3.1. Physical Analysis of the Surface

The AFM is adopted to scan the control group. Samples are processed at 10 and 60 s, while the peak voltage is about 90 kV and the PRF is set as 500 Hz. The scanning area is 1 µm × 1 µm, and

Figure 4 shows the scan results.

As is shown in

Figure 4a, the unprocessed sample surface seems to be very flat. It has few protrusions. The surface roughness (

Ra) of the control sample is 3.794 nm. Through

Figure 4b,c, after the glow-like plasma treatment, many protrusions have appeared on the fabric surface. Moreover, the

Ra increases to 7.221 and 8.392 nm, respectively. The surface becomes rougher with the increase of the processing time. Nevertheless, the augment of the protrusion number from 10 to 60 s is not significant. It indicates that the surface of the PA66 fabric is modified, and there isn’t an obvious effect on its internal characteristics. As an important feature, the amelioration of the fabric’s hydrophilic characteristic can be recognized by this etching phenomenon [

20,

21]. The plasma etching can cause the surface to become rough with the crosslinking on the surface and incorporation of polar functional groups, which leads to the cracking of macromolecules and the degrading of the surface layer. Accordingly, the hydrophilicity of the PA66 material can be improved.

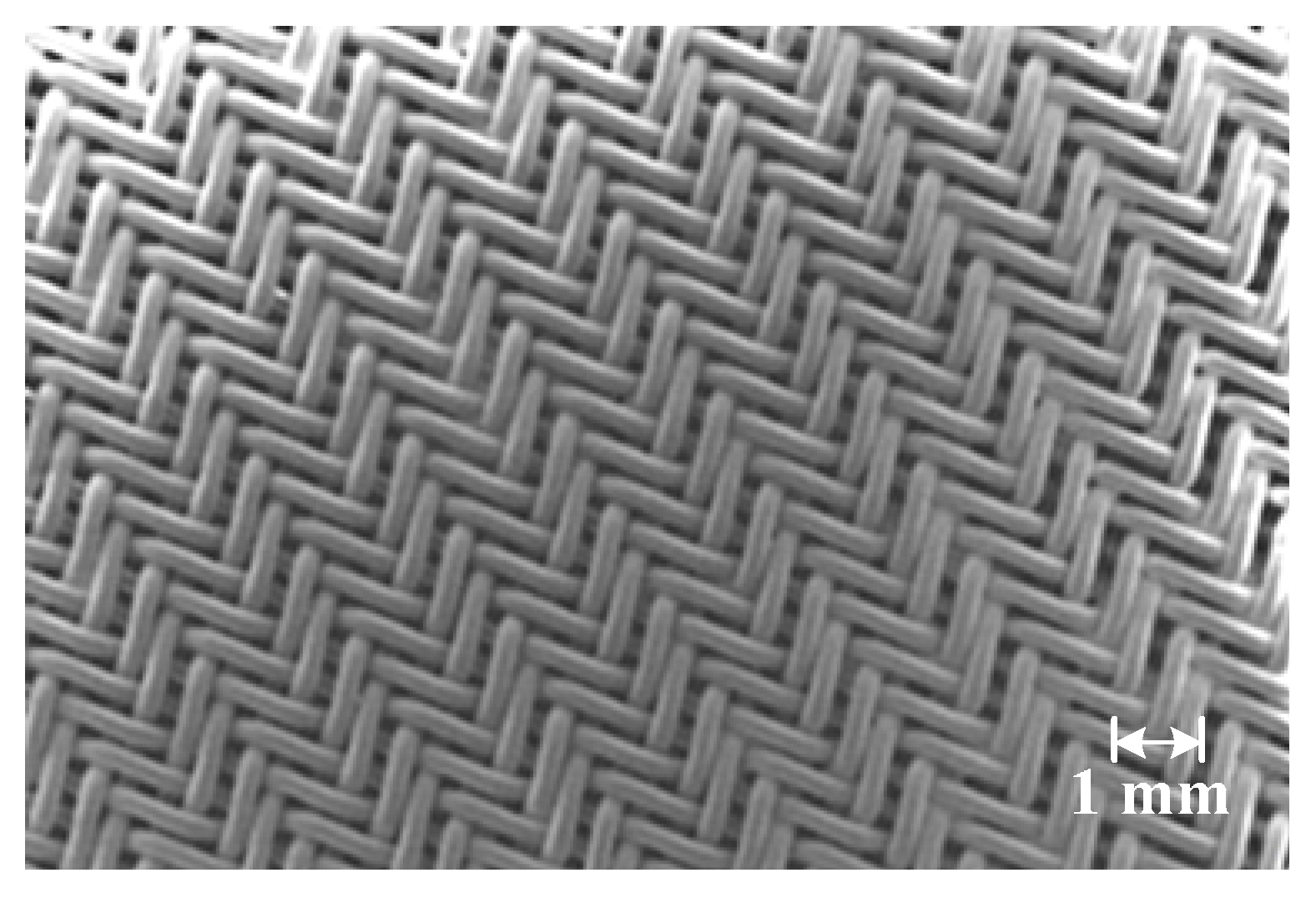

As is shown in

Figure 1, there are some micron-sized apertures between the filaments that constitute the PA66 fabric. The plasmas will traverse these apertures, which are acting as the channels. This demonstrates that after the stable or metastable state, active particles, including high-energy electrons, arrive at the surface of the PA66 fabric. A few of these act on the fabric surface. However, most of the particles will go through the fibrage. There will be several collisions, but under the effect of the electric field, they will continue to accelerate and ionize the air in the gap until reaching the ground.

On the other hand, the protrusions on the fabric obtained by the glow-like plasma process are distributed relatively evenly. As such, the corresponding treatment’s efficiency is proved to be homogeneous by this phenomenon.

