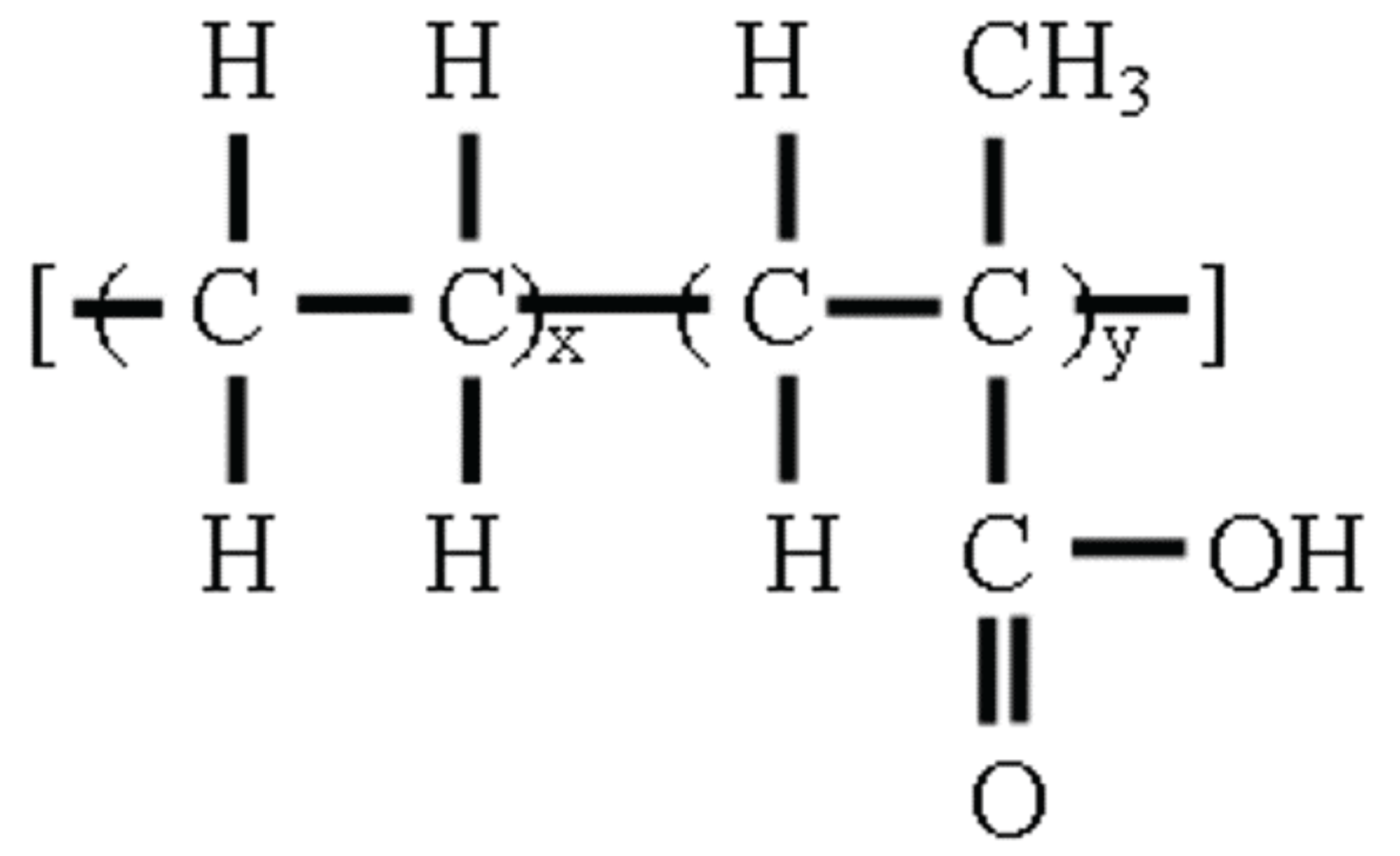

Spreading Behavior and Morphology of Ethylene Methacrylic Acid (EMAA) Deposits via the Flame Spray Process

