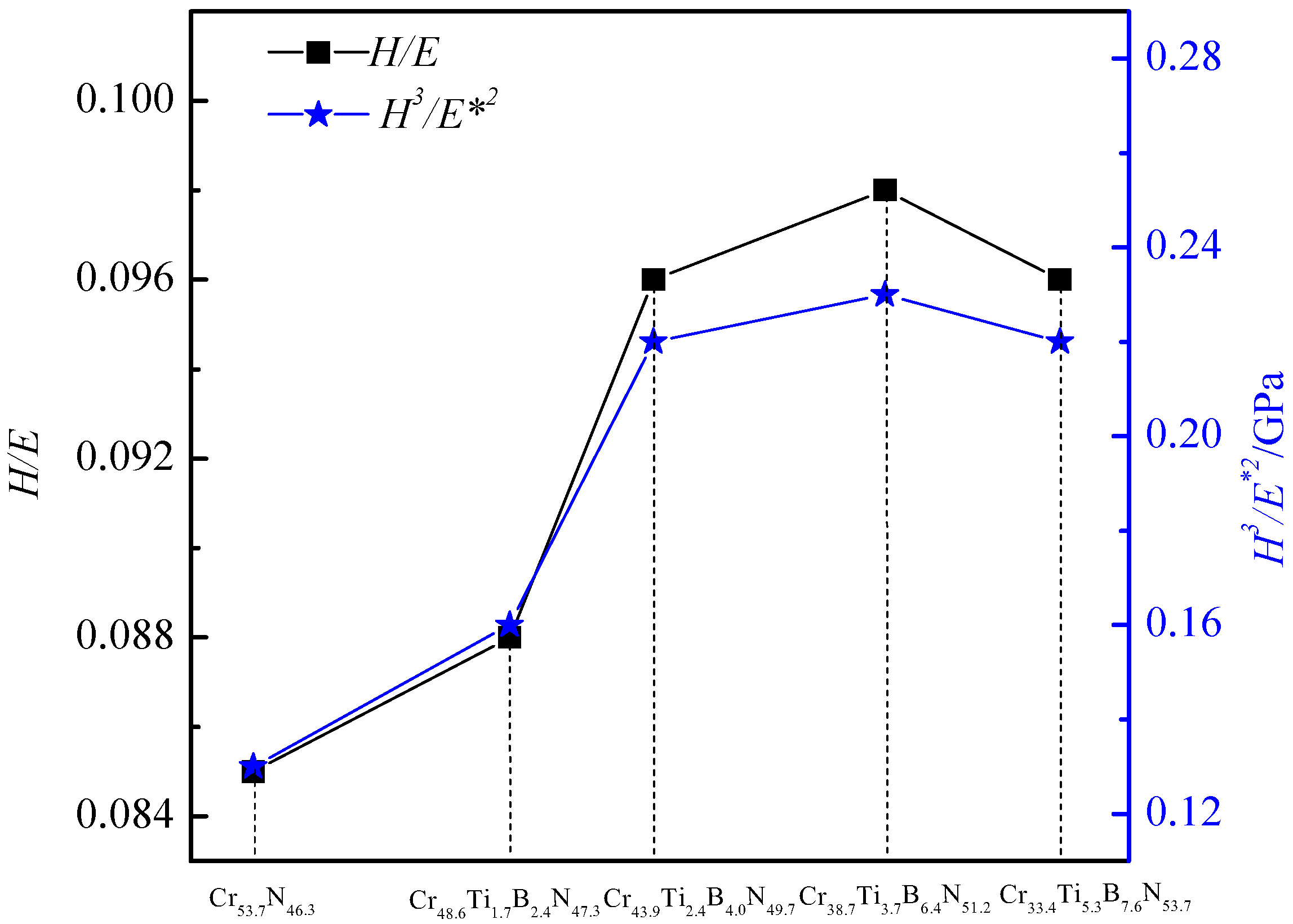

Musil [

23] and Leyland [

24] suggested that the fracture toughness of nanocrystalline films would be improved by high ratios of

H/

E (resistance against elastic strain to failure) and

H3/

E*

2 (resistance against plastic deformation). By examining the

H/E and

H3/E*

2 values of the films, as shown in

Figure 5, it can be seen that Cr-Ti-B-N films exhibit improved

H3/E*

2 values of between 0.16 and 0.22 GPa, as compared to a low value of 0.13 GPa of CrN film. The variation tendency of the values with

H/E and

H3/

E*

2 are corresponding to the variation of the hardness. The highest

H/

E value of 0.098 was found in Cr

38.7Ti

3.7B

6.4N

51.2 films, suggesting this film may exhibit better toughness and wear resistance as compared to the other films.

