Microstructure and Mechanical Properties of TaN Thin Films Prepared by Reactive Magnetron Sputtering

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

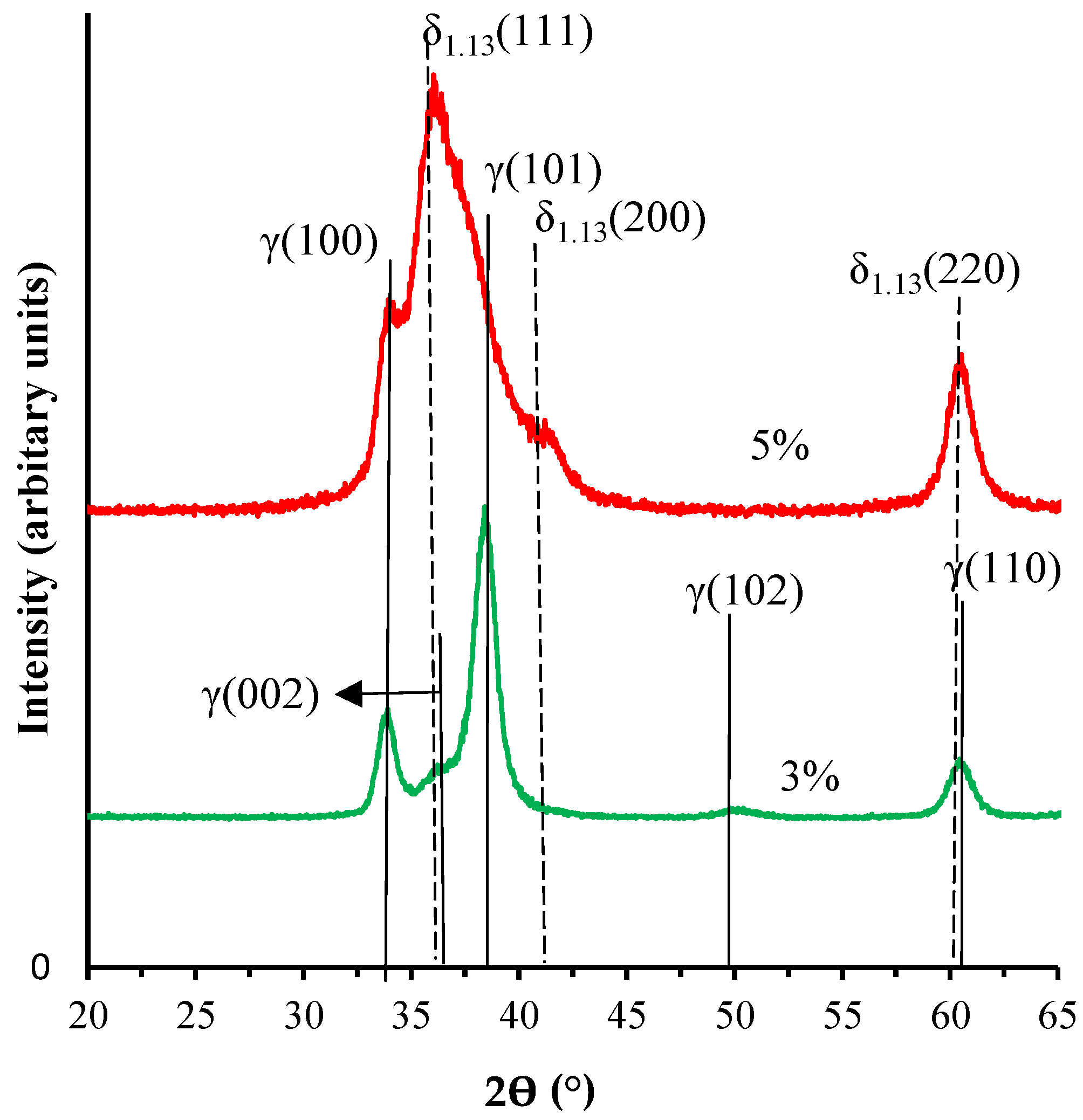

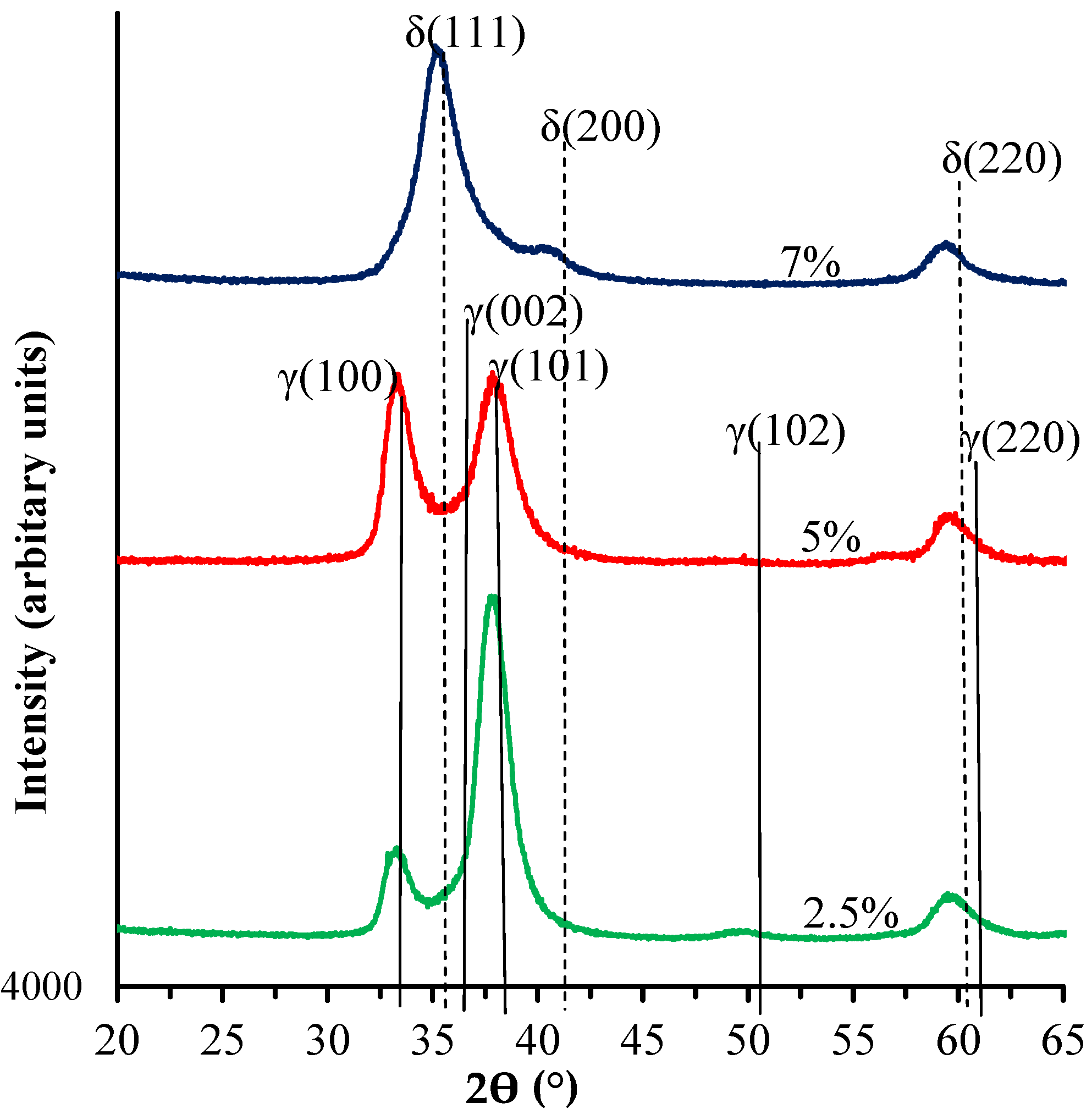

3.1. XRD Analysis

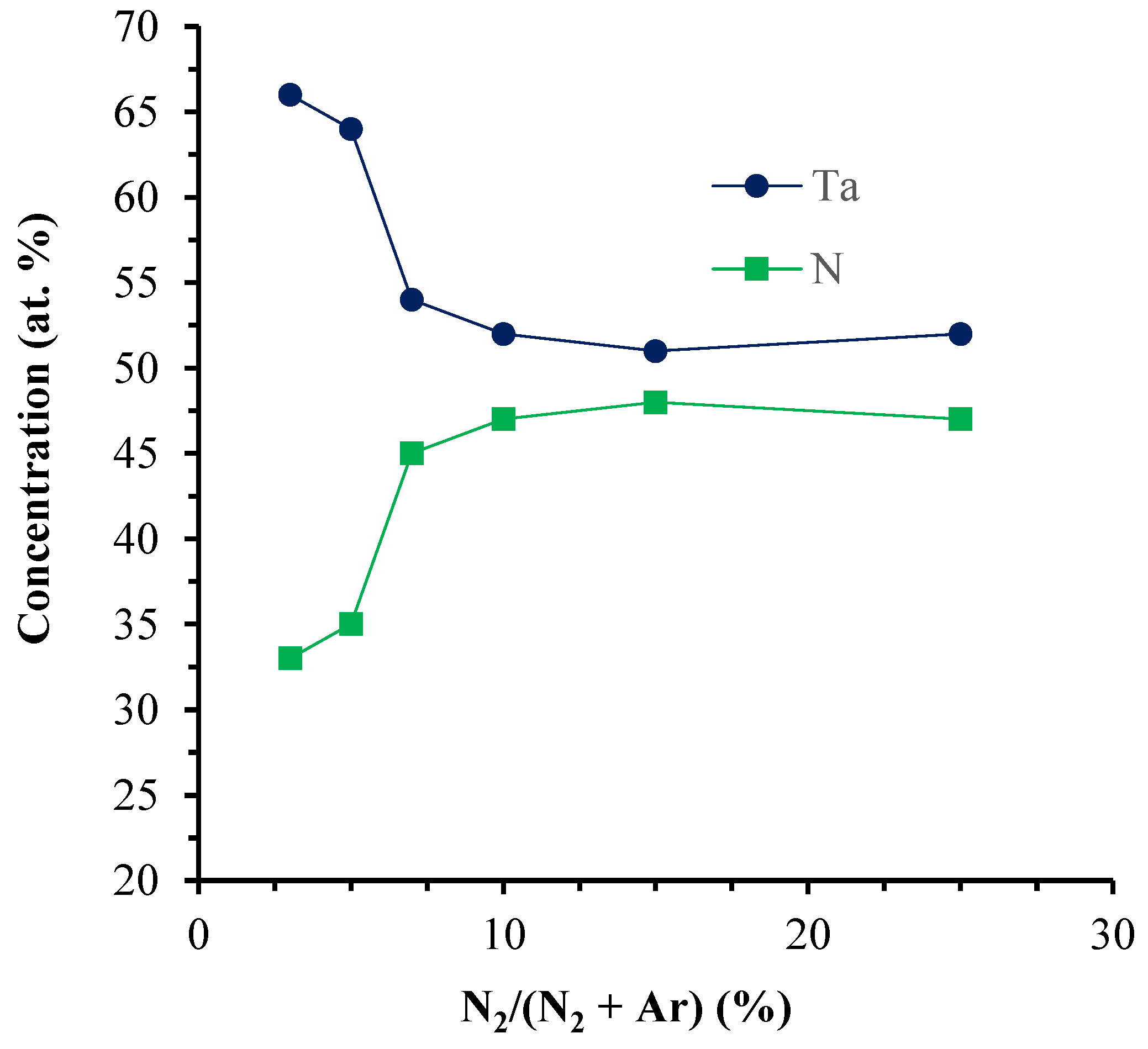

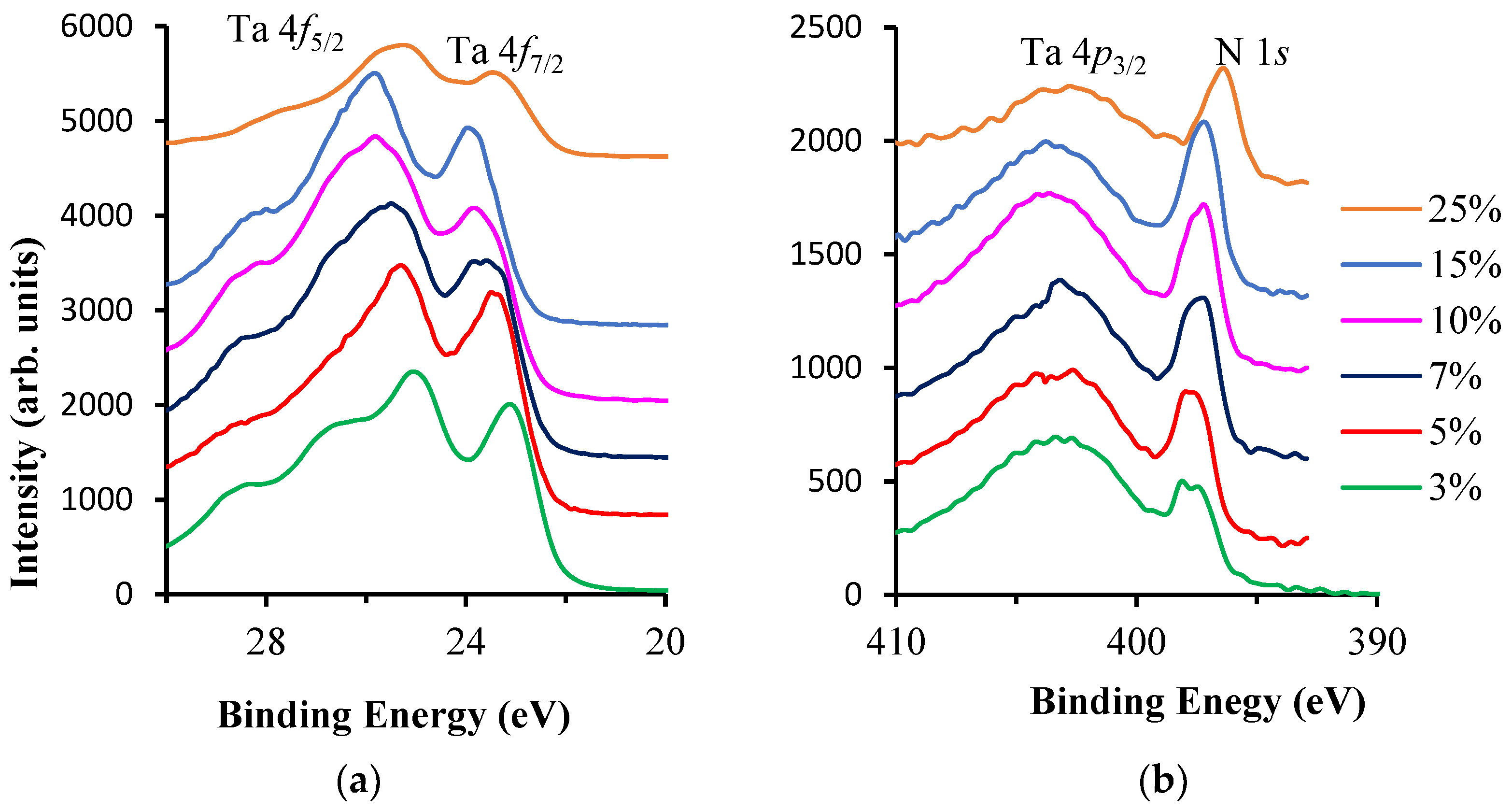

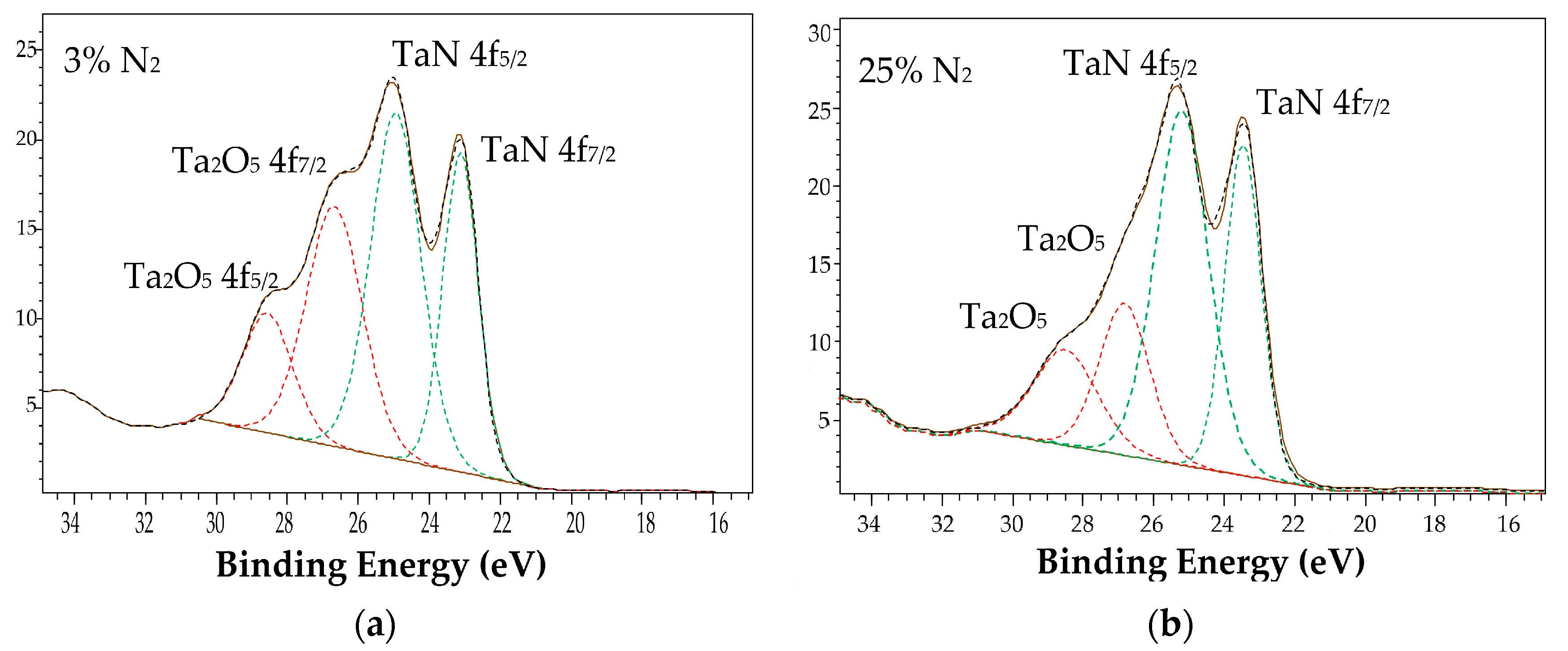

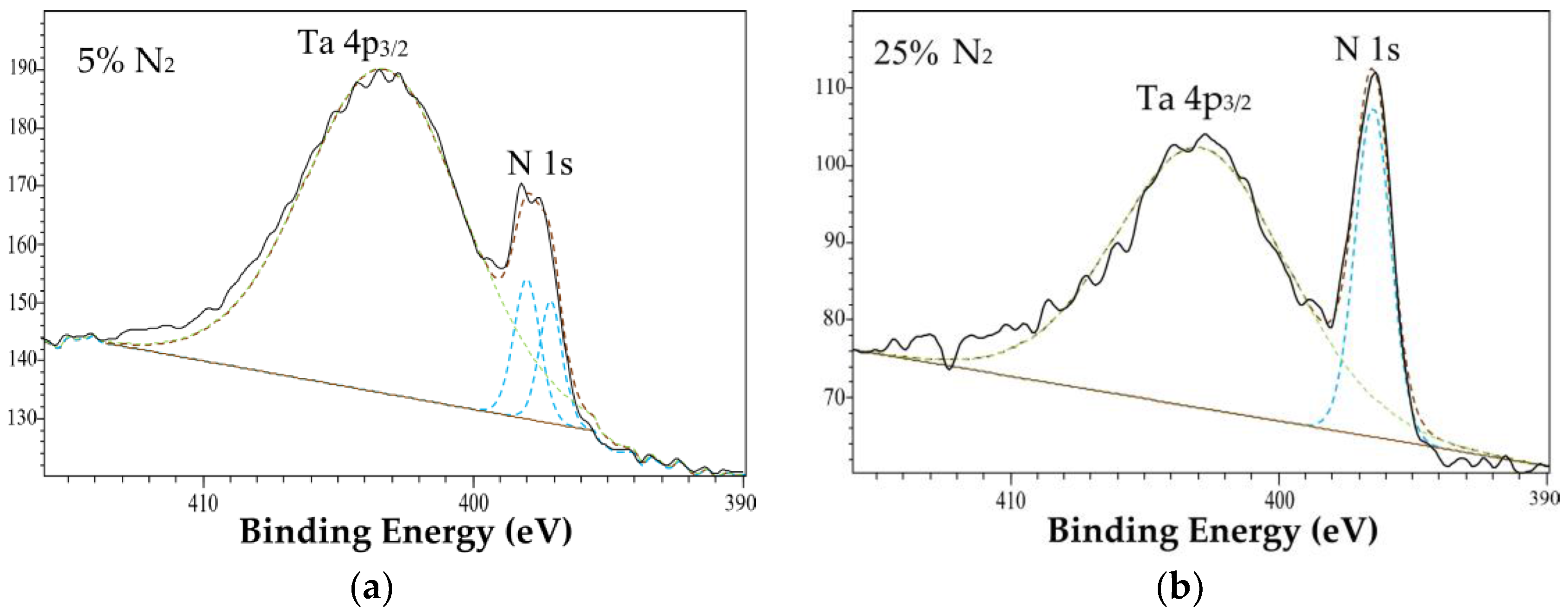

3.2. XPS Studies

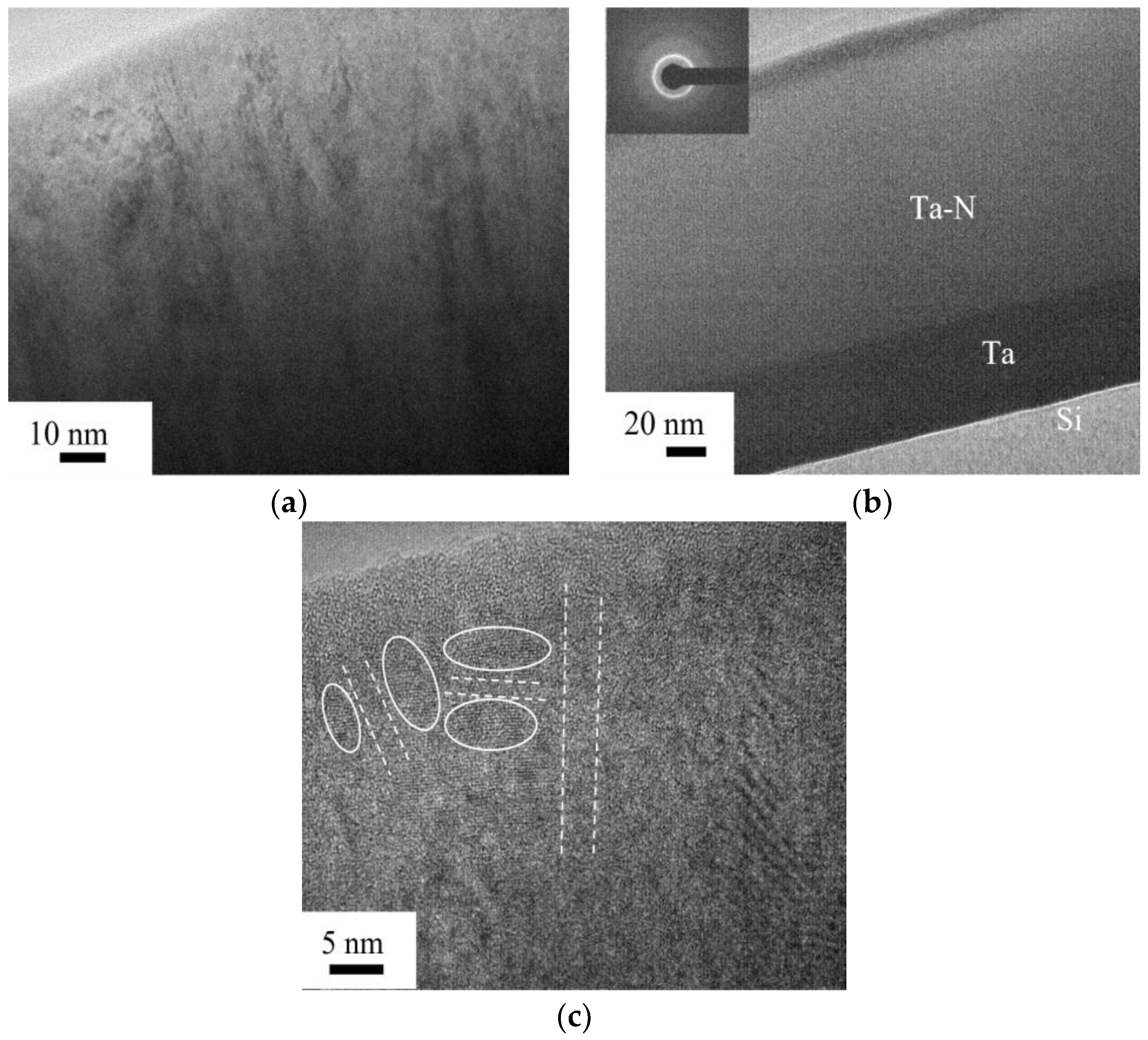

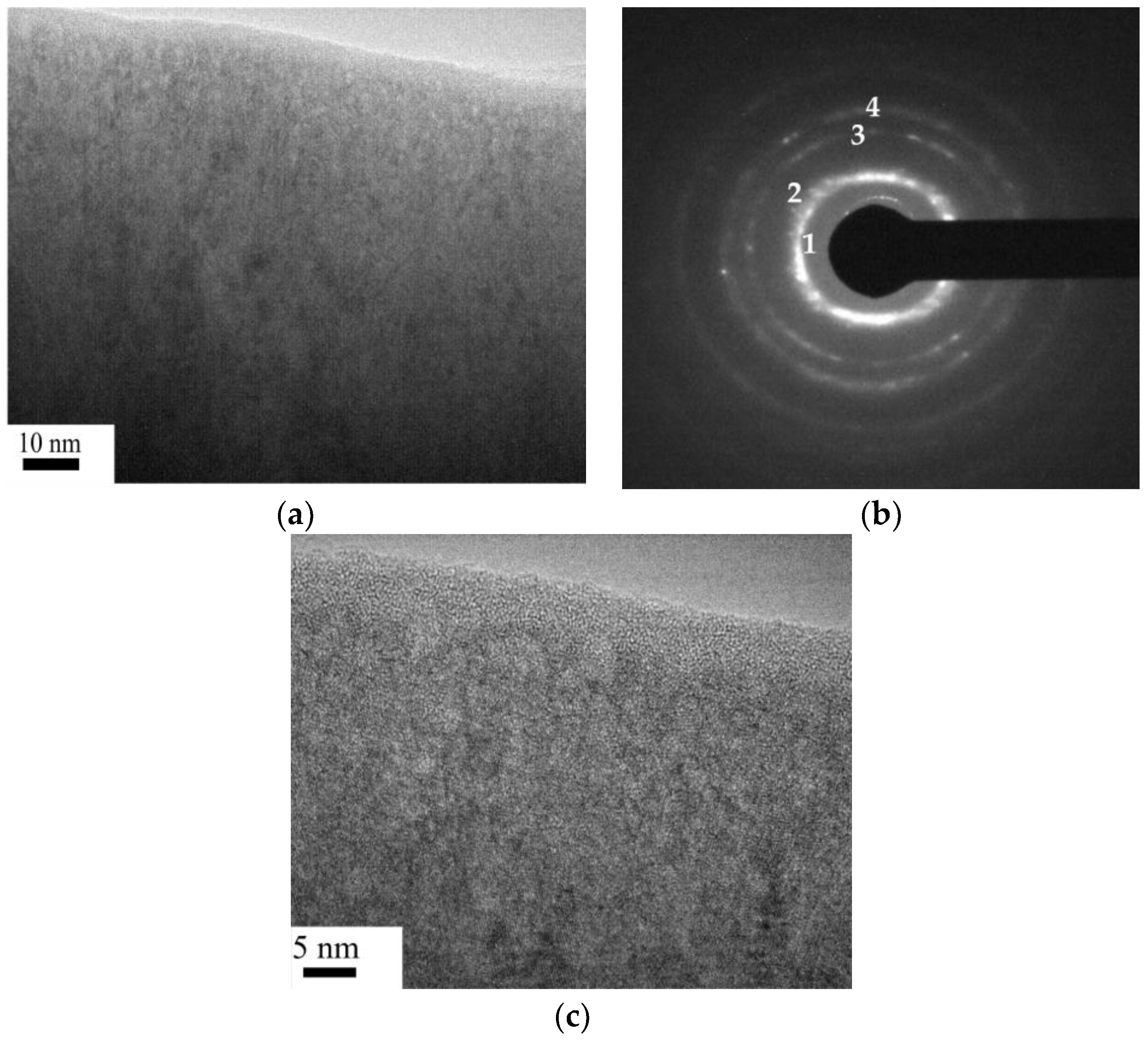

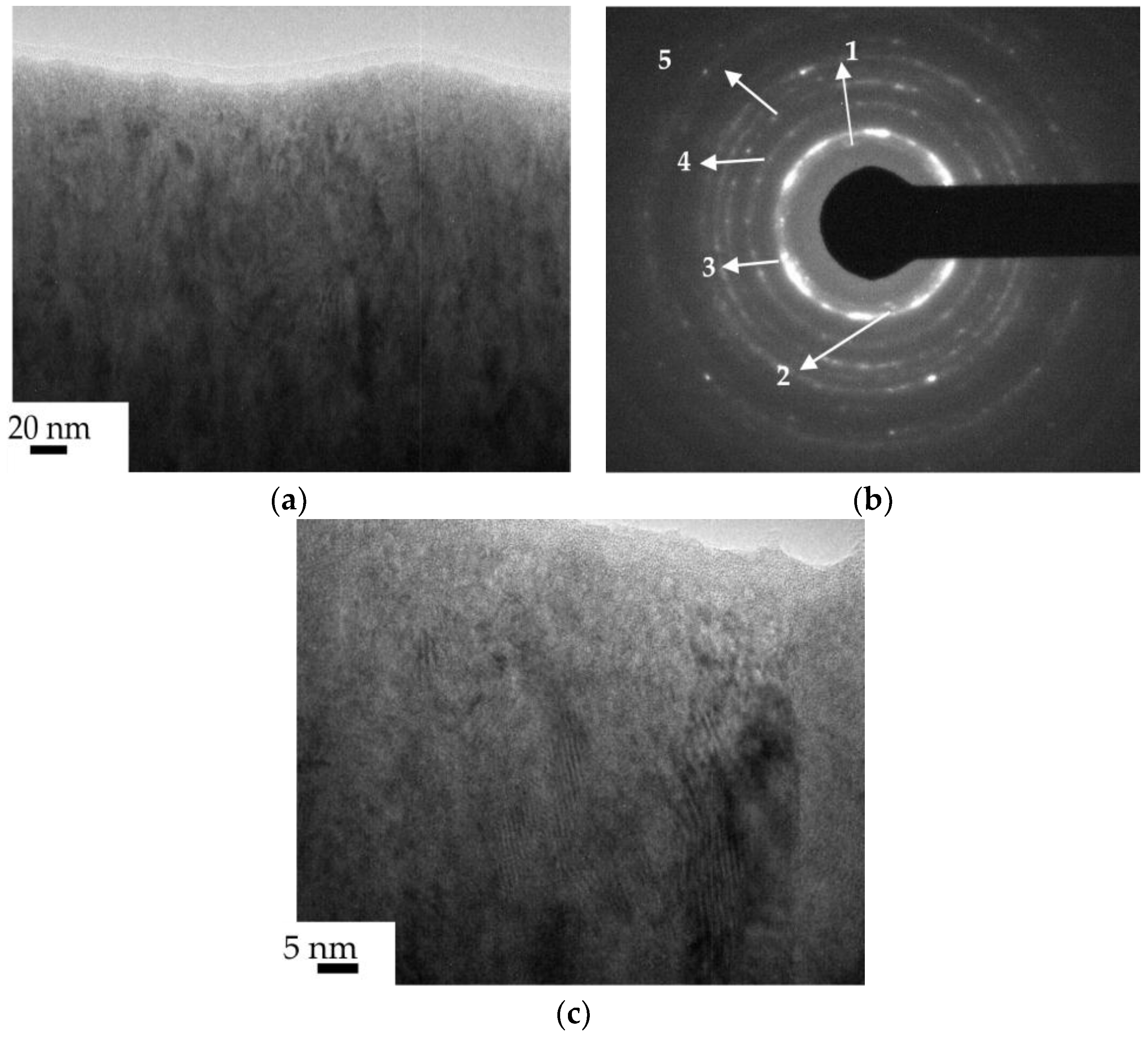

