Influence of Power Pulse Parameters on the Microstructure and Properties of the AlCrN Coatings by a Modulated Pulsed Power Magnetron Sputtering

Abstract

:1. Introduction

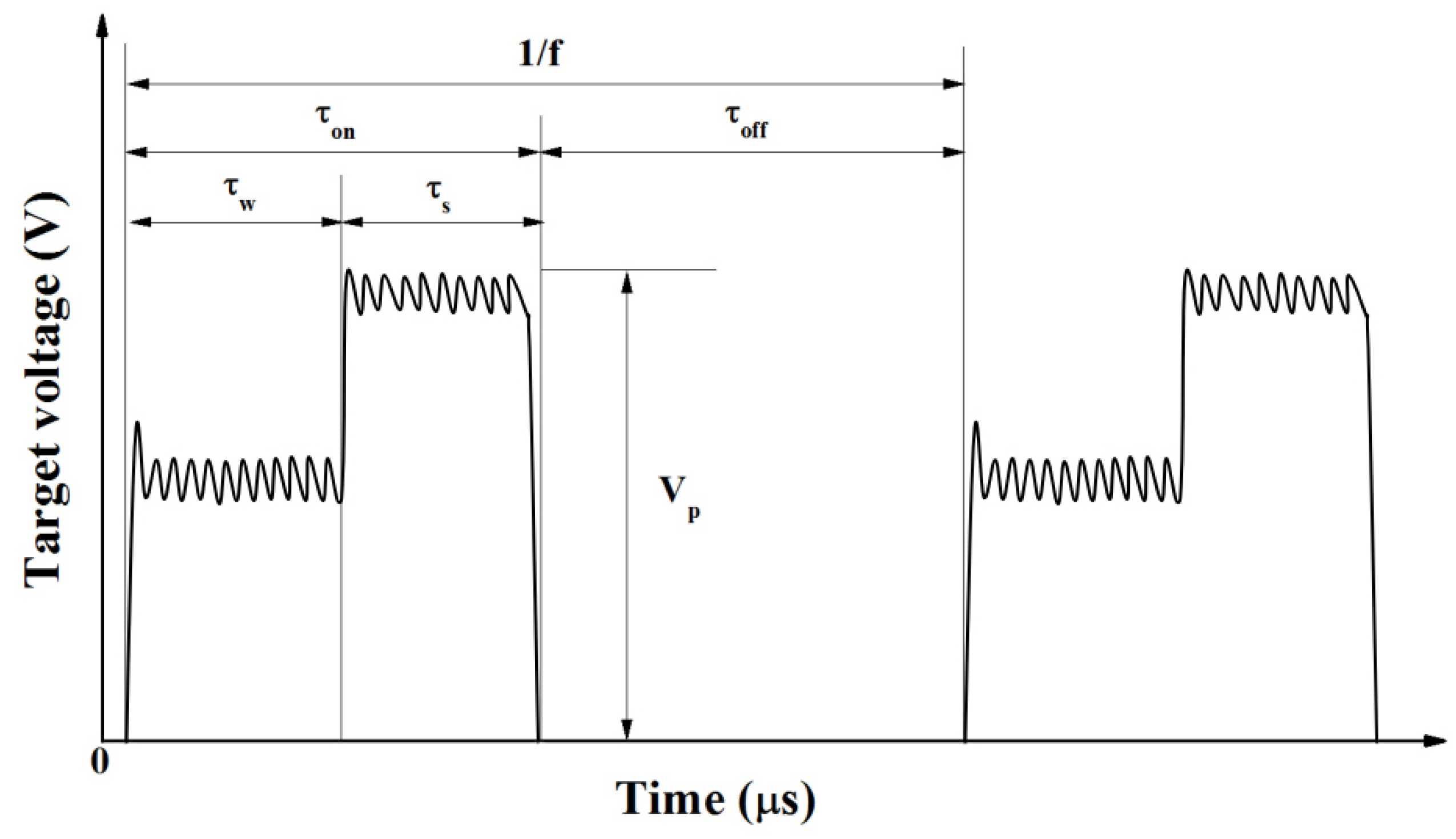

2. Materials and Methods

3. Results and Discussion

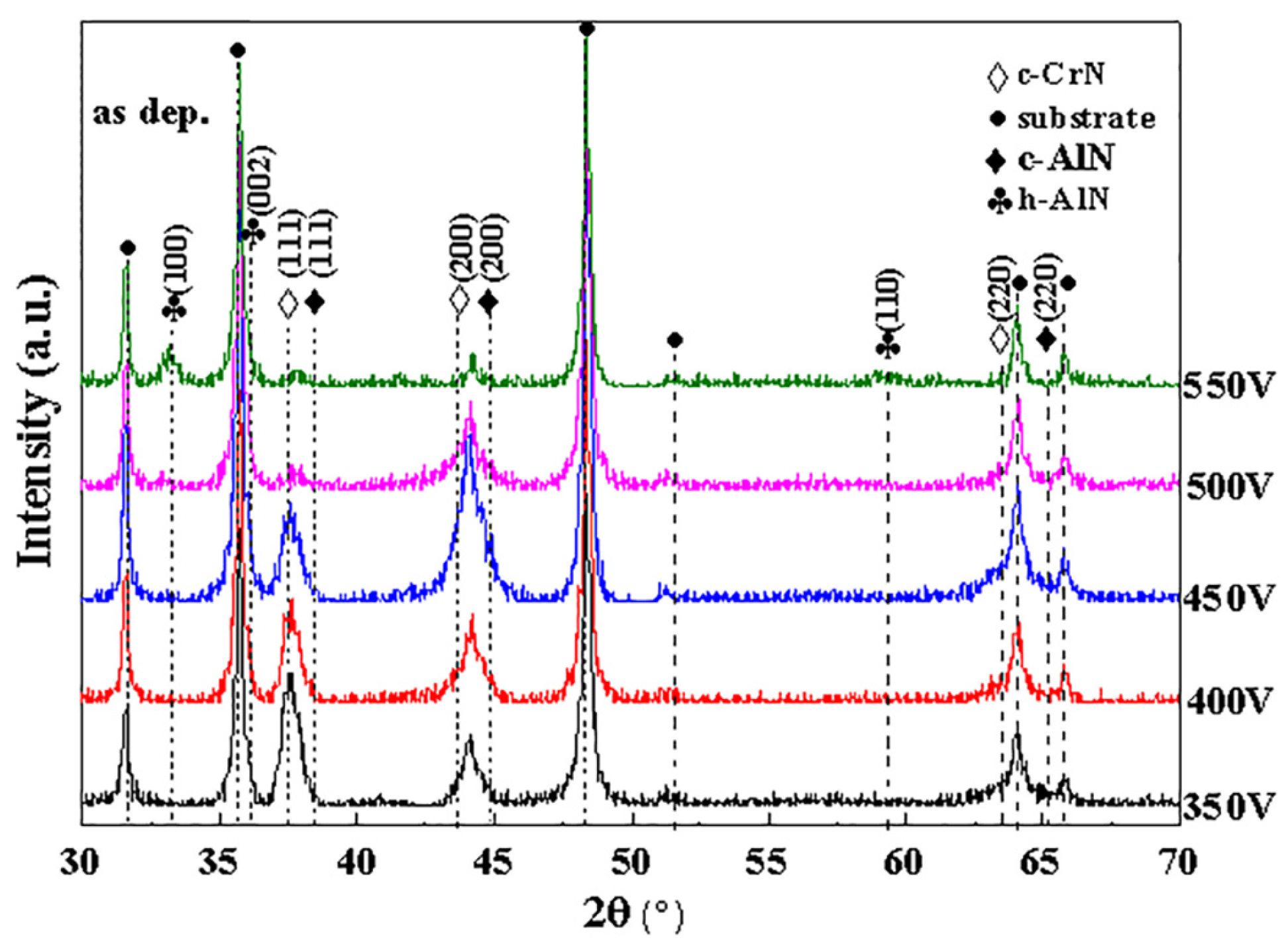

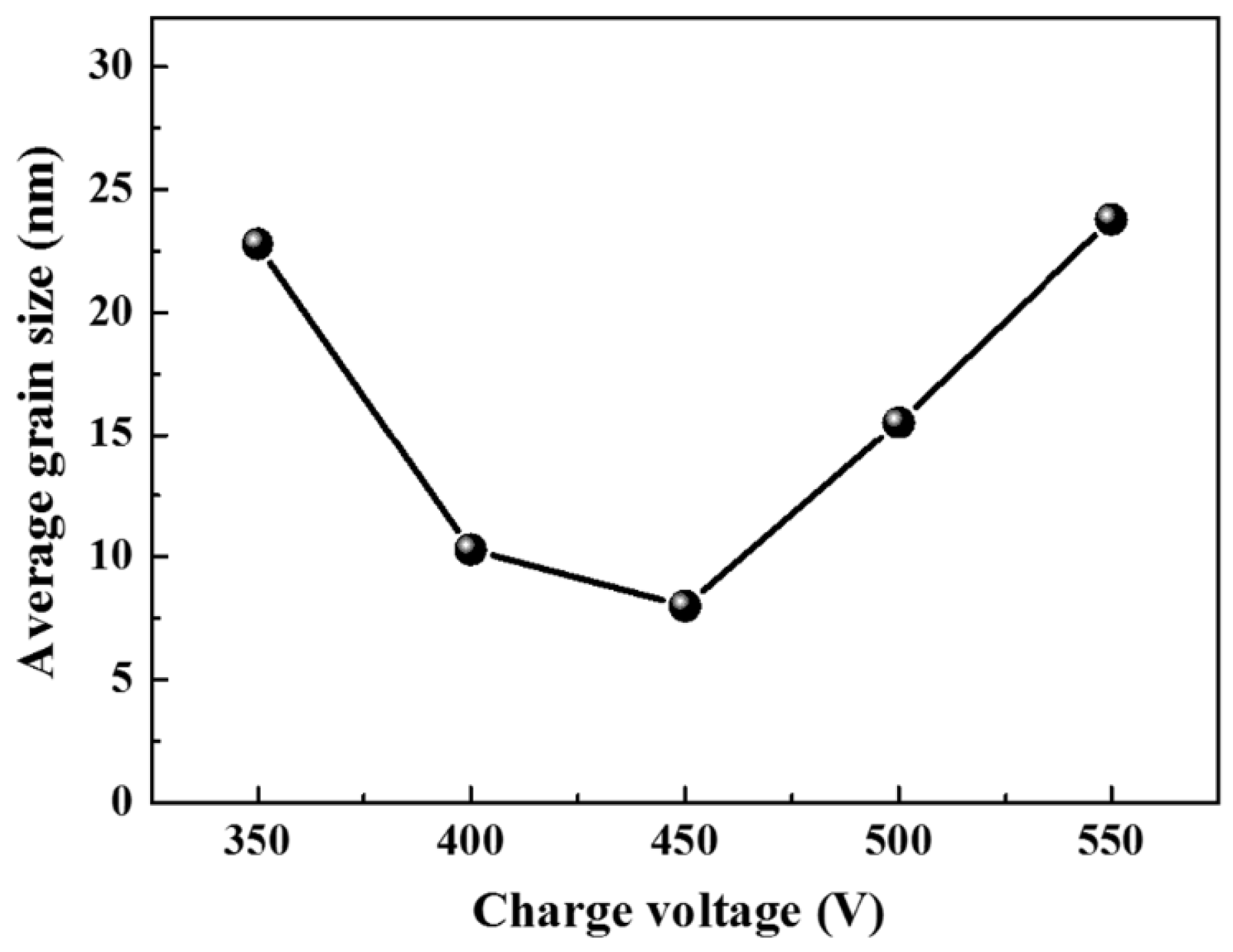

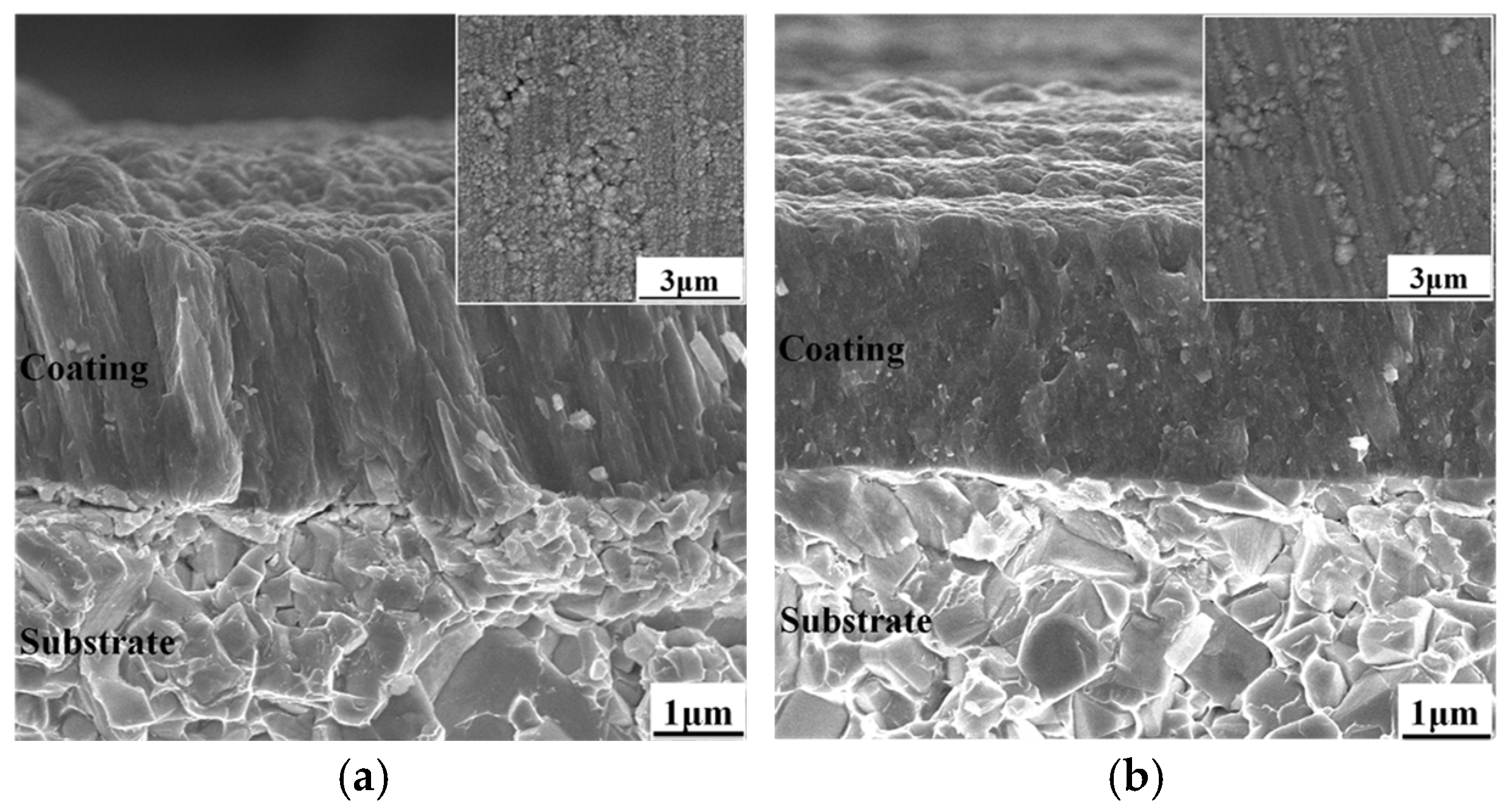

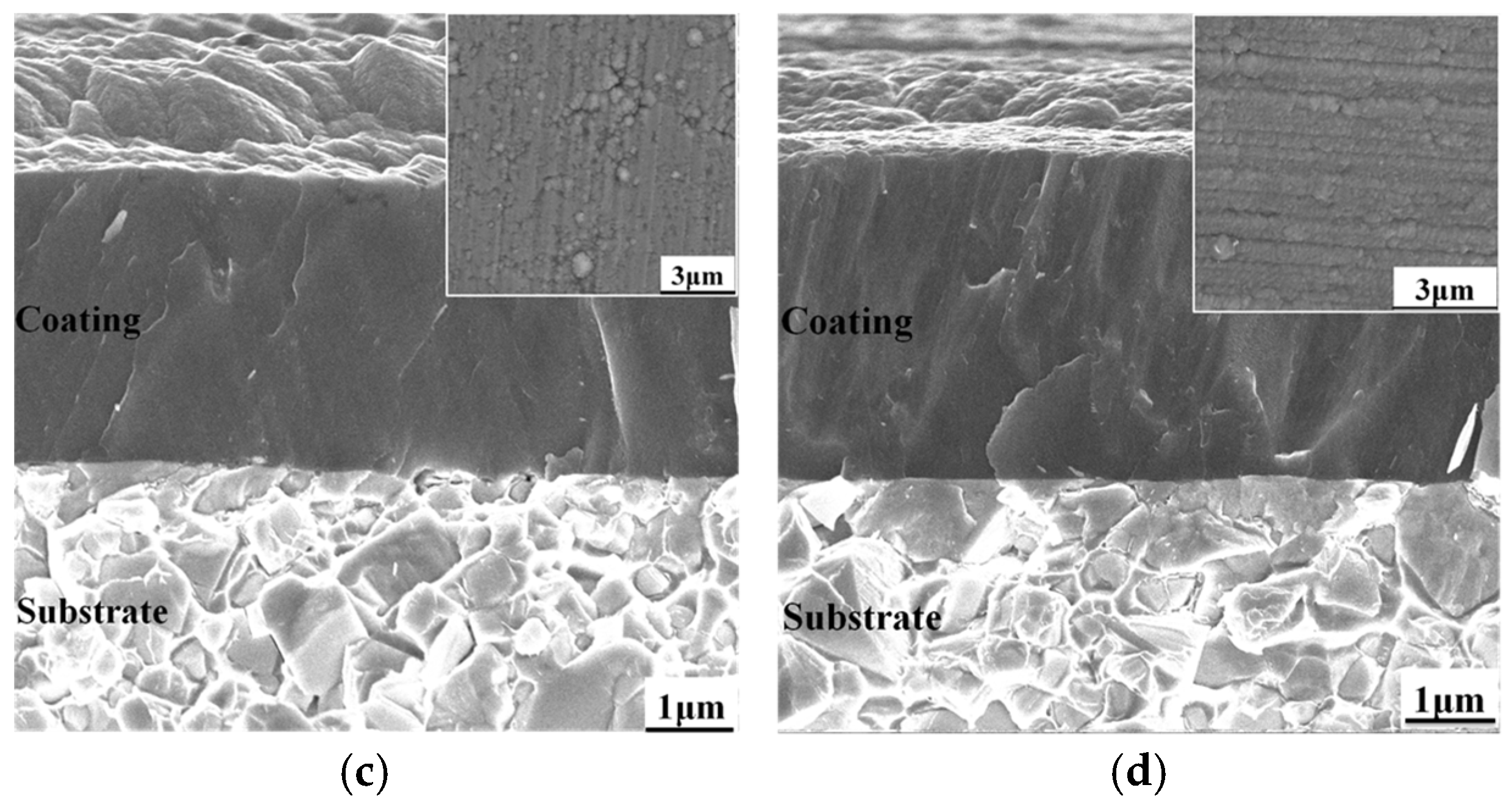

3.1. Chemical Composition, Morphology, and Phase Structure of the Coatings

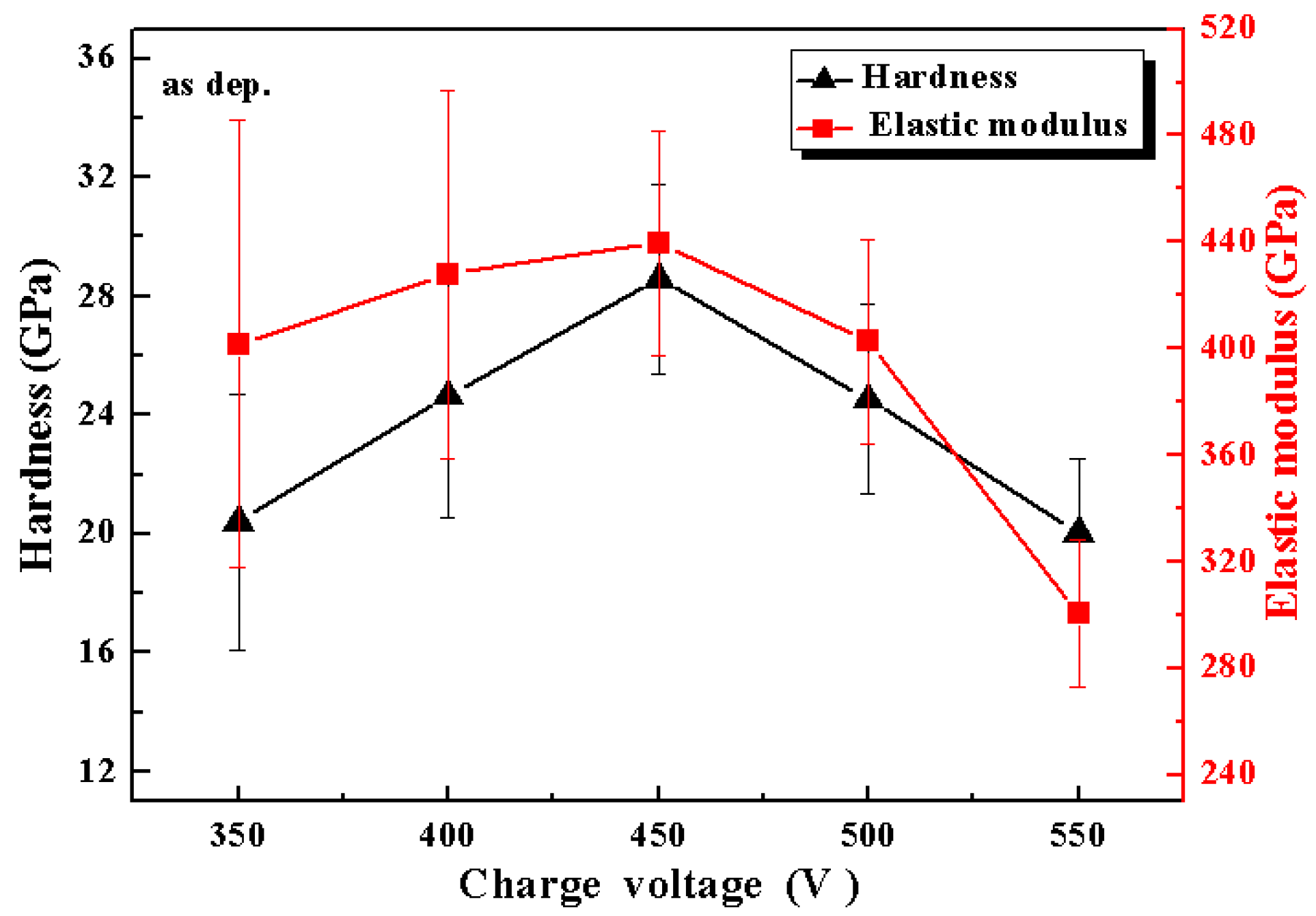

3.2. Mechanical Properties of the Coatings

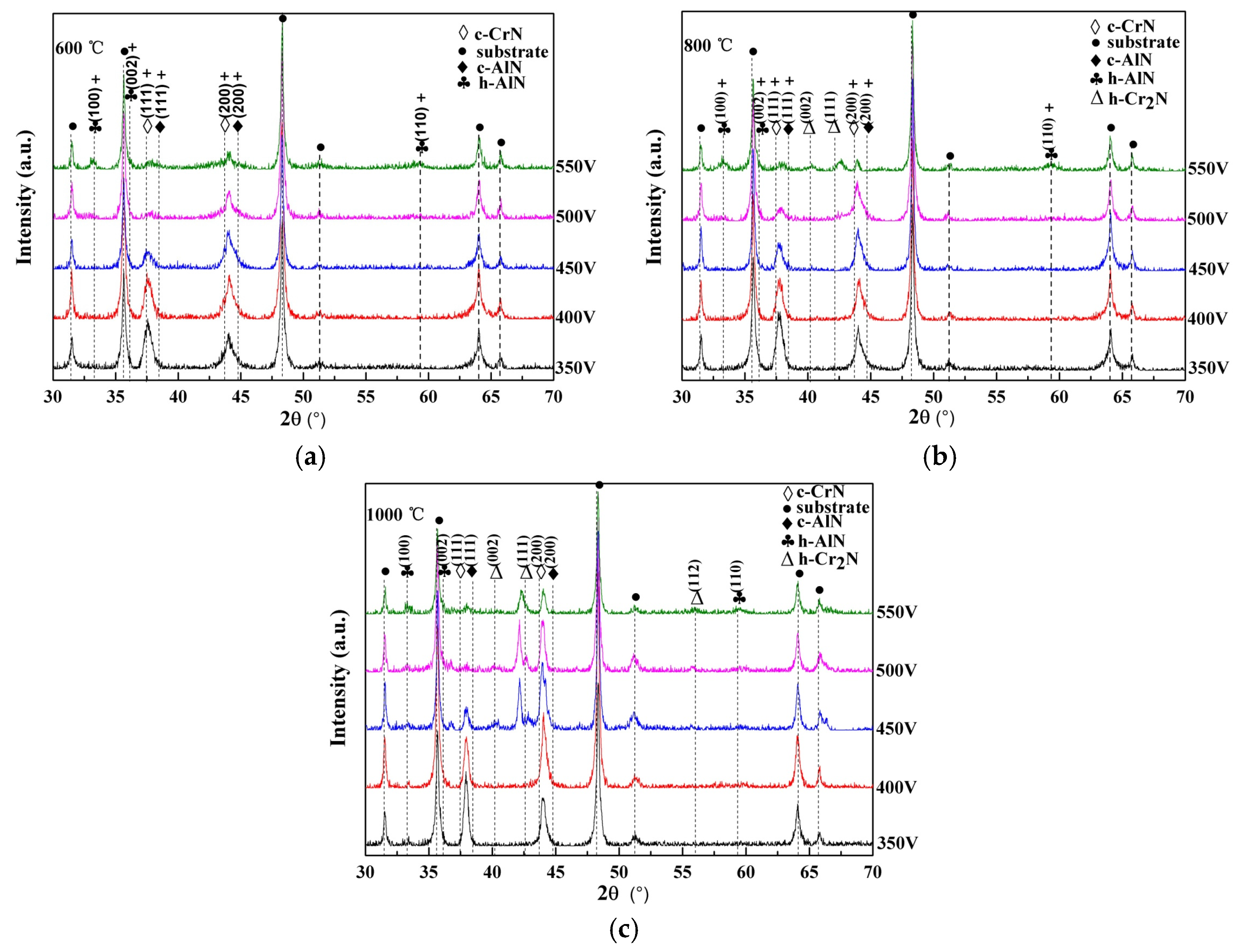

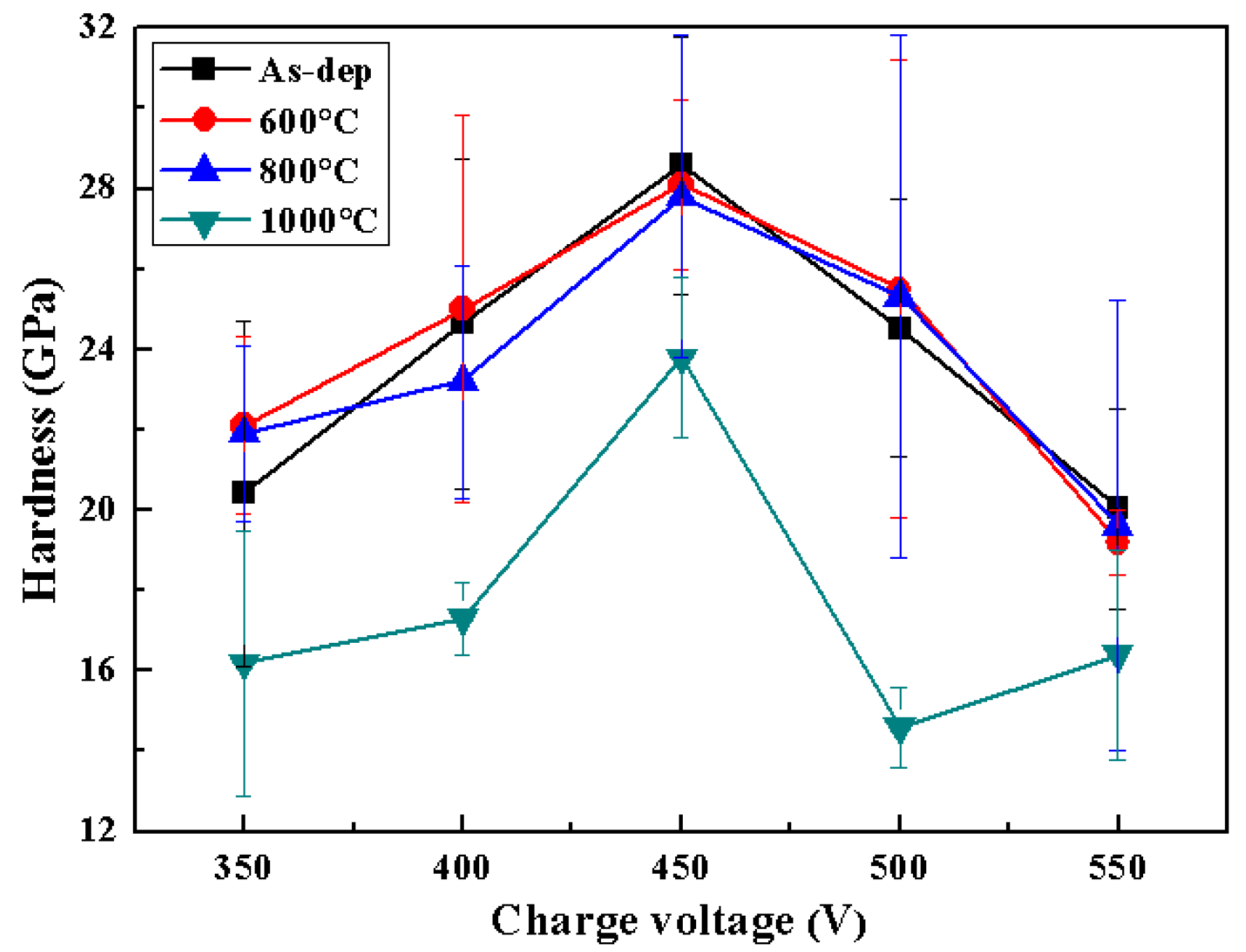

