4.1. Microstructure

When discussing the microstructures of the SPS layers produced in this study, it is important to mention that differences in microstructure relate to three possible changes in the experimental set-up:

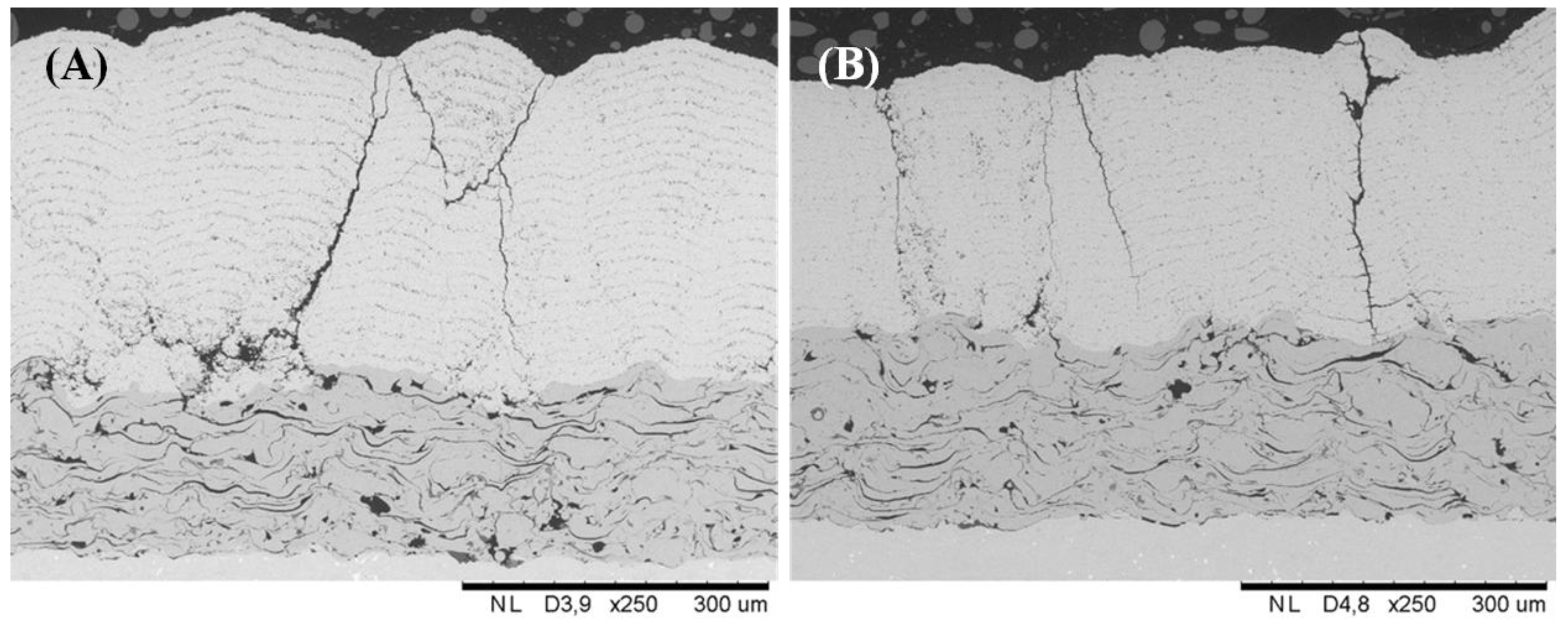

Example microstructures for Type 1 and 2 coatings are displayed for HVOF and APS bond coats in

Figure 2 and

Figure 3, respectively. In the case of the Type 1 and 2 coatings, a nano-suspension was used for spraying. Due to its higher viscosity, the nano-suspension leads to larger fragmented suspension droplets, generating larger spray particles that results in what shall be referred to as a cracked-columnar structure.

Figure 2.

HVOF bond coat with Type 1 SPS coating (H1) (A); HVOF bond coat with Type 2 SPS coating (H2) (B).

Figure 2.

HVOF bond coat with Type 1 SPS coating (H1) (A); HVOF bond coat with Type 2 SPS coating (H2) (B).

Figure 3.

Plasma bond coat with Type 1 SPS coating, (P1) (A); plasma bond coat with Type 2 SPS coating (P2) (B).

Figure 3.

Plasma bond coat with Type 1 SPS coating, (P1) (A); plasma bond coat with Type 2 SPS coating (P2) (B).

The differences in microstructure between coatings deposited on HVOF bond coats (see

Figure 2)

versus APS bond coats (see

Figure 3) are due to the surface roughness differences of the bond coats. As coating build-up is influenced by the asperities on the substrate, coatings (P1 or P2) that formed on a rough surface, such as a plasma-sprayed bond coat, will form wider and less uniform columns than those (H1 and H2) on a smoother surface, such as an HVOF bond coat. It can be observed that the Type 1 coatings (H1 and P1) have more pronounced layers within the cross-section that are separated by zones of higher porosity, which are attributed to the overspray between deposited layers. This overspray results from the deposition of particles treated in the plasma periphery that land ahead of and behind the material within the plume core as the plasma moves over the substrate. Because the particles in the plume periphery experience less heating from the plasma and more cooling from the atmosphere, they tend to deposit in a partially-molten or solid state, which reduces spreading during impact and produces higher porosity zones. Hence, the lower surface speed during deposition is primarily responsible for the presence of more distinct inter-pass porosity layers in the Type 1 coatings, as compared to the Type 2 coatings, which were produced with roughly twice the surface speed.

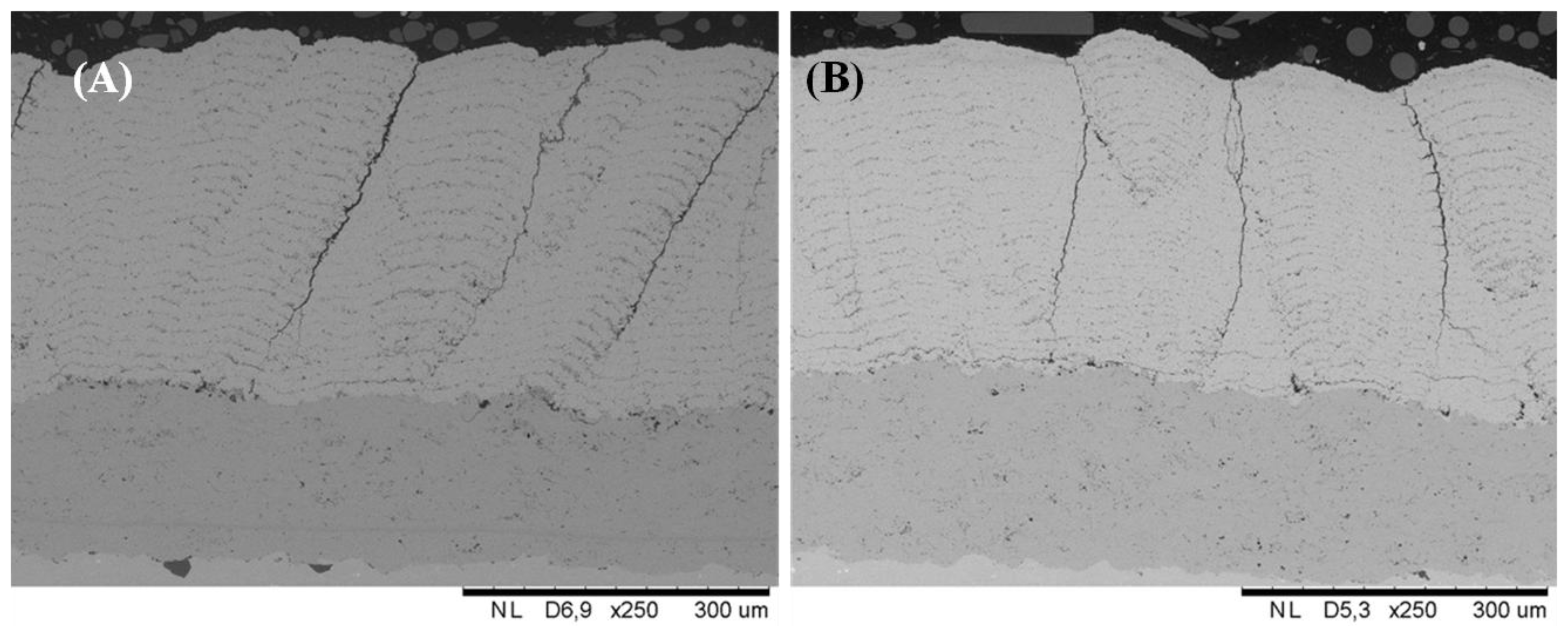

The microstructure of a Type 3 (A3) coating produced with the sub-micron suspension is shown in

