Influence of Isothermal Heat Treatment on Porosity and Crystallite Size in Axial Suspension Plasma Sprayed Thermal Barrier Coatings for Gas Turbine Applications

Abstract

:1. Introduction

2. Experimental Section

2.1. Coating Preparation

2.2. Heat Treatment of the of Coatings Studied in this Work

2.3. Microstructure Analysis

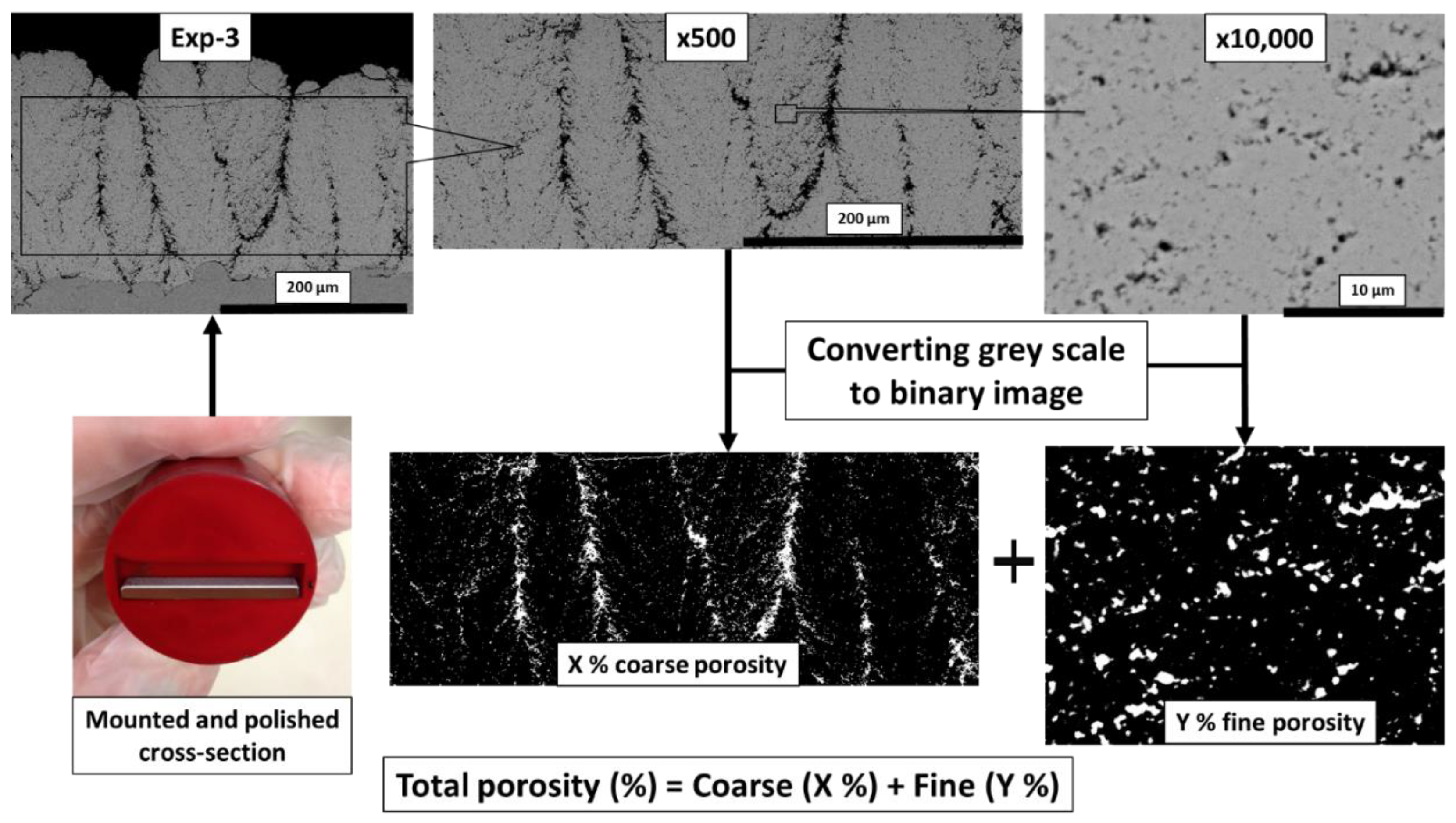

2.4. Porosity Measurement of Coatings