3.3. Microstructural Investigation

3.3.1. Ta–N Film Deposited with 7% N2

3.3.2. Ta–N Film Deposited with 5% N2

3.3.3. Ta–N Film Deposited with 3% N2

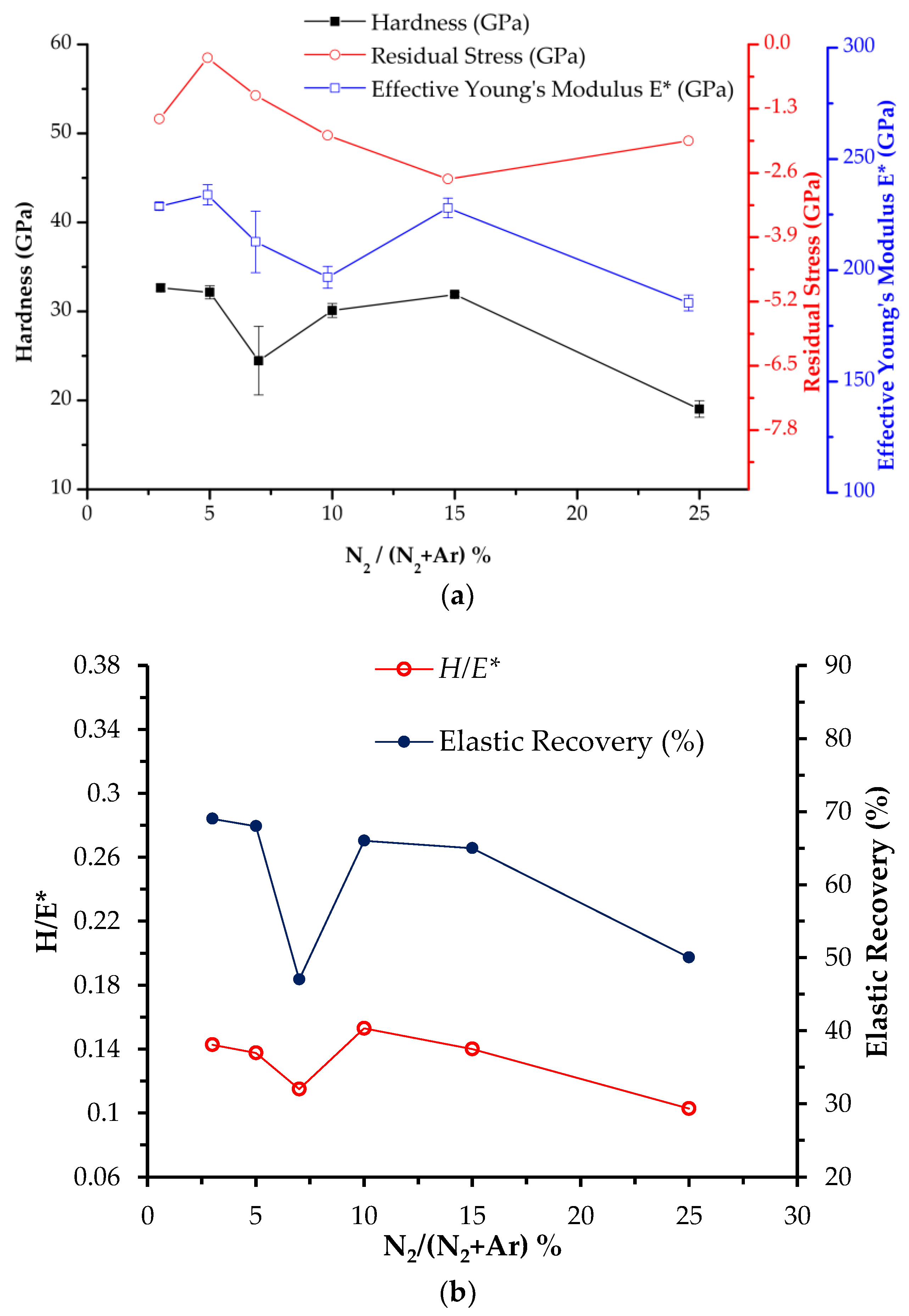

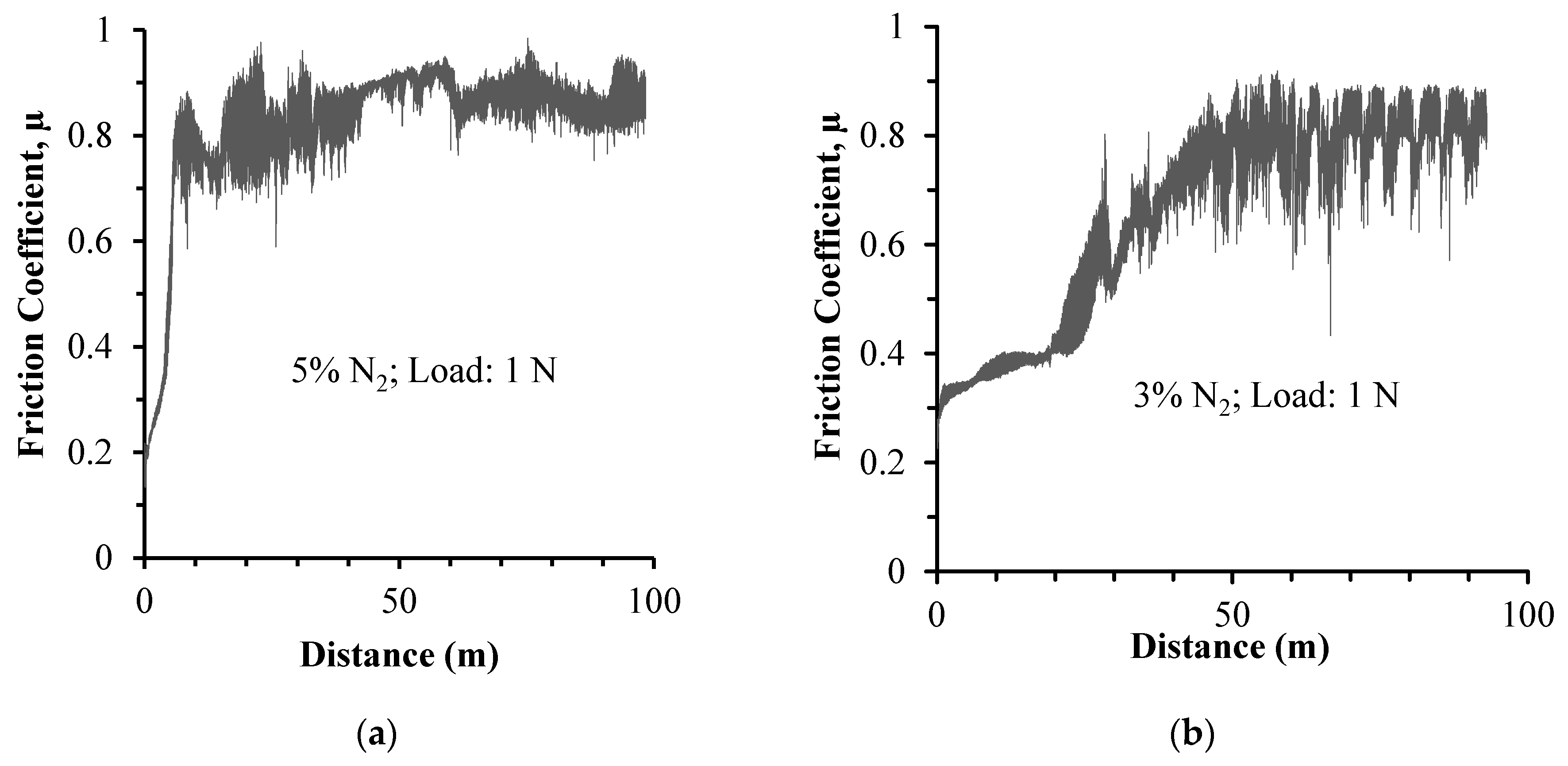

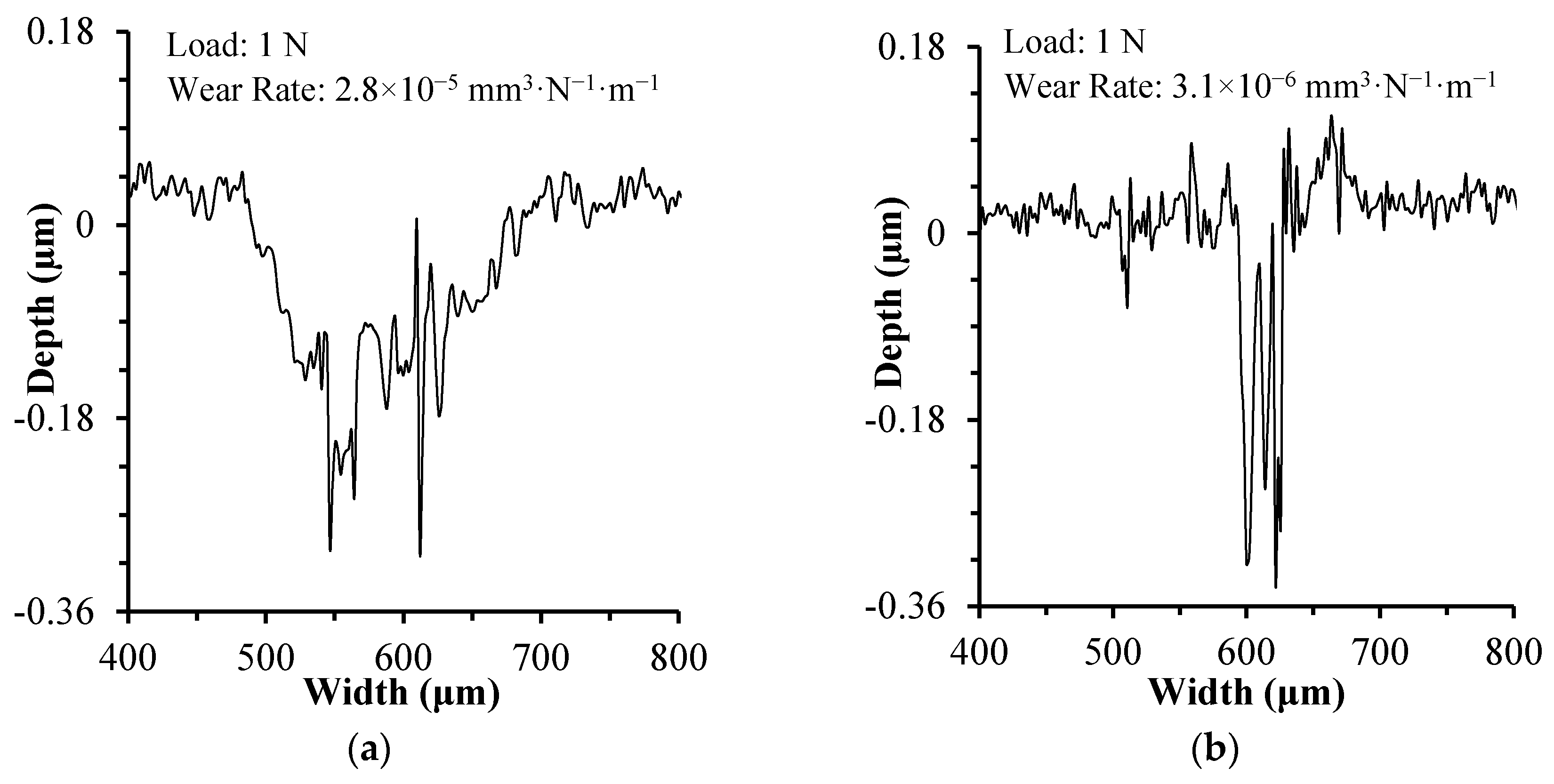

3.4. Film Morphology, Mechanical and Tribological Properties

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Hultman, L. Thermal stability of nitride thin films. Vacuum 2000, 57, 1–30. [Google Scholar] [CrossRef]

- Sundgren, J.E.; Johansson, B.O.; Rockett, A.; Barnett, S.A.; Greene, J.E. TiN: A Review of the Present