Stiffness of Plasma Sprayed Thermal Barrier Coatings

Abstract

:1. Introduction

1.1. Background

1.2. Reported Young’s Modulus Values of Plasma Sprayed TBC Top Coats

1.2.1. General Remarks

1.2.2. Indentation

1.2.3. Beam Bending

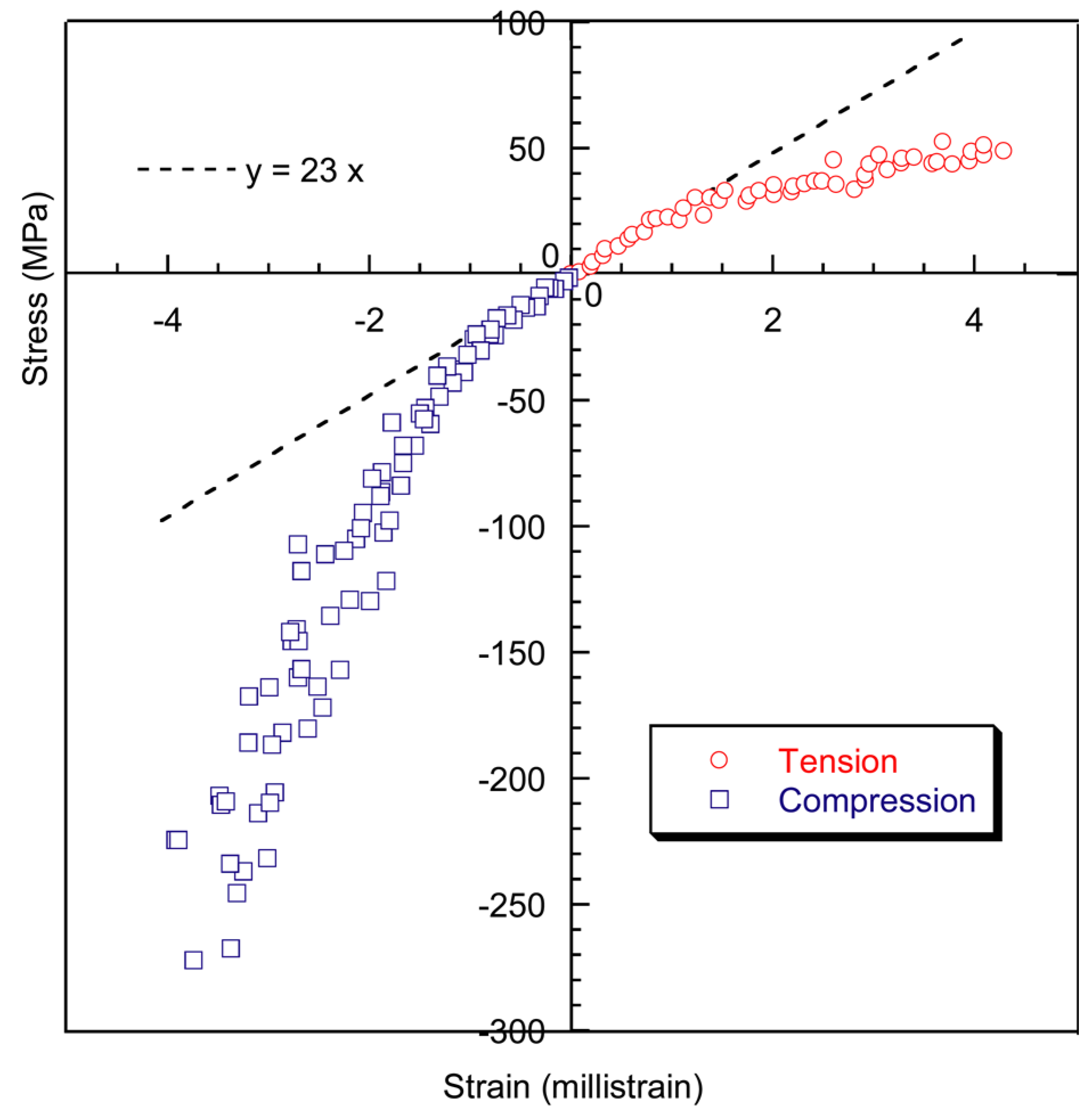

1.2.4. Behaviour in Tension and Compression

1.3. Sintering Effects on Young’s Modulus Values of Plasma Sprayed TBCs

1.4. Scope of the Paper

2. Materials and Methods

2.1. Sample Preparation

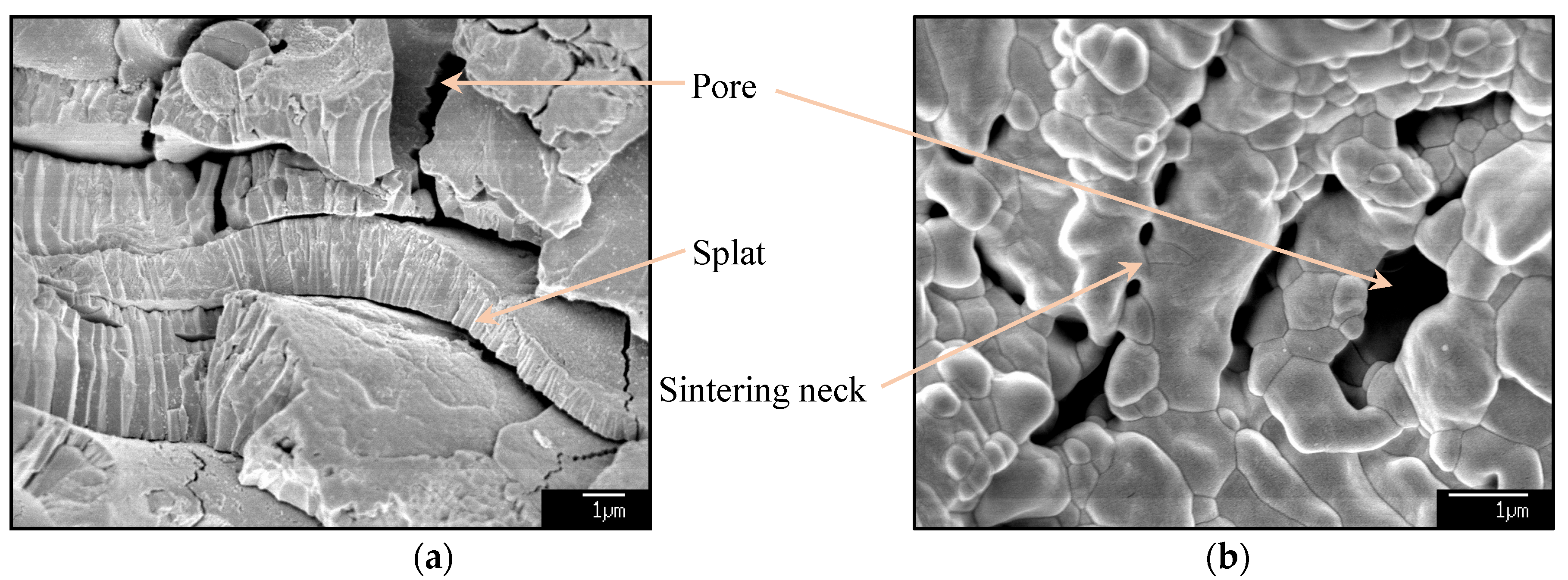

2.2. Microstructural and Pore Architectural Characterisation

2.3. Measurement of Coating Stiffness

