Inkjet-Printed Chemical Solution Y2O3 Layers for Planarization of Technical Substrates

Abstract

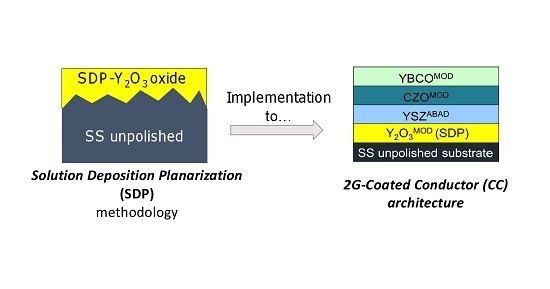

:1. Introduction

2. Materials and Methods

2.1. Metal-Organic Precursor Inks

2.1.1. Materials

2.1.2. Metal-Organic Precursor Ink Preparation

2.1.3. Metal-Organic Precursor Ink Characterization

Viscosity Measurement

Surface Tension and Contact Angle Measurements

Density Measurement

Metal Concentration

2.2. Metal-Organic Precursor Ink Deposition and Film Characterization

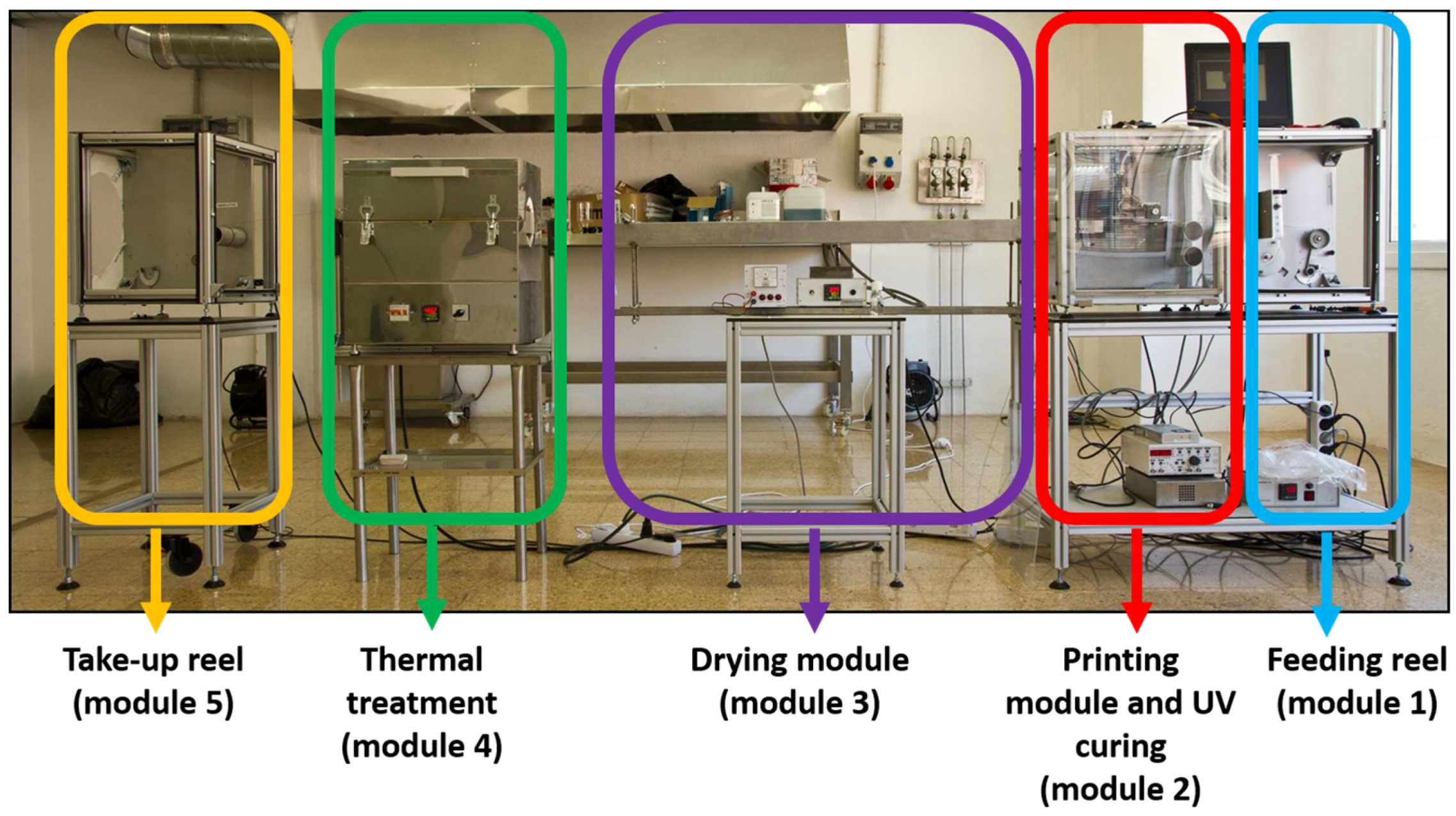

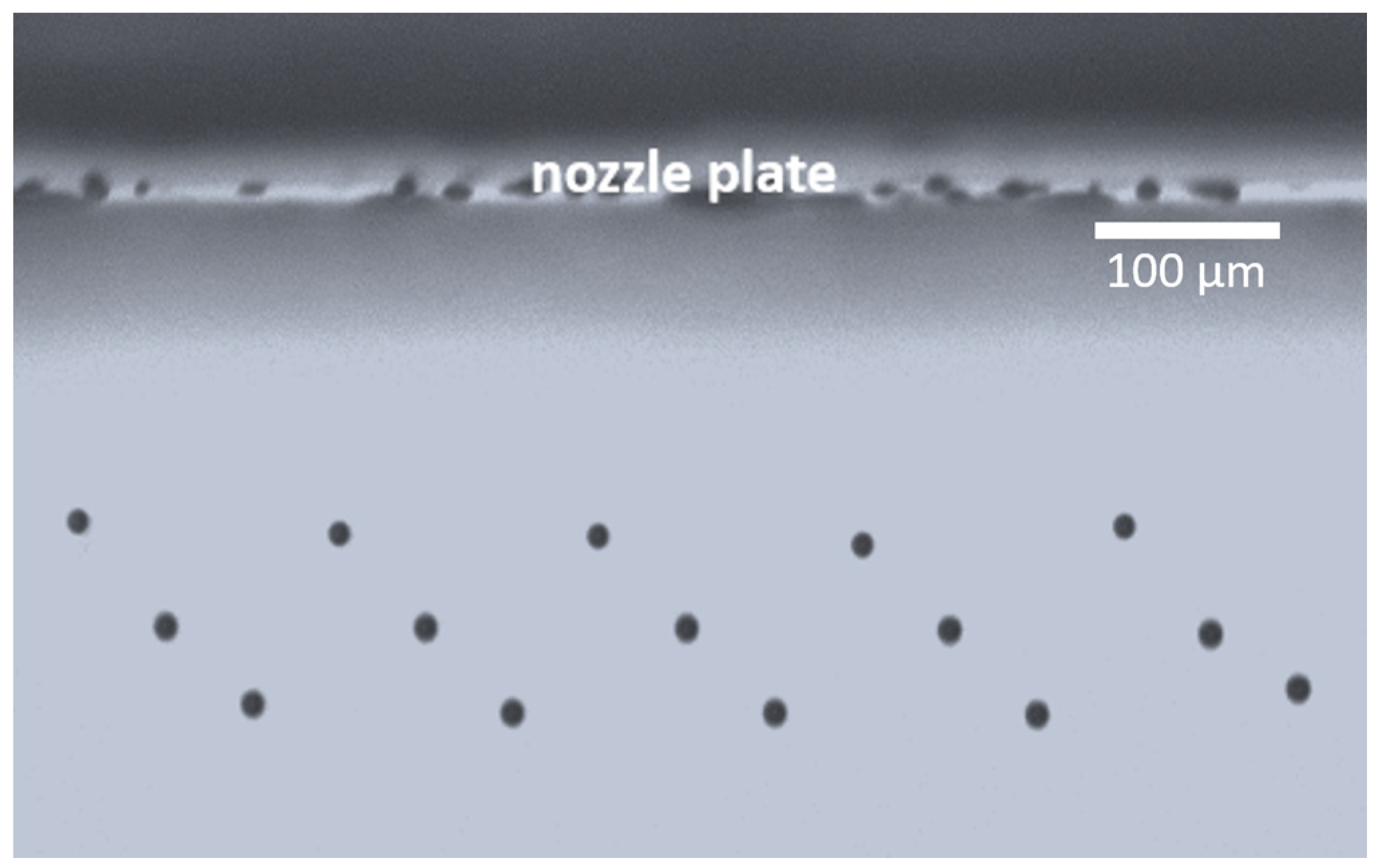

2.2.1. Metal-Organic Precursor Ink Deposition

2.2.2. Film Drying