Figure 4. Compared to the nano-suspension coatings, the samples were composed of significantly narrower columns with a higher degree of branching along their length. The sub-micron suspension displays a lower viscosity than the nano-suspension used for the Type 1 and 2 samples. This fact results in smaller droplets generated during suspension break-up. The resulting smaller spray particles are more susceptible to plasma flow changes close to the substrate surface, which enhances the formation of columnar structures in the coating. Furthermore, like the Type 1 and 2 coatings, the A3 coatings were influenced by the surface topography of the substrate due to the build-up of material on asperities. The HVAF bond coat used for the A3 coatings has a lower roughness than either the HVOF or APS bond coats, meaning that the surface asperities are more closely spaced, which results in more columns per unit surface area relative to the other coatings.

Figure 4.

HVAF bond coat with Type 3 SPS coating (A3).

Figure 4.

HVAF bond coat with Type 3 SPS coating (A3).

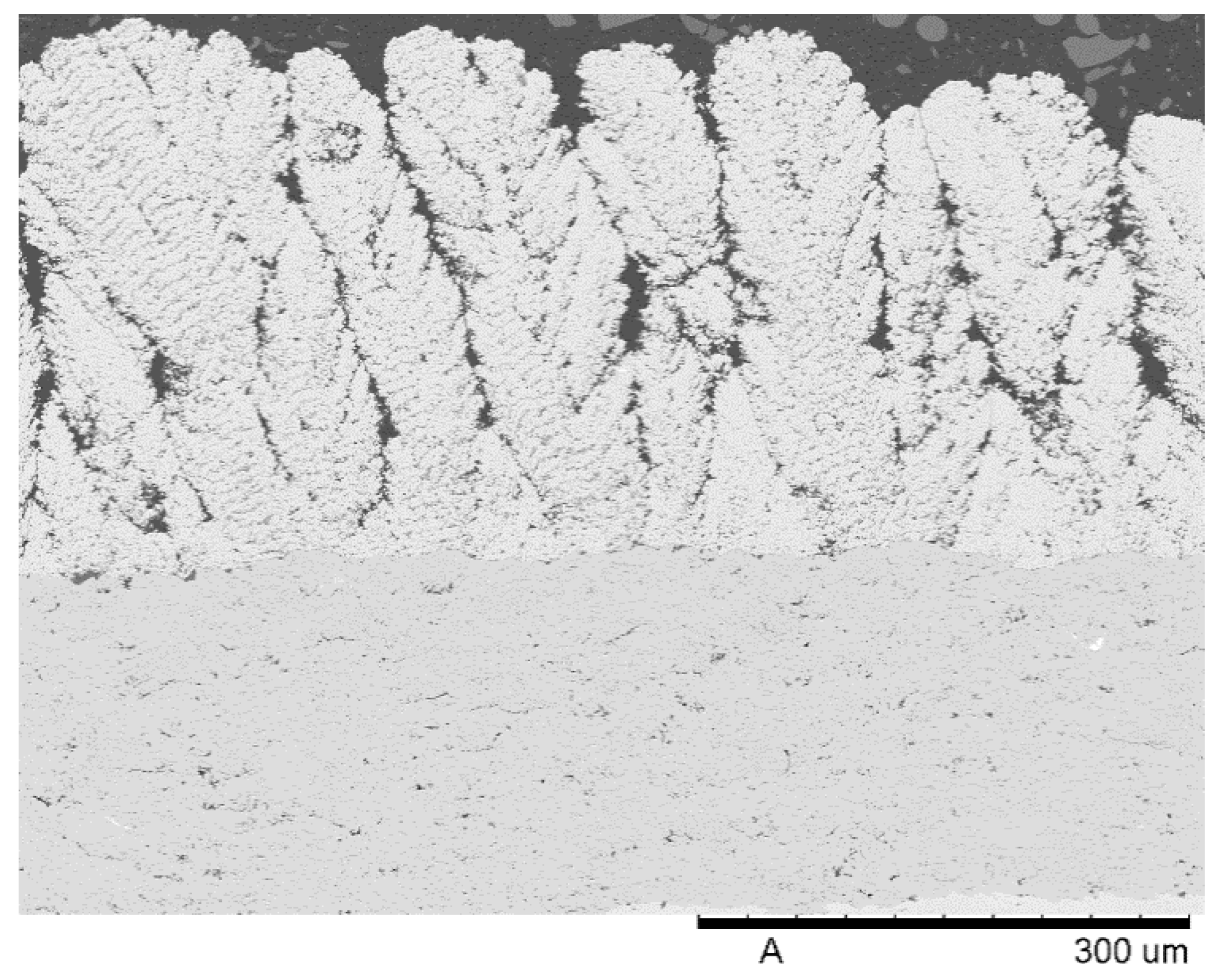

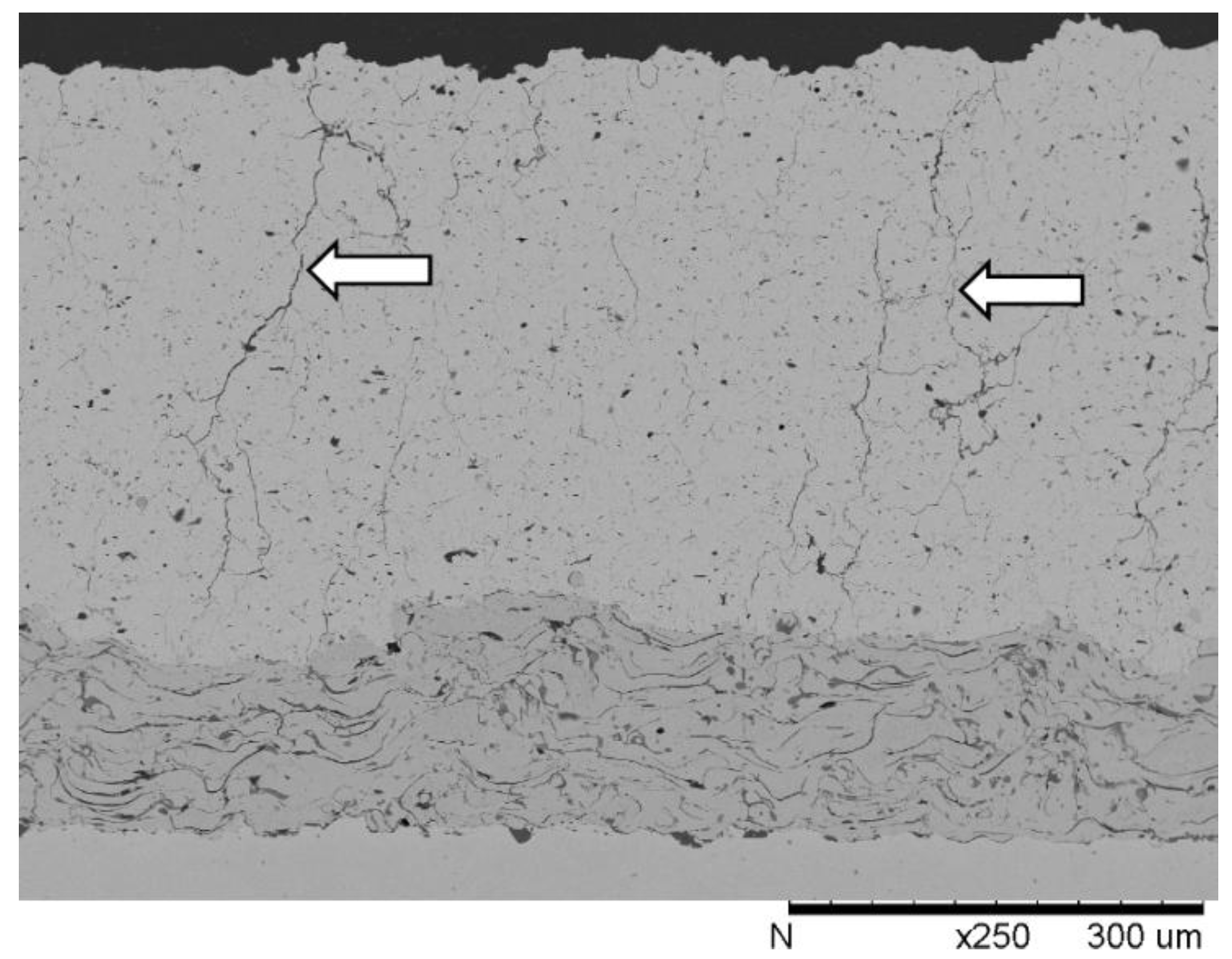

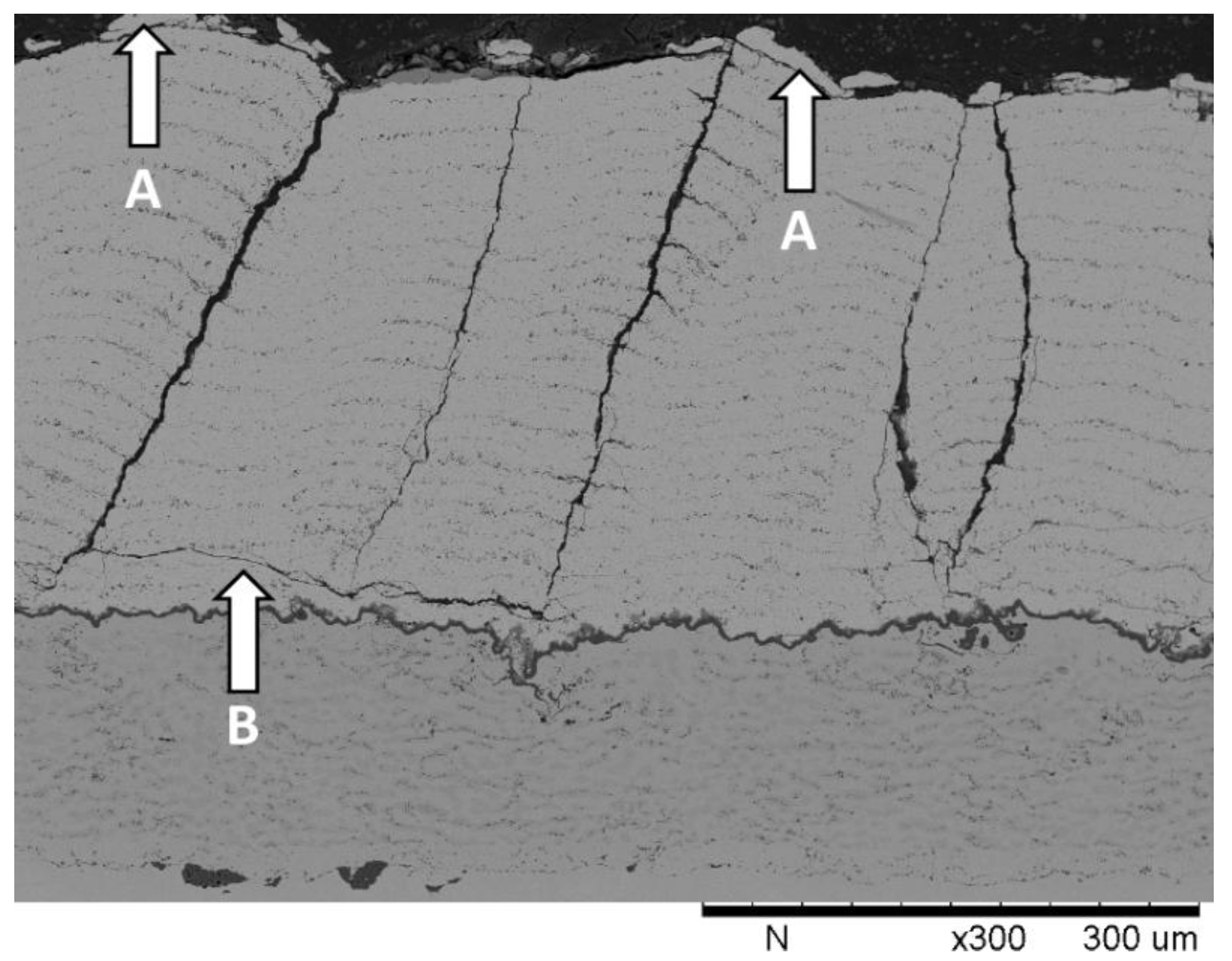

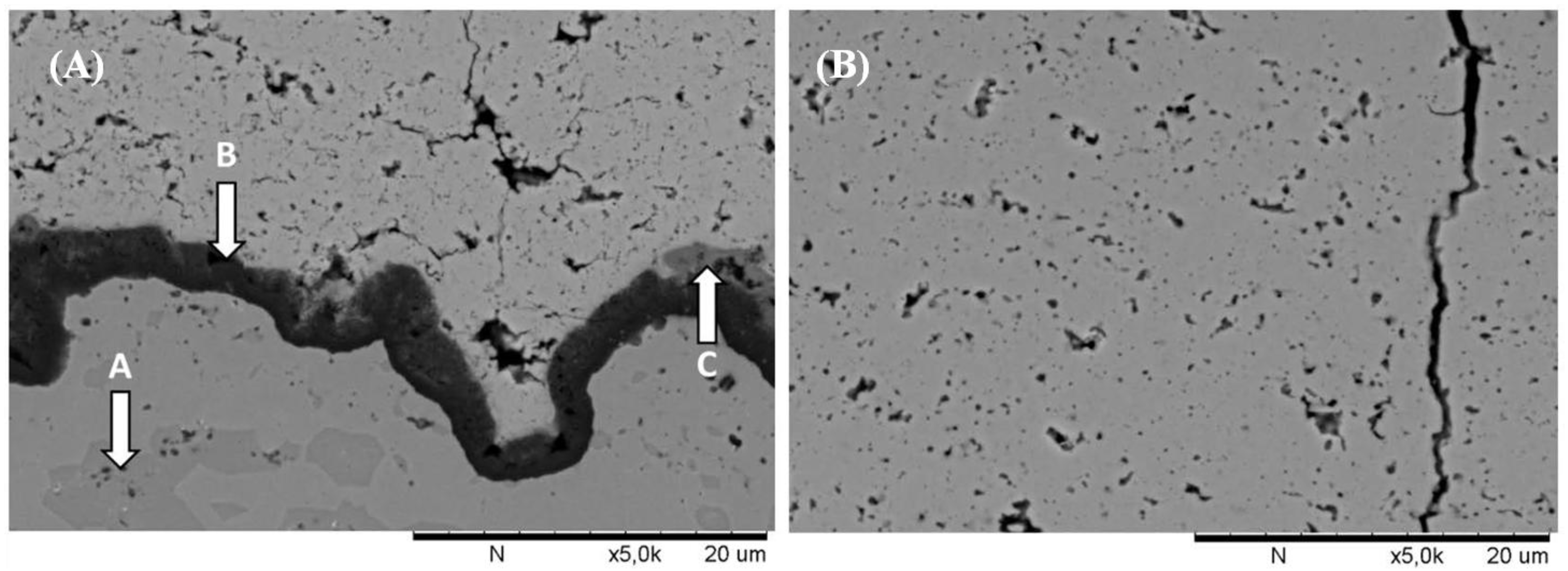

The reference APS DVC microstructure can be seen in

Figure 5. As is common within these coatings, vertical cracks (indicated by arrows) are shown along the length within the coating cross-section. Additionally, the area between the cracks is characterized by isolated pores and regions of dense microstructure.

Figure 5.

Dense vertically cracked APS coating with vertical cracks arrowed.

Figure 5.

Dense vertically cracked APS coating with vertical cracks arrowed.