2.5. Phase Analysis and Crystallite Size Measurement

2.6. Thermal Conductivity Measurement

3. Results and Discussion

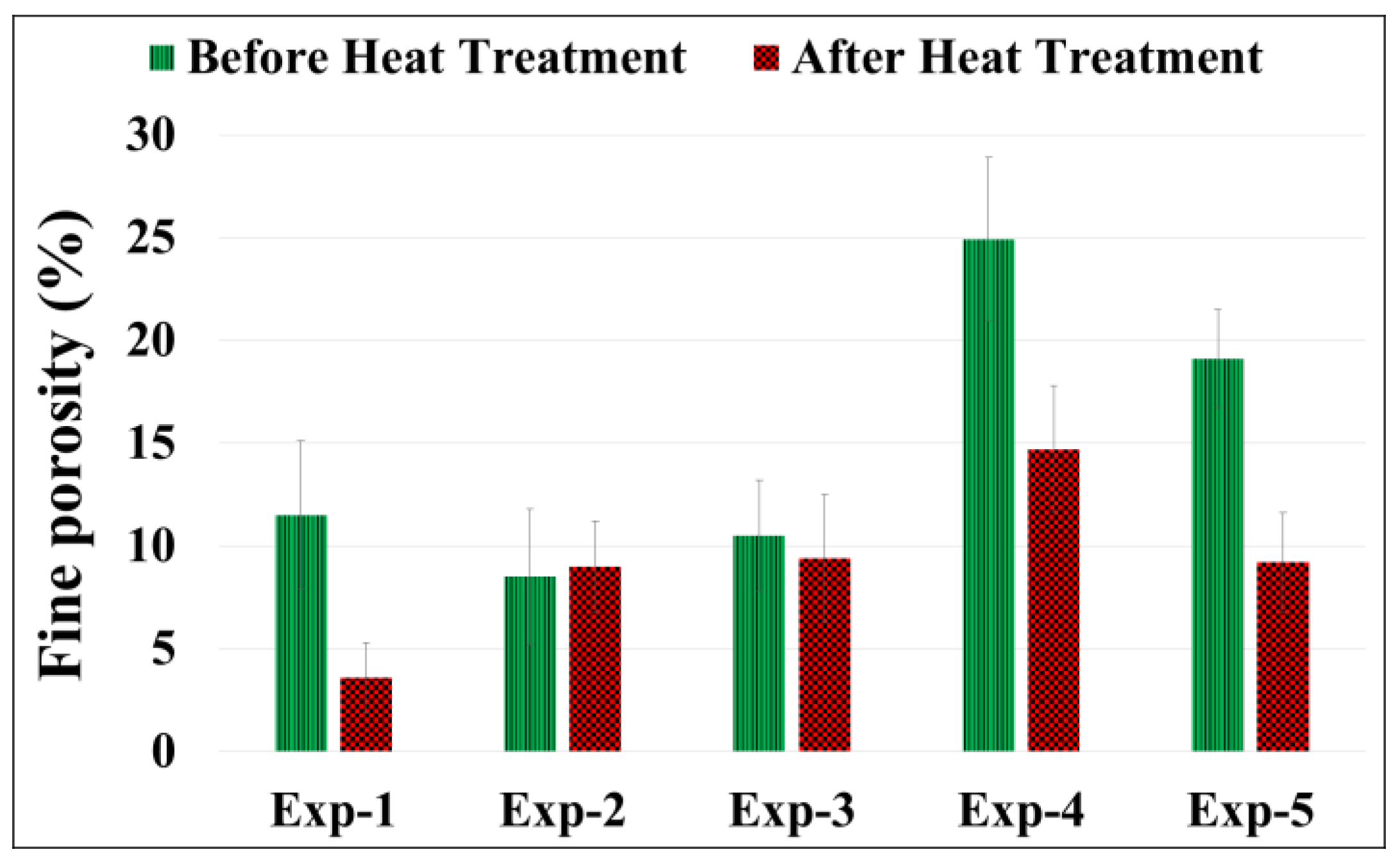

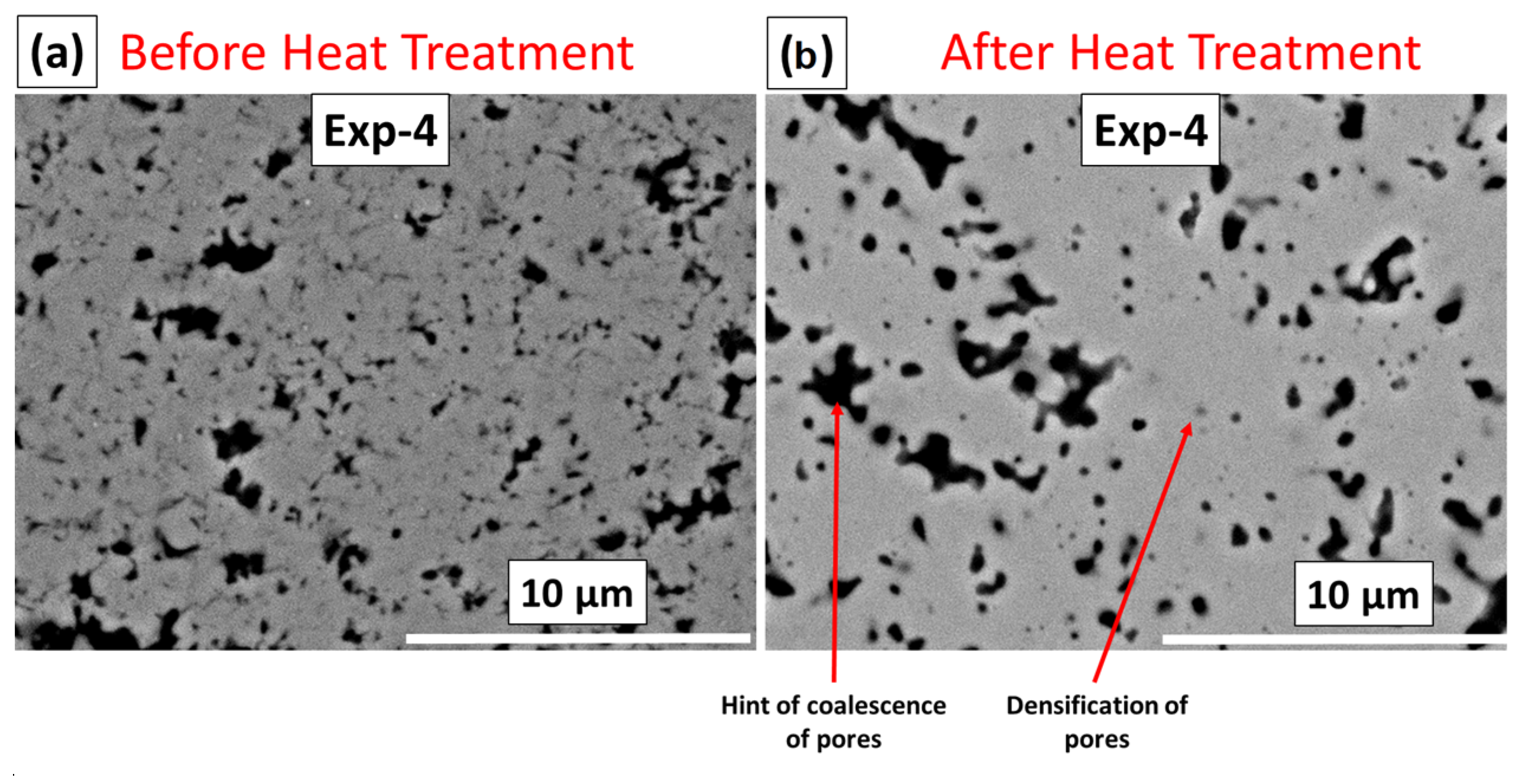

3.1. Microstructural Changes after Heat Treatment

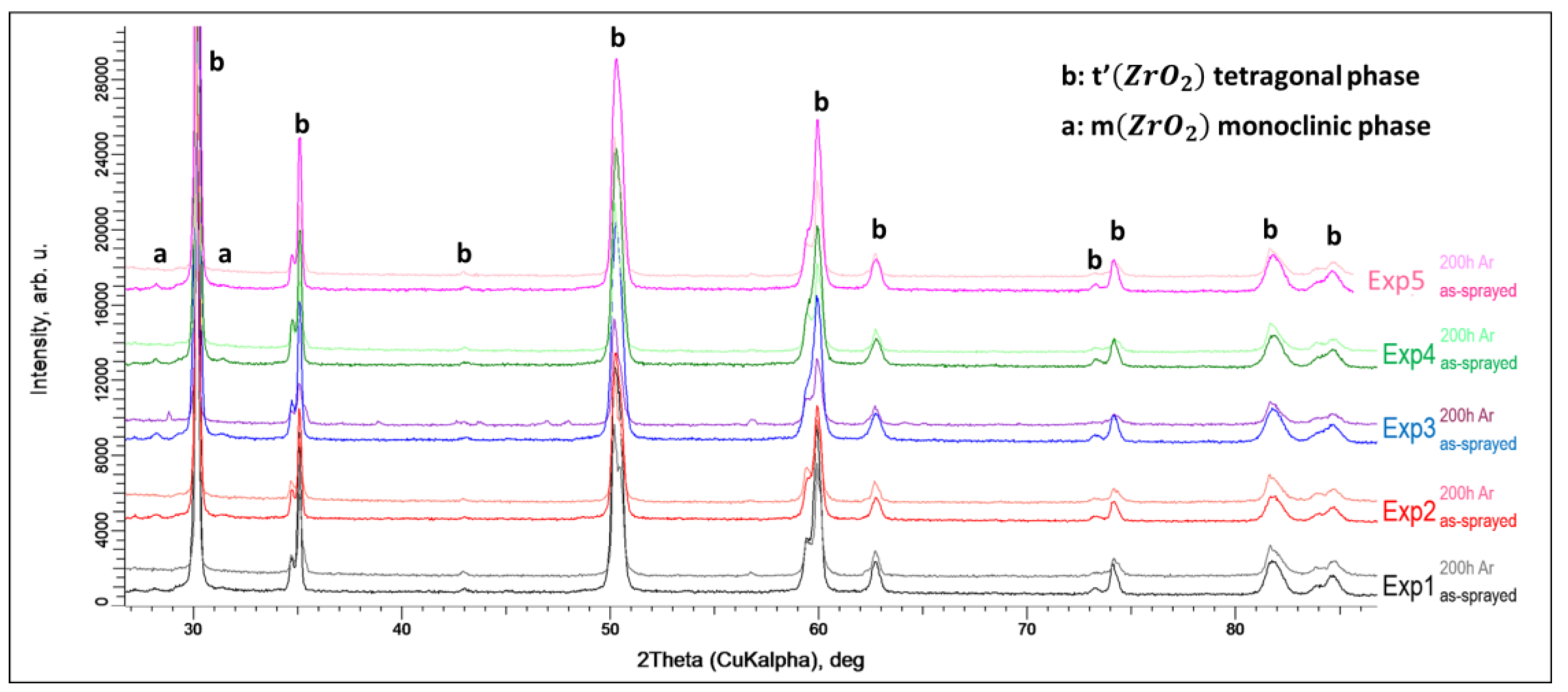

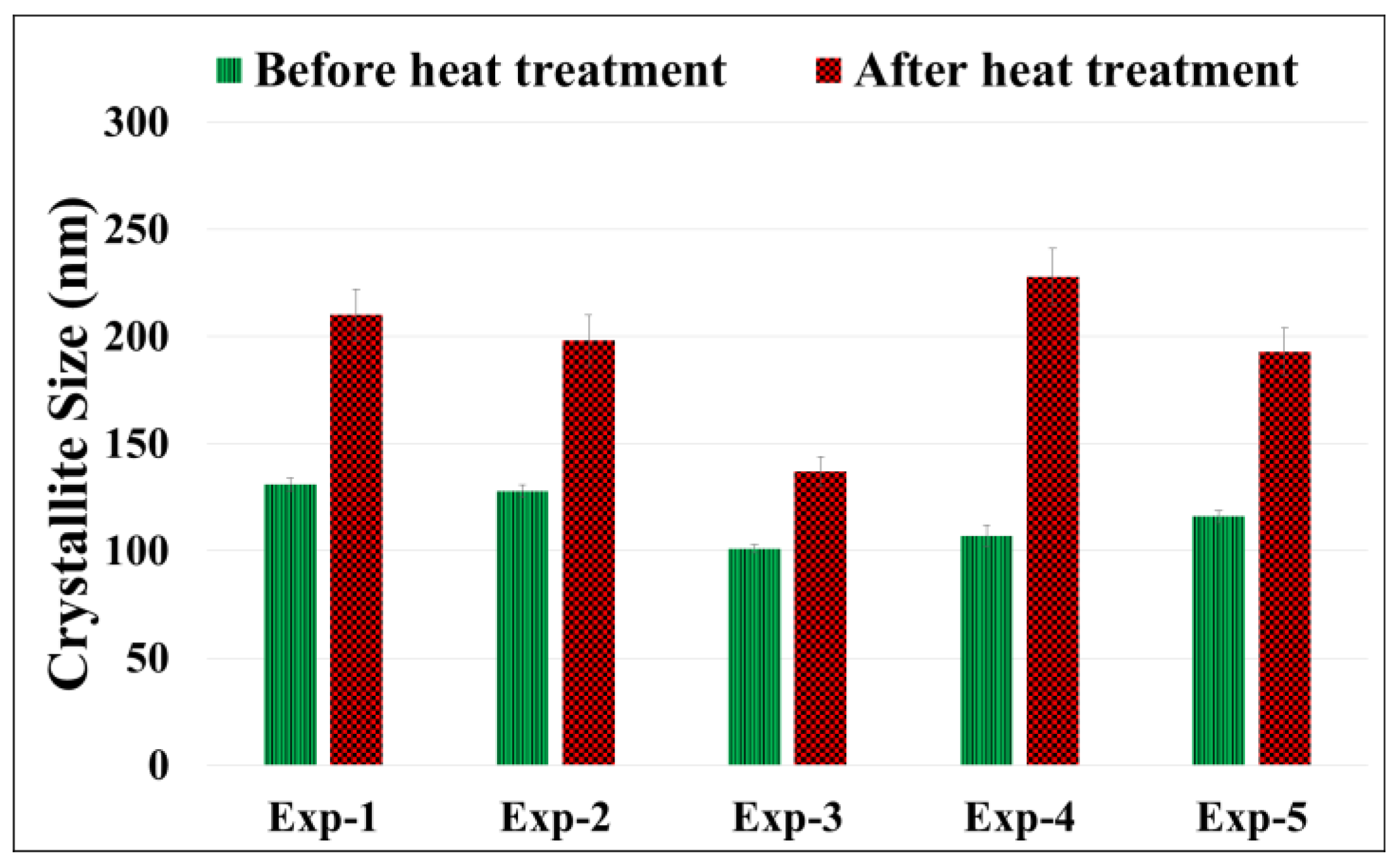

3.2. Phase Analysis and Crystallite Size Measurement Using XRD

3.3. Effect of Microstructural Changes on Thermal Conductivity

