Study of Toner Penetration in Papers by Laser Induced Plasma Spectroscopy and Optical Profilometry

Abstract

:1. Introduction

2. Experimental

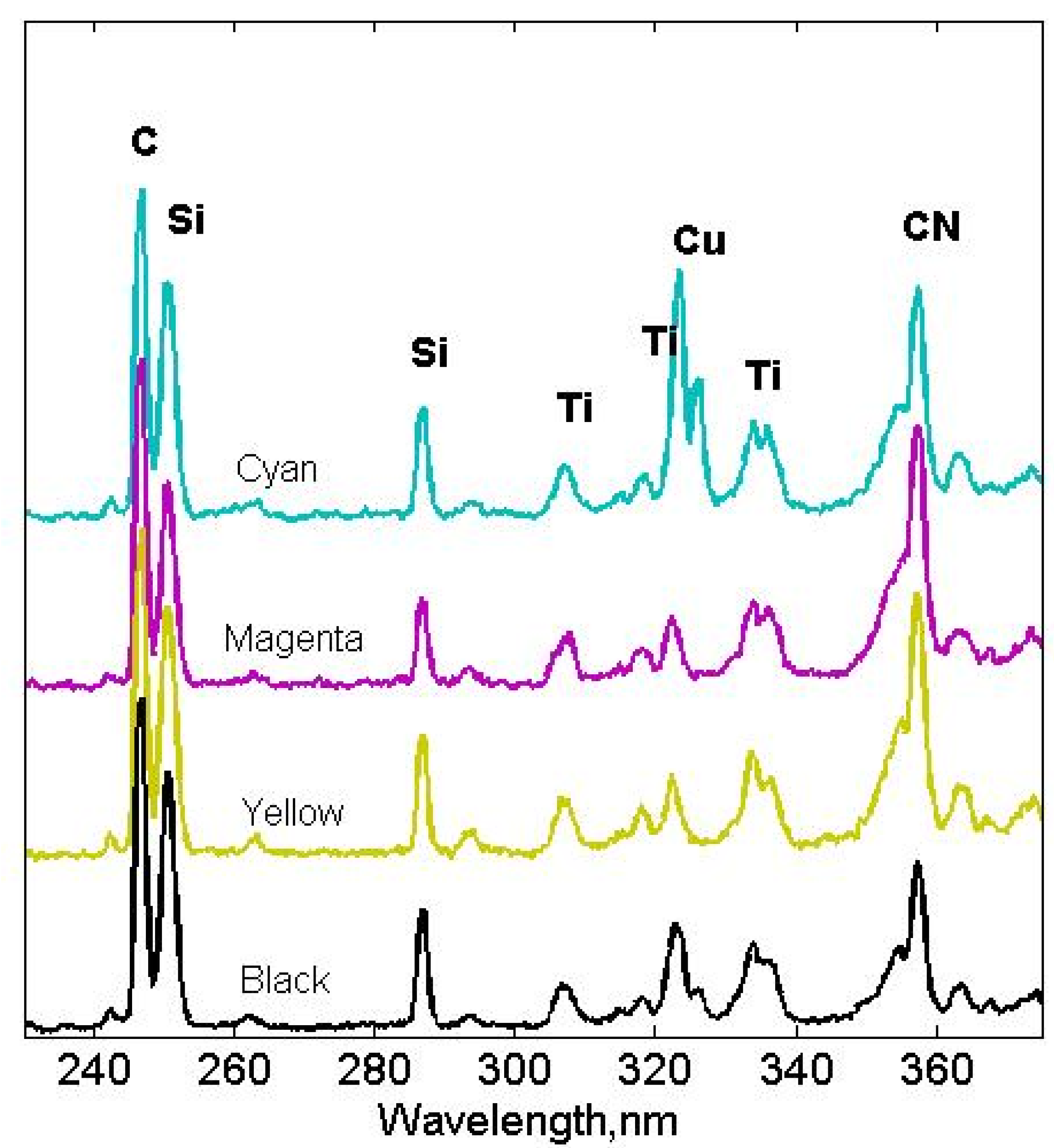

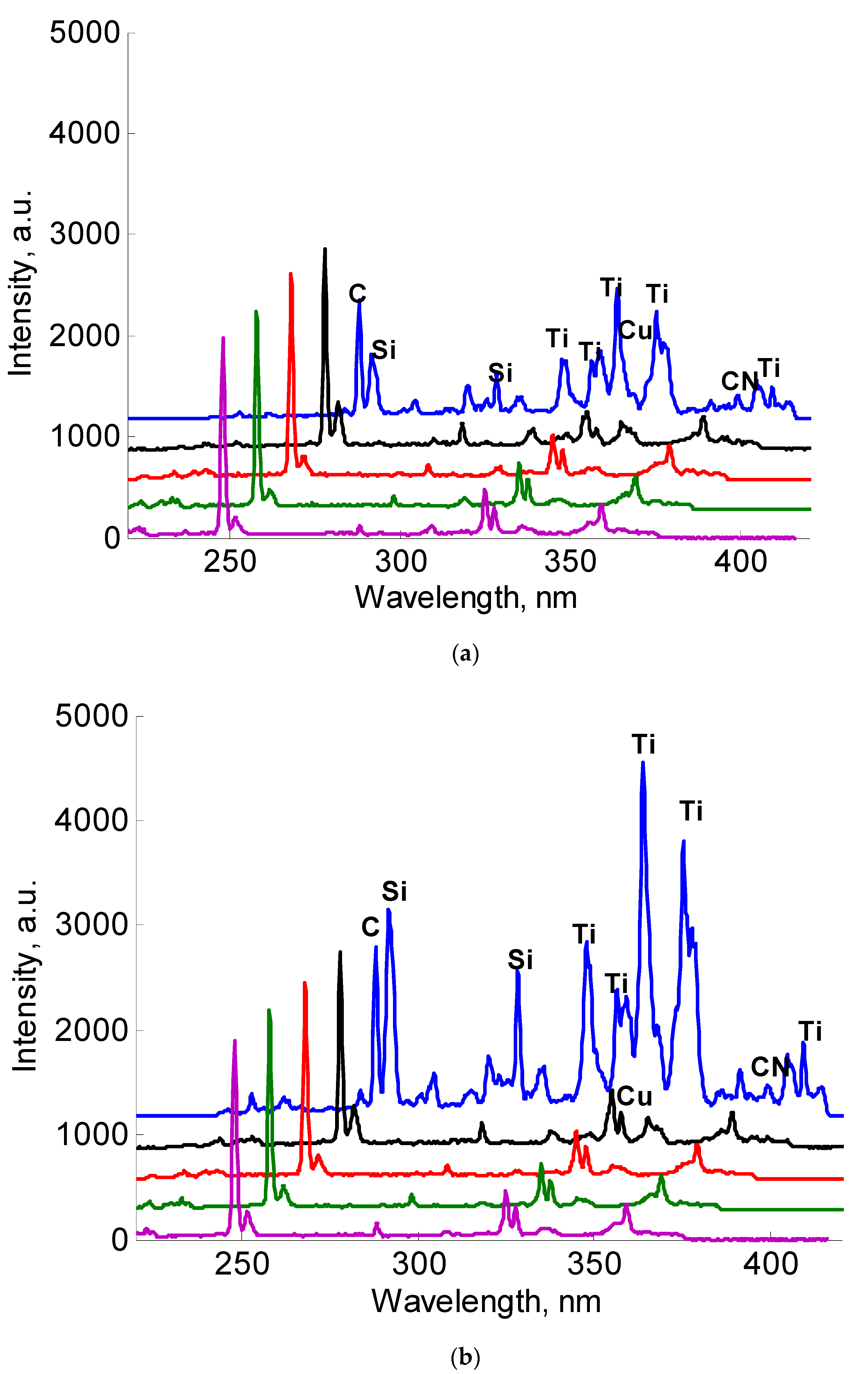

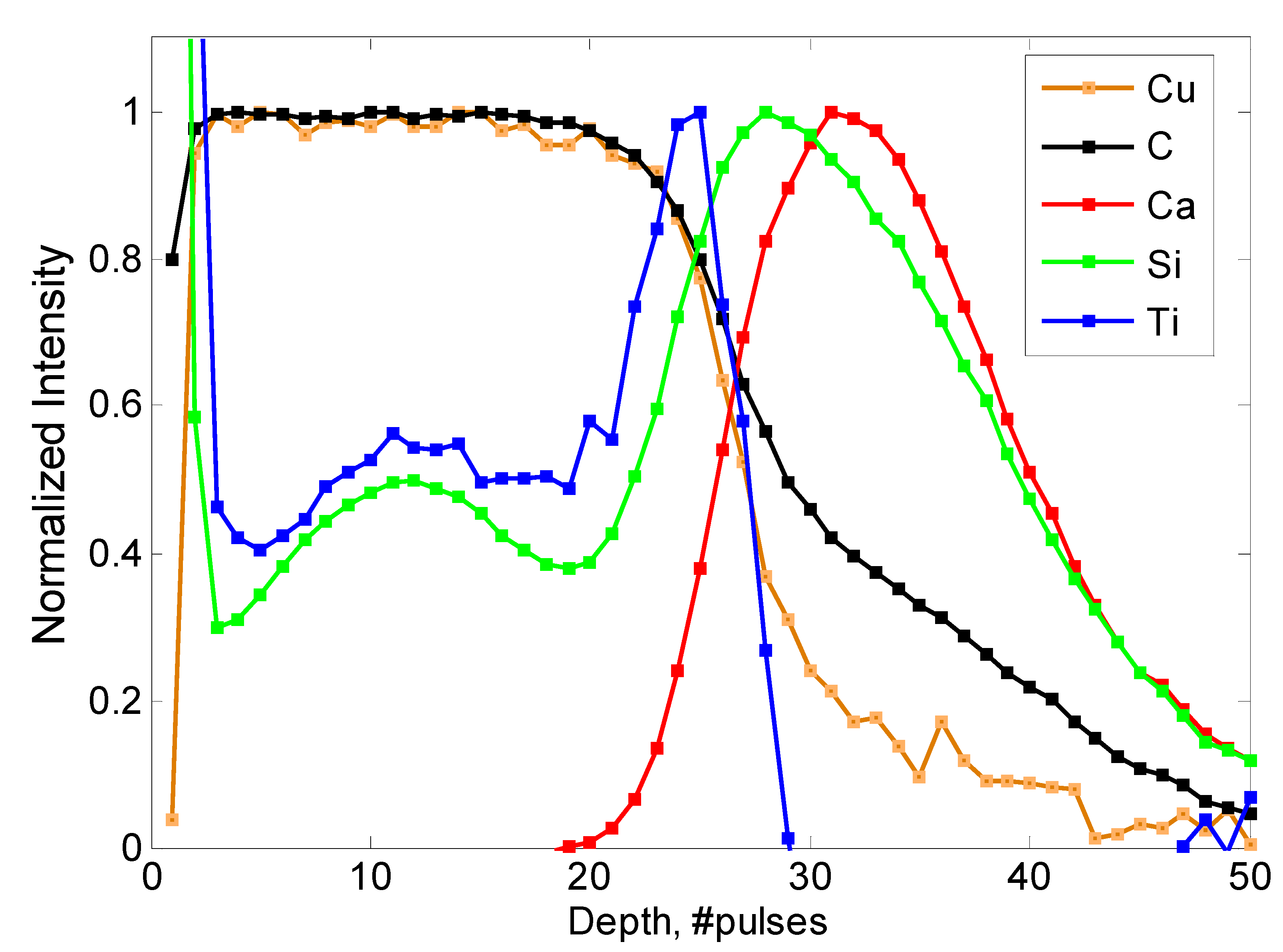

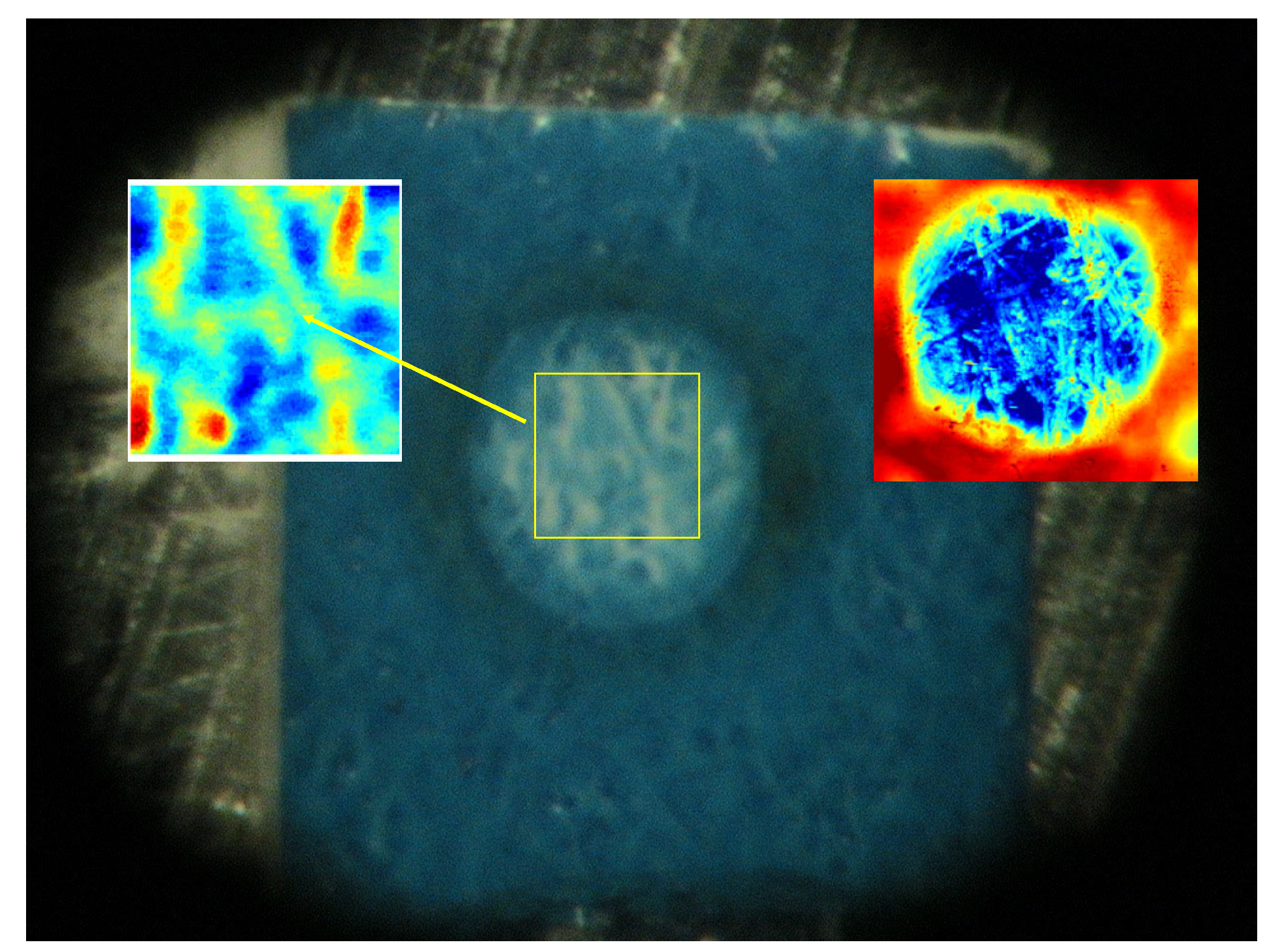

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Vadillo, J.M.; Laserna, J. Laser-induced plasma spectrometry: