Characterization of Hydroxyapatite (HA) Sputtering Targets by APS Methods

Abstract

:1. Introduction

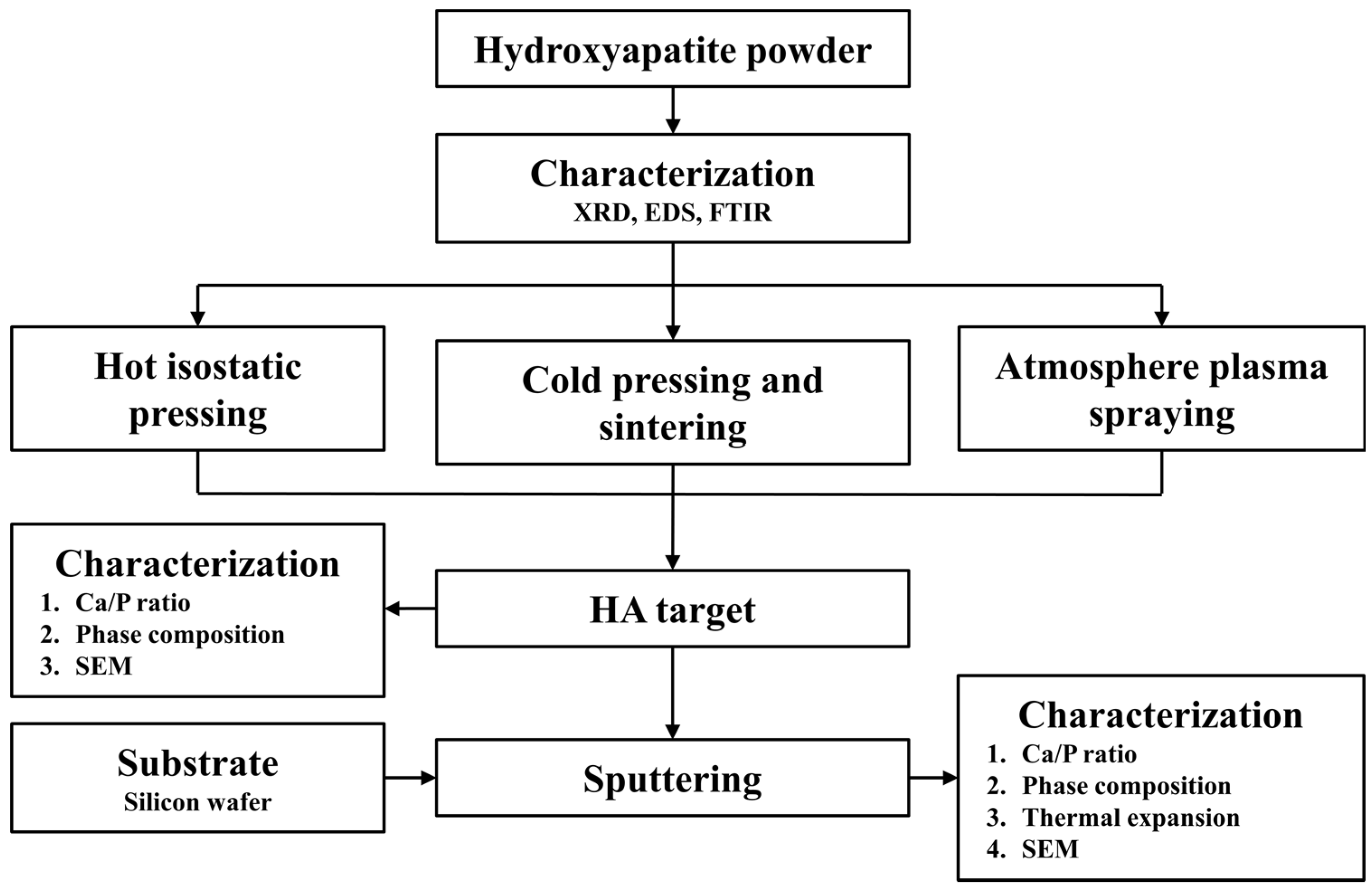

2. Materials and Methods

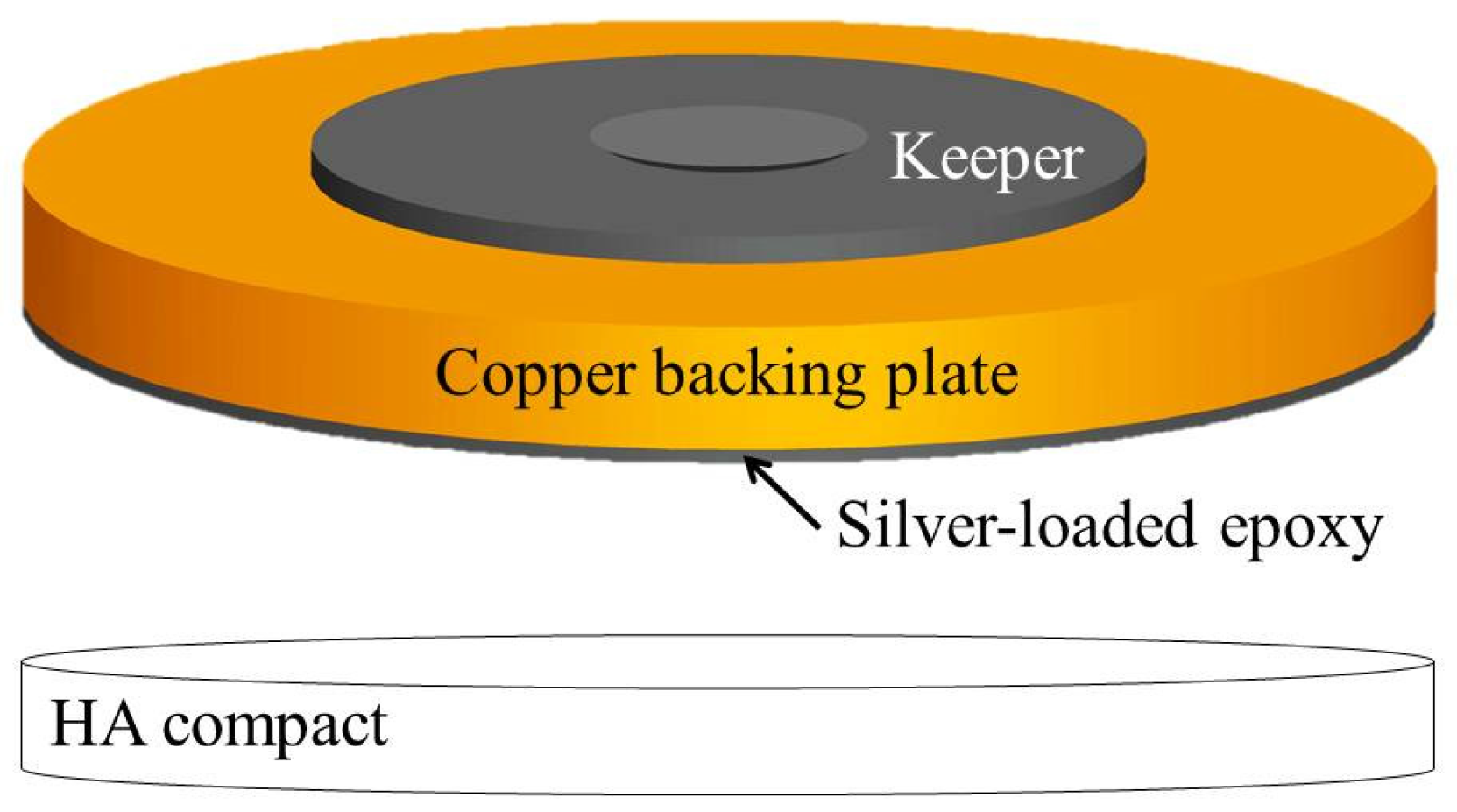