3.2. Chemical Analysis of the Surface

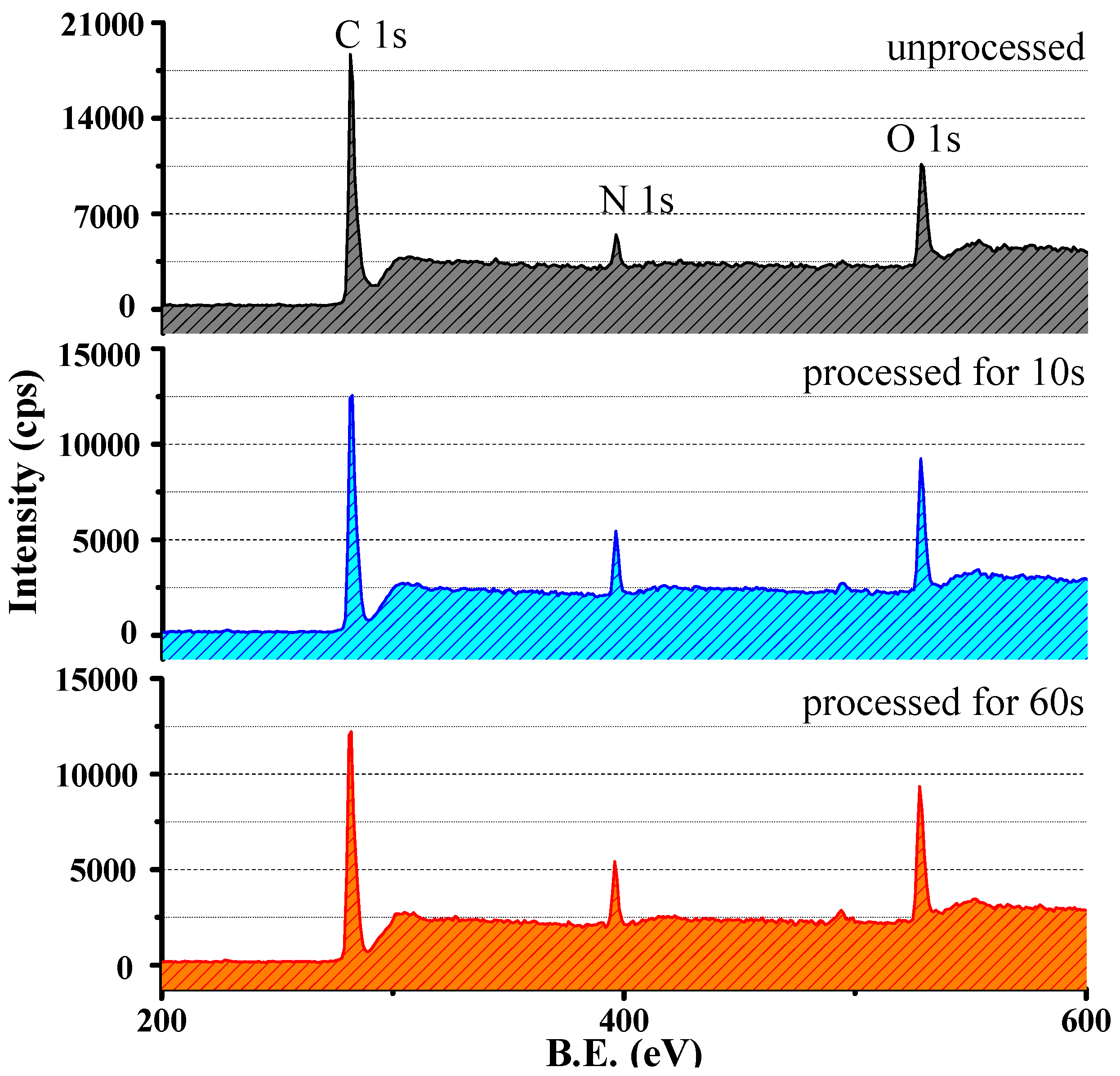

Figure 5 shows the spectra characteristics of the PA66 fabrics, unprocessed and processed, with different treatment times, while the peak voltage is about 90 kV and the PRF is set as 500 Hz.

Table 1 and

Figure 6 give the details about the relative chemical compositions andatomic ratios for the PA66 fabric unprocessed and processed by glow-like plasma obtained by XPS. The element content is calculated by the ratio of the corresponding integral area of the peaks. As shown in the XPS spectrums in

Figure 5, it is obvious that the highest C1s peak occurs on the control group. After the plasma treatment, the C-element content of the processed sample reduces significantly. Meanwhile, O-element content is augmented distinctly. N-element content has also changed. Some polar functional groups will be imported into the nylon material surface by the glow-like plasma processing [

22,

23], which results in the microstructural changes of the fiber surface. In addition, the relevant chemical bonds are cracked and the new functional groups are generated—all of these will be represented by the C-, O- and N-element content changes of the XPS spectrums. With the increase of the treatment time, the element’s content-varying amplitude will become more notable.

To make further analyses about the changes on the types and ratios of the surface functional groups, the C1s and O1s spectra are analyzed by XPS peak. As is shown in

Figure 6, the C1s peak of unprocessed fabrics is able to be divided into four peaks, they respectively indicate four carbon-containing groups: C–C (285.0 eV), C–N (285.3 eV), C–O/C–OH (286.5 eV) and CONH (288.0 eV) [

24,

25].

Table 2 gives the relative amounts of carbon-containing groups for various peaks, and then

Figure 6 gives the peak splitting diagrams of the samples processed at 10 s and 60 s; the corresponding changes of the contents of carbon functional groups are shown in

Table 2, line 2&3.