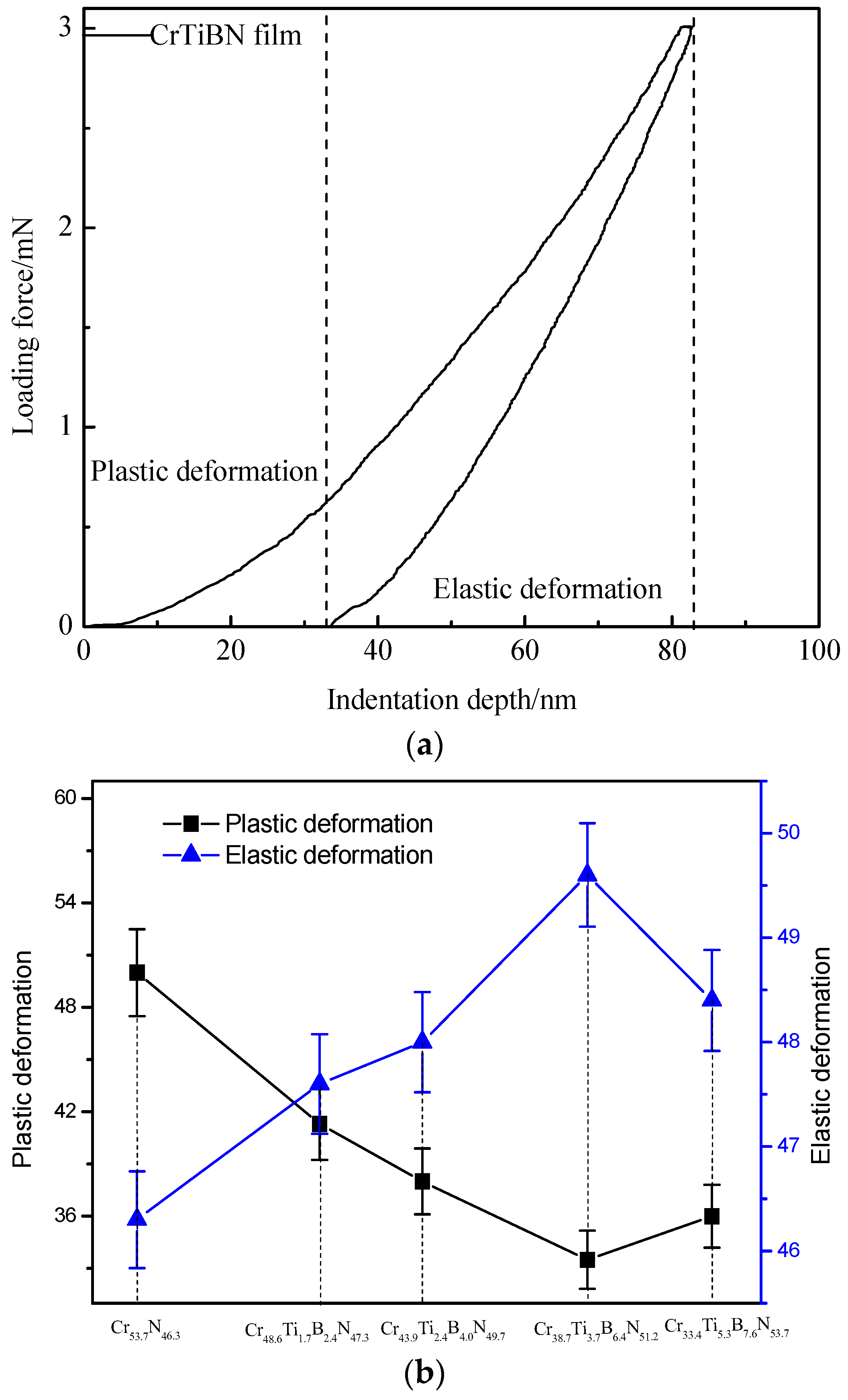

Figure 6a shows the load-displacement curves of Cr

38.7Ti

3.7B

6.4N

51.2 film (3.7 at.% Ti) obtained from the nanoindentation measurement. The amounts of Plastic deformation and Elastic deformation are shown clearly.

Figure 6b shows amount of Plastic deformation and Elastic deformation of Cr-Ti-B-N films with various Ti and B contents. We can conclude that with an increasing of the Ti and B contents, the plastic deformation depths are 50, 41.3, 38.5, 33.6, 36 nm; the elastic deformation displacements are 46.3, 47.6, 48, 49.6, 48.4 nm, respectively which are corresponding to the results of examined

H/

E and

H3/

E*

2 values. The indentation depth decreased with an increasing of the Ti and B contents whiles the hardness increases with an increase of the Ti and B contents.