2.1. Manufacture of the Hydroxyapatite Target

2.2. Sputtering Procedure and Characterization of the Hydroxyapatite Films

3. Results and Discussion

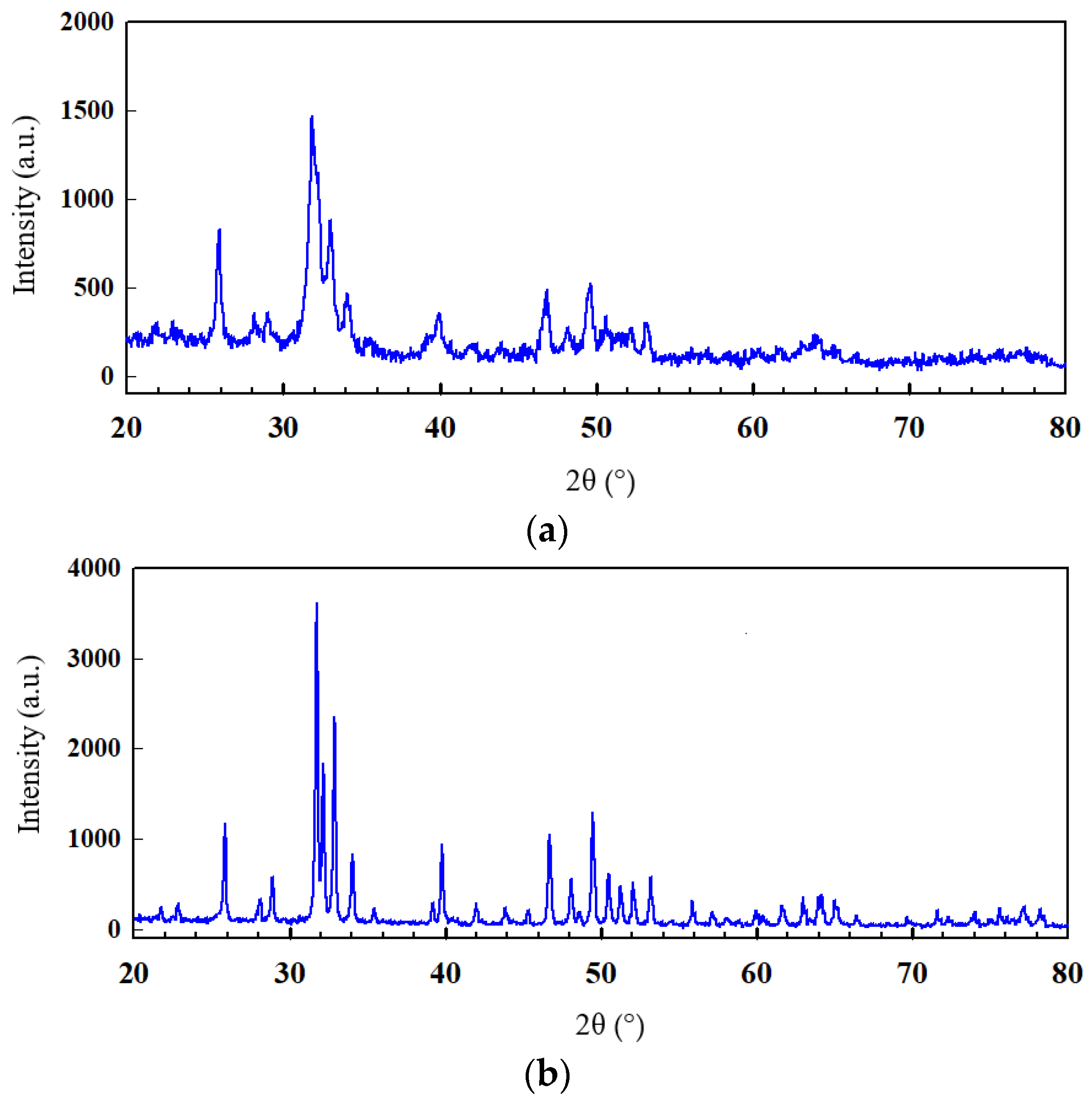

3.1. Characterization of the Hydroxyapatite Powders