2.2.3. Film Pyrolysis

2.2.4. Film Characterization: Morphology, Microstructure and Texture

3. Results and Discussion

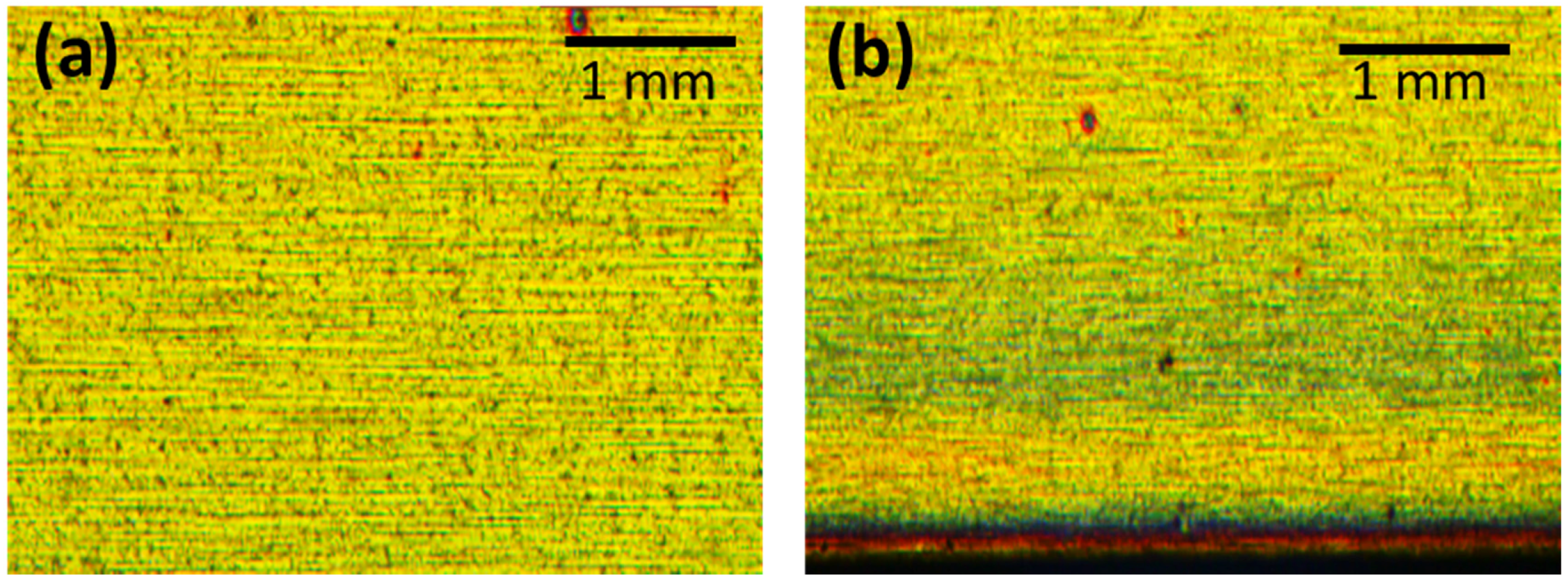

3.1. Inkjet Printing Deposition of Short-Length SDP-Y2O3 Films

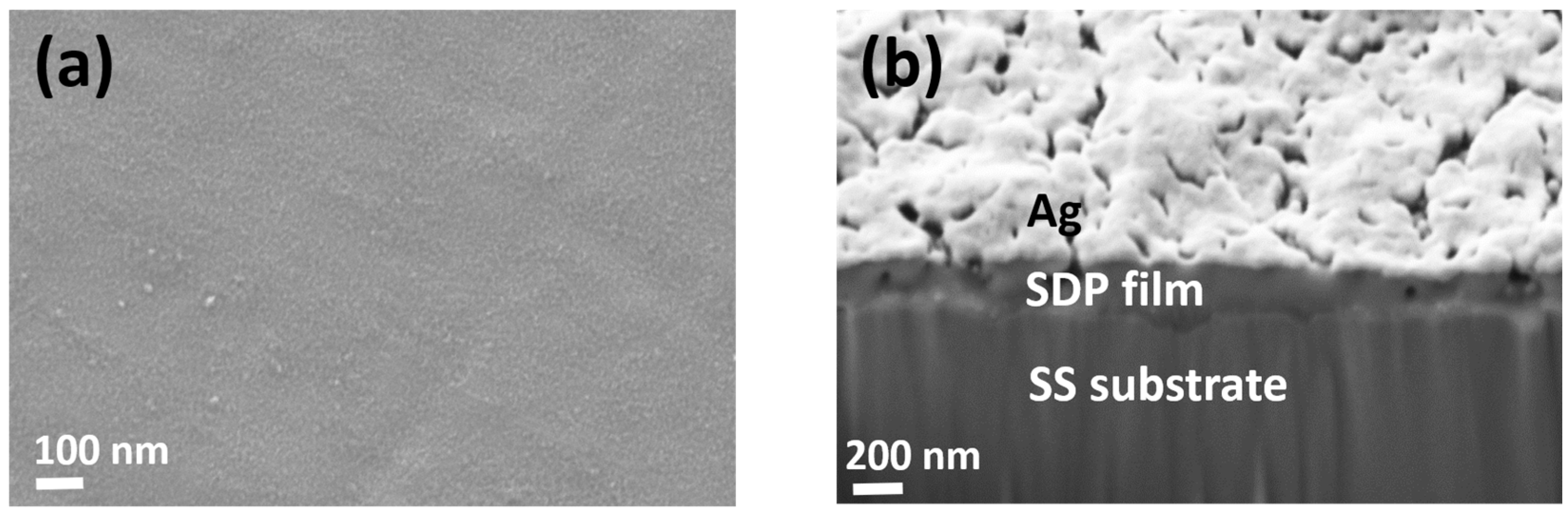

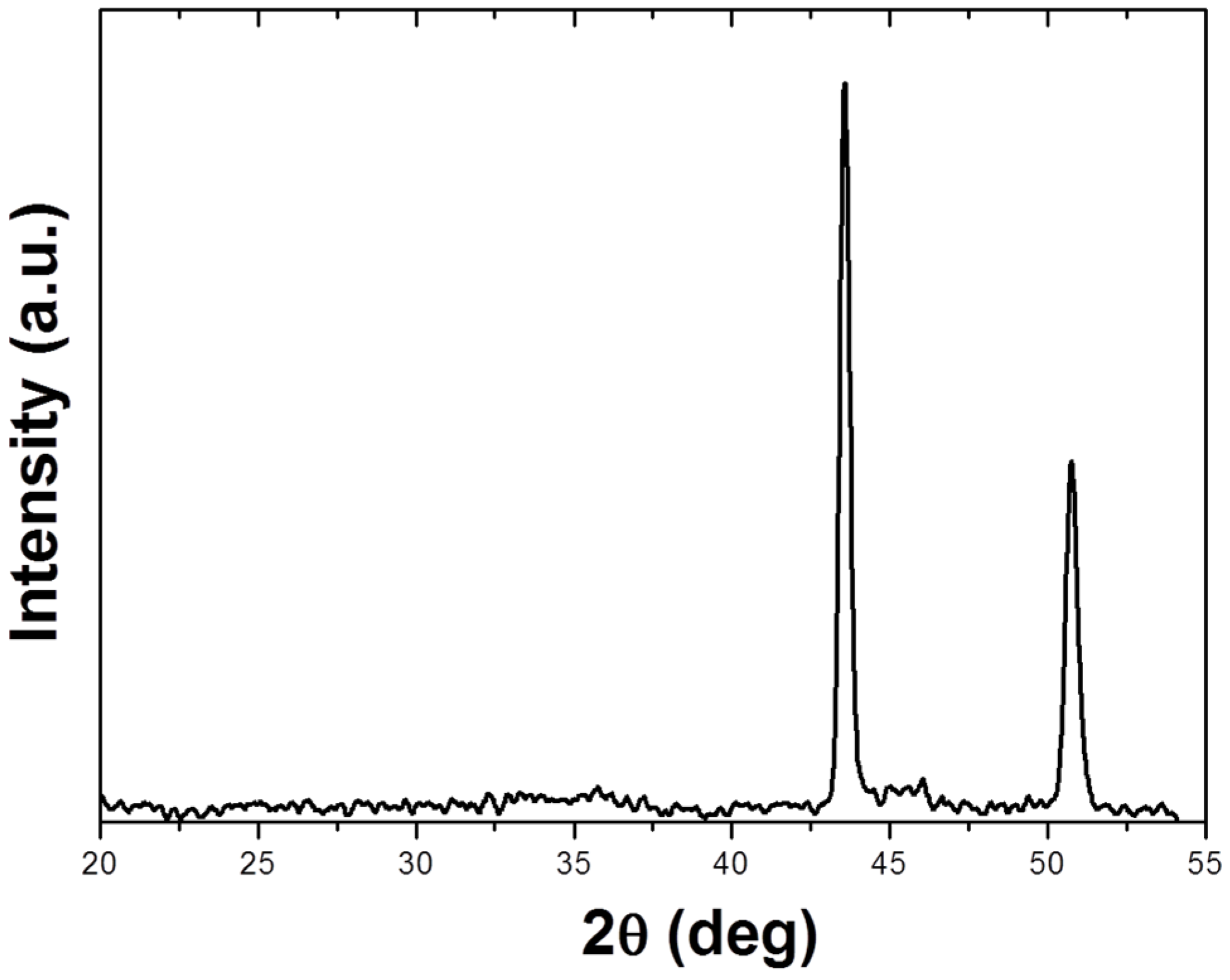

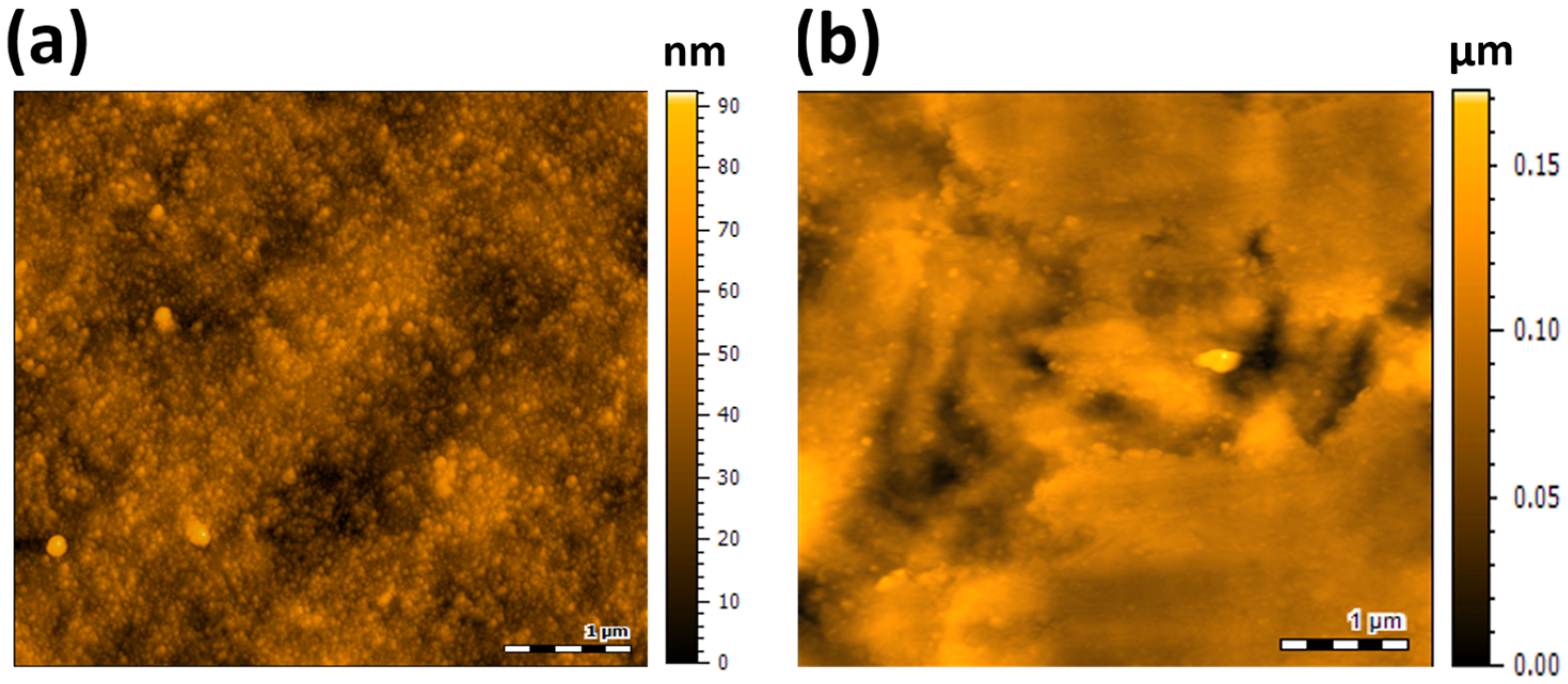