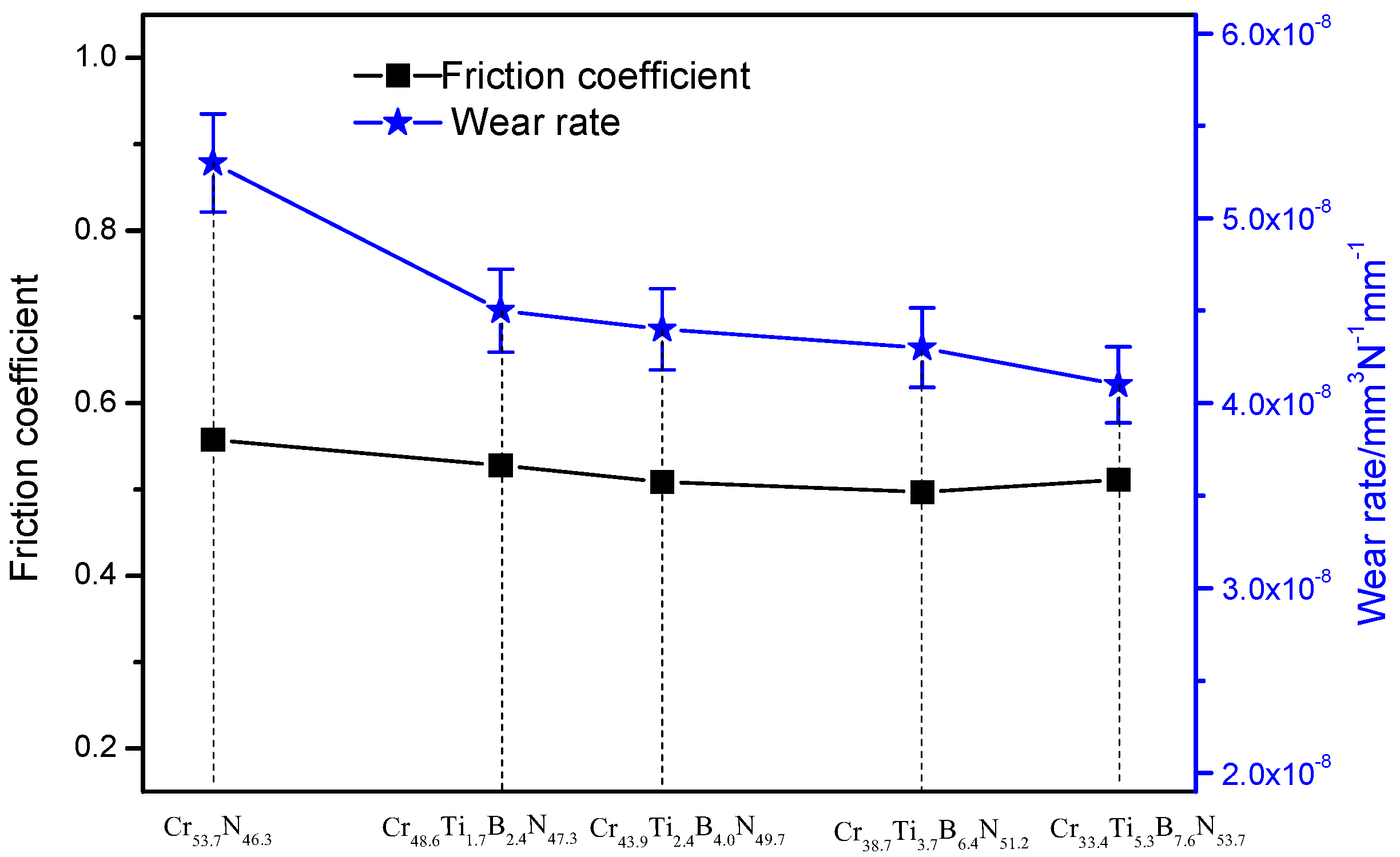

3.3. Tribological Performance at Room Temperature

The ball-on-disk wear test was conducted to evaluate the tribological properties of the films. The wear tests on the film with various Ti and B contents using an Alumina (Al

2O

3) ball was performed. As shown in

Figure 7, the wear rate and friction coefficient decreased with an increase in Ti and B contents from Cr

53.7N

46.3 film to Cr

33.4Ti

5.3B

7.6N

53.7 film and a further increases in Ti and B contents resulted in increase in both wear rate and friction coefficient. Hence the optimal parameter was obtained at a Titanium content of 3.7 at.%, which is in complete agreement with the suggestion that higher wear resistance is achieved with better

H/E and

H3/E*

2 values. The addition of Ti and B marginally decreased the friction coefficient at room temperature.