2.3.1. General Remarks

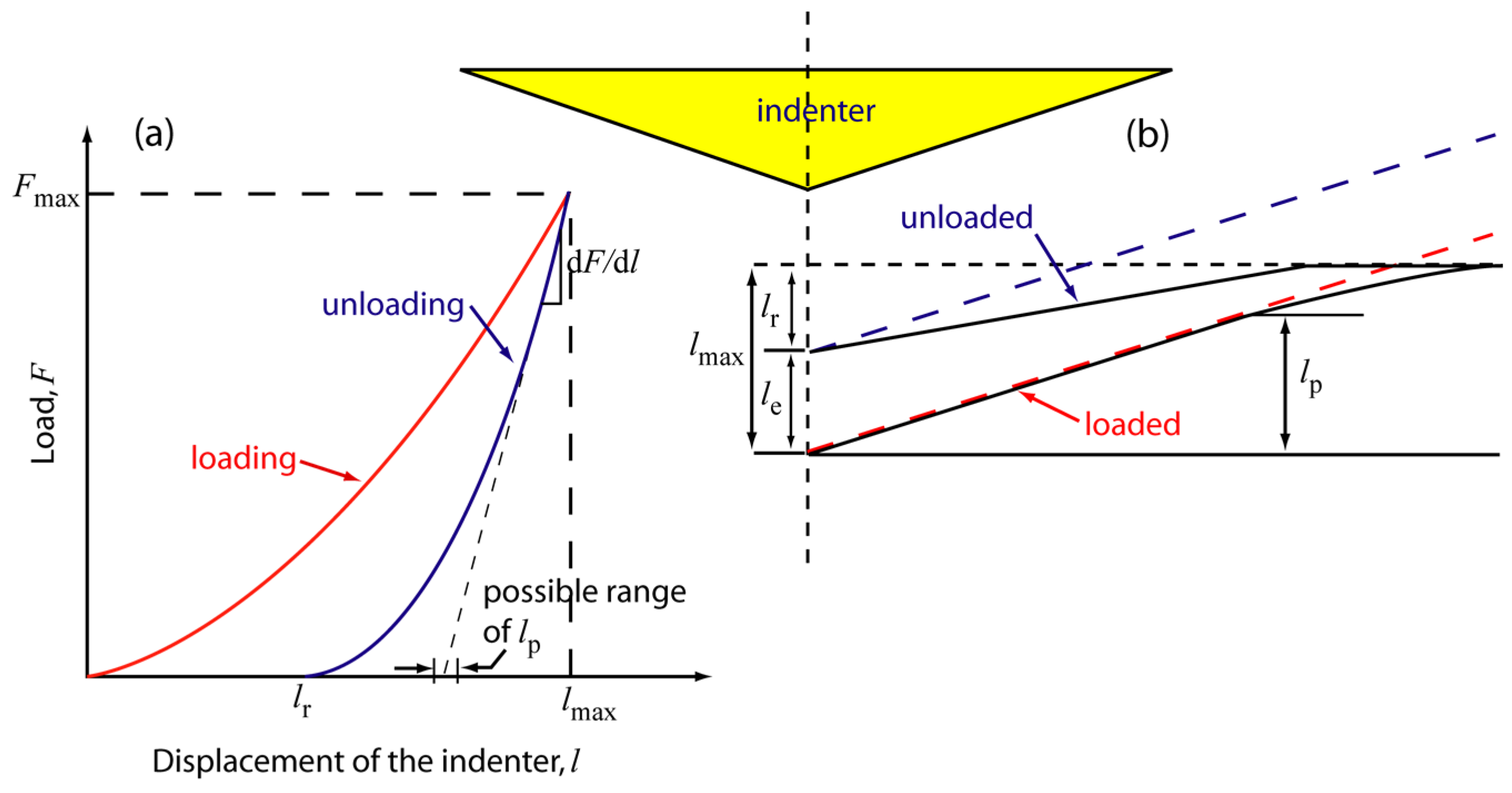

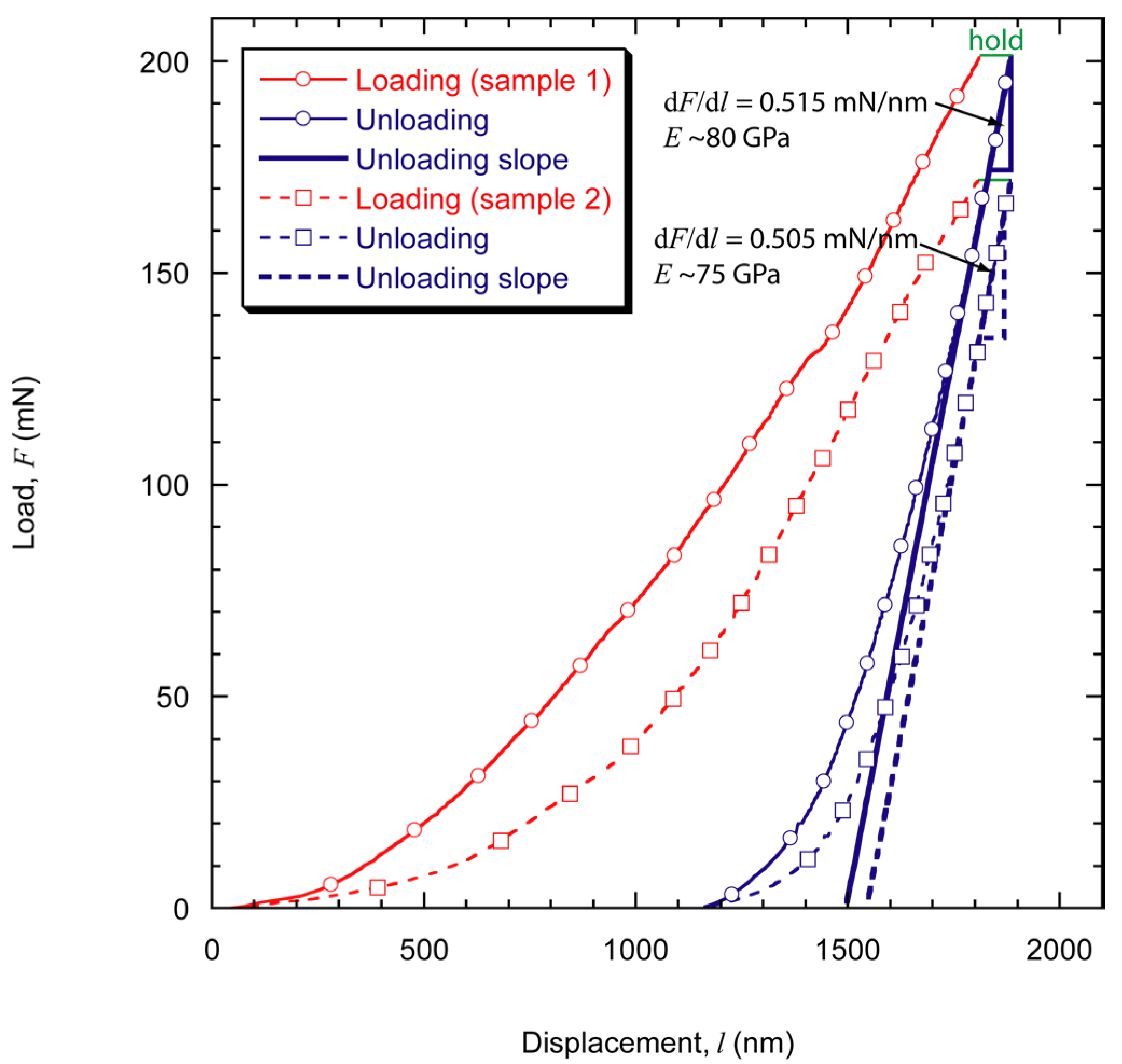

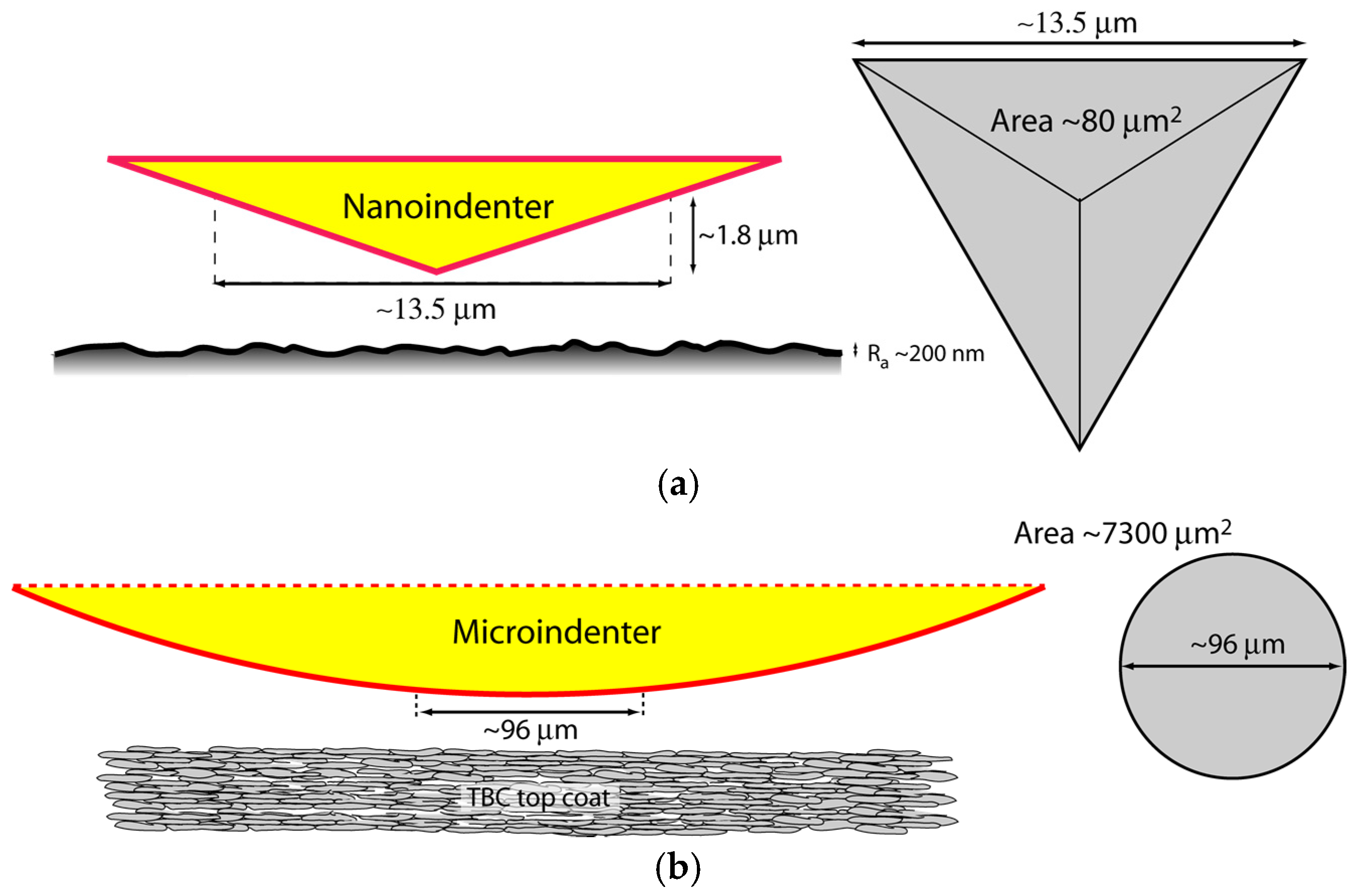

2.3.2. Indentation

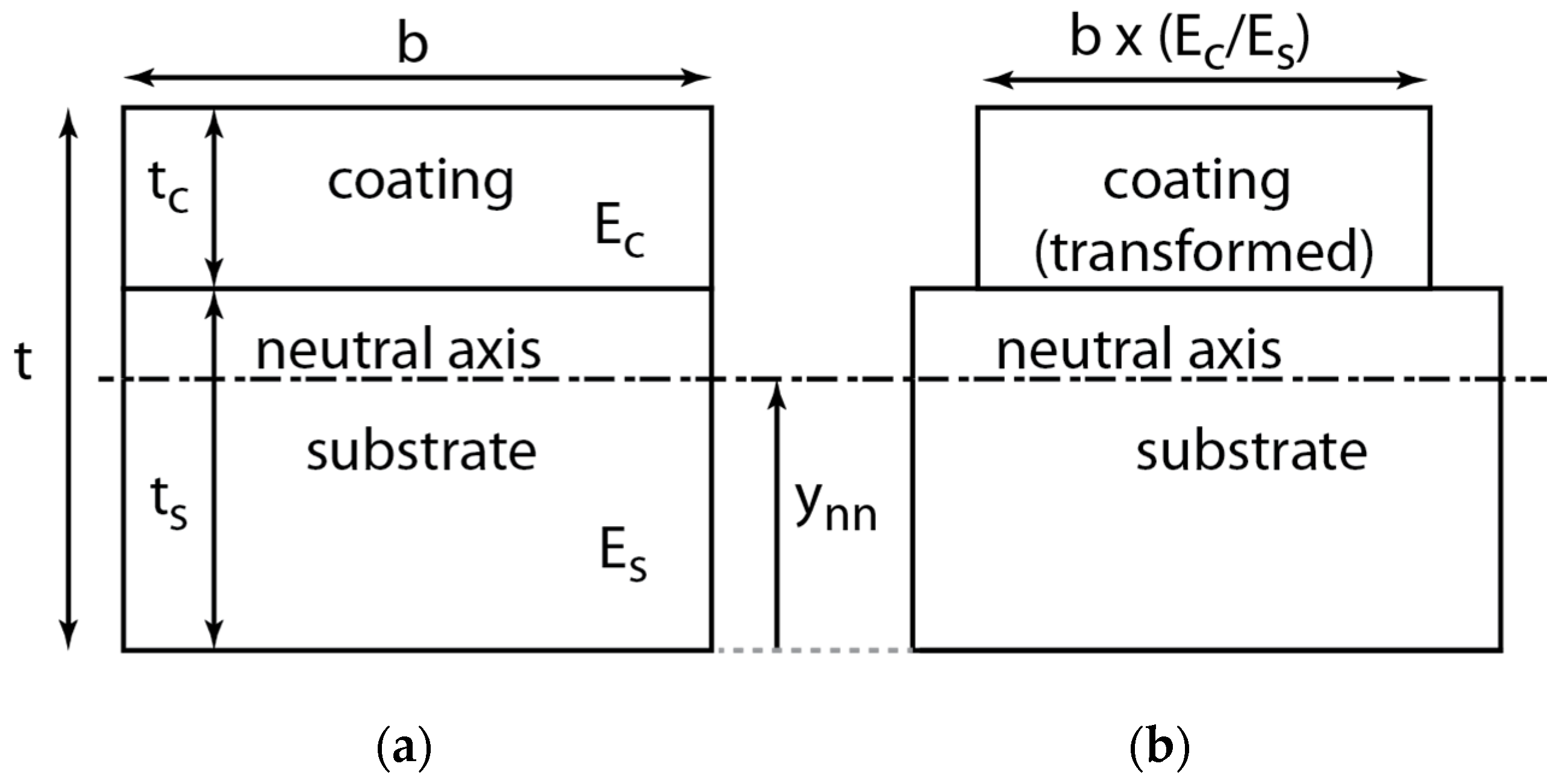

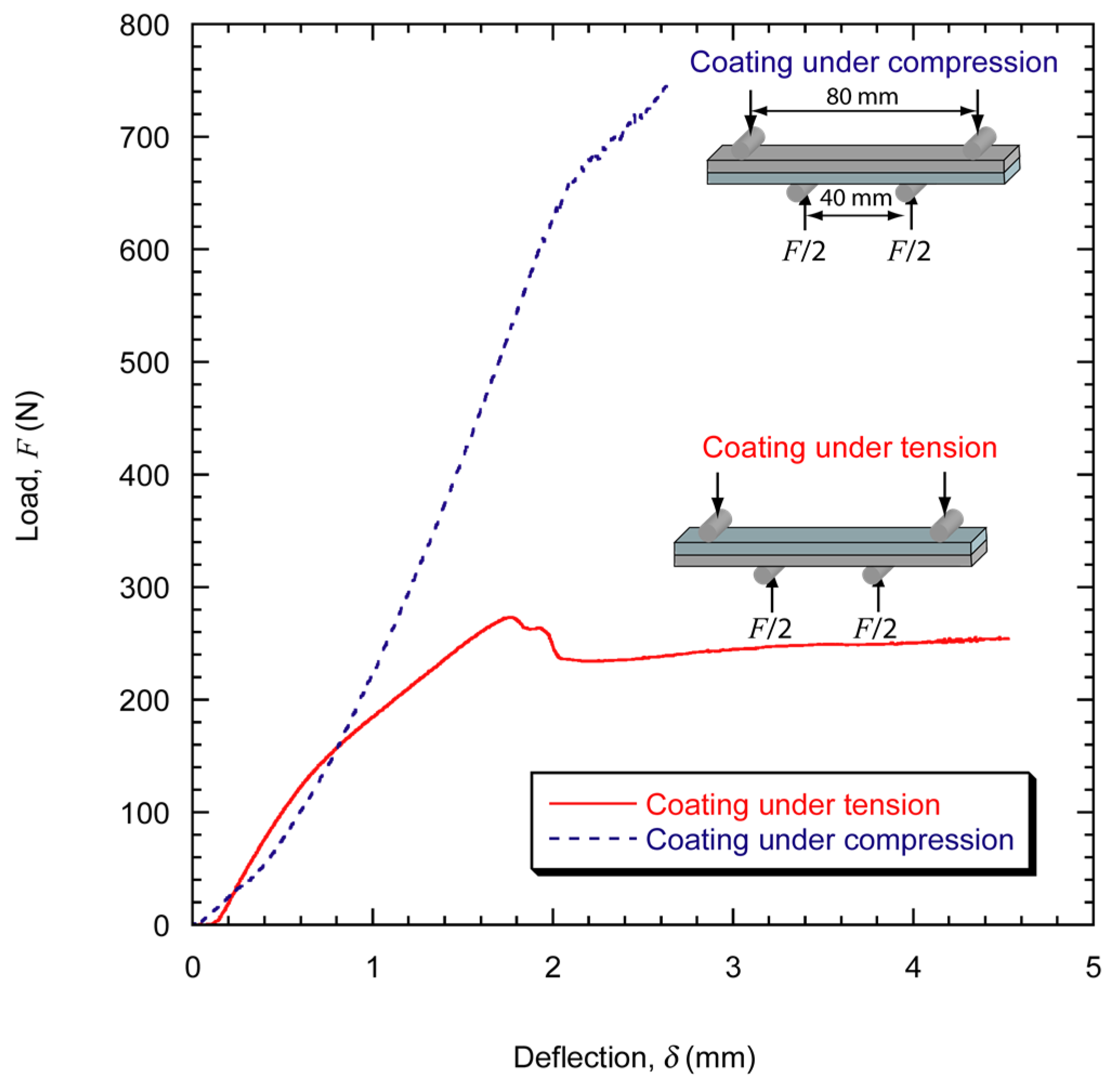

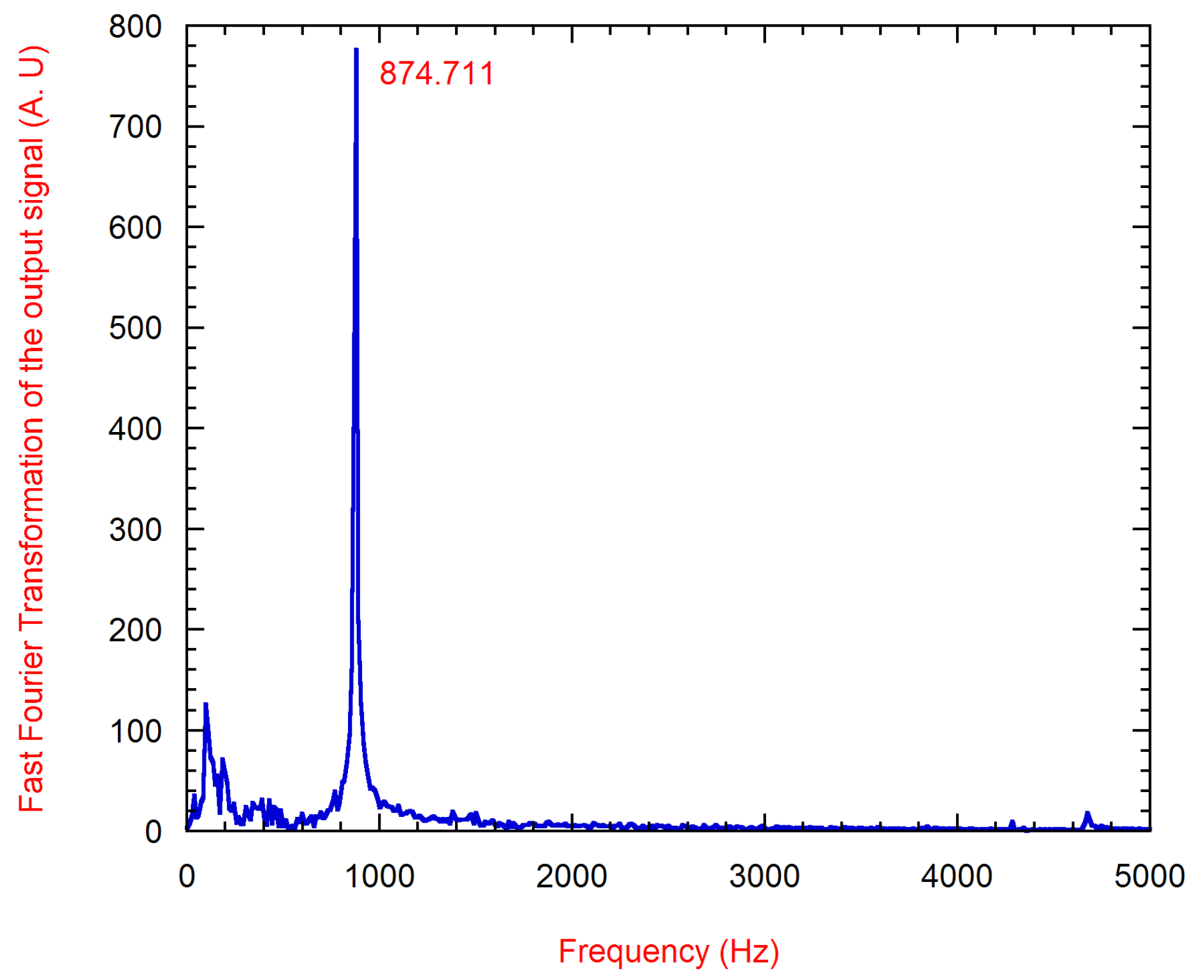

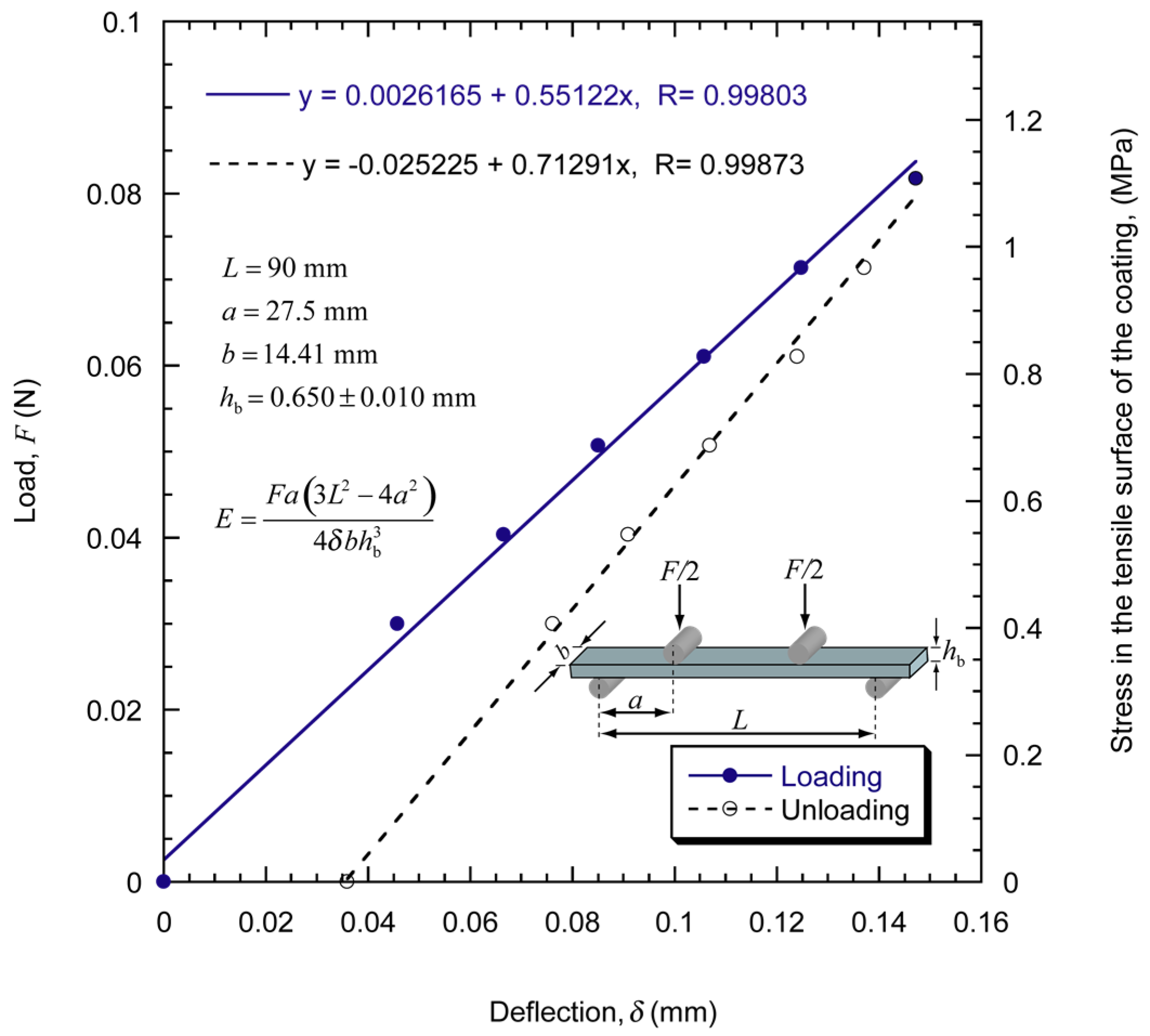

2.3.3. Beam Bending

3. Results

3.1. Indentation

3.2. Beam Bending

3.2.1. Attached Coatings

3.2.2. Detached or Free-Standing TBC Top Coats

3.3. Effect of Heat Treatment

3.3.1. Stiffness of Detached or Free-Standing Coatings

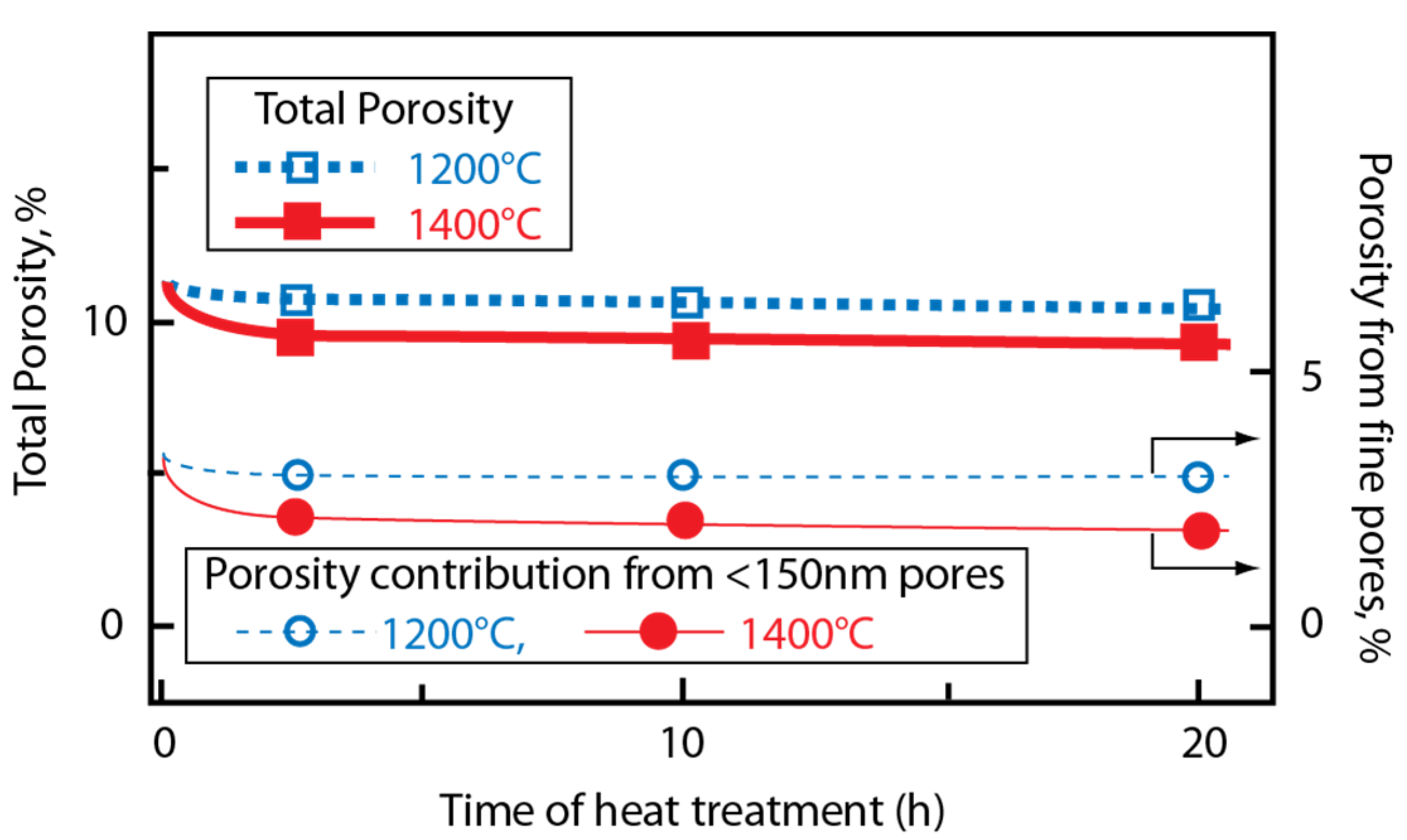