3.2. Characterization of Short-Length SDP-Y2O3 Films

3.3. Printing on Smoother Substrates

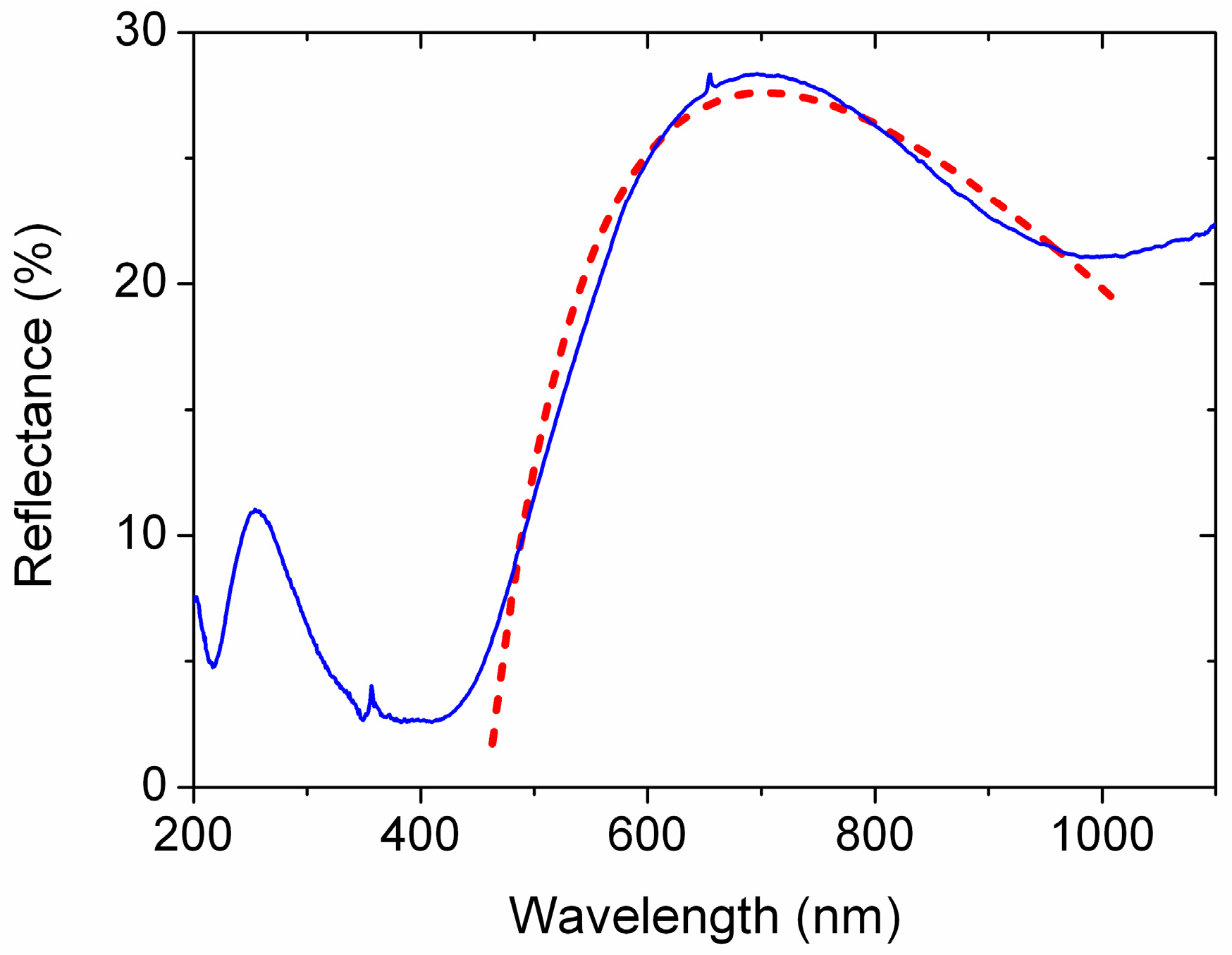

3.4. Validation of Short-Length SDP-Y2O3 Films

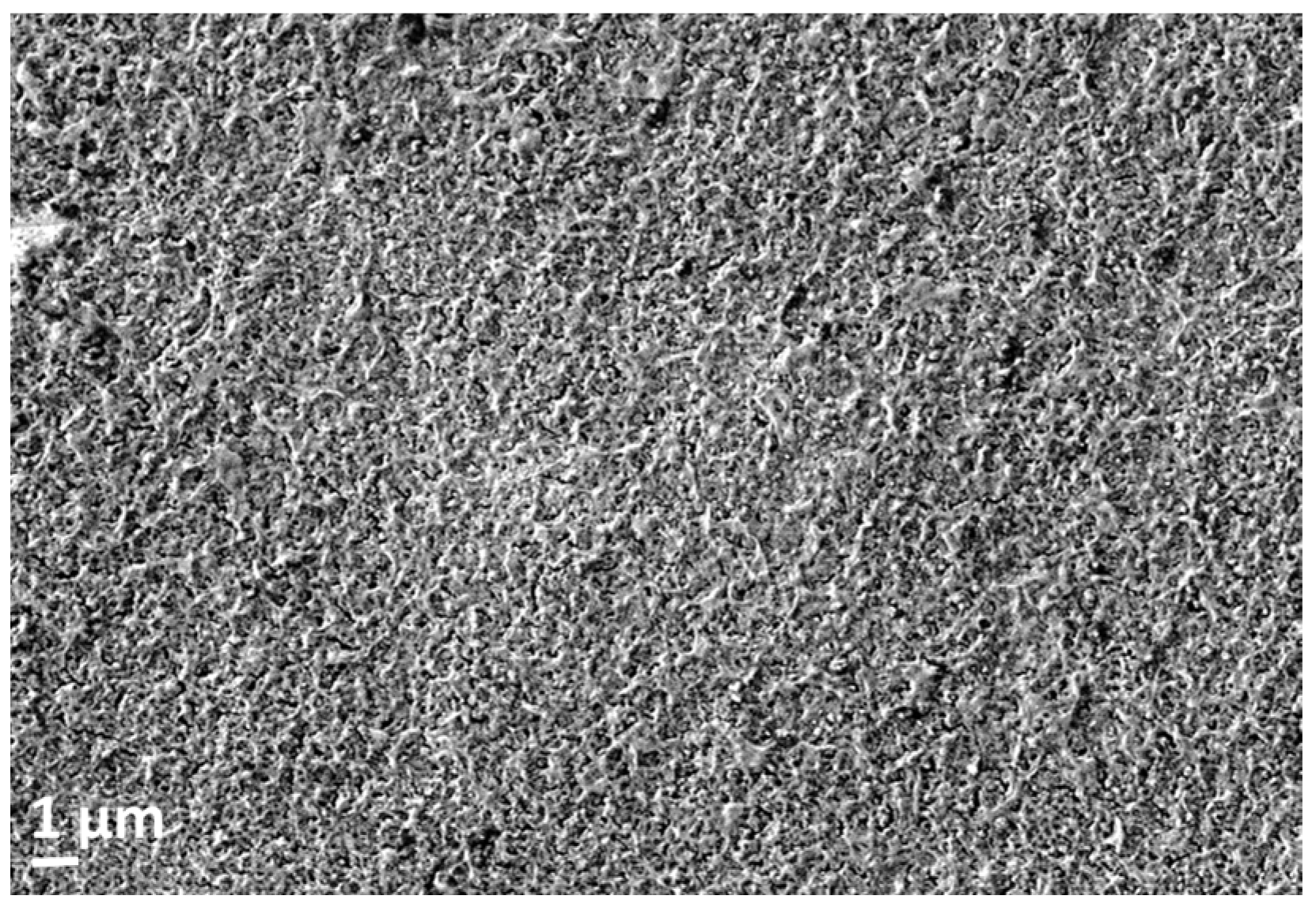

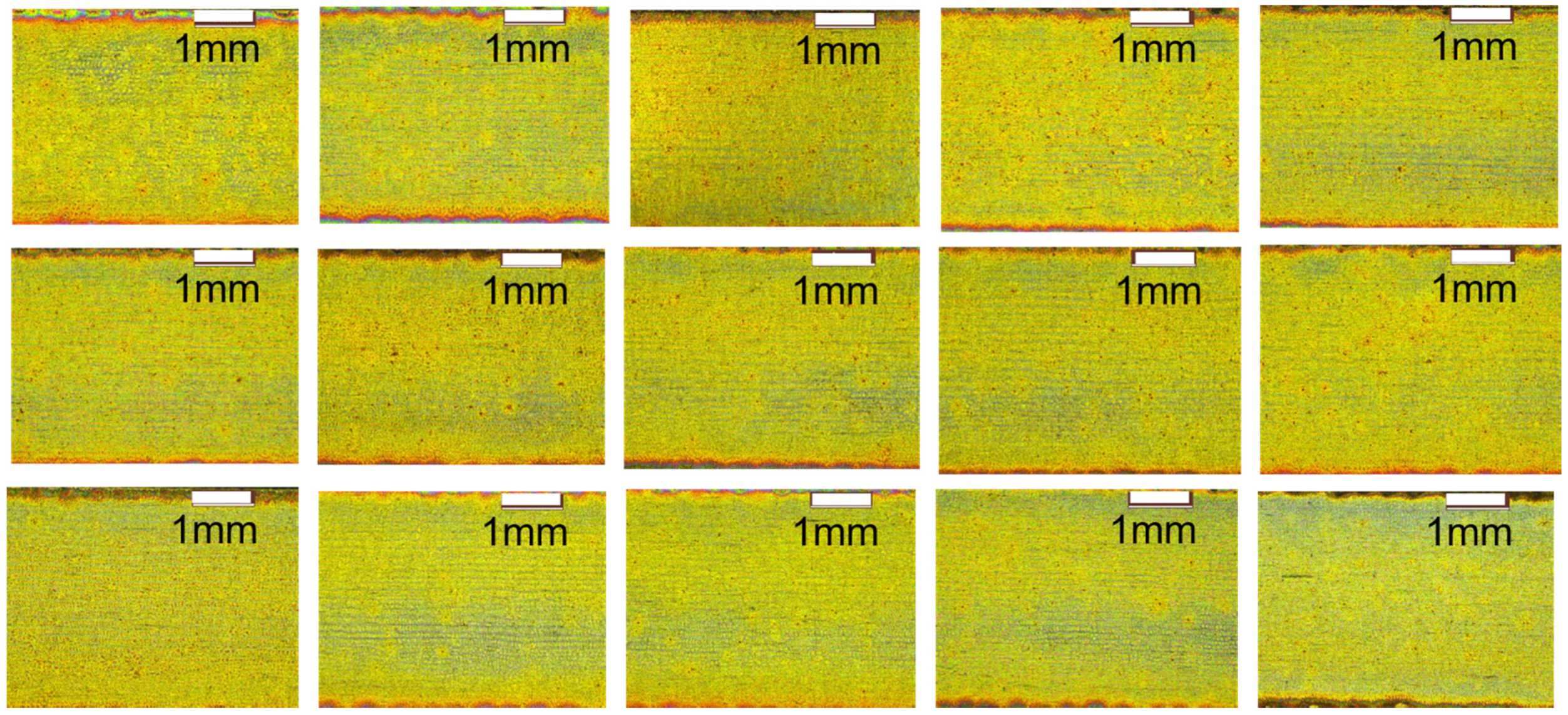

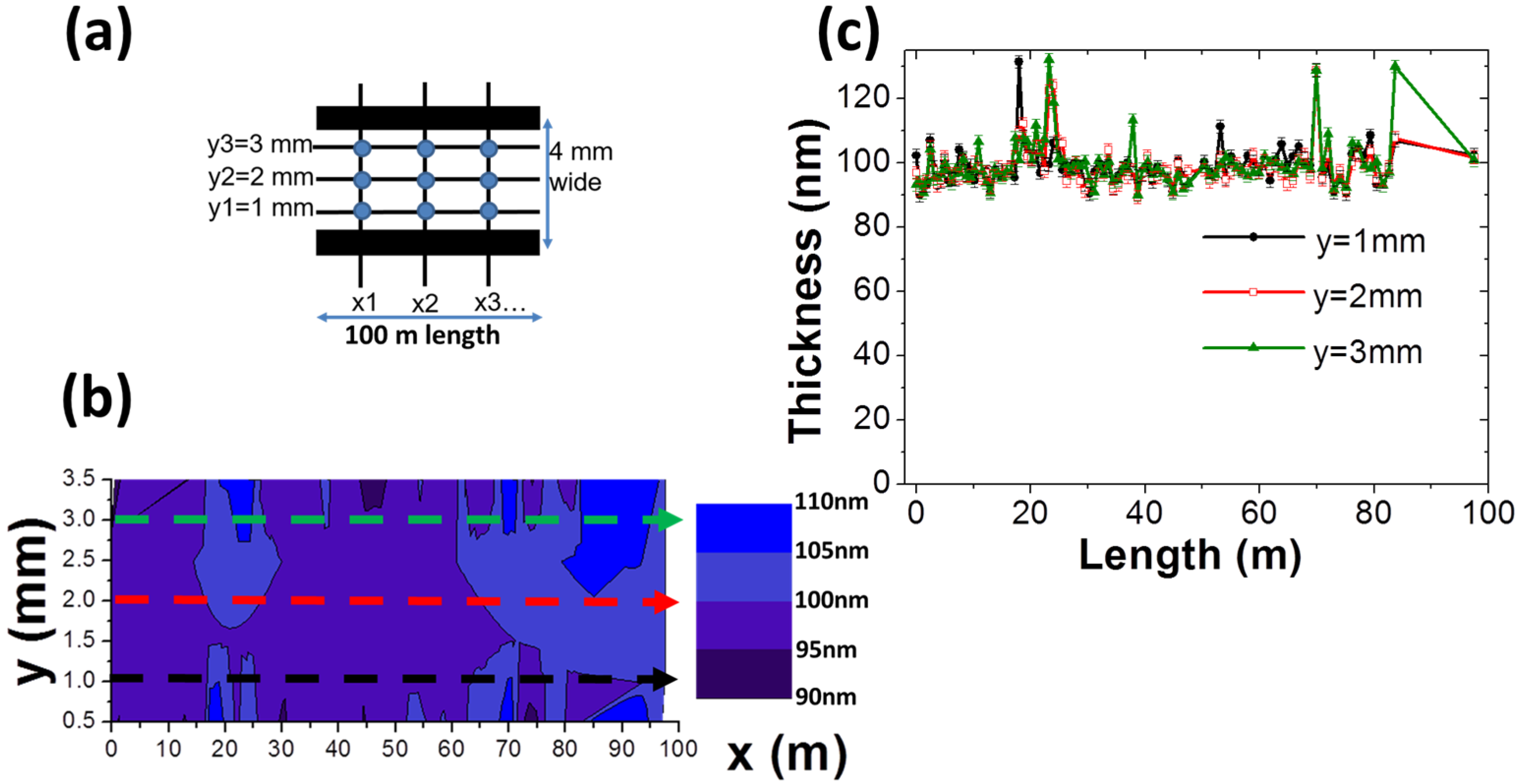

3.5. Scale-up of the SDP-Y2O3 Films

4. Summary and Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Sascha, K.; Paul, N.A.; Coulter, J.Y.; Paul, C.D.; Stephen, R.F.; Brady, J.G.; Vladimir, M.; Chris, J.S. Reel-to-reel preparation of ion-beam assisted deposition (IBAD)-MgO based coated conductors. Supercond. Sci. Technol. 2004, 17, S132–S134. [Google Scholar] [CrossRef]