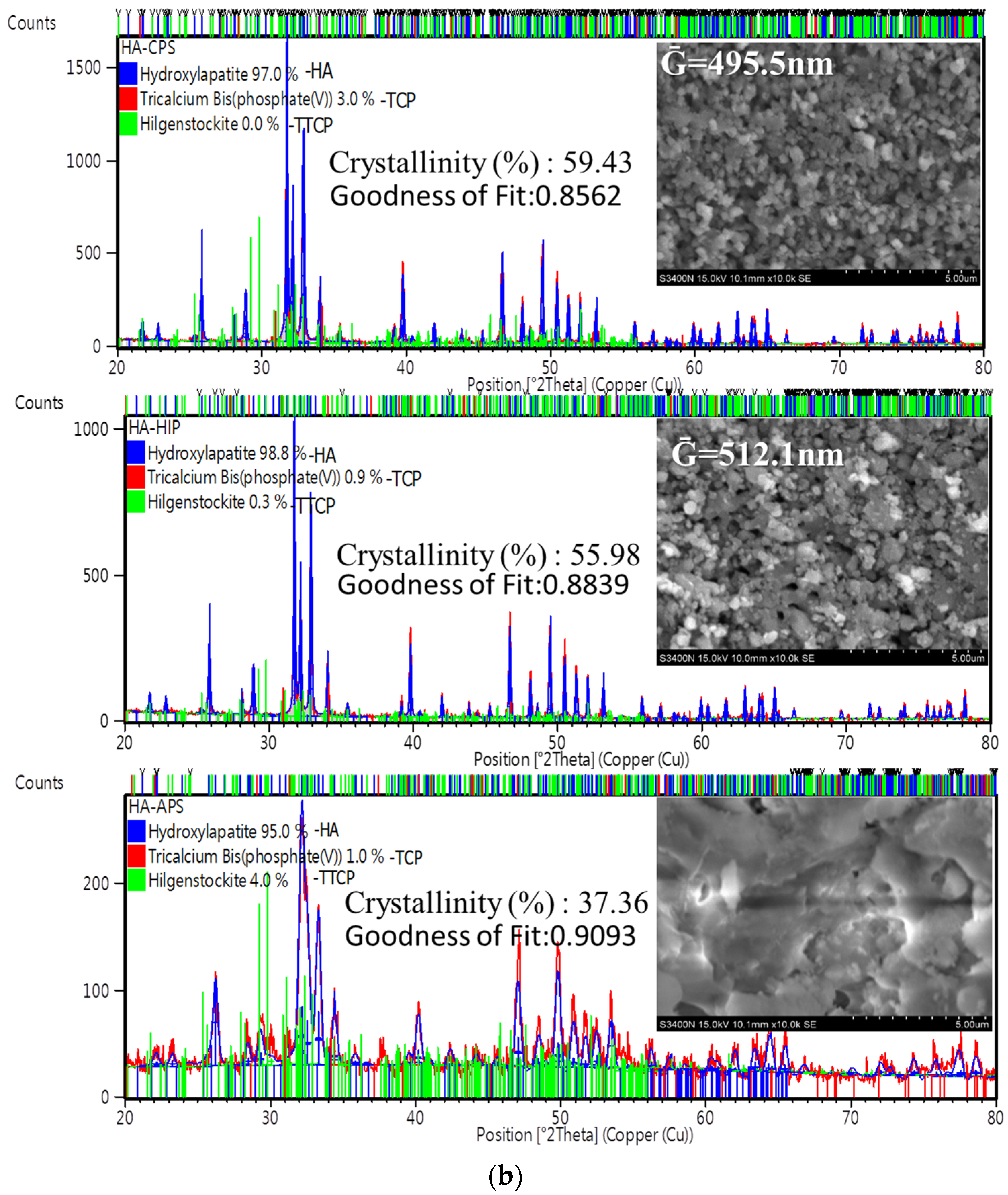

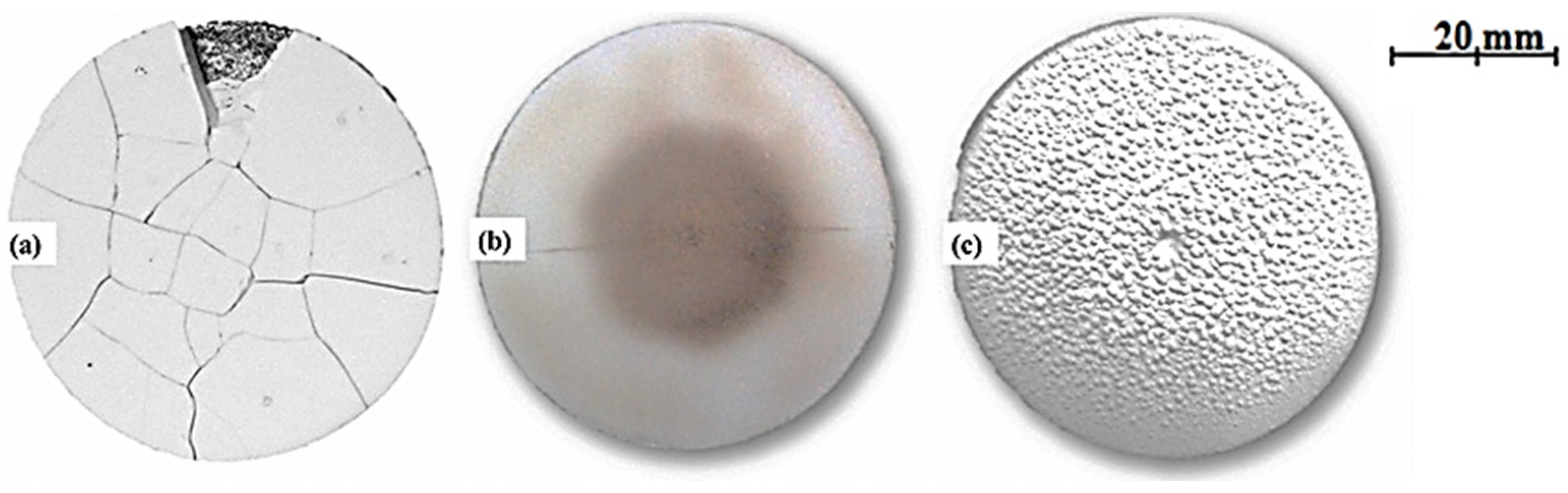

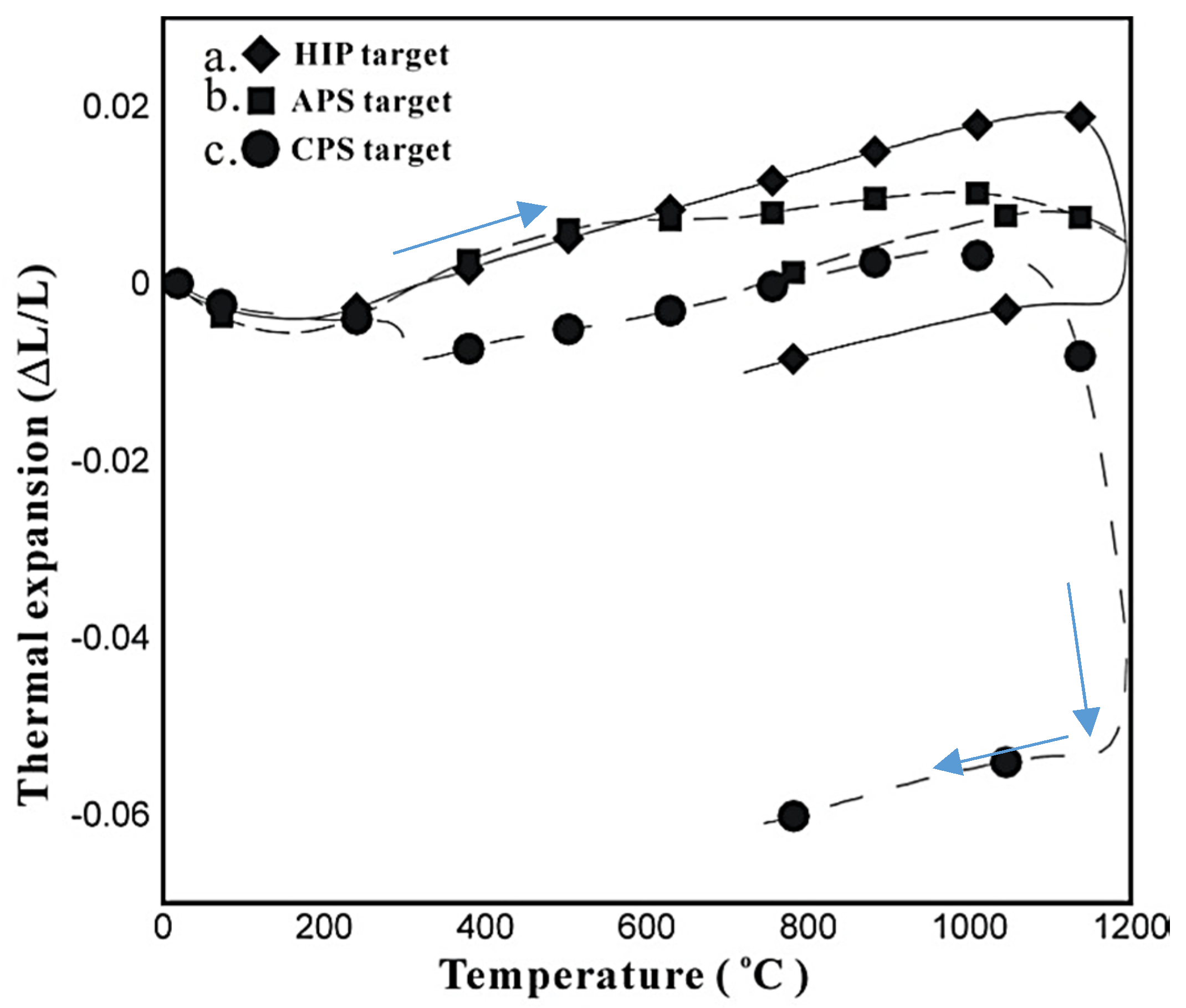

3.2. Characterization of the Hydroxyapatite Targets

3.2.1. Phase and Composition

3.2.2. The Performance of Hydroxyapatite Targets