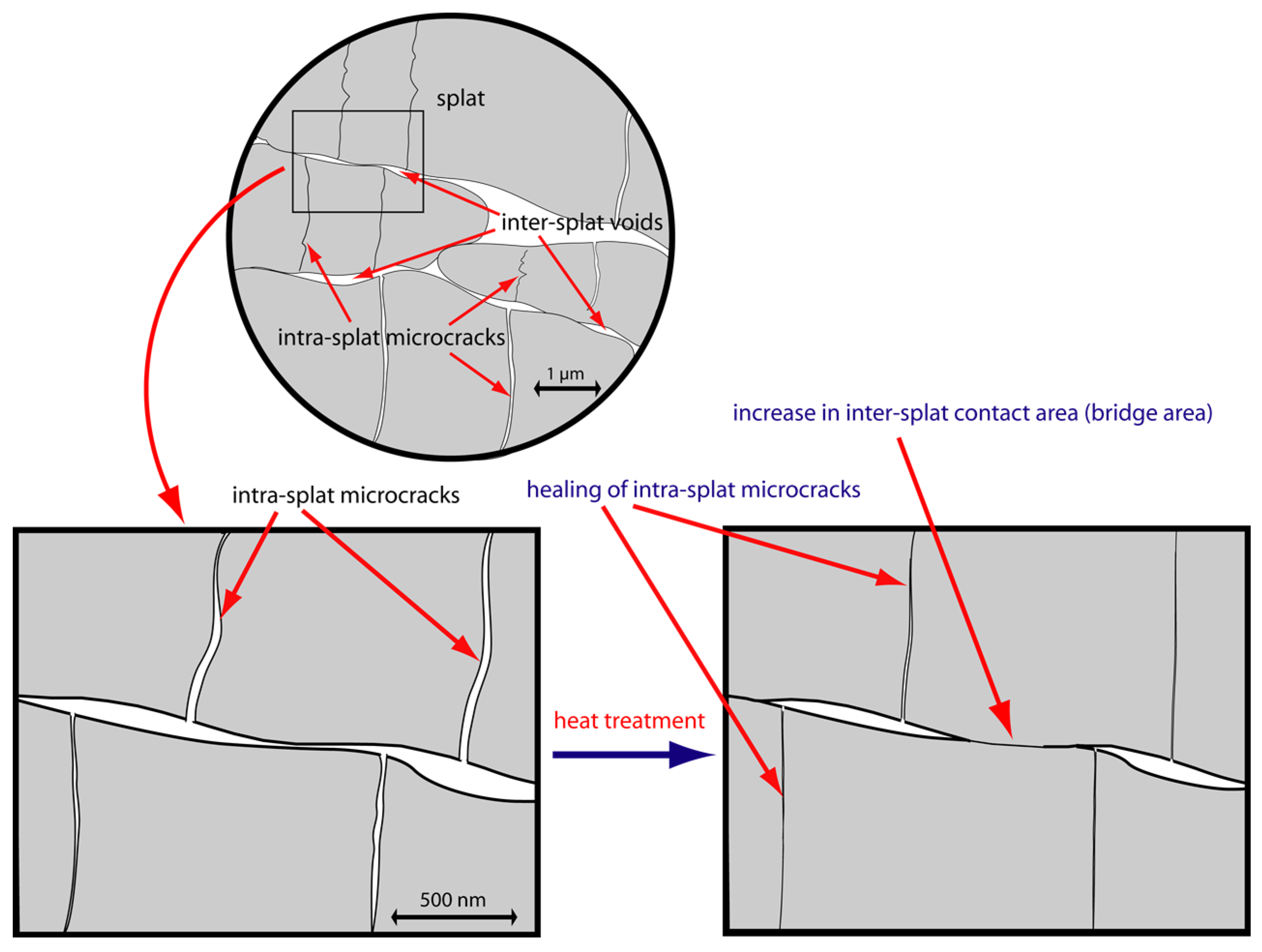

3.3.2. Pore Architecture in Detached or Free-Standing Coatings

4. Discussion

4.1. Local Stiffness

4.2. Global Stiffness

4.3. Effect of Service Conditions

5. Conclusions

Acknowledgments

Conflicts of Interest

Nomenclature

Roman Symbols

| a, m | Characteristic length in beam bending |

| A, m2 | Area |

| b, m | Beam width |

| C | Constant |

| C1 | Correction factor for IET |

| Cf, nm mN−1 | Frame compliance |

| dgrain, m | Grain diameter |

| D, m | Diffusion coefficient |

| E, N m−2 (Pa) | Young’s modulus |

| Ec, N m−2 (Pa) | Young’s modulus of the coating |