4. Summary and Conclusion

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Miller, R.A. Current status of thermal barrier coatings—An overview. Surf. Coat. Technol. 1987, 30, 1–11. [Google Scholar] [CrossRef]

- Miller, R.A. Thermal barrier coatings for aircraft engines: History and directions. J. Therm. Spray Technol. 1997, 6, 35–42. [Google Scholar] [CrossRef]

- Sirignano, W.A.; Liu, F. Performance increases for gas-turbine engines through combustion inside the turbine. J. Propuls. Power 1999, 15, 111–118. [Google Scholar] [CrossRef]

- Schulz, U.; Leyens, C.; Fritscher, K.; Peters, M.; Saruhan-Brings, B.; Lavigne, O.; Dorvaux, J.-M.; Poulain, M.; Mévrel, R.; Caliez, M. Some recent trends in research and technology of advanced thermal barrier coatings. Aerosp. Sci. Technol. 2003, 7, 73–80. [Google Scholar] [CrossRef]

- Wang, C.-L.; Hwang, W.-S.; Chu, H.-L.; Yen, F.-L.; Hwang, C.-Y.; Hsi, C.-S.; Lee, H.-E.; Wang, M.-C. Phase transformation and crystalline growth of 4 mol% yttria partially stabilized zirconia. J. Sol-Gel Sci. Technol. 2014, 70, 428–440. [Google Scholar] [CrossRef]

- Levi, C.G. Emerging materials and processes for thermal barrier systems. Curr. Opin. Solid State Mater. Sci. 2004, 8, 77–91. [Google Scholar] [CrossRef]