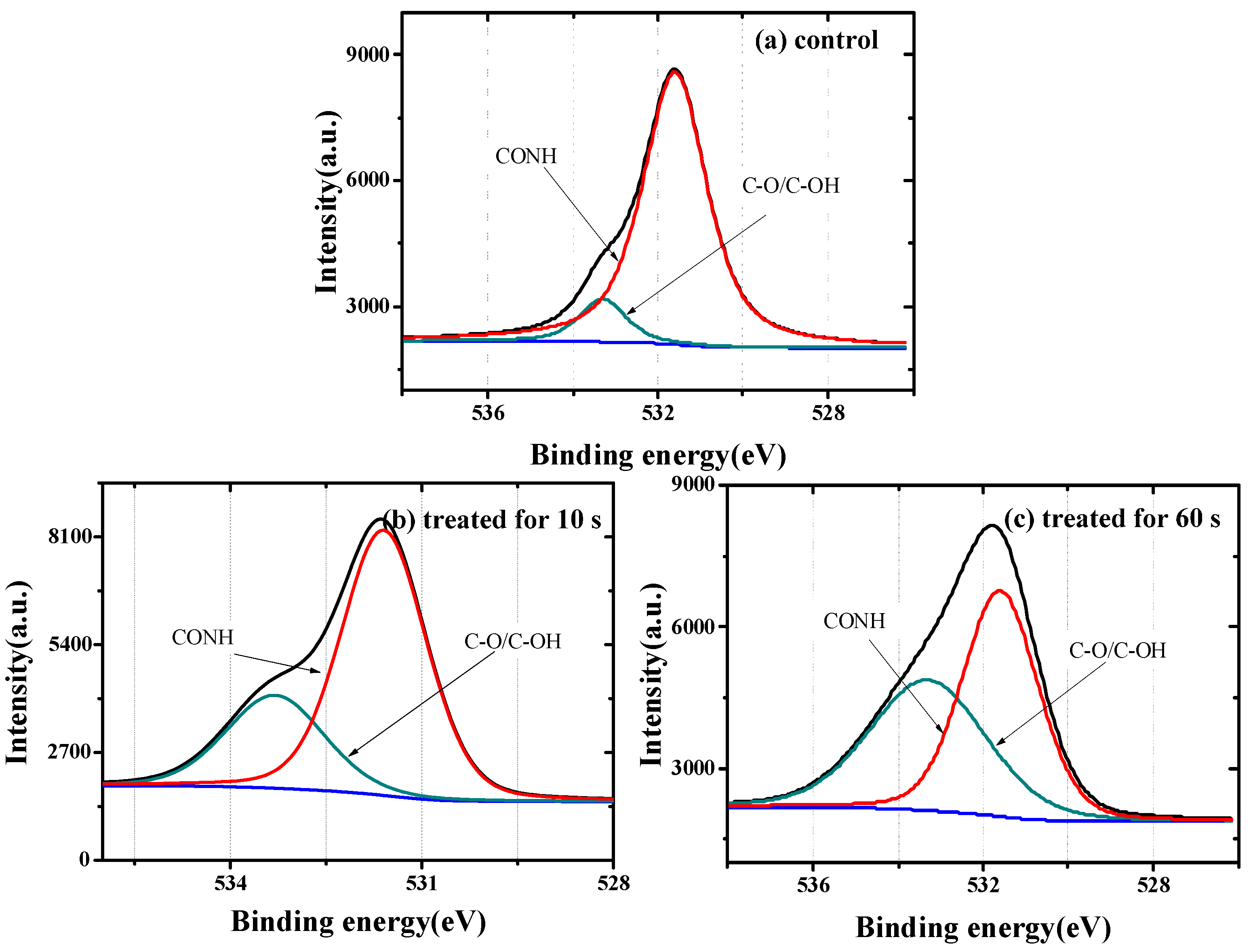

The Ols XPS spectra under different conditions are shown in

Figure 7. The O1s peak of the fabrics is able to be divided into two peaks; they indicate two oxygen-containing groups: C–O/C–OH (533.3 eV), CONH/COOH (531.6 eV) [

26,

27].

Table 3 gives the relative content of oxygen-containing groups corresponding to each peak. It is shown that, when the treatment time is 10 s, the ratio of C–O/C–OH increases from 10.04% to 18.06%, and the content of CONH/COOH decreases from 89.96% to 81.94%. When the treatment time reaches 60 s, the content of C–O/C–OH increases from 10.04% to 47.10%; the content of CONH/COOH decreases from 89.96% to 52.90%.

It is shown that the total amount of C–C bonds and C–N bonds on the unprocessed sample, the processed 10 s sample and the processed 60 s sample are 87.4%, 76.74% and 60.05%, respectively. The oxygen-containing groups’ content rises together with the decrease of the primary C–C and C–N bonds in all. The primary carbon-containing bonds are cracked by the glow-like plasmas, which is helpful to generate hydroxyl, carboxyl and double bonds of carbon to oxygen under atmospheric air conditions. Furthermore, these hygrophilous groups are beneficial to the enhancement of the samples’ hydrophilicity. The CONH is the primary chemical bond in the polyamides molecules, the COOH and C–OH appears after the treatment. As shown in

Table 2 and

Table 3, when it has reached a certain time for a longer oxidation reaction, it is easier for the hydroxyl to be transmuted into carboxyl, but the over-handling will cause the C–O/C–OH to combine closely to the PA66 molecules. The carboxyl converts into other substances or just sheds, which results in the fact that few of the carboxyls can be found after being processed for 60 s. We can clearly distinguish the changes of the functional groups varied within the treatment time through the peaks of the corresponding peak-splitting diagrams in

Figure 6 and

Figure 7. This phenomenon corresponds to the element content changes in

Figure 5.

3.3. Sterilization Effect

The high-energy electrons, ions, other active particles and the ultraviolet rays during the discharge have, to some extent, an inactivation effect on the microorganisms [

28]. This kind of inactivation effect is achieved by their damage on the cytomembrane, cytoderm and the genetic material. To study the bactericidal performance of this kind of glow-like plasma, the

Escherichia coli (

E. coli) HT115 is chosen to be the test object. Before the experiment, the wire electrodes and the whole reactor are sterilized; the

E. coli undergoes penicillin resistance processing to eliminate the disturbance from the microbial contamination in the air.