Abstract

:1. Introduction

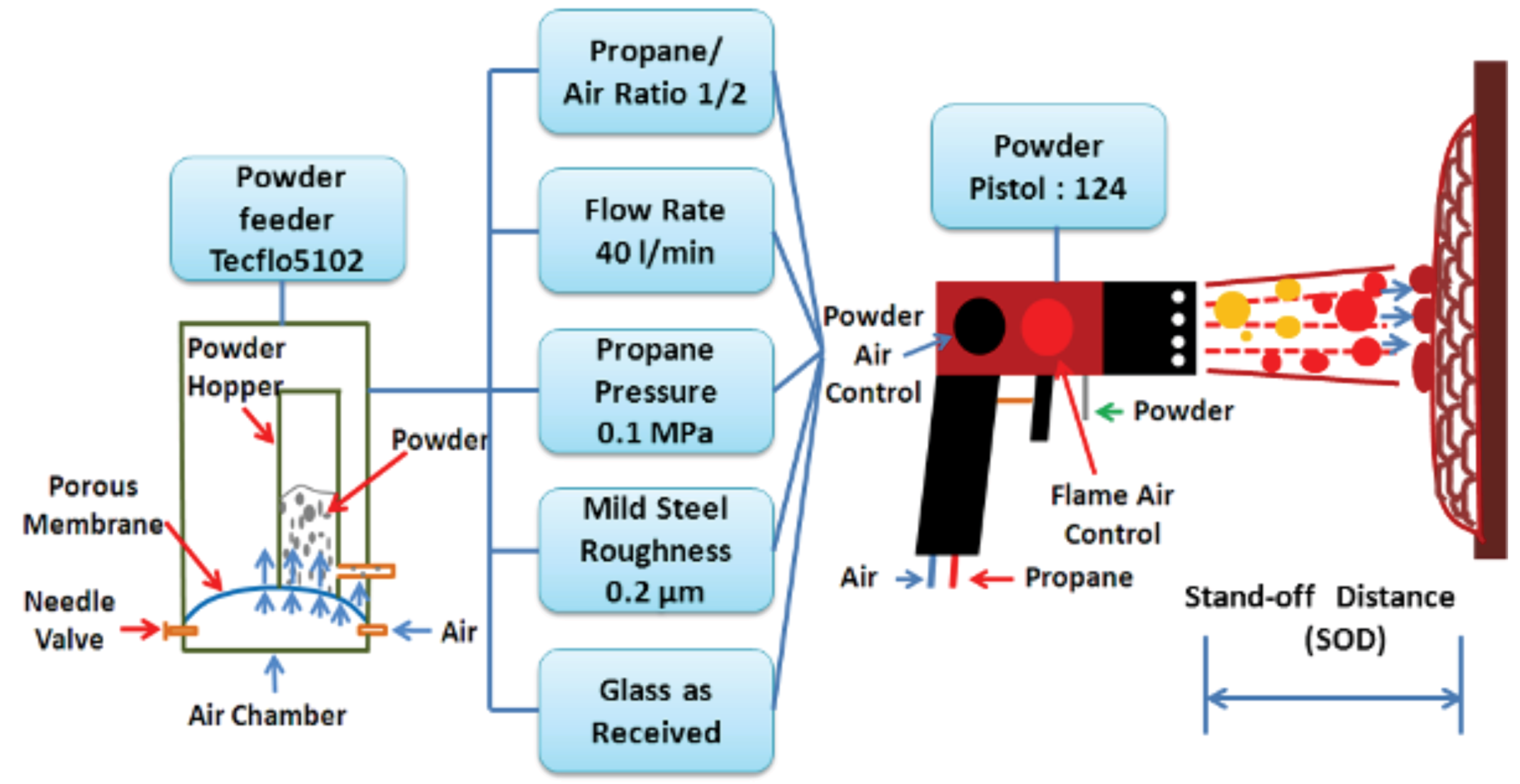

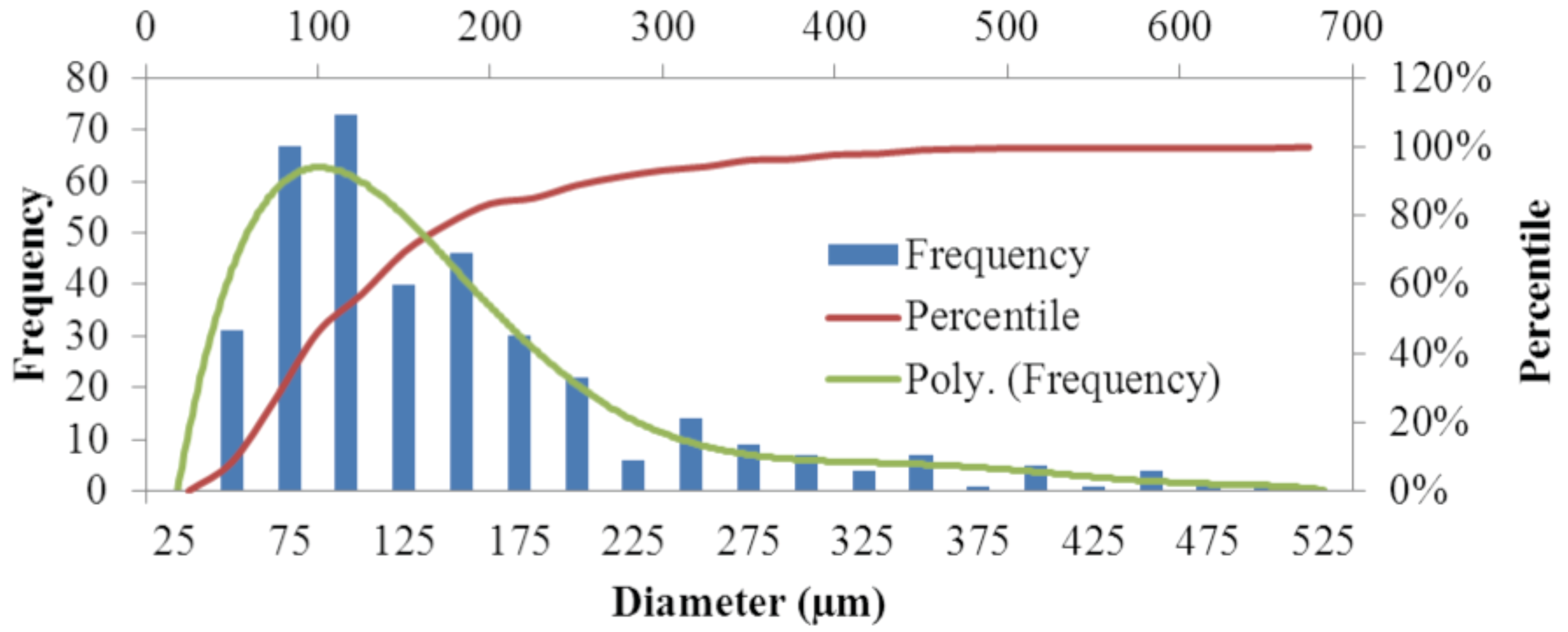

2. Experimental Procedure

| Property | Value |

|---|---|

| Melting Point | 80–105 °C |

| Thermal Conductivity | 0.33 wm−1·K−1 [25] |

| Specific Gravity | >0.93 |

| % Volatiles | negligible |

| Solubility in Water | negligible |

| Appearance and Odor | finely divided powder-mildly acidic odour |