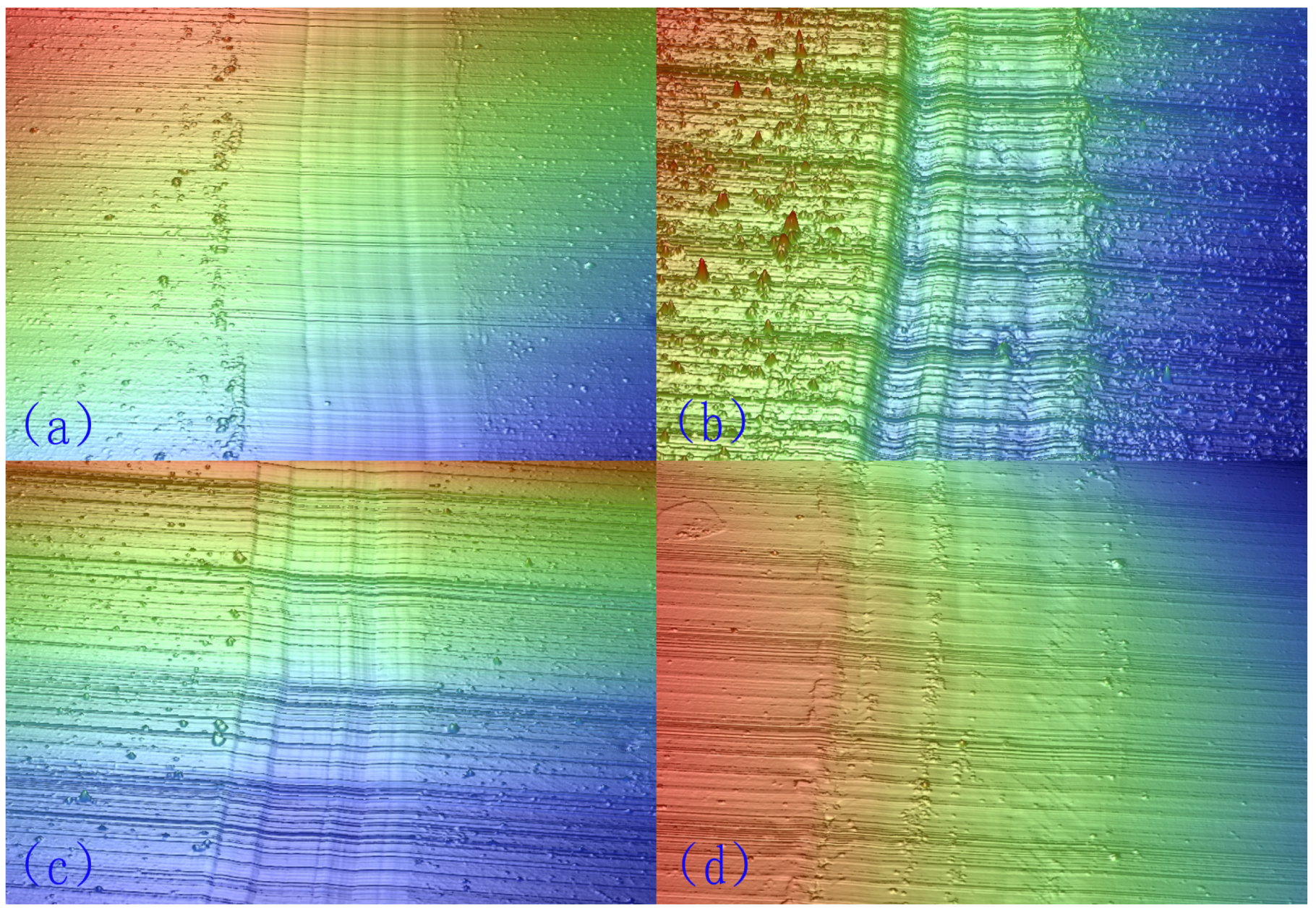

The wear track morphologies of Cr-Ti-B-N films with different Ti and B contents are shown in

Figure 8. The confined and superficial wear track corresponded with the uppermost hardness and a better

H/

E value when the Ti content reached 3.7%. From

Figure 8 we can conclude that the main wear patterns of Cr-Ti-B-N film with different Ti and B contents was abrasive wear, and the wear debris were accumulated at the edge of the wear track. In general, the film showed excellent wear resistance.