Understanding of the Atomic Electronic Structure and Recent Results on the Growth and Physical Properties of Epitaxial TiNx (0.6 < x < 1.2) Layers. In Physics and Chemistry of Protective Coatings: Universal City, CA, 1985; Greene, J.E., Sproul, W.D., Thornton, J.A., Eds.; AIP Conference Proceedings Series 149; American Institute of Physics: New York, NY, USA, 1986; p. 95. [Google Scholar]

- Liu, X.; Ma, G.; Sun, G.; Duan, Y.; Liu, S. Effect of deposition and annealing temperature on mechanical properties of TaN film. Appl. Surf. Sci. 2011, 258, 1033–1037. [Google Scholar] [CrossRef]

- Riekkinen, T.; Molarius, J.; Laurila, T.; Nurmela, A.; Suni, I.; Kivilahti, J.K. Reactive sputter deposition and properties of TaxN thin films. Microelectron. Eng. 2002, 64, 289–297. [Google Scholar] [CrossRef]

- Lin, J.C.; Lee, C. Growth of Tantalum Nitride Films on Si by Radio Frequency Reactive Sputtering of Ta in N2/Ar Gas Mixtures: Effect of Bias. J. Electrochem. Soc. 2000, 147, 713–718. [Google Scholar] [CrossRef]

- Hieber, K. Structural and electrical properties of Ta and Ta nitrides deposited by chemical vapour deposition. Thin Solid Films 1974, 24, 157–164. [Google Scholar] [CrossRef]