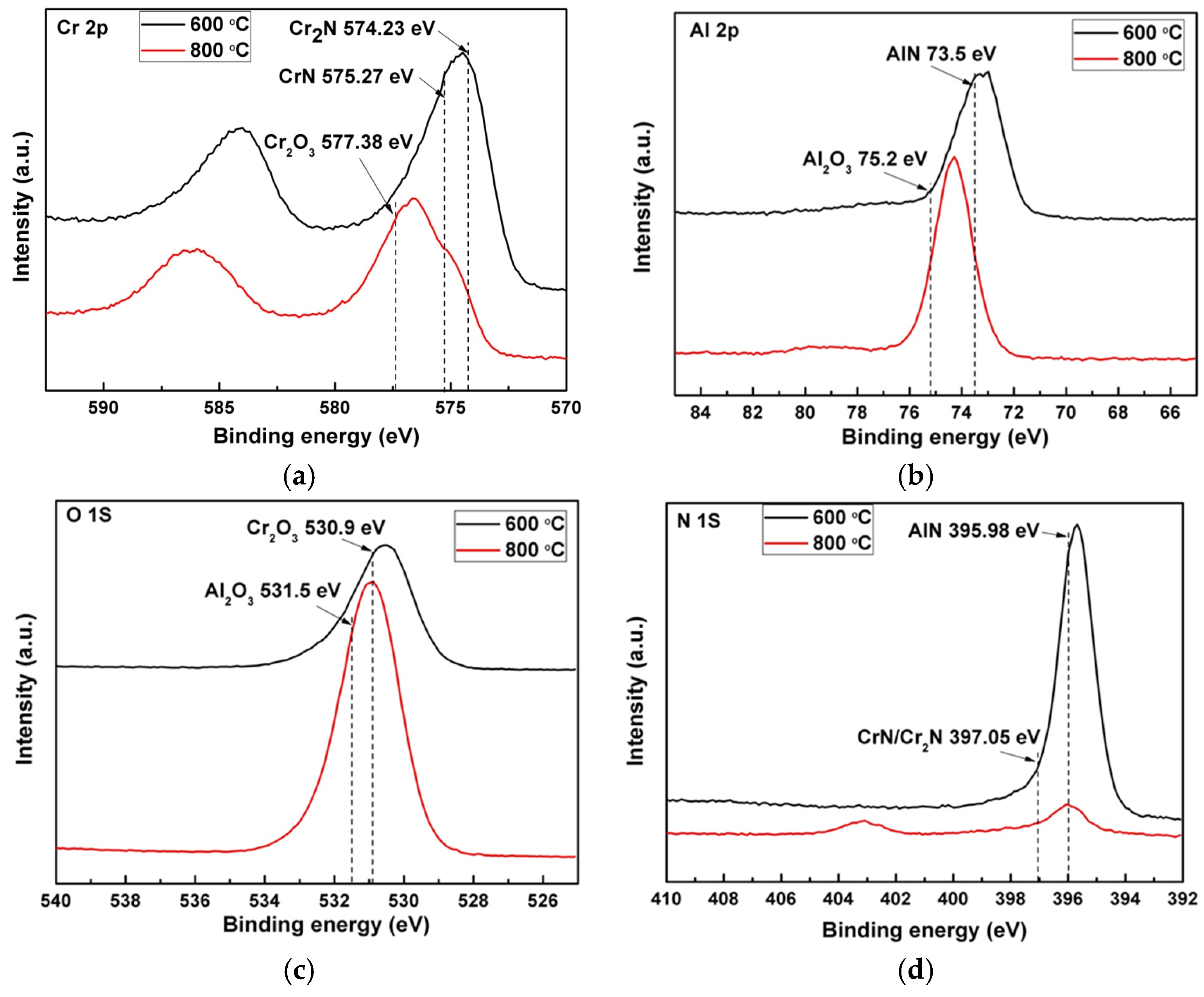

3.3. Thermal Stability of the Coatings

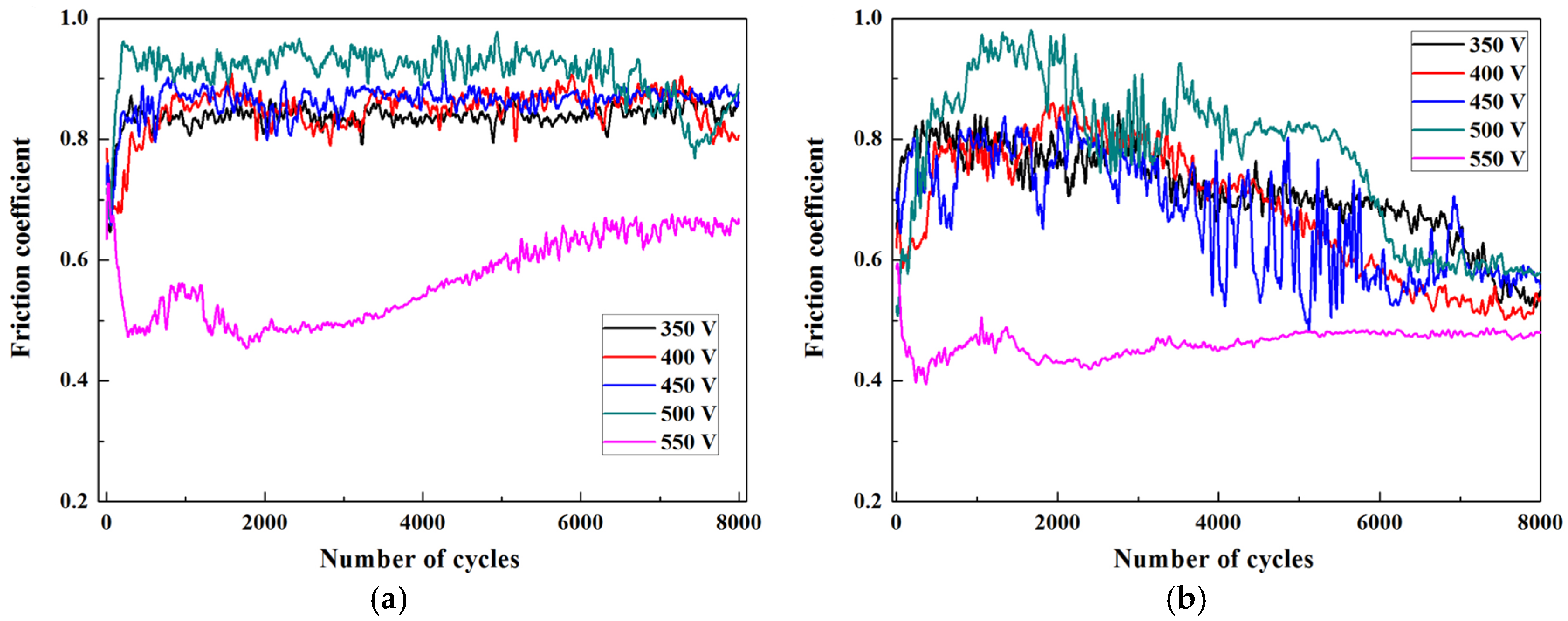

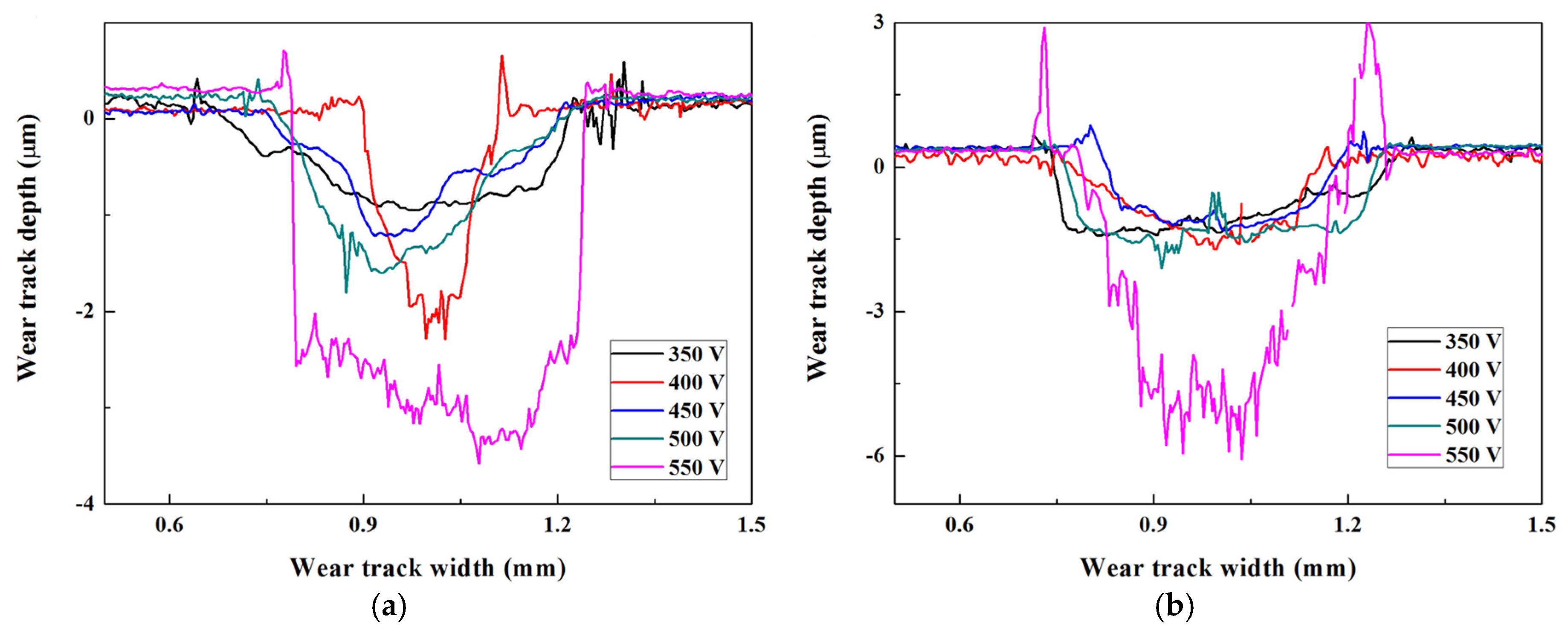

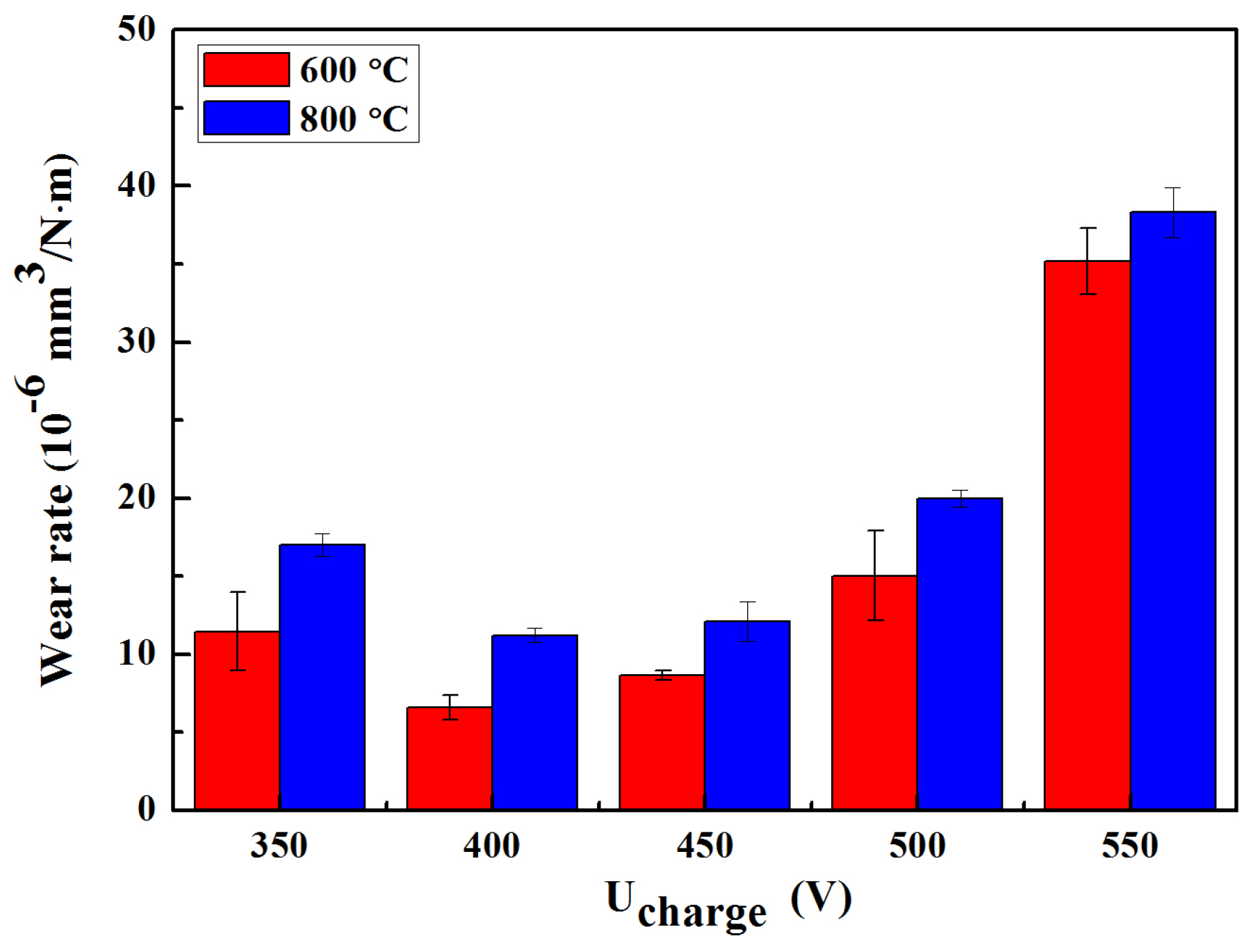

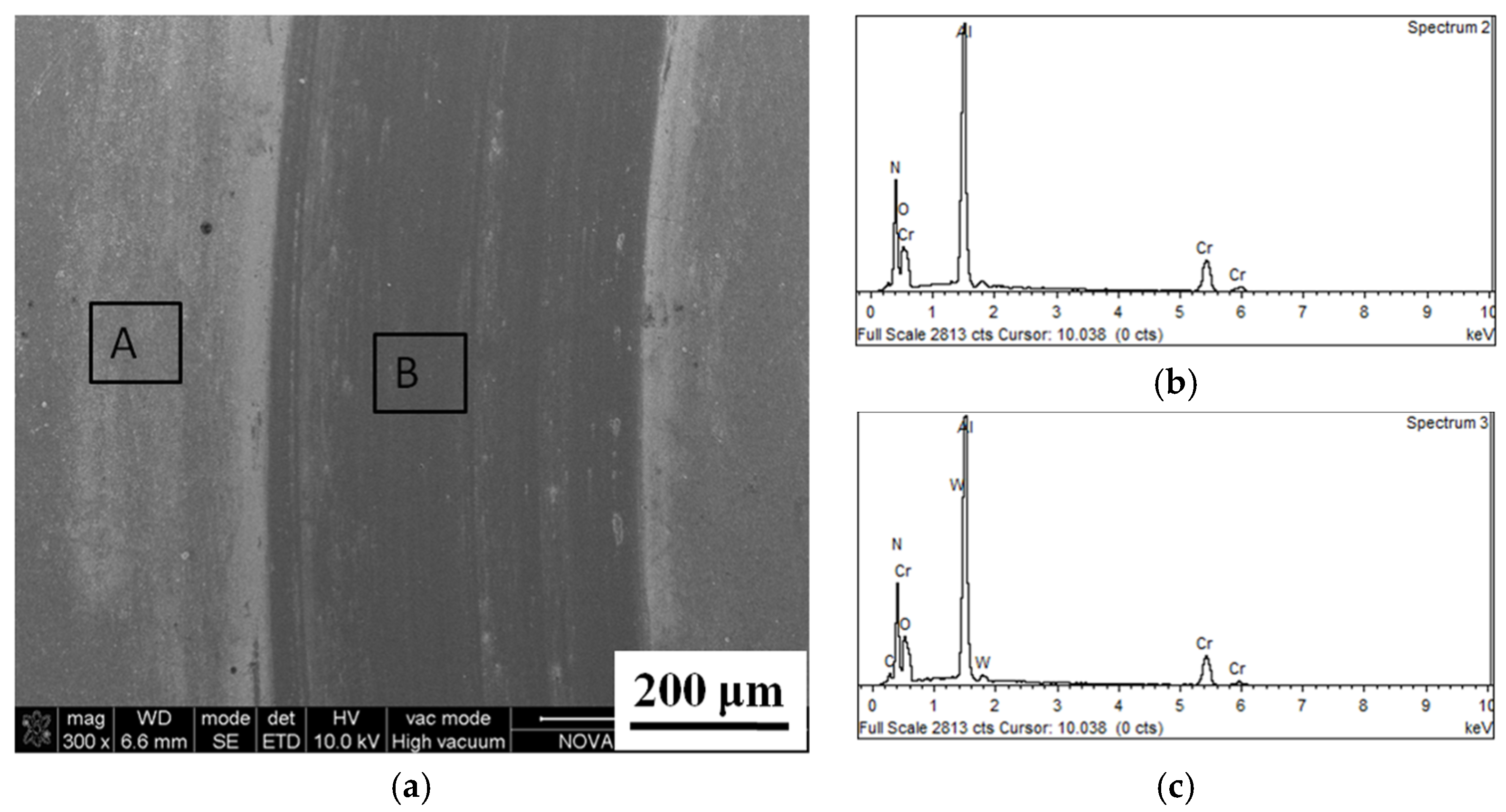

3.4. Tribological Properties of the Coatings

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Sarakinos, K.; Alami, J.; Konstantinidis, S. High power pulsed magnetron sputtering: A review on scientific and engineering state of the art. Surf. Coat. Technol. 2010, 204, 1661–1684. [Google Scholar] [CrossRef]

- Ehiasarian, A.P.; Hovsepian, P.E.; Hultman, L.; Helmersson, U. Comparison of microstructure and mechanical