Effect of Initial Surface Roughness on Cavitation Erosion Resistance of Arc-Sprayed Fe-Based Amorphous/Nanocrystalline Coatings

Abstract

:1. Introduction

2. Experimental Procedure

3. Results and Discussion

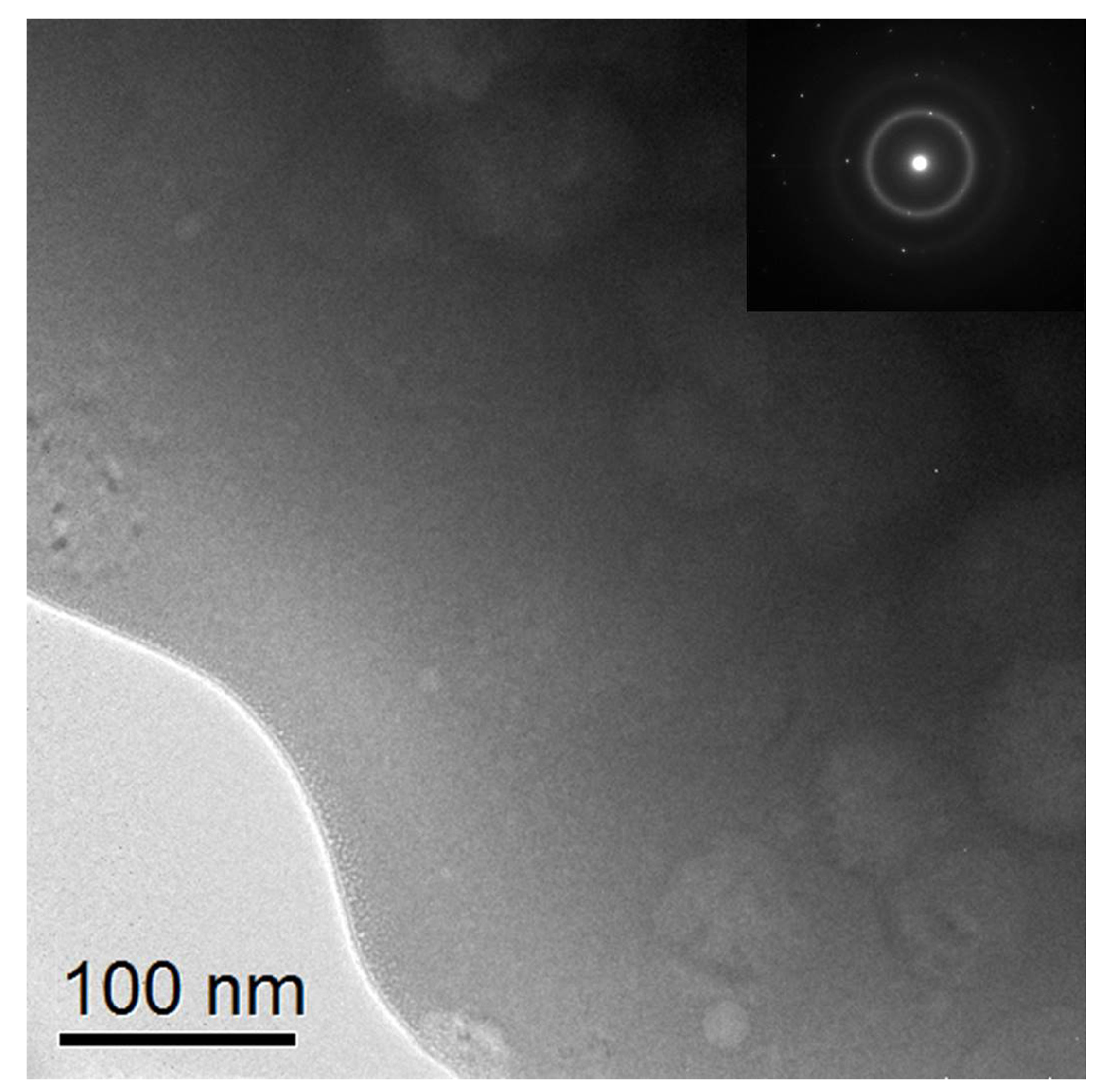

3.1. Characterization of the Coating

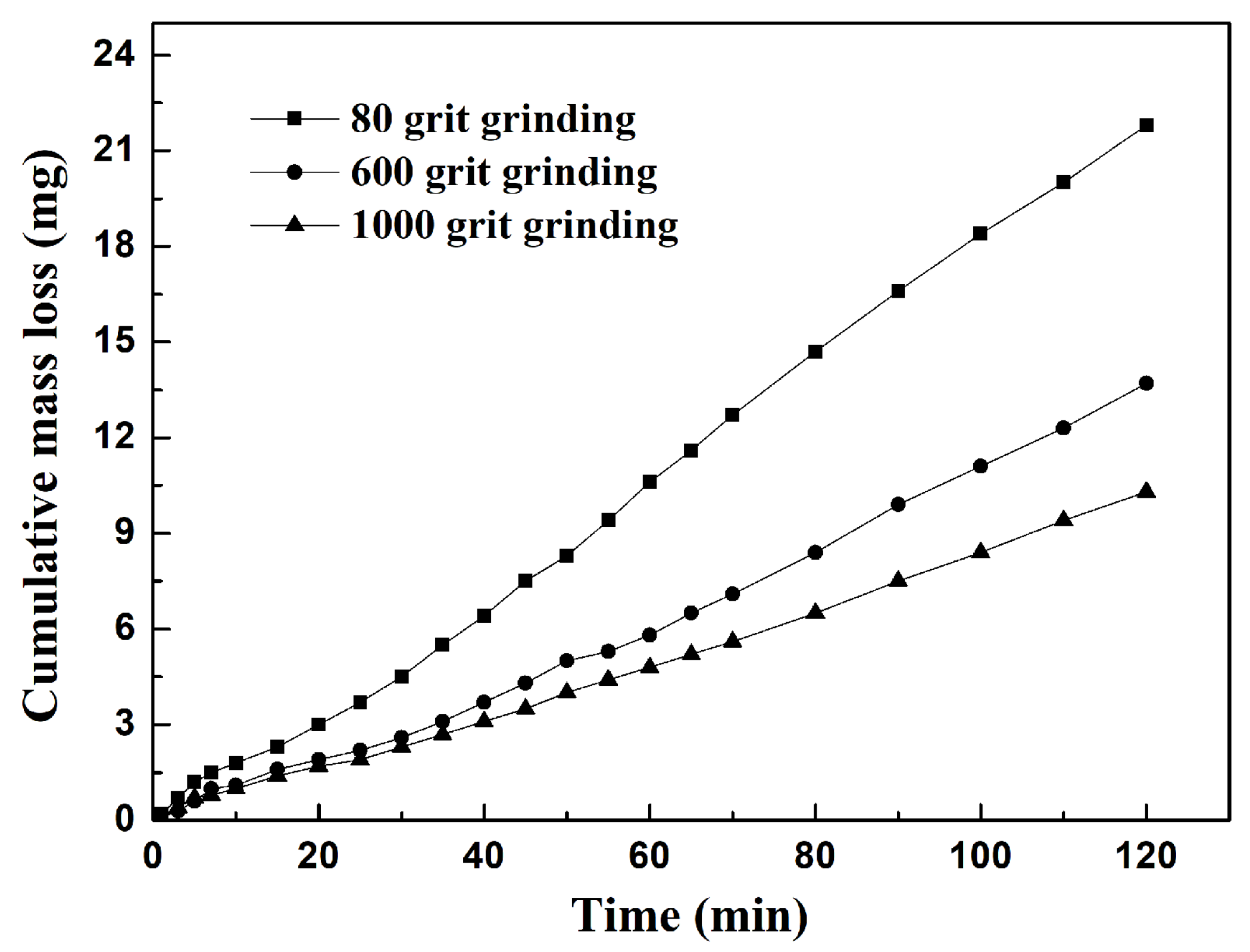

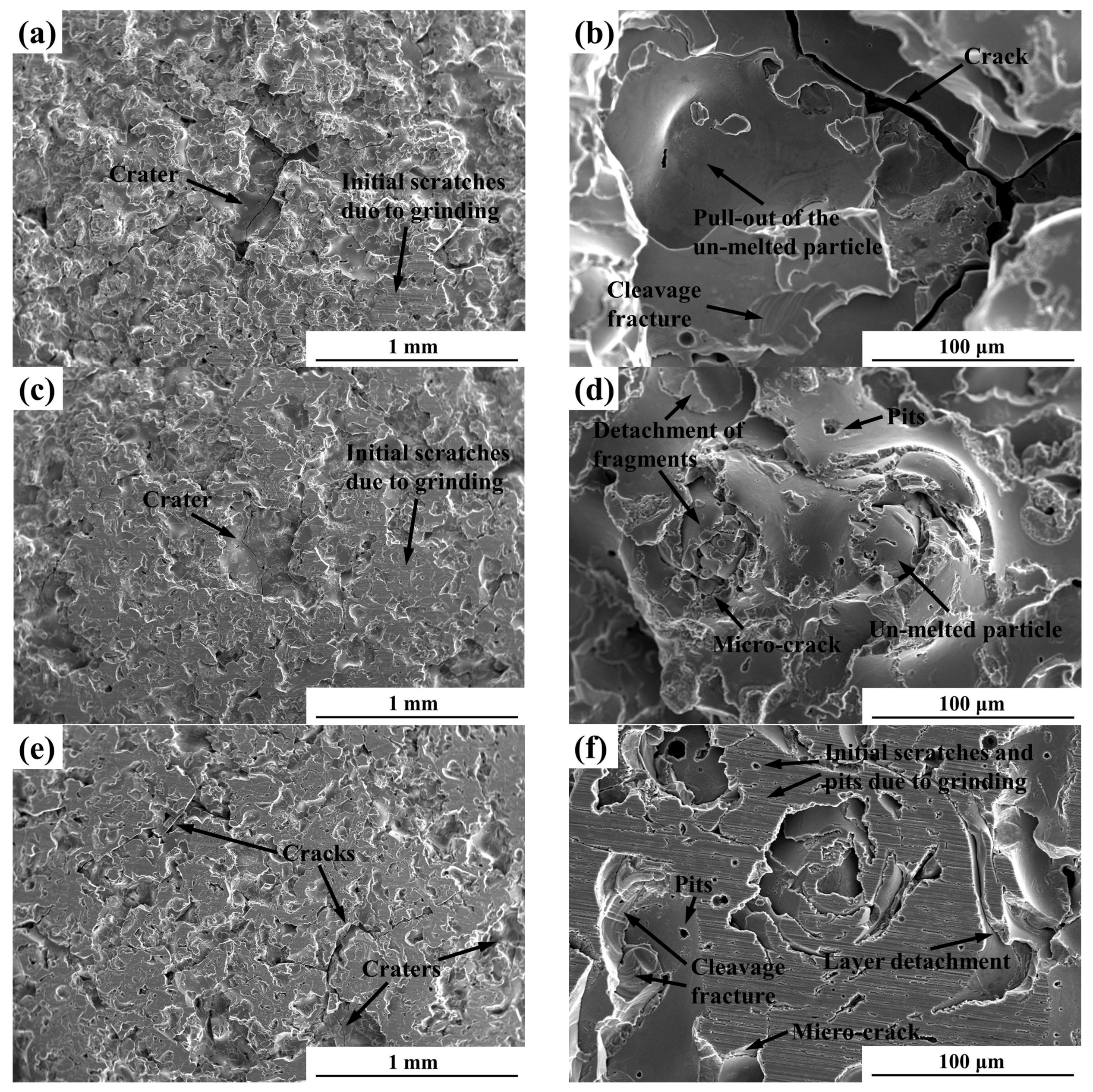

3.2. Cavitation Erosion Behavior of the Coatings

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Karimi, A.; Martin, J.-L. Cavitation erosion of materials. Int. Met. Rev. 1986, 31, 1–26. [Google Scholar] [CrossRef]

- Wu, C.L.; Zhang, S.; Zhang, C.H.; Zhang, H.; Dong, S.Y. Phase evolution and cavitation erosion-corrosion behavior of FeCoCrAlNiTix high entropy alloy coatings on 304 stainless steel by laser surface alloying. J. Alloys Compd. 2017, 698, 761–770. [Google Scholar] [CrossRef]

- Li, D.; Kang, Y.; Wang, X.C.; Ding, X.L.; Fang, Z.L. Effects of nozzle inner surface roughness on the cavitation erosion characteristics of high speed submerged jets. Exp. Therm. Fluid Sci. 2016, 74, 444–452. [Google Scholar] [CrossRef]

- Chiu, K.Y.; Cheng, F.T.; Man, H.C. Evolution of surface roughness of some metallic materials in cavitation erosion. Ultrasonics 2005, 43, 713–716. [Google Scholar] [CrossRef] [PubMed]

- Hutli, E.; Nedeljkovic, M.S.; Bonyar, A.; Radovic, N.A.; Llic, V.; Debeljkovic, A. The ability of using the cavitation phenomenon as a tool to modify the surface characteristics in micro- and in nano-level. Tribol. Int. 2016, 101, 88–97. [Google Scholar] [CrossRef]