| Ei, N m−2 (Pa) | Young’s modulus of the indenter |

| Es, N m−2 (Pa) | Young’s modulus of the substrate or specimen |

| ΔE, J mol−1 | Activation energy |

| fr, Hz | Resonance frequency |

| F, N | Force or Load |

| h, m | Height |

| hb, m | Height of beam in 4-pt bending |

| hgb, m | Grain boundary thickness |

| I, m4 | Second moment of area |

| L, m | Length or distance |

| l, m | Indentation depth |

| le, m | Depth of elastic recovery during indentation |

| lmax, m | Maximum depth attained by the indenter |

| lp, m | Contact depth during indentation |

| lr, m | Residual depth during indentation |

| m, kg | Mass |

| Ri, m | Radius of the indenter |

| t, m | Thickness |

| tc, m | Thickness of the coating |

| ts, m | Thickness of the substrate |

| ynn, m | Position of the neutral axis |

Greek Symbols

| β | Geometrical constant (for an indenter) |

| δ, m | Displacement/deflection |

| ε | Strain |

| φ | Porosity |

| υ | Poisson’s ratio |

| υi | Poisson’s ratio of the indenter |

| υs | Poisson’s ratio of the sample |

Acronyms

| APS | Atmospheric (Air) Plasma Spray |

| BET | Brunauer–Emmett–Teller (N2 adsorption isotherm) |

| EB-PVD | Electron Beam Physical Vapour Deposition |

| FFF | Fundamental Flexural Frequency |

| HVOF | High Velocity Oxy-Fuel |

| IET | Impulse Excitation Technique |

| MIP | Mercury Intrusion Porosimetry |

| NDT | Non-Destructive Testing |

| PS | Plasma Spray |

| RFDA | Resonance Frequency and Damping Analyser |

| SEM | Scanning Electron Microscopy |

| TWAS | Twin Wire Arc Apray |

| TBC | Thermal Barrier Coating |

| YSZ | Yttria Stabilised Zirconia |

Appendix A

References

- Choi, S.R.; Zhu, D.M.; Miller, R.A. Effect of Sintering on Mechanical Properties of Plasma-Sprayed Zirconia-Based Thermal Barrier Coatings. J. Am. Ceram. Soc. 2005, 88, 2859–2867. [Google Scholar] [CrossRef]