properties of chromium nitride-based coatings deposited by high power impulse magnetron sputtering and by the combined steered cathodic arc/unbalanced magnetron technique. Thin Solid Films 2004, 457, 270–277. [Google Scholar] [CrossRef]

- Reinhard, C.; Ehiasarian, A.P.; Hovsepian, P.E. CrN/NbN superlattice structured coatings with enhanced corrosion resistance achieved by high power impulse magnetron sputtering interface pre-treatment. Thin Solid Films 2007, 515, 3685–3692. [Google Scholar] [CrossRef]

- Anders, A. Discharge physics of high power impulse magnetron sputtering. Surf. Coat. Technol. 2011, 205, S1–S9. [Google Scholar] [CrossRef]

- Lin, J.; Sproul, W.D.; Moore, J.J.; Wu, Z. Recent advances in modulated pulsed power magnetron sputtering for surface engineering. JOM J. Miner. Met. Mater. Soc. 2011, 63, 48–58. [Google Scholar] [CrossRef]

- Lin, J.; Zhang, N.; Sproul, W.D.; Moore, J.J. A comparison of the oxidation behavior of CrN films deposited using continuous dc, pulsed dc and modulated pulsed power magnetron sputtering. Surf. Coat. Technol. 2012, 206, 3283–3290. [Google Scholar] [CrossRef]

- Lin, J.; Moore, J.J.; Sproul, W.D.; Mishra, B.; Wu, Z. Modulated pulse power sputtered chromium coatings. Thin Solid Films 2009, 518, 1566–1570. [Google Scholar] [CrossRef]