- Lange, F.F. Chemical Solution Routes to Single-Crystal Thin Films. Science 1996, 273, 903–909. [Google Scholar] [CrossRef] [PubMed]

- Schwartz, R.W. Chemical Solution Deposition of Perovskite Thin Films. Chem. Mater. 1997, 9, 2325–2340. [Google Scholar] [CrossRef]

- Schwartz, R.W.; Schneller, T.; Waser, R. Chemical solution deposition of electronic oxide films. Comptes Rendus Chim. 2004, 7, 433–461. [Google Scholar] [CrossRef]

- Obradors, X.; Puig, T.; Pomar, A.; Sandiumenge, F.; Mestres, N.; Coll, M.; Cavallaro, A.; Romà, N.; Gázquez, J.; González, J.C.; et al. Progress towards all-chemical superconducting YBa2Cu3O7-coated conductors. Supercond. Sci. Technol. 2006, 19, S13–S26. [Google Scholar] [CrossRef]

- Derby, B. Inkjet Printing of Functional and Structural Materials: Fluid Property Requirements, Feature Stability and Resolution. Annu. Rev. Mater. Res. 2010, 40, 395–414. [Google Scholar] [CrossRef]

- Wijshoff, H. The dynamics of the piezo inkjet printhead operation. Phys. Rep. 2010, 491, 77–177. [Google Scholar] [CrossRef]

- Dong, H.; Carr, W.W.; Morris, J.F. An experimental study of drop-on-demand drop formation. Phys. Fluids 2006, 18, 072102. [Google Scholar] [CrossRef]

- Vilardell, M.; Granados, X.; Ricart, S.; van Driessche, I.; Palau, A.; Puig, T.; Obradors, X. Flexible manufacturing of functional ceramic coatings by inkjet printing. Thin Solid Films 2013, 548, 489–497. [Google Scholar] [CrossRef]

- Feys, J.; Vermeir, P.; Lommens, P.; Hopkins, S.C.; Granados, X.; Glowacki, B.A.; Baecker, M.; Reich, E.; Ricard, S.; Holzapfel, B.; et al. Ink-jet printing of YBa2Cu3O7 superconducting coatings and patterns from aqueous solutions. J. Mater. Chem. 2012, 22, 3717–3726. [Google Scholar] [CrossRef]

- Larbalestier, D.; Gurevich, A.; Feldmann, D.M.; Polyanskii, A. High-Tc superconducting materials for electric power applications. Nature 2001, 414, 368–377. [Google Scholar] [CrossRef] [PubMed]

- MacManus-Driscoll, J.L. Recent developments in conductor processing of high irreversibility field superconductors. Annu. Rev. Mater. Sci. 1998, 28, 421–462. [Google Scholar] [CrossRef]

- Rogalla, H.; Kes, P.H. 100 Years of Superconductivity; CRC Press Taylor & Francis Group: Boca Raton, FL, USA, 2011. [Google Scholar]

- Obradors, X.; Puig, T. Coated conductors for power applications: Materials challenges. Supercond. Sci. Technol. 2014, 27, 044003. [Google Scholar] [CrossRef]

- Lee, S.; Petrykin, V.; Molodyk, A.; Samoilenkov, S.; Kaul, A.; Vavilov, A.; Vysotsky, V.; Fetisov, S. Development and production of second generation high Tc superconducting tapes at SuperOx and first tests of model cables. Supercond. Sci. Technol. 2014, 27, 044022. [Google Scholar] [CrossRef]

- Iijima, Y.; Kakimoto, K.; Yamada, Y.; Izumi, T.; Saitoh, T.; Shiohara, Y. Research and Development of Biaxially Textured IBAD-GZO Templates for Coated Superconductors. MRS Bull. 2004, 29, 564–571. [Google Scholar] [CrossRef]

- Goyal, A.; Paranthaman, M.P.; Schoop, U. The RABiTS Approach: Using Rolling-Assisted Biaxially Textured Substrates for High-Performance YBCO Superconductors. MRS Bull. 2004, 29, 552–561. [Google Scholar] [CrossRef]

- Paranthaman, M.P.; Aytug, T.; Zhai, H.Y.; Heatherly, L.; Goyal, A.; Christen, D.K. Growth of YBCO films on MgO-based rolling-assisted biaxially textured substrates templates. Supercond. Sci. Technol. 2005, 18, 223–228. [Google Scholar] [CrossRef]

- Usoskin, A.; Kirchhoff, L. In-Plane Texturing of Buffer Layers by Alternating Beam Assisted Deposition: Large Area and Small Area Applications; Cambridge University Press: New York, NY, USA, 2008; Volume 1150. [Google Scholar] [CrossRef]

- Hassini, A.; Pomar, A.; Gutiérrez, J.; Coll, M.; Romà, N.; Moreno, C.; Ruyter, A.; Puig, T.; Obradors, X. Atomically flat MOD La0.7Sr0.3MnO3 buffer layers for high critical current YBa2 Cu3O7 TFA films. Supercond. Sci. Technol. 2007, 20, S230–S238. [Google Scholar] [CrossRef]

- Usoskin, A.; Betz, U.; Dietrich, R.; Schlenga, K. Long HTS Coated Conductor Processed via Large-Area PLD/ABAD for High-Field Applications. IEEE Trans. Appl. Supercond. 2016, 26, 1–4. [Google Scholar] [CrossRef]

- Samoilenkov, S.; Molodyk, A.; Lee, S.; Petrykin, V.; Kalitka, V.; Martynova, I.; Makarevich, A.; Markelov, A.; Moyzykh, M.; Blednov, A. Customised 2G HTS wire for applications. Supercond. Sci. Technol. 2016, 29, 024001. [Google Scholar] [CrossRef]

- Bhuiyan, M.S.; Paranthaman, M.; Sathyamurthy, S.; Aytug, T.; Kang, S.; Lee, D.F.; Goyal, A.; Payzant, E.A.; Salama, K. MOD approach for the growth of epitaxial CeO2 buffer layers on biaxially textured Ni–W substrates for YBCO coated conductors. Supercond. Sci. Technol. 2003, 16, 1305–1309. [Google Scholar] [CrossRef]

- Engel, S.; Knoth, K.; Hühne, R.; Schultz, L.; Holzapfel, B. An all chemical solution deposition approach for the growth of highly textured CeO2 cap layers on La2Zr2O7-buffered long lengths of biaxially textured Ni–W substrates for YBCO-coated conductors. Supercond. Sci. Technol. 2005, 18, 1385–1390. [Google Scholar] [CrossRef]

- Yang, C.; He, Y.Y.; Chu, J.W.; Xue, Y.; Zhang, F.; Hui, W.; Tao, B.W.; Xiong, J. Tailoring surface roughness of LaMnO3 buffer layers for YBCO-coated conductors. Rare Met. 2015, 34, 859–863. [Google Scholar] [CrossRef]