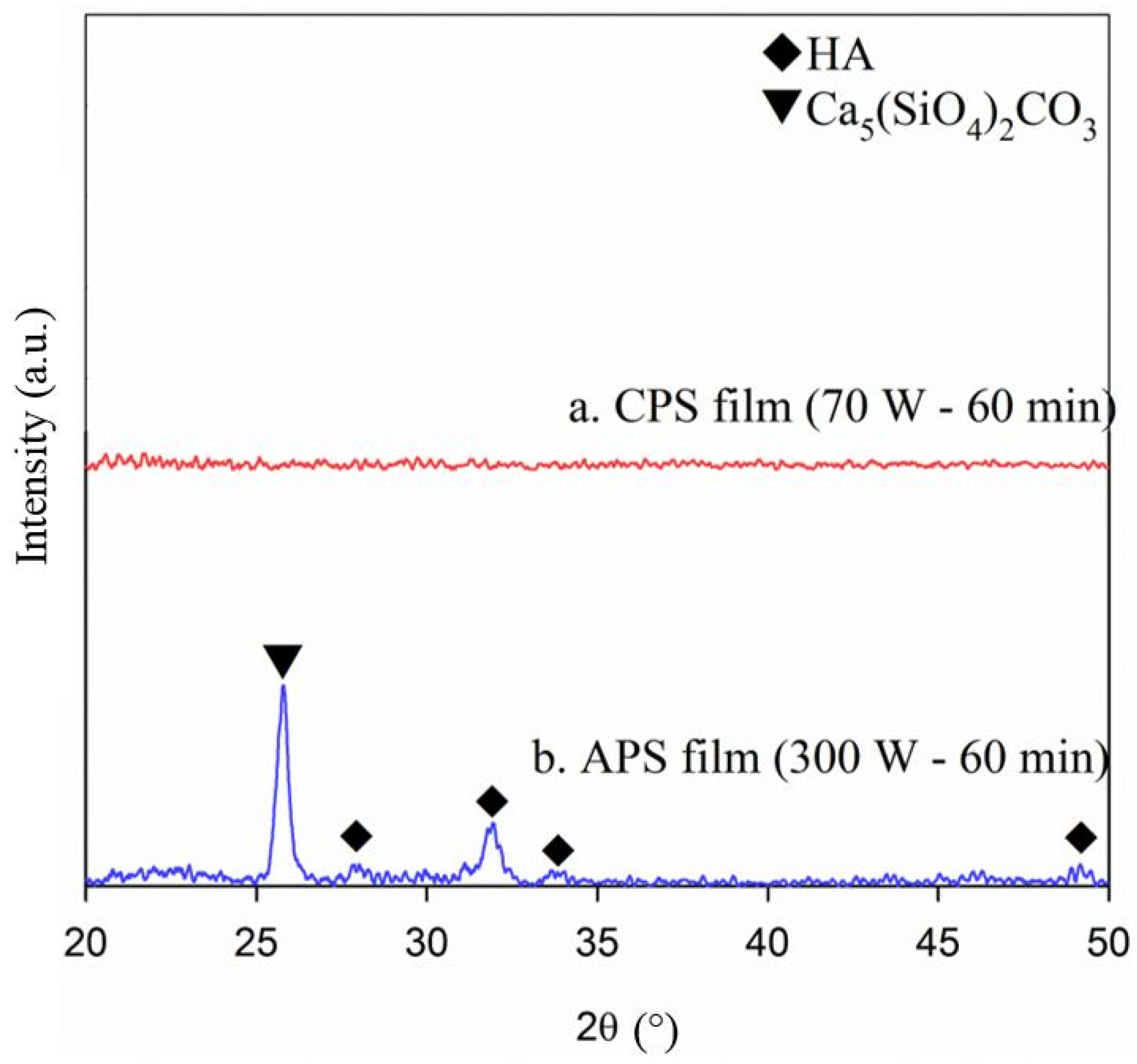

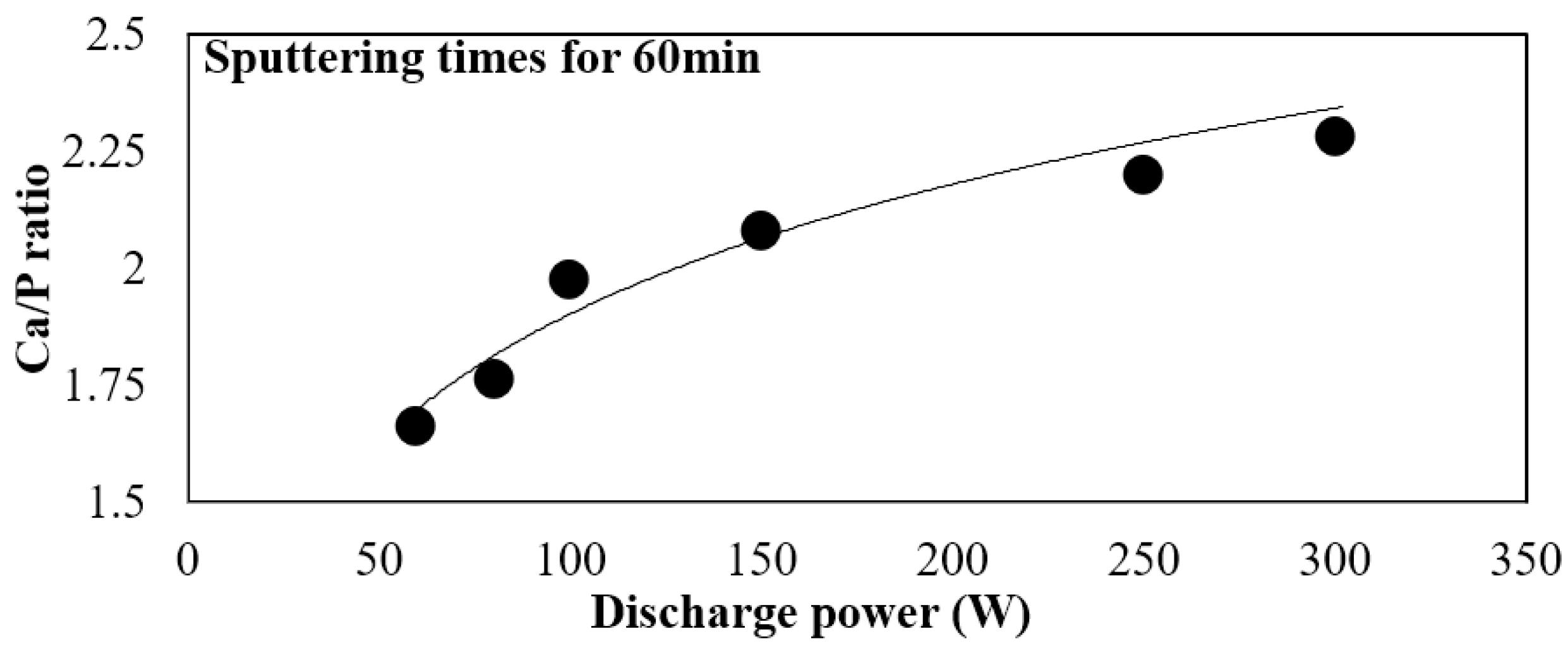

3.3. Characterization of Hydroxyapatite-Sputtered Films

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Bruck, S.D. Properties of Biomaterials in the Physiological Environment; CRC Press Inc.: Boca Raton, FL, USA, 1980; p. 142. [Google Scholar]

- Hench, L.L.; Ceram, J.A. Bioceramics: From Concept to Clinic. J. Am. Ceram. Soc. 1991, 74, 1487–1510. [Google Scholar] [CrossRef]

- Kühne, J.H.; Bartl, R.; Frisch, B.; Hammer, C.; Jansson, V.; Zimmer, M. Bone formation in coralline hydroxyapatite. Effects of pore size studied in rabbits. Acta Orthop. Scand. 1994, 64, 246–252. [Google Scholar] [CrossRef]