The experimental procedures are as follows: (1) the samples are soaked in 70% alcohol, then placed in the high-pressure steam sterilization pot for drying and sterilizing with the temperature at 121 °C and the pressure is 0.1 MPa; (2) on the clean nench, 10 μL bacteria solution (culturing for 13 h) is inoculated onto the PA66 fabric surface and a control group and a series of experimental groups are set; (3) having the samples processed by glow-like plasma under different processing times, the peak voltage is about 90 kV and the PRF is set as 500 Hz. The process is conducted in sterile room; (4) after the treatment, the region of the PA66 fabric that was inoculated by the E. coli is cut off. This piece of fabric is vibrated fully in 5 mL sterile water to elute the thalli. 100 μL solution is absorbed and coated onto the solid medium of penicillin resistance; (5) having the solid media of control group and experimental groups cultured in the 37 °C thermostat for a certain time, then the number of E. coli colonies are counted on the solid media.

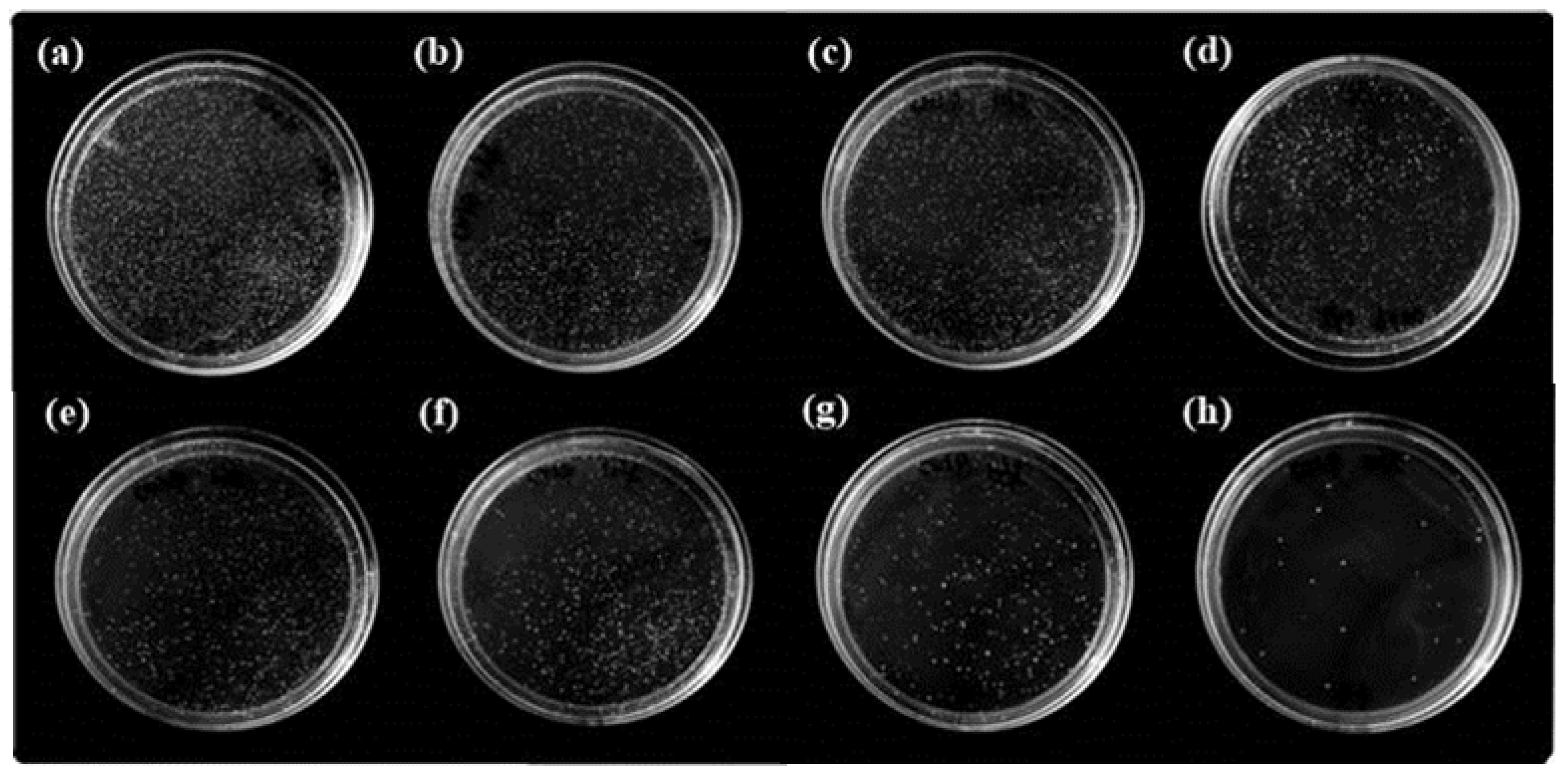

Figure 8 is the effect picture of the atmospheric-air glow-like plasmas processed