- Lin, J.; Sproul, W.D.; Moore, J.J.; Chistyakov, R.; Avraham, B. Structurally laminated CrN films deposited by multi pulse modulated pulsed power magnetron sputtering. Surf. Coat. Technol. 2011, 207, 1780–1786. [Google Scholar] [CrossRef]

- Li, H.; Liu, Y.; Jiang, B.; Kan, J.; Liu, Z. The structure and toughness of TiN coatings prepared by modulated pulsed power magnetron sputtering. Vacuum 2016, 125, 165–169. [Google Scholar] [CrossRef]

- Papa, F.; Gerdes, H.; Bandorf, R.; Ehiasarian, A.P. Deposition rate characteristics for steady state high power impulse magnetron sputtering (HIPIMS) discharges generated with a modulated pulsed power (MPP) generator. Thin Solid Films 2011, 520, 1559–1563. [Google Scholar] [CrossRef]

- Lin, J.; Zhang, Z.; Wu, Z.; Sproul, W.D.; Kaufman, M. Thick CrN/AlN superlattice coatings deposited by the hybrid modulated pulsed power and pulsed dc magnetron sputtering. Surf. Coat. Technol. 2013, 228, 601–606. [Google Scholar] [CrossRef]

- Myers, S.; Lin, J.; Souza, R.M.; Sproul, W.D.; Moore, J.J. The β to α phase transition of tantalum coatings deposited by modulated pulsed power magnetron sputtering. Surf. Coat. Technol. 2013, 214, 38–45. [Google Scholar] [CrossRef]

- Liebig, B.; Braithwaite, N.S.J.; Kelly, P.J.; Chistyakov, R.; Abraham, B.; Bradley, J.W. Time-resolved plasma characterization of modulated pulsed power magnetron sputtering of chromium. Surf. Coat. Technol. 2011, 205, S312–S316. [Google Scholar] [CrossRef]

- Wang, Q.M.; Kwon, S.H.; Hui, K.N.; Kim, D.I.; Hui, K.S. Synthesis and properties of crystalline TiO2 films deposited by a HIPIMS+ technique. Vacuum 2013, 89, 90–95. [Google Scholar] [CrossRef]

- Birol, Y.; Isler, D. Abrasive wear performance of AlCrN-coated hot work tool steel at elevated temperatures under three-body regime. Wear 2011, 270, 281–286. [Google Scholar] [CrossRef]

- Sánchez-López, J.C.; Contreras, A.; Domínguez-Meister, S.; García-Luis, A.; Brizuela, M. Tribological behavior at high temperature of hard CrAlN coatings doped with Y or Zr. Thin Solid Films 2014, 550, 413–420. [Google Scholar] [CrossRef]