| Color | grey |

| Flexibility (conical mandrel) | 1/8 inch, no cracks (greater than 32%) |

| Adhesion | >1,000psi / (5A) |

| Impact Resistance | >384 in./lbs. |

| Gloss (at 60 degrees) | 35–60 |

| Hardness (Shore D) | 48 |

| Taber Abrasion | 90 (mg loss, CS 10 wheel)*100 (mg loss, CS 17 wheel)* |

| Dielectric Breakdown | 893+/- 163 volts/mil** |

| Volume Resistivity | 4.67 X 10 13 Ohms/cm. |

| Salt Spray Resistance | >4,000 Hours |

| Humidity Resistance | No blistering or loss of gloss after 1,000 hours |

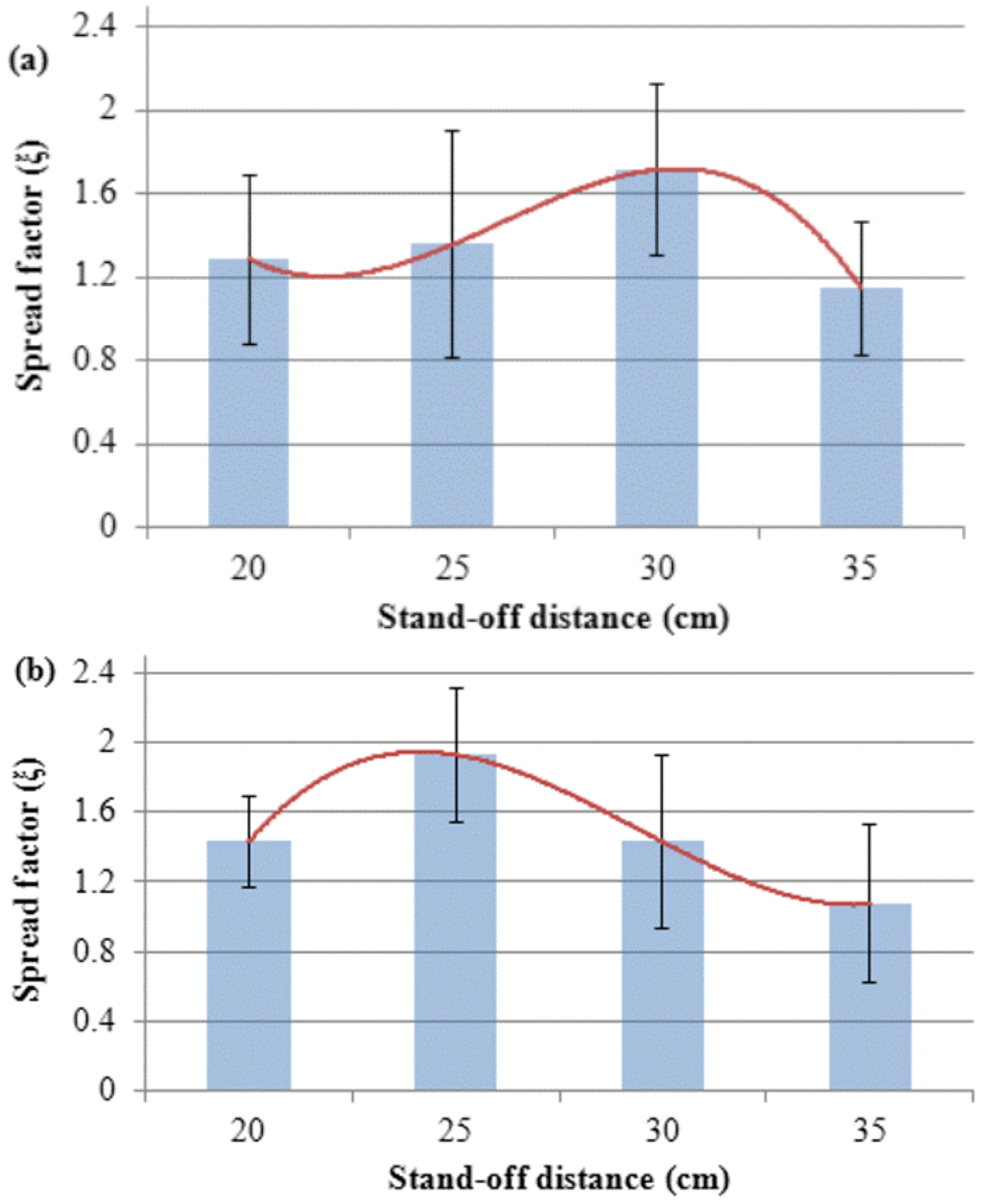

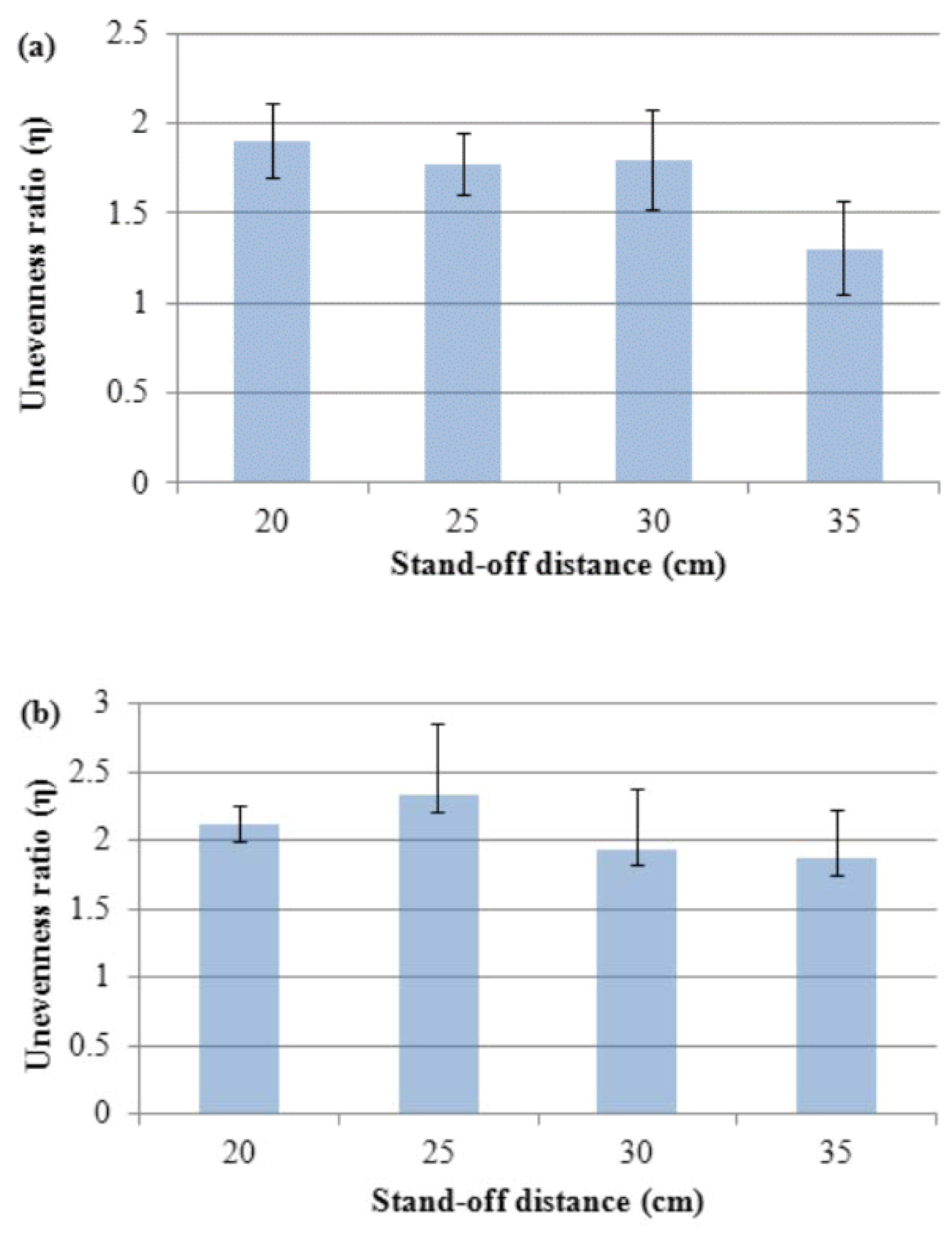

3. Influence of Stand off Distance

3.1. The Effect of Stand-off Distance on the Spread Factor of EMAA Single Splats

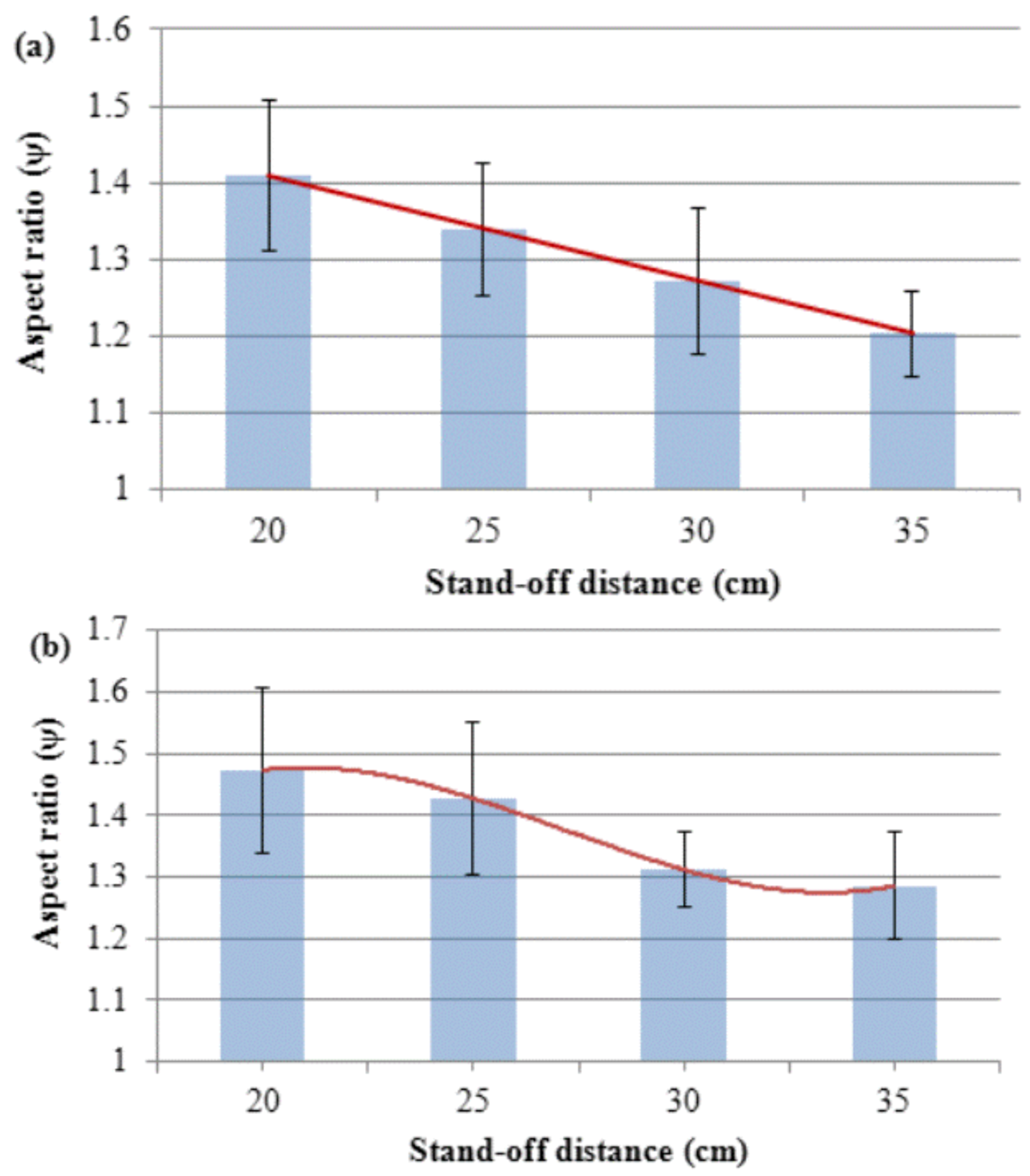

The Effect of Stand-off Distance on the Aspect Ratio of EMAA Single Splats

(2)

(2)