E. coli colonies under different treatment times.

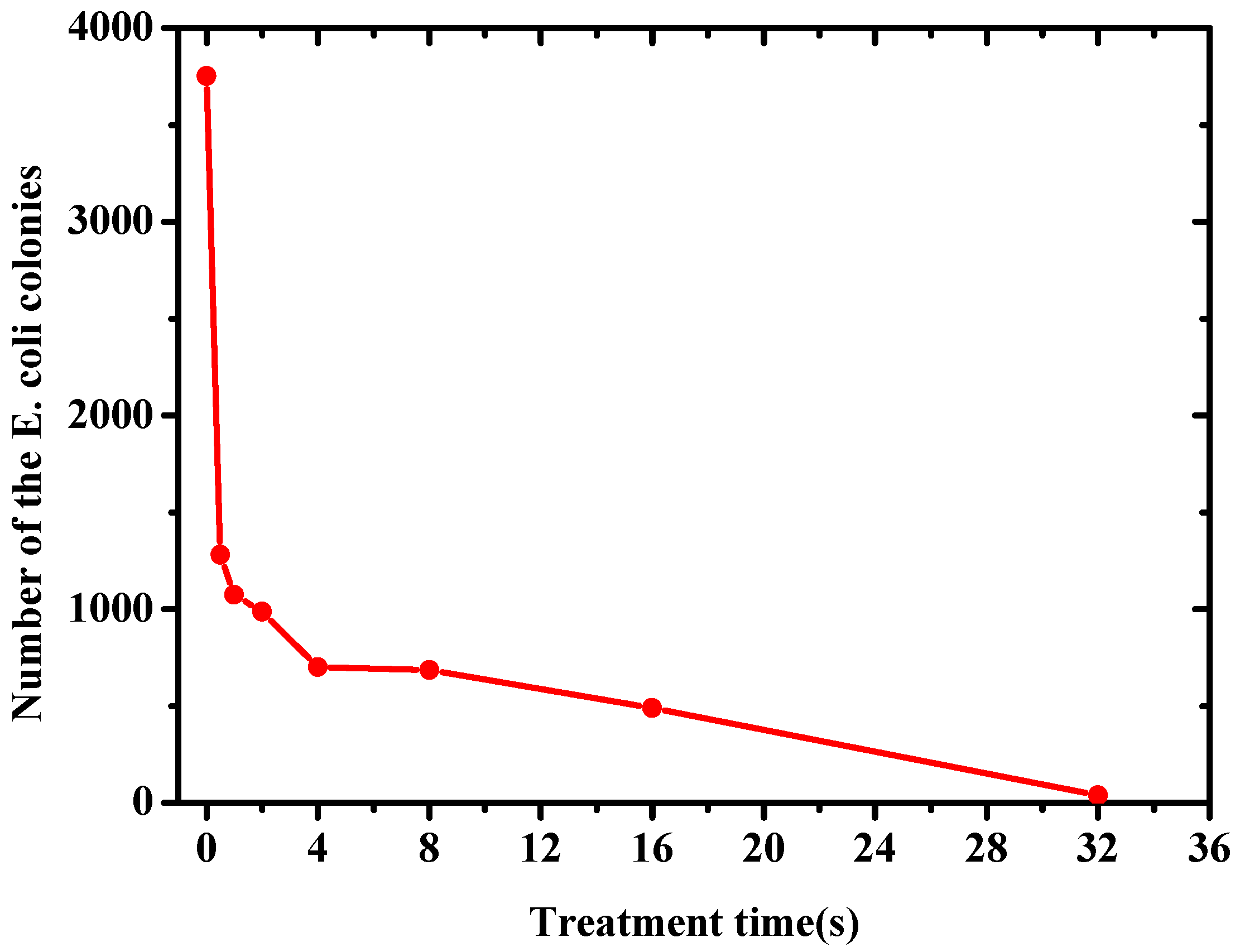

Figure 9 gives the changing curve of the number of the

E. coli colonies with treatment time varied.

Figure 8a is the control group, the

Figure 8b–h are sterilizing effect pictures of

E. coli colonies processed 0.5–32 s. During the experiment, the PRF is 500 Hz. It is clear that the sterilizing effect achieved by the glow-like plasma is enhanced with an increase in the treatment time. When the treatment time reaches 32 s, there is nearly no colony appearing on the solid medium. After having 0.5 s of treatment of glow-like plasmas, there is approximately only one-third of the colonies left on the solid medium compared with the control group. These observations prove that this kind of atmospheric-air glow-like plasma has a promising sterilizing effect.