- Curry, N.; Markocsan, N.; A–stergren, L.; Li, X.-H.; Dorfman, M. Evaluation of the lifetime and thermal conductivity of dysprosia-stabilized thermal barrier coating systems. J. Therm. Spray Technol. 2013, 22, 864–872. [Google Scholar] [CrossRef]

- Schulz, U.; Bernardi, O.; Ebach-Stahl, A.; Vassen, R.; Sebold, D. Improvement of EB-PVD thermal barrier coatings by treatments of a vacuum plasma-sprayed bond coat. Surf. Coat. Technol. 2008, 203, 160–170. [Google Scholar] [CrossRef]

- Kakuda, T.R.; Limarga, A.M.; Bennett, T.D.; Clarke, D.R. Evolution of thermal properties of EB-PVD 7YSZ thermal barrier coatings with thermal cycling. Acta Mater. 2009, 57, 2583–2591. [Google Scholar] [CrossRef]

- Renteria, A.F.; Saruhan, B.; Schulz, U.; Raetzer-Scheibe, H.-J.; Haug, J.; Wiedenmann, A. Effect of morphology on thermal conductivity of EB-PVD PYSZ TBCs. Surf. Coat. Technol. 2006, 201, 2611–2620. [Google Scholar] [CrossRef]

- Curry, N.; Markocsan, N.; Li, X.-H.; Tricoire, A.; Dorfman, M. Next generation thermal barrier coatings for the gas turbine industry. J. Therm. Spray Technol. 2011, 20, 108–115. [Google Scholar] [CrossRef]

- VanEvery, K.; Krane, M.J.M.; Trice, R.W.; Wang, H.; Porter, W.; Besser, M.; Sordelet, D.; Ilavsky, J.; Almer, J. Column formation in suspension plasma-sprayed coatings and resultant thermal properties. J. Therm. Spray Technol. 2011, 20, 817–828. [Google Scholar] [CrossRef]

- Kassner, H.; Siegert, R.; Hathiramani, D.; Vassen, R.; Stover, D. Application of suspension plasma spraying (SPS) for manufacture of ceramic coatings. J. Therm. Spray Technol. 2008, 17, 115–123. [Google Scholar] [CrossRef]

- Killinger, A.; Gadow, R.; Mauer, G.; Guignard, A.; Vassen, R.; Stover, D. Review of new developments in suspension and solution precursor thermal spray processes. J. Therm. Spray Technol. 2011, 20, 677–695. [Google Scholar] [CrossRef]

- Guignard, A.; Mauer, G.; Vassen, R.; Stover, D. Deposition and characteristics of submicrometer-structured thermal barrier coatings by suspension plasma spraying. J. Therm. Spray Technol. 2012, 21, 416–424. [Google Scholar] [CrossRef]

- Ganvir, A.; Curry, N.; Markocsan, N.; Nylén, P.; Joshi, S.; Vilemova, M.; Pala, Z. Influence of microstructure on thermal properties of axial suspension plasma-sprayed YSZ thermal barrier coatings. J. Therm. Spray Technol. 2015, 25, 202–212. [Google Scholar] [CrossRef]

- Ganvir, A.; Curry, N.; Markocsan, N.; Nylén, P.; Toma, F.-L. Comparative study of suspension plasma sprayed and suspension high velocity oxy-fuel sprayed YSZ thermal barrier coatings. Surf. Coat. Technol. 2015, 268, 70–76. [Google Scholar] [CrossRef]

- Ganvir, A.; Curry, N.; Markocsan, N.; Nylen, P.; Vilemova, M.; Pala, Z. Influence of Microstructure on Thermal Properties of Columnar Axial Suspension Plasma Sprayed Thermal Barrier Coatings. In Proceedings of the International Thermal Spray Conference, Long Beach, CA, USA, 11–14 May 2015.