- Walker, J.C.; Ross, I.M.; Reinhard, C.; Rainforth, W.M.; Hovsepian, P.E. High temperature tribological performance of CrAlYN/CrN nanoscale multilayer coatings deposited on γ-TiAl. Wear 2009, 267, 965–975. [Google Scholar] [CrossRef]

- Fox-Rabinovich, G.S.; Beake, B.D.; Endrino, J.L.; Veldhuis, S.C.; Parkinson, R. Effect of mechanical properties measured at room and elevated temperatures on the wear resistance of cutting tools with TiAlN and AlCrN coatings. Surf. Coat. Technol. 2006, 200, 5738–5742. [Google Scholar] [CrossRef]

- Magai, M.; Yukimura, K.; Kuze, E.; Maruyama, T.; Kohata, M. Macroparticles on titanium nitride thin film prepared by cathodic-arc plasma-based ion implantation and deposition. Surf. Coat. Technol. 2003, 169, 401–404. [Google Scholar]

- Kumar, C.S.; Patel, S.K. Hard machining performance of PVD AlCrN coated Al2O3/TiCN ceramic inserts as a function of thin film thickness. Ceram. Int. 2017, 43, 13314–13329. [Google Scholar] [CrossRef]

- Kim, G.S.; Lee, S.Y. Microstructure and mechanical properties of AlCrN films deposited by CFUBMS. Surf. Coat. Technol. 2006, 201, 4361–4366. [Google Scholar] [CrossRef]

- Hsiao, Y.C.; Lee, J.W.; Yang, Y.C.; Lou, B.S. Effects of duty cycle and pulse frequency on the fabrication of AlCrN thin films deposited by high power impulse magnetron sputtering. Thin Solid Films 2013, 549, 281–291. [Google Scholar] [CrossRef]

- Bzin, K.; Brögelmann, T.; Brugnara, R.H. Aluminum-rich HPPMS (Cr1−xAlx)N coatings deposited with different target compositions and at various pulse lengths. Vacuum 2015, 122, 201–207. [Google Scholar] [CrossRef]

- Christie, D.J. Target material pathways model for high power pulsed magnetron sputtering. J. Vac. Sci. Technol. A 2005, 23, 330–335. [Google Scholar] [CrossRef]

- Berg, S.; Nyberg, T. Fundamental understanding and modeling of reactive sputtering processes. Thin Solid Films 2005, 476, 215–230. [Google Scholar] [CrossRef]

- Bagcivan, N.; Bobzin, K.; Theiß, S. (Cr1−xAlx)N: A comparison of direct current, middle frequency pulsed and high power pulsed magnetron sputtering for injection molding components. Thin Solid Films 2013, 528, 180–186. [Google Scholar] [CrossRef]

- Paulitsch, J.; Mayrhofer, P.; Münz, W.D.; Schenkel, M. Structure and mechanical properties of CrN/TiN multilayer coatings prepared by a combined HIPIMS/UBMS deposition technique. Thin Solid Films 2008, 517, 1239–1244. [Google Scholar] [CrossRef]

- Petrov, I.; Hultman, L.; Sundgren, J.E.; Greene, J.E. Polycrystalline TiN films deposited by reactive bias magnetron sputtering: Effects of ion bombardment on resputtering rates, film composition, and microstructure. J. Vac. Sci. Technol. A 1992, 10, 265–272. [Google Scholar] [CrossRef]

- Luo, Q.; Lewis, D.B.; Hovsepian, P.E.; Münz, W.D. Transmission electron microscopy and X-ray diffraction investigation of the microstructure of nano-scale multilayers TiAlN/VN grown by unbalanced magnetron deposition. J. Mater. Res. 2004, 19, 1093–1104. [Google Scholar] [CrossRef]

- Lewis, D.B.; Luo, Q.; Zhou, Z.; Hovsepian, P.E.; Münz, W.D. Interrelationship between atomic species, bias voltage, texture and microstructure of nano-scale multilayers. Surf. Coat. Technol. 2004, 184, 225–232. [Google Scholar] [CrossRef]

- Williamson, G.K.; Hall, W.H. X-ray line broadening from filed aluminium and wolfram. Acta Metall. 1953, 1, 22–31. [Google Scholar] [CrossRef]

- Petrov, I.; Barna, P.B.; Hultman, L.; Greene, J.E. Microstructural evolution during film growth. J. Vac. Sci. Technol. A 2003, 21, 117–128. [Google Scholar] [CrossRef]

- Feng, Y.P.; Zhang, L.; Ke, R.X.; Wan, Q.L.; Wang, Z.; Lu, Z.H. Thermal stability and oxidation behavior of AlTiN, AlCrN and AlCrSiWN coatings. Int. J. Refract. Met. Hard Mater. 2014, 43, 241–249. [Google Scholar] [CrossRef]

- Lin, J.; Mishra, B.; Moore, J.J.; Sproul, W.D. A study of the oxidation behavior of CrN and CrAlN thin films in air using DSC and TGA analysis. Surf. Coat. Technol. 2008, 202, 3272–3283. [Google Scholar] [CrossRef]

- Luo, Q. Origin of friction in running-in sliding wear of nitride coatings. Tribol. Lett. 2010, 37, 529–539. [Google Scholar] [CrossRef]

- Kong, D.J.; Guo, H.Y. Friction-wear behaviors of cathodic arc ion plating AlTiN coatings at high temperatures. Tribol. Int. 2015, 88, 31–39. [Google Scholar]

- Gassner, G.; Mayrhofer, P.H.; Kutschej, K.; Mitterer, C.; Kathrein, M. Magnéli phase formation of PVD Mo-N and W-N coatings. Surf. Coat. Technol. 2006, 201, 3335–3341. [Google Scholar] [CrossRef]

| Sample | Charge Voltage Va [V] | MPP Pulse Parameters | Coating Hardness [GPa] | Coating Thickness [μm] | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| τon [μs] | τw/τs [μs] | f [Hz] | Pa [Kw] | PP [kW] | VP [V] | IP [A] | ||||

| C1 | 350 | 1500 | 800/700 | 203 | 10.0 | 56 | 433 | 130 | 24.9 ± 7.3 | 3.3 |

| C2 | 400 | 1500 | 800/700 | 120 | 10.0 | 95 | 492 | 192 | 26.6 ± 5.9 | 2.9 |

| C3 | 450 | 1500 | 800/700 | 87 | 10.0 | 134 | 552 | 243 | 30.8 ± 5.5 | 3.0 |

| C4 | 500 | 1500 | 800/700 | 68 | 10.0 | 158 | 622 | 253 | 26.5 ± 5.4 | 3.5 |

| C5 | 550 | 1500 | 800/700 | 45 | 10.0 | 197 | 691 | 287 | 20.6 ± 6.6 | 3.9 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, J.; Zhou, H.; Gui, B.; Luo, Q.; Li, H.; Wang, Q. Influence of Power Pulse Parameters on the Microstructure and Properties of the AlCrN Coatings by a Modulated Pulsed Power Magnetron Sputtering. Coatings 2017, 7, 216. https://doi.org/10.3390/coatings7120216

Zheng J, Zhou H, Gui B, Luo Q, Li H, Wang Q. Influence of Power Pulse Parameters on the Microstructure and Properties of the AlCrN Coatings by a Modulated Pulsed Power Magnetron Sputtering. Coatings. 2017; 7(12):216. https://doi.org/10.3390/coatings7120216

Chicago/Turabian StyleZheng, Jun, Hui Zhou, Binhua Gui, Quanshun Luo, Haixu Li, and Qimin Wang. 2017. "Influence of Power Pulse Parameters on the Microstructure and Properties of the AlCrN Coatings by a Modulated Pulsed Power Magnetron Sputtering" Coatings 7, no. 12: 216. https://doi.org/10.3390/coatings7120216