- Wang, Y.; Li, C.; Feng, J.; Yu, Z.; Jin, L.; Zhang, P. Epitaxial growth of CSD modified lanthanum zirconium oxide buffer layer for coated conductors. J. Alloys Compd. 2016, 682, 424–431. [Google Scholar] [CrossRef]

- Hühne, R.; Güth, K.; Gärtner, R.; Kidszun, M.; Thoss, F.; Rellinghaus, B.; Schultz, L.; Holzapfel, B. Application of textured IBAD-TiN buffer layers in coated conductor architectures. Supercond. Sci. Technol. 2010, 23, 014010. [Google Scholar] [CrossRef]

- Dürrschnabel, M.; Aabdin, Z.; Große, V.; Bauer, M.; Sigl, G.; Prusseit, W.; Eibl, O. Growth of Biaxially-Textured MgO Buffer Layers by Inclined Substrate Deposition. Phys. Procedia 2012, 36, 1546–1551. [Google Scholar] [CrossRef]

- Xiong, J.; Xue, Y.; Xia, Y.D.; Zhang, F.; Zhang, Y.X.; Li, L.H.; Zhao, X.H.; Tao, B.W. Fabrication of long-length ion beam-assisted deposited MgO templates for YBCO-coated conductors. Rare Met. 2013, 32, 574–578. [Google Scholar] [CrossRef]

- Paranthaman, M.P.; Tolga, A.; Liliana, S.; Quanxi, J.; Claudia, C.; Wee, S.H. Chemical solution derived planarization layers for highly aligned IBAD-MgO templates. Supercond. Sci. Technol. 2014, 27, 022002. [Google Scholar] [CrossRef]

- Shi, X.; Rock, S.E.; Turk, M.C.; Roy, D. Minimizing the effects of galvanic corrosion during chemical mechanical planarization of aluminum in moderately acidic slurry solutions. Mater. Chem. Phys. 2012, 136, 1027–1037. [Google Scholar] [CrossRef]

- Jia, Q.; Wang, Y.; Suo, H.L.; Wang, P.; Li, M.Y.; Huo, Q.Y. Electropolishing technique of Hastelloy C-276 alloy. Rare Met. 2017, 36, 635–639. [Google Scholar] [CrossRef]

- Wang, X.; Li, C.; Yu, Z.; Zheng, H.; Ji, Y.; Ji, P.; Chen, Z.; Fan, Z. Electropolishing of Ni–5 at.% W substrates for YBCO coated conductors. Mat. Chem. Phys. 2012, 133, 212–217. [Google Scholar] [CrossRef]

- Sheehan, C.; Jung, Y.; Holesinger, T.; Feldmann, D.M.; Edney, C.; Ihlefeld, J.F.; Clem, P.G.; Matias, V. Solution deposition planarization of long-length flexible substrates. Appl. Phys. Lett. 2011, 98, 071907. [Google Scholar] [CrossRef]

- Martynova, I.A.; Tsymbarenko, D.M.; Kamenev, A.A.; Mudretsova, S.N.; Streletsky, A.N.; Vasiliev, A.L.; Kuzmina, N.P.; Kaul, A.R. Chemical deposition of smooth nanocrystalline Y2O3 films from solutions of metal-organic precursors. Russ. Chem. Bull. 2013, 62, 1454–1458. [Google Scholar] [CrossRef]

- Martynova, I.; Tsymbarenko, D.; Kamenev, A.; Amelichev, V.; Molodyk, A.; Kuzmina, N.; Kaul, A. Solution deposition of ultrasmooth alumina on long-length metallic substrate for 2G superconducting tapes. Mater. Res. Bull. 2016, 78, 64–71. [Google Scholar] [CrossRef]

- Smith, P.J. The Chemistry of InkJet Inks; World Scientific: Singapore, 2010; pp. 55–72. [Google Scholar]

- Anastasiadis, S.H.; Chen, J.K.; Koberstein, J.T.; Siegel, A.F.; Sohn, J.E.; Emerson, J.A. The determination of interfacial tension by video image processing of pendant fluid drops. J. Colloid Interface Sci. 1987, 119, 55–66. [Google Scholar] [CrossRef]

- Girault, H.H.J.; Schiffrin, D.J.; Smith, B.D.V. The measurement of interfacial tension of pendant drops using a video image profile digitizer. J. Colloid Interface Sci. 1984, 101, 257–266. [Google Scholar] [CrossRef]

- Rotenberg, Y.; Boruvka, L.; Neumann, A.W. Determination of surface tension and contact angle from the shapes of axisymmetric fluid interfaces. J. Colloid Interface Sci. 1983, 93, 169–183. [Google Scholar] [CrossRef]

- Boyce, J.F.; Schürch, S.; Rotenberg, Y.; Neumann, A.W. The measurement of surface and interfacial tension by the axisymmetric drop technique. Colloids Surf. 1984, 9, 307–317. [Google Scholar] [CrossRef]

- Usoskin, A.; Kirchhoff, L.; Knoke, J.; Prause, B.; Rutt, A.; Selskij, V.; Farrell, D.E. Processing of Long-Length YBCO Coated Conductors Based on Stainless Steel Tapes. IEEE Trans. Appl. Supercond. 2007, 17, 3235–3238. [Google Scholar] [CrossRef]

- Jang, D.; Kim, D.; Moon, J. Influence of fluid physical properties on ink-jet printability. Langmuir 2009, 25, 2629–2635. [Google Scholar] [CrossRef] [PubMed]

- Kozuka, H.; Takenaka, S.; Tokita, H.; Hirano, T.; Higashi, Y.; Hamatani, T. Stress and Cracks in Gel-Derived Ceramic Coatings and Thick Film Formation. J. Sol-Gel Sci. Technol. 2003, 26, 681–686. [Google Scholar] [CrossRef]

- He, B.B. Two-Dimensional X-ray Diffraction; John Wiley & Sons: Hoboken, NJ, USA, 2009. [Google Scholar]

- Fischer-Cripps, A.C. Nanoindentation; Springer: New York, NY, USA, 2002. [Google Scholar]

- Chet, L.; Furse, C. Noise-domain reflectometry for locating wiring faults. IEEE Trans. Electromagn. Compat. 2005, 47, 97–104. [Google Scholar] [CrossRef]

- Jenkins, F.A.; White, H.E. Fundamentals of Optics; McGraw-Hill: New York, NY, USA, 1957; pp. 464–487. [Google Scholar]

- Chibowski, E. On some relations between advancing, receding and Young’s contact angles. Adv. Colloid Interface Sci. 2007, 133, 51–59. [Google Scholar] [CrossRef] [PubMed]

- Ström, G.; Fredriksson, M.; Stenius, P. Contact angles, work of adhesion and interfacial tensions at a dissolving Hydrocarbon surface. J. Colloid Interface Sci. 1987, 119, 352–361. [Google Scholar] [CrossRef]

- Marcè, A.; Fernández, J.C.; Chimigraf Ibérica, S.L. Method for Producing a Digital Inkjet Printing Ink and Thus Obtained Digital Inkjet Printing Ink; WO 2017/158217 A1; WIPO: Geneva, Switzerland, 2017. [Google Scholar]