Truly a surface analytical tool. Spectrochim. Acta Part B At. Spectrosc. 2004, 59, 147–161. [Google Scholar] [CrossRef]

- Kaski, S.; Häkkänen, H.; Korppi-Tommola, J. Sulfide mineral identification using laser-induced plasma spectroscopy. Miner. Eng. 2003, 16, 1239–1243. [Google Scholar] [CrossRef]

- Rieger, G.; Taschuk, M.; Tsui, Y.; Fedosejevs, R. Laser-Induced Breakdown Spectroscopy for Two-Dimensional Microanalysis of using sub-millijoule UV laser pulses. Appl. Spectrosc. 2002, 56, 689–698. [Google Scholar] [CrossRef]

- Romero, D.; Romero, J.M.F.; Laserna, J.J. Distribution of metal impurities in silicon wafers using imaging-mode multi-elemental laser-induced breakdown spectrometry. J. Anal. At. Spectrom. 1999, 14, 199–204. [Google Scholar] [CrossRef]

- Vadillo, J.M.; Garcıa, C.C.; Palanco, S.; Laserna, J.J. Nanometric range depth-resolved analysis of coated-steels using laser-induced breakdown spectrometr y with a 308 nm collimated beam. J. Anal. At. Spectrom. 1998, 13, 793–797. [Google Scholar] [CrossRef]

- Papazoglou, D.G.; Papadakis, V.; Anglos, D. In situ interferometric depth and topography monitoring in LIBS elemental profiling of multi-layer structures. J. Anal. At. Spectrom. 2004, 19, 483–488. [Google Scholar] [CrossRef]