Figure 10 shows the relative numbers of

E. coli colonies processed by glow-like plasma with PRF varied. The experiment has been repeated three times, the relative deviation is small. It is shown that when the treatment time is constant, the

E. coli colonies on the solid medium reduce observably along with the increase of the PRF. When PRF increases from 10 to 500 Hz, the number of

E. coli colonies decreases from 2579 to 87 monotonically. In addition, when the number of discharges is constant, the

E. coli colonies reduce at first and then increase while the PRF is augmenting. The extreme value point appears at approximately 100 Hz. This is due to the fact that, for a certain treatment time, the higher the PRF, the higher the concentration of the bactericidal-effect active substances in glow-like plasma. It will have a strong impact on the

E. coli colonies.

With a constant number of discharges, the interval between two sequential pulses is long while the PRF is relatively low. The short-lived active particles in the plasma will disappear, and the long-lived active particles will diffuse to a certain extent, so that the concentration of the bactericidal-effect active substances in the reacting chamber won’t be high enough to have a valid sterilizing effect on the E. coli on the PA66 fabrics. While the PRF augments to a certain frequency, about 100 Hz, the active particles reach a certain concentration to have the best sterilizing effect on the E. coli. However, when the PRF continues augmenting to a certain extent, even though the activity of the plasmas is enhanced, the acting time is too short to have a sufficient contact between the active particles and the PA66 fabrics. As such, the sterilizing effect is weakened. According to this phenomenon in the practical application, the treatment time can be shortened by increasing the PRF. Meanwhile, the same sterilizing effect can be achieved by extending the treatment time at an optimal PRF.