- Deeb, M.E.; Holmes, R.E. Tissue response to facial contour augmentation with dense and porous hydroxyapatite in rhesus monkeys. J. Oral Maxillofac. Surg. 1989, 47, 1282–1289. [Google Scholar] [CrossRef]

- Cizek, J.; Khor, K.A.; Prochazka, Z. Influence of spraying conditions on thermal and velocity properties of plasma sprayed hydroxyapatite. Mater. Sci. Eng. C 2007, 27, 340–344. [Google Scholar] [CrossRef]

- Sun, L.; Berndt, C.C.; Grey, C.P. Phase structural and microstructural investigation of plasma sprayed hydroxyapatite coating. Mater. Sci. Eng. 2003, 360, 70–84. [Google Scholar] [CrossRef]

- Bosco, R.; Beucken, J.V.D.; Leeuwenburgh, S.; Jansen, J. Surface Engineering for Bone Implants: A Trend from Passive to Active Surfaces. Coatings 2012, 2, 95–119. [Google Scholar] [CrossRef] [Green Version]

- Tsui, Y.C.; Doyle, C.; Clyne, T.W. Plasma sprayed hydroxyapatite coatings on titanium substrates Part 1: Mechanical properties and residual stress levels. Biomaterials 1998, 19, 2015–2029. [Google Scholar] [CrossRef]

- Mercioniu, S.; Ciuca, I.; Pasuk, A.; Slav, A.; Morosanu, C.; Bercu, M. Thickness dependence of crystallization process for hydroxyapatite thin films. J. Optoelectron. Adv. Mater. 2007, 9, 2535–2538. [Google Scholar]

- Wolke, J.G.C.; van Dijk, K.; Schaeken, H.G.; de Groot, K.; Jansen, J.A. Study of the surface characteristics of magnetron-sputter calcium phosphate coatings. J. Biomed. Mater. Res. 1994, 27, 1477–1484. [Google Scholar] [CrossRef] [PubMed]

- Wan, T.; Aoki, H.; Hikawa, J.; Lee, J.H. RF-magnetron sputtering technique for producing hydroxyapatite coating film on various substrates. Biomed. Mater. Eng. 2007, 17, 291–297. [Google Scholar] [PubMed]

- Wolke, J.G.C.; Waerden, V.D.; Schaeken, H.G.; Jansen, J.A. In vivo dissolution behavior of various RF magnetron-sputtered Ca-P coatings on roughened titanium implants. Biomaterials 2003, 24, 2623–2629. [Google Scholar] [CrossRef]

- Massaro, C.; Baker, M.A.; Cosentino, F.; Ramires, P.A.; Klose, S.; Milella, E. Surface and biological evaluation of hydroxyapatite-based coatings on titanium deposited by different techniques. J. Biomed. Mater. Res. 2001, 58, 651–657. [Google Scholar] [CrossRef] [PubMed]

- Ding, S.J. Properties and immersion behavior of magnetron-sputtered multi-layered hydroxyapatite/titanium composite coatings. Biomaterials 2003, 27, 4233–4238. [Google Scholar] [CrossRef]

- Aronov, A.M.; Pichugin, V.F.; Eshenko, E.V.; Ryabtseva, M.A.; Surmenev, R.A.; Tverdokhlebov, S.I.; Shesterikov, E.V. Thin calcium-phosphate coating produced by RF-magnetron sputtered and prospects for their use in biomedical engineering. Biomed. Eng. 2008, 42, 123–127. [Google Scholar] [CrossRef]

- Verestiuca, L.; Morosanub, C.; Bercuc, M.; Pasuik, I.; Mihailescu, I.N. Chemical growth of calcium phosphate layers on magnetron sputtered HA films. J. Cryst. Growth 2004, 264, 483–491. [Google Scholar] [CrossRef]

- Narushima, T.; Ueda, K.; Goto, T.; Masumoto, H.; Katsube, T.; Kawamura, H.; Ouchi, C.; Iguchi, Y. Preparation of Calcium Phosphate Films by Radiofrequency Magnetron Sputtering. Mater. Trans. 2005, 46, 2246–2252. [Google Scholar] [CrossRef]

- Lai, H.C.; Tsai, H.H.; Hung, K.Y.; Feng, H.P. Fabrication of Hydroxyapatite Targets in RF-sputtering for Surface Modification of Titanium Dental Implants. J. Intell. Mater. Syst. Struct. 2015, 26, 1050–1058. [Google Scholar] [CrossRef]

- Hung, K.Y.; Lo, S.C.; Shih, C.S.; Yang, Y.C.; Feng, H.P.; Lin, Y.C. Titanium Surface Modified by Hydroxyapatite Coating for Dental Implants. Surf. Coat. Technol. 2013, 231, 337–345. [Google Scholar] [CrossRef]

- Bohner, M. Calcium orthophosphates in medicine: From ceramics to calcium phosphate cements. Injury 2000, 31, 37–47. [Google Scholar] [CrossRef]