- Hedwig, R.; Budi, W.S.; Abdulmadjid, S.N.; Pardede, M.; Suliyanti, M.M.; Lie, T.J.; Kurniawan, D.P.; Kurniawan, K.H.; Kagawa, K.; Tjia, M.O. Film analysis employing subtarget effect using 355 nm Nd-YAG laser-induced plasma at low pressure. Spectrochim. Acta B 2006, 61, 1285–1293. [Google Scholar] [CrossRef]

- Häkkänen, H.J.; Korppi-Tommola, J.E.I. UV-Laser Plasma Study of Elemental Distributions of Paper Coatings. Appl. Spectrosc. 1995, 49, 1721–1728. [Google Scholar] [CrossRef]

- Häkkänen, H.J.; Jouko, E.I.; Tommola, K. Laser–Induced Plasma Emission Spectrometric Study of Pigments and Binders in Paper Coatings: Matrix Effects. Anal. Chem. 1998, 70, 472–4729. [Google Scholar] [CrossRef]

- Häkkänen, H.; Houni, J.; Kaski, S.; Korppi-Tommola, J. Analysis of paper by laser-induced plasma spectroscopy. Spectrochim. Acta Part B At. Spectrosc. 2001, 56, 737–742. [Google Scholar] [CrossRef]

- Kansanaho, J.; Korppi-Tommola, J.I.; Hakkanen, H. Print quality vs. coat weight and binder distribution in coated paper. In Proceedings of the Advanced Coating Fundamentals Symposium, San Diego, CA, USA, 4–5 May 2001; pp. 47–52. [Google Scholar]

- Ochocińska, K.; Sawczak, M.; Martin, M.; Jorgensen, J.; Kaminska, A.; Śliwiński, G. LIPS spectroscopy for the contamination analysis and laser cleaning diagnostics of historical paper documents. Radiat. Phys. Chem. 2003, 68, 227–232. [Google Scholar] [CrossRef]

- Stewart, R.; Li, L.; Thomas, D. Laser ablation of multilayers of ink from a paper substrate for tactile printing. Opt. Laser Technol. 2000, 32, 301–305. [Google Scholar] [CrossRef]

- Leal-Ayala, D.R.; Allwood, J.M.; Counsell, T.A.M. Paper un-printing: Using lasers to remove toner-print in order to reuse office paper. Appl. Phys. A 2011, 105, 801–818. [Google Scholar] [CrossRef]

- Iwata, N.; Tani, K.; Watada, A.; Ikeura-Sekiguchi, H.; Araki, T.; Hitchcock, A.P. Chemical component mapping of pulverized toner by scanning transmission X-ray microscopy. Micron 2006, 37, 290–295. [Google Scholar] [CrossRef] [PubMed]

- Pettersson, T.; Fogden, A. Spreading of individual toner particles studied using in situ optical microscopy. J. Colloid Interface Sci. 2005, 287, 249–260. [Google Scholar] [CrossRef] [PubMed]

- Hakola, E.; Koskinen, J.; Forsström, U.; Oittinen, P. Toner Penetration into Porous Substrates. J. Imaging Sci. Technol. 2008, 52, 40501. [Google Scholar] [CrossRef]

- Vikman, K.; Sipi, K. Application of FTIR and Raman spectroscopic methods to the study of paper-ink interactions in digital prints. J. Imaging Sci. Technol. 2003, 47, 139–148. [Google Scholar]

- Myllys, M.; Häkkänen, H.; Korppi-Tommola, J.; Backfolk, K.; Sirviö, P.; Timonen, J. X-ray microtomography and laser ablation in the analysis of ink distribution in coated paper. J. Appl. Phys. 2015, 117, 144902. [Google Scholar] [CrossRef] [Green Version]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Häkkänen, H.; Backfolk, K.; Sirviö, P.; Korppi-Tommola, J. Study of Toner Penetration in Papers by Laser Induced Plasma Spectroscopy and Optical Profilometry. Coatings 2023, 13, 346. https://doi.org/10.3390/coatings13020346

Häkkänen H, Backfolk K, Sirviö P, Korppi-Tommola J. Study of Toner Penetration in Papers by Laser Induced Plasma Spectroscopy and Optical Profilometry. Coatings. 2023; 13(2):346. https://doi.org/10.3390/coatings13020346

Chicago/Turabian StyleHäkkänen, Heikki, Kaj Backfolk, Petri Sirviö, and Jouko Korppi-Tommola. 2023. "Study of Toner Penetration in Papers by Laser Induced Plasma Spectroscopy and Optical Profilometry" Coatings 13, no. 2: 346. https://doi.org/10.3390/coatings13020346