4. Influence of Surface Chemistry

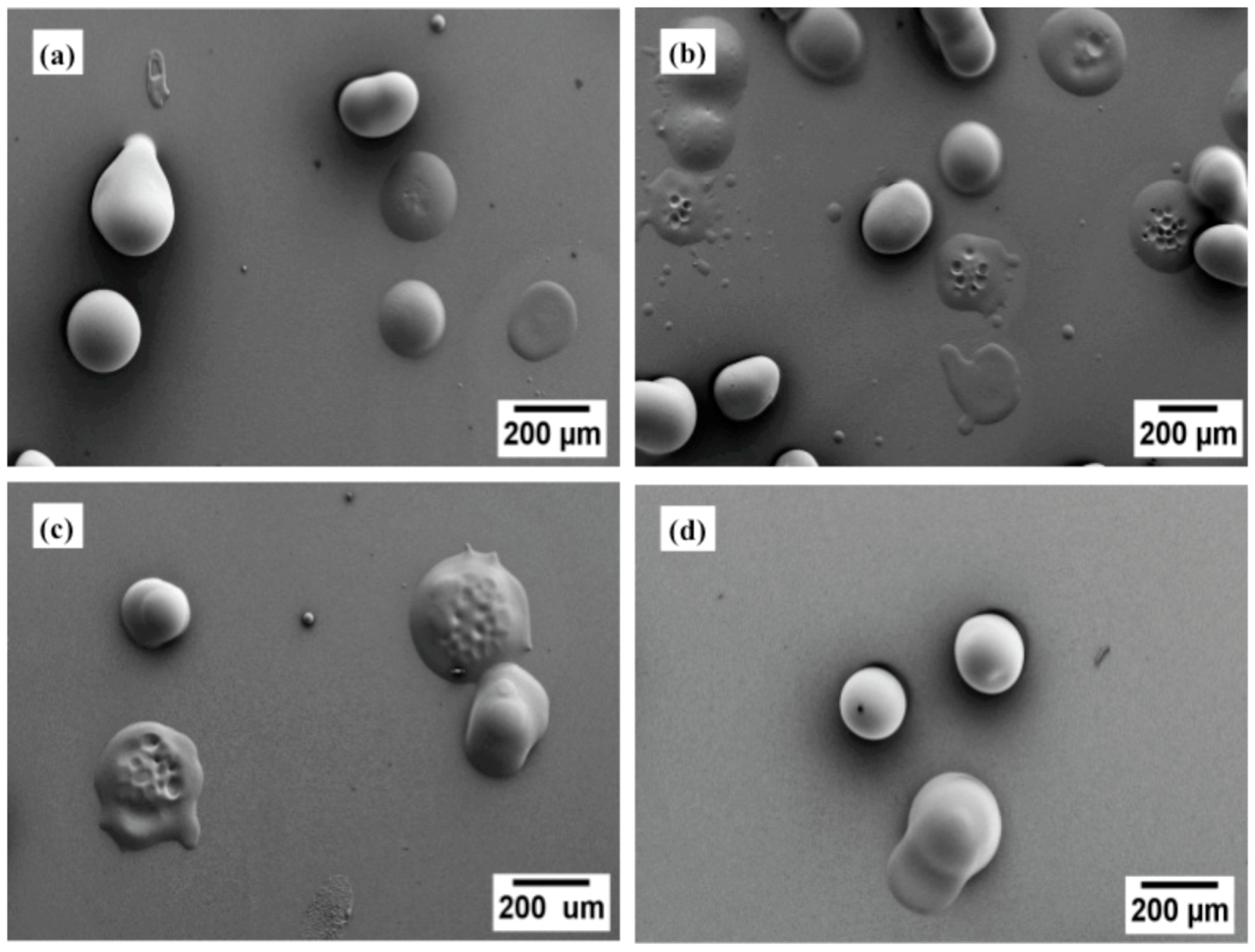

4.1. The Effect of Surface Chemistry on the Underside of EMAA Single Splat Morphology

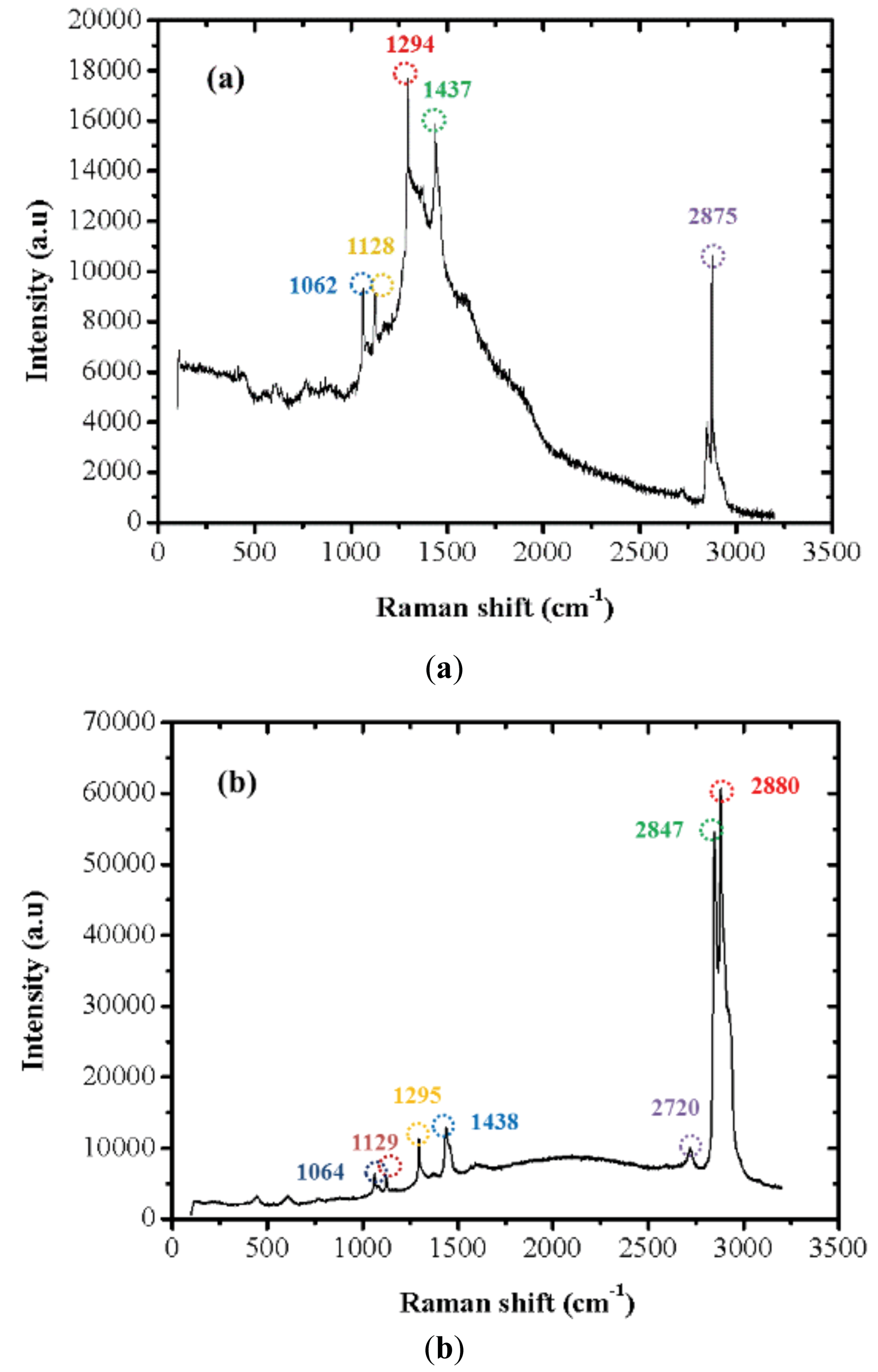

4.2. Raman Spectrum Analysis of EMAA

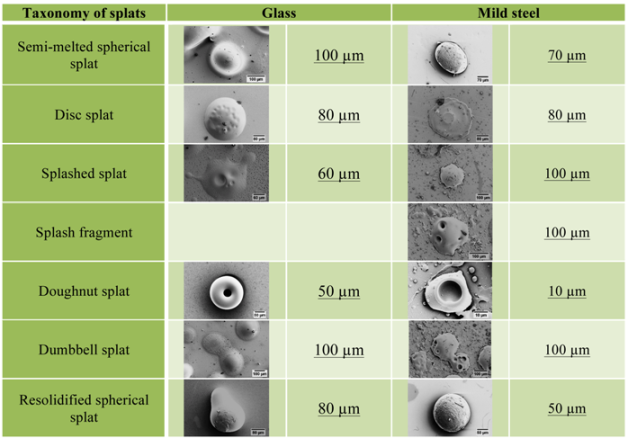

5. Taxonomic Analysis of Spats

5.1. Analysis of the Splat Morphology

|

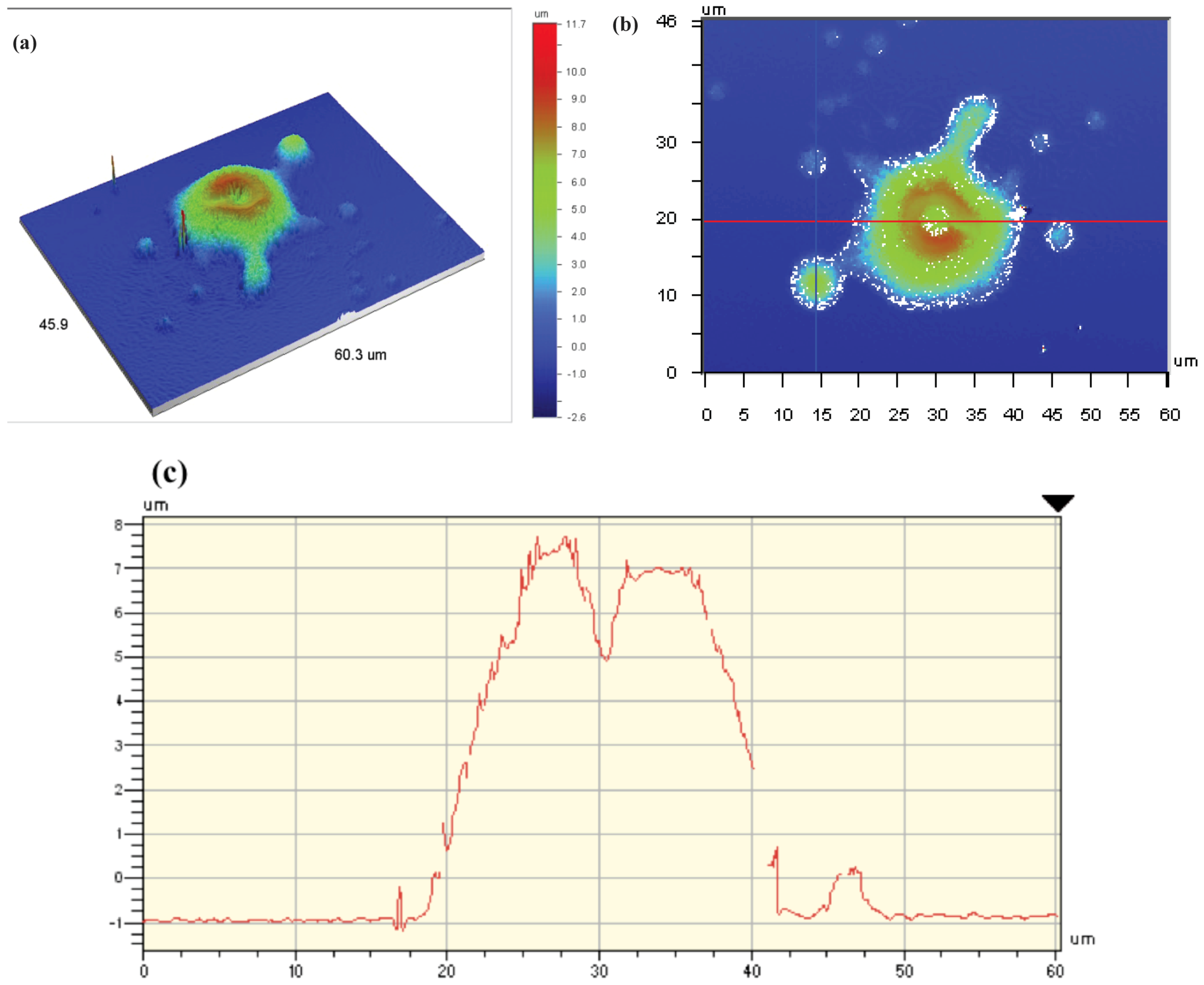

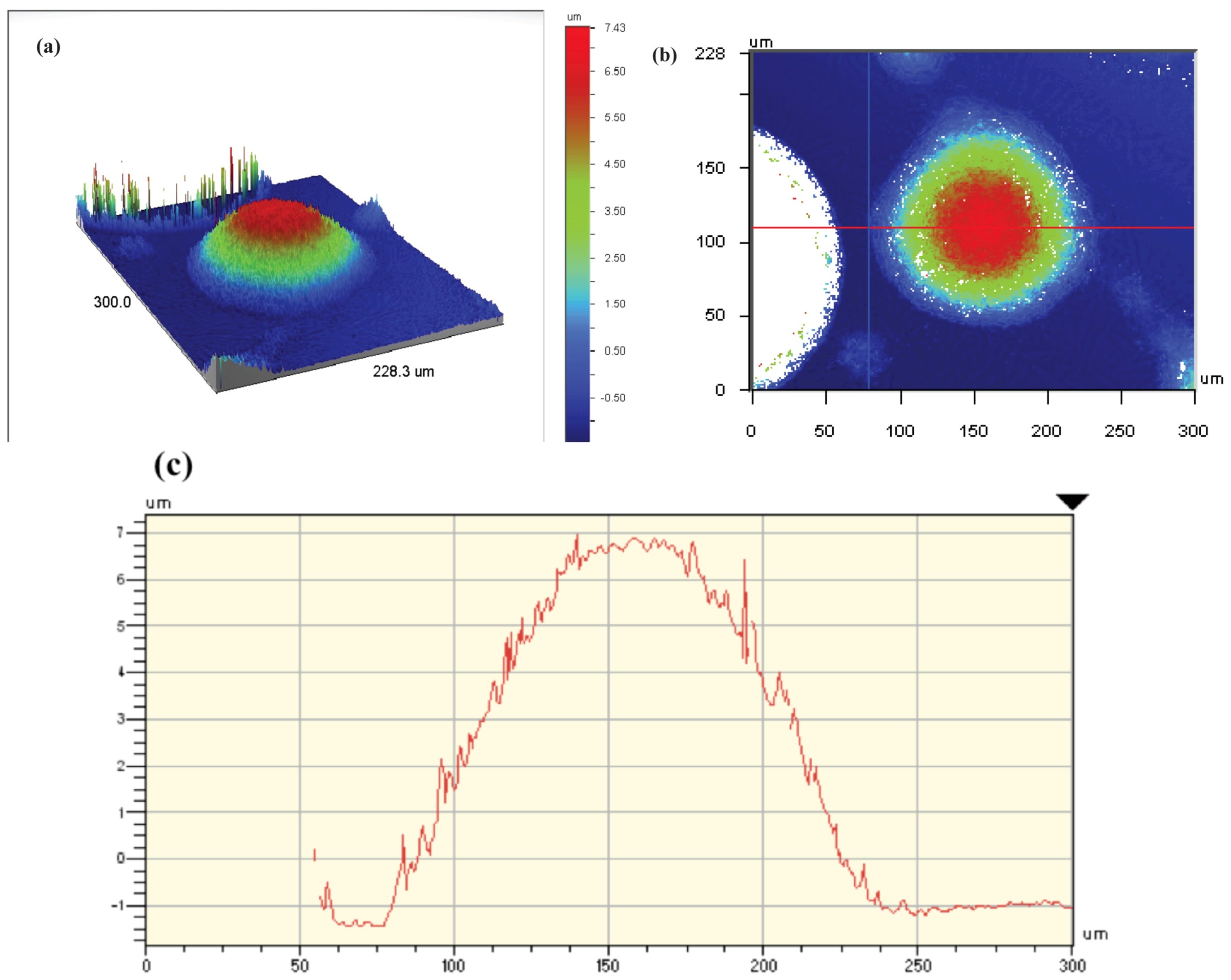

5.2. Surface Profile of Splat Morphology

6. Conclusions

Acknowledgments

References

- Fauchais, P.; Fukumoto, M.; Vardelle, A.; Vardelle, M. Knowledge concerning splat formation: An invited review. J. Therm. Spray Technol. 2004, 13, 337–360. [Google Scholar] [CrossRef]

- Verdian, M.M.; Salehi, M.; Raeissi, K. Effect of feedstock particle size on microstructure of aps coatings prepared from mechanically alloyed nickel-titanium powders. Surf. Eng. 2010, 26, 447–452. [Google Scholar] [CrossRef]

- Sweet, G.K. Applying Thermoplastic/Thermoset Powder with a Modified Plasma System. In Proceedings of the 1993 National Thermal Spray Conference , Anaheim, CA, USA, 7-11 June 1993; ASM International: Materials Park, OH, USA, 1993; pp. 381–384. [Google Scholar]