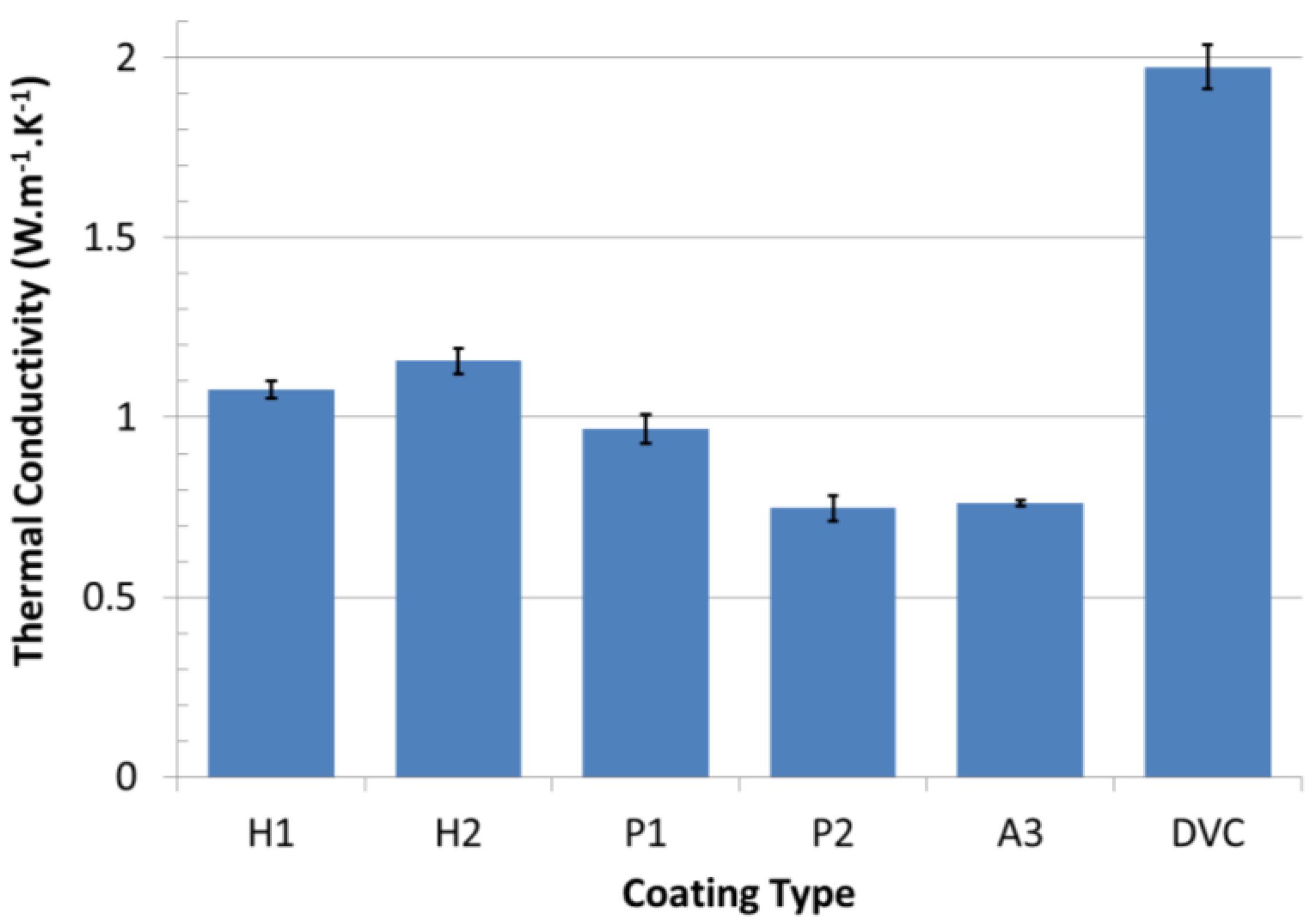

4.2. Thermal Conductivity

Thermal conductivity results are shown in

Figure 6. Trends in the coating thermal conductivity can be related to the microstructures shown in

Figure 2,

Figure 3,

Figure 4 and

Figure 5. In comparison with the more porous SPS coatings, the APS DVC coating displays a higher thermal conductivity in the as-sprayed state. While a porous APS coating may have an as-produced thermal conductivity in the region 0.5–1.0 (W·m

−1·K

−1) depending on the microstructure [

5], the thermal conductivity of a DVC coating is 2–4-times higher due to its more dense structure. This conductivity increase displays the trade-off required in conventional APS spraying in order to produce a strain-tolerant coating.

Figure 6.

Thermal conductivity of the coating systems.

Figure 6.

Thermal conductivity of the coating systems.

The difference in thermal properties amongst the SPS samples with different bond coats can also be connected to expected and observable microstructural differences. The coatings on plasma-sprayed bond coat (P1 and P2) show lower thermal conductivity than their HVOF counterparts (H1 and H2). This difference is consistent with the more irregular structure of the SPS YSZ on the rougher plasma-sprayed bond coat surface, increasing the coating porosity. However, because the nano-suspension was used for both the H and P coatings, the depositing particle sizes were comparable, which resulted in a similar porosity orientation between these sample sets (

Figure 2 and

Figure 3). The thermal conductivity of the P2 samples was lower than that of the P1 samples. The P2 samples were comprised of more layers than the P1 samples, due to the 1.6-times faster surface speed relative to that used for the P1 samples. Therefore, the P2 samples contained more overspray porosity zones, which were oriented roughly perpendicular to the heat flow during the laser flash testing, which would act as barriers to heat transport. The same trend is not observed in the H1 and H2 samples, though there is no statistically significant difference in thermal conductivity between the two coating types. The lack of expected variation may again be related to the bond coat influence on the microstructure. The smoother HVOF interface produces less variability in coating porosity due to the different surface speeds used for spraying.

The sub-micron suspension used for the A3 samples produced a porosity distribution that differed from that of the Type 1 and 2 samples. The A3 samples exhibited wider inter-columnar gaps and a higher number of these gaps per cross-sectional area. This porosity, which is orientated parallel to the primary direction of heat flow, does not lower the thermal conductivity as significantly as that which is oriented perpendicular to the heat flow. Consequently, although the A3 coatings contained a significantly higher amount of porosity, these samples display the same level of thermal conductivity as the P2 coatings.