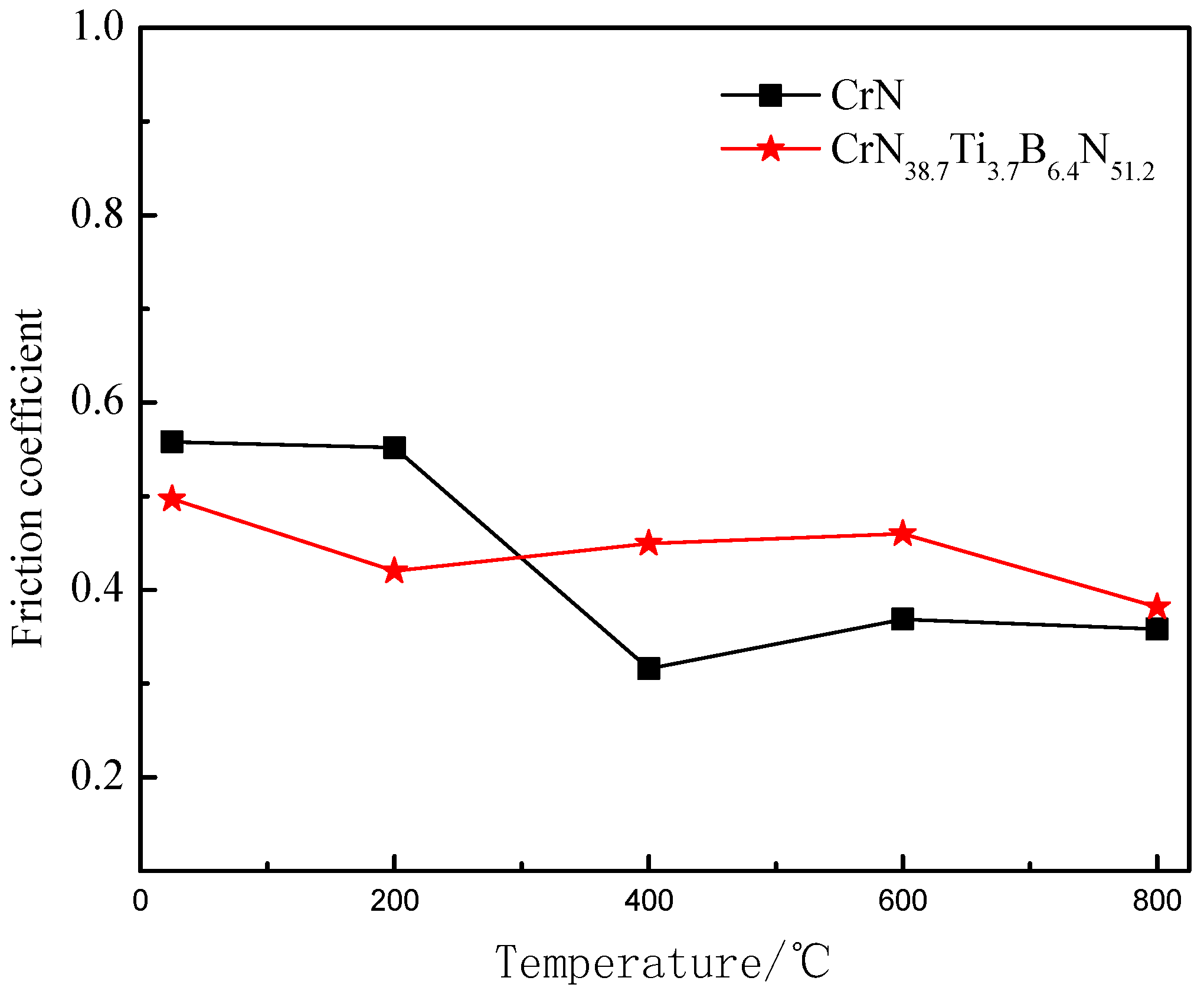

3.4. Tribological Performance at Elevated Temperature

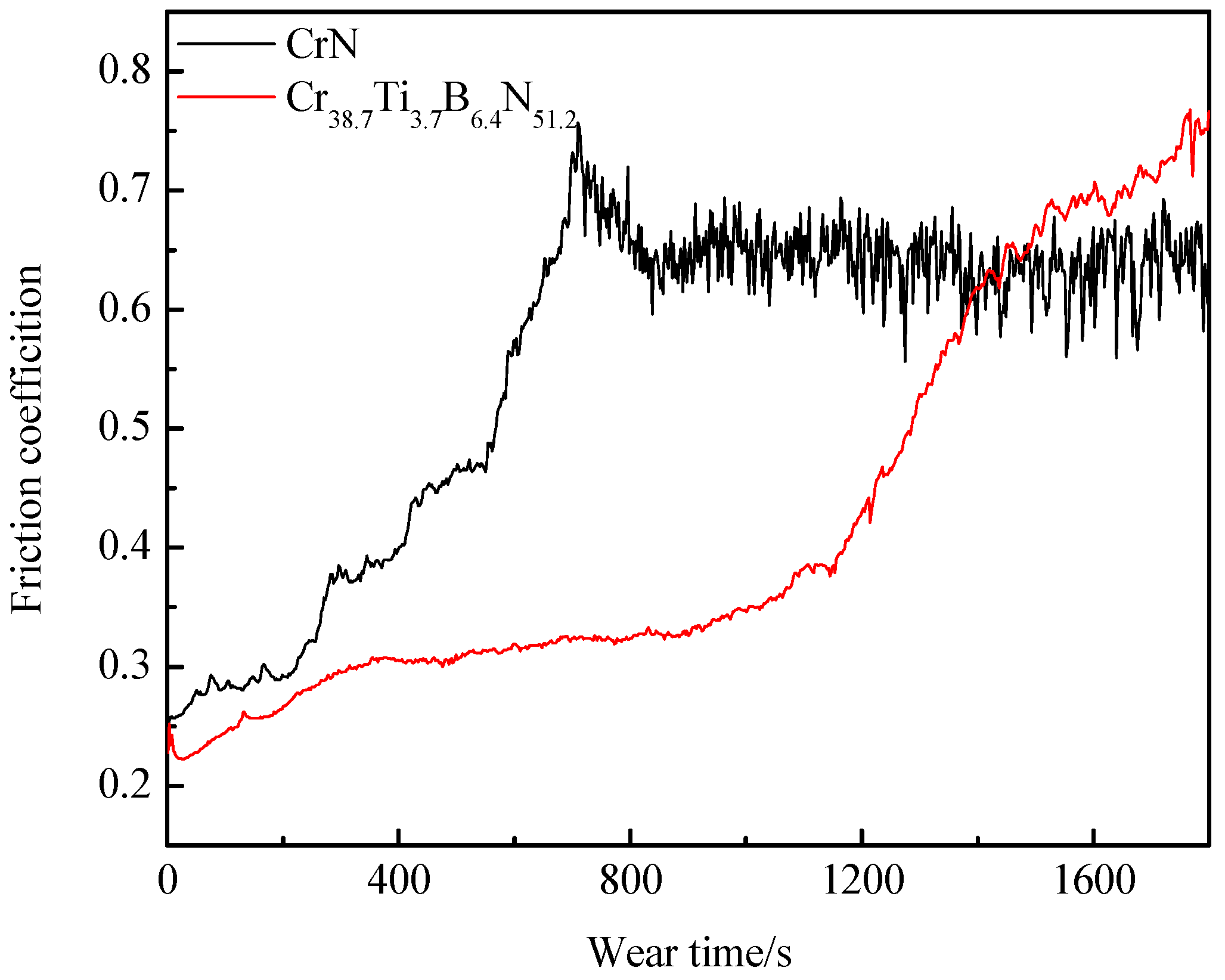

Plots of friction coefficient about CrN film and Cr

38.7Ti

3.7B

6.4N

51.2 composite film at different temperature are shown in

Figure 9. The friction coefficient of both films decreased continually and then tended to a stable value while the value tested at 800 °C showed a decline. The minimum friction coefficient of CrN film was 0.32 obtained at 400 °C while the CrTiBN composite film was 0.38 acquired at 800 °C. As shown in

Figure 9, the addition of Ti and B elements significantly improved the friction resistance under 200 °C. This attributed to the production of boron oxide which with lower shear modulus. With the elevated temperature higher than 400 °C, the boron oxide will melt and volatilization gradually and lots of defects generated at grain boundary, resulting in the rise of friction coefficient [

25].