- Wang, Y.; Stella, J.; Darut, G.; Poirier, T.; Liao, H.L.; Planche, M.P. APS prepared NiCrBSi-YSZ composite coatings for protection against cavitation erosion. J. Alloys Compd. 2017, 699, 1095–1103. [Google Scholar] [CrossRef]

- Woo, Y.B.; Lee, S.J.; Jeong, J.Y.; Kim, S.J. Evaluation on cavitation characteristics of CoNiCrAlY/ZrO2-Y2O3 coating layer by atmospheric pressure plasma coating process. Mater. Res. Bull. 2014, 58, 78–82. [Google Scholar] [CrossRef]

- Hong, S.; Wu, Y.P.; Zhang, J.F.; Zheng, Y.G.; Zheng, Y.; Lin, J.R. Synergistic effect of ultrasonic cavitation erosion and corrosion of WC-CoCr and FeCrSiBMn coatings prepared by HVOF spraying. Ultrason. Sonochem. 2016, 31, 563–569. [Google Scholar] [CrossRef] [PubMed]

- Cheng, J.B.; Liang, X.B.; Xu, B.S.; Wu, Y.X. Characterization of mechanical properties of FeCrBSiMnNbY metallic glass coatings. J. Mater. Sci. 2009, 44, 3356–3363. [Google Scholar] [CrossRef]

- Wu, Y.P.; Lin, P.H.; Wang, Z.H.; Li, G.Y. Microstructure and microhardness characterization of a Fe-based coating deposited by high-velocity oxy-fuel thermal spraying. J. Alloys Compd. 2009, 481, 719–724. [Google Scholar] [CrossRef]

- Lin, J.R.; Wang, Z.H.; Lin, P.H.; Cheng, J.B.; Zhang, X.; Hong, S. Effects of post annealing on the microstructure, mechanical properties and cavitation erosion behavior of arc-sprayed FeNiCrBSiNbW coatings. Mater. Des. 2015, 65, 1035–1040. [Google Scholar] [CrossRef]

- Wang, Y.; Li, K.Y.; Scenini, F.; Jiao, J.; Qu, S.J.; Luo, Q.; Shen, J. The effect of residual stress on the electrochemical corrosion behavior of Fe-based amorphous coatings in chloride-containing solutions. Surf. Coat. Technol. 2016, 302, 27–38. [Google Scholar] [CrossRef]

- Wu, Y.P.; Lin, P.H.; Chu, C.L.; Wang, Z.H.; Cao, M.; Hu, J.H. Cavitation erosion characteristics of a Fe-Cr-Si-B-Mn coating fabricated by high velocity oxy-fuel (HVOF) thermal spray. Mater. Lett. 2007, 61, 1867–1872. [Google Scholar]

- Hahn, M.; Fischer, A. Characterization of thermally sprayed micro- and nanocrystalline cylinder wall coatings by means of a cavitation test. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2009, 223, 27–37. [Google Scholar] [CrossRef]

- Hahn, M.; Fischer, A. Characterization of thermal spray coatings for cylinder running surfaces of diesel engines. J. Therm. Spray Technol. 2010, 19, 866–872. [Google Scholar] [CrossRef]

- Wang, Z.H.; Zhang, X.; Cheng, J.B.; Lin, J.R.; Zhou, Z.H. Cavitation erosion resistance of Fe-based amorphous/nanocrystal coatings prepared by high-velocity arc spraying. J. Therm. Spray Technol. 2014, 23, 742–749. [Google Scholar] [CrossRef]

- Lin, J.R.; Wang, Z.H.; Lin, P.H.; Cheng, J.B.; Zhang, X.; Hong, S. Microstructure and cavitation erosion behavior of FeNiCrBSiNbW coating prepared by twin wires arc spraying process. Surf. Coat. Technol. 2014, 240, 432–436. [Google Scholar] [CrossRef]

- Hou, G.L.; Zhao, X.Q.; Zhou, H.D.; Lu, J.J.; An, Y.L.; Chen, J.M.; Yang, J. Cavitation erosion of several oxy-fuel sprayed coatings tested in deionized water and artificial seawater. Wear 2014, 311, 81–92. [Google Scholar] [CrossRef]

- Kim, Y.J.; Jang, J.W.; Lee, D.W.; Yi, S. Porosity effects of a Fe-based amorphous/nanocrystals coating prepared by a commercial high velocity oxy-fuel process on cavitation erosion behaviors. Met. Mater. Int. 2015, 21, 673–677. [Google Scholar] [CrossRef]