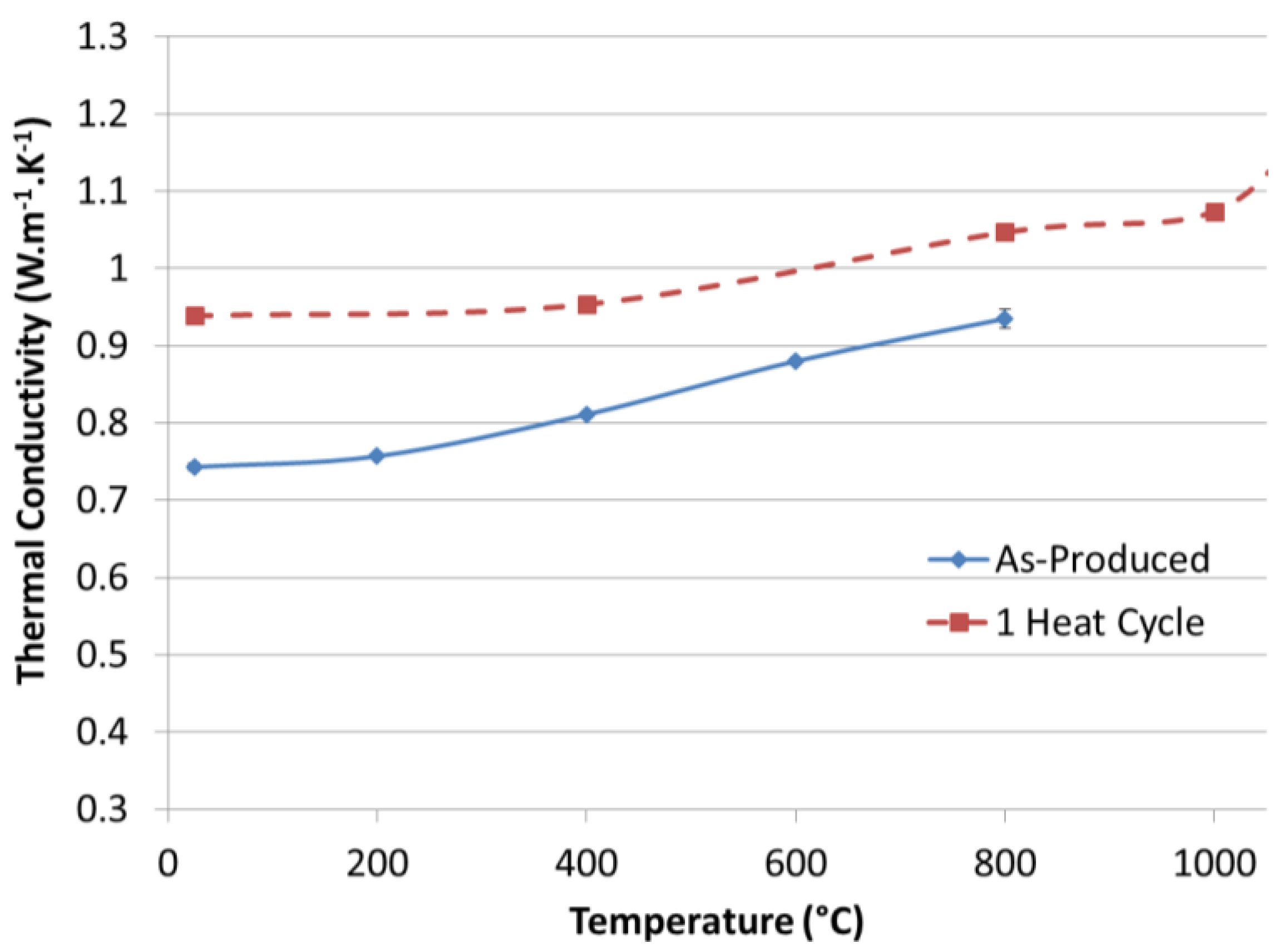

Thermal conductivity

versus temperature data is displayed in

Figure 7 for the A3 sample. The full line represents the as-sprayed thermal properties; whereas the dashed line represents the thermal properties after several hours at high temperature. It can be noted that, as with an APS coating, there is some increase in thermal conductivity after high temperature exposure, due to sintering of the microstructure after several hours at high temperature [

9]. The degree of microstructural change is expected to be consistent with Stage 1 sintering, as defined by Cernuschi

et al. [

7], which occurs during the first hours of exposure at high temperatures. During this time, crack healing and bridging of the microstructure occurs, resulting in improved thermal conduction through the coating.