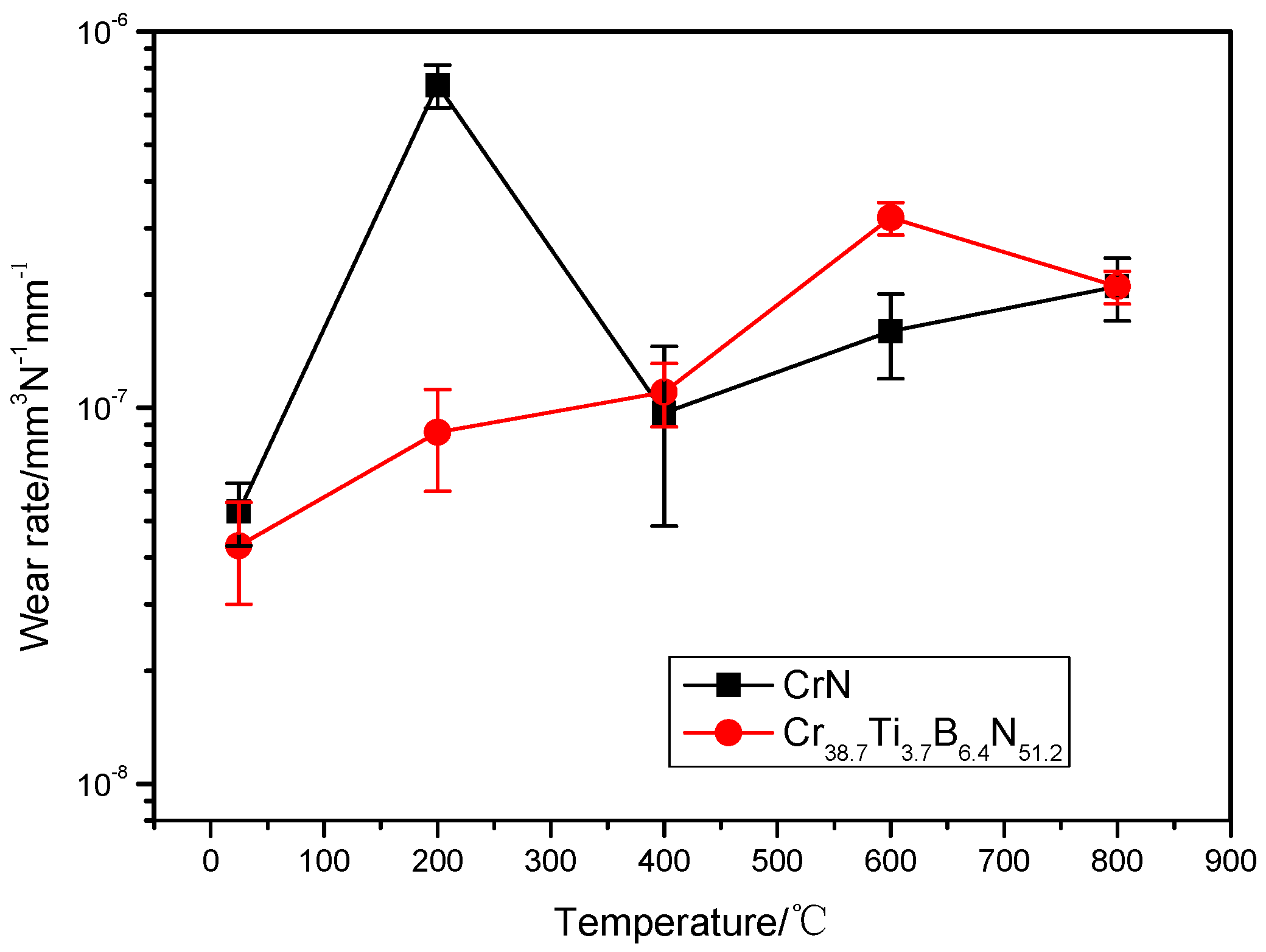

Figure 10 shows the wear rate of CrN film and Cr

38.7Ti

3.7B

6.4N

51.2 composite film at different temperatures. It can be observed that the wear rate increases with an increase in temperature. With the lifted temperature, the wear rate increased gradually which, due to the reduction of hardness and oxidation. The wear rate of CrN film tested at 200 °C rose sharply because of the wear out of the film. The wear resistance of Cr

38.7Ti

3.7B

6.4N

51.2 film was enhanced obviously under 400 °C.

Figure 11 shows the friction coefficient of CrN film and Cr

38.7Ti

3.7B

6.4N

51.2 composite film as a function of wear duration at 200 °C in sliding against Al

2O

3 ball. The CrN film was worn out in 10 min while the Cr

38.7Ti

3.7B

6.4N

51.2 composite film was worn out after 20 min, which indicated an obvious improvement of the friction and wear resistance ability at 200 °C. The wear out of CrN film leads to a relative high value of the results, which are in good agreement of

Figure 9 and

Figure 10.