- Choi, S.R.; Zhu, D.M.; Miller, R.A. Mechanical Properties/database of Plasma-Sprayed ZrO2–8 wt % Y2O3 Thermal Barrier Coatings. Int. J. Appl. Ceram. Technol. 2004, 1, 330–342. [Google Scholar] [CrossRef]

- Malzbender, J.; Steinbrech, R.W. Determination of the Stress-Dependent Stiffness of Plasma-Sprayed Thermal Barrier Coatings Using Depth-Sensitive Indentation. J. Mater. Res. 2003, 18, 1975–1984. [Google Scholar] [CrossRef]

- Choi, S.R.; Zhu, D.M.; Miller, R.A. Deformation and Strength Behaviour of Plasma Sprayed ZrO2–8 wt % Y2O3 Thermal Barrier Coatings in Biaxial Flexure and Trans-Thickness Tension. Ceram. Eng. Sci. Proc. 2000, 21, 653–661. [Google Scholar]

- Thompson, J.A.; Clyne, T.W. The Effect of Heat Treatment on the Stiffness of Zirconia Top Coats in Plasma-Sprayed TBCs. Acta. Mater. 2001, 49, 1565–1575. [Google Scholar] [CrossRef]

- Schwingel, D.; Taylor, R.; Haubold, T.; Wirgen, J.; Gaulco, C. Mechanical and Thermophysical Properties of Thick PYSZ Thermal Barrier Coatings: Correlation with Microstructure and Spraying Parameters. Surf. Coat. Technol. 1998, 108–109, 99–106. [Google Scholar] [CrossRef]

- Nakamura, T.; Qian, G.; Berndt, C.C. Effects of Pores on Mechanical Properties of Plasma-Sprayed Ceramic Coatings. J. Am. Ceram. Soc. 2000, 83, 578–584. [Google Scholar] [CrossRef]

- Basu, D.; Funke, C.; Steinbrech, R.W. Effect of Heat Treatment on Elastic Properties of Separated Thermal Barrier Coatings. J. Mater. Res. 1999, 14, 4643–4650. [Google Scholar] [CrossRef]

- Siebert, B.; Funke, C.; Vassen, R.; Stover, D. Changes in Porosity and Young’s Modulus due to Sintering of Plasma Sprayed Thermal Barrier Coatings. J. Mater. Process. Technol. 1999, 93, 217–223. [Google Scholar] [CrossRef]

- Eskner, M.; Sandstrom, R. Measurement of the Elastic Modulus of a Plasma-Sprayed Thermal Barrier Coating using Spherical Indentation. Surf. Coat. Technol. 2004, 177–178, 165–171. [Google Scholar] [CrossRef]

- Wallace, J.S.; Ilavsky, J. Elastic Modulus Measurements in Plasma Sprayed Deposits. J. Therm. Spray. Technol. 1998, 7, 521–526. [Google Scholar] [CrossRef]

- Leigh, S.H.; Lin, C.K.; Berndt, C.C. Elastic Response of Thermal Spray Deposits under Indentation Tests. J. Am. Ceram. Soc. 1997, 80, 2093–2099. [Google Scholar] [CrossRef]

- Duan, K.; Steinbrech, R.W. Influence of Sample Deformation and Porosity on Mechanical Properties by Instrumented Microindentation Technique. J. Eur. Ceram. Soc. 1998, 18, 87–93. [Google Scholar]

- Guo, S.; Kagawa, Y. Young’s Moduli of Zirconia Top-Coat and Thermally Grown Oxide in a Plasma-Sprayed Thermal Barrier Coating System. Scripta Mater. 2004, 50, 1401–1406. [Google Scholar] [CrossRef]

- Li, G.R.; Lv, B.W.; Yang, G.J.; Zhang, W.X.; Li, C.X.; Li, C.J. Relationship Between Lamellar Structure and Elastic Modulus of Thermally Sprayed Thermal Barrier Coatings with Intra-splat Cracks. J. Therm. Spray Technol. 2015, 24, 1355–1367. [Google Scholar] [CrossRef]

- Kulkarni, A.; Wang, Z.; Nakamura, T.; Sampath, S.; Goland, A.; Herman, H.; Allen, J.; Ilavsky, J.; Long, G.; Frahm, J.; et al. Comprehensive Microstructural Characterization and Predictive Property Modeling of Plasma-Sprayed Zirconia Coatings. Acta. Mater. 2003, 51, 2457–2475. [Google Scholar] [CrossRef]

- Waki, H.; Takizawa, K.; Kato, M.; Takahashi, S. Accuracy of Young’s Modulus of Thermal Barrier Coating Layer Determined by Bending Resonance of a Multilayered Specimen. J. Therm. Spray Technol. 2016, 25, 684–693. [Google Scholar] [CrossRef]

- Wei, Q.; Zhu, J.; Chen, W. Anisotropic Mechanical Properties of Plasma-Sprayed Thermal Barrier Coatings at High Temperature Determined by Ultrasonic Method. J. Therm. Spray Technol. 2016, 25, 605–612. [Google Scholar] [CrossRef]

- Wakui, T.; Malzbender, J.; Steinbrech, R.W. Strain Dependent Stiffness of Plasma Sprayed Thermal Barrier Coatings. Surf. Coat. Technol. 2006, 200, 4995–5002. [Google Scholar] [CrossRef]

- Choi, S.R.; Zhu, D.M.; Miller, R.A. Deformation and Tensile Cyclic Fatigue of Plasma-Sprayed ZrO2–8 wt % Y2O3 Thermal barrier Coatings. Ceram. Eng. Sci. Proc. 2001, 22, 427–434. [Google Scholar]

- Kroupa, F.; Dubsky, J. Pressure Dependence of Young’s Moduli of Thermal Sprayed Materials. Scripta Mater. 1999, 40, 1249–1254. [Google Scholar] [CrossRef]

- Malzbender, J. The Use of Theories to Determine Mechanical and Thermal Stresses in Monolithic, Coated and Multilayered Elastic Modulus or Gradient in Elastic Materials with Stress-Dependent Modulus Exemplified for Thermal Barrier Coatings. Surf. Coat. Technol. 2004, 186, 416–422. [Google Scholar] [CrossRef]

- Fox, A.C.; Clyne, T.W. Oxygen Transport through the Zirconia Top Coat in Thermal Barrier Coating Systems. In Thermal Spray: Meeting the Challenges of the 21st Century, Proceedings of the 15th International Thermal Spray Conference, Nice, France, 25–29 May 1998; ASM International: Materials Park, OH, USA, 1998. [Google Scholar]

- Paul, S. Pore Architecture in Ceramic Thermal Barrier Coatings. Ph.D. Thesis, University of Cambridge, Cambridge, UK, September 2007. [Google Scholar]