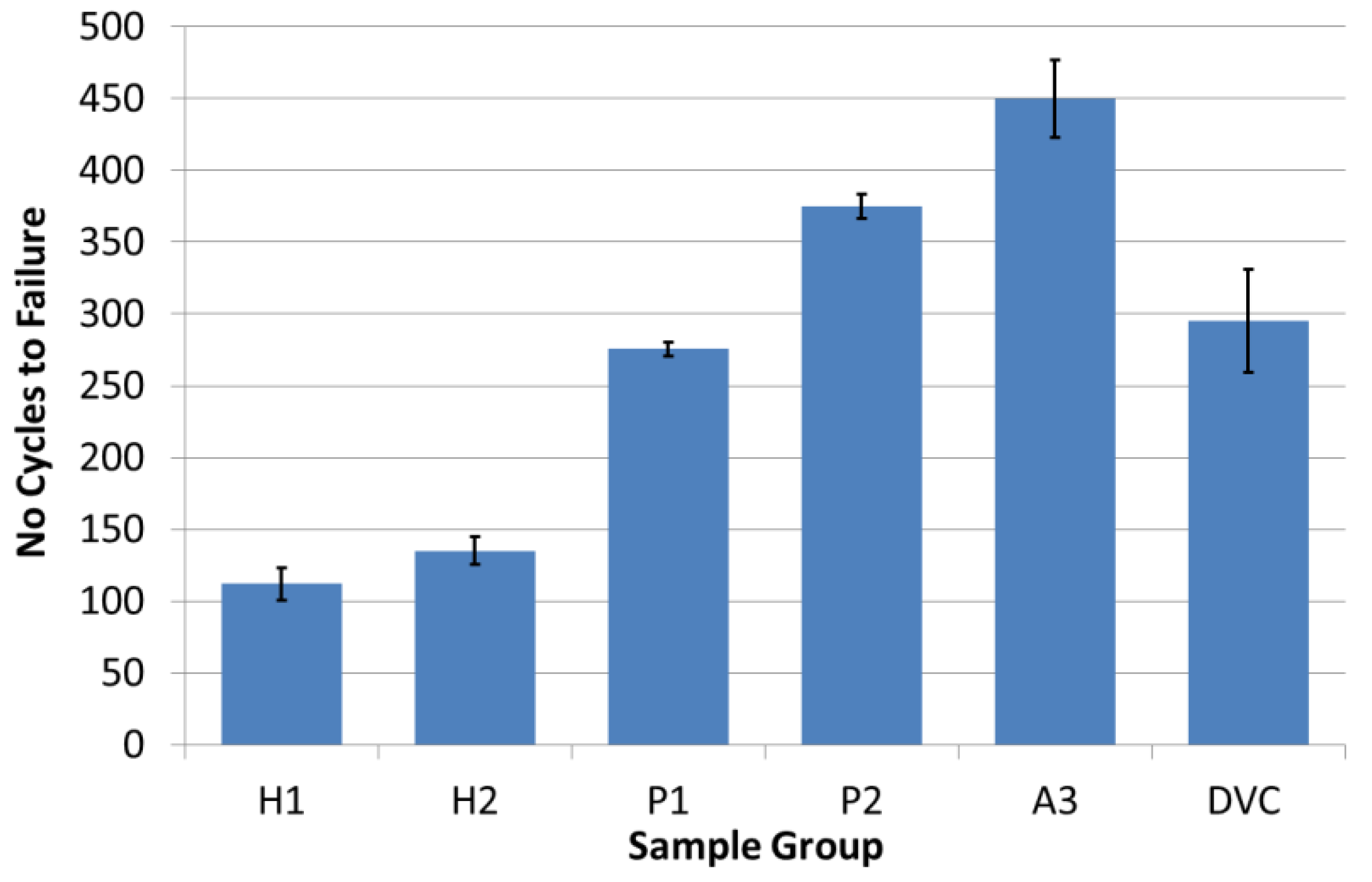

4.3. Thermo-Cyclic Fatigue Lifetime and Failure Microstructures

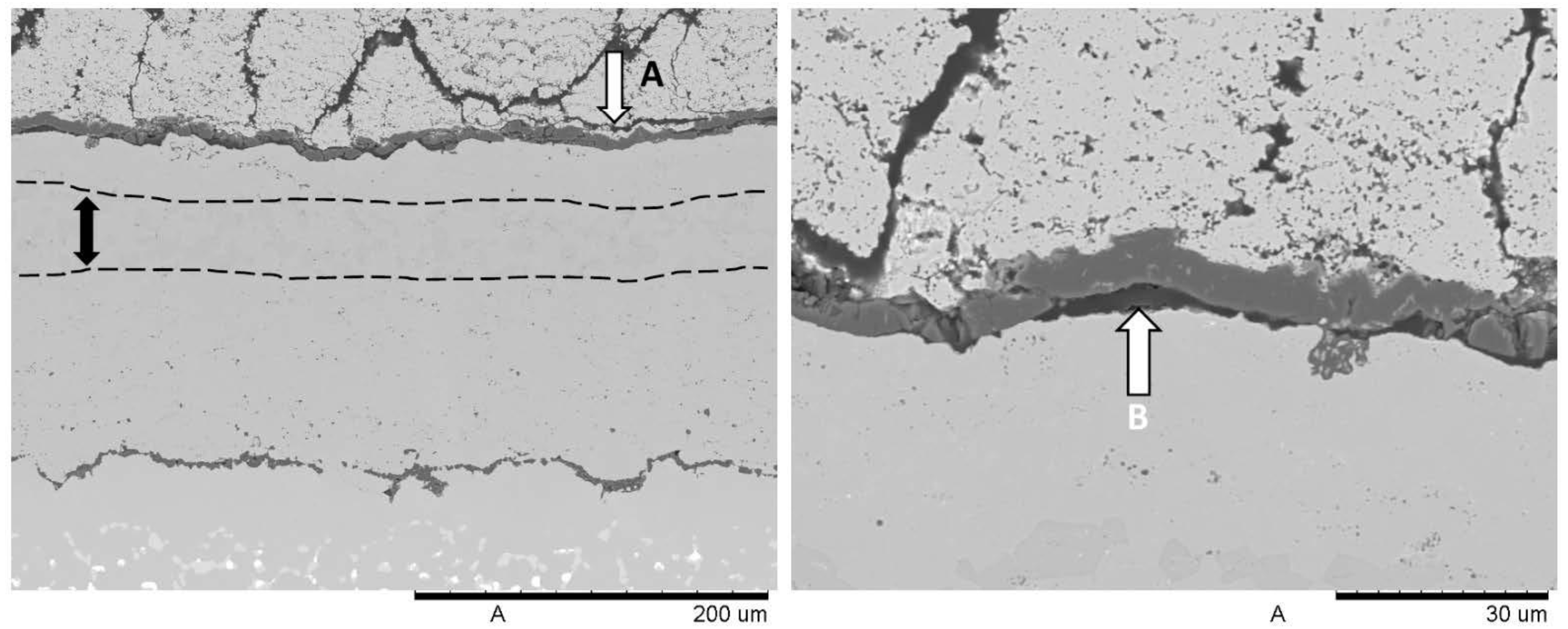

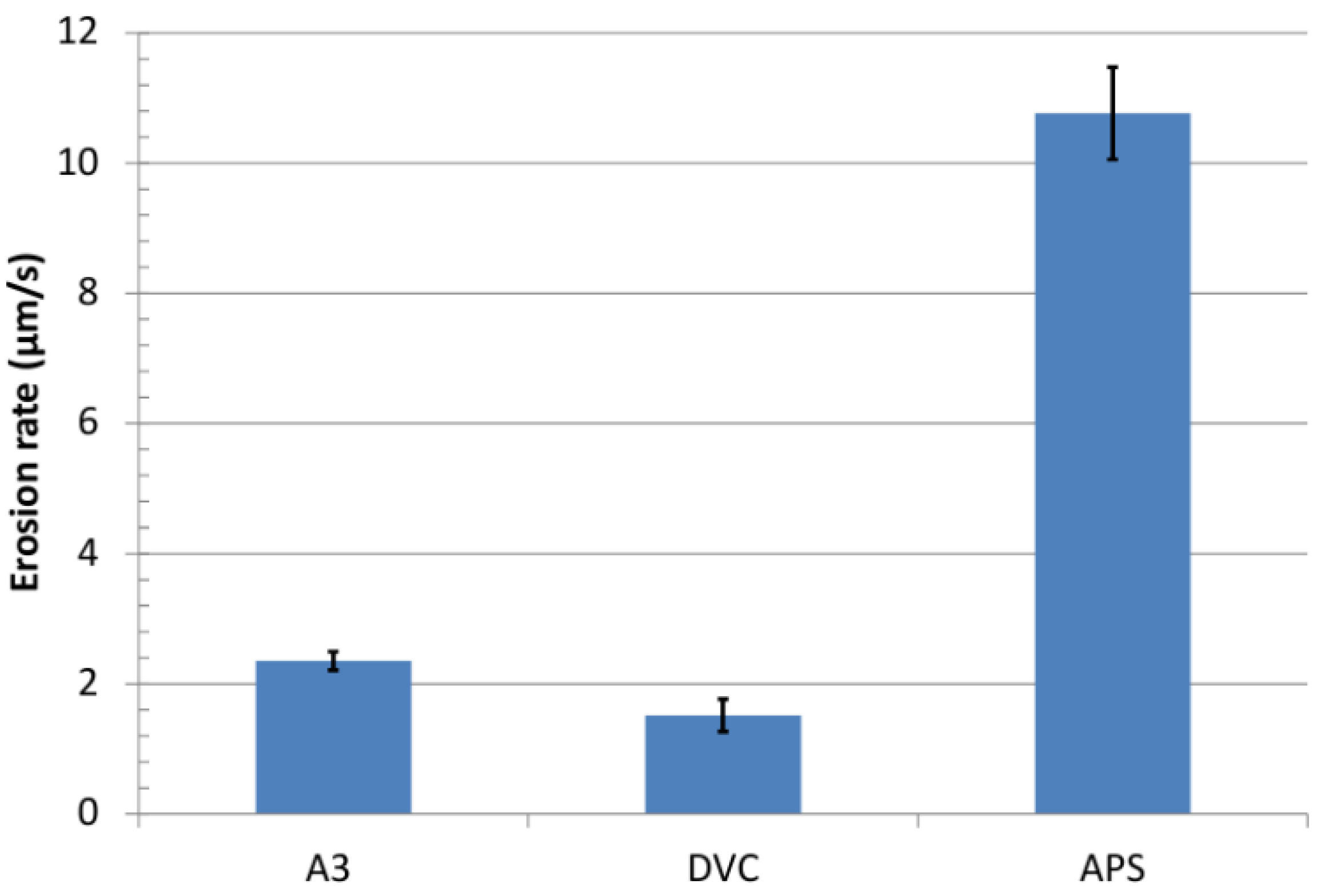

The results of TCF sample testing are shown in

Figure 8. The standard deviation of each sample set is shown by the error bars. It can be seen that large differences in thermal fatigue life were achieved with different bond coat systems. Samples with HVOF bond coats (H1 and H2) exhibited less than half the lifetime of samples with the same top coat type on air plasma-sprayed bond coats (P1 and P2). Similar results for APS

versus HVOF bond coats have been reported previously with conventional APS top coats [

6].

Figure 7.

Thermal conductivity versus temperature for coating A3 in the as-produced state and after one heat cycle.

Figure 7.

Thermal conductivity versus temperature for coating A3 in the as-produced state and after one heat cycle.

Figure 8.

Thermo-cyclic fatigue lifetime of experimental coatings.

Figure 8.

Thermo-cyclic fatigue lifetime of experimental coatings.

For all of the coating combinations tested, failure resulted from transverse crack propagation that could be connected to stress produced by a thermally-grown oxide (TGO) layer at the bond coat-top coat interface [

28,

29]. This layer is an unavoidable by-product during the high temperature exposure of YSZ-MCrAlY TBCs in atmospheric conditions and results from oxygen diffusing to and reacting with the bond coat material. Thus, the lifetime of a YSZ-MCrAlY system in TCF testing was determined by a combination of the oxygen diffusion rate to the bond coat, the reaction rate at the bond coat, the top coat strain tolerance and the ease of crack propagation along the top coat-TGO interface.

Initially, the rate of oxygen reaching the bond coat is determined by gas infiltration into the cracks and pores of and lattice diffusion through the YSZ top coat. As the TGO develops, oxygen must then diffuse through this layer to react with the bond coat; thus, the TGO composition can affect bond coat oxidation. For example, a reaction between the diffusing oxygen and the aluminum of the bond coat can form an alumina layer that produces a slower growing oxide layer than reactions yielding mixed oxides consisting of nickel, chromia spinels, which are considered highly detrimental to coating lifetime [

28]. Hence, the bond coat chemistry also influences TGO development by determining which oxides form. For instance, a β Ni-Al phase in the bond coat acts as an aluminum reservoir that promotes the formation of a passivating alumina layer, so that the beta phase content can be tracked and used to determine the degree of bond coat oxidation and the remaining chemical life of the bond coat [

28]. A slower growing, passivating oxide is preferred, because the formation of any TGO introduces stress into the TBC system. The greater the capacity of the top coat to accommodate this stress, the better the TCF performance of the TBC tends to be [

6]. Once the TGO-induced stress exceeds a critical level, cracks will be initiated and propagate along the lowest energy pathway. The planarity of the interface may influence the rate of propagation; less planar interfaces generate higher total stresses, but make crack propagation more difficult.

Considering the above factors, the lifetime disparity between H and P samples was likely to have resulted mainly from bond coat topography differences. As mentioned previously, the P samples contained more porosity than the H samples, but, given the similarities in the coating cross-sections, the higher porosity in the P samples would not be expected to improve the strain tolerance enough to account for the majority of the ~2.5 increase in the average TCF lifetime when comparing the H samples to the P samples. Therefore, while porosity may have contributed to the TCF lifetime differences between the H and P samples, the dominant factor was most probably that the TGO-induced cracking required more energy to propagate along the interface structure produced by the plasma-sprayed bond coat (P samples), because it was significantly rougher than the interface structure producing the HVOF bond coat (H samples).