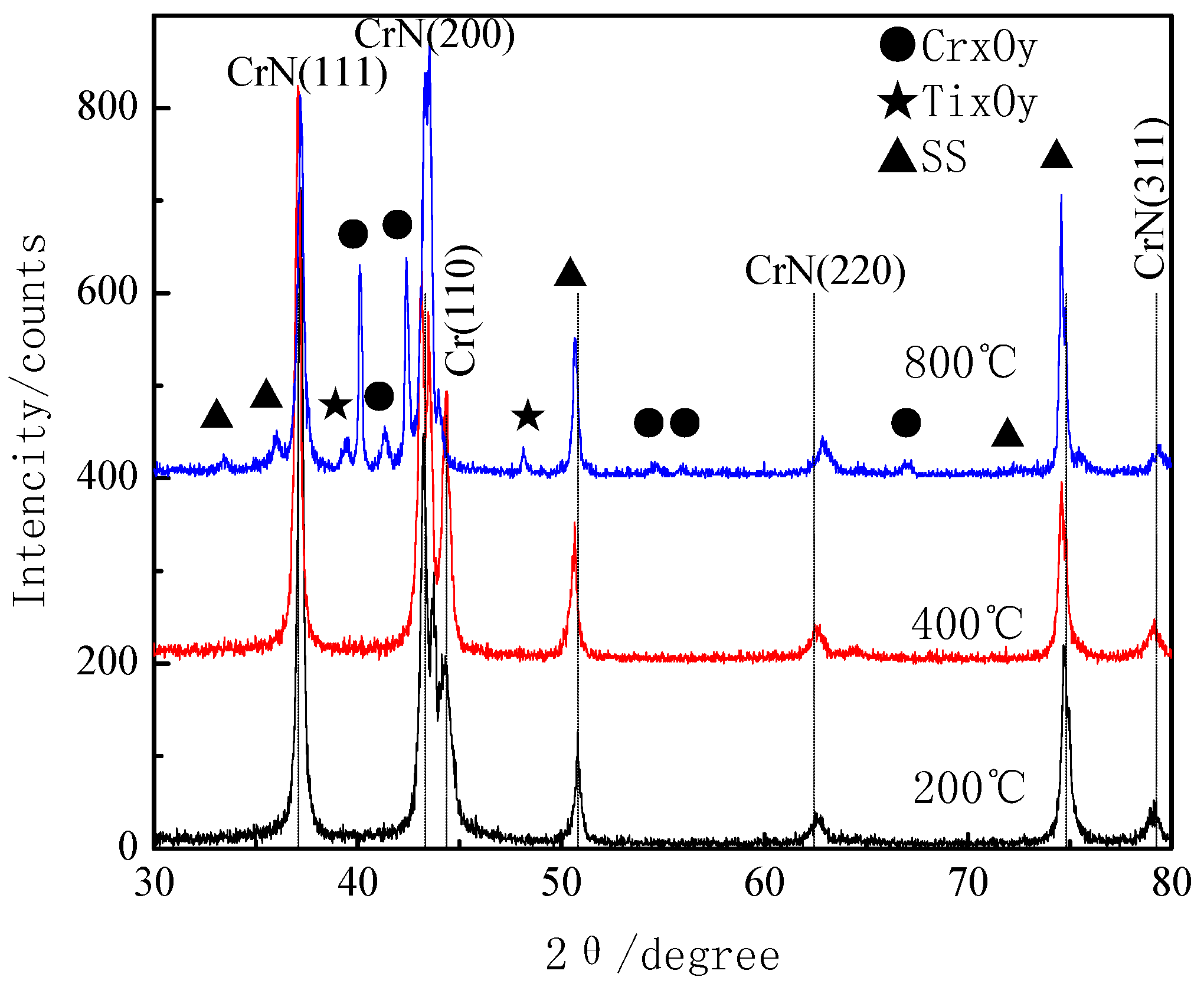

To further confirm the changes in wear rate at different temperatures, the XRD pattern of Cr

38.7Ti

3.7B

6.4N

51.2 film at different temperature are shown in

Figure 12. The slight increase in coefficient of friction and wear rate values are attributed to low hardness, the grains growth and the broader cracks at elevated temperature. While the sudden decrease in values at 800 °C may be as a result of the generation of mass lubricants of oxides such as TiO

2, Cr

2O

3 [

20,

26]. Several oxide peaks of Ti and Cr were detected only at 800 °C which confirms the appearance of oxide lubricants. Pilling and Bedworth first put forward the integrity of the oxide film. The ratio of volume fraction of metal oxide compared to metal is as a judgment of oxide film intactness, namely the PBR (Pilling Bedworth Ratio). Practice has proved that good protective oxide film of PBR value should be 1 < PBR < 2.5. The PBR values of TiO

2 and Cr

2O

3 were 1.95 and 1.99, respectively. In other words, the temperature of the grinding crack area is higher than the actual set temperature, and then the phase change of materials [

27,

28] caused by the high temperature and the flash temperature of friction made the wear aggravation.

Figure 13 shows the changes of atomic fraction of Oxygen (O) of Cr

38.7Ti

3.7B

6.4N

51.2 film after wear test at different temperature. EDS results show increase in Oxygen content as a function of temperature. Compared with the film out of the grinding crack zone, the oxygen content within the trajectory was significantly increased. This is mainly because friction makes the contact surface temperature higher and then oxidation reactions are more likely to proceed.