- Vardelle, A.; Moreau, C.; Fauchais, P. The dynamics of deposit formation in thermal-spray processes. MRS Bull. 2000, 25, 32–37. [Google Scholar]

- Bussmann, M.; Chandra, S.; Mostaghimi, J. Modeling the splash of a droplet impacting a solid surface. Phys. Fluids 2000, 12, 3121–3132. [Google Scholar] [CrossRef]

- Herman, H.; Sampath, S.; McCune, R. Thermal spray: Current status and future trends. MRS Bull. 2000, 25, 17–25. [Google Scholar]

- Jiang, X.; Wan, Y.; Herman, H.; Sampath, S. Role of condensates and adsorbates on substrate surface on fragmentation of impinging molten droplets during thermal spray. Thin Solid Films 2001, 385, 132–141. [Google Scholar] [CrossRef]

- Tran, A.T.T.; Hyland, M.M.; Qiu, T.; Withy, B.; James, B.J. Effects of surface chemistry on splat formation during plasma spraying. J. Therm. Spray Technol. 2008, 17, 637–645. [Google Scholar] [CrossRef]

- Tran, A.T.T.; Hyland, M.M.; Shinoda, K.; Sampath, S. Influence of substrate surface conditions on the deposition and spreading of molten droplets. Thin Solid Films 2011, 519, 2445–2456. [Google Scholar] [CrossRef]