The plasma-sprayed bond coat data also show a larger difference in lifetime between the Type 1 and Type 2 SPS top coats. This can be explained firstly by the greater difference in microstructure generated by changing surface speed when depositing coatings on an APS bond coat. Additionally, the P2 coatings have exhibited lower thermal properties than P1 coatings; this could insulate the P2 samples further during thermal transient stages in the TCF cycle. The lack of a significant lifetime difference between the H1 and H2 samples is again related to the influence of the bond coat on the coating microstructure. As the HVOF bond coat induces little variability in microstructure between Type 1 and 2 coatings, there is similarly little difference in their TCF lifetimes.

The TCF lifetime of A3 samples with a HVAF bond coat are also shown on the right of the graph in

Figure 8. The A3 samples featured a different powder composition (AMDRY 386) for the HVAF bond coat than that used for the HVOF and plasma spray bond coats (AMDRY 365). The suspension used for the A3 top coat utilized a different particle size distribution than that sprayed to produce the H and P samples. Both of these changes likely helped to improve the TCF lifetime. As stated above, the AMDRY 386 bond coat chemistry may reduce the oxidation rate and formation of spinel oxides relative to the AMDRY 365 bond coats. Additionally, the sub-micron suspension used for the A3 top coat produced a more porous columnar and, thus, strain-tolerant microstructure than that resulting from the nano-suspension used to generate the H and P samples.

The TCF results for the reference DVC APS samples are shown on the far right of the graph in

Figure 8. The DVC samples used the same AMDRY 386 bond coat composition as was used for the A3 samples, but the bond coat was applied via plasma spray instead of HVAF. The TCF lifetime of the DVC samples was on par with that of the P1 samples and gives a useful benchmark for the TCF performance of current industry standard strain-tolerant plasma spray coatings.

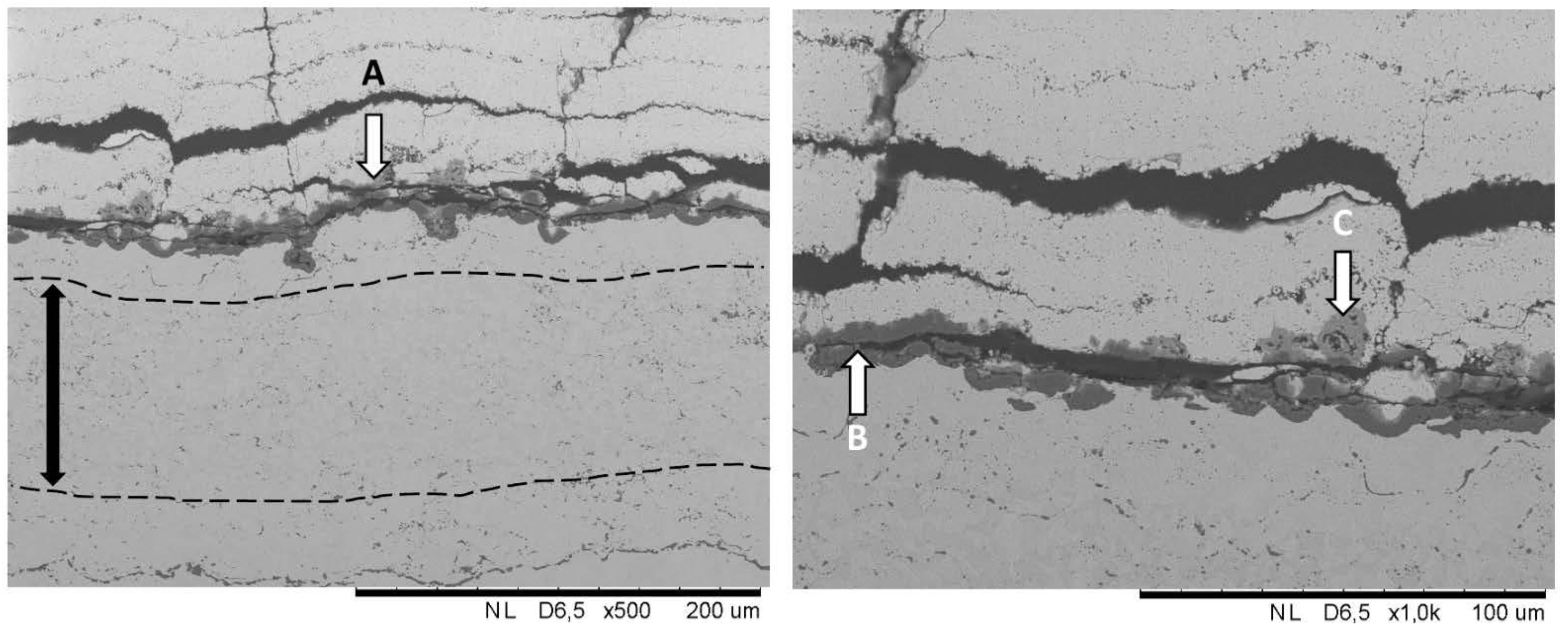

The cross-section of a failed H1 sample is shown in

Figure 9. This figure shows that failure was connected to cracks (labeled A) propagating along the interface between the thermally-grown oxide (TGO) layer and the bases of the columnar structures forming the top coat. In addition to this cracking, propagation also occurred through the inter-pass porosity at some locations. Due to the higher porosity of the inter-pass layers, they represent a low energy pathway for crack propagation.

The TGO layer consists of a dark alumina oxide layer (labeled B) at the bond coat interface that acts to prevent further oxidation. There is, however, a large amount of lighter colored mixed oxide regions above the alumina layer (labeled C). The mixed oxide consists of nickel, chromia spinels, and due to its faster growth, it is considered highly detrimental to coating lifetime [

28]. Investigation of the HVOF bond coat after 100–140 cycles reveals that a substantial amount of the beta phase (β Ni-Al) remained within the bond coat. This phase can be seen in

Figure 9 as the darker regions within the bond coat layer indicated by the dashed lines and double arrow.

Figure 9.

Microstructure of an H1 sample after approximately 120 thermo-cyclic fatigue cycles. A: Interface cracking; B: alumina thermally-grown oxide; C: mixed oxide.

Figure 9.

Microstructure of an H1 sample after approximately 120 thermo-cyclic fatigue cycles. A: Interface cracking; B: alumina thermally-grown oxide; C: mixed oxide.