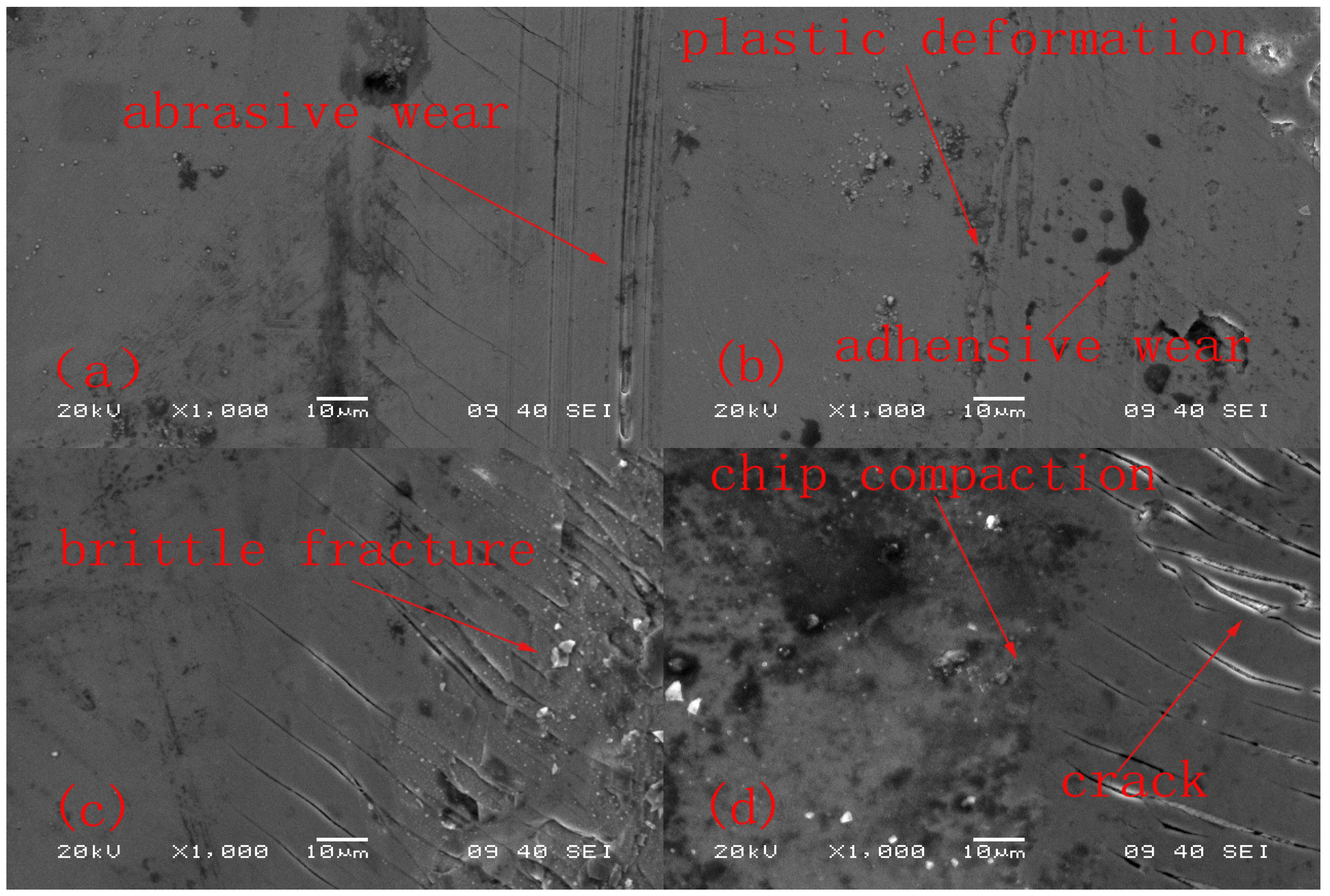

The SEM morphologies of wear track of Cr

38.7Ti

3.7B

6.4N

51.2 film at elevated temperatures are shown in

Figure 14. The wear track morphologies at different temperature reveal diverse worn out mechanisms such as abrasive wear, adhesive wear, plastic deformation, and crack etc. The wear track of Cr

38.7Ti

3.7B

6.4N

51.2 film tested at 800 °C exhibited obvious micro-cracks. Surface micro-cracks may have an effect of storing lubricants and collecting the wear debris produced in the process of wear testing. The hard grinding grain was collected within the micro cracks, reducing the damage for lubricating film. As a result, the friction coefficient and wear rate decreased evidently and thus prolong the life of the film.

With the oxidation of materials at different temperatures, there were changes in surface morphology and color of the films; this is due to the diverse morphologies of the film under different temperature and the generation of new oxides, respectively. After the wear test, the color of Cr-Ti-B-N film changed from silver to purple at the temperature of 600 °C; however, the uncoated samples color changed to gold at 400 °C. This indicated a higher oxidation resistance of the Cr-Ti-B-N film.

4. Conclusions

Several films of Cr-Ti-B-N with a pure Cr target at a constant radio frequency power of 200 W and a series of TiB2 compound targets were fabricated using the reactive magnetron sputtering system. The microstructure, mechanical, and tribological properties of the film was strongly influenced by the TiB2 target power. The cross-sectional morphology showed that the growth mechanism changed from the columnar crystal to isometric crystal with the addition of Titanium and Boron to CrN film. The Cr-Ti-B-N films exhibited a double face-centered cubic (fcc)-CrN and amorphous-BN structure. As the Ti and B elements were introduced, the hardness and elastic modulus of Cr-Ti-B-N films increased from 21 and 246.5 GPa to a maximum value of approximately 28 and 283.6 GPa for Cr38.7Ti3.7B6.4N51.2 film, and then decreased slightly with further increase of Ti and B contents. The hardness enhancement was attributed to the residual compressive stress. The friction and wear resistance of the film was improved obviously by the addition of Cr and B as compared with the CrN film under 200 °C. It can be conclude that the Cr38.7Ti3.7B6.4N51.2 film exhibited improved hardness and wear resistance over broad ranges of ambient conditions.