- Bhushan, B.; Gupta, B.K. Handbook of Tribology: Materials, Coatings, and Surface Treatments; McGraw-Hill Book Company: New York, NY, USA, 1991; p. 1168. [Google Scholar]

- Kim, S.K.; Cha, B.C. Deposition of tantalum nitride thin films by D.C. magnetron sputtering. Thin Solid Films 2005, 475, 202–207. [Google Scholar] [CrossRef]

- Schauer, A.; Roschy, M.R.F. sputtered β-tantalum and bcc tantalum films. Thin Solid Films 1972, 12, 313–317. [Google Scholar] [CrossRef]

- Sun, X.; Kolawa, E.; Chen, J.; Reid, J.; Nicolet, M.A. Properties of reactively sputter-deposited TaN thin films. Thin Solid Films 1993, 236, 347–351. [Google Scholar] [CrossRef]

- Stampfl, C.; Freeman, A.J. Stable and metastable structures of the multiphase tantalum nitride system. Phys. Rev. B 2005, 71, 024111. [Google Scholar] [CrossRef]

- Stavrev, M.; Fischer, D.; Wenzel, C.; Dreschen, K.; Mattern, N. Crystallographic and morphological characterization of reactively sputtered Ta, TaN and TaNO thin films. Thin Solid Films 1997, 307, 79–88. [Google Scholar] [CrossRef]

- Nakao, S.; Numata, M.; Ohmi, T. Thin and low-resistivity tantalum nitride diffusion barrier and giant-grain copper interconnects for advanced ULSI metallization. J. Appl. Phys. 1999, 38, 2401–2405. [Google Scholar] [CrossRef]

- Nie, H.; Xu, S.; You, L.; Yang, Z.; Wang, S.; Ong, C. Structural and electrical properties of tantalum nitride thin films fabricated by using reactive radio-frequency magnetron sputtering. Appl. Phys. A 2001, 73, 229–236. [Google Scholar] [CrossRef]

- Lee, W.H.; Lin, J.C.; Lee, C. Characterization of tantalum nitride films deposited by reactive sputtering of Ta in N2/Ar gas mixtures. Mater. Chem. Phys. 2001, 68, 266–271. [Google Scholar] [CrossRef]