- Fukumoto, M.; Nagai, H.; Yasui, T. Influence of surface character change of substrate due to heating on flattening behavior of thermal sprayed particles. J. Therm. Spray Technol. 2006, 15, 759–764. [Google Scholar] [CrossRef]

- Zhao, B.; Yadian, B.L.; Li, Z.J.; Liu, P.; Zhang, Y.F. Improvement on wettability between carbon nanotubes and sn. Surf. Eng. 2009, 25, 31–35. [Google Scholar] [CrossRef]

- Fukumoto, M.; Nishioka, E.; Matsubara, T. Effect of interface wetting on flattening of freely fallen metal droplet onto flat substrate surface. J. Therm. Spray Technol. 2002, 11, 69–74. [Google Scholar] [CrossRef]

- Tanaka, Y.; Fukumoto, M. Investigation of dominating factors on flattening behavior of plasma sprayed ceramic particles. Surf. Coat. Technol. 1999, 120-121, 124-130. [Google Scholar]

- Christoulis, D.K.; Pantelis, D.I.; Borit, F.; Guipont, V.; Jeandin, M. Effect of Substrate Roughness and Temperature on splat Formation in Plasma Sprayed Aluminium Bronze. In Proceedings of the 18th International Conference on Surface Modification Technologies, Dijon, France, 15-17 November 2004; pp. 73–83.