- Ozeki, K.; Yuhta, T.; Fukui, Y.; Aoki, H. Phase composition of sputtered films from a hydroxyapatite target. Surf. Coat. Technol. 2002, 160, 54–61. [Google Scholar] [CrossRef]

- Kweh, S.W.K.; Khor, K.A.; Cheang, P. Plasma-sprayed hydroxyapatite (HA) coatings with flame-spheroidized feedstock: Microstructure and mechanical properties. Biomaterials 2000, 21, 1223–1234. [Google Scholar] [CrossRef]

- Lu, Y.; Li, S.; Zhu, R.; Li, M. Further studies on the effect of stand-off distance on characteristics of plasma sprayed hydroxyapatite coating. Surf. Coat. Technol. 2002, 157, 221–225. [Google Scholar] [CrossRef]

- Schneider, S.J., Jr. Engineered Materials Handbook, Volume 4: Ceramics and Glasses; ASM International: Materials Park, OH, USA, 1991. [Google Scholar]

- Heimann, R.B. Thermal spraying of biomaterials. Surf. Coat. Technol. 2006, 201, 2012–2019. [Google Scholar] [CrossRef]

- Anil, S.; Anand, P.S.; Alghamdi, H.; Jansen, J.A. Dental Implant Surface Enhancement and Osseointegration. In Implant Dentistry—A Rapidly Evolving Practice; Turkyilmaz, I., Ed.; InTech: London, UK, 2011. [Google Scholar]

| Process | Parameter |

|---|---|

| Powder | SIGMA Sigma-Aldrich H0252 |

| Sintering Temperature | 1100 °C |

| Post Heat Treatment | 1000 °C at a set time of 2 h |

| Cooling | Naturally in furnace |

| Adhesion Glue | AB type Ag glue |

| Target Thickness | 2 mm |

| Target Size | 2 inches in diameter |

| Process | Parameter |

|---|---|

| Powder | SIGMA Sigma-Aldrich H0252 |

| Press Type | Hydraulically pressing |

| Sintering Furnace | Tube type |

| Sintering Temperature | 1050 °C in air environment |

| Heating Rate | 3 °C/min |

| Sintering Duration | 2 h |

| Cooling | naturally in furnace |

| Adhesion Glue | AB type Ag glue |

| Target Thickness | 2 mm |

| Target Size | 2 inches in diameter |

| Process | Parameter |

|---|---|

| Powder | Sulzer Metco XPT-D-703 |

| Environment | In air |

| Flow Rate of Primary Gas (Ar) | 50 L/min |

| Flow Rate of Secondary Gas (H2) | 14 L/min |

| Torch Current | 660 A |

| Power | 47.9 kW |

| Stand-off Distance | 7.5 cm |

| Surface Speed | 150 rpm |

| Transverse Speed | 5 mm/s |

| Flow Rate of Powder Carrier Gas (Ar) | 3 L/min |

| Powder Feed Rate | 10 rpm |

| Spraying Loop | 120 |

| Voltage | 72.5 V |

| Target Thickness | 2 mm |

| Target Size | 2 inches in diameter |

| Target | Element | k-Ratio | ZAF | at.% | Ca/P Ratio |

|---|---|---|---|---|---|

| HIP | P | 0.3345 | 1.077 | 36.01 | 1.679 |

| Ca | 0.5737 | 1.053 | 60.41 | ||

| CPS | P | 0.2792 | 1.073 | 29.94 | 2.04 |

| Ca | 0.6663 | 1.043 | 61.07 | ||

| APS | P | 0.2166 | 1.076 | 24.71 | 2.401 |

| Ca | 0.7427 | 1.033 | 59.33 |

| Process | Parameter |

|---|---|

| Sputtering Time | 60 min |

| Base Pressure | 7.5 × 10−6 torr |

| Process Pressure | 3.0 × 10−3 torr |

| Ar Flow Rate | 20 sccm |

| Working Distance | 70 mm |

| Power | 50–300 W |

| Parameter | Element | k-Ratio | ZAF | at.% | Ca/P Ratio |

|---|---|---|---|---|---|

| CPS Film, 70 W-60 min | P | 0.0257 | 1.735 | 1.07 | 1.51 |

| Ca | 0.1003 | 1.167 | 1.62 | ||

| APS Film, 300 W-60 min | P | 0.0317 | 1.693 | 5.37 | 2.38 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hung, K.-Y.; Lai, H.-C.; Yang, Y.-C.; Feng, H.-P. Characterization of Hydroxyapatite (HA) Sputtering Targets by APS Methods. Coatings 2017, 7, 197. https://doi.org/10.3390/coatings7110197

Hung K-Y, Lai H-C, Yang Y-C, Feng H-P. Characterization of Hydroxyapatite (HA) Sputtering Targets by APS Methods. Coatings. 2017; 7(11):197. https://doi.org/10.3390/coatings7110197

Chicago/Turabian StyleHung, Kuo-Yung, Hong-Chen Lai, Yung-Chin Yang, and Hui-Ping Feng. 2017. "Characterization of Hydroxyapatite (HA) Sputtering Targets by APS Methods" Coatings 7, no. 11: 197. https://doi.org/10.3390/coatings7110197