- Ganvir, A.; Curry, N.; Govindarajan, S.; Markocsan, N. Characterization of thermal barrier coatings produced by various thermal spray techniques using solid powder, suspension, and solution precursor feedstock material. Int. J. Appl. Ceram. Technol. 2015, 13, 324–332. [Google Scholar] [CrossRef]

- Ganvir, A.; Curry, N.; Björklund, S.; Markocsan, N.; Nylén, P. Characterization of microstructure and thermal properties of YSZ coatings obtained by axial suspension plasma spraying (ASPS). J. Therm. Spray Technol. 2015, 24, 1195–1204. [Google Scholar] [CrossRef]

- Bacciochini, A.; Montavon, G.; Ilavsky, J.; Denoirjean, A.; Fauchais, P. Porous architecture of SPS thick YSZ coatings structured at the nanometer scale (50 nm). J. Therm. Spray Technol. 2010, 19, 198–206. [Google Scholar] [CrossRef]

- Kassner, H.; Stuke, A.; Rodig, M.; Vassen, R.; Stover, D. Influence of Porosity on Thermal Conductivity and Sintering in Suspension Plasma Sprayed Thermal Barrier Coatings. In Advanced Ceramic Coatings and Interfaces III: Ceramic Engineering and Science Proceedings; Lin, H.-T., Zhu, D., Eds.; John Wiley & Sons: Hoboken, UK, 2009; Volume 29, pp. 147–158. [Google Scholar]

- Golosnoy, I.O.; Tsipas, S.A.; Clyne, T.W. An analytical model for simulation of heat flow in plasma-sprayed thermal barrier coatings. J. Therm. Spray Technol. 2005, 14, 205–214. [Google Scholar] [CrossRef]

- Curry, N.; Janikowski, W.; Pala, Z.; Vilémová, M.; Markocsan, N. Impact of impurity content on the sintering resistance and phase stability of dysprosia- and yttria-stabilized zirconia thermal barrier coatings. J. Therm. Spray Technol. 2013, 23, 160–169. [Google Scholar] [CrossRef]

- Curry, N.; VanEvery, K.; Snyder, T.; Markocsan, N. Thermal conductivity analysis and lifetime testing of suspension plasma-sprayed thermal barrier. Coatings 2014, 4, 630–650. [Google Scholar] [CrossRef]

- Deshpande, S. High temperature sintering and oxidation behavior in plasma sprayed TBCs (single splat studies) Paper 2—Relevance of variation in materials systems of TBC components. J. Surf. Eng. Mater. Adv. Technol. 2013, 3, 116–132. [Google Scholar] [CrossRef]

- Exner, H.E.; Müller, C. Particle rearrangement and pore space coarsening during solid-state sintering. J. Am. Ceram. Soc. 2009, 92, 1384–1390. [Google Scholar] [CrossRef]

- Siebert, B.; Funke, C.; Vassen, R.; Stover, D. Changes in porosity and Young’s Modulus due to sintering of plasma sprayed thermal barrier coatings. J. Mater. Process. Technol. 1999, 92, 217–223. [Google Scholar] [CrossRef]

- Cipitria, A.; Golosnoy, I.O.; Clyne, T.W. A sintering model for plasma-sprayed zirconia thermal barrier coatings. Part II: Coatings bonded to a rigid substrate. Acta Mater. 2009, 57, 993–1003. [Google Scholar] [CrossRef]

- Wang, K.; Peng, H.; Guo, H.; Gong, S. Effect of Sintering on Thermal conductivity and thermal barrier effects of thermal barrier coatings. Chin. J. Aeronaut. 2012, 25, 811–816. [Google Scholar] [CrossRef]

- Kumar, S.; Cocks, A.C.F. Sintering and mud cracking in EB-PVD thermal barrier coatings. J. Mech. Phys. Solids 2012, 60, 723–749. [Google Scholar] [CrossRef]

- Zhao, X.; Wang, X.; Xiao, P. Sintering and failure behaviour of EB-PVD thermal barrier coating after isothermal treatment. Surf. Coat. Technol. 2006, 200, 5946–5955. [Google Scholar] [CrossRef]

- Lughi, V.; Tolpygo, V.K.; Clarke, D.R. Microstructural aspects of the sintering of thermal barrier coatings. Mater. Sci. Eng. A 2004, 368, 212–221. [Google Scholar] [CrossRef]

- Wigren, J. High Insulation Thermal Barrier Systems–HITS, Brite Euram Project BE96–3226, 1996.