- Li, R.; Ashgriz, N.; Chandra, S. Maximum spread of droplet on solid surface: Low reynolds and weber numbers. J. Fluids Eng. Trans. Asme 2010, 132. [Google Scholar] [CrossRef]

- Fukumoto, M.; Huang, Y. Flattening mechanism in thermal sprayed nickel particle impinging on flat substrate surface. J. Therm. Spray Technol. 1999, 8, 427–432. [Google Scholar] [CrossRef]

- Fauchais, P.; Vardelle, A.; Dussoubs, B. Quo vadis thermal spraying? J. Therm. Spray Technol. 2001, 10, 44–66. [Google Scholar] [CrossRef]

- Leger, A.C.; Vardelle, M.; Vardelle, A.; Dussoubs, B.; Fauchais, P. Splat formation: Ceramic particles on ceramic substrates. In Proceedings of the 8th National Thermal Spray Conference, Houston, TX, USA, 11-15 September 1995; Sampath, S., Ed.; ASM International: Materials Park, OH, USA, 1995; pp. 169–174. [Google Scholar]

- Sampath, S.; Jiang, X.Y.; Matejicek, J.; Leger, A.C.; Vardelle, A. Substrate temperature effects on splat formation, microstructure development and properties of plasma sprayed coatings part I: Case study for partially stabilized zirconia. Mater. Sci. Eng. A 1999, 272, 181–188. [Google Scholar] [CrossRef]

- Brogan, J.A.; Berndt, C.C. The coalescence of combustion-sprayed ethylene-methacrylic acid copolymer. J. Mater. Sci. 1997, 32, 2099–2106. [Google Scholar] [CrossRef]

- Petrovicova, E.; Schadler, L.S. Thermal spraying of polymers. Int. Mater. Rev. 2002, 47, 169–190. [Google Scholar] [CrossRef]

- Lin, C.-K. Statistical Approaches to Study Variations in Thermal Spray Coatings Variations in Thermal Spray Coatings. Ph.D. Dissertation. 1995. [Google Scholar]

- Withy, B.P.; Hyland, M.M.; James, B.J. The effect of surface chemistry and morphology on the properties of hvaf peek single splats. J. Therm. Spray Technol. 2008, 17, 631–636. [Google Scholar] [CrossRef]

- Rasband, W.S. Imagej; U.S. National Institutes of Health: Bethesda, MD, USA; 1997-2010.

- Brogan, J.A. Processing and Property Relationships of Thermally Sprayed Polymer Systems. Ph.D. Dissertation. 1996. [Google Scholar]

- Kang, C.W.; Ng, H.W. Splat morphology and spreading behavior due to oblique impact of droplets onto substrates in plasma spray coating process. Surf. Coat. Technol. 2006, 200, 5462–5477. [Google Scholar] [CrossRef]

- Amada, S.; Tomoyasu, K.; Haruyama, M. Splat formation of molten sn, cu and ni droplets. Surface and Coatings Technology 1997, 96, 176–183. [Google Scholar] [CrossRef]

- Tran, A.T.T.; Hyland, M.M. The role of substrate surface chemistry on splat formation during plasma spray deposition by experiments and simulations. J. Therm. Spray Technol. 2010, 19, 11–23. [Google Scholar] [CrossRef]

- Jiang, X.; Matejicek, J.; Sampath, S. Substrate temperature effects on the splat formation, microstructure development and properties of plasma sprayed coatings part II: Case study for molybdenum. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 1999, 272, 189–198. [Google Scholar] [CrossRef]

- Nishioka, A.; Nishio, M.; Koda, T.; Ikeda, S.; Koyama, K. The effects of metal cation types on zero shear viscosities for ethylene-co-methacrylic ionomer melts. Nihon Reoroji Gakkaishi 2005, 33, 199–204. [Google Scholar] [CrossRef]

- Bianchi, L.; Grimaud, A.; Blein, F.; Lucchese, P.; Fauchais, P. Comparison of plasma-sprayed alumina coatings by rf and dc plasma spraying. J. Therm. Spray Technol. 1995, 4, 59–66. [Google Scholar] [CrossRef]

- Nishioka, A.; Koda, T.; Miyata, K.; Murasawa, G.; Koyama, K. The effects of small contents of water on melt rheology for ethylene-methacrylic zinc ionomers. Polym. J. 2008, 40, 350–353. [Google Scholar] [CrossRef]

© 2012 by the authors; licensee MDPI, Basel, Switzerland. This article is an open-access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Xie, W.; Wang, J.; Berndt, C.C. Spreading Behavior and Morphology of Ethylene Methacrylic Acid (EMAA) Deposits via the Flame Spray Process. Coatings 2012, 2, 76-93. https://doi.org/10.3390/coatings2020076

Xie W, Wang J, Berndt CC. Spreading Behavior and Morphology of Ethylene Methacrylic Acid (EMAA) Deposits via the Flame Spray Process. Coatings. 2012; 2(2):76-93. https://doi.org/10.3390/coatings2020076

Chicago/Turabian StyleXie, Wei, James Wang, and Christopher C. Berndt. 2012. "Spreading Behavior and Morphology of Ethylene Methacrylic Acid (EMAA) Deposits via the Flame Spray Process" Coatings 2, no. 2: 76-93. https://doi.org/10.3390/coatings2020076