- Gerstenberg, D.; Calbick, C.J. Effects of nitrogen, methane, and oxygen on structure and electrical properties of thin tantalum films. J. Appl. Phys. 1964, 35, 402. [Google Scholar] [CrossRef]

- Terao, N. Structure of tantalum nitrides. Jpn. J. Appl. Phys. 1971, 10, 248. [Google Scholar] [CrossRef]

- Leng, Y.X.; Sun, H.; Yang, P.; Chen, J.Y.; Wang, J.; Wan, G.J.; Huang, N.; Tian, X.B.; Wang, L.P.; Chu, P.K. Biomedical properties of tantalum nitride films synthesized by reactive magnetron sputtering. Thin Solid Films 2001, 398–399, 471–475. [Google Scholar] [CrossRef]

- Valleti, K.; Subrahmanyam, A.; Joshi, S.V.; Phani, A.R.; Passacantando, M.; Santucci, S. Studies on phase dependent mechanical properties of dc magnetron sputtered TaN thin films: Evaluation of super hardness in orthorhombic Ta4N phase. J. Phys. D Appl. Phys. 2008, 41, 045409. [Google Scholar] [CrossRef]

- Mori, H.; Imahori, J.; Oku, T.; Murakami, M. Diffusion barriers between Si and Cu. AIP Conf. Proce. 1998, 418, 475. [Google Scholar]

- Stavrev, M.; Wenzel, C.; Moller, A.; Drescher, K. Sputtering of tantalum-based diffusion barriers in SiCu metallization: Effects of gas pressure and composition. Appl. Surf. Sci. 1995, 91, 257–262. [Google Scholar] [CrossRef]

- Lee, Y.K.; Khin, L.M.; Kim, J.; Kangsoo, L. Study of diffusion barrier properties of ionized metal plasma (IMP) deposited TaN between Cu and SiO2. Mater. Sci. Semicond. Process. 2000, 3, 179–184. [Google Scholar] [CrossRef]

- Westergard, R.; Bromark, M.; Larsson, M.; Hedenqvist, P.; Hogmark, S. Mechanical and tribological characterization of DC magnetron sputtered tantalum nitride thin films. Surf. Coat. Technol. 1997, 97, 779–784. [Google Scholar] [CrossRef]

- Lee, G.R.; Kim, H.; Choi, H.S.; Lee, J.J. Superhard tantalum-nitride films formed by inductively coupled plasma-assisted sputtering. Surf. Coat. Technol. 2007, 201, 5207–5210. [Google Scholar] [CrossRef]

- Bernoulli, D.; Müller, U.; Schwarzenberger, M.; Hauert, R.; Spolenak, R. Magnetron sputter deposited tantalum and tantalum nitride thin films: An analysis of phase, hardness and composition. Thin Solid Films 2013, 548, 157–161. [Google Scholar] [CrossRef]

- Chang, C.C.; Jeng, J.S.; Chen, J.S. Microstructural and electrical characteristics of reactively sputtered Ta–N thin films. Thin Solid Films 2002, 413, 46–51. [Google Scholar] [CrossRef]

- Arshi, N.; Lu, J.; Lee, C.G.; Koo, B.H.; Ahmed, F. Effects of nitrogen content on the phase and resistivity of TaN thin films deposited by electron beam evaporation. J. Miner. Met. Mater. Soc. 2014, 66, 1893–1899. [Google Scholar] [CrossRef]

- Zaman, A. Characterization of Tantalum Nitride Thin Films Synthesized by Magnetron Sputtering. Master’s Thesis, University of Texas at Arlington, Arlington, TX, USA, May 2014. [Google Scholar]

- Adjaottor, A.A.; Ma, E.; Meletis, E.I. On the mechanism of intensified plasma-assisted processing. Surf. Coat. Technol. 1997, 89, 197–203. [Google Scholar] [CrossRef]

- Veprek, S.; Karvankova, P.; Veprek-Heijman, M.G.J. Possible role of oxygen impurities in degradation of nc-TiN/a-Si3N4 nanocomposites. J. Vac. Sci. Technol. B 2005, 23, L17–L21. [Google Scholar] [CrossRef]

- Shin, C.-S.; Kim, Y.-W.; Gall, D.; Greene, J.E.; Petrov, I. Phase composition and microstructure of polycrystalline and epitaxial TaNx layers grown on oxidized Si (001) and MgO (001) by reactive magnetron sputter deposition. Thin Solid Films 2002, 402, 172–182. [Google Scholar] [CrossRef]

- Toth, L. Transition Metal Carbides and Nitrides; Academic Press: New York, NY, USA, 1971; pp. 150–160. [Google Scholar]

- Kuo, Y. Reactive ion etching of sputter deposited tantalum oxide and its etch selectivity to tantalum. J. Electrochem. Soc. 1992, 139, 579. [Google Scholar] [CrossRef]

- Sasaki, K.; Noya, A.; Umezawa, T. Stoichiometry of Ta–N Film and Its Application for Diffusion Barrier in the Al3Ta/Ta–N/Si Contact System. Jpn. J. Appl. Phys. 1990, 29, 1043. [Google Scholar] [CrossRef]

- Lim, Y.L.; Chaudhri, M.M. The influence of grain size on the indentation hardness of high-purity copper and aluminium. Philos. Mag. A 2002, 82, 2071–2080. [Google Scholar] [CrossRef]

- Musil, J. Hard nanocomposite coatings: Thermal stability, oxidation resistance and toughness. Surf. Coat. Technol. 2012, 207, 50–65. [Google Scholar] [CrossRef]

- Zhang, M.; Jiang, J.; Houska, J.; Kohout, J.; Vlcek, J.; Meletis, E.I. A study of the microstructure evolution of hard Zr–B–C–N films by high-resolution transmission electron microscopy. Acta Mater. 2014, 77, 212–222. [Google Scholar] [CrossRef]

- Leyland, A.; Matthews, A. On the significance of the H/E ratio in wear control: A nanocomposite coating approach to optimised tribological behaviour. Wear 2000, 246, 1–11. [Google Scholar] [CrossRef]

- Yan, X.; Yin, J.; Cheng, X.; Liu, J. Tribological properties of Ta–C–N and Ta–N thin films. Mater. Sci. Eng. Technol. 2013, 44, 50–65. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zaman, A.; Meletis, E.I. Microstructure and Mechanical Properties of TaN Thin Films Prepared by Reactive Magnetron Sputtering. Coatings 2017, 7, 209. https://doi.org/10.3390/coatings7120209

Zaman A, Meletis EI. Microstructure and Mechanical Properties of TaN Thin Films Prepared by Reactive Magnetron Sputtering. Coatings. 2017; 7(12):209. https://doi.org/10.3390/coatings7120209

Chicago/Turabian StyleZaman, Anna, and Efstathios I. Meletis. 2017. "Microstructure and Mechanical Properties of TaN Thin Films Prepared by Reactive Magnetron Sputtering" Coatings 7, no. 12: 209. https://doi.org/10.3390/coatings7120209