- Harok, V.; Neufuss, K. Elastic and Inelastic Effects in Compression in Plasma-Sprayed Ceramic Coatings. J. Therm. Spray. Technol. 2001, 10, 126–132. [Google Scholar] [CrossRef]

- Zhu, D.M.; Miller, R.A. Thermal Conductivity and Elastic Modulus Evolution of Thermal Barrier Coatings under High Heat Flux Conditions. J. Therm. Spray. Technol. 2000, 9, 175–180. [Google Scholar] [CrossRef]

- Paul, S.; Cipitria, A.; Golosnoy, I.O.; Xie, L.; Dorfman, M.R.; Clyne, T.W. Effects of Impurity Content on the Sintering Characteristics of Plasma-Sprayed Zirconia. J. Therm. Spray. Technol. 2007, 16, 798–803. [Google Scholar] [CrossRef]

- Zhu, J.; Ma, K. Microstructural and mechanical properties of thermal barrier coating at 1400 °C treatment. Theor. Appl. Mech. Lett. 2014, 4, 021008. [Google Scholar] [CrossRef]

- Eaton, H.E.; Novak, R.C. Sintering Studies of Plasma Sprayed Zirconia. Surf. Coat. Technol. 1987, 32, 227–236. [Google Scholar] [CrossRef]

- Paul, S.; Cipitria, A.; Tsipas, S.A.; Clyne, T.W. Sintering characteristics of plasma sprayed zirconia coatings containing different stabilisers. Surf. Coat. Technol. 2009, 203, 1069–1074. [Google Scholar] [CrossRef]

- Wesling, K.F.; Socie, D.F.; Beardsley, B. Fatigue of Thick Thermal Barrier Coatings. J. Am. Ceram. Soc. 1994, 77, 1863–1868. [Google Scholar] [CrossRef]

- Paul, S. Assessing Coating Reliability through Pore Architecture Evaluation. J. Therm. Spray Technol. 2010, 19, 779–786. [Google Scholar] [CrossRef]

- Curry, N.; Janikowski, W.; Pala, Z.; Vilémová, M.; Markocsan, N. Impact of Impurity Content on the Sintering Resistance and Phase Stability of Dysprosia- and Yttria-Stabilized Zirconia Thermal Barrier Coatings. J. Therm. Spray Technol. 2014, 23, 160–169. [Google Scholar] [CrossRef]

- Tillmann, W.; Selvadurai, U.; Luo, W. Measurement of the Young’s Modulus of Thermal Spray Coatings by Means of Several Methods. J. Therm. Spray Technol. 2013, 22, 290–298. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An Improved Technique for Determining Hardness and Elastic Modulus Using Load and Displacement Sensing Indentation Experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Lugovy, M.; Slyunyayev, V.; Teixeira, V. Residual Stress Relaxation Processes in Thermal Barrier Coatings under Tension at High Temperature. Surf. Coat. Technol. 2004, 184, 331–337. [Google Scholar] [CrossRef]

- Khor, K.A.; Gu, Y.W. Effects of Residual Stress on the Performance of Plasma Sprayed Functionally Graded ZrO2/NiCoCrAlY. Mat. Sci. Eng. A Struct. 2000, 277, 64–76. [Google Scholar] [CrossRef]

- Roebben, G.; Bollen, B.; Brebels, A.; Van Humbeeck, J.; Van Der Biest, O. Impulse Excitation Apparatus to Measure Resonant Frequencies, Elastic Moduli, and Internal Friction at Room and High Temperature. Rev. Sci. Instrum. 1997, 68, 4511–4515. [Google Scholar] [CrossRef]

- Green, D.J. An Introduction to the Mechanical Properties of Ceramics (Cambridge Solid State Science Series), 1st ed.; Clarke, D.R., Suresh, S., Ward, I.M., Eds.; Cambridge University Press: Cambridge, UK, 1998. [Google Scholar]

- Bobji, M.S.; Biswas, S.K. Deconvolution of Hardness from Data obtained from Nanoindentation of Rough Surfaces. J. Mater. Res. 1999, 14, 2259–2268. [Google Scholar] [CrossRef]

- Dwivedi, G.; Nakamura, T.; Sampath, S. Determination of Thermal Spray Coating Property with Curvature Measurements. J. Therm. Spray Tech. 2013, 22, 1337–1347. [Google Scholar] [CrossRef]

- Paul, S. Thermal Barrier Coatings. Encyclopedia of Aerospace Engineering; Wiley: Somerset, NJ, USA, 2010. [Google Scholar]

- Solomon, H.; Chaumont, J.; Dolin, C.; Monty, C. Zr, Y and O Self Diffusion in Zr(1−x)YxO2−x/2. In Point Defects and Related Properties of Ceramics; Ceramic Transactions Volume 24; Manson, T.O., Routbourt, J.L., Eds.; American Ceramic Society: Westerville, OH, USA, 1991; p. 175. [Google Scholar]

- Anthony, A.M. Sintering and Related Phenomena. In Structure of Point Defects in Ionic Materials; Springer: New York, NY, USA, 1973. [Google Scholar]

- Swaroop, S.; Kilo, M.; Argirusis, C.; Borchardt, G.; Chokshi, A.H. Lattice and Grain Boundary Diffusion of Cations in 3YTZ Analyzed using SIMS. Acta Mater. 2005, 53, 4975–4985. [Google Scholar]

- Chien, F.R.; Heuer, A.H. Lattice Diffusion Kinetics in Y2O3-Stabilized Cubic ZrO2 Single Crystals: A Dislocation Loop Annealing Study. Philos. Mag. A 1996, 73, 681–697. [Google Scholar] [CrossRef]

- Jimenez-Melendo, M.; Dominguez-Rodriguez, A.; Gomez-Garcia, D.; Bravo-Leon, A.; Martinez-Fernandez, J. Cation Lattice Diffusion in Yttria-Stabilized Zirconia deduced from Deformation Studies. Mater. Sci. Forum. 1997, 239–241, 61–64. [Google Scholar] [CrossRef]

- Lakki, A.; Herzog, R.; Weller, M.; Schubert, H.; Reetz, C.; Gorke, O.; Kilo, M.; Borchardt, G. Mechanical Loss, Creep, Diffusion and Ionic Conductivity of ZrO2–8 mol %Y2O3 Polycrystals. J. Eur. Ceram. Soc. 2000, 20, 285–296. [Google Scholar] [CrossRef]

| Test | Coating Thickness, t (mm) | Comments |

|---|---|---|

| Four-point bending and IET of stand-alone coatings | 0.65 | Detached coatings were used |

| Four-point bending and IET of coatings on steel substrate | 1.40 | Attached coatings were used |

| Microindentation | 0.30 | The samples were polished before testing |

| Nanoindentation | 0.30 |

| Diffusion Type | Pre-Exponential Factor, D0 (m2·s−1) | Activation Energy, ΔE (kJ·mol−1) |

|---|---|---|

| Lattice | 5 × 10−4 | 515 |

| Grain Boundary | 1 × 10−3 | 370 |

© 2017 by the author and TWI. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Paul, S. Stiffness of Plasma Sprayed Thermal Barrier Coatings. Coatings 2017, 7, 68. https://doi.org/10.3390/coatings7050068

Paul S. Stiffness of Plasma Sprayed Thermal Barrier Coatings. Coatings. 2017; 7(5):68. https://doi.org/10.3390/coatings7050068

Chicago/Turabian StylePaul, Shiladitya. 2017. "Stiffness of Plasma Sprayed Thermal Barrier Coatings" Coatings 7, no. 5: 68. https://doi.org/10.3390/coatings7050068