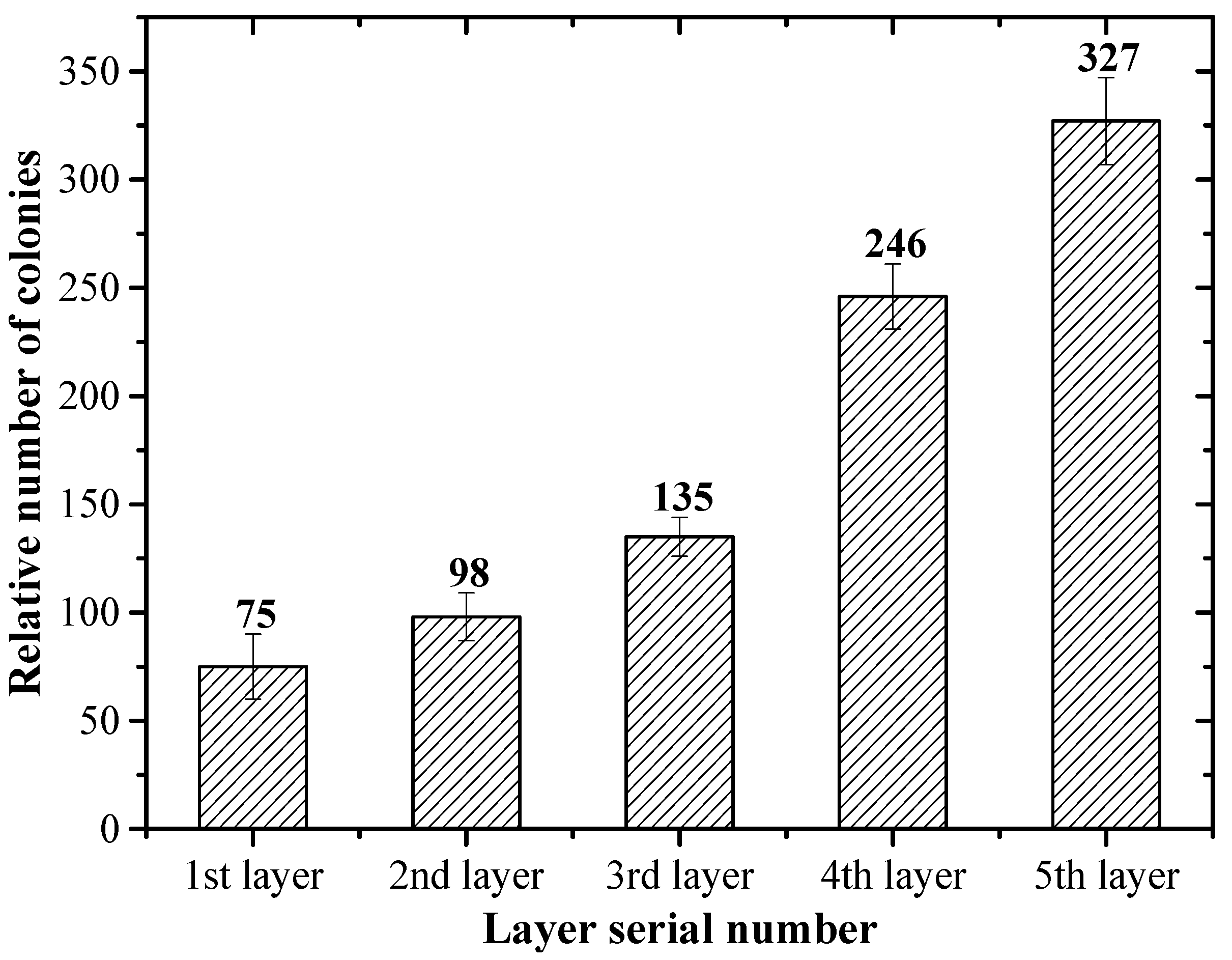

Figure 11 shows the relative numbers of the

E. coli colonies of the side-by-side processed PA66 fabrics through the atmospheric-air glow-like plasma with when the PRF is 500 Hz. According to the error bar, the relative deviation is small. Before the treatment, the different layers of PA66 fabrics are inoculated by

E. coli culture solution of the same concentration. During the discharge, the total five layers of PA66 fabrics are placed side-by-side. From the

Figure 11, it is shown that the first layer, i.e., the top layer, has the best sterilizing effect with the fewest

E. coli colonies left; the number is about 75. The bottom layer has the worst sterilizing effect; the number of colonies is about 327. It is still a relatively good treatment effect compared with the

Figure 10. The relative number of

E. coli colonies increases sequentially from the 1st layer to the 5th layer. This is because most of the active particles in the plasma, which have the bactericidal effect, are absorbed by the top layer–few of them can reach the bottom layer. It should be noted that by extending the treatment time appropriately, the bottom layer can also achieve a better treatment effect. The reasons leading to this phenomenon may be as follows: Firstly, there will be more active particles surrounding the layers of PA66 fabrics while the treatment time increases, and then more active particles can touch the bottom layer. For another, the bactericidal, active substances in the plasma may dissolve in the solution on the fabrics. In that case, some properties, like the acid-base property, may be changed so that the

E. coli will be inactivated. This solution may penetrate to the bottom layer through the apertures of the PA66 fabrics to influence the corresponding living environment of the

E. coli.

3.4. Aging Effect