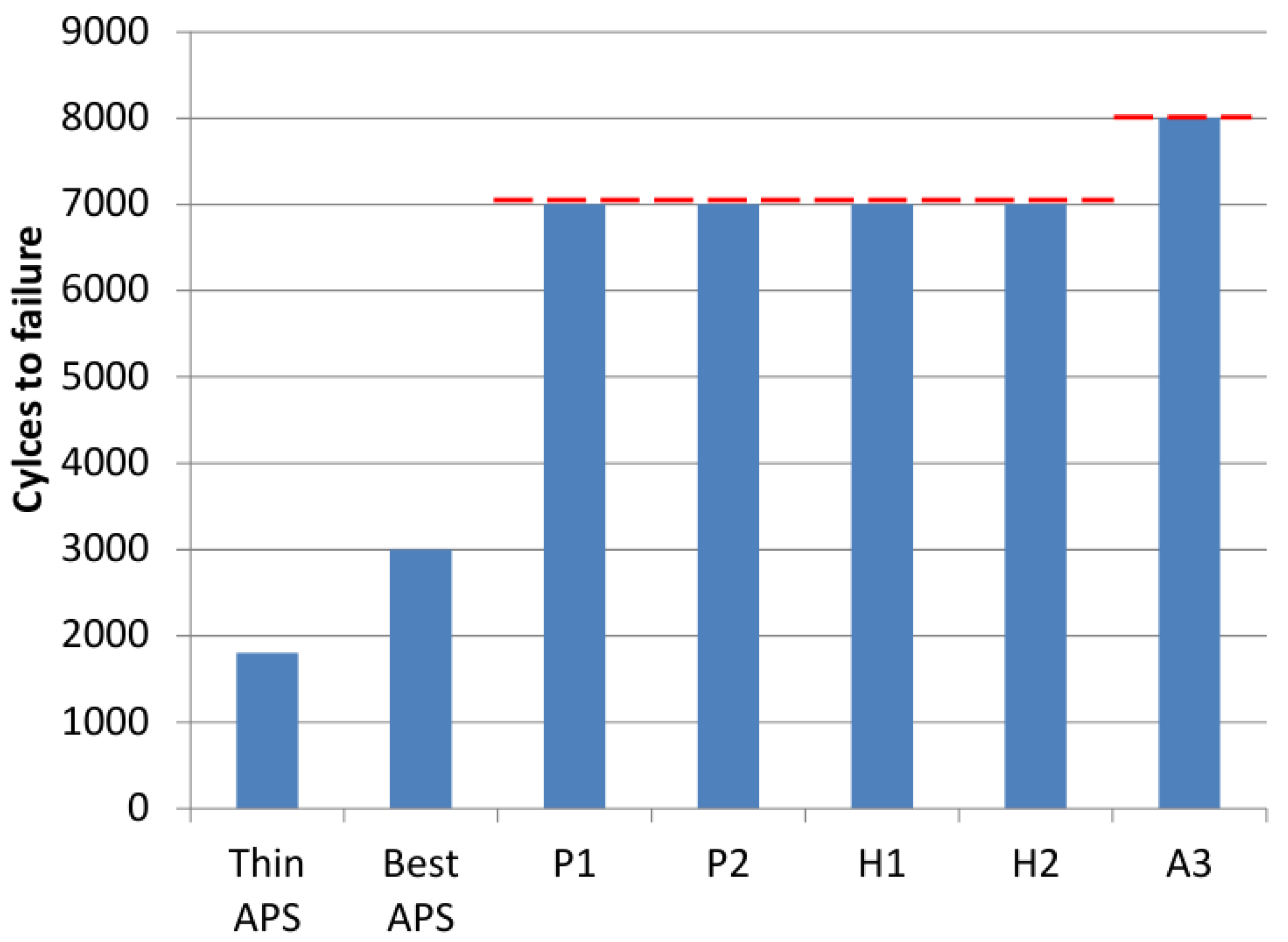

A cross-sectioned HVAF bond coat sample after failure is displayed in

Figure 10. Like the HVOF bond coat samples, failure resulted from cracking at the TGO-top coat interface; though cracks propagating through inter-pass porosity were not observed, cracking within the ceramic layer above the TGO is indicated by the white arrow (labeled A). The remaining beta phase region is denoted by a double-headed arrow, with an approximate width of the region being 45 µm. As expected, there is less beta phase remaining compared to the HVOF bond coat sample; this decreased beta content is due to the four-times longer exposure time at high temperatures. Unlike the TGO layer in the HVOF coating, the HVAF TGO layer is denser in structure and contains very little of the mixed oxides found within the HVOF or plasma bond coats. In some locations, rumpling of the oxide layer has been observed (labeled B); this may contribute to crack initiation and failure [

28]. The improved oxidation performance in TCF testing explains the longer cyclic lifetime. The reason for the improved performance may be related to the HVAF deposition itself or the different chemistry of the starting powder.

Figure 10.

Failure microstructure of an A3 coating system after approximately 450 thermo-cyclic fatigue cycles. A: Interface cracking; B: Oxide rumpling.

Figure 10.

Failure microstructure of an A3 coating system after approximately 450 thermo-cyclic fatigue cycles. A: Interface cracking; B: Oxide rumpling.

4.4. Thermal Shock Testing

The results for the thermal shock testing of the coatings are shown in

Figure 11. It should be noted that in the case of all SPS coatings, the thermal shock test was discontinued with no observed failures, due to limitations on testing time. Previous testing experience with this thermal shock rig over several decades has shown an “average” lifetime for thin (~300 µm) TBC to be 1800 cycles. The maximum lifetime achieved has been 3000 cycles, though without the ability to replicate the result. As

Figure 11 shows, the SPS coatings of this study have significantly greater thermal shock life than exhibited by APS systems tested on this rig. Long thermal shock lifetimes are corroborated by Guignard

et al. [

15] for vertically cracked SPS coatings at similar temperature levels. The results indicate that the structures produced by SPS praying are highly strain tolerant. Further testing against EB-PVD coatings would be required to show their ultimate performance.

Figure 11.

Thermal shock testing data. The red dashed line indicates the number of cycles at which the test was halted.

Figure 11.

Thermal shock testing data. The red dashed line indicates the number of cycles at which the test was halted.

After testing was discontinued, exposed samples were sectioned and prepared for microstructural investigation. A cross-section of an H1 sample is displayed in

Figure 12. The H1 microstructure can be considered representative of the H2 sample after the same amount of cyclic exposure. Deposits labeled A in the micrograph are not part of the coating and are in fact transferred iron-chrome oxides from the test rig fixture. The bond coat can be observed to contain two phases: the darker beta-phase and the lighter gamma phase. There is also a thin TGO layer at the bond coat-top coat interface that contains both an alumina layer (dark) and regions of mixed oxides (light). There is some evidence of cracking (labeled B) close to the TGO layer and at the edges of the columns/segments, though this cracking had yet to be significant enough after the 7000 cycles to produce any spallation. Furthermore, it cannot be discounted that cracking may have been induced during microstructural preparation. The minimal depletion of the beta-phase and relatively thin TGO suggest that many more hours of exposure at high temperatures would be possible before failure would occur.

Figure 12.

H1 coating microstructure after 7000 thermal shock cycles. Deposits from A: the combustor burner; B: interface cracking.

Figure 12.

H1 coating microstructure after 7000 thermal shock cycles. Deposits from A: the combustor burner; B: interface cracking.

Figure 13 displays the microstructure of a P2 sample after approximately 7000 cycles. The sample is also representative of the P1 samples after the same number of test cycles. The growth of a thin TGO layer at the interface between bond coat and top coat can be observed. Additionally there has been growth of TGO along the inter-splat boundaries or delaminations internally within the bond coat. This P2 sample likewise shows evidence of some cracking (arrowed) in the inter-pass porosity layers at the edges of the columns/segments, which again may have occurred during metallographic preparation.

Figure 14 shows a comparison of the SPS coating close to the bond coat interface (left) and close to the top surface (right) for A3 coating after 8000 cycles. Beta phase zones are present within the HVAF bond coat close to the interface, (labeled A). The thin alumina layer can be seen at the interface between bond coat and top coat (labeled B). Unlike in in A3 TCF testing samples, the presence of mixed oxides (labeled C) was found above the alumina layer. These mixed oxides likely grow during early cycling of the coating before the alumina layer has a chance to completely form. Comparing the left and right images of

Figure 14 shows that a difference in morphology exists between SPS coating porosity near the bond coat and that near the top surface. Pores close to the bond coat interface are irregularly shaped, while those close to the interface show a more rounded shape. This difference results from the temperatures close to the top surface being high enough to enable sintering. However, sintering in SPS coatings results in only minor changes in pore structure, primarily spheroidization of the pores and healing of boundaries and cracks. As the microstructure changes are not uniform throughout the coating, it can be expected that the impact of this sintering will be lower than that suggested in the thermal conductivity data of

Figure 7, which corresponds to an isothermally exposed sample. The lower thermal conductivity increase for samples subjected to thermal gradient conditions indicates that the degradation in performance for real applications within a gas turbine will not be as severe as isothermal testing would suggest.

Figure 13.

P2 coating after 7000 thermal shock cycles. Interface cracking arrowed.

Figure 13.

P2 coating after 7000 thermal shock cycles. Interface cracking arrowed.

Figure 14.

A3 coating microstructure after 8000 thermal shock cycles. (A) The bond coat interface is shown with: A: beta phase; B: alumina oxide TGO; C: mixed oxide; (B) The microstructure close to the surface is shown.

Figure 14.

A3 coating microstructure after 8000 thermal shock cycles. (A) The bond coat interface is shown with: A: beta phase; B: alumina oxide TGO; C: mixed oxide; (B) The microstructure close to the surface is shown.