- Leyland, A.; Matthews, A. On the significance of the H/E ratio in wear control: A nanocomposite coating approach to optimised tribological behaviour. Wear 2000, 246, 1–11. [Google Scholar] [CrossRef]

- Rebholz, C.; Leyland, A.; Schneider, J.M.; Voevodin, A.A.; Matthews, A. Structure, hardness and mechanical properties of magnetron-sputtered titanium–aluminium boride films. Surf. Coat. Technol. 1999, 120, 412–417. [Google Scholar] [CrossRef]

| Ink Physicochemical and Rheological Properties | Value |

|---|---|

| Density (g/cm3) | 0.915 ± 0.018 |

| Surface tension (mN/m) | 24.7 ± 0.3 |

| Viscosity (mPa·s) | 7.7 ± 0.5 |

| Contact angle (°) | 25 ± 2 |

| Jetting Parameters | Value |

|---|---|

| High pulse width (µs) | 6.4 |

| High-low pulse delay (µs) | 0 |

| Drop period (µs) | 32 |

| Low pulse width (µs) | 12.8 |

| Phase length (µs) | 32.6 |

| Voltage up (V) | 11.4 |

| Voltage down (V) | 5.7 |

| Printhead Temperature (°C) | 25 |

| Ink Physicochemical and Rheological Properties | Value |

|---|---|

| Density (g/cm3) | 0.927 ± 0.015 |

| Surface tension (mN/m) | 25.4 ± 0.2 |

| Viscosity (mPa·s) | 7.7 ± 0.5 |

| Contact angle (°) | 27 ± 2 |

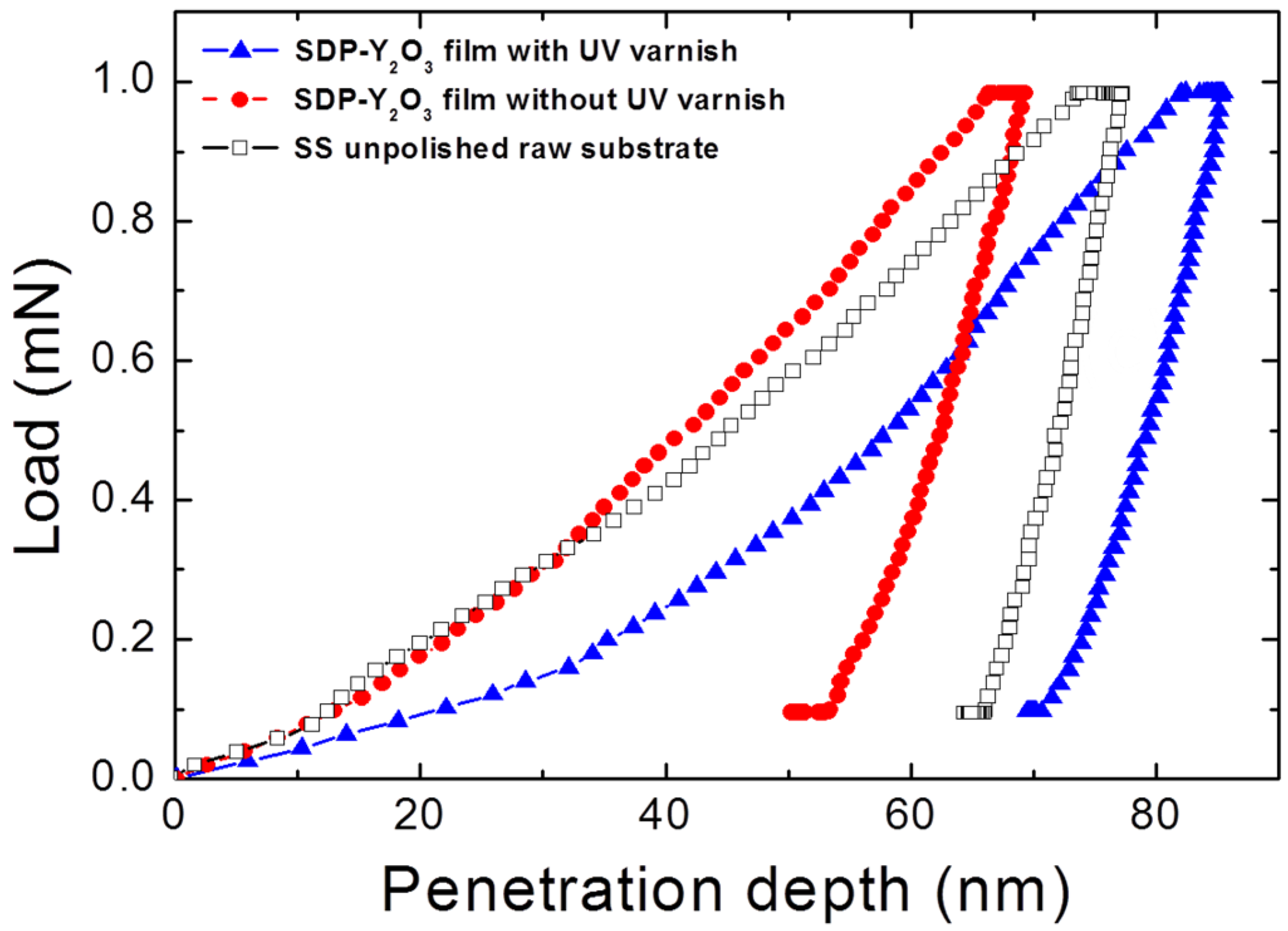

| Mechanical Parameters at 1 mN | SDP-Y2O3 Film without UV Varnish | SDP-Y2O3 Film with UV Varnish | SS Unpolished Substrate |

|---|---|---|---|

| Hardness H (GPa) | 8.5 ± 0.5 | 5.2 ± 1.8 | 6.2 ± 1.1 |

| Reduced Young modulus Er (GPa) | 202 ± 15 | 177 ± 45 | 234 ± 26 |

| H/Er | 0.042 | 0.025 | 0.026 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vilardell, M.; Fornell, J.; Sort, J.; Vlad, R.; Fernández, J.C.; Puig, J.; Usoskin, A.; Palau, A.; Puig, T.; Obradors, X.; et al. Inkjet-Printed Chemical Solution Y2O3 Layers for Planarization of Technical Substrates. Coatings 2017, 7, 227. https://doi.org/10.3390/coatings7120227

Vilardell M, Fornell J, Sort J, Vlad R, Fernández JC, Puig J, Usoskin A, Palau A, Puig T, Obradors X, et al. Inkjet-Printed Chemical Solution Y2O3 Layers for Planarization of Technical Substrates. Coatings. 2017; 7(12):227. https://doi.org/10.3390/coatings7120227

Chicago/Turabian StyleVilardell, Marta, Jordina Fornell, Jordi Sort, Roxana Vlad, Juan Carlos Fernández, Joaquim Puig, Alexander Usoskin, Anna Palau, Teresa Puig, Xavier Obradors, and et al. 2017. "Inkjet-Printed Chemical Solution Y2O3 Layers for Planarization of Technical Substrates" Coatings 7, no. 12: 227. https://doi.org/10.3390/coatings7120227

APA StyleVilardell, M., Fornell, J., Sort, J., Vlad, R., Fernández, J. C., Puig, J., Usoskin, A., Palau, A., Puig, T., Obradors, X., & Calleja, A. (2017). Inkjet-Printed Chemical Solution Y2O3 Layers for Planarization of Technical Substrates. Coatings, 7(12), 227. https://doi.org/10.3390/coatings7120227