- Zheng, Z.B.; Zheng, Y.G.; Sun, W.H.; Wang, J.Q. Effect of heat treatment on the structure, cavitation erosion and erosion-corrosion behavior of Fe-based amorphous coatings. Tribol. Int. 2015, 90, 393–403. [Google Scholar] [CrossRef]

- Qiao, L.; Wu, Y.P.; Hong, S.; Zhang, J.F.; Shi, W.; Zheng, Y.G. Relationships between spray parameters, microstructures and ultrasonic cavitation erosion behavior of HVOF sprayed Fe-based amorphous/nanocrystalline coatings. Ultrason. Sonochem. 2017, 39, 39–46. [Google Scholar] [CrossRef] [PubMed]

- Cheng, J.B.; Wang, B.L.; Liu, Q.; Liang, X.B. In-situ synthesis of novel Al-Fe-Si metallic glass coating by arc spraying. J. Alloys Compd. 2017, 716, 88–95. [Google Scholar] [CrossRef]

- ASTM G32-10-Standard Test Method for Cavitation Erosion Using Vibratory Apparatus; ASTM International: West Conshohocken, PA, USA, 2010.

- Jonas, O.; Steltz, W.; Dooley, B. Steam Turbine Efficiency and Corrosion: Effects of Surface Finish, Deposits; Report 1003997; Electrical Power Research Institute (EPRI): Palo Alto, CA, USA, 2001. [Google Scholar]

- Lin, J.R.; Wang, Z.H.; Lin, P.H.; Cheng, J.B.; Zhang, J.J.; Zhang, X. Microstructure and corrosion resistance of Fe-based coatings prepared by twin wires arc spraying process. J. Therm. Spray Technol. 2014, 23, 333–339. [Google Scholar] [CrossRef]

- Sharma, P.; Majumdar, J.D. Surface characterization and mechanical properties evaluation of Boride-dispersed Nickel-based coatings deposited on copper through thermal spray routes. J. Therm. Spray. Technol. 2012, 21, 800–809. [Google Scholar] [CrossRef]

- Cheng, J.B.; Zhao, S.; Liu, D.; Feng, Y.; Liang, X.B. Microstructure and fracture toughness of the FePSiB-based amorphous/nanocrystalline coatings. Mater. Sci. Eng. A 2017, 696, 341–347. [Google Scholar] [CrossRef]

- Heni, W.; Vonna, L.; Fioux, P.; Vidal, L.; Haidara, H. Ultrasonic cavitation test applied to thin metallic films for assessing their adhesion with mercaptosilanes and surface roughness. J. Mater. Sci. 2014, 49, 6750–6761. [Google Scholar] [CrossRef]

- Jiang, N.N.; Liu, S.H.; Chen, D.R. Effect of roughness and wettability of silicon wafer in cavitation erosion. Chin. Sci. Bull. 2008, 53, 2879–2885. [Google Scholar] [CrossRef]

- Friction, Lubrication, and Wear Technology. In ASM Handbook (Volume 18); ASM International: Materials Park, OH, USA, 1992; pp. 408–435.

- Santa, J.F.; Espitia, L.A.; Blanco, J.A.; Romo, S.A.; Toro, A. Slurry and cavitation erosion resistance of thermal spray coatings. Wear 2009, 267, 160–167. [Google Scholar] [CrossRef]

- Scardina, P.; Edwards, M. Prediction and measurement of bubble formation in water treatment. J. Environ. Eng. 2001, 11, 968–973. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, J.; Wang, Z.; Cheng, J.; Kang, M.; Fu, X.; Hong, S. Effect of Initial Surface Roughness on Cavitation Erosion Resistance of Arc-Sprayed Fe-Based Amorphous/Nanocrystalline Coatings. Coatings 2017, 7, 200. https://doi.org/10.3390/coatings7110200

Lin J, Wang Z, Cheng J, Kang M, Fu X, Hong S. Effect of Initial Surface Roughness on Cavitation Erosion Resistance of Arc-Sprayed Fe-Based Amorphous/Nanocrystalline Coatings. Coatings. 2017; 7(11):200. https://doi.org/10.3390/coatings7110200

Chicago/Turabian StyleLin, Jinran, Zehua Wang, Jiangbo Cheng, Min Kang, Xiuqing Fu, and Sheng Hong. 2017. "Effect of Initial Surface Roughness on Cavitation Erosion Resistance of Arc-Sprayed Fe-Based Amorphous/Nanocrystalline Coatings" Coatings 7, no. 11: 200. https://doi.org/10.3390/coatings7110200