Table 4 is focused on the timeliness of this kind of glow-like plasma treatment. In this experiment, five pieces of the PA66 fabrics are processed by the atmospheric-air glow-like plasma with the processing time set at 10 s and the PRF set at 500 Hz. One piece of the processed fabric has been taken out to have the XPS test directly. Two pieces of the processed PA66 fabrics are placed in the air for 1 day and 3 days. The last two pieces of the processed PA66 fabrics are stored in sealed polythene bags for 1 day and 3 days, respectively. They are then tested by XPS. The results of relative chemical compositions and atomic ratios of processed PA66 fabrics stored under different conditions are shown in the

Table 4.

The plasma treatment can generate oxygen-containing functional groups and it can smooth the surface impurities, which makes the surface energy augmented. That is why plasma treatment is able to enhance the hydrophilicity of the PA66 samples. However, after the processed samples are laid up under air condition, the impurities will adsorb on the sample once more to reduce the hydrophilicity. So that the aging effect, i.e., the timeliness, is a significant influence factor under industrial application of the surface modification [

29]. Comparing the data in the

Table 4, laying up the processed samples in the same external conditions, the O/C ratio remains almost unchanged in the air during the storage time. When stored in sealed polythene bags, the O/C ratio of storing for 3 days is only 4.3% less than the one stored for 1 day.

All of the data reveals that this kind of glow-like plasma has relatively good timeliness. Meanwhile, the aging effect can be delayed to some degree. What’s more, the sample stored in the sealed polythene bag has the higher O/C ratio while the storage time is constant. This is due to the small quantity of oxygen and impurities that restrict the oxidation-reduction reaction and the repetition pollution, respectively. On the other hand, the less the flow disturbance is, the longer time the newly generated polar functional groups will survive.

Table 5 and

Table 6 give relative amounts of different carbon-containing and oxygen-containing groups with storage time and environment varying.