- Rietveld, H.M. Line profiles of neutron powder-diffraction peaks for structure refinement. Acta Crystallogr. 1967, 22, 151–152. [Google Scholar] [CrossRef]

- Yashima, M.; Sasaki, S.; Kakihana, M.; Yamaguchi, Y.; Arashi, H.; Yoshimura, M. Oxygen-induced structural change of the tetragonal phase around the tetragonal–cubic phase boundary in ZrO2–YO1.5 solid solutions. Acta Crystallogr. B 1994, 50, 663–672. [Google Scholar] [CrossRef]

- Curry, N.; Donoghue, J. Evolution of thermal conductivity of dysprosia stabilised thermal barrier coating systems during heat treatment. Surf. Coat. Technol. 2012, 209, 38–43. [Google Scholar] [CrossRef]

- Taylor, R. Thermal conductivity determinations of thermal barrier coatings. Mater. Sci. Eng. A 1998, 245, 160–167. [Google Scholar] [CrossRef]

- Cernuschi, F.; Lorenzoni, L.; Ahmaniemi, S.; Vuoristo, P.; Mäntylä, T. Studies of the sintering kinetics of thick thermal barrier coatings by thermal diffusivity measurements. J. Eur. Ceram. Soc. 2005, 25, 393–400. [Google Scholar] [CrossRef]

- Krishnamurthy, R.; Srolovitz, D.J. Sintering and microstructure evolution in columnar thermal barrier coatings. Acta Mater. 2009, 57, 1035–1048. [Google Scholar] [CrossRef]

- Zotov, N.; Bartsch, M.; Chernova, L.; Schmidt, D.A.; Havenith, M.; Eggeler, G. Effects of annealing on the microstructure and the mechanical properties of EB-PVD thermal barrier coatings. Surf. Coat. Technol. 2010, 205, 452–464. [Google Scholar] [CrossRef]

- Schulz, U.; Fritscher, K.; Leyens, C.; Peters, M. High-Temperature Aging of EB-PVD Thermal Barrier Coating; John Wiley & Sons, Inc.: Chichester, UK, 2001; pp. 347–356. [Google Scholar]

- Kingery, W.D.; Francois, B. The Sintering of Crystalline Oxides, I. Interactions between Grain Boundaries and Pores. In Sintering Key Papers; Sōmiya, S., Moriyoshi, Y., Eds.; Springer: Berlin, Germany, 1990; pp. 449–466. [Google Scholar]

- Carpio, P.; Blochet, Q.; Pateyron, B.; Pawlowski, L.; Salvador, M.D.; Borrell, A.; Sanchez, E. Correlation of thermal conductivity of suspension plasma sprayed yttria stabilized zirconia coatings with some microstructural effects. Mater. Lett. 2013, 107, 370–373. [Google Scholar] [CrossRef]

- Latka, L.; Goryachev, S.B.; Kozerski, S.; Pawlowski, L. Sintering of fine particles in suspension plasma sprayed coatings. Materials 2010, 3, 3845–3866. [Google Scholar] [CrossRef]

| Spraying Parameter | Five Different Coatings Studied in This Work | ||||

|---|---|---|---|---|---|

| Exp-1 | Exp-2 | Exp-3 | Exp-4 | Exp-5 | |

| Suspension feed rate (mL/min) | 70 | 45 | 45 | 100 | 45 |

| Total power during spray (kW) | 125 | 101 | 124 | 124 | 116 |

| Surface speed (cm/s) | 145.5 | 75 | 75 | 216 | 216 |

| Spray distance (mm) | 75 | 50 | 100 | 100 | 100 |

| Total gas flow rate (L/min) | 250 | 200 | 300 | 300 | 200 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ganvir, A.; Markocsan, N.; Joshi, S. Influence of Isothermal Heat Treatment on Porosity and Crystallite Size in Axial Suspension Plasma Sprayed Thermal Barrier Coatings for Gas Turbine Applications. Coatings 2017, 7, 4. https://doi.org/10.3390/coatings7010004

Ganvir A, Markocsan N, Joshi S. Influence of Isothermal Heat Treatment on Porosity and Crystallite Size in Axial Suspension Plasma Sprayed Thermal Barrier Coatings for Gas Turbine Applications. Coatings. 2017; 7(1):4. https://doi.org/10.3390/coatings7010004

Chicago/Turabian StyleGanvir, Ashish, Nicolaie Markocsan, and Shrikant Joshi. 2017. "Influence of Isothermal Heat Treatment on Porosity and Crystallite Size in Axial Suspension Plasma Sprayed Thermal Barrier Coatings for Gas Turbine Applications" Coatings 7, no. 1: 4. https://doi.org/